- 1Department of Civil Engineering, SRM Institute of Science and Technology, Kattankulathur, India

- 2Department of Building Engineering, Energy Systems and Sustainability Science, Faculty of Engineering and Sustainable Development, University of Gävle, Gävle, Sweden

Concrete production requires a wealth of resources, including cement, aggregate, and water. Therefore, in terms of maintaining the Earth’s natural ecosystems and resources, researchers need to find sustainable and green methods for producing concrete. The focus of the current research was the use of potentially harmful alternative aggregates to manufacture lightweight concrete bricks. In this study, cement, fine aggregates, and vermiculite were the concrete brick mix components. Three trail mixes were followed by a replacement ratio of 60:40, 50:50, and 40:60 for fine aggregates in bricks. Statistical techniques were exerted to compare all the experimental results. Initially, regression analysis was employed to determine the precise relationship between the dependent and independent variables of the study. Furthermore, the compressive strength of the concrete brick was investigated. As a result of the research, vermiculite concrete bricks with the compressive strengths ranging from 3.2 to 5.9 N/mm2 and densities ranging from 1,780 to 2,142 kg/m3 were obtained. The regression model captured the variability of the data, as evidenced by the suitable R2 threshold (R2 > 0.9935). Subsequently, every property of the concrete bricks was predicted using regression, surface plots, main plots, and a heatmap. The conclusion of the study demonstrated that the models generated very effective results.

1 Introduction

The expansion of the building sector in recent years has resulted in the increased consumption and production of concrete. Moreover, environmental pollution is caused by population growth, industrialization, and the construction of new infrastructures (Kaplan et al., 2021; Babalghaith et al., 2022). Lightweight aggregate concrete is a common and useful material used in construction. Several advantages of lightweight aggregates include lower transportation costs, savings in forming and maintaining structures due to decreased applied loads on foundations, resistance improvements in acoustic and thermal performances, reduction in energy consumption, and resistance to fire, which would result in a more economical building structure (Shafigh et al., 2011; Muntohar and Rahman, 2014; Nandhini and Vallabhy, 2018; Domagala, 2020; Kumar et al., 2022; Lyra et al., 2022).

Lightweight concrete and lightweight aggregates are utilized to make lightweight solid bricks. Lightweight concrete brick is a concrete brick with an over-dry density between 300 and a maximum of 2,000 kg/m3. It is a mixture of cement, water, vermiculite (Nandhini and Vallabhy, 2018; Viana et al., 2022), and fines (sand). As a result, it is easier for the aggregates to be incorporated into cement when wetted with water first (Shafigh et al., 2010; Liu et al., 2022).

Cement paste bonds lightweight aggregates to each other and eliminates voids in concrete (Bheel et al., 1947). Voids are interconnected in no-fine aggregate concrete to provide an open, smooth, and porous concrete which reduces density, shrinkage, and strength. Aggregates of a single size create the lowest possible densities. Typically, the aggregates of a single size yield between 7 and 75 mm, but lightweight aggregates are more likely to reduce the concrete density. The aggregate/cement ratios (60:40, 50:50, and 40:60) have densities between 1,200 and 1,900 kg/m3 for traditional aggregates (Koksal et al., 2020a; Jayadurgalakshmi and Kandasamy, 2022; Mukesh, 2022).

Vermiculite, a naturally occurring mineral made of hydrated aluminum and magnesium silicate, increases in volume by an order of magnitude (8–30) when subjected to high temperatures to exfoliate. Expanded vermiculite retains its volume after cooling, with tiny air pockets between its leaves (Koksal et al., 2015; Koksal et al., 2020b). Thin air-filled plates best describe the expanded vermiculite particles. Vermiculite’s water-absorbing capacity rises between 64 and 160 kg/m3, depending on the particle size. Annealed vermiculite is extremely fireproof and has excellent soundproofing properties and low thermal conductivity. Vermiculite can withstand temperatures up to 1,100°C. Products made from vermiculite have stable strength and deformation resistance in addition to being inflammable, biostable, acid-neutral, and combustible. These suggestions support the application of vermiculite as a thermal insulator and acoustic buffer. As a result, fewer building supplies would be required if high-temperature and thermal insulation materials are used. In addition, vermiculite weighs relatively little after expansion (Gencel et al., 2021; Koksal et al., 2021).

Lightweight aggregates like pumice, perlite, expanded clay, and expanded polystyrene are the topic of significant research works, as mentioned previously. However, studies on the use of vermiculite are limited. Brick mixtures containing vermiculite were tested for their properties at various vermiculite concentrations. By increasing the porosity, vermiculite improves thermal efficiency. As a bonus, vermiculite-enhanced brick samples have the potential of being an insulating building material. Building with vermiculite in gypsum plaster for energy efficiency reported improved thermal performance. However, gypsum plaster has a characteristic feature of being easily damaged in fires due to its brittleness at room temperature and its lack of resistance to crack opening and propagation (Koksal et al., 2020a).

The increase in concrete strength can be predicted using statistical methods. Another advantage of statistical modeling is that it can define a confidence interval for your prediction, making it more accurate than other techniques (Asadollahfardi et al., 2015; Köksal et al., 2015; Zhang et al., 2021; Muchhadiya et al., 2022; Szymański et al., 2022). Strong relationships between aerated lightweight concrete’s strength characteristics and their controlling factors were modeled using multiple regression analysis (Ng et al., 2012; Gencel et al., 2013).

The purpose of this research was to develop a method for designing concrete using vermiculite in concrete bricks. Vermiculite is liable to be used in the production of environmentally friendly concrete bricks. The primary goals of this investigation were to determine if vermiculite can be used in concrete bricks to increase the concrete’s compressive strength and the development of regression models to establish relationships between variables that can be described empirically on the compressive strength and density.

2 Materials and methods

Cement, M-sand, and vermiculite were the raw materials employed in manufacturing bricks in this study. Except for vermiculite, all the raw materials used for investigation were sourced locally. Throughout the testing process, potable tap water was utilized to mix and cure. Due to the lightweight nature of vermiculite, the mix was prepared by volume base. Only cement, M-sand, and vermiculite were present. 40%, 50%, and 60% vermiculite replacements were considered. Before water was added, M-sand, vermiculite, and cement were mixed in a standard pan mixer. After a 5-minute blending session, the mixture was poured into plywood molds (120 × 90 × 90 mm). Vibration compaction was used on all the mixes to reduce the segregation that occurred during the process. The specimens were demolded and cured until the age of the test became 7, 14, and 28 days, as the standard curing method. In total, 60 bricks were cast for every mix ratio, with three samples cast at 7, 14, and 28 days.

2.1 Cement

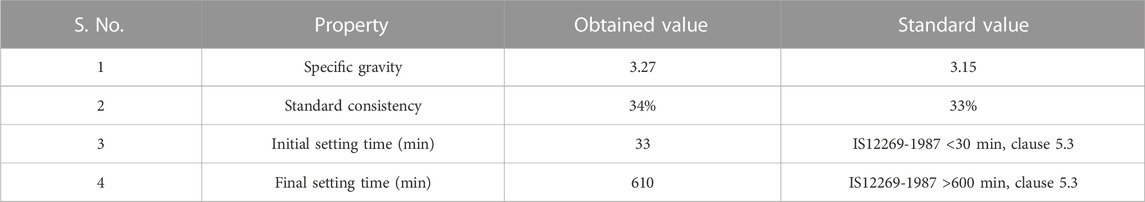

Concrete materials are tested according to relevant criteria for enhancing performance, quality, and long-term reliability. Accordingly, cement and fine aggregate’s physical and chemical properties have been investigated based on Indian standards. The properties of ordinary Portland cement are presented in Table 1.

2.2 Vermiculite

Vermiculite from the mines in Andhra Pradesh, India, was activated with the physical characteristics, as mentioned in Table 2.

3 Results and discussion

Results of the research are presented and discussed in this section.

3.1 Testing of concrete bricks

3.1.1 Compressive strength test

Dry density and compressive strength tests were performed on the hardened concrete. Three samples were prepared and averaged for each of the other analyses. In accordance with IS 2572 (2005), specimens per batch of the concrete mixture were prepared for this test. In this study, the compressive strength of vermiculite concrete bricks was tested on 7, 14, and 28 days.

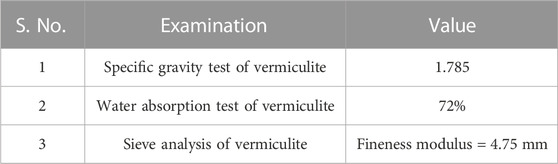

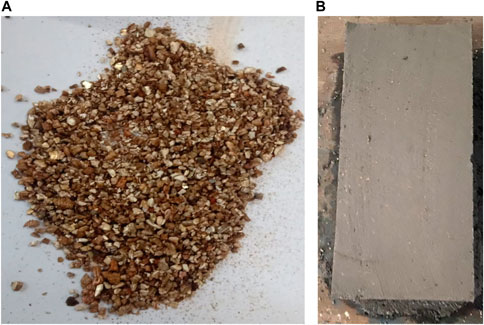

3.2 Compressive strength

The compressive strength of the lightweight concrete brick unit can be determined by considering both the maximum load in N and the gross cross-sectional area in mm2. A lightweight concrete brick has a unit’s significance of gross area when its total size (brick) is perpendicular to the direction of the load. This applies to areas at interval cells and between reentrant spaces as well. Cast brick and compression testing are shown in Figures 1, 2, respectively.

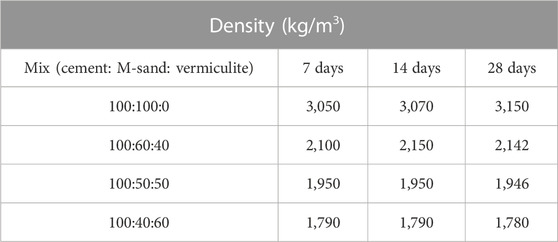

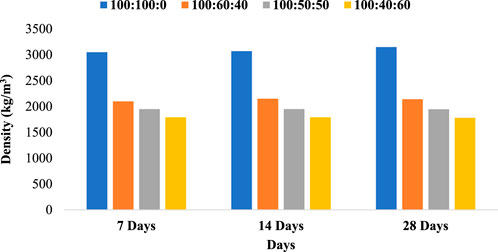

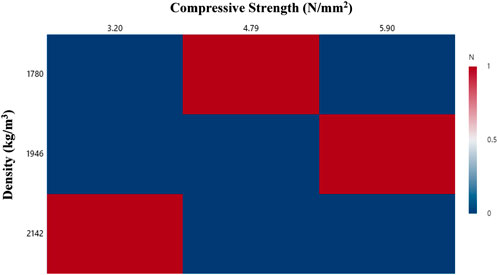

The combination of materials used for bricks is cement, M-sand, and vermiculite, with the obtained compressive strengths of 3.2 N/mm2, 5.9 N/mm2, and 4.79 N/mm2 after 28 days, respectively for mixes 100:60:40, 100:50:50, and 100:40:60, as listed in Table 3 and represented in Figure 3. Results demonstrate that 50% of fine aggregates replaced with vermiculite had significant results. Table 4 summarizes density results which are displayed in Figure 4. Density is less with the significant compressive strength in the mix ratio of 100:50:50, as seen from the experimental data.

3.3 Regression analysis

Regression analysis is a technique used in statistics for estimating the connections between different variables. When studying the connection between a dependent and one or more independent variables, it employs several methods for modeling and analyzing a large number of variables.

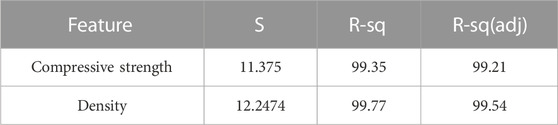

For each variable, the regression coefficients indicate the changes in materials, while the other predictors remain constant. The p-values indicate the statistical significance of the corresponding regression coefficients. It should be noted that p-values less than 0.05 indicate that the predictor is deemed statistically significant in regression models. In this study, the 95 percent confidence interval was considered (Khademi et al., 2017). As illustrated by the stepwise regression, the correlation is excellent. Table 5 provides the R2 values that were found. The regression equations formed for the density and compressive strength are presented in Eqs 1, 2.

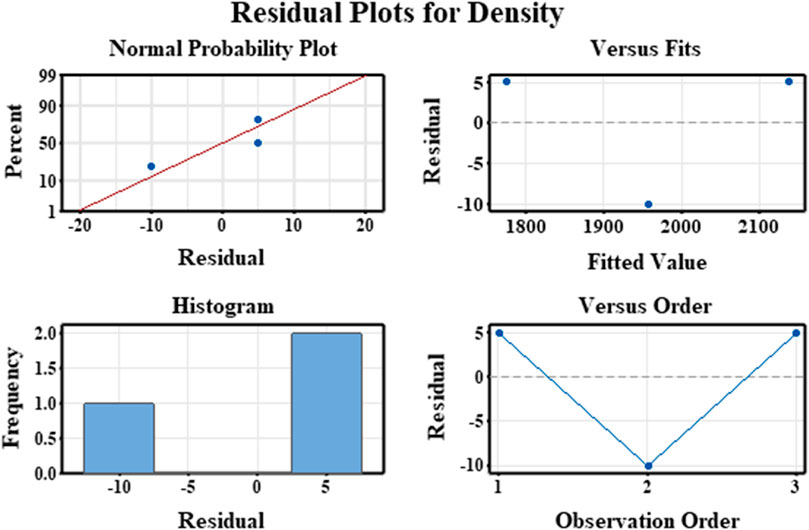

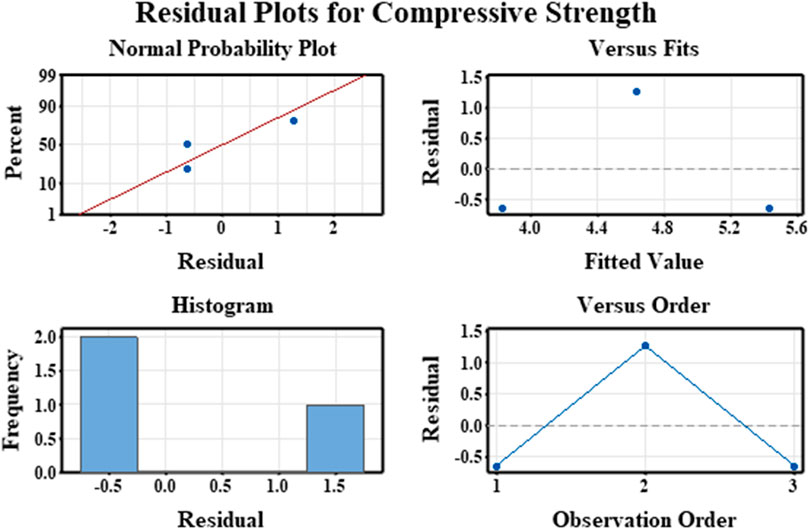

An ANOVA or regression of a residual plot is a visual representation of data used to investigate the fit of a regression model. It is important to examine residual plots to see if the conventional least squares have been confirmed. The standard least squares regression will yield accurate coefficient estimates with the smallest R2 values if the aforementioned assumptions can be verified (Mohr et al., 2022). Residential plots are depicted for the compressive strength and density of vermiculite concrete bricks, as shown in Figures 5, 6.

Figures 5, 6 demonstrate that the points in the plot of residuals versus fitted values are more dispersed for the highest fitted values (corresponding to level 1), but there are a few points where it is difficult to reject assumption (1) of constant variance in the residuals. A bell-shaped distribution appears to exist for the residuals, but the normal probability plot has two values outside the straight line at either end, representing high and low values in the data, respectively (level 1).

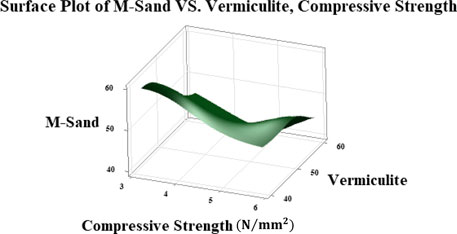

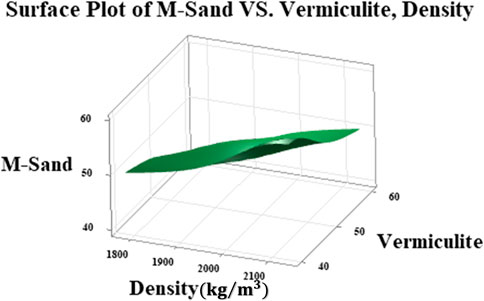

A surface plot can be used to see how the fitted response relates to two continuous variables for any model. The x and y axes represent the variables, while the response variable (z) is represented by a smooth surface in a surface plot (Figures 7, 8). The correlation between vermiculite and concrete bricks has been studied in the past too (Haque et al., 2021; Jamaludin et al., 2022).

The relationships between vermiculite and the compressive strength and density are displayed in Figures 7, 8.

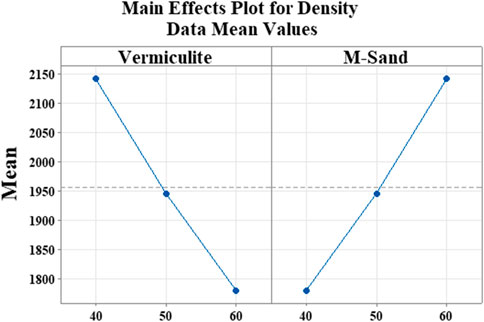

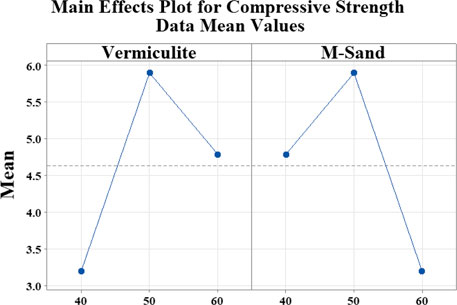

A direct influence of parameters on the response and dependent variables is known as the main effect. Figures 9, 10, show two examples of main effect plots of parameters versus the compressive strength. Maximum compressive strength was optimized in 50% of vermiculite replacement of fine aggregates.

Analysis of variance for one or more variables is carried out using the main effects graph. An important effect occurs when different concentrations of a factor have a significant impact on a response. The response means for each factor level are represented by a line in the main effects plot, as demonstrated in Figures 9, 10.

Figure 11 represents a heatmap of vermiculite, cement, and fine aggregates with different percentages used in this study to investigate the compressive and density relationships.

4 Discussion of results

In this study, we focused on three predictors comparing the vermiculite to M-sand ratio. 60 samples of different concrete bricks were examined. The tests yielded many results, including the compressive strength and density after 7, 14, and 28 days of curing time.

When fine aggregates were replaced with vermiculite, there was a gradual increase in the compressive strength. Simultaneously, density was decreased after fine aggregates were replaced with vermiculite. Results, thus, indicate that a lightweight concrete brick with significant compressive strength can be obtained.

Analysis of variance was used to model the experimental program’s test results as a polynomial (DataFit). The average value of the R2 coefficient determined from the resulting regression model was 0.99. To determine if a regression equation is well-fitting, this R2 coefficient is used. R2 = 1 indicates a perfect agreement between the observed and predicted values.

5 Conclusion

The purpose of this study was to evaluate the effects of adding vermiculite to concrete bricks. Casting and testing of lightweight vermiculite concrete bricks yielded the following concluding results:

➢ The compressive strength of vermiculite concrete bricks illustrated that replacing 50% of fine aggregates with vermiculite increased the compressive strength and decreased the brick density, which provided positive results for lightweight concrete bricks.

➢ R2 depicted a 99.35% compressive strength, while 99.77% density was displayed in regression.

➢ Surface plots, main plots, and a heatmap demonstrated a relation between vermiculite with the compressive strength and density.

➢ Since there are only a few studies on the effect of vermiculite as a replacement for fine aggregates in cement-based bricks, this article contributes greatly to the field.

Based on the obtained compressive strengths, vermiculite was used to replace fine aggregates in concrete, and this shows potential to greatly lessen the concrete brick’s negative effect on the environment. We conclude that replacing fine aggregates with vermiculite demonstrates potential to create concrete bricks with desirable properties while having fewer negative effects on the environment. In the future, different mix combinations and different statistical tools will be examined.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding authors.

Author contributions

NG: conceptualization, methodology, investigation, data curation, and original draft writing. AB: conceptualization, methodology, investigation, original draft writing, formal analysis, validation, and review and editing. KL: methodology, original draft writing, and validation.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Asadollahfardi, G., Asadi, M., Jafari, H., Moradi, A., and Asadollahfardi, R. (2015). Experimental and statistical studies of using wash water from ready-mix concrete trucks and a batching plant in the production of fresh concrete. Constr. Build. Mater 98, 305–314. doi:10.1016/j.conbuildmat.2015.08.053

Babalghaith, A. M., Koting, S., Sulong, N. H. R., Khan, M. Z. H., Milad, A., Yusoff, N. I. M., et al. (2022). A systematic review of the utilization of waste materials as aggregate replacement in stone matrix asphalt mixes. Environ. Sci. Pollut. Res. 29, 35557–35582. doi:10.1007/s11356-022-19447-w

Bheel, N., Khoso, S., Mereen, S., Baloch, H., Benjeddou, O., and Alwetaishi, M. (1947). Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Environ. Sci. Pollut. Res. 1, 52399–52411. doi:10.1007/s11356-022-19478-3

Domagala, L. (2020). Size Effect in compressive strength tests of cored specimens of lightweight aggregate concrete. Mater. (Basel) 13, 1187. doi:10.3390/ma13051187

Gencel, O., Koksal, F., Sahin, M., Durgun, M. Y., Lobland, H. E. H., and Brostow, W. (2013). Modeling of thermal conductivity of concrete with vermiculite by using artificial neural networks approaches. Exp. Heat. Transf. 26 (4), 360. doi:10.1080/08916152.2012.669810

Gencel, O., Sarı, A., Ustaoglu, A., Hekimoglu, G., Erdogmus, E., Yaras, A., et al. (2021). Eco-friendly building materials containing micronized expanded vermiculite and phase change material for solar based thermo-regulation applications. Constr. Build. Mater 308, 125062. doi:10.1016/J.CONBUILDMAT.2021.125062

Haque, M., Ray, S., Mita, A. F., Bhattacharjee, S., and Shams, M. J. B. (2021). Prediction and optimization of the fresh and hardened properties of concrete containing rice husk ash and glass fiber using response surface methodology. Case Stud. Constr. Mater. 14, e00505. doi:10.1016/J.CSCM.2021.E00505

Jamaludin, N. F. A., Muthusamy, K., Md Jaafar, M. F., Putra Jaya, R., and Ismail, M. A. (2022). Performance of palm oil clinker lightweight aggregate concrete comprising spent garnet as fine aggregate replacement. Adv. Civ. Eng. 2022, 1–13. doi:10.1155/2022/9674096

Jayadurgalakshmi, M., and Kandasamy, S. (2022). A comparative study on the various alternative materials for fine aggregate in concrete. Mater Today Proc. 65, 1614–1622. doi:10.1016/J.MATPR.2022.04.670

Kaplan, G., Gulcan, A., Cagdas, B., and Bayraktar, O. Y. (2021). The impact of recycled coarse aggregates obtained from waste concretes on lightweight pervious concrete properties. Environ. Sci. Pollut. Res. 28, 17369–17394. doi:10.1007/s11356-020-11881-y

Khademi, F., Akbari, M., Jamal, S. M., and Nikoo, M. (2017). Multiple linear regression, artificial neural network, and fuzzy logic prediction of 28 days compressive strength of concrete. Front. Struct. Civ. Eng. 11 (11), 90–99. doi:10.1007/S11709-016-0363-9

Koksal, F., Gencel, O., and Kaya, M. (2015). Combined effect of silica fume and expanded vermiculite on properties of lightweight mortars at ambient and elevated temperatures. Constr. Build. Mater 88, 175–187. doi:10.1016/J.CONBUILDMAT.2015.04.021

Koksal, F., Mutluay, E., and Gencel, O. (2020a). Characteristics of isolation mortars produced with expanded vermiculite and waste expanded polystyrene. Constr. Build. Mater 236, 117789. doi:10.1016/J.CONBUILDMAT.2019.117789

Koksal, F., Nazlı, T., Benli, A., Gencel, O., and Kaplan, G. (2021). The effects of cement type and expanded vermiculite powder on the thermo-mechanical characteristics and durability of lightweight mortars at high temperature and RSM modelling. Case Stud. Constr. Mater. 15, e00709. doi:10.1016/J.CSCM.2021.E00709

Koksal, F., Sahin, Y., and Gencel, O. (2020b). Influence of expanded vermiculite powder and silica fume on properties of foam concretes. Constr. Build. Mater 257, 119547. doi:10.1016/J.CONBUILDMAT.2020.119547

Köksal, F., Serrano-López, M. A., Şahin, M., Gencel, O., and López-Colina, C. (2015). Combined effect of steel fibre and expanded vermiculite on properties of lightweight mortar at elevated temperatures. Mater. Structures/Materiaux Constr. 48, 2083–2092. doi:10.1617/s11527-014-0294-7

Kumar, R., Lakhani, R., and Kumar, A. (2022). Physico-Mechanical and thermal properties of lightweight structural concrete with light expanded clay aggregate for energy-efficient buildings. Lect. Notes Civ. Eng. 196, 175–185. doi:10.1007/978-981-16-6557-8_14

Liu, J., Zhuge, Y., Ma, X., Liu, M., Liu, Y., Wu, X., et al. (2022). Physical and mechanical properties of expanded vermiculite (EV) embedded foam concrete subjected to elevated temperatures. Case Stud. Constr. Mater. 16, e01038. doi:10.1016/J.CSCM.2022.E01038

Lyra, G. P., Carlos, B., Santis, D., Santos, V., Eliria, R., de Jesus, M., et al. (2022). Microwave fast sintering production of sustainable lightweight aggregates with agroindustrial waste. J. Mater. Civ. Eng. 34, 4302. doi:10.1061/(ASCE)MT.1943-5533.0004302

Mohr, D. L., Wilson, W. J., and Freund, R. J. (2022). Linear regression. Stat. Methods 2022, 301–349. doi:10.1016/B978-0-12-823043-5.00007-2

Muchhadiya, P. D., Pitroda, J. R., Gujar, R., and Soni, J. (2022). Multiple regression models for compressive and flexural strength of recycled printed circuit board concrete. Mater Today Proc. 62, 6992–6997. doi:10.1016/J.MATPR.2021.12.539

Mukesh, T. S. (2022). Comparative analysis on mechanical properties of polymer concrete by using various lightweight aggregates. Sustain. Mater. Smart Pract. 23, 297–303. doi:10.21741/9781644901953-34

Muntohar, A. S., and Rahman, M. E. (2014). Lightweight masonry block from oil palm kernel shell. Constr. Build. Mater 54, 477–484. doi:10.1016/J.CONBUILDMAT.2013.12.087

Nandhini, R., and Vallabhy, S. (2018). A review of light weight concrete using vermiculite. Indian J. Sci. Res. 17, 245–248.

Ng, S. C., Low, K. S., and Tioh, N. H. (2012). Potential use of clayey soil in aerated lightweight concrete. KSCE J. Civ. Eng. 16 (16), 809–815. doi:10.1007/S12205-012-1380-4

Shafigh, P., Zamin Jumaat, M., and Mahmud, H. (2010). Mix design and mechanical properties of oil palm shell lightweight aggregate concrete: A review. Int. J. Phys. Sci. 5, 2127–2134.

Shafigh, P., Jumaat, M. Z., and Mahmud, H. (2011). Oil palm shell as a lightweight aggregate for production high strength lightweight concrete. Constr. Build. Mater 25, 1848–1853. doi:10.1016/J.CONBUILDMAT.2010.11.075

Szymański, K., Walendzik, B., Janowska, B., and Sidełko, R. (2022). The use of a regression model in the variability analysis of the leachate quality from heaps of the production of the building materials. Appl. Water Sci. 12, 97–14. doi:10.1007/s13201-022-01639-x

Viana, Q. S., Eugênio, T. M. C., Sabino, T. P. F., Scolforo, J. R. S., and Mendes, R. F. (2022). Physical, mechanical, and thermal properties of concrete roof tiles produced with vermiculite. Environ. Sci. Pollut. Res. 29, 48964–48974. doi:10.1007/S11356-022-19337-1

Keywords: lightweight brick, vermiculite, cement, regression, surface plot, main plot, heatmap

Citation: Ganasen N, Bahrami A and Loganathan K (2023) Experimental investigation and optimization of lightweight concrete bricks developed using vermiculite. Front. Mater. 10:1117138. doi: 10.3389/fmats.2023.1117138

Received: 06 December 2022; Accepted: 06 February 2023;

Published: 24 February 2023.

Edited by:

Yasin Onuralp Özkılıç, Necmettin Erbakan University, TürkiyeReviewed by:

Humphrey Danso, Akenten Appiah-Menka University of Skills Training and Entrepreneurial Development, GhanaOsman Gençel, Bartin University, Türkiye

Copyright © 2023 Ganasen, Bahrami and Loganathan. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Nakkeeran Ganasen, bmcyNjgzQHNybWlzdC5lZHUuaW4=; Alireza Bahrami, QWxpcmV6YS5CYWhyYW1pQGhpZy5zZQ==

Nakkeeran Ganasen

Nakkeeran Ganasen Alireza Bahrami

Alireza Bahrami Krishnaraj Loganathan1

Krishnaraj Loganathan1