- 1Department of Conservative Dentistry, School of Dentistry, Dental Research Institute, Pusan National University, Yangsan, Republic of Korea

- 2Endodontic Department, Hamdan Bin Mohammed College of Dental Medicine, Mohammed Bin Rashid University of Medicine and Health Sciences, Dubai, United Arab Emirates

- 3Endodontic Department, Emirates Health Services Establishment, Dubai, United Arab Emirates

- 4Emirates Endodontic Society, Dubai, United Arab Emirates

This study aimed to evaluate the effect from usage and autoclaving on torsional fracture resistance of heat-treated nickel-titanium rotary instruments. ProTaper Gold F2 (PG) and TruNatomy Prime (TN) were selected. For group-N, new files were tested to make a baseline torsional resistance. For group-U, files underwent instrumentation in a J-shaped canal block, and files were tested. For group-S, files underwent instrumentation as in the group-U and followed by autoclave sterilization then were tested. Maximum torsional strength and distortion angel until fracture were measured using a customized device and toughness was calculated. Statistical analysis was conducted at the significance level of 95%. The topographic appearances of torsional fracture fragments were examined under scanning electron microscopy. PG showed significantly higher torsional strength after usage and sterilization; however, TN had reduced torsional strength (p < 0.05). PG showed significantly higher torsional strength in group-S than subgroup-N, while TN showed significantly lower torsional strength in group-U than group-N (p < 0.05). Regardless of the test conditions, PG showed significantly higher torsional strength and toughness than TN while TN had bigger distortion angle than PG (p < 0.05). The mechanical loads from usage and heat application during sterilization may result in alteration of torsional resistances according to geometry and alloy characteristics.

1 Introduction

Around 3 decades ago, nickel-titanium (NiTi) technology was first applied to clinical endodontics (Walia et al, 1988; Sattapan et al, 2000; Peters, 2004). Rotary NiTi alloy exhibits super elastic properties and shape memory capabilities compared with stainless-steel (SS) hand files, thereby increasing success rates and reducing the likelihood of procedural errors (Sonntag et al, 2003; Peters, 2004; Cheung and Liu, 2009). Despite these benefits, the NiTi file is susceptible to sudden fractures, a problem that adversely impacts the prognosis (McGuigan et al, 2013).

Torsional fracture is one of the primary cause of instrument fracture in clinical practice. Although operators usually use the endodontic motors which control the maximum torque generation, the torsional failure may occur when the tip of an instrument, or some other part, gets locked in the canal walls while its shank continues to rotate until the force surpasses the plastic limit of the alloy, ending up with breakage (Sattapan et al, 2000). Various manufacturing strategies have been developed to optimize mechanical properties and reduce the incidence of file fractures (Shen et al, 2013). The strategies include geometric changes for the cross section and longitudinal aspects, kinematics, surface treatment and alloy alteration by heat-treatment (Kim et al, 2010; Yum et al, 2011; Goo et al, 2017). It has been reported that alterations in the transition temperatures of NiTi through heat treatment (thermal processing) had favorable effects on the mechanical and physical properties of NiTi files (Yahata et al, 2009; Pereira et al, 2012; Shen et al, 2013). There are various kinds of heat-treatments technology for the purpose of NiTi file manufacturing, such as M-wire, Gold-wire, Blue-wire, CM-wire, T-wire, and so on (Goo et al, 2017).

Endodontic files should be sterilized before use, according to the manufacturers. If practitioners move files from one case to another, regardless of whether they were used or not, additional sterilization procedure is necessarily required. The sterilization procedures basically require heat application in various range of temperature and for various extent of time. Previous researches investigated that the potential impacts of heat sterilizing on fracture resistance of NiTi instruments. Silvaggio and Hicks (1997) reported an increase in the torsional strength of NiTi files after sterilization, while other investigators have reported increased susceptibility to cyclic fatigue and decreased torsional moments (Canalda-Sahli et al, 1998; Viana et al, 2006). A study confirmed that the irregularities present on the file surface became more prominent after having autoclave cycles for reuse (Nair et al, 2015). Although it was reported that sterilization procedures did not cause significant surface deteriorations, Can Sağlam and Görgül (2015) also recommended to consider a fracture tendency of reuse file.

ProTaper Gold (Dentsply Sirona, Ballaigues, Switzerland) rotary files are made of a heat-treated alloy (Gold-wire) that has the same design as the ProTaper Universal, which includes a convex triangular cross-section and variable taper of 0.08v with a few millimeters of 8% (Elnaghy and Elsaka, 2016; Elnaghy and Elsaka, 2017). The advanced metallurgy showed superior flexibility and exhibited 2-stage transformation behavior and a high Af (austenite-finishing) temperature that is similar to controlled memory wires (Hieawy et al, 2015; Goo et al, 2017).

TruNatomy rotary instruments (Denstply Sirona) has been developed as a novel type of heat-treated NiTi instrument with a special design. It is constructed from a 0.8 mm NiTi wire instead of up to 1.2 mm NiTi shaft wire and it has an off-centered parallelogram cross-section (Bürklein et al, 2021). The TruNatomy shaping instruments are provided in three different sizes which are small (size #20/.04 taper), prime (size #26/.04 taper) and medium (size #36/.03 taper). Due to the advanced technology, it had been reported that the TruNatomy instruments preserve the structural dentine, tooth integrity, and improved performance and efficacy as well (Silva et al, 2022).

It is not easy to find proper studies about the torsional fracture resistances of heat-treated ProTaper Gold and TruNatomy rotary file systems with controlled conditions considering mechanical loading during usage and heat application during autoclaving sterilization. Therefore, this study purposed to evaluate the torsional fracture resistances of heat-treated NiTi files after usage and/or autoclaving sterilization.

2 Materials and methods

2.1 Group designation and specimen preparation

ProTaper Gold size F2 (PG) and TruNatomy size Prime (TN) were chosen as the two heat-treated NiTi rotary endodontic files. The tip sizes for PG and TN files are #25/.08v and #26/.04v, respectively, and both have a variable taper. Under a dental operating microscope (Leica M320; Leica Microsystems, Wetzlar, Germany), the files were examined under 16X magnification, and any defective instruments were discarded.

The sample size for the tests was calculated using G*Power v3.1 (Heinrich Heine, University of Düsseldorf, Düsseldorf, Germany) setting a significance level of 5% and a test power of 0.80. Total of 30 files for each file systems were randomly subdivided into three testing subgroups (n = 10). The subgroup designation and specimen preparation were performed as described by El Abed et al (2022).

New files were tested as group-N to establish baseline torsional resistance. In group-U, files were activated in J-shape simulated canals modeled in resin blocks (Dentsply Sirona) with 16.5 mm length and a 35-degree curvature using an X-smart Plus endodontic motor (Dentsply Sirona). PG files were operated in a speed of 350 rpm and 2.5 Ncm and TN files were operated in a speed of 500 rpm and 1.5 Ncm, according to the manufacturer instructions. One endodontic specialist instrumented the simulated canals for pre-enlargement with SS files #10K and #15K (Mani, Tochigi, Japan) with manual balanced force and turn-and-pull techniques. The PG and TN files in group-U were used for shaping the pre-instrumented canals and then tested for torsional failure. During the manual shaping and rotary NiTi instrumentation procedures, normal saline was used for canal irrigation using a 27-gauge needle (Endo-Eze; Ultradent, South Jordan, UT, United States).

The files of PG and TN in group-S after shaping the resin canals were sterilized using an autoclave (Steris Amsco Century autoclave: Steris Co., Mentor, OH, United States) at 132°C for 30 min and then they were tested for torsional failure.

2.2 Experimental test of torsional resistance

According to the modified method by Ha et al (2013), the torsional resistance test was carried out using a customized device (AEndoS; DMJ Systems, Busan, Korea) (Figure 1). The 3 mm of the instrument tip was secured between two brass plates. To simulate body temperature as 37°C, a heat control element (TK4N/S/SP Autonics, Busan, Korea) was added to transfer heat three-dimensionally to the testing plate (Figures 1B, C).

FIGURE 1. Customized device (AEndoS; DMJ Systems, Busan, Korea) used in this study. (A) File holding part connected to torsion sensor, (B) Heat pad and (C) Heat control element (TK4N/S/SP Autonics, Busan, Korea).

The files were kept straight throughout the experiments, and the clockwise rotation was applied at a constant speed of 2 rpm until the file fractures. Using a customized software, the ultimate strength (Ncm) and distortion angle (degree or) were measured at a rate of 50 Hz while the files were rotating.

Using Origin v6.0 Professional (Microcal Software Inc., Northampton, MA, United States), the toughness until fracture was determined by calculating from the area under the plot presenting distortion angle (X-axis) and torsional load (Y-axis).

2.3 Statistical analysis

To evaluate the data and compare the file systems and subgroups, SPSS (version 25.0; SPSS Inc., Chicago, IL, United States) was used. The Kolmogorov–Smirnov test was used to evaluate the normality of the continuous results. The maximum torsional strength had normal distribution and was evaluated using two-way ANOVA of file systems and test groups. One-way ANOVA and post hoc comparison were applied to compare the three groups for each file system. The distortion angle and toughness do not have normal distribution and the data was analyzed using a nonparametric Kruskal–Wallis test. In all experiments, a p-value of less than 0.05 was considered significant.

2.4 Scanning electron microscopy (SEM) evaluation

Scanning electron microscopy (SU8220; Hitachi High Technologies, Tokyo, Japan) was used to examine the topographic characteristics of the fractured fragments after the torsional fracture tests. From each group, 4 specimens of fracture fragments were examined. Apical fragments were examined for cross-sectional evaluation and the longer fragments were examined for lateral aspects.

3 Results

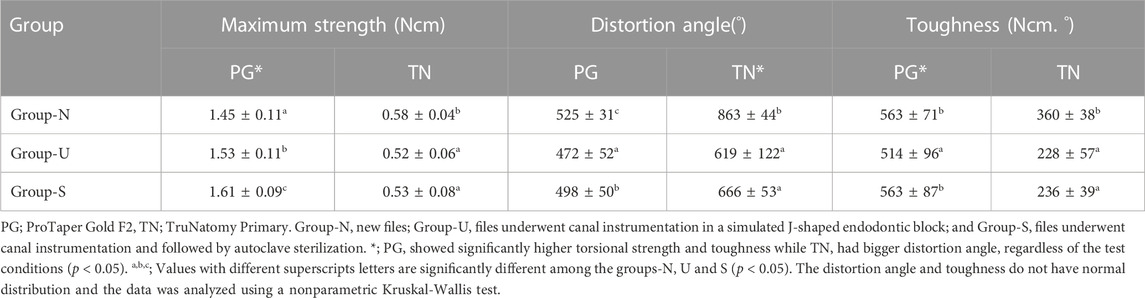

For both NiTi file systems with three test groups, the maximum torsional strength (Ncm), distortion angle (°) and toughness (Ncm⋅°) are shown in Table 1.

In this test, under the body temperature conditions, PG showed significantly higher torsional strength after usage (group-U) and sterilization (group-S); however, TN had reduced torsional strength in groups-U and -S than group-N (p < 0.05). The distortion angle and toughness do not have normal distribution and they showed significant differences by Kruskal–Wallis nonparametric test (p < 0.05). Regardless of the tested groups, PG showed significantly higher torsional strength and toughness than TN, while TN had bigger distortion angle than PG, regardless of the test conditions (p < 0.05).

The SEM topography examination revealed the typical appearances of torsional failure modes. On the cross-sectional views, specimens from the torsional resistance tests had typical appearances such as circular abrasion marks and skewed dimples near the center of rotation (Figure 2). On the longitudinal aspects of the fractured specimens (Figure 3), TN shows the longer unwound helix than the PG. Both systems showed irregular and curved machining grooves around the fracture area while linear and straight machining grooves were found on the area with normal helix winding. The test conditions of the three subgroups in terms of usage and sterilization did not show any significant differences from the SEM evaluations.

FIGURE 2. Cross-sectional scanning electron micrographs of the fracture fragments after torsional fracture tests. Specimens of (A, C) ProTaper Gold and (B, D) TruNatomy from Group-S after usage and sterilization. Circular arrows (A, B) show circular abrasion mark and multiple fibrous dimples (C, D) at the center of rotation.

FIGURE 3. Longitudinal scanning electron micrographs of the fracture fragments after torsional fracture tests. Specimens of (A, C) ProTaper Gold and (B, D) TruNatomy from Group-U after usage. Vacant double-sided arrows indicate the unwound helix of the flute and TruNatomy shows the longer unwinding than the ProTaper Gold. Linear and straight machining grooves (*) were found on the surfaces but irregular and curved machining grooves (C, D) were found around the fracture area. White arrows indicate microcracks along with the machining grooves near the fracture area.

4 Discussion

NiTi endodontic instruments offer excellent flexibility and improved cutting efficiency (Sonntag et al, 2003; Peters, 2004). The superelastic characteristics of NiTi instruments allows preservation of the root canal anatomy, while preserving root dentin structure and integrity (Sonntag et al, 2003; Cheung and Liu, 2009). In spite of the advantages, NiTi instruments seem to be vulnerable to fracture (Sattapan et al, 2000; Parashos et al, 2006; Shen et al, 2013). File fracture is a main concern for the clinician because when it happens the treatment prognosis would be poorer than the cases without file fracture (Sattapan et al, 2000; Cheung and Liu, 2009). Therefore, there have been various trials and research to develop a new instrument with a better property of fracture resistance (Yahata et al, 2009; Kim et al, 2010; Yum et al, 2011; Shen et al, 2013).

Mechanical fracture test and fractographic evaluation are most combined for fracture resistance tests of the NiTi instruments as they represent the instruments’ basic properties (Kim et al, 2010; Yum et al, 2011; El Abed et al, 2022). Other metallurgical tests such as differential scanning calorimetry (DSC), X-ray diffraction (XRD), atomic force microscopy (AFM), energy-dispersive X-ray spectroscopy (EDS) could be used for the evaluation of instruments’ characteristics and potential effects from the sterilization procedure and usage (Zanza et al, 2022 methods). In the present study, the SEM evaluation as a topographic analysis was done along with the mechanical tests of torsional fracture resistance.

NiTi files have to be machined during manufacturing and it usually causes surface irregularities (milling or machining grooves), which can lead to crack initiation and propagated to fracture (Kim et al, 2010; Ha et al, 2013). During manufacturing procedures, the heat-treatment and/or surface treatment make different surface textures which result in different fracture resistances (Yum et al, 2011; Ha et al, 2013; Goo et al, 2017).

Pre-sterilization cleaning, drying, packaging, heat sterilization, and storage are the common steps for the instrument sterilization process (Bagg et al, 2007). These procedures usually generate high level of temperatures. It was reported that the surface concentrations of nickel, titanium, oxygen, and carbon in NiTi alloys altered because of repeated autoclaving conditions (Pun and Berzins, 2008). It was observed that titanium oxides increased, and nickel surface concentrations decreased when exposed to autoclave sterilization, indicating that surface oxidation may be occurring (Shabalovskaya and Anderegg, 1995; Rapisarda et al, 1999). Corrosion of NiTi alloys has been identified with increased temperature in which repeated autoclaving conditions altered the surface concentrations of nickel, titanium, oxygen and carbon in NiTi alloys (Pun and Berzins, 2008).

Therefore, the mechanical properties and fracture resistances of endodontic instruments can be affected by heat sterilizing processes (Silvaggio and Hicks, 1997). Cyclic flexural fatigue of the instrument occurs by repeated tensile and compressive stresses when an instrument rotates in a curved root canal. However, torsional failure may occur in a straight root canal because it may happen when the file tip binds in the canal while the motor continues to rotate (Cheung and Liu, 2009; Kim et al, 2010). Cyclic loading by usage and heat-treatment during sterilization may result in different cyclic fatigue resistance according to the geometry and alloy characteristics (El Abed et al, 2022). This study evaluated the effects from same conditions on the torsional fracture resistance of the heat-treated instruments.

Studies on torsional stress resistance have linked the number of sterilization cycles to torsional characteristics, indicating differences in the resistance to torsional resistance (Hilt et al, 2000; Casper et al, 2011; King et al, 2012; Ha et al, 2013). Viana et al (2006) reported that 5 autoclave cycles did not affect the fatigue resistance of the ProFile files which coincide with earlier study of Hilt et al (2000) that no influence on the torsional properties of both SS and NiTi instruments. Additionally, it was found that multiple autoclave sterilization cycles do not significantly affect the torsional properties of Profile Vortex made from M-Wire, Twisted Files, and 10 Series files made from CM-Wire (Casper et al, 2011). On the other hand, Canalda-Sahili et al (1998) found that 10 autoclave cycles resulted in an overall decreasing trend of torque resistance of files.

Clinical knowledge of the maximal torque (torsional strength) and distortion angle at fracture is crucial given that torsional failure may result in file separation (Yum et al, 2011). Another parameter such as toughness may help better understand the torsional properties of NiTi files, which means the total energy to break the files (Yum et al, 2011). TN files in the current study showed lower toughness after usage and sterilization while no effect observed for PG files. Manufacturer instruction state that TN instruments intended for single patient use therefore such guidance seems reasonable given the low toughness properties result in this study. Currently tested PG files showed favorable torsional resistance behavior than TN files which could be related to the fact that torsional stress is influenced by tip and taper of the instrument and canal size, an increase in instrument diameter and corresponding increase in cross-sectional area may contribute to increased resistance to torsional failure (Parashos and Messer, 2006). Besides, both tested files are innovative NiTi heat treated files with reports of superior properties compared with standard or conventional NiTi files (Hieawy et al, 2015; Goo et al, 2017). Since heat-treatment played an important role in determining the fracture resistance of the NiTi file, heat generation during autoclave sterilization may affect them (Zhao et al, 2016; Zupanc et al, 2018).

SEM study of thermally treated NiTi endodontic files suggested that multiple autoclaving sterilization cycles enhance the surface topography, an increased surface roughness has been observed (Alexandrou et al, 2006). However, the SEM findings in this study did not show specific differences from the autoclaving or usage. A currently published study reported surface roughness by autoclave sterilization could be increased or decreased depending on their original surface roughness (Almohareb et al, 2022). They found that the surface roughness of conventional NiTi Race (FKG Dentaire, La Chaux-de-Fonds, Switzerland) was decreased while in Race Evo (FKG Dentaire) surface roughness increased following the first autoclaving cycle.

Autoclave sterilization can influence the physical and mechanical characteristics of NiTi files, but decision about whether the effect is favorable or unfavorable for clinical use are not always consistent between studies. Further, testing files after multiple autoclave cycles may have different outcome. Thus, future studies using different file systems made of various alloys would be required under various conditions of heat applications and repetitive usage.

5 Conclusion

All This in vitro study showed that loading from usage and heat treatment during sterilization may result in variable torsional fracture resistances according to the geometry and alloy characteristics.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

The H-CK and RE contributed to conception and design of the study. YK organized the database. YK and H-CK performed the statistical analysis. YK wrote the first draft of the manuscript. MJ, AA, and ZA wrote sections of the manuscript. DA and H-CK reviewed and edited the manuscript. All authors contributed to the article and approved the submitted version.

Funding

This research was Supported by Mohammed Bin Rashid University of Medicine and Health Sciences (grant no. RG2019-5).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alexandrou, G., Chrissafis, K., Vasiliadis, L., Pavlidou, E., and Polychroniadis, E. K. (2006). Effect of heat sterilization on surface characteristics and microstructure of Mani NRT rotary nickel-titanium instruments. Int. Endod. J. 39 (10), 770–778. doi:10.1111/j.1365-2591.2006.01147.x

Almohareb, R. A., Barakat, R., and Albohairy, F. (2022). New heat-treated vs electropolished nickel-titanium instruments used in root canal treatment: Influence of autoclave sterilization on surface roughness. PloS one 17 (3), e0265226. doi:10.1371/journal.pone.0265226

Bagg, J., Smith, A. J., Hurrell, D., McHugh, S., and Irvine, G. (2007). Pre-sterilisation cleaning of re-usable instruments in general dental practice. Br. Dent. J. 202 (9), E22–E551. doi:10.1038/bdj.2007.124

Bürklein, S., Zupanc, L., Donnermeyer, D., Tegtmeyer, K., and Schäfer, E. (2021). Effect of core mass and alloy on cyclic fatigue resistance of different nickel-titanium endodontic instruments in matching artificial canals. Mater. (Basel) 14 (19), 5734. doi:10.3390/ma14195734

Can Sağlam, B., and Görgül, G. (2015). Evaluation of surface alterations in different retreatment nickel-titanium files: AFM and SEM study. Microsc. Res. Tech. 78 (5), 356–362. doi:10.1002/jemt.22481

Canalda-Sahli, C., Brau-Aguadé, E., and Sentís-Vilalta, J. (1998). The effect of sterilization on bending and torsional properties of K-files manufactured with different metallic alloys. Int. Endod. J. 31 (1), 48–52. doi:10.1046/j.1365-2591.1998.t01-1-00114.x

Casper, R. B., Roberts, H. W., Roberts, M. D., Himel, V. T., and Bergeron, B. E. (2011). Comparison of autoclaving effects on torsional deformation and fracture resistance of three innovative endodontic file systems. J. Endod. 37 (11), 1572–1575. doi:10.1016/j.joen.2011.07.008

Cheung, G. S., and Liu, C. S. (2009). A retrospective study of endodontic treatment outcome between nickel-titanium rotary and stainless steel hand filing techniques. J. Endod. 35 (7), 938–943. doi:10.1016/j.joen.2009.04.016

El Abed, R., Alshehhi, A., Kang, Y. J., Al Raeesi, D., Khamis, A. H., Jamal, M., et al. (2022). Fracture resistance of heat-treated nickel-titanium rotary files after usage and autoclave sterilization: An in vitro study. J. Endod. 48 (11), 1428–1433. doi:10.1016/j.joen.2022.08.004

Elnaghy, A. M., and Elsaka, S. E. (2017). Laboratory comparison of the mechanical properties of TRUShape with several nickel-titanium rotary instruments. Int. Endod. J. 50 (8), 805–812. doi:10.1111/iej.12700

Elnaghy, A. M., and Elsaka, S. E. (2016). Mechanical properties of ProTaper Gold nickel-titanium rotary instruments. Int. Endod. J. 49 (11), 1073–1078. doi:10.1111/iej.12557

Goo, H. J., Kwak, S. W., Ha, J. H., Pedullà, E., and Kim, H. C. (2017). Mechanical properties of various heat-treated nickel-titanium rotary instruments. J. Endod. 43 (11), 1872–1877. doi:10.1016/j.joen.2017.05.025

Ha, J. H., Kim, S. K., Cohenca, N., and Kim, H. C. (2013). Effect of R-phase heat treatment on torsional resistance and cyclic fatigue fracture. J. Endod. 39 (3), 389–393. doi:10.1016/j.joen.2012.11.028

Hieawy, A., Haapasalo, M., Zhou, H., Wang, Z. J., and Shen, Y. (2015). Phase transformation behavior and resistance to bending and cyclic fatigue of ProTaper Gold and ProTaper Universal instruments. J. Endod. 41 (7), 1134–1138. doi:10.1016/j.joen.2015.02.030

Hilt, B. R., Cunningham, C. J., Shen, C., and Richards, N. (2000). Torsional properties of stainless-steel and nickel-titanium files after multiple autoclave sterilizations. J. Endod. 26 (2), 76–80. doi:10.1097/00004770-200002000-00004

Kim, H. C., Yum, J., Hur, B., and Cheung, G. S. (2010). Cyclic fatigue and fracture characteristics of ground and twisted nickel-titanium rotary files. J. Endod. 36 (1), 147–152. doi:10.1016/j.joen.2009.09.037

King, J. B., Roberts, H. W., Bergeron, B. E., and Mayerchak, M. J. (2012). The effect of autoclaving on torsional moment of two nickel-titanium endodontic files. Int. Endod. J. 45 (2), 156–161. doi:10.1111/j.1365–2591.2011.01958.x

McGuigan, M. B., Louca, C., and Duncan, H. F. (2013). Clinical decision-making after endodontic instrument fracture. Br. Dent. J. 214 (8), 395–400. doi:10.1038/sj.bdj.2013.379

Nair, A. S., Tilakchand, M., and Naik, B. D. (2015). The effect of multiple autoclave cycles on the surface of rotary nickel-titanium endodontic files: An in vitro atomic force microscopy investigation. J. Conserv. Dent. 18 (3), 218–222. doi:10.4103/0972-0707.157256

Parashos, P., and Messer, H. H. (2006). Rotary NiTi instrument fracture and its consequences. J. Endod. 32 (11), 1031–1043. doi:10.1016/j.joen.2006.06.008

Pereira, E. S., Peixoto, I. F., Viana, A. C., Oliveira, I. I., Gonzalez, B. M., Buono, V. T., et al. (2012). Physical and mechanical properties of a thermomechanically treated NiTi wire used in the manufacture of rotary endodontic instruments. Int. Endod. J. 45 (5), 469–474. doi:10.1111/j.1365-2591.2011.01998.x

Peters, O. A. (2004). Current challenges and concepts in the preparation of root canal systems: A review. J. Endod. 30 (8), 559–567. doi:10.1097/01.don.0000129039.59003.9d

Pun, D. K., and Berzins, D. W. (2008). Corrosion behavior of shape memory, superelastic, and nonsuperelastic nickel-titanium-based orthodontic wires at various temperatures. Dent. Mater. 24 (2), 221–227. doi:10.1016/j.dental.2007.05.003

Rapisarda, E., Bonaccorso, A., Tripi, T. R., and Condorelli, G. G. (1999). Effect of sterilization on the cutting efficiency of rotary nickel-titanium endodontic files. Oral. Surg. Oral. Med. Oral. Pathol. Oral. Radiol. Endod. 88 (3), 343–347. doi:10.1016/s1079-2104(99)70040-5

Sattapan, B., Nervo, G. J., Palamara, J. E., and Messer, H. H. (2000). Defects in rotary nickel-titanium files after clinical use. J. Endod. 26 (3), 161–165. doi:10.1097/00004770-200003000-00008

Shabalovskaya, S. A., and Anderegg, J. W. (1995). Surface spectroscopic characterization of TiNi nearly equiatomic shape memory alloys for implants. J. Vac. Sci. Technol. A. 13 (5), 2624–2632. doi:10.1116/1.579461

Shen, Y., Zhou, H. M., Zheng, Y. F., Peng, B., and Haapasalo, M. (2013). Current challenges and concepts of the thermomechanical treatment of nickel-titanium instruments. J. Endod. 39 (2), 163–172. doi:10.1016/j.joen.2012.11.005

Silva, E. J. N. L., Lima, C. O., Barbosa, A. F. A., Lopes, R. T., Sassone, L. M., and Versiani, M. A. (2022). The impact of TruNatomy and ProTaper Gold instruments on the preservation of the periradicular dentin and on the enlargement of the apical canal of mandibular molars. J. Endod. 48 (5), 650–658. doi:10.1016/j.joen.2022.02.003

Silvaggio, J., and Hicks, M. L. (1997). Effect of heat sterilization on the torsional properties of rotary nickel-titanium endodontic files. J. Endod. 23 (12), 731–734. doi:10.1016/S0099-2399(97)80344-5

Sonntag, D., Guntermann, A., Kim, S. K., and Stachniss, V. (2003). Root canal shaping with manual stainless steel files and rotary Ni-Ti files performed by students. Int. Endod. J. 36 (4), 246–255. doi:10.1046/j.1365-2591.2003.00661.x

Viana, A. C., Gonzalez, B. M., Buono, V. T., and Bahia, M. G. (2006). Influence of sterilization on mechanical properties and fatigue resistance of nickel-titanium rotary endodontic instruments. Int. Endod. J. 39 (9), 709–715. doi:10.1111/j.1365-2591.2006.01138.x

Walia, H. M., Brantley, W. A., and Gerstein, H. (1998). An initial investigation of the bending and torsional properties of Nitinol root canal files. J. Endod. 14 (7), 346–351. doi:10.1016/s0099-2399(88)80196-1

Yahata, Y., Yoneyama, T., Hayashi, Y., Ebihara, A., Doi, H., Hanawa, T., et al. (2009). Effect of heat treatment on transformation temperatures and bending properties of nickel-titanium endodontic instruments. Int. Endod. J. 42 (7), 621–626. doi:10.1111/j.1365-2591.2009.01563.x

Yum, J., Cheung, G. S., Park, J. K., Hur, B., and Kim, H. C. (2011). Torsional strength and toughness of nickel-titanium rotary files. J. Endod. 37 (3), 382–386. doi:10.1016/j.joen.2010.11.028

Zanza, A., Seracchiani, M., Reda, R., Miccoli, G., Testarelli, L., and Di Nardo, D. (2022). Metallurgical tests in endodontics: A narrative review. Bioeng. (Basel) 9 (1), 30. doi:10.3390/bioengineering9010030

Zhao, D., Shen, Y., Peng, B., and Haapasalo, M. (2016). Effect of autoclave sterilization on the cyclic fatigue resistance of thermally treated Nickel-Titanium instruments. Int. Endod. J. 49 (10), 990–995. doi:10.1111/iej.12550

Keywords: fracture resistance, heat treatment, nickel-titanium files, torsional fracture, usage, sterilization

Citation: Kang YJ, Alshehhi A, Al Raeesi D, Alkhatib Z, Jamal M, El Abed R and Kim H-C (2023) Effect from usage and autoclave sterilization on torsional fracture resistance of heat-treated nickel-titanium instruments: an in-vitro study. Front. Mater. 10:1215780. doi: 10.3389/fmats.2023.1215780

Received: 02 May 2023; Accepted: 29 May 2023;

Published: 07 June 2023.

Edited by:

Giusy Rita Maria La Rosa, Università degli Studi di Catania, ItalyReviewed by:

Alfredo Iandolo, University of Salerno, ItalyLuca Testarelli, Sapienza University of Rome, Italy

Copyright © 2023 Kang, Alshehhi, Al Raeesi, Alkhatib, Jamal, El Abed and Kim. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hyeon-Cheol Kim, Z29sZGRlbnRAcHVzYW4uYWMua3I=; Rashid El Abed, cmFzaGlkLmVsYWJlZEBtYnJ1LmFjLmFl

†These authors have contributed equally to this work

Yoo Jung Kang1

Yoo Jung Kang1 Mohamed Jamal

Mohamed Jamal Hyeon-Cheol Kim

Hyeon-Cheol Kim