- 1College of Civil Engineering, Suzhou University of Science and Technology, Suzhou, Jiangsu, China

- 2Jiangsu Technology Industrialization and Research Center of Ecological Road Engineering, Suzhou, China

- 3Suzhou Institute of Nano-Tech and Nano-Bionics, Chinese Academy of Sciences, Suzhou, Jiangsu, China

- 4Jiangsu Sitong Road and Bridge Engineering Co., Ltd., Suzhou, Jiangsu, China

In this work, an aged asphalt was mixed with a new modified asphalt based on styrene–butadiene–styrene (SBS) in different proportions, and the warm mixing agent was added to simulate the asphalt fusion behaviour in the warm mixed recycled asphalt with different aged asphalt fertilizer (reclaimed asphalt pavement, RAP) content. Low field nuclear magnetic resonance (LF-NMR), atomic force microscopy (AFM), and Fourier transform infrared spectroscopy (FTIR) were used as analytical techniques to study the role of the warm mixing agent in terms of molecular bond energy, apparent morphology, and functional groups. It was found that the softening point and penetration of asphalt are reduced, and the ductility is increased, during the regeneration process. Sasobit warm mix agent can reduce the penetration and ductility of asphalt and improve the softening point. Its viscosity reduction effect is mainly achieved by adsorbing saturated components and decreasing the bond energy between 1H and other molecules; Sasobit warm mix agent can improve the aging state of mixed asphalt. On the AFM two-dimensional adhesion diagram, the number of bee-shaped structures and the single area is reduced; in the new and old mixed asphalt, the greater the proportion of new asphalt, the more evident the effect of Sasobit warm mix agent is.

1 Introduction

At present, China’s highway construction has entered a period of large-scale maintenance, which is bound to produce a large number of waste asphalt pavement materials (RAP). It is urgent to recycle RAP for recycling (Guo et al., 2021). Hot mix recycled asphalt mixture (HRAM) technology can consume a lot of RAP (Chen et al., 2017), and the following critical issues arise (Tang et al., 2016; Da, 2018; Wu, 2019):

i) the high content of RAP will make it difficult for the mixture to reach the designed compaction temperature, resulting in the possibility of using limited RAP content

ii) the mixing temperature of HRAM is usually above 160 °C, which requires a lot of energy.

Warm mix agents can significantly reduce the mixing temperature of recycled asphalt and increase the content of RAP (Kim et al., 2018; Wang, 2018), a process with good application perspectives. Sasobit warm mix agent is an organic viscosity-reducing warm mix agent, which can reduce the penetration and ductility of asphalt and improve the softening point (Liu et al., 2015; Xiao et al., 2019; He et al., 2020) and high-temperature stability and fatigue performance of asphalt mixture, but it is slightly unfavorable to the low-temperature performance (Yang et al., 2012; Wang et al., 2017; Nan, 2019; Wang et al., 2020a; Ma et al., 2021). The interaction between old asphalt on RAP surface, newly added asphalt, and warm mix agent will directly affect the performance of warm mix recycled asphalt mixture. Warm mix agent can improve the aging degree of old asphalt to a certain extent and promote the fusion of old and new asphalt (Dinis-Almeida et al., 2016; Wang et al., 2020b). However, there are few reports on its multi-dimensional action mechanism.

At present, low field nuclear magnetic resonance (LF-NMR), atomic force microscopy (AFM), Fourier transform infrared spectroscopy (FTIR), and other nano detection technologies are gradually mature and widely used, providing strong technical support for the study of the involved micro mechanisms. LF-NMR identifies the components in asphalt by distinguishing the hydrogen elements in different functional groups and studies the modification and aging properties of asphalt (Siddiqui, 2009; Barbosa et al., 2013; He, 2013; Zhang, 2016; Cesare et al., 2018; Hong et al., 2019); AFM mainly characterizes the performance of asphalt through the change of asphalt surface morphology height and can characterize the aging degree, Young’s modulus, and adhesion of asphalt (Yu et al., 2018; Liu et al., 2018; Shan et al., 2020a; Jing et al., 2020; Xu et al., 2021); FTIR characterizes the performance of asphalt through the vibration peak of functional groups, including aging degree, fusion degree, and SBS content (Wang and Jian’ge, 2021; Wang et al., 2020c; Qin et al., 2022; Sun et al., 2022; Shan et al., 2020b). The abovementioned findings show that LF-NMR, AFM, and FTIR are mature and reliable in asphalt characterization.

In this study, the aging asphalt was obtained by simulating the aging process in the laboratory; this material was then mixed with new SBS-modified asphalt, according to different proportions, to simulate the mixing of old and new asphalt in warm mix asphalt mixture under different content of reclaimed asphalt pavement. The warm mix agent was added to the new and old blended asphalt, and then we carried out the study of the action mechanism of the warm mix agent on the new and aged asphalt under different mixing proportions in terms of molecular bond energy, apparent morphology, and functional groups through LF-NMR, AFM, and FTIR experimental techniques so as to provide a theoretical basis for the application of warm mix recycled asphalt.

2 Materials and methods

2.1 Material

The asphalt used in the test is a shell styrene–butadiene–styrene (SBS)-modified asphalt processed by Suzhou Sanchuang Pavement Engineering Co., Ltd., and its performance indexes are shown in Table 1 (where it can be seen that the selected indexes fall within the specification values). The selected warm mixing agent is Sasobit, produced by the Sasol group in South Africa. It consists of fine white solid particles at room temperature, with a structural mixture of long-chain saturated hydrocarbons. It belongs to the class of organic warm mixing agents that reduce viscosity. Sasobit basic characteristics are shown in Table 2.

2.2 Preparation of aged asphalt

SBS-modified asphalt was subjected to laboratory short-term aging (RTFO) and long-term aging (PAV) to obtain the aged asphalt required for the test. The aged asphalt was mixed with the new SBS-modified asphalt in five proportions of 0, 20, 50, 80, and 100%. The mixer was used for 30min, and then 1.5% Sasobit warm mix agent was added. Finally, a high-speed shear was used to fully mix the system at 160 °C, with a rotating speed of 4500 rad for 40 min (Fan, 2020). Further details are given in Table 3.

2.3 Basic performance of asphalt

The penetration, softening point, and 5°C ductility of asphalt samples were tested according to the “Test Code for Asphalt and Asphalt Mixture in Highway Engineering” (JTG E20-2011).

2.4 Low field NMR test

VTNR20-010V-I NMR crosslinking density imaging analyzer (Suzhou NewMai Analytical Instrument Co., Ltd.) was used for 1H spectrum analysis. The operating temperature was 25°C, and the system was kept warm for 20 min before the test. Carr–Purcell–Meiboom–Gill (CPMG) pulse sequence was selected for the test. The echo time was set to 0.05 ms, the number of echoes was 5,000, and the scanning superposition times were 32.

2.5 Atomic force microscope test

An atomic force microscope produced by Bruker was used. PeakForce QNM mode and 0.4 N/m probe were selected. The scanning dimensional range was 10 μm × 10 μm, and the scanning rate was 1 Hz. The hot casting method was used to prepare the sample. First, the asphalt sample was heated to the flowing state, and then a few samples were taken out and dropped in the center of the glass slide, which was obliquely placed in an oven at 135°C for 10min-heating to make the surface flow naturally into a smooth and flat film. Then, surface morphology and detection force curve were recorded by AFM at room temperature (25°C).

2.6 Fourier infrared test

NICOLET IS5 instrument was used for FTIR tests. KBr smear method was used to prepare the sample. First, the asphalt was mixed with CS2 in a ratio of 1:19. Then, it was gently dropped in the middle of the KBr window and then put into the UV drying oven to dry CS2. Finally, the FTIR test was carried out. The scanning range of the infrared spectrum was 400-4000 cm−1, and the scanning times were set to 32.

3 Results and discussion

3.1 Asphalt characteristics

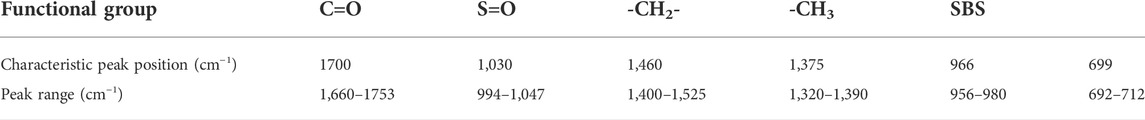

Figure 1 shows the results in terms of indexes such as penetration, softening point, and ductility. It can be seen from Figure 1A that when the content of new asphalt gradually changes from 0 to 100%, the penetration and ductility of new and old mixed asphalt are improved, while the softening point is decreased. Among them, the change in ductility is the most marked, with an increase of 144%. In contrast, the softening point was slightly affected and decreased by only 13%. This is mainly because there is a high content of asphaltene in the aged asphalt, which makes the asphalt hard and the viscosity higher. After adding new asphalt, the content of asphaltene and gum can be effectively adjusted to restore the performance of the old asphalt. In terms of macro performance, the material becomes soft, and the ductility, correspondingly, increases. From a comparison between Figures 1A and B, it can be seen that Sasobit warm mix agent has an adverse impact on the low-temperature performance of new and old mixed asphalt, in which the maximum ductility loss can reach 24.8%. The main reason is that Sasobit warm mix agent is an organic viscosity-reducing material. When the temperature is higher than its melting point, it will adsorb the saturated components in the asphalt. When the temperature is lower, it will form a network lattice structure in the asphalt. Therefore, it will harden the asphalt macroscopically and change the elasticity behaviour, which is reflected in the decrease of ductility and penetration and in the increase of softening point (Zhang and Zhang, 2016). When there is a higher fresh asphalt content (more than 50%) in the mixed asphalt, the effect of Sasobit is more significant, mainly because there is a higher saturated component content, which improves the effect of Sasobit warm mix. Altogether, the penetration ranged from 35.3 to 52.6 mm in the absence of Sasobit, and from 33.4 to 42.5 mm in its presence. The softening point was lowered in the range 89.9–78.6 °C and 91.6–82.9 °C in the absence and presence of Sasobit, respectively, while the ductility increased from 12.3 to 30.1 cm (no Sasobit) or from 12.7 to 27.6 cm (presence of Sasobit).

FIGURE 1. Penetration, softening point, and ductility for mixed asphalt samples (cf. Table 3 for numbering).

3.2 Low field NMR analysis

Asphalt is mainly composed of C- and H-compounds and their derivatives, and the LF-NMR technique can characterize the difference between 1H and other molecular bond energies according to the relaxation time T2. When T2 is short, this indicates that 1H can be closely connected with other molecules, the bond energy is greater, and the degree of freedom is smaller. The relative content of hydrogen protons can be expressed by the signal amplitude covered by T2 peak at different relaxation times (i.e., the integral area of T2 interval).

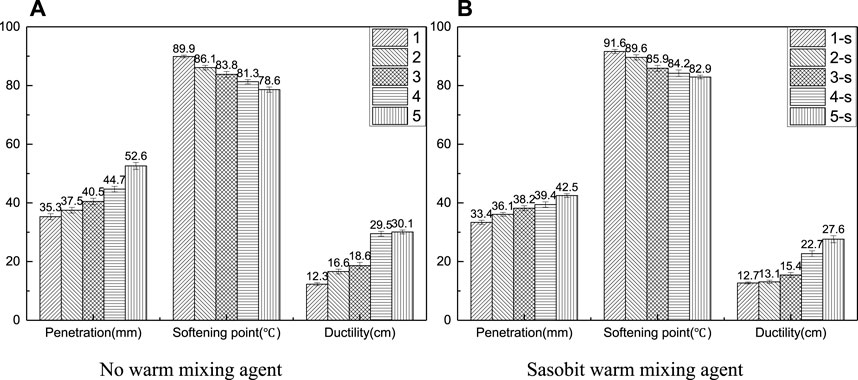

When the number of LF-NMR inversion fitting iterations is set to 1,000, there is only one peak on each T2 inversion spectrum curve (peaks with a relative area less than 2% are not considered). It can be seen from Figure 2A that in the absence of warm mix agent, the T2 diffraction peak of each group of mixed asphalt has basically the same starting time, but the ending time is delayed with the increase of the proportion of new asphalt. The reason is that during the aging process of asphalt, some bond energy is released due to the breaking of light alkyl components, low molecular weight compounds volatilization, and C=C cracking/reorganization. At the same time, it is also found that the larger the proportion of new asphalt, the lower the peak value, i.e., the smaller the corresponding diffraction peak area. This is because when the content of C and H remains unchanged, it will react with oxygen during asphalt aging, resulting in an increase in the relative content of oxygen and a decrease in the relative content of hydrogen.

FIGURE 2. LF-NMR spectra of mixed asphalt (cf. Table 3 for numbering).

By observing Figures 2B–F, it can be found that after adding Sasobit, the ending time of T2 diffraction peak moves backward at varying degrees. The most significant backward movement is observed in the mixed asphalt with the highest proportion of new asphalt. Among them, 1-s backward shift is within 0.02 ms, and 5-s backward shift reaches 0.08 ms. This shows that when Sasobit warm mix adsorbs the saturated components in asphalt, the bond energy between 1H and other molecules is reduced so as to achieve the effect of viscosity reduction. The higher the content of saturated components, the better the viscosity reduction effect. The reason why Sasobit warm mix can increase both peak value and area of T2 is mainly because it is composed of C- and H-based polymers, which can increase the content of hydrogen in new and old mixed asphalt.

3.3 Atomic force microscopy analysis

In the asphalt morphology obtained by AFM, the “bee-like structure” is generally considered the most prominent feature. This concept was first proposed by Loeber et al. (2003). After that, Li (Li et al., 2015) conducted AFM tests on a variety of asphalts and found that the “bee-like structure” was formed by precipitation during cooling because asphaltene could not be well integrated with other asphalt components. Figure 3 represents the height variation diagram of different phase structure areas for non-aged asphalt. It can be found that its micro surface structure has different shapes, and the peak height relationship of each phase is as follows: (white) bee structure > continuous phase structure > (black) bee structure.

FIGURE 3. Height variation diagram of asphalt structure area with different phases, as observed by AFM.

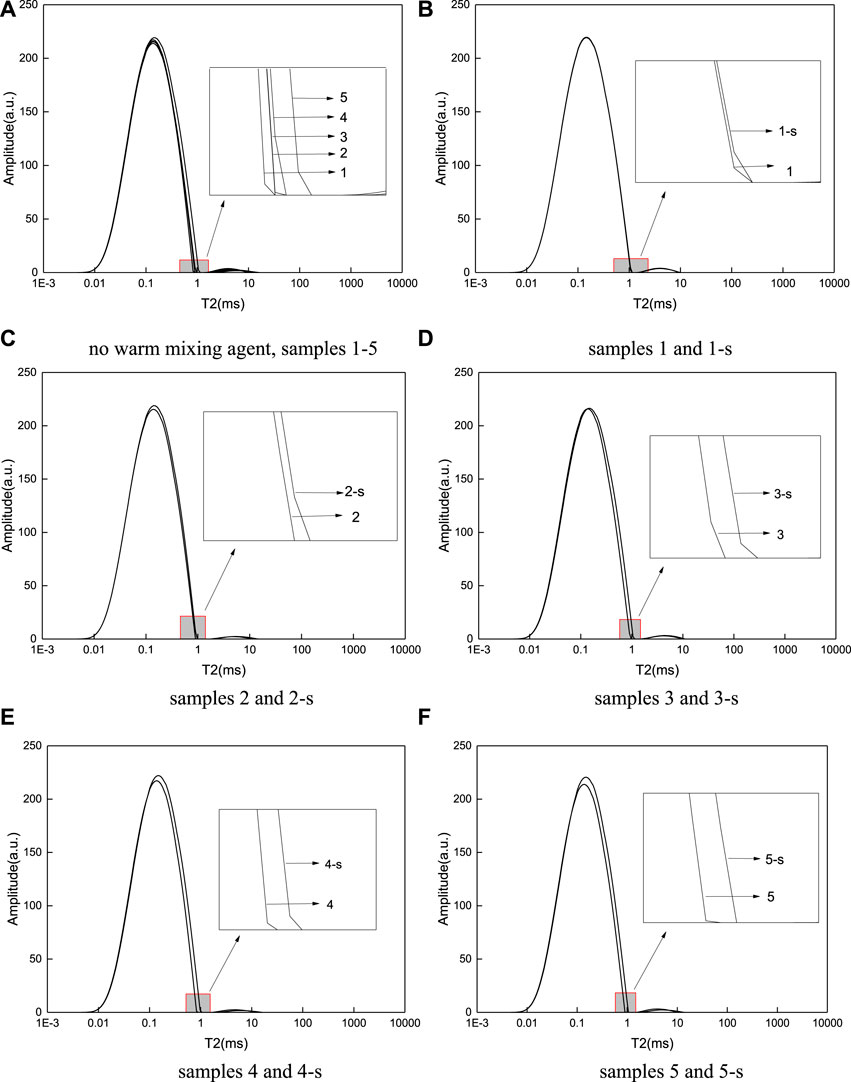

3.3.1 Two-dimensional adhesion diagram

Nanoscope analysis software was used to analyze the AFM results with a second-order flattening procedure that was applied to preprocess the image so as to obtain two-dimensional diagrams of asphalt adhesion, as shown in Figure 4. These diagrams include the dark aggregation that we term “bee-like structure”, i.e., an area with darker color with a surrounding lighter color area. Previous studies have shown (Yu et al., 2015) that the adhesion extent referring to the dark “bee-like structure” area is greater than that referring to the lighter color area, namely, the darker the color, the greater the adhesion. It can be seen from Figure 4 that the higher the proportion of new asphalt in the mixed asphalt, 0–20–50–80–100% in the 1-2-34-5 samples, respectively, the more and finer the bee-like structures. The main reason is that when mixing the old and new asphalt at a high temperature, the asphaltene will fuse. If a higher content of old asphalt is used, the asphaltene content will increase significantly and flocculation will occur, resulting in the reduction of the parts that can provide crystallization for wax components. The number of bee-like structures will decrease accordingly. However, the asphaltene particles after flocculation are large, which increases the area of a single bee structure attached to this crystallization point.

FIGURE 4. Two-dimensional adhesion diagrams for the samples presented in Table 3.

By comparing Figure 4 for the samples without ((a), (c), (e), (g), and (i)) and with ((b), (d), (f), (h), and (j)) the addition of Sasobit warm mix, it is seen that the number of bee-like structures gradually decreases when Sasobit is present in the system. The main reason is that the AFM test is carried out at room temperature, and this temperature is lower than the melting point of Sasobit warm mix. Sasobit warm mix agent is mixed in the molten state of asphalt, which can adsorb the saturated components in asphalt. When the temperature decreases, it will form a spatial network structure, reducing the content of wax components that can form the bee structures and, thus, reducing the number of bee structures. At the same time, the asphaltene content that can provide crystallization points remains basically unchanged, and the wax components adsorbed on each crystallization point will be reduced, which implies that the area of a single bee structure will be reduced. In the mixed asphalt, the higher the proportion of new asphalt is, the more saturated components are present. For example, after adding Sasobit warm mix agent, the change of bee structures in sample number 5 (cf. Figures 4I and J; no new asphalt content) is much greater than in sample number 1 (cf. Figures 4A and B; new asphalt content is 100%, apart from the presence of Sasobit).

3.3.2 Young’s modulus

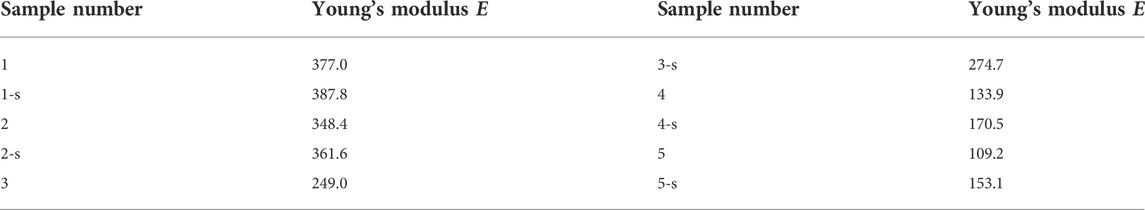

Young’s modulus E can be used to describe the ability of materials to resist deformation. Generally speaking, the greater the E, the harder the asphalt will be, and the less the deformation tendency will be. In this research, 20 points were randomly selected on the two-dimensional adhesion diagram, using the AFM probe contact method, to read the E data and calculate its average value. Results are listed in Table 4. When the content of new asphalt changes from 0 to 100% (going from sample one to sample 5), E is significantly reduced, from 377 to 109 MPa, with a maximum decrease of 71.0%. The main reason is that the regeneration degree of new and old mixed asphalt increases, and the asphaltene content decreases, which makes the asphalt softer and the viscosity lower. After adding Sasobit warm mix agent, the asphalt will form a network lattice structure at room temperature, which makes the old and new mixed asphalt difficult to deform, so increasing E (cf. Sample 1-s vs sample 1, and so on, up to sample 5-s vs sample 5). The greater the proportion of new asphalt, the more significant the effect of Sasobit on the increase of E. For example, E for sample 5-s is 40.2% higher than the value for sample 5, while E for sample 1-s is only 2.9% higher than the value for sample 1. These results are consistent with those concerning indexes of penetration, softening point, and ductility.

TABLE 4. Young’s modulus (values expressed in MPa) for the samples presented in Table 3.

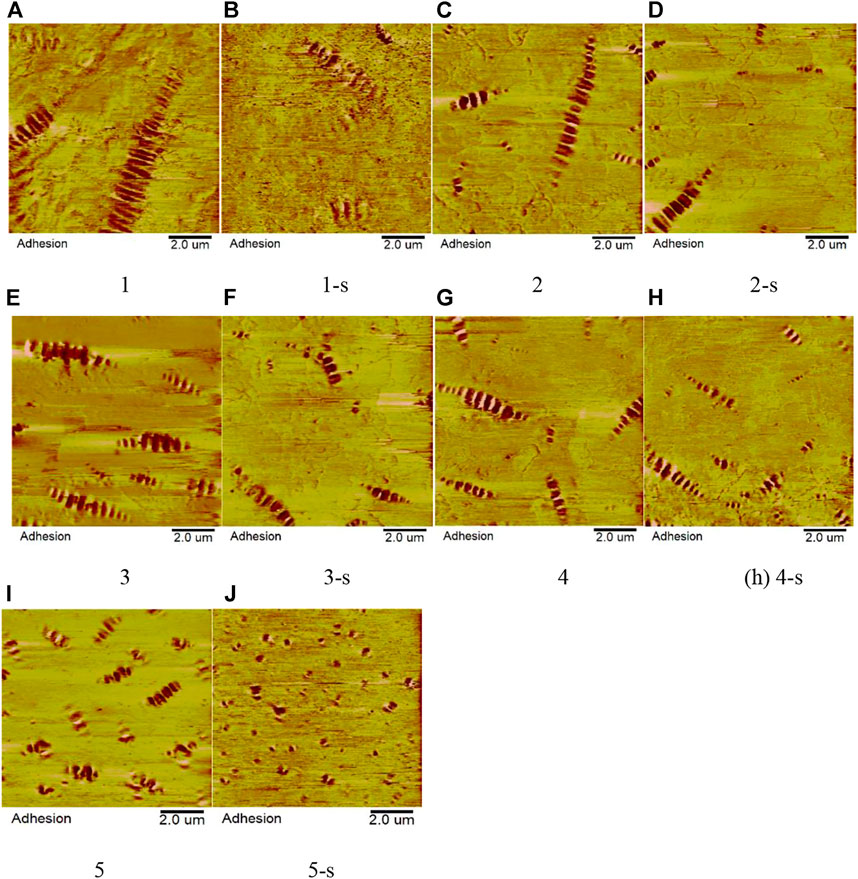

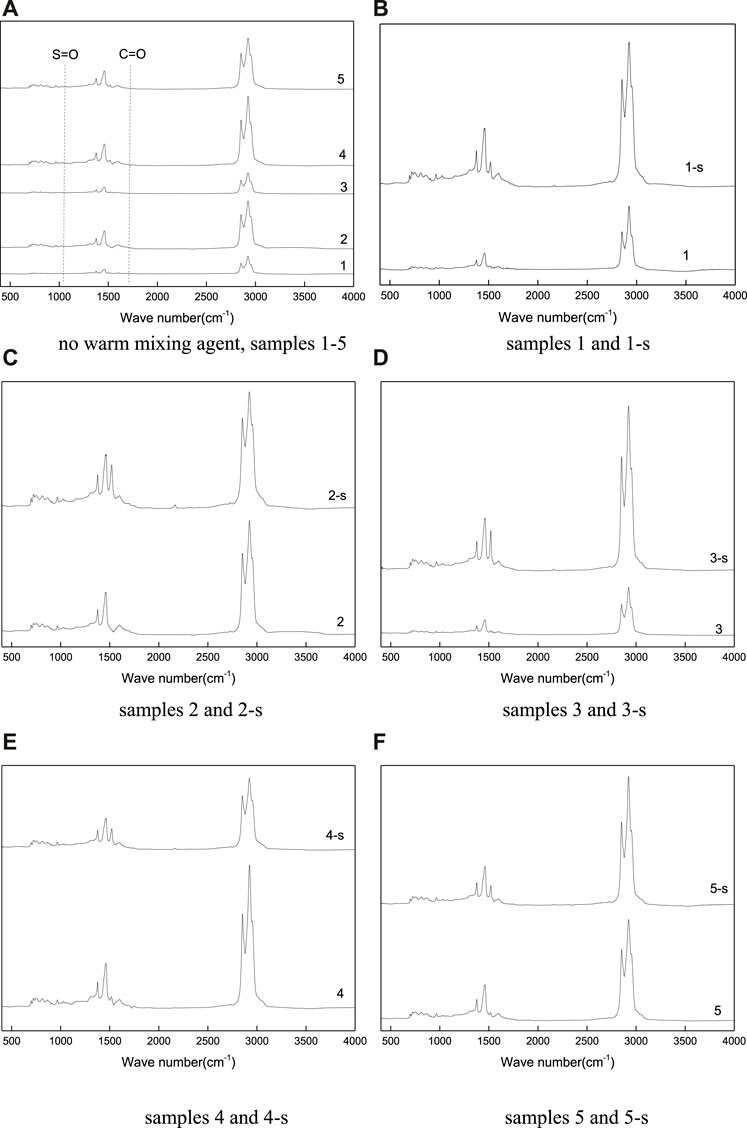

3.4 FTIR analysis

In the infrared spectrum of asphalt, methylene (-CH2-), seen at 1460 cm−1, and methyl (-CH3), seen at 1375cm−1, are not easy to undergo chemical or physical changes in the aging process of asphalt due to their stable properties. The aging degree of asphalt mainly depends on the structural index of carbonyl (C=O), seen at 1700cm−1, and sulfoxide (S=O), seen at 1030cm−1. For the calculation formulas of carbonyl (IC=O), sulfoxide (IS=O), and SBS (ISBS) structure indexes, see Eqs 1–3 (Jiang, 2018):

These indexes were calculated through the aid of OMNIC software. The specific location and range of characteristic peaks for each functional group are shown in Table 5.

Figure 5 shows the infrared spectra for the samples under investigation. In Figure 5A, the dotted lines show the absorption peaks of carbonyl (C=O, 1700 cm−1) and sulfoxide (S=O, 1030 cm−1). For sample 5, the characteristic peaks of carbonyl and sulfoxide groups are not clear, but the characteristic peaks of these two functional groups become more prominent with the increase of the aged asphalt proportion (i.e., going back from sample 5 to sample 1, cf. Table 3). By observing Figures 5B–F, it can be found that, after the warm mix agent is added, there is no new characteristic peak or shift in the position of the characteristic peaks, indicating that there is no chemical reaction between Sasobit warm mix agent and new/old mixed asphalt. Sasobit warm mix agent can weaken the characteristic peaks of carbonyl and sulfoxide groups of new and old mixed asphalt, indicating that the warm mix agent can improve the aging state of asphalt.

FIGURE 5. FTIR spectra of the samples under investigation (cf. Table 3 for numbering).

Table 6 lists the values for the structure indexes defined in Eqs 1–3. It can be found that, at an increasing proportion of new asphalt (from sample one to sample 5), IC=O decreased from 0.0331 to 0.0035, with a decrease of 89.4%, and IS=O decreased from 0.0341 to 0.0106, with a decrease of 68.9%, indicating that the proportion of carbonyl and sulfoxide groups also gradually decreases in the process of asphalt regeneration. After adding Sasobit warm mix agent, IC=O and IS=O are reduced, indicating that warm mix agent can improve the aging state of the materials under investigation. However, ISBS were all between 0.04–0.06, and there is no clear trend in ISBS when going from samples 1 to 5, neither in the absence nor in the presence of Sasobit. Actually, tests carried out in this work simulate asphalt aging under laboratory hot oxygen conditions and lack the influence of ultraviolet on SBS under natural light conditions (Marsac et al., 2014).

TABLE 6. Group structure index the samples under investigation (cf. Table 3 for numbering).

4 Conclusion

In this work, it has been observed that, for the new and old mixed asphalt, the carbonyl structure index IC = O and sulfoxide structure index IS = O both significantly decrease by increasing the content of new asphalt from 0 to 100%. Macroscopically, the softening point and penetration decreased, and the ductility increased. Moreover, Sasobit warm mix agent reduces the ductility and penetration of mixed asphalt and improves the softening point. When the content of new asphalt in the mixed asphalt exceeds 50%, the effect of Sasobit is more significant. Furthermore, Sasobit warm mix agent can reduce the bond energy between 1H and other molecules by adsorbing saturated components in asphalt so as to achieve the effect of viscosity reduction. Finally, Sasobit warm mix agent can improve the aging degree of mixed asphalt. In a two-dimensional adhesion diagram, the number of bee-shaped structures increases, the single area decreases, and Young’s modulus increases; In the infrared spectrum, the values of IC = O and IS = O decrease.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

BT: conception of ideas, data processing, and manuscript writing. XS: funding acquisition. JS: experimental site. TJ: assistance in experimentation. JC: microscopic test conduction. JN: experimental raw materials handling.

Funding

Postgraduate Research and Practice Innovation Program of Jiangsu Province (SJCX19_0839); the research fund of Jiangsu Technology Industrialization and Research Center of Ecological Road Engineering; the National Natural Science Foundation of China (51378328).

Acknowledgments

The authors acknowledge the financial support provided by the Postgraduate Research and Practice Innovation Program of Jiangsu Province (SJCX19_0839) and the National Natural Science Foundation of China (51378328).

Conflict of interest

JN is employed by Jiangsu Sitong Road and Bridge Engineering Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Barbosa, L. L., Kock, F. V. C., Silva, R. C., Freitas, J. C. C., Lacerda, V., and Castro, E. V. R. (2013). Application of low-field NMR for the determination of physical properties of petroleum fractions. Energy fuels. 27, 673–679. doi:10.1021/ef301588r

Cesare, O. R., Paolino, C., and Giuseppina, D. L. (2018). 1H-NMR spectroscopy A possible approach to advanced bitumen characterization for industrial and PavingApplications. J. Appl. 8 (2), 229. doi:10.3390/app8020229

Chen, J., Jian, L., and Wang, W. (2017). Performance of warm recycled asphalt binders with different aged asphalt percentage[J]. J. Shenyang Jianzhu Univ. Nat. Sci. 33 (05), 863–869. (in Chinese).

Da, L. I. (2018). Influence of RAP content on durability of warm-mix recycled asphalt mixture[J]. J. Chang'an Univ. Nat. Sci. Ed. 38 (05), 25–48. (in Chinese).

Dinis-Almeida, M., Castro-Gomes, J., Sangiorgi, C., Zoorob, S. E., and Afonso, M. L. (2016). Performance of warm mix recycled asphalt containing up to 100% RAP. Constr. Build. Mater. 112, 1–6. doi:10.1016/j.conbuildmat.2016.02.108

Fan, W. (2020). Study on performance of double-warm-mix asphalt and its mixture based on water foaming and warm-mix additives[D]. Suzhou China: Suzhou University of Science and Technology. (in Chinese).

Guo, P., Lu, C., and Xie, F. (2021). Interfacial fusion characteristics of new old asphalt of warm mix recycled mixture at micro scale[J]. China J. Highw. Transp. 34 (10), 89–97. (in Chinese).

He, M. (2013). Structural behavior and performance characterization of road petroleum asphalt [D]. Xi'an China: Chang’an University. (in hinese).

He, Y., Li, W., Lei, J., Li, Z., and Wang, Z. (2020). Study on the influence of different warm mix agents on the performance of asphalt and mixture. Highway 65 (09), 59–64. (in Chinese).

Hong, H., Zhang, H., and Huang, L. (2019). Study progress of characterization of asphalt materials by nuclear magnetic resonance, thermal analysis and scanning electron microscopy[J]. J. Highw. Transp. Res. Dev. 36 (12), 15–28. (in Chinese).

Jiang, Y. (2018). Study on performance evaluation of recycled asphalt and microscopic mechanism of asphalt blends in hot recycled asphalt mixture[D]. Bangladesh: Southeast University. (in Chinese).

Jing, L., Shi, P., and Shen, J. (2020). Regeneration mechanism of asphalt based on atomic force microscope[J]. Sci. Technol. Eng. 20 (08), 3272–3279. (in Chinese).

Kim, M., Mohamma, L. N., Jordan, T., and Cooper, S. B. (2018). Fatigue performance of asphalt mixture containing recycled materials and warm-mix technologies under accelerated loading and four point bending beam test. J. Clean. Prod. 192 (AUG.10), 656–664. doi:10.1016/j.jclepro.2018.04.070

Li, R., Wang, P., Xue, B., and Pei, J. (2015). Experimental study on aging properties and modification mechanism of Trinidad lake asphalt modified bitumen[J]. Constr. Build. Mater. 101, 878–883. doi:10.1016/j.conbuildmat.2015.10.155

Liu, Y., Shen, J., Shi, P., Zhu, H., and Gao, Q. (2018). Nanosized morphology and mechanical properties of recovered binders from weathered asphalt mixtures. J. Test. Eval. 46 (6), 20170038. doi:10.1520/jte20170038

Liu, Z., Du, Y., and Wan, T. (2015). Experimental study on influence of warm mix Sasobit on viscoelastic properties of asphalt[J]. J. China & Foreign Highw. 35 (03), 296–298. (in Chinese).

Loeber, L., Sutton, O., Morel, J., Valleton, J. M., and Muller, G. (2003). New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 182 (1), 32–39. doi:10.1046/j.1365-2818.1996.134416.x

Ma, F., Yuan, K., Fu, Z., Dai, J., and Guo, X. (2021). Influence of different warm mix agents on pavement performance of asphalt mixture[J]. J. Hefei Univ. Technol. Sci. 44 (11), 1500–1505. (in Chinese). doi:10.3390/ma14133534

Marsac, P., Piérard, N., Porot, L., Van den bergh, W., Grenfell, J., Mouillet, V., et al. (2014). Potential and limits of FTIR methods for reclaimed asphalt characterisation. Mat. Struct. 47 (8), 1273–1286. doi:10.1617/s11527-014-0248-0

Nan, Q. (2019). Study on Influencing Factors of compaction characteristics of warm mix asphalt mixture[J]. J. Chongqing Jiaot. Univ. Sci. 38 (12), 63–68. (in Chinese).

Qin, R., Ou, S., and Xie, T. (2022). Effect of two silicate materials on thermal oxidative aging properties of nano ZnO modified asphalt[J]. Highway 67 (04), 292–298. (in Chinese).

Shan, G., Yuan, Y., Pang, L., Zhou, L., Li, N., and Zhan, H. (2020). Effect of high temperature heating with geothermal regeneration on rheological properties of asphalt with different depth of aging[J]. Sci. Technol. Eng. 20 (07), 2864–2869. (in Chinese).

Shan, L., Zhang, E., Liu, S., Xu, H., and Tan, Y. (2020). Analysis of micro damage mechanism of asphalt based on atomic force microscope[J]. China J. Highw. Transp. 33 (10), 171–177. (in Chinese).

Siddiqui, M. N. (2009). NMR finger printing of chemical changes in asphalt fractions on oxidation. Petroleum Sci. Technol. 27 (17), 2033–2045. doi:10.1080/10916460802668622

Sun, J., Zhang, W., Wang, Z., and Qi, Y. (2022). Quantitative characterization of fusion degree of new and old asphalt based on infrared spectrometer[J]. Sci. Technol. Eng. 22 (10), 4143–4151. (in Chinese).

Tang, W., Sheng, X., Xie, X., and Zhou, X. (2016). Performance of warm mix asphalt mixture containing different RAP contents[J]. J. Build. Mater. 19 (01), 204–208. (in Chinese).

Wang, C., Peiwen, H., and Zhang, X. (2020). Study on long-term performance of warm mix asphalt based on accelerated loading test[J]. J. Shenyang Jianzhu Univ. Sci. 36 (05), 860–868. (in Chinese).

Wang, D., Luo, G., Deng, X., and Zhou, Z. (2017). Study on application performance of warm mix flame retardant asphalt and asphalt mixture [J]. China J. Highw. Transp. 30 (05), 59–66. (in Chinese).

Wang, L., Zhang, Q., and Lei, F. (2020). Performance evaluation of warm-mixed crumb rubber asphalt based on rheological and microscopic characteristics analysis[J]. J. Build. Mater. 23 (06), 1458–1495. (in Chinese).

Wang, W., Huang, S., Qin, Y., Sun, Y., and Chen, J. (2020). Constr. Build. Mater. 252 (C), 119124. doi:10.1016/j.conbuildmat.2020.119124

Wang, W. (2018). Performance study of warm mix recycled asphalt binders and mixtures containing high percentages of RAP[D]. Dalian China: Dalian University of Technology. (in Chinese).

Wang, Z., and Jian'ge, L. (2021). Determination model of SBS content in modified asphalt based on DNN[J]. J. Build. Mater. 24 (03), 630–636. (in Chinese).

Wu, X. (2019). Study on performance of warm mix recycled SBS modified asphalt mixture[D]. Guangzhou, China: South China University of Technology. (in Chinese).

Xiao, L., Wu, C., and Zhou, Z. (2019). Effect of Sasobit warm mix on high and low temperature properties of asphalt mortar[J]. ShanDong Commun. Technol. 1 (01), 70–72. (in Chinese).

Xu, Z., Shen, J., Liu, Y., Shi, P., Song, X., and Li, X. (2021). Nonlinear aging prediction of all climate aging asphalt based on atomic force microscope[J]. J. Mater. Sci. Eng. 39 (02), 288–316. (in Chinese).

Yang, L., Tan, Y., Dong, Y., and Li, E. (2012). Fatigue performance of warm mix recycled asphalt mixture[J]. J. Highw. Transp. Res. Dev. 29 (10), 7–10. (in Chinese).

Yu, J., Dai, Z., Shen, J., Zhu, H., and Shi, P. (2018). Aging of asphalt binders from weathered asphalt mixtures compared with a SHRP process. Constr. Build. Mater. 160, 475–486.

Yu, X., Burnham, N. A., and Tao, M. (2015). Surface microstructure of bitumen characterized by atomic force microscopy. Adv. Colloid Interface Sci. 218, 17–33. doi:10.1016/j.cis.2015.01.003

Zhang, K., and Zhang, Z. (2016). Efficiency evaluation of different warm-mixed agents based on warm-mixed asphalt performance[J]. J. Mater. Sci. Eng. 34 (03), 389–393. (in Chinese).

Keywords: mixed asphalt, Sasobit, LF-NMR, AFM, FTIR

Citation: Tong B, Song X, Shen J, Jiang T, Chen J and Niu J (2022) Effect of Sasobit warm mix on micro properties of asphalt with different degrees of regeneration. Front. Mater. 9:950550. doi: 10.3389/fmats.2022.950550

Received: 23 May 2022; Accepted: 25 August 2022;

Published: 16 September 2022.

Edited by:

Hosam Saleh, Egyptian Atomic Energy Authority, EgyptReviewed by:

Augusto Cannone Falchetto, Aalto University, FinlandSongtao Lv, Changsha University of Science and Technology, China

Copyright © 2022 Tong, Song, Shen, Jiang, Chen and Niu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Xuyan Song, c29uZ3h1eWFuMjAwMkAxNjMuY29t

Bin Tong

Bin Tong Xuyan Song1*

Xuyan Song1*