- 1State Key Laboratory of Fire Science, University of Science and Technology of China, Hefei, China

- 2School of Safety Science and Emergency Management, Wuhan University of Technology, Wuhan, China

- 3Department of Industrial Art (Textiles), Kwame Nkrumah University of Science and Technology, Kumasi, Ghana

- 4Department Materials Science and Engineering, City University of Hong Kong, Kowloon, Hong Kong SAR, China

- 5HP-NTU Digital Manufacturing Corporate Lab, School of Mechanical and Aerospace Engineering, Nanyang Technological University, Singapore, Singapore

Editorial on the Research Topic

Fire risk and prevention technologies of polymeric and composite materials

Introduction

Polymeric materials have been widely applied in various fields in our modern society. However, most natural and synthetic polymeric materials are highly flammable; once ignited, they may cause severe fire incidents. Fire accidents caused by flammable polymeric materials have resulted over 40,000 deaths worldwide and regarded as a major challenge to be tackled in the public safety field. Therefore, how to reduce the fire risk of these flammable polymeric materials has become a hot Research Topic for their practical application. At present, the mainstream effective strategy for reducing fire risk includes the addition of flame-retardant (FR) fillers and the construction of flame-retardant coating to obtain high-performance flame-retardant polymers and composite materials. Besides, its important to develop and propose new methods or techniques to investigate the oxidation behaviors and combustion characteristics of energy source materials, e.g., coal-based polymers and composites.

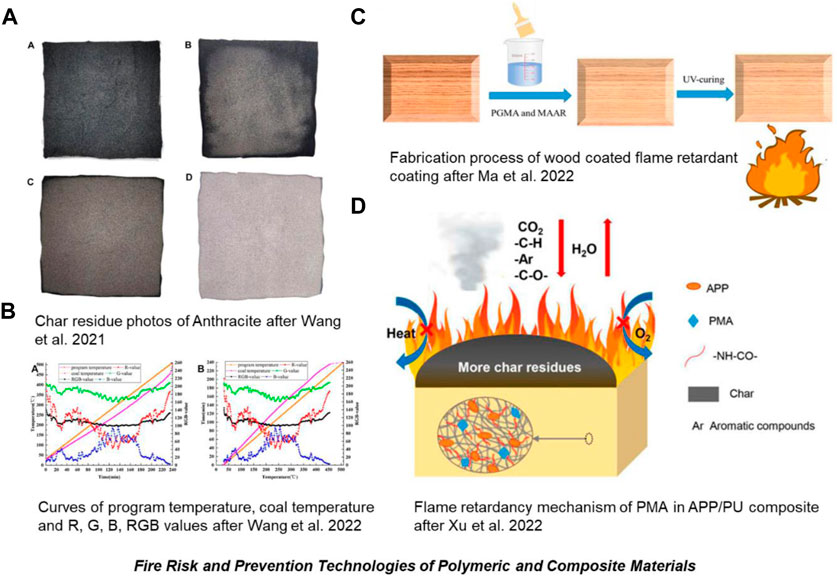

This Research Topic, Fire Risk and Prevention Technologies of Polymeric and Composite Materials, aims to feature the latest technologies and advances in fire risk and prevention technologies of polymeric and composite materials. This Research Topic will be of great interest and value to researchers, engineers and others who are working in academia and industry concerning fire safety. Meanwhile, it will greatly contribute to promoting the discovery and development of new fire risk and prevention technologies for polymeric and composite materials. As shown in Figure 1, the fire risk and prevention technologies of polymeric and composite materials can be divided into two main categories: 1) fire risk evaluation technology, and 2) fire prevention technology, e.g., the addition of FRs and construction of FR coating.

FIGURE 1. Advancement of fire risk and prevention technologies of polymeric and composite materials. Images in (A), (B), (C) and (D) are adapted from Wang et al.; Wang et al.; Ma et al.; Xu et al. respectively, published under the terms of Creative Commons Attribution 4.0 (CC BY 4.0).

This series includes four research articles that involve fire risk and prevention technologies of polymeric and composite material, including fire risk evaluation technologies of coal-based polymers and composites (Wang et al.; Wang et al.) and flame-retardant technologies of flammable polymers, i.e., wood (Ma et al.) and polyurethane foam (Xu et al.).

Wang et al. investigated the influence of high-temperature thermal radiation on the transformation behaviors and characteristics of coal oxidation and spontaneous combustion based on a series of cone calorimeter data. The results indicate that with increasing the thermal radiation value, the ignition time of coal gradually reduces. The peak heat release rate (pHRR), total heat release (THR) and total smoke release (TSR) gradually increase. Besides, the total CO release reduces gradually, while the peak carbon dioxide production rate (PCO2PR) increases gradually. This work presents a novel strategy to investigate coal oxidation and spontaneous combustion.

Wang et al. also presented an infrared thermal image RGB-value characterization method for investigating the oxidation process and spontaneous combustion characteristics of anthracite. The related results imply that the characteristics of coal oxidation and spontaneous combustion cannot be accurately characterized by temperature alone, there exists a correlation between the R value, G value, B value, and RGB value in the infrared thermal imaging data with the process of oxidation and spontaneous combustion of coal, and can be characterized by the RGB-value online and in real-time.

Ma et al. used phosphate acrylate monomer (PGMA) and melamine acrylic ester (MAAR) to obtain a series of wood fireproof coatings with various proportions, and the fire resistance of wood was studied. The results showed that with the composite coating of 33.3% PGMA and 66.7% MAAR, the total heat release value and total smoke release of the wood were significantly decreased, indicating a desirable improvement effect on fire retardancy and smoke suppression of natural wood. Plastics are classified as thermoplastic or thermosetting polymers. Polyurethane (PU) is a typical thermosetting resin with high flammability when exposed to fire. To address the inherent flammability of PU, Xu et al. studied Phosphomolybdic acid (PMA) as a synergist flame retardant for rigid PU foam with ammonium polyphosphate (APP). The thermal degradation behavior and combustion performance of PU materials were investigated. The results showed that the introduction of PMA can effectively improve the flame-retardant performance of PU/APP composites and significantly increase the mass of char residue. In addition, the presence of PMA can also reduce the emission of small-molecule gas-phase pyrolysis products.

For most thermoplastics, several flame retardant coatings can be applied to improve their fire resistance. Some of the typical fire resistance coatings are a group of chemicals that contain halogens such as chlorine or bromine which can be applied in thermoplastics as coatings or additives to improve their fire resistance by releasing halogen compounds when heated, which can interfere with the combustion process (Hull et al., 2014).

A typical fire resistance coating applied to thermoplastics is phosphorus-based flame retardants. These can also be used as coatings or additives to improve the fire resistance of thermoplastics by releasing phosphorus compounds when heated, which suppresses flames.

Similarly, nitrogenous compounds are also important to fire retardant additive/coating that acts by releasing ammonia gas when exposed to heat, which dilutes the concentration of oxygen in the air and prevents combustion (Vorkamp et al., 2019).

Intumescent coatings are applied to thermoplastic materials to create a protective layer that expands when exposed to heat, preventing ignition. More so, certain inorganic materials such as aluminum hydroxide or magnesium hydroxide are used as coatings or fillers in thermoplastic materials to improve their fire resistance. When heated, they release water vapor or other gases which suppress flames (Lee et al., 2022).

Nanocomposite coatings are also applied to thermoplastics to improve their fire resistance. They work by creating a barrier layer that can help to prevent heat and flames from reaching the materials (Teles et al., 2022). Most of the flame retardants used to reduce and prevent fire risk in polymeric materials work using a combination of mechanisms depending on the method of application and the nature of the polymeric material.

These research works contribute to a body of knowledge in the field of Fire Risk and Prevention Technologies for Polymeric and Composite Materials and provides insight into novel fire prevention strategies for composite materials at the molecular level.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication. Chengfei Cao and BnY writes the manuscript; BhY, BT, WW, and YH revised the manuscript.

Funding

This work is financially supported by the National Natural Science Foundation of China (No. 52106187) and the National Key Research and Development Program of China (No. 2021YFB3700202).

Acknowledgments

This Research Topic would not have been possible without the contributions of talented authors, hardworking and professional reviewers, and the dedicated editorial team of Frontiers in Materials. Congratulations to all authors who have contributed to this Research Topic. In addition, we would like to express our sincere gratitude to all reviewers and the editorial team of Frontiers in Materials.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Hull, T., Law, R., and Bergman, Å. (2014). Environmental drivers for replacement of halogenated flame retardants. Polym. Green Flame Retard. 22, 119–179. doi:10.1016/b978-0-444-53808-6.00004-4

Lee, S. H., Lee, S. G., Lee, J. S., and Ma, B. C. (2022). Understanding the flame retardant mechanism of intumescent flame retardant on improving the fire safety of rigid polyurethane foam. Polymers 14, 4904. doi:10.3390/polym14224904

Teles, F., Martins, G., and Antunes, F. (2022). Fire retardancy in nanocomposites by using nanomaterial additives. J. Anal. Appl. Pyrolysis 163, 105466. doi:10.1016/j.jaap.2022.105466

Keywords: fire risk, fire prevention, flame retardancy, polymer, composites materials

Citation: Yu B, Yuan B, Tawiah B, Wu W and Hou Y (2023) Editorial: Fire risk and prevention technologies of polymeric and composite materials. Front. Mater. 10:1129598. doi: 10.3389/fmats.2023.1129598

Received: 22 December 2022; Accepted: 27 March 2023;

Published: 03 April 2023.

Edited by:

Kalappa Prashantha, Adichunchanagiri University (ACU), IndiaReviewed by:

Long Yan, Central South University, ChinaCopyright © 2023 Yu, Yuan, Tawiah, Wu and Hou. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bin Yu, eXViaW5AdXN0Yy5lZHUuY24=

Bin Yu

Bin Yu Bihe Yuan

Bihe Yuan Benjamin Tawiah

Benjamin Tawiah Wei Wu

Wei Wu Yanbei Hou

Yanbei Hou