95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater. , 21 February 2023

Sec. Ceramics and Glass

Volume 10 - 2023 | https://doi.org/10.3389/fmats.2023.1110688

The effects of multiple firings on the color and translucency of monolithic zirconia were investigated in this paper. One hundred specimens were milled using three types of monolithic zirconia: multilayered zirconia (UTML, Katana) (UT), highly translucent zirconia (Organic Translucent, R + K) (OT), and nanosized zirconia (DIAZIR ST9810, Zhong Xin Tang Guo Ye) (ST). The group UT was divided into three subgroups: the incisal (UT-I), middle (UT-M), and cervical (UT-C). After sintering (T0), the specimens of each group (n = 20) were repeatedly fired 3 times. The L*, a*, and b* values were measured by using a spectrophotometer at T0, and after the first (T1), second (T2), and third (T3) firings. The translucency parameter (TP), contrast ratio (CR), opalescence parameter (OP), and color difference (∆E00) were calculated and statistically analyzed (α = 0.05). The surface morphologies of the specimens were observed using SEM. Multiple firings significantly affected the OP and the ∆E00 values of the materials tested (both p < 0.001). The ∆E00 values of group ST at T1-T3 were greater than the 50%:50% acceptability threshold (∆E00 > 1.8). Moreover, multiple firings did not exhibit significant effects on the TP and contrast ratio values of any materials (both p > 0.05). The surface topographies of the specimens after multiple firings were quite similar. Changes in opalescence were found for the multilayered zirconia and nanosized zirconia after multiple firings, but the clinical significance was low. Clinically unacceptable color changes were found in the nanosized zirconia after multiple firings, which were attributed to the higher L* values and the lower b* values after multiple firings. However, the optical properties and composition of surface elements of multilayered 5Y-TZP with over three layers need to be investigated in future studies.

The global market size of zirconia was valued at 187 million USD in 2020 and is expected to continue expanding in the next decades (Grand View Research, 2020). Yttria-stabilized tetragonal zirconia polycrystals (Y-TZPs) are considered materials of choice in dentistry because of their excellent mechanical and biological properties (Miyazaki et al., 2013). In particular, monolithic zirconia restorations have been advocated to avoid porcelain chipping, and thinner restorations have been produced to preserve more tooth tissues (Silva et al., 2017). According to the literature, several generations of Y-TZPs are available on the market. First-generation zirconias are 3 mol% (5.2 wt%) yttria-stabilized tetragonal zirconia polycrystals (3Y-TZP) with flexural strengths ranging from 900 to 1,200 MPa (Shah et al., 2008; Zhang and Lawn, 2018). Nevertheless, insufficient light transmittance through zirconia results in poor restoration aesthetics, especially in the anterior regions (Vichi et al., 2016; Bömicke et al., 2019; Pekkan et al., 2020b; Leitão et al., 2021). To improve monolithic zirconia and provide it with acceptable translucency, second-generation zirconia has been refined by drastically reducing the concentration of the alumina additive of 3Y-TZP, which is also known as highly translucent zirconia (Zhang et al., 2012; Zhang and Lawn, 2018). Third-generation zirconias contain yttria contents as high as 4 or 5 mol% (6.93 or 8.67 wt%), and the samples are named 4Y-TZP or 5Y-TZP, respectively (Zhang and Lawn, 2018). Third-generation zirconia forms more cubic crystals and is also known as supertranslucent zirconia (Miura et al., 2022; Rinke et al., 2022). With the increased cubic phase exhibiting non-birefringence, 4Y-TZP and 5Y-TZP display markedly improved translucency (Zhang and Lawn, 2018). Kwon (Kwon et al., 2018) reported that the translucency parameter (TP) of 5Y-TZP was between those of 3Y-TZP and lithium disilicate. However, the strength and toughness of third-generation zirconia are diminished because cubic zirconia does not have a phase transformation toughening mechanism (Zhang et al., 2016; Kontonasaki et al., 2019; Sulaiman et al., 2020).

In addition to increasing the yttria content, reducing the grain sizes of Y-TZP to the nanometer range improves its translucency (Damestani et al., 2013; Arena et al., 2019). The improved translucency of nanosized zirconia is achieved by high in-line transmission between the nanosized grains (Zhang, 2014). Furthermore, nanotechnology (e.g., MXenes) with distinctive and superior physicochemical properties at the nanoscale has been considered for achieving environmental remediation (Chaudhary et al., 2022a). Nanotechnology enhanced surface size effects and quantum confinement effects due to nanoscale confinement of the dimensions of the materials (Chaudhary et al., 2022b; Khosla et al., 2022). However, few nanosized zirconia materials are commercially available, and information regarding these products is limited (Arena et al., 2019; Hu et al., 2019).

CAD/CAM technology is the main manufacturing technique to fabricate zirconia restorations, although the machining of restorations produces a large amount of waste and releases vast quantities of pollution (Batra et al., 2022). In this fabrication process, multiple firings are often needed for glazing, dyeing, and adding porcelain (Oilo et al., 2008). In our previous study, multiple firings affected the marginal fits of conventionally sintered and speed-sintered monolithic zirconia crowns, which was potentially related to grain coarsening and the t → m phase transformation (Yang et al., 2022). In addition, different sintering temperatures have been reported to lead to varied colors of nanosized 3Y-TZP, possibly due to enlargement of the grain sizes and increased t → m phase transformations (Dimitriadis et al., 2022). Although multiple firings are usually performed at relatively low temperatures, they may change the grain sizes and increase the t → m phase transformations of Y-TZPs and further affect their color and translucency characteristics (Cho and Seol, 2021; Zhang et al., 2021; Dimitriadis et al., 2022). Fehmi (Fehmi et al., 2018) reported a statistically significant change in the color of monolithic glass ceramics (IPS e. max press, Ivoclar Vivadent AG, Liechtenstein) after 5 rounds of firing. Likewise, statistically significant changes in the colors of bilayered zirconias (veneering porcelain: IPS e. max, Ivoclar Vivadent AG, Liechtenstein; zirconia core: ZircoStar, Kerox Dental Ltd., Hungary) were reported after multiple firings (Fathi et al., 2019). All of the reported color changes were above the 50%:50% acceptability threshold (∆E00 = 1.8) (Paravina et al., 2015; International Organization for Standardization, 2016), indicating that the color changes were clinically unacceptable. Moreover, statistically significant changes in TP values were found for monolithic glass ceramics (Nejatidanesh et al., 2020) and bilayered zirconia (Fathi et al., 2019), although the detected ∆TP values were all below the perceivability threshold (∆TP = 1.33) (Xia and Xiong, 2021). Altan (Altan and Cinar, 2022) studied the color and translucency changes exhibited by zirconia (YZ, Vita Zahnfabrik, Germany) after multiple firings at 1,530°C. They found that the color and translucency of zirconia were affected by multiple firings. In contrast, Ozdoan (Ozdoan and Ozdemir, 2020) reported that multiple firings at 895°C did not cause changes in the color and phase characteristics of the zirconia frameworks. However, limited information is available regarding whether the color and translucency of highly translucent monolithic zirconias change after multiple firings.

Therefore, the purpose of this in vitro study was to investigate the influence of multiple firings on the color and translucency characteristics of different types of monolithic zirconia. The following null hypotheses were proposed: 1) the color and translucency characteristics of different monolithic zirconias would be the same after multiple firings; 2) multiple firings have no influence on the color of monolithic zirconias; and 3) multiple firings have no influence on the translucency of monolithic zirconias.

A total of 100 specimens were milled using three types of zirconia blocks: multilayered 5Y-TZP (UTML, Kuraray Dental, Japan) (UT), monochrome highly translucent 3Y-TZP (Organic Translucent, R + K CAD/CAM Technologie GmbH and Co. KG, Germany) (OT), and monochrome nanosized 3Y-TZP (DIAZIR ST9810, Zhong Xin Tang Guo Ye Technology Corp., Ltd., China) (ST). Unlike monochrome materials, multilayered 5Y-TZP was introduced to simulate the different parts of teeth (Kwon et al., 2018). Therefore, the specimens of the UT groups were further divided into three subgroups based on the different layers they were made of: the incisal layer (UT-I), the middle layer (UT-M), and the cervical layer (UT-C). The specimens of each group (n = 20) were sintered by following the manufacturers’ instructions. The details of the materials tested are shown in Table 1.

To simulate glaze dyeing or porcelain additions in the clinical procedures, all of the specimens were repeatedly fired 3 times in a ceramic furnace (Programat P300, Ivoclar Vivadent AG, Liechtenstein) (Yang et al., 2022). The protocols for the multiple firings are listed in Table 1.

According to CIELAB and CIEDE 2000, the L* (lightness), a* (red‒green), and b* (yellow‒blue) values of the specimens were measured on white (11-4001 tpg, Pantone, United States), black (19-3911 tpg, Pantone, United States), and gray (14-4107 tpg, Pantone, United States) backgrounds with a spectrophotometer (Easyshade Ⅳ, Vita Zahnfabrik, Germany) after sintering (baseline, T0) and after the first (T1), second (T2), and third firings (T3). The spectrophotometer was calibrated according to the manufacturer’s instructions before each measurement. A silicone mold was used to stabilize the probe of the spectrophotometer at the center of the specimen for each measurement. Each specimen was tested 3 times, and the average value was recorded. All measurements were performed by the same researcher.

The TP and contrast ratio (CR) of the specimens at different times were calculated with the following equations (Juntavee and Attashu, 2018):

where B and W are the CIELAB color coordinates for each specimen with black and white backgrounds, respectively.

The opalescence parameter (OP) of the specimens at different time points was calculated with the following equation (Juntavee and Attashu, 2018):

where B and W are the CIELAB color coordinates for each specimen with black and white backgrounds, respectively.

The ∆E00 values of specimens between the baseline (T0) and the T1, T2, and T3 values were calculated with the following equation (Luo et al., 2001):

where ΔL', ΔC', and ΔH' are the differences in lightness, chroma, and hue before and after multiple firings, which could be calculated by the L*, a*, and b* values of the specimens.

Two additional specimens were prepared for each group by using the methods described above. The specimens were sputter-coated with gold before being observed. The surface morphologies were analyzed with a scanning electron microscope (SEM) (Nova NanoSEM230, FEI, United States) operated with an acceleration voltage of 8 kV. Representative images showing the morphological changes of the specimens at baseline and after multiple firings were obtained at ×30,000 magnification.

Statistical analyses were performed with a statistical software package (SPSS Statistics v26.0, IBM, United States). The assumptions of a normal distribution and homogeneity of the variance were confirmed with the Shapiro‒Wilk test and Levene’s test, respectively. Two-way repeated-measures analysis of variance (ANOVA) and multiple-paired t tests with Bonferroni correction were performed to analyze the impacts of multiple firings on the color and translucency characteristics of monolithic zirconia (α = 0.05).

Significant differences were found in the L*, a*, b*, TP, CR, OP, and ∆E00 values among the different highly translucent monolithic zirconia samples (all p < 0.05). Multiple firings significantly affected the OP and ∆E00 values of the materials tested (both p < 0.001).

The OP values of all the groups are listed in Table 2. The OP values of the group UT-M at T3 and the group ST at T1-T3 were significantly lower than those at T0 (all p < 0.05). However, the changes in the OP values were small (within 0.5). The OP values of the remaining groups remained unchanged after multiple firings (all p > 0.05).

The ∆E00 values of all groups are listed in Table 3. The ∆E00 values of group UT-I were significantly lower at T2 and T3 than at T1 (p < 0.05). The ∆E00 values of the remaining groups remained unchanged throughout T1-T3 (all p > 0.05). According to the literature and ISO/TR 28642 (Paravina et al., 2015; International Organization for Standardization, 2016), the 50:50% perceptibility thresholds (PT) and AT of the color changes were 0.8 and 1.8, respectively. The ∆E00 values of groups UT-I, UT-M, and UT-C were between 0.8 and 1.8. The ∆E00 values of group OT were below 0.8, while those in group ST were greater than 1.8.

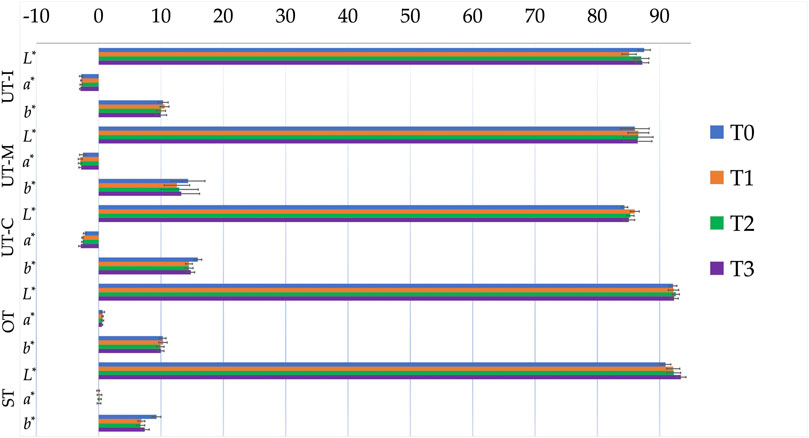

The L*, a*, and b* values of all groups are shown in Figure 1. The L* values of the groups UT-C and ST at T1-T3 were significantly higher than those at T0 (all p < 0.05). The L* values of group UT-I at T1 were significantly lower than those at T0 (p < 0.001), while no significant differences were found at T2 and T3 compared with T0. The L* values of groups UT-M and OT remained unchanged at T0-T3 (all p > 0.05). The a* values of groups UT-I, UT-M, and UT-C at T1-T3 were significantly lower than those at T0 (all p < 0.05), indicating a color switch to greenness after 1-3 firing rounds. The a* values of groups OT and ST remained unchanged over T0-T3 (all p > 0.05). The b* values of all groups at T1-T3 were significantly lower than those at T0 (all p < 0.05), indicating a color switch to blueness after 1-3 firing rounds.

FIGURE 1. Changes in L*, a* and b*values of the tested groups at different time points. T0: baseline; T1: after the first firing; T2: after the second firing; and T3: after the third firing. UT-I: incisal layer of multilayered 5Y-TZP; UT-M: middle layer of multilayered 5Y-TZP; UT-C: cervical layer of multilayered 5Y-TZP; OT: highly translucent 3Y-TZP; and ST: nanosized 3Y-TZP.

Multiple firings did not exhibit significant effects on the TP and CR values of any groups (both p > 0.05). The TP and CR values of all groups are listed in Tables 4, 5.

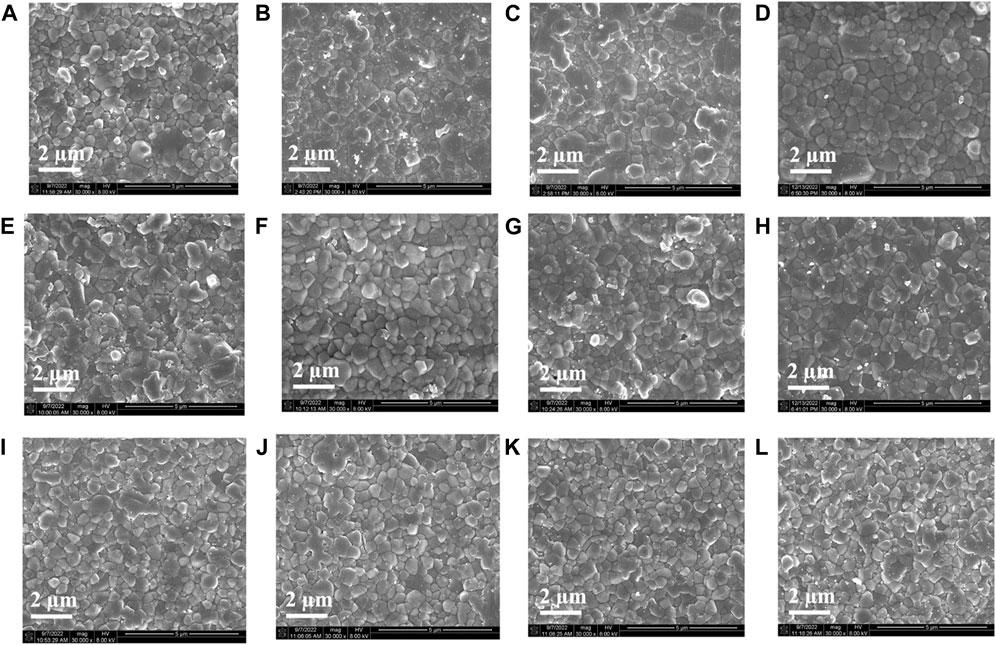

SEM images for all groups are shown in Figure 2. The surface topographies of the specimens after multiple firings were quite similar to those seen at the baseline. It is worth noting that a few larger grains were distributed in certain areas and revealed non-homogeneous grain structures in groups UT and OT, while the microstructure of group ST was uniformly distributed with a narrow grain size range.

FIGURE 2. Representative SEM images (300,00×) taken for different monolithic zirconias as a baseline (A, E, I) and after the first (B, F, J), second (C, G, K), and third (D, H, L) firings. (A–D) specimens in the UT group (multilayered 5Y-TZP). (E–H) specimens in the OT group (monochrome highly translucent 3Y-TZP). (I, J, K, L): specimens in the ST group (monochrome nanosized 3Y-TZP).

The color and translucency characteristics of zirconia ceramics have a decisive effect on restoration aesthetics. In clinical practice, it is necessary to dye or add porcelain to prostheses several times during try-in procedures (Manziuc et al., 2021). Therefore, the prostheses are likely to undergo multiple firings before being cemented. This study could be considered the first to evaluate the effects of multiple firings on the color and translucency characteristics of monolithic zirconia. Based on the present findings, the null hypotheses that multiple firings have no influence on the color of monolithic zirconias and that the color and translucency characteristics of different monolithic zirconias would be the same after multiple firings were rejected. The null hypothesis that multiple firings have no influence on the translucency of monolithic zirconias was accepted. The materials tested in this study included highly translucent monolithic zirconias available for clinical applications. Translucency is a material property in which a major portion of the transmitted light encounters diffusion (Tabatabaian, 2019), which is usually defined by the TP or CR values (Yu et al., 2009). However, the TP is limited by the non-linearity in L* because (L*B—L*W) is 0 when the absolute translucency approaches 50% (Spink et al., 2013). Moreover, CR may lose its sensitivity as the opacity increases (Spink et al., 2013). Therefore, both the TP and CR values were employed to evaluate the translucency of the zirconia in this study. Moreover, the OP and ∆E00 values were adopted to evaluate the color changes occurring in the zirconia after multiple firings, which was consistent with previous studies (Khashayar et al., 2014; Kim et al., 2016; Fathi et al., 2019).

The International Commission on Illumination (CIE) recommended using the CIELAB formula (∆Eab) for color difference research in 1976 (Luo et al., 2001). Considering the factors affecting color difference judgment and the lack of color space uniformity of the CIELAB formula, the CIEDE2000 formula (∆E00) has been approved and widely applied over the past decades (Luo et al., 2001). The 50%:50% perceivability threshold and the 50%:50% acceptability threshold are the two major thresholds used for assessing color differences, and they serve as quality control tools guiding the selection of dental materials and evaluating their performance in clinical dentistry and dental research (International Organization for Standardization, 2016). The 50%:50% perceivability threshold and the 50%:50% acceptability threshold for CIEDE2000 are 0.8 and 1.8, respectively. These values constituted the lower perceptual limit to estimate the maximum number of colors discernible by the human visual system (Paravina et al., 2015).

In this study, an unacceptable color change was observed in nanosized 3Y-TZP after multiple firings, which was attributed to increased lightness and a color switch to redness and blueness. For the multilayered 5Y-TZP, acceptable color changes were observed after multiple firings (0.8<∆E00 < 1.8), while the color changes in the highly translucent 3-TZP were not perceivable. In a previous study on nanosized zirconia, relatively higher sintering temperatures led to significantly lower color differences in the vita shade of the zirconia materials (1,460°C: ∆Eab = 4.4; 1,600°C: ∆Eab = 2.4) (Juntavee and Attashu, 2018). The color changes of the nanosized zirconia (grain size = 550 nm) were considered to be attributed to the reduction of pores between the grains and increase in the grain sizes (Juntavee and Attashu, 2018). Given that the temperatures of the multiple firings (∼820°C) were lower than those adopted during the sintering process, it could be assumed that the color and microstructure changes in nanosized 3Y-TZP detected in the previous study occurred at the firing temperature. Importantly, as the grain size of nanosized 3Y-TZP in this study was quite small (200–300 nm, data reported by the manufacturer), the impact of firing on the pores between the grains or the grain sizes of the nanosized 3Y-TZP may be greater than those for multilayered 5Y-TZP and highly translucent 3Y-TZP. However, further studies are needed to clarify this issue.

The reproduction of the optical properties of natural teeth can be designed by controlling the translucency and opalescence characteristics of ceramic materials (Kim, 2020). Opalescence results from light scattering at wavelengths less than or equal to visible light wavelengths, which is quantified by the OP values (Cho et al., 2009). Ideal aesthetic restorative materials should have opalescence characteristics similar to those of natural teeth. The OP values of human enamel and lithium disilicate ranged from 19.8 to 27.6 (Lee and Yu, 2007) and 4.4 to 6.6 (Della Bona et al., 2014), respectively. In this study, the OP values of all zirconia tested (3.0–6.6) were much lower than those of human enamel and comparable to those of lithium disilicate (Pecho et al., 2012), indicating a need for improvement in the opalescence of highly translucent monolithic zirconia. Moreover, the OP values of the multilayered 5Y-TZP middle layer and nanosized 3Y-TZP significantly decreased after multiple firings. However, it is important to note that the changes seen in the OP values for these groups were within 0.5 and may have no clinical significance.

Regarding the translucency characteristics, the TP values for all of the zirconia materials remained unchanged, indicating the excellent stability of the zirconia translucency after multiple firings. Interestingly, the highest TP values and lowest CR values were found for groups UT-I and UT-M, indicating the superior translucency of multilayered 5Y-TZP. Although it has been reported that the reductions in the grain sizes of Y-TZP can improve its translucency (Damestani et al., 2013; Arena et al., 2019), the translucency of group ST was still lower than those of groups UT-I and UT-M. This phenomenon could have occurred because the grain sizes of the nanosized 3Y-TZP used in this study were much larger than 70–80 nm (in theory, the ideal grain size leads to optimum translucency) (Zhang, 2014). Moreover, the TP values of human enamel and dentin are 18.7 and 16.4, respectively, and their CR values are 0.75 and 0.62, respectively (Yu et al., 2009). Although the highest translucency was found in the multilayered 5Y-TZP, this characteristic was only close to that of dentin but far smaller than that of enamel. Moreover, it has been reported that corrosion of the zirconia surface, which increased the surface roughness, significantly decreased the TP values (Habib et al., 2021). Likewise, generalized irregular surfaces with microretentive areas were observed in a previous study of the zirconia surface after aging, which significantly decreased the TP values (Kilinc and Sanal, 2021). In the present study, the surface morphology of the zirconia remained unchanged after multiple firings, which correlated well with the present results for the translucency characteristics.

Interestingly, although the A1 shade of different highly translucent monolithic zirconia was chosen in this research, there were significant differences in color characteristics among the different groups. These results were similar to those of previous reports (Pecho et al., 2012; Tabatabaian, 2019). This phenomenon may be attributed to the different compositions and shade systems used by different manufacturers. Therefore, it is recommended that the shadeguide provided or recommended by the manufacturers of the zirconia materials should be used during aesthetic rehabilitation.

In the present study, unacceptable color changes in the nanosized 3Y-TZP were observed after multiple firings, while the color changes in highly translucent 3Y-TZP and multilayered 5Y-TZP were clinically acceptable. Clinicians should note that shade correction may be necessary when nanosized 3Y-TZP restorations are repeatedly fired. Moreover, the tested zirconia materials exhibited acceptable stability in terms of the opalescence and translucency during the multiple firing processes.

The changes in the color and translucency characteristics of highly translucent monolithic zirconia were evaluated by ignoring the effects of cements, which could be considered a limitation of the present study (Pekkan et al., 2020). Moreover, multilayered 5Y-TZP with more than three layers has recently become available (Toma et al., 2022). Therefore, future studies are needed to investigate the effects of multiple firing cycles on the color and translucency characteristics of zirconia, including multilayered 5Y-TZP with over three layers. Moreover, the color changes of zirconia might be related to changes in the composition of surface elements (Habib et al., 2021). The surface elements of zirconia after multiple firings will be tested in future studies.

Based on the present findings, it can be concluded that different types of highly translucent zirconia exhibited varied colors, opalescence, and translucency. After multiple firings, clinically unacceptable color changes were found in nanosized 3Y-TZP, while the color changes in highly translucent 3Y-TZP and multilayered 5Y-TZP were clinically acceptable. Moreover, the opalescence, translucency and surface morphologies of highly translucent 3Y-TZP, multilayered 5Y-TZP, and nanosized 3Y-TZP remained unchanged after multiple firings. Future studies are needed to investigate the effects of multiple firing cycles on the color and translucency characteristics of multilayered 5Y-TZP with over three layers.

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding author.

Methodology and writing—original draft, LJ; Investigation, writing and formal analysis, M-QX and X-LL; Conceptualization, review and editing, HY and X-JL; Methodology and supervision, X-WT; All authors have read and agreed to the published version of the manuscript.

This research was funded in part by the Innovation and Entrepreneurship Training Program of Fujian Medical University, grant #C20181, and the Natural Science Foundation of Fujian Province, grants #2021J01808 and 2022J01269.

X-JL was employed by Zhong Xin Tang Guo Ye Technology Corp, Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Altan, B., and Cinar, S. (2022). Effect of repeated firings and thickness on optical properties of variable preshaded and shaded novel translucent zirconia blocks. Biomed. Res. Int. 2022, 1–6. doi:10.1155/2022/8572782

Arena, A., Prete, F., Rambaldi, E., Bignozzi, M. C., Monaco, C., Di Fiore, A., et al. (2019). Nanostructured zirconia-based ceramics and composites in dentistry: A state-of-the-art review. Nanomater. (Basel) 9, 1393. doi:10.3390/nano9101393

Batra, V., Kaur, I., Pathania, D., and Chaudhary, V. (2022). Efficient dye degradation strategies using green synthesized ZnO-based nanoplatforms: A review. Appl. Surf. Sci. Adv. 11, 100314. doi:10.1016/j.apsadv.2022.100314

Bömicke, W., Rammelsberg, P., Zenthöfer, A., and Ohlmann, B. (2019). Clinical performance of zirconia-ceramic cantilever fixed partial dentures-Longitudinal nine-year results from a prospective, randomized, controlled pilot study. J. Prosthodont Res. 63, 334–339. doi:10.1016/j.jpor.2019.01.007

Chaudhary, V., Awan, H. T. A., Khalid, M., Bhadola, P., Tandon, R., and Khosla, A. (2022a). Progress in engineering interlayer space modulated MXenes to architect next-generation airborne pollutant sensors. Sensors Actuators B Chem. 379, 133225. doi:10.1016/j.snb.2022.133225

Chaudhary, V., Kaushik, A. K., Furukawa, H., and Khosla, A. (2022b). Review—towards 5th generation AI and IoT driven sustainable intelligent sensors based on 2D MXenes and borophene. ECS Sensors Plus 1, 013601. doi:10.1149/2754-2726/ac5ac6

Cho, M. H., and Seol, H. J. (2021). Effect of cooling rate during glazing on the mechanical and optical properties of monolithic zirconia with 3 mol% yttria content. Materials 14, 7474. doi:10.3390/ma14237474

Cho, M. S., Yu, B., and Lee, Y. K. (2009). Opalescence of all-ceramic core and veneer materials. Dent. Mater. 25, 695–702. doi:10.1016/j.dental.2008.11.013

Damestani, Y., Reynolds, C. L., Szu, J., Hsu, M. S., Kodera, Y., Binder, D. K., et al. (2013). Transparent nanocrystalline yttria-stabilized-zirconia calvarium prosthesis. Nanomedicine 9, 1135–1138. doi:10.1016/j.nano.2013.08.002

Della Bona, A., Nogueira, A. D., and Pecho, O. E. (2014). Optical properties of CAD-CAM ceramic systems. J. Dent. 42, 1202–1209. doi:10.1016/j.jdent.2014.07.005

Dimitriadis, K., Sfikas, A. K., Kamnis, S., Tsolka, P., and Agathopoulos, S. (2022). Influence of heat treatment on the microstructure and the physical and mechanical properties of dental highly translucent zirconia. J. Adv. Prosthodont. 14, 96–107. doi:10.4047/jap.2022.14.2.96

Fathi, A., Farzin, M., Giti, R., and Kalantari, M. H. (2019). Effects of number of firings and veneer thickness on the color and translucency of 2 different zirconia-based ceramic systems. J. Prosthet. Dent. 122, 565.e1–565.e7. doi:10.1016/j.prosdent.2019.08.020

Fehmi, G., Ersan, Ç., and Caner, Ö. (2018). Influence of repeated firings on the color parameters of two different all-ceramic materials. Color Res. Appl. 43, 606–611. doi:10.1002/col.22219

Grand View Research (2020). Zirconia based dental materials market size, share and trends analysis report by product (zirconia dental disc, zirconia dental block), by application (dental crowns, dental bridges, dentures), by region, and segment forecasts, 2021- 2028. Availale at: https://www.grandviewresearch.com/industry-analysis/zirconia-based-dental-materials-market-report (Accessed February 2, 2023).

Habib, A. W., Aboushelib, M. N., and Habib, N. A. (2021). Effect of chemical aging on color stability and surface properties of stained all-ceramic restorations. J. Esthet. Restor. Dent. 33, 636–647. doi:10.1111/jerd.12719

Hu, C., Sun, J., Long, C., Wu, L., Zhou, C., and Zhang, X. (2019). Synthesis of nano zirconium oxide and its application in dentistry. Nanotechnol. Rev. 8, 396–404. doi:10.1515/ntrev-2019-0035

International Organization for Standardization (2016). Dentistry-Guidance on colour measurement. Geneva: ISO. ISO/TR 28642(E).

Juntavee, N., and Attashu, S. (2018). Effect of sintering process on color parameters of nano-sized yttria partially stabilized tetragonal monolithic zirconia. J. Clin. Exp. Dent. 10, e794–e804. doi:10.4317/jced.55034

Khashayar, G., Bain, P. A., Salari, S., Dozic, A., Kleverlaan, C. J., and Feilazr, A. J. (2014). Perceptibility and acceptability thresholds for colour differences in dentistry. J. Dent. 42, 637–644. doi:10.1016/j.jdent.2013.11.017

Khosla, A., SonuAwan, H. T. A., Singh, K., GauravWalvekar, R., Zhao, Z., Kaushik, A., et al. (2022). Emergence of MXene and MXene-polymer hybrid membranes as future- environmental remediation strategies. Adv. Sci. (Weinh) 9, e2203527. doi:10.1002/advs.202203527

Kilinc, H., and Sanal, F. A. (2021). Effect of sintering and aging processes on the mechanical and optical properties of translucent zirconia. J. Prosthet. Dent. 126, 129.e1–129.e7. doi:10.1016/j.prosdent.2021.03.024

Kim, H. K., Kim, S. H., Lee, J. B., and Ha, S. R. (2016). Effects of surface treatments on the translucency, opalescence, and surface texture of dental monolithic zirconia ceramics. J. Prosthet. Dent. 115, 773–779. doi:10.1016/j.prosdent.2015.11.020

Kim, H. K. (2020). Optical and mechanical properties of highly translucent dental zirconia. Mater. (Basel) 13, 3395. doi:10.3390/ma13153395

Kontonasaki, E., Rigos, A. E., Ilia, C., and Istantsos, T. (2019). Monolithic zirconia: An update to current knowledge. Optical properties, wear, and clinical performance. Dent. J. 7, 90. doi:10.3390/dj7030090

Kwon, S. J., Lawson, N. C., Mclaren, E. E., Nejat, A. H., and Burgess, J. O. (2018). Comparison of the mechanical properties of translucent zirconia and lithium disilicate. J. Prosthet. Dent. 120, 132–137. doi:10.1016/j.prosdent.2017.08.004

Lee, Y. K., and Yu, B. (2007). Measurement of opalescence of tooth enamel. J. Dent. 35, 690–694. doi:10.1016/j.jdent.2007.05.010

Leitão, C., Fernandes, G. V. O., Azevedo, L. P. P., Araújo, F. M., Donato, H., and Correia, A. R. M. (2021). Clinical performance of monolithic CAD/CAM tooth-supported zirconia restorations: systematic review and meta-analysis. J. Prosthodont Res. 66, 374–384. doi:10.2186/jpr.JPR_D_21_00081

Luo, M. R., Cui, G., and Rigg, B. (2001). The development of the CIE 2000 colour-difference formula: CIEDE2000. Color Res. Appl. 26, 340–350. doi:10.1002/col.1049

Manziuc, M. M., Gasparik, C., Burde, A. V., and Dudea, D. (2021). Color and masking properties of translucent monolithic zirconia before and after glazing. J. Prosthodont Res. 65, 303–310. doi:10.2186/jpr.JPR_D_20_00039

Miura, S., Tsukada, S., Fujita, T., Isogai, T., Teshigawara, D., Saito-Murakami, K., et al. (2022). Effects of abutment tooth and luting agent colors on final color of high-translucent zirconia crowns. J. Prosthodont Res. 66, 243–249. doi:10.2186/jpr.JPR_D_21_00025

Miyazaki, T., Nakamura, T., Matsumura, H., Ban, S., and Kobayashi, T. (2013). Current status of zirconia restoration. J. Prosthodont Res. 57, 236–261. doi:10.1016/j.jpor.2013.09.001

Nejatidanesh, F., Azadbakht, K., Savabi, O., Sharifi, M., and Shirani, M. (2020). Effect of repeated firing on the translucency of CAD-CAM monolithic glass-ceramics. J. Prosthet. Dent. 123, 530.e1–530.e6. doi:10.1016/j.prosdent.2019.10.028

Oilo, M., Gjerdet, N. R., and Tvinnerim, H. M. (2008). The firing procedure influences properties of a zirconia core ceramic. Dent. Mater. 24, 471–475. doi:10.1016/j.dental.2007.04.008

Ozdoan, A., and Ozdemir, H. (2020). The effects of repetitive firing processes on the optical, thermal, and phase formation changes of zirconia. J. Adv. Prosthodont. 12, 9–14. doi:10.4047/jap.2020.12.1.9

Paravina, R. D., Ghinea, R., Herrera, L. J., Bona, A. D., Igiel, C., Linninger, M., et al. (2015). Color difference thresholds in dentistry. J. Esthet. Restor. Dent. 27, S1–S9. doi:10.1111/jerd.12149

Pecho, O. E., Ghinea, R., Ionescu, A. M., Cardonajde, L., Paravina, R. D., and Pérez Mdel, M. (2012). Color and translucency of zirconia ceramics, human dentine and bovine dentine. J. Dent. 40, e34–e40. doi:10.1016/j.jdent.2012.08.018

Pekkan, G., Özcan, M., and Subaşı, M. G. (2020). Clinical factors affecting the translucency of monolithic Y-TZP ceramics. Odontology 108, 526–531. doi:10.1007/s10266-019-00446-2

Pekkan, G., Pekkan, K., Bayindir, B., Özcan, M., and Karasu, B. (2020). Factors affecting the translucency of monolithic zirconia ceramics: A review from materials science perspective. Dent. Mater J. 39, 1–8. doi:10.4012/dmj.2019-098

Rinke, S., Metzger, A., and Ziebolz, H. (2022). Multilayer super-translucent zirconia for chairside fabrication of a monolithic posterior crown. Case Rep. Dent. 2022, 1–10. doi:10.1155/2022/4474227

Shah, K., Holloway, J. A., and Denry, I. L. (2008). Effect of coloring with various metal oxides on the microstructure, color, and flexural strength of 3Y-TZP. J. Biomed. Mater Res. B Appl. Biomater. 87 (2), 329–337. doi:10.1002/jbm.b.31107

Silva, L. H. D., Lima, E., Miranda, R. B. P., Favero, S. S., Lohbauer, U., and Cesar, P. F. (2017). Dental ceramics: a review of new materials and processing methods. Braz Oral Res. 31, e58. doi:10.1590/1807-3107BOR-2017.vol31.0058

Spink, L. S., Rungruangaut, P., Megremis, S., and Kelly, J. R. (2013). Comparison of an absolute and surrogate measure of relative translucency in dental ceramics. Dent. Mater. 29, 702–707. doi:10.1016/j.dental.2013.03.021

Sulaiman, T. A., Abdulmajeed, A. A., Delgado, A., and Donovan, T. E. (2020). Fracture rate of 188695 lithium disilicate and zirconia ceramic restorations after up to 7.5 years of clinical service: A dental laboratory survey. J. Prosthet. Dent. 123, 807–810. doi:10.1016/j.prosdent.2019.06.011

Tabatabaian, F. (2019). Color aspect of monolithic zirconia restorations: A review of the literature. J. Prosthodont. 28, 276–287. doi:10.1111/jopr.12906

Toma, F. R., Bîrdeanu, M. I., Uțu, I. D., Vasiliu, R. D., Moleriu, L. C., and Porojan, L. (2022). Surface characteristics of high translucent multilayered dental zirconia related to aging. Mater. (Basel) 15, 3606. doi:10.3390/ma15103606

Vichi, A., Sedda, M., Fabian Fonzar, R., Carrabba, M., and Ferrari, M. (2016). Comparison of contrast ratio, translucency parameter, and flexural strength of traditional and "augmented translucency" zirconia for CEREC CAD/CAM system. J. Esthet. Restor. Dent. 28, S32–S39. doi:10.1111/jerd.12172

Xia, H., and Xiong, F. (2021). Clinical threshold of the translucency parameter of maxillary central incisors. Dent. Mater J. 40, 547–551. doi:10.4012/dmj.2020-137

Yang, S., Li, Q., Chen, S. Y., and Yu, H. (2022). Effect of multiple firings on the marginal fit of monolithic zirconia crowns: An in vitro study. J. Prosthet. Dent. doi:10.1016/j.prosdent.2021.12.030

Yu, B., Ahn, J. S., and Lee, Y. K. (2009). Measurement of translucency of tooth enamel and dentin. Acta Odontol. Scand. 67, 57–64. doi:10.1080/00016350802577818

Zhang, Y., and Lawn, B. R. (2018). Novel zirconia materials in dentistry. J. Dent. Res. 97, 140–147. doi:10.1177/0022034517737483

Zhang, H. A., Li, Z. B., Kim, B. N. A., Morita, K. A., Yoshida, H. A., Hiraga, K. A., et al. (2012). Effect of alumina dopant on transparency of tetragonal zirconia. J. Nanomater. 2012, 1–5. doi:10.1155/2012/269064

Zhang, F., Inokoshi, M., Batuk, M., Hadermann, J., Naert, I., Van Meerbeek, B., et al. (2016). Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent. Mater. 32, e327–e337. doi:10.1016/j.dental.2016.09.025

Zhang, C. Y., Agingu, C., Tsoi, J. K. H., and Yu, H. (2021). Effects of aging on the color and translucency of monolithic translucent Y-TZP ceramics: A systematic review and meta-analysis of in vitro studies. Biomed. Res. Int. 2021, 1–10. doi:10.1155/2021/8875023

Keywords: dentistry, zirconia, colour, translucency, firing

Citation: Jiang L, Xu M-Q, Lu X-L, Tong X-W, Liang X-J and Yu H (2023) Effect of multiple firings on the color and translucency of monolithic zirconia. Front. Mater. 10:1110688. doi: 10.3389/fmats.2023.1110688

Received: 29 November 2022; Accepted: 06 February 2023;

Published: 21 February 2023.

Edited by:

Praveen Sekhar, Washington State University, United StatesReviewed by:

Evangelia Vouvoudi, Aristotle University of Thessaloniki, GreeceCopyright © 2023 Jiang, Xu, Lu, Tong, Liang and Yu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hao Yu, aGFveXVAZmptdS5lZHUuY24=, aGFveXUtY25AaG90bWFpbC5jb20=

†These authors have contributed equally to this work

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.