- 1Guangxi Guizhong Engineering Consulting Co., Ltd., Liuzhou, China

- 2Department of Road Engineering, Changsha University of Science and Technology, Changsha, China

In order to investigate the pullout characteristics of a toothed geogrid, a commercialized warp-knitted geogrid was combined with rigid angle aluminum to form a qualified toothed geogrid and used to perform pullout model tests in which four different gradations of fillers, three denti-strip heights, and three normal stress levels were adopted. The research shows that: 1) at the initial stage of the pullout test, pullout resistance rises rapidly and only the curves of the pullout force (T) and pullout displacement (△L) under lower normal stress reach the peak. The maximum pullout resistance is positively related to normal stress on the model, the denti-strip height, and the coarse particle content. 2) As the denti-strip’s height increases, the coefficient of the reinforcing effect, the quasi-shear strength parameters, and the quasi-frictional coefficient all show enhancements to some extent, as well as the drawing coefficient. When the normal stress rises, the quasi-shear strength parameters increase, while the quasi-frictional coefficients gradually decrease. The quasi-shear strength parameters and the quasi-frictional coefficient are positively correlated with the coarse particle content, while the drawing coefficient has a negative correlation with the coarse grain proportion. 3) It could be inferred that the denti-strip with a suitable height and coarser gradation of the filler would be beneficial to enhance the anti-pullout performance in reinforcement project entities, and the bearing resistance acting on the denti-strip is able to play a more dominant role in a low backfill condition. The research results can further enrich the relevant achievements in the field of spatial reinforcement and provide useful evidence for the design and construction of related projects, especially for low embankment filling.

1 Introduction

As one of the most commonly used geosynthetic materials in reinforcement structures, the geogrid has achieved good economic benefits in practical applications and is widely used in retaining walls, embankment slopes, soft foundations, and other engineering fields. The warp-knitted geogrid, with outstanding engineering properties such as simple construction, low cost, and good durability, can effectively enhance the strength and stability of reinforcement structures (Tang et al., 2011; Maleki et al., 2021; Mehrdad and Seyed, 2021; Ye et al., 2022).

The interface interaction between geosynthetics and soil is the key performance indicator of reinforcement, which has been extensively studied by researchers. At present, the direct shear test and pullout test are the main means to explore the interface characteristics. Some scholars have made foundational research studies in different directions such as reinforcing materials and fillers and have provided many valuable experiences to investigate the pullout characteristics and the reinforcing mechanism. Some researchers adopted the pullout test on various reinforcing materials and fillers (Wu et al., 2002; Yang et al., 2006; Shi et al., 2009) and analyzed the specific performance by drawing the coefficient and reinforcement effects. Some reasonable suggestions were provided for the applicability of reinforcement materials and the selection of the reinforcement filler. Xu et al. (2004) proposed the concept of “equivalent drawing displacement” and divided the whole pullout process into several stages to further explore the influence of various test conditions on the test results during each stage. Moreover, some research studies have been accomplished on the interfacial characteristics of the reinforcement by using numerical simulations. Tang et al. (2017) adopted the numerical analysis tool to investigate the interface characteristics of geogrid reinforcement with 11 different mesh sizes and proposed an optimal mesh size for the geogrid sheet through the variation of the interfacial friction coefficient. Based on the discrete element numerical simulation, Wang et al. (2019) realized the visual analysis of the stress transfer law in reinforcement and soil during the pullout process under two rigid or flexible boundary conditions at the meso level. The results show that when the pullout displacement is relatively large, the flexible boundary has less impact on the results of the pullout test. Nicola and Piergiorgio (2006) conducted multiple pullout tests on three different specifications of HDPE geogrids in sand and discussed the influence of geogrid length, normal stress, and other factors on the test results. Raju and Fannin (1997) analyzed the variation of the strain and displacement of the reinforcing material with the change of the load level under cyclic load, pointing out that the load frequency and amplitude have little influence on the interfacial friction coefficient of the reinforcement, while normal stress has significant influence on the friction coefficient.

With the rapid development of reinforcement technology, the idea of three-dimensional or spatial reinforcement was put forward. Some scholars compared the reinforcing effect of three-dimensional reinforcement and horizontal reinforcement of the geogrid and found that the three-dimensional reinforcement had an obviously better performance (Zhang and Min, 2006; Zhao et al., 2011; Cai et al., 2012; Li et al., 2012; Li and Zhang, 2017; Zhang et al., 2020). Mosallanezhad et al. (2016a) and Mosallanezhad et al. (2016b) studied the effect of adding polymer anchors to the geogrid on the reinforcement efficiency of two types of geogrids in well-graded sand under the direct shear and pullout mechanisms. Taghavi and Mosallanezhad (2016) proposed the anchored geogrid, which is formed by adding steel transverse elements (a set of steel equal angles) to the ordinary polyester geogrids by means of nuts and bolts. The experimental results show that, with an optimum arrangement, this system is capable of increasing the pullout resistance of the ordinary geogrid system by 65% in sandy soil. A. Mirzaalimohammadi et al. (2019) conducted a pullout test study on the geogrid anchor systems and confirmed that compared with ordinary geogrids and geosynthetics, the optimal arrangement of steel crossbars and plastic push pins attached to the geogrids and geocomposites can increase the pullout resistance by 37% and 46%, respectively.

So far, although there are numerous achievements relevant to the pullout characteristics of geogrids, they are quite limited to ordinary planar reinforcements and no research on the influence of different parameters such as particle gradation on the pullout performance of horizontal–vertical (H–V) reinforcement was reported. In order to further investigate the pullout characteristics of H–V reinforcement, the pullout test on the performance of reinforcement with a toothed warp-knitted geogrid was carried out. Based on the laboratory test results, the difference of the pullout characteristics of the reinforcement under different particle gradations, as well as different normal stresses and different tooth heights, was compared and analyzed, thereby further enriching the research results in the field of horizontal–vertical reinforcement.

2 Laboratory pullout test

2.1 Test apparatus

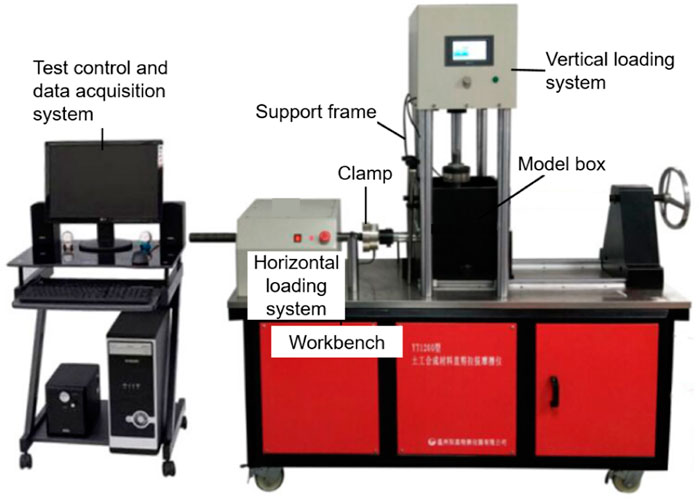

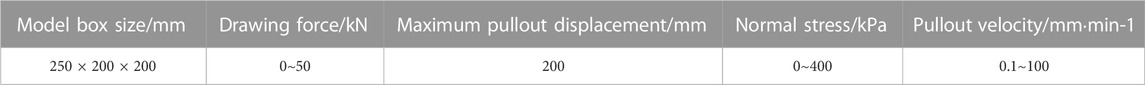

A type YT direct shear/pullout tester for geosynthetics developed by Wenzhou Jigao Testing Instrument Co., Ltd. (Figure 1) was adopted in the following research. The test apparatus is mainly composed of four components: a vertical loading system, horizontal loading system, controlling—logging system, and the model box. The pullout model box is rectangular, which meets the design requirements of Test Methods of Geosynthetics (Ministry of Communications of the People’s Republic of China, 2006) for Highway Engineering (JTG E50-2006), with a 15-mm-thick bottom plate and two 10-mm-thick transparent toughened glass on both lateral sides, as well as a 5-mm-wide slit in the middle of the front end through which the geogrid could be connected with the clamp. The apparatus is highly automatic, comprehensively functional, and easy to operate. It is competent in direct shear or pullout tests for interfacial friction between various geosynthetic materials and different fillers. The main indexes of the tester are shown in Table 1.

2.2 Test materials

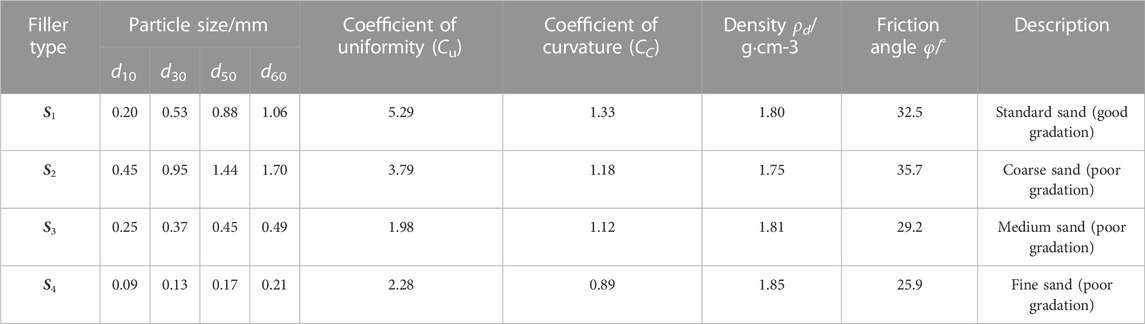

The filler for this pullout test was prepared from Xiamen ISO standard sand. The standard sand was sieved in advance for preparation using an oscillating screener. The apertures of the sieves were 4.75, 2.36, 1.18, 0.6, 0.3, 0.15, and 0.075 mm, respectively. According to the specification requirements, the sieved sand samples with different particle sizes were first prepared into a well-graded filler S1, according to a specified proportion. Subsequently, the poorly graded fillers S2, S3, and S4, which were mainly composed of coarse sand, medium sand, and fine sand, were prepared by the same means. The particle gradations and other basic properties of the four filler types are shown in Table 2.

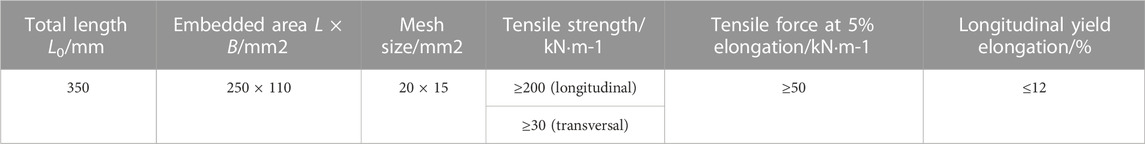

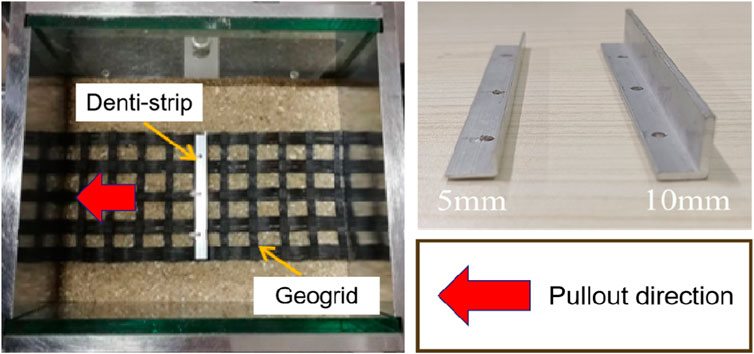

The polyester warp-knitted geogrid (MacGrid WG 20) was used to investigate the drawing characteristics of toothed geogrid reinforcement. The physical and mechanical indexes of the geogrid are shown in Table 3. The rigid angle aluminum was adopted as the vertical tooth or denti-strip. The heights of the denti-strips were 5 mm and 10 mm, and the base of angle aluminum was drilled with a row of equidistant circular holes of 3 mm in diameter. The angle aluminum and the horizontal ribs of the geogrid were firmly fastened with tie wraps to form the qualified toothed geogrid. The length of the denti-strip was set equal to the width of the horizontal geogrid, and the toothed-geogrid sample was placed horizontally, as shown in Figure 2.

2.3 Test scheme

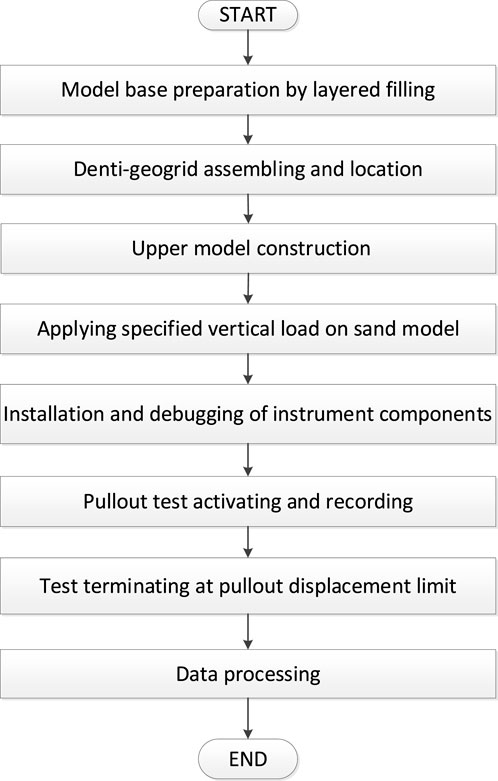

The pullout tests were carried out by combining the toothed geogrid with fillers S1, S2, S3, and S4. Considering different denti-strip heights and load levels, the effects of filler gradation on the pullout characteristics of toothed geogrids were observed. The prepared sand was constructed and compacted by four layers, controlling the weight and height of each layer according to the compactness of the test design. After the lower half of the model was constructed, the base surface was flattened and the toothed geogrid was then laid on it, ensuring that the denti-strip was located in the middle of the test chamber with symmetrical margins on both sides, and filling the upper half of the model upon the geogrid to complete the model installation. The normal loads were applied at three levels: 10, 20, and 30 kPa; the pullout velocity was set to be 0.5 mm/min. Additionally, the limit pullout displacement in this research was designated to be 20 mm. The test scheme is shown in Table 4, and the test procedure is given in Figure 3.

3 Characteristic parameter calculation

3.1 Coefficient of the reinforcing effect

The coefficient of the reinforcing effect Q could be used to evaluate the enhancement of pullout resistance attributed by the denti-strip:

in which Tmax and T′max are the maximum pullout resistance of a toothed geogrid and a common geogrid within the observation range, respectively.

3.2 Interfacial shear strength parameters

The interfacial quasi cohesion c* and the interfacial quasi friction angle φ* are often used to describe the friction characteristics of the reinforcement interface, as shown as follows:

where σn represents the normal stress (kPa) acting on the geogrid, τ is the interfacial friction strength (kPa), and L and B are the length and width (m) of the embedded geogrid, respectively. It should be noted that as a horizontal–vertical (H–V) reinforcement, τ hereby covers the resistance of the denti-strips.

3.3 The quasi-frictional coefficient

The quasi-frictional coefficient f* is defined as the ratio of the interfacial shear strength to the normal stress σn:

It considers the cohesion and, thus, presents comprehensive strength characterization rather than the pure friction effect.

3.4 Drawing coefficient

The drawing coefficient K* is also often used to evaluate the interface characteristics between the geogrid and the filler (Ministry of Communications of the People’s Republic of China, 2012). According to the Technical Code for Application of Highway Geosynthetics (JGT/TD32-2012), it could be defined as follows:

in which φ is the friction angle of the filler.

4 Results and analysis

4.1 Pullout process

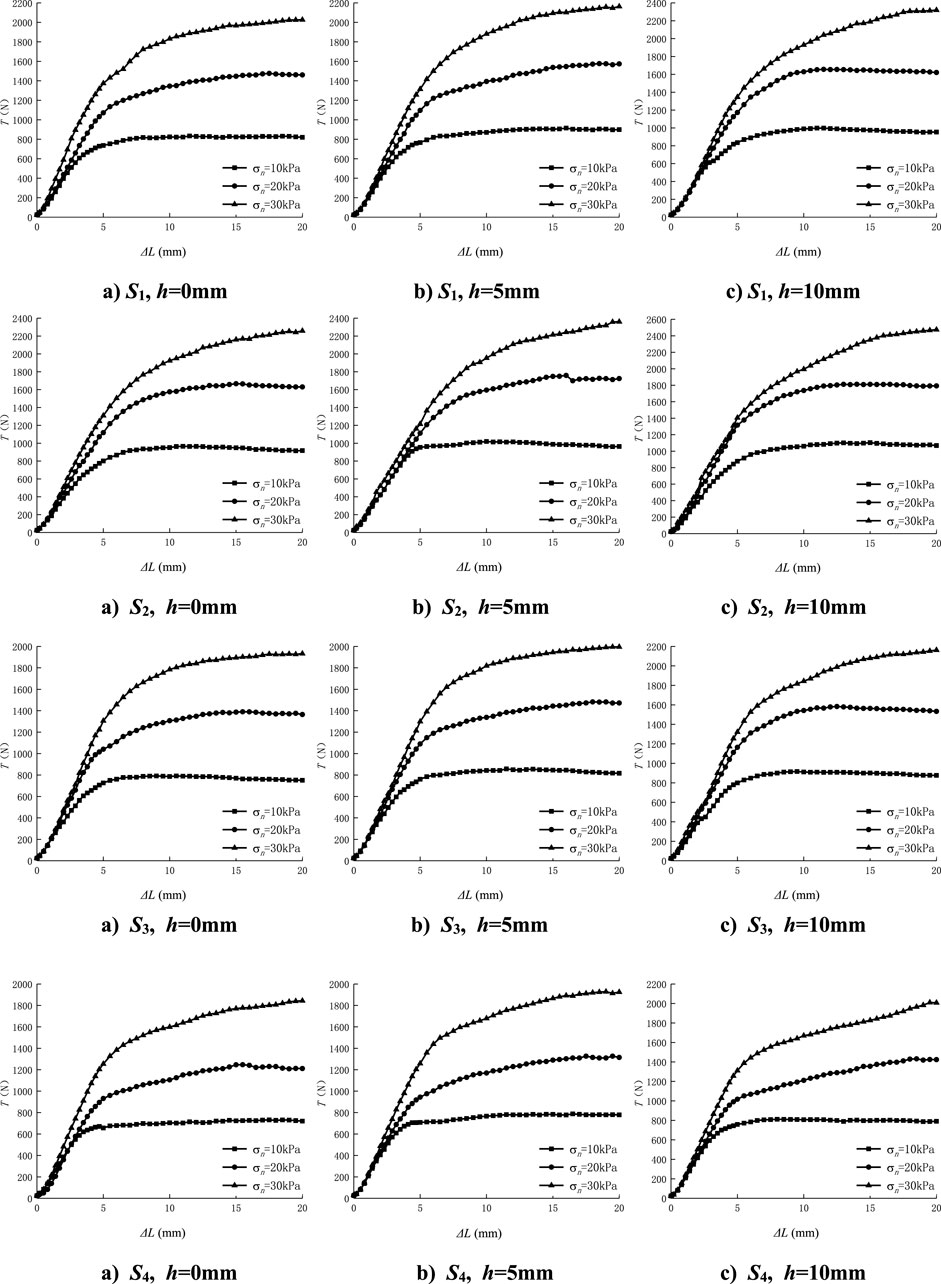

Under the conditions of different denti-strip heights and particle gradations, the relationship between the pullout force (T) and pullout displacement (△L) of the toothed warp-knitted geogrid is given in Figure 4. At the initial stage of drawing, the pullout force at all levels of gradations rises linearly with the increase of pullout displacement and its inclination amplifies roughly with the increase of the coarse particle content. Subsequently, the pullout curve trend starts to differentiate. The curves under a higher external load (σn = 30 kPa) do not show obvious peaks and are characterized by strain hardening during the whole displacement observation extent. The increases of both normal load and denti-strip height will lead to enhancement of the pullout resistance.

The effect of filler gradation on the pullout force under different denti-strip heights presents a consistent pattern, i.e., the pullout resistance presents to be S4 < S3 < S1 < S2. It means that with the increase of coarse particle content, the pullout resistance magnifies gradually. The coarse particle content of filler S1 with a well-graded filler locates between S3 and S2; thus, the pullout force value is also located between the two. Since the coarse particle can cause a rougher interface for the reinforcement structure and provide a more significant interlocking effect which enhances the inter-particle occlusion and friction, the pullout force shows a certain degree of increase.

4.2 Coefficient of the reinforcing effect

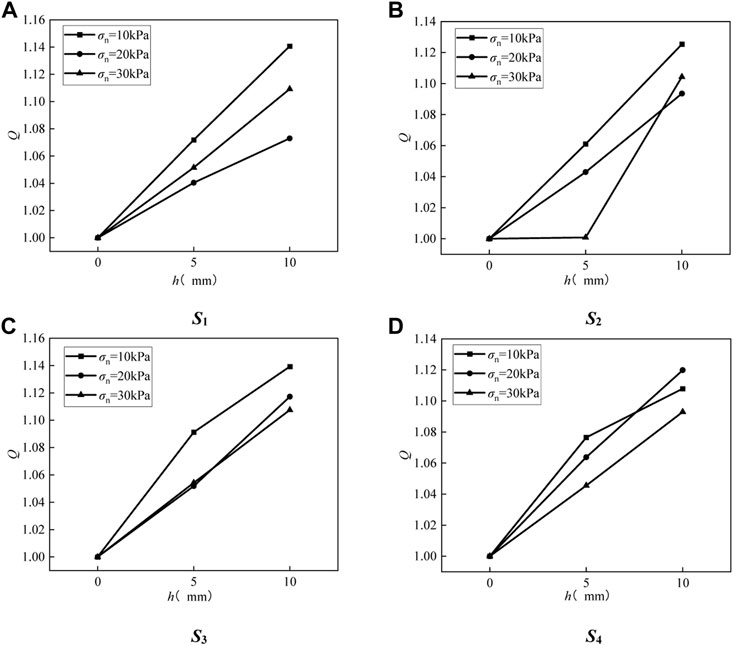

The coefficients of the reinforcing effect with different load levels and various denti-strip heights are given in Figure 5. It shows that all coefficients of the warp-knitted toothed geogrid are larger than 1.0, presenting a better reinforcing effect than the traditional geogrid sheet. On one hand, the coefficient of the reinforcing effect keeps growing as the denti-strip height increases. Although the denti-strip height would be constrained by many construction factors, a proper height of the tooth should be adopted and would be beneficial to the reinforcing effect. On the other hand, it is inferred that the coefficient of the reinforcing effect never reaches its largest when the highest normal stress σn = 30 kPa is applied on the test model. It denotes that the bearing resistance acting on the denti-strip might contribute a larger proportion in the total pullout resistance under lower load conditions. Thus, the bearing resistance acting on denti-strips is capable to play a more dominant role in certain cases such as low-backfill reinforcement. However, the coefficient of the reinforcing effect has no obvious correlation with the coarse particle content for all filler types. Furthermore, due to insufficient height and inadequate amount of the tooth in the warp-knitted toothed geogrid, the coefficients remain at a low level.

4.3 Interfacial shear strength parameters

As shown in Figure 6, the interfacial shear strength parameters of reinforcement under each particle gradation can be obtained by linear fitting. In the figure, c5* and φ5* represent quasi cohesion and the quasi-frictional angle with the condition h = 5 mm. As indicated by the fitting equations, the values of the quasi cohesion c* and the quasi-frictional angle φ* show the same rule, that is, with the increase in the denti-strip height, both the parameters increase. Meanwhile, under the same denti-strip height, the values of the shear strength parameters increase with the increase in the coarse particle content. Under the condition of h = 10 mm, with the rise in the coarse particle content, the maximum increase of quasi cohesion (31.4%) from gradation S4 to gradation S2 was observed, while the quasi-frictional angle increases by about 15.8%. By contrast, under the S1 gradation level, with the rise of the denti-strip height, the maximum increase of the quasi-cohesion (12.8%) from h = 0 mm to h = 10 mm was observed, while the quasi-frictional angle increases by only 5.0%. The comparison shows that the effect of gradation and the denti-strip height on quasi-cohesion is much more significant than on the quasi-frictional angle.

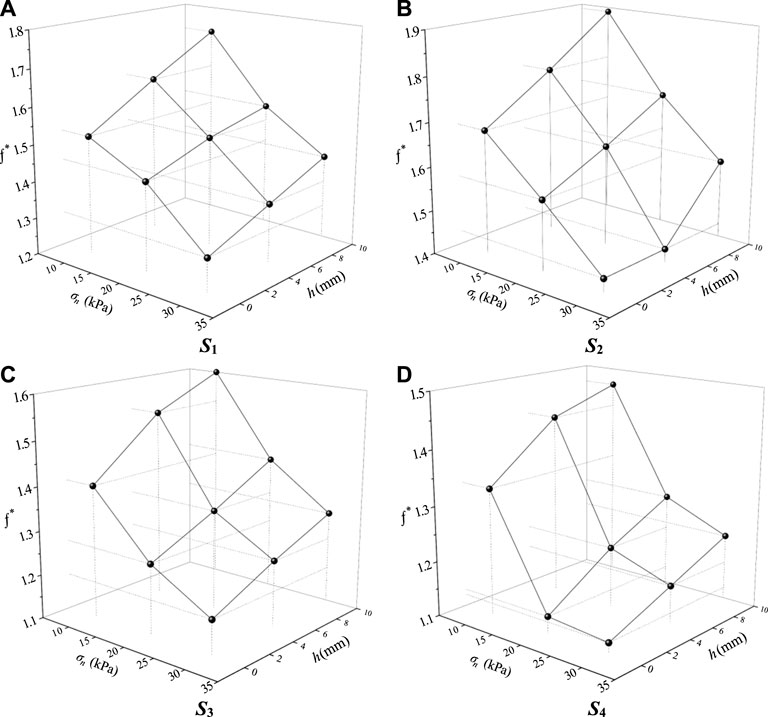

4.4 Quasi-frictional coefficient

The relation mesh of the quasi-frictional coefficient between the toothed warp-knitted geogrids and the sand is presented in Figure 7. Take the normal stress σn = 30 kPa as an example, the quasi-frictional coefficient f* of S1, S2, S3, and S4 are 1.29, 1.43, 1.18, and 1.12, when h = 0mm, respectively. When h = 10 mm, the quasi-frictional coefficient f* of gradation S1, S2, S3, and S4 are 1.43, 1.58, 1.31, and 1.22, respectively. The quasi-frictional coefficient increases with the rise in the coarse particle content under the same denti-strip height. With the same filler gradation, the quasi-frictional coefficient tends to decrease or increase with the growth of normal stress σn or tooth height h, respectively.

4.5 Drawing coefficient

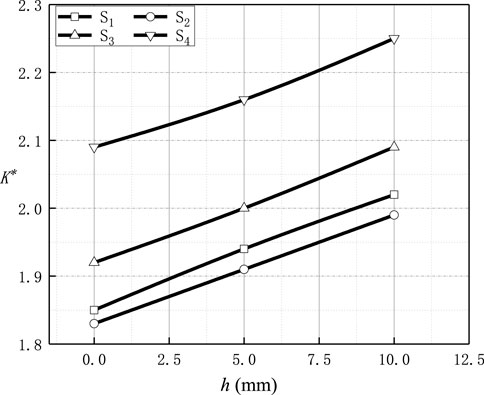

As shown in Figure 8, the drawing coefficient K* of the toothed geogrid shows an approximately linear increase with the growth of denti-strip height. Moreover, the pullout coefficients K* of the toothed geogrid are all larger than 1.8 under different test conditions, which shows that the toothed geogrid can greatly enhance the interfacial friction effect. With the same denti-strip height, the values of the drawing coefficient of the toothed geogrid are ranked as follows: S4 (fine sand with poor gradation) > S3 (medium sand with poor gradation) > S1 (standard sand with good gradation) > S2 (coarse sand with poor gradation). It could be seen that the order is just opposite to that of the quasi-shear strength parameters and quasi-frictional coefficient.

Generally, under the same test conditions, with the increase of the coarse particle content of the filler, the drawing coefficient gradually decreases, and the reasons can be attributed to as follows: 1) the reinforcement effect consists of two parts, namely, quasi cohesion and the quasi-frictional angle, while the drawing coefficient only reflects the enhancement of the latter; 2) for plain sand, the friction angle of coarse sand is usually much larger than that of fine sand; thus, the extent of further improvement after being reinforced is quite limited.

5 Conclusion

(1) The curves under a higher external load (σn = 30 kPa) do not show obvious peaks and are characterized by strain hardening during the whole displacement’s observation extent. Both increments of the normal load and denti-strip height will lead to enhancement of the pullout resistance. With the increase of the coarse particle content, the pullout resistance gradually rises. Since the coarse particle can cause a rougher interface for the reinforcement structure and provide a more significant interlocking effect which enhances the inter-particle occlusion and friction, the pullout force shows a certain degree of increase.

(2) The quasi cohesion and the quasi-frictional angle show an increasing trend as the denti-strip height increases. Under the same denti-strip height, the values of the shear strength parameters increase with the increase in the coarse particle content. The quasi-frictional coefficient increases with the increasing coarse particle content under the same denti-strip height. The drawing coefficient of the toothed geogrid shows an approximately linear increase with the growth of the denti-strip height. With the increase of the coarse particle content of the filler, the drawing coefficient gradually decreases.

(3) The pullout test data, which are of good integrity and regularity, prove satisfactory with consistency of the characteristic variations. The influence of different parameters such as particle gradation on the interfacial characteristics of toothed geogrid reinforcement was evaluated for the first time. It is inferred that the projects such as low embankment would be most suitable for a toothed geogrid application. However, due to an insufficient height and inadequate amount of the tooth on the upper side of the warp-knitted toothed geogrid, the reinforcing effect coefficients remain at a low level. Moreover, the pullout characteristics of the toothed geogrid reinforcement with different filler gradations would be further investigated by using visualization instruments for real-time monitoring and mesoscopic analysis.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

FW contributed to the conception and design of the study. FY wrote the first draft of the manuscript. All authors contributed to manuscript revision, and read and approved the submitted version.

Funding

This work was funded by Natural Science Foundation, China, grant number: 52178413, and Natural Science Foundation, Hunan Province, grant number: 2022JJ30593.

Conflict of interest

Author FY was employed by the company Guangxi Guizhong Engineering Consulting Co. Ltd.

The remaining author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Cai, C., Zhang, M. X., and Zhao, G. F. (2012). Pulling test of unidirectional geogrid with reinforced ribs. Rock Soil Mech. 33 (1), 53–59+64. doi:10.16285/j.rsm.2012.01.039

Li, G. C., and Zhang, M. X. (2017). Experimental study on two-way geogrid pulling with reinforced anchoring sheet. J. Hydroelectr. Eng. 36 (5), 104–111. doi:10.11660/slfdxb.20170512

Li, L., Zhang, M. X., and Zhou, X. F. (2012). Study on pulling experiment of two-way geogrid with reinforced node. J. Hydraulic Eng. 43 (12), 1494–1499+1506. doi:10.13243/j.cnki.slxb.2012.12.015

Maleki, A., Lajevardi, S. H., Briançon, L., Nayeri, A., and Saba, H. (2021). Experimental study on the L-shaped anchorage capacity of the geogrid by the pullout test. Geotext. Geomembranes 49 (4), 1046–1057. doi:10.1016/j.geotexmem.2021.02.003

Mehrdad, T., and Seyed, H. L. (2021). Laboratory large-scale pullout investigation of a new reinforcement of composite geosynthetic strip. J. Rock Mech. Geotechnical Eng. 13 (5), 1147–1159. doi:10.1016/j.jrmge.2021.03.014

Ministry of Communications of the People's Republic of China (2012). JGT/TD 32-2012 Technical code for application of highway geosynthetics. Beijing China: China Communications Press.

Ministry of Communications of the People's Republic of China (2006). JTG E50-2006 Test methods of geosynthetics for highway engineering. Beijing China: China Communications Press.

Mirzaalimohammadi, A., Ghazavi, M., Lajevardi, S., and Roustaei, M. (2019). Pullout response of strengthened geosynthetic interacting with fine sand. Geotext. Geomembranes 47 (4), 530–541. doi:10.1016/j.geotexmem.2019.02.006

Mosallanezhad, M., Alfaro, M. C., Hataf, N., and Sadat Taghavi, S. (2016a). Performance of the new reinforcement system in the increase of shear strength of typical geogrid interface with soil. Geotext. Geomembranes 44 (3), 457–462. doi:10.1016/j.geotexmem.2015.07.005

Mosallanezhad, M., Taghavi, S. H. S., Hataf, N., and Alfaro, M. (2016b). Experimental and numerical studies of the performance of the new reinforcement system under pull-out conditions. Geotext. Geomembranes 44 (1), 70–80. doi:10.1016/j.geotexmem.2015.07.006

Nicola, M., and Piergiorgio, R. (2006). Factors affecting the pullout behaviour of extruded geogrids embedded in a compacted granular soil. Geotext. Geomembranes 24 (4), 220–242. doi:10.1016/j.geotexmem.2006.03.001

Raju, D. M., and Fannin, R. J. (1997). Monotonic and cyclic pull-out resistance of geogrids. Géotechnique 47 (2), 331–337. doi:10.1680/geot.1997.47.2.331

Shi, D. D., Liu, W. B., and Shui, W. H. (2009). Comparative experimental study on the interfacial characteristics of single and bi-directional plastic geogrids and different packings. Rock Soil Mech. 30 (8), 2237–2244. doi:10.16285/j.rsm.2009.08.037

Taghavi, S. H. S., and Mosallanezhad, M. (2016). Experimental analysis of large-scale pullout tests conducted on polyester anchored geogrid reinforcement systems. Can. Geotechnical J. 54 (5), 621–630. doi:10.1139/cgj-2016-0365

Tang, X. S., Zheng, Y. R., and Wang, Y. F. (2011). Application of geogrid reinforced Earth retaining wall in landslide control engineering of an airport. China Civ. Eng. J. 44 (S2), 60–64. doi:10.15951/j.tmgcxb.2011.s2.046

Tang, X. S., Zheng, Y. R., and Wang, Y. F. (2017). Research on reasonable mesh size of geogrid. Rock Soil Mech. 38 (6), 1583–1588. doi:10.16285/j.rsm.2017.06.006

Wang, Z. J., Yang, G. Q., and Wang, H. (2019). Mesoscopic numerical study on the interface characteristics of reinforced soil under rigid and flexible top boundary. Chin. J. Geotechnical Eng. 41 (5), 967–973. doi:10.11779/CJGE201905021

Wu, J. H., Wang, D. Q., and Wang, L. J. (2002). Experimental study on reinforcement of geosynthetic materials. China Civ. Eng. J. 35 (6), 93–99. doi:10.3321/j.issn:1000-131X.2002.06.017

Xu, L. R., Ling, J. M., and Liu, B. C. (2004). Experimental study on frictional Resistance coefficient of geogrid and expanding soil interface. J. Tongji Univ. Nat. Sci. 32 (02), 172–176. doi:10.3321/j.issn:0253-374X.2004.02.007

Yang, G. Q., Li, G. X., and Zhang, B. J. (2006). Experimental study on friction characteristics of geogrid Interface. Chin. J. Geotechnical Eng. 28 (8), 948–952. doi:10.3321/j.issn:1000-4548.2006.08.004

Ye, Y. Q., Han, J., Liu, H., Rachford, S. M., Parsons, R. L., Dolton, B., et al. (2022). Pullout resistance of geogrid and steel reinforcement embedded in lightweight cellular concrete backfill. Geotext. Geomembranes 50 (3), 432–443. doi:10.1016/j.geotexmem.2022.01.001

Zhang, M. X., Ma, Y., and Qiu, C. C. (2020). The influence of strengthening node arrangement on pulling characteristics of two-way geogrid. J. Shanghai Jiao Tong Univ. 54 (12), 1307–1315. doi:10.16183/j.cnki.jsjtu.2019.275

Zhang, M. X., and Min, X. (2006). Triaxial experimental study on the traits of single-layer three-dimensional reinforced sand soil. Chin. J. Geotechnical Eng. 28 (8), 931–936. doi:10.3321/j.issn:1000-4548.2006.08.001

Keywords: grain composition, interfacial characteristic, pullout test, toothed warp-knitted geogrid, reinforcement effect

Citation: Yawei F and Wei F (2023) Experimental study on the pullout characteristics of toothed warp knitted geogrid in different sand fillers. Front. Mater. 10:1128274. doi: 10.3389/fmats.2023.1128274

Received: 20 December 2022; Accepted: 09 January 2023;

Published: 25 January 2023.

Edited by:

Hui Yao, Beijing University of Technology, ChinaReviewed by:

Hancheng Dan, Central South University, ChinaZhiman Su, Institute of Mountain Hazards and Environment (CAS), China

Copyright © 2023 Yawei and Wei. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Fang Wei, ZmFuZ3dlaTU2NDIzNjZAMTYzLmNvbQ==

Fu Yawei1

Fu Yawei1 Fang Wei

Fang Wei