94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater., 03 May 2023

Sec. Structural Materials

Volume 10 - 2023 | https://doi.org/10.3389/fmats.2023.1193225

This article is part of the Research TopicMultiscale Characterization of Advanced Pavement MaterialsView all 10 articles

Recycling waste tires, crushing them into crumb rubber (CR) and adding them to asphalt can effectively improve the performance and prolong the service life of asphalt pavement. However, the crumb rubber modified asphalt (CRMA) prepared by aforementioned process is prone to segregation during storage and transportation. The terminal blend rubber asphalt (TB) prepared with fine rubber powder by high-speed shearing at high temperature for long time, which effectively improves the storage stability and working performance of crumb rubber modified asphalt, but reduces the high-temperature performance. In this study, grafting activated crumb rubber (GACR) was incorporated into TB to improve its high temperature performance without impairing storage stability. Using shearing temperature, shearing time and grafting activated crumb rubber content as influencing factors, the response surface method (RSM) was carried out to optimize the preparation process. The results indicated that 180°C was a critical temperature, and the swelling of crumb rubber dominated with the temperature below it, but the desulfurization prevailed with the temperature above it. The extension of time favored the swelling of crumb rubber at low temperature but promoted desulfurization at high temperature. With the increase of crumb rubber content, the high temperature performance of modified asphalt improved whereas the storage stability deteriorated. According to the determination of response values and the prediction of optimal values, the suitable preparation conditions and parameters were recommended as shearing temperature of 190°C, shearing time of 90 min, and GACR content of 15%. The composite modified asphalt prepared through the optimized process showed good high temperature stability and storage stability.

At present, the concept of sustainable development and the principles based on the “4R” (reclaim, recycle, reuse, and reduce) have attracted widespread attention (Jamshidi et al., 2016). As a sustainable low-cost composite material, crumb rubber has been widely used in industries such as roads, construction, electricity, and power sources (Khaloo et al., 2015; Xu et al., 2020; Phiri et al., 2021; Zhang et al., 2021). Adding crumb rubber (CR) to asphalt can not only improve various performances of asphalt but also provide an environmentally friendly way for the recycling of waste tires. Studies have found that crumb rubber modified asphalt (CRMA) has the advantages of excellent high temperature stability, low temperature crack resistance, fatigue resistance, anti-aging performance and less traffic noise (Yu et al., 2020). However, the storage stability is poor due to the “solid-liquid” two-phase system of rubber powder and asphalt and the density difference between them, which greatly hinders the use of rubber asphalt in actual engineering (Han et al., 2016; Ma et al., 2021a).

In order to solve the above problems, the rubber powder is pretreated before being added to the base asphalt to improve its compatibility with the asphalt, which in turn improves the storage stability of the CRMA. Wang et al. (2020) introduced tetraethyl orthosilicate (TEOS) to modify the surface of CR, and determined the optimal amount of TEOS. This research has a positive effect on improving the storage stability of CRMA. Hosseinnezhad et al. (2019) pretreated CR by the combination of microwave radiation and bio-modification. The results showed that the storage stability of CRMA was significantly improved, and its performance was also improved. It is worth mentioning that Xiao et al. innovatively applied a cold plasma surface treatment technology to the surface treatment of CR, which enhanced the compatibility of CR and base asphalt and thus improved the storage stability of CRMA (Li et al., 2020). At the same time, our group’s previous research also found that graft activation of rubber powder could improve the storage stability of modified asphalt (Xie et al., 2019a; Xie et al., 2019b; Xie et al., 2020a). But generally speaking, the incorporation of CR leads to high viscosity of CRMA and decreases its workability (Yu et al., 2021). In addition, adding admixtures has been proven to improve the storage stability of CRMA, but which made the factors affecting the performance more complicated and the preparation process more difficult to control (Liu et al., 2014; Fini et al., 2017; Ma et al., 2021b).

Moreover, some existing studies indicated the storage stability of CRMA could be increased by adjusting the preparation process (Sienkiewicz et al., 2017). It has been confirmed that the solubility of CR in asphalt could be improved under strict shearing conditions (such as high temperature, high pressure and long-time), and when it is up to 97% (Huang et al., 2017), CRMA will not segregate during storage. Terminal Blend rubber asphalt (TB) is developed on this basis and solves the defects of poor storage stability and high viscosity of traditional rubber asphalt (Han et al., 2016). TB is usually prepared with 40–80 mesh rubber powder through high-speed shearing for a long time at temperature above 220°C (Huang et al., 2017; Xie et al., 2020b). During the process the rubber powder conducts desulfurization and degradation, its molecular chains gradually break into small molecules and dissolve in asphalt (Ragab and Abdelrahman, 2018). On the one hand, this preparation process reduces the viscosity of the rubber asphalt and improves the storage stability significantly (Huang et al., 2016). But on the other hand, this process decreases the high temperature performance of modified asphalt and keeps it from being used alone (Polacco et al., 2015). Compounding with other modifiers is considered to be an effective way to solve this problem, and the most common modifiers include SBS (Lin et al., 2017; Tang et al., 2017), nano-materials (Han et al., 2017; Zheng et al., 2018), polyphosphoric acid (PPA) (Niu, 2017), rock asphalt (Zhong et al., 2017) and other chemical modifiers (Wen et al., 2018). But the high cost of SBS and nano-materials, and the deterioration of low temperature performance caused by rock asphalt and PPA are issues for composite modification (Huang et al., 2016; Lin et al., 2018).

Therefore, the research objectives of this article are as follows.

• Attempt to composite the acrylamide grafted activated crumb rubber prepared earlier with TB to improve its high-temperature performance. Simultaneously utilizing the unique advantages of GACR (Xie et al., 2020a), ensuring the excellent storage stability and other performance of TB will not be affected.

• Based on response surface methodology (RSM), to determine the optimal preparation for TB/GACR modified asphalt (TB/GACR). Shearing temperature, shearing time and crumb rubber content were selected as influencing factors, and their effects on the penetration, ductility, storage stability and viscosity of modified asphalt were explored.

• To study the synergistic effect of GACR and terminal blend technology on the high temperature performance and storage stability of composite modified asphalt, GACR modified asphalt (GACR-MA) and TB asphalt were also prepared as the reference via the optimized process.

Base asphalt of PG 64-22, 70#A grade was supplied by Hunan Poly Company (Hunan, China), crumb rubber of 80 mesh was purchased from Sichuan Lubaotong Company (Chengdu, China), and all other reagents were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China).

GACR was prepared according to the literature (Xie et al., 2020a), and the process was sketched as follows: crumb rubber, potassium persulfate and acrylamide were mixed at a certain ratio and stirred for 4 h at 65°C. Through grafting action, amide groups were introduced into the molecular chains of crumb rubber, which could improve the compatibility between rubber powder and base asphalt.

TB asphalt was prepared by homemade high-speed shearing instrument with nitrogen protective device (Figure 1). The steps of preparation were as follows:15% (by the weight of base asphalt, the same hereinafter) untreated crumb rubber and base asphalt were mixed and swelled in an oven for 30 min at 180°C, followed by being sheared at a rate of 4,000 r/min for 3 h at 220°C (Xie et al., 2020c). During the preparation process, nitrogen protection was adopted to alleviate the aging of asphalt.

The wet process was employed to prepare TB/GACR and was illustrated as below. TB asphalt was heated at 145°C–165°C to fluid state and then mixed with dried GACR (10%–20% dosages). The mixture was sheared at 160°C–200°C for 30–90 min, followed by being placed in an oven at 165°C for 1 h.

Detailed physical performance test methods are listed in Table 1.

In addition, the storage stability was tested according to the “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011). A standard aluminium tube (diameter 25 mm, height 140 mm) was filled with the obtained asphalt and sealed. Then it was placed vertically in the oven at 163°C for 48 h to simulate the segregation during high temperature storage. Afterwards the aluminium tube was taken out and frozen for 240 min at 4°C, followed by being divided into 3 sections to measure the softening point of the upper and lower sections. The softening point difference and rutting factor separation index (SI) of the upper and lower sections of modified asphalt were measured to appraise storage stability. The value of SI was calculated by the following formula:

where (G*/sinδ)bottom and (G*/sinδ)top are the rutting resistance factor of modified asphalt at the bottom and top of tube, respectively.

Response surface methodology (RSM) is a method that combines experimental design and mathematical modeling for optimization, whose advantage is that it can continuously analyze various levels of the experiment, more intuitively reflecting the optimal value of the dependent variable (Chelladurai et al., 2021). There are two main types of design in RSM: Central Composite Design (CCD) and Box-Behnken Design (BBD). By comparison, the latter can provide more accurate responses with fewer combination schemes (Goo et al., 2020). So, BBD was used to optimize the preparation process of TB/GACR through a three-factor composite design. In this study, shearing temperature (160°C–200°C), shearing time (30–90 min) and GACR content (10%–20%) were chosen as influencing factors, and the penetration (25°C), softening point, ductility (15°C), softening point difference and viscosity were defined as response values.

The experimental schemes and performance test results obtained through RSM were shown in Table 2. The results of simulation showed that the values obtained by the quadratic equation were close to the actual values. Therefore, the quadratic equation was used to simulate the response values and influencing factors, so as to estimate the significance of the variables. The three influencing factors: shearing temperature, shearing time, and GACR content were recorded as A, B, and C, respectively. Analysis of variance of the experimental data in Table 4 was performed and the results are described below. Therein F represents the significance of the whole fitting equation, and P represents the correlation between the control group and the experimental group. Generally, the larger the value of F, the higher the fitting degree, and the smaller the value of P, the more significant the analysis result.

The results of analysis of variance on penetration are shown in Table 3. It can be seen that this model had a high degree of fitting with small error and could be used to predict and analyze the variation law of penetration. The significant variables of the model were A, B, C, AB, BC and A2, which meant in the single effect, the influence of shearing temperature, shearing time and GACR content were significant. But in the quadratic effects, the interaction between shearing temperature and shearing time, and the interaction between shearing time and GACR content were significant. Moreover, in the quadratic effect, the influence of shearing temperature was significant.

The fitting equation of penetration based on significant variables is.

where: R1 is the penetration value of TB/GACR.

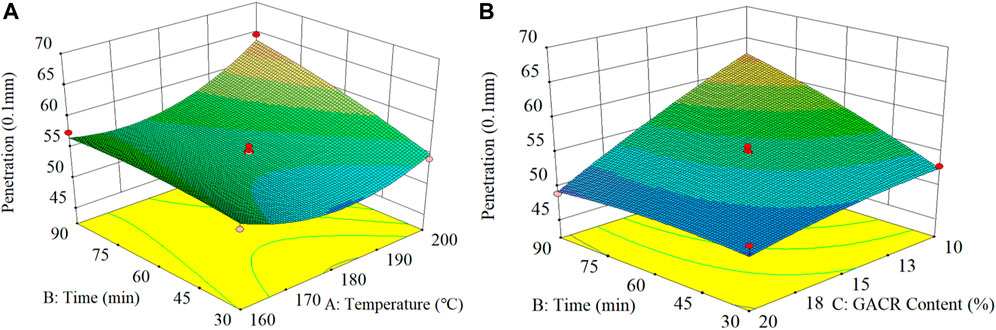

The RSM models of GACR content, shearing temperature and shearing time on penetration were obtained according to Eq. 2, as shown in Figure 2. With the increase of shearing temperature, the penetration of TB/GACR decreased first and increased afterwards, which may be due to the swelling and desulfurization of crumb rubber during the shearing process (Xie et al., 2019b). In the range of 160°C–180°C, GACR absorbed the light component and swelled. With the increase of temperature, the swell degree increased and a network structure was gradually formed, leading to the rise in viscosity and the reduction in penetration. When the shearing temperature exceeded 180°C, the network was broken and the solubility of GACR improved because of the desulfurization and degradation, causing the increase in penetration (Navarro et al., 2007; Nanjegowda and Biligiri, 2020).

FIGURE 2. Response surface plot of penetration (A) Under the interaction of temperature and time; (B) Under the interaction of time and GACR content.

The penetration increased with time in the whole temperature range. But interestingly, the extent of increase was slight when the temperature was below 180°C and was remarkable when the temperature was above 180°C. Similarly, that was ascribed to the swelling and desulfurization of GACR.

The effect of GACR content on the penetration of TB/GACR showed obvious regularity, that is, the penetration declined with the increase of GACR content. It can be illustrated by volume expansion of crumb rubber caused by swelling (Ghavibazoo et al., 2013; Pais et al., 2019) and enhanced interaction between GACR and base asphalt due to the grafting activation (Xie et al., 2019a; Xie et al., 2019b).

The analysis of variance of softening point (shown in Table 4) indicated that the model was significant with small P (<0.05) and the correlation coefficient was high. The fitting effect of the model was accurate, so it could be used to predict the variation law of softening point. The significant variables were A, C, A2 and C2 when variables with non-significant effects were removed. Among the single effect, the shearing time and GACR content were significant, but among the quadratic effects, the significant variables turned to be shearing temperature and GACR content.

The response surface fitting equation of softening point according to the significant variables is:

where: R2 is the softening point value of TB/GACR.

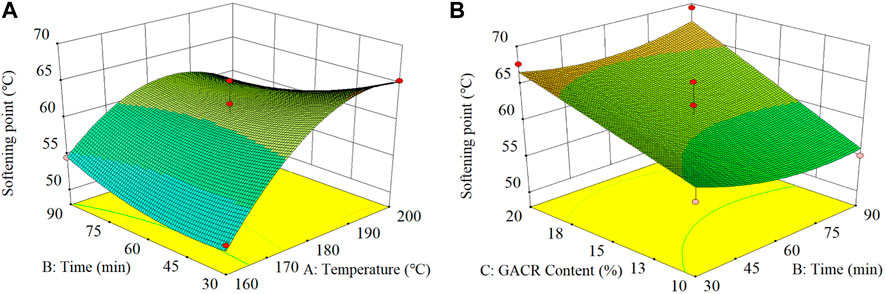

From Eq. 3, the RSM models of GACR content, shearing temperature and shearing time with softening point were obtained, as shown in Figure 3.

FIGURE 3. Response surface plot of softening point (A) Under the interaction of temperature and time; (B) Under the interaction of time and GACR content.

As illustrated in Figure 3A, with the temperature increasing, the softening point rose at first and then declined. Meanwhile, the effect of shearing time on the softening point was a little bit complicated. Under the temperature condition of 160°C the softening point gradually increased with the increase of shearing time. When the shearing temperature increased to 200°C, the opposite trend appeared. The above results can be explained by the swelling and desulfurization of crumb rubber as mentioned before.

It can be seen from Figure 3B that the addition of GACR improved the softening point of TB/GACR, which could be explained from two aspects: one is that the increased GACR absorbed more light components; the other is that the chemical reaction between the basic groups on the molecular chains of GACR and the acidic groups in the asphalt reinforced the interfacial bonding between them (Xie et al., 2019a).

The results of analysis of variance on ductility are listed in Table 5. It is observed that the fitting effect of the model was good and the correlation coefficient between predicted values and actual values was high.

The significant variables were determined as A, B, C, AC and BC. And the fitting equation of this model based on the significant variables is:

where: R3 is the ductility value of TB/GACR.

According to Eq. 4, the RSM models of shearing temperature, shearing time and GACR content with respect to ductility were obtained, as shown in Figure 4.

FIGURE 4. Response surface plot of ductility (A) Under the interaction of temperature and time; (B) Under the interaction of time and GACR content.

Raising temperature not only favored the swelling of the GACR and the generation of the network structure in modified asphalt but also accelerated the chemical reaction between acrylamide groups of GACR and anhydride groups of base asphalt (Xie et al., 2019a; Xie et al., 2019b). To sum up, the homogeneity of TB/GACR increased with temperature, which improved the ductility consequently.

Even GACR has higher compatibility with asphalt and dispersed more uniformly compared with original crumb rubber (Li et al., 2021), the ductility still gradually decreased with the increase of its content. This is because that GACR cannot dissolve in asphalt and the particles aggregate easily with the increase of content. Hence the homogeneity of TB/GACR got worse and the stress concentration formed, resulting in a fall in ductility.

The results of analysis of variance on storage stability are shown in Table 6. It can be seen that the fitting model of quadratic equation was significant (p = 0.0004). After correction, the correlation coefficient between predicted values and measured values was 91%, indicating that this model was reasonable to predict and analyze the softening point difference.

The significant variables were A, B, AC, C2, and the response surface fitting equation obtained based on the variables is:

where: R4 is the softening point difference value of TB/GACR.

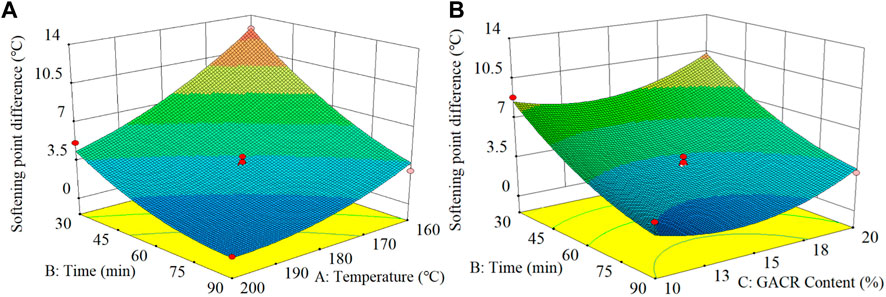

From Eq. 5, the RSM models of shearing temperature, shearing time and GACR content on softening point difference can be obtained, as shown in Figure 5.

FIGURE 5. Response surface plot of softening point difference (A) Under the interaction of temperature and time; (B) Under the interaction of time and GACR content.

It can be seen from Figure 5A that with the increase of shearing temperature, the softening point difference of TB/GACR decreased, indicating that the storage stability improved. However, the way temperature affected storage stability was not same in different range. When the temperature was raised from 160°C to 180°C, the swelling degree of GACR increased and a gel film formed on the surface of GACR, which led to the semi-solid continuous phase of TB/GACR (Xie et al., 2019a; Xie et al., 2019b). When the temperature exceeded 180°C, GACR conducted desulfurization and degradation to generate small molecules. According to Stokes’ law, the reduction of particle size helps to reduce the speed of its falling (Wen et al., 2018). Therefore, the generation of small molecules improved the storage stability.

With the increase of shearing time, the softening point difference showed a downward trend, indicating that the longer the shearing time, the better the dispersion of GACR and the better the storage stability of TB/GACR.

The grafting activation of crumb rubber strengthened the interaction between it and base asphalt but not improved its solubility in base asphalt very much, and so the aggregation of GACR could not be avoided when the content was high. That’s why the storage stability dropped with the increase of GACR content.

The results of analysis of variance on viscosity are shown in Table 7.

It can be seen that the model had high correlation and fitting degree to predict and analyze the change law of viscosity. The response surface fitting equation of viscosity based on significant variables is:

where: R5 is the viscosity value of TB/GACR.

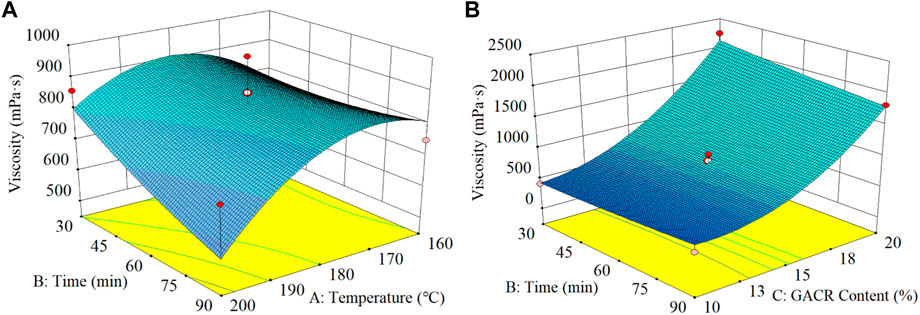

From Eq. 6, the RSM models of GACR content, shearing temperature and shearing time on viscosity were obtained, as shown in Figure 6.

FIGURE 6. Response surface plot of viscosity. (A) Under the interaction of temperature and time; (B) Under the interaction of time and GACR content.

The change trend of viscosity with temperature was the same with that of softening point, namely, first rose then descended. Also, the prolongation of shearing time raised viscosity at lower temperature (160°C–180°C) but reduced it at higher temperature (>180°C). Simultaneously, the reason causing this phenomenon was identical to that discussed in the softening point section.

When talking about GACR content, it increased the viscosity TB/GACR regardless of temperature and time. This could be attributed to the decrease in light components because of GACR swelling and the reinforcement in interaction between GACR and base asphalt.

On the basis of the analysis and discussion of the influence of GACR content, shearing temperature, and shearing time on the performance of TB/GACR, using the desired goal values as control, the optimal process parameters were predicted through Optimization module of RSM and listed in Table 8. Since TB system contained 15% rubber powder, in view of operation convenience and comprehensive properties of TB/GACR, the process parameters were proposed as shearing temperature of 190°C, shearing time of 90min and GACR content of 15%.

Three kinds of modified asphalts: TB, GACR-MA, and TB/GACR, were prepared by the optimal process parameters, and the penetration, softening point, viscosity and rheological properties of the modified asphalts were tested to evaluate the high-temperature performance. As shown in Figure 7, the penetration of TB, GACR-MA and TB/GACR decreased and the softening point increased sequentially. Compared with TB, the penetration of TB/GACR decreased by 28.4%, and the softening point increased by 20.5%. Meanwhile, the high temperature rheological properties of modified asphalts were measured and the rutting factor (G*/sinδ) was used to characterize the abilities of resistance to rutting and permanent deformation. As shown in Figure 8, the rutting factor of TB was the smallest and that of TB/GACR was the largest at the same temperature.

The creep stiffness (S) and creep rate (m-value) measured by bending beam rheometer (BBR) are used to evaluate the performance of TB/GACR under low temperature environment. The test results were listed in Table 9. At the same temperature, the smaller the S and the greater the m-value of the modified asphalt, the better its low-temperature performance. It is obvious that under the low temperature environment of −12°C and −18°C, the S of TB/GACR was significantly lower than that of TB and GACR, and TB/GACR had the smallest S and the largest m-value among the three modified asphalt.

To sum up, TB/GACR had the best high and low temperature properties among these three kinds of modified asphalts. It could be explained that GACR had a positive effect on improving high temperature performance of TB asphalt, and the addition of GACR did not affect its low-temperature performance.

Segregation tests were carried out on the three kinds of modified asphalts, and the results of softening point difference are shown in Figure 9A. The softening point difference was greater for TB/GACR compared to TB because the addition of the rubber powder disrupted the homogeneous structure of the asphalt, thus increasing the possibility of segregation. In comparison to GACR asphalt, the softening point difference of TB/GACR was reduced by 38%, indicating that TB/GACR still maintained the excellent storage stability of TB and further reduced the segregation phenomenon of GACR in modified asphalt.

To further evaluate the storage stability of modified asphalts, the SIs were calculated from the temperature sweep test (Figure 9B). It could be seen that the SI of TB asphalt was stable at about 1.0 within the scanning temperature range. Among the three kinds of modified asphalts, GACR-MA had the largest SI, which indicating the poorest storage stability. Compared with TB asphalt, the SI of TB/GACR increased slightly but obviously lower than that of GACR-MA. The results of SI are consistent with the results of softening point difference, which fully indicates that the storage stability of TB/GACR is slightly inferior to that of TB bitumen, but superior to that of GACR-MA.

GACR and TB asphalt were compounded to prepare rubber asphalt with good storage stability and high temperature performance. With the penetration, softening point, ductility, storage stability and viscosity as indexes, RSM was adopted to optimize the process parameters. The main conclusions were summarized as follow.

(1) In the range of 160°C–180°C, GACR mainly swelled in TB asphalt by absorbing the light components. Both the increase of temperature and prolongation of time facilitated the swelling degree and thus improved the high temperature performance and storage stability of TB/GACR asphalt.

(2) In the range of 180°C–200°C, GACR degraded obviously. The crosslink bonds tended to break easily with increasing temperature and time, and consequently, the low temperature property and storage stability of compound modified asphalt were further improved but the high temperature property decreased.

(3) The increase of GACR content was beneficial to the high temperature performance of TB/GACR asphalt. But at the same time the aggregation possibility of the insoluble crumb rubber also increased, which reduced the storage stability and low temperature performance.

(4) According to the experiment results and the operation convenience, the optimum preparation parameters of TB/GACR asphalt were suggested as follows: shearing temperature of 190°C, shearing time of 90min and GACR content of 15%.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

JX is the supervisor of this research work and responsible for experimental design, the editing and writing of manuscript. XZ completing data analysis and writing the first draft of the paper. YZ helped in software support and data analysis. FY, HL, XC, and WH participated in the testing of experimental samples. All authors reviewed the results and approved the final version of the manuscript.

This work was supported by the National Natural Science Foundation of China (52178411 and 51608056), the Education Department of Hunan Province (22A0209), Changsha Municipal Natural Science Foundation (kq2014108), Postgraduate Scientific Research Innovation Project of Hunan Province (CX20210757), and Graduate Research Innovation Project of Changsha University of Science and Technology (CXCLY2022016).

Author YZ was employed by Shanghai Municipal Engineering Design Institute (Group) Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Chelladurai, S. J. S., Murugan, K., Ray, A. P., Upadhyaya, M., and Narasimharaj, V. (2021). Optimization of process parameters using response surface methodology: A review. Mater. Today Proc. 37 (2), 1301–1304. doi:10.1016/j.matpr.2020.06.466

Fini, E. H., Hosseinnezhad, S., Oldham, D., McLaughlin, Z., Alavi, Z., and Harvey, J. (2017). Bio-modification of rubberised asphalt binder to enhance its performance. Int. J. Pavement Eng. 20 (10), 1216–1225. doi:10.1080/10298436.2017.1398548

Ghavibazoo, A., Abdelrahman, M., and Ragab, M. (2013). Mechanism of crumb rubber modifier dissolution into asphalt matrix and its effect on final physical properties of crumb rubber–modified binder. Transp. Res. Rec. 2370 (1), 92–101. doi:10.3141/2370-12

Goo, Y. T., Park, S. Y., Chae, B. R., Yoon, H. Y., Kim, C. H., Choi, J. Y., et al. (2020). Optimization of solid self-dispersing micelle for enhancing dissolution and oral bioavailability of valsartan using Box-Behnken design. Int. J. Pharm. 585, 119483. doi:10.1016/j.ijpharm.2020.119483

Han, L., Han, H., and Zheng, L. (2017). Viscosity-temperature relationship and low temperature toughness of terminal blend crumb rubber-nano SiO2 modified asphalt. J. Mater. Sci. Eng. 35 (6), 902–920. doi:10.14136/j.cnki.issn1673-2812.2017.06.009

Han, L., Zheng, M., and Wang, C. (2016). Current status and development of terminal blend tyre rubber modified asphalt. Constr. Build. Mater. 128, 399–409. doi:10.1016/j.conbuildmat.2016.10.080

Hosseinnezhad, S., Kabir, S. F., Oldham, D., Mousavi, M., and Fini, E. H. (2019). Surface functionalization of rubber particles to reduce phase separation in rubberized asphalt for sustainable construction. J. Clean. Prod. 225, 82–89. doi:10.1016/j.jclepro.2019.03.219

Huang, W., Lin, P., Tang, N., Hu, J., and Xiao, F. (2017). Effect of crumb rubber degradation on components distribution and rheological properties of Terminal Blend rubberized asphalt binder. Constr. Build. Mater. 151, 897–906. doi:10.1016/j.conbuildmat.2017.03.229

Huang, W., Lv, Q., and Chai, C. (2016). Research on composite modification by terminal blend asphalt. J. Build. Mater. 19 (1), 111–118. doi:10.3969/j.issn.1007-9629.2016.01.019

Jamshidi, A., Kurumisawa, K., Nawa, T., and Igarashi, T. (2016). Performance of pavements incorporating waste glass: The current state of the art. Renew. Sustain. Energy Rev. 64, 211–236. doi:10.1016/j.rser.2016.06.012

Khaloo, A. R., Esrafili, A., Kalani, M., and Mobini, M. H. (2015). Use of polymer fibres recovered from waste car timing belts in high performance concrete. Constr. Build. Mater. 80, 31–37. doi:10.1016/j.conbuildmat.2015.01.011

Li, J., Chen, Z., Xiao, F., and Amirkhanian, S. N. (2021). Surface activation of scrap tire crumb rubber to improve compatibility of rubberized asphalt. Resour. Conservation Recycl. 169, 105518. doi:10.1016/j.resconrec.2021.105518

Li, J., Xiao, F., and Amirkhanian, S. N. (2020). High temperature rheological characteristics of plasma-treated crumb rubber modified binders. Constr. Build. Mater. 236, 117614. doi:10.1016/j.conbuildmat.2019.117614

Lin, P., Huang, W., Tang, N., Xiao, F., and Li, Y. (2018). Understanding the low temperature properties of Terminal Blend hybrid asphalt through chemical and thermal analysis methods. Constr. Build. Mater. 169, 543–552. doi:10.1016/j.conbuildmat.2018.02.060

Lin, P., Huang, W., Tang, N., and Xiao, F. (2017). Performance characteristics of Terminal Blend rubberized asphalt with SBS and polyphosphoric acid. Constr. Build. Mater. 141, 171–182. doi:10.1016/j.conbuildmat.2017.02.138

Liu, H., Chen, Z., Wang, W., Wang, H., and Hao, P. (2014). Investigation of the rheological modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR additive. Constr. Build. Mater. 67, 225–233. doi:10.1016/j.conbuildmat.2013.11.031

Ma, T., Chen, C., Zhang, Y., and Zhang, W. (2021). Development of using crumb rubber in asphalt modification: A review. China J. Highw. Transp. 34 (10), 1–16. doi:10.19721/j.cnki.1001-7372.2021.10.001

Ma, Y., Wang, S., Zhou, H., Hu, W., Polaczyk, P., Zhang, M., et al. (2021). Compatibility and rheological characterization of asphalt modified with recycled rubber-plastic blends. Constr. Build. Mater. 270, 121416. doi:10.1016/j.conbuildmat.2020.121416

Nanjegowda, V. H., and Biligiri, K. P. (2020). Recyclability of rubber in asphalt roadway systems: A review of applied research and advancement in technology. Resour. Conservation Recycl. 155, 104655. doi:10.1016/j.resconrec.2019.104655

Navarro, F. J., Partal, P., Martínez-Boza, F. J., and Gallegos, C. (2007). Influence of processing conditions on the rheological behavior of crumb tire rubber-modified bitumen. J. Appl. Polym. Sci. 104 (3), 1683–1691. doi:10.1002/app.25800

Niu, W. (2017). Rheological properties of polyphosphoric acid composite TB crumb rubber modified asphalt and pavement performance of its asphalt mixture. Highway 62 (8), 234–243.

Pais, J., Lo Presti, D., Santos, C., Thives, L., and Pereira, P. (2019). The effect of prolonged storage time on asphalt rubber binder properties. Constr. Build. Mater. 210, 242–255. doi:10.1016/j.conbuildmat.2019.03.155

Phiri, M. M., Phiri, M. J., Formela, K., and Hlangothi, S. P. (2021). Chemical surface etching methods for ground tire rubber as sustainable approach for environmentally-friendly composites development– a review. Compos. Part B Eng. 204, 108429. doi:10.1016/j.compositesb.2020.108429

Polacco, G., Filippi, S., Merusi, F., and Stastna, G. (2015). A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 224, 72–112. doi:10.1016/j.cis.2015.07.010

Ragab, M., and Abdelrahman, M. (2018). Enhancing the crumb rubber modified asphalt’s storage stability through the control of its internal network structure. Int. J. Pavement Res. Technol. 11 (1), 13–27. doi:10.1016/j.ijprt.2017.08.003

Sienkiewicz, M., Borzędowska-Labuda, K., Wojtkiewicz, A., and Janik, H. (2017). Development of methods improving storage stability of bitumen modified with ground tire rubber: A review. Fuel Process. Technol. 159, 272–279. doi:10.1016/j.fuproc.2017.01.049

Tang, N., Huang, W., Hu, J., and Xiao, F. (2017). Rheological characterisation of terminal blend rubberised asphalt binder containing polymeric additive and sulphur. Road Mater. Pavement Des. 19 (6), 1288–1300. doi:10.1080/14680629.2017.1305436

Wang, Z., Xu, X., Wang, X., Jinyang, H., Guo, H., and Yang, B. (2020). Performance of modified asphalt of rubber powder through tetraethyl orthosilicate (TEOS). Constr. Build. Mater. 267, 121032. doi:10.1016/j.conbuildmat.2020.121032

Wen, Y., Wang, Y., Zhao, K., Chong, D., Huang, W., Hao, G., et al. (2018). The engineering, economic, and environmental performance of terminal blend rubberized asphalt binders with wax-based warm mix additives. J. Clean. Prod. 184, 985–1001. doi:10.1016/j.jclepro.2018.03.011

Xie, J., Yang, Y., Lv, S., Peng, X., and Zhang, Y. (2019). Investigation on preparation process and storage stability of modified asphalt binder by grafting activated crumb rubber. Mater. (Basel) 12 (12), 2014. doi:10.3390/ma12122014

Xie, J., Yang, Y., Lv, S., Zhang, Y., Zhu, X., and Zheng, C. (2019). Investigation on rheological properties and storage stability of modified asphalt based on the grafting activation of crumb rubber. Polym. (Basel) 11 (10), 1563. doi:10.3390/polym11101563

Xie, J., Zhang, Y., and Yang, Y. (2020). Development trends of terminal blend rubber modified asphalt. Plastics 49 (04), 124–130+140.

Xie, J., Zhang, Y., Yang, Y., Ma, Y., Li, J., and Huang, M. (2020). The effect of activation method of rubber on the performance of modified asphalt binder. Mater. (Basel) 13 (17), 3679. doi:10.3390/ma13173679

Xie, J., Zhang, Y., and Yang, Y. (2020). Study on preparation method of terminal blend rubberized asphalt binder. Front. Mater. 7, 279. doi:10.3389/fmats.2020.00279

Xu, J., Yu, J., Xu, J., Sun, C., He, W., Huang, J., et al. (2020). High-value utilization of waste tires: A review with focus on modified carbon black from pyrolysis. Sci. Total Environ. 742, 140235. doi:10.1016/j.scitotenv.2020.140235

Yu, H. Y., Deng, G. S., Wang, D. Y., Zhang, Z. Y., and Oeser, M. (2020). Warm asphalt rubber: A sustainable way for waste tire rubber recycling. J. Central South Univ. 27 (11), 3477–3498. doi:10.1007/s11771-020-4467-y

Yu, H., Deng, G., Zhang, Z., Zhu, M., Gong, M., and Oeser, M. (2021). Workability of rubberized asphalt from a perspective of particle effect. Transp. Res. Part D Transp. Environ. 91, 102712. doi:10.1016/j.trd.2021.102712

Zhang, W., Luan, Y., Ma, T., Wang, S., Chen, J., Li, J., et al. (2021). Multilevel analysis of the aging mechanisms and performance evolution of rubber-modified asphalt. J. Mater. Civ. Eng. 33 (12), 4. doi:10.1061/(asce)mt.1943-5533.0004000

Zheng, L., Han, Y., Li, S., and Liu, Y. (2018). Morphology effect on properties and microstructure of terminal blend crumb rubber modified asphalt. J. Mater. Sci. Eng. 36 (5), 720–725.

Keywords: modified asphalt, terminal blend, grafting activated crumb rubber, response surface methodology, high temperature performance, storage stability

Citation: Xie J, Zhao X, Zhang Y, Yu F, Luo H, Chen X and He W (2023) Preparation of terminal blend/ grafting activated crumb rubber composite modified asphalt based on response surface methodology . Front. Mater. 10:1193225. doi: 10.3389/fmats.2023.1193225

Received: 24 March 2023; Accepted: 21 April 2023;

Published: 03 May 2023.

Edited by:

Hui Yao, Beijing University of Technology, ChinaReviewed by:

Yue Xiao, Wuhan University of Technology, ChinaCopyright © 2023 Xie, Zhao, Zhang, Yu, Luo, Chen and He. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Juan Xie, eGllanVhbjA4QDEyNi5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.