94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Mater., 19 August 2022

Sec. Smart Materials

Volume 9 - 2022 | https://doi.org/10.3389/fmats.2022.929795

This article is part of the Research TopicCharacterization and Application of Magneto-sensitive Soft MaterialsView all 20 articles

A magnetic fluid seal is often used in complex working conditions with harsh environmental requirements. Timely and accurate identification of the seal status can help avoid the major economic losses and even casualties caused by the seal failure. However, research on the recognition of magnetic fluid seal status is still at the exploratory stage internationally. Aiming at the problem of inclusion of other components and Gaussian noise when using acoustic emission nondestructive testing technology to detect the magnetic fluid seal status, a new recognition method based on the combination of high-order cumulant image and VGG16 convolutional neural network is proposed to identify the magnetic fluid seal status in this paper. In this method, high-order cumulant images are used for the denoising and feature selecting of detected signals, and the VGG16 convolutional neural network is trained to automatically learn image features to classify and recognize high-order cumulant images representing different sealing states. Experiments show that the accuracy of image recognition using VGG16 is significantly higher than that of other methods. The VGG16 method can identify the magnetic fluid seal state accurately and effectively, with strong robustness and Gaussian noise suppression ability.

A magnetic fluid seal is a new sealing method that is often applied to important parts that have strict requirements on sealing performance (Hasegawa et al., 2016; Mitamura and Durst, 2017), such as movable parts of spacesuits, X-ray diffractometer, radar waveguide components, and the main pump shaft of a sodium cooled fast reactor, etc. The operating conditions of these components are complicated. Seal failure can not only cause significant economic losses but also serious environmental pollution and even casualties. It is therefore necessary to accurately identify the seal status when using magnetic fluid to seal components so that timely preventive measures can be taken to ensure the safe operation of seals.

To date, there is no mature identification method of magnetic fluid seal status, and relevant research is mainly focused on the exploration of magnetic fluid seal performance and failure mechanisms. For example, Chen et al. (Chen et al., 2020) used pressure sensors to measure magnetic fluid seal signals and simulated the seal status. Parmar et al. (Parmar et al., 2020) tested the performance of a two-stage magnetic fluid seal under variable speed and radial clearance. Gao, (2014) used X-ray and CT image brightness to detect the existence of magnetic liquid in sealing clearance. Wang, (2018) achieved real-time monitoring of magnetic fluid leakage by using a pressure detection device. The above research provides a good beginning for monitoring the status of the magnetic fluid seal, but the detection technology has certain limitations and is destructive to the seal. In this paper, acoustic emission nondestructive testing technology is used to detect the seal status without destroying the original structure of the seal.

In recent years many recognition methods for acoustic signals have been developed, mainly including K-means clustering (Glowacz, 2019), fully integrated empirical mode decomposition (Delgado-Arredondo et al., 2017), support vector machine (Shi et al., 2018), and convolutional neural network (CNN) (Zhang D. et al., 2020), etc. In this research field, a recognition method based on CNN that automatically extracts signal features is one of the present research hotspots. Han et al. (Han et al., 2020) used CNN to effectively identify the two-dimensional time-domain waveform image features of signals. Chen et al. (2015) used CNN to identify frequency spectrum images of timing signals and achieved high accuracy. In addition, studies have shown that the convolutional neural network model of VGG16 has better performance in the practical application of abstract image recognition (Qassim et al., 2018; Theckedath and Sedamkar, 2020). Therefore, the recognition process can be more efficient by converting one-dimensional signals into images and inputting them into the VGG16 model. Among the many methods of transforming one-dimensional signals into two-dimensional images, high-order cumulant image processing has the characteristics of suppressing Gaussian colored noise and depicting signal phase information and has more advantages than traditional images such as time-spectrum graphs (Shao et al., 2008).

In this paper, a state recognition method based on a high-order cumulant image and VGG16 convolutional neural network is proposed, which provides a new approach to effectively identifying the magnetic fluid seal state. In this method, the acoustic signal of the magnetic fluid seal is collected by an acoustic emission experiment, and the magnetic fluid seal states can be detected without damage. The high-order cumulant image processing method for detecting acoustic signals is introduced theoretically, and the generated image samples are input into the VGG16 convolution neural network. Finally, by comparing the NIN, GooLeNet, and ResNet models, we found that the VGG16 model can effectively identify the magnetic fluid seal state and that the network performance is significantly better than other models.

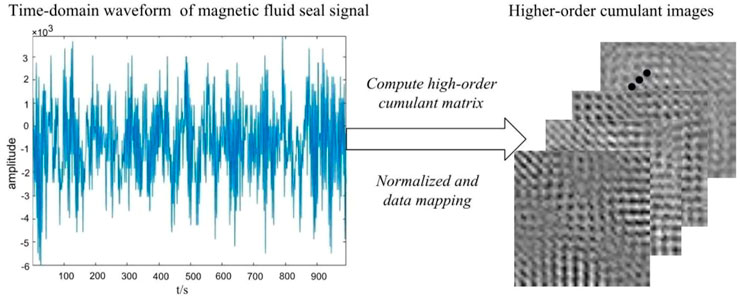

High-order cumulant is a new signal processing technology, which has the advantages of suppressing Gaussian colored noise and extracting phase information (Shao et al., 2008; Wang et al., 2014). It is gradually being applied to signal filtering, signal detection, and target classification and recognition. High-order cumulant image is a grayscale image transformed from a sealed acoustic signal through high-order cumulant calculation and data mapping, which is used as the input sample data of VGG16 and other convolutional network models, and it can contain richer feature information while suppressing various noises. Figure 1 shows a schematic diagram of the high-order cumulant image transformation process.

FIGURE 1. Schematic diagram of high-order cumulant image transformation process in the magnetic fluid seal state.

As shown in Figure 1, the key Cto generating high-order cumulant images lies in high-order cumulant calculation and data mapping processing. The calculation formula of high-order cumulant is as follows:

Where

In a Gaussian stochastic process with zero mean, the third-order and higher-order cumulants are equal to zero, that is, the third-order and higher-order cumulants can suppress the influence of additive Gaussian noise in the signal theoretically. Therefore, the third-order cumulant with less computation is used in this paper, and the calculation formula is as follows:

Where

The one-dimensional acoustic signal is calculated by the third-order cumulant and the two-dimensional matrix is obtained. The delay

Where,

Convolutional Neural Networks (CNN), a feedforward Neural network, are widely used in image recognition, text recognition, and speech recognition. Typical CNN is mainly composed of an input layer, convolution layer, activation function, pooling layer, full connection layer, and output layer, among which, the convolution layer, pooling layer, and full connection layer are relatively key components. The convolutional layer is mainly used to extract the features of the input image, the pooling layer is mainly used to reduce the size of the feature image, and the full connection layer is mainly used to classify the feature vectors obtained.

Many excellent CNN models have evolved based on the classic network structure of CNN, such as VGGNet, NIN, GoogLeNet, and ResNet (Alzubaidi et al., 2021). VGGNet is mainly divided into VGG16 and VGG19 according to different network layers. All the convolution layers of VGGNet use the same small convolution kernel (3 × 3), such connection mode makes the number of network parameters smaller, and the use of a multi-layer activation function makes the learning ability of the network stronger. In the NIN model, multi-layer perceptron is used for filtering operation, and global average pooling is introduced to replace the last full connection layer, which effectively improves the parameter inflation problem and nonlinear mapping ability of the network model. The core of GoogLeNet is the Inception structure. Inception Module uses multiple parallel and small dense convolution and pooled connections. In addition, the auxiliary classifier adopted by GoogLeNet solves the problem of gradient disappearance. Resnet-50 was one of the first networks to adopt batch regularization by designing deeper network layers to improve network generation. These CNN models gradually reduce the error rate of image classification while improving the universality and robustness of the model. In particular, VGG16, with its simplicity and practicability, has been widely used in image classification. VGG16 model is used to identify the seal states with the high-order cumulant images of acoustic signals in this paper.

VGG16 is a CNN model capable of image recognition with high accuracy. Proposed by the Visual Geometry Group of Oxford University in 2014, VGG16 is an ideal choice for image recognition problems of high-order cumulants with abstract characteristics. The structure of the VGG16 model is very regular, and the main components are the repeatedly stacked convolutional layers and pooling layers, as well as the full connection layer and output layer at the bottom of the model (Simonyan and Zisserman, 2008). The convolution layer achieves the purpose of extracting image features by convolution operation in two ways: “local perception” and “parameter sharing”. The convolution kernel size

It can be found from the above formula that although the convolution operation of this model increases the number of channels, it does not change the size of the image. Therefore, pooling is required after several convolutional operations. After pooling, the size of feature images is reduced to half of the original, which can greatly reduce the computing requirements. The pooling method of this model is maximum pooling. The size of the pooling box is 2 × 2 and the step size is 1.

The full connection layer and output layer at the bottom of the model are responsible for sample classification (Liu et al., 2018). Figure 2 shows the schematic diagram of the VGG16 convolutional neural network. The input size of the 224 × 224×3 image enters the convolution layer, after two convolution operations and the ReLU function, the size becomes 224 × 224×64, and then a Max pooling layer is connected. In this way, after repeatedly stacking convolutional layers and pooling layers, three fully connected layers are connected, and the probability distribution of sample recognition is obtained by the softmax activation function.

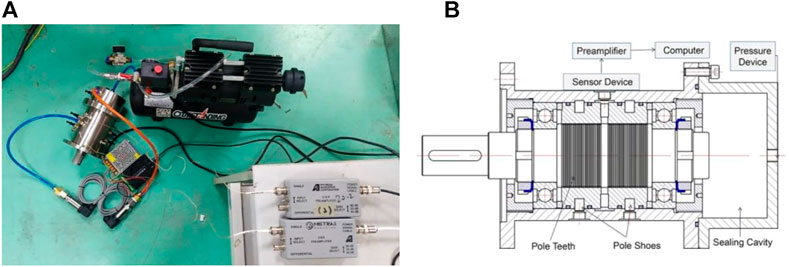

In this study, the signal acquisition experiment was carried out in the State Key Laboratory of Tribology, Tsinghua University. Taking the magnetic fluid seal as the research object, acoustic emission nondestructive testing technology was used to collect signals during the failure process of the magnetic fluid seal under static conditions. Magnetic fluid seal mainly uses the response characteristics of the magnetic fluid to the magnetic field. Under the action of the magnetic field, the magnetic fluid filled the magnetic loop, forming several liquid ring seals. These magnetic fluid ring seals will remain well sealed under the action of the magnetic field. However, when the external instability worsens, the liquid film of some annular sealing rings will appear multiple times of rupture and self-recovery, until each magnetic fluid annular sealing ring flows at the same time, and the sealing ring generates an air gap resulting in seal failure. Based on the failure principle of the magnetic liquid seal, combined with the application of acoustic emission in liquid film seal monitoring and two-phase flow pattern identification (Zhang Y. et al., 2020), this paper adopts acoustic emission nondestructive testing technology to monitor magnetic liquid seal status. Figure 3 is the schematic diagram of the magnetic fluid seal signal acquisition experiment.

FIGURE 3. Schematic diagram of magnetic fluid seal signal acquisition experiment. (A) Device of magnetic fluid seal signal acquisition experiment, (B) Principle of magnetic fluid seal signal acquisition experiment.

In this experiment, the magnetic fluid seal selected is a two-stage pole shoe seal structure, each stage of the pole shoe is distributed under 30 pole teeth, the distance between the pole teeth is 0.1mm, and the distance between the magnetic liquid film and the shell is about 25 mm. The acoustic signal acquisition equipment is THE PICO acoustic emission sensor of PAC. Two acoustic emission sensors are respectively glued to the ends of the two pole boots of the seal, and the coupling agent is applied on the contact surface to avoid acoustic signal loss between the sensor plane and the rotating shaft surface. The acoustic emission sensor transmits the collected acoustic signal through the preamplifier to the AE-WIN software provided by PAC. The software records a short acoustic emission wave with a specified sampling rate and number of sampling points at specific time intervals, and the data contained in each short acoustic wave are saved as a sample. In this experiment, the short-time wave recording period is T_w = 1.3 m s, the sampling rate is F_S = 2MHz, and the sampling number of each sample is N = 1,024. A total of 401,185 acoustic signal samples were collected in the whole seal failure experiment. The pressure signal was used as a reference for analysis, and 500 acoustic signal samples of no leakage, micro leakage, and complete leakage in the magnetic fluid seal state were selected.

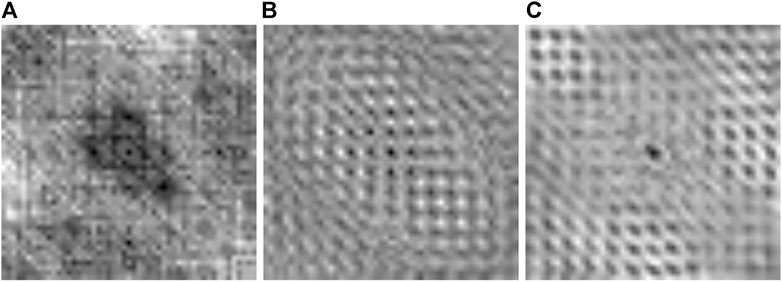

The collected one-dimensional acoustic signal samples are processed by high-order cumulant image processing on Matlab, and the third-order cumulants of the three kinds of acoustic signal samples are calculated respectively. The maximum delay is 25 (

FIGURE 4. High-order cumulant grayscale images in different magnetic fluid seal states. (A) No Leakage, (B) Micro Leakage, (C) Complete Leakage.

In this section, the model was built based on python and the deep learning framework Tensorflow2.6.0, and the software environment was Pycharm. To verify the superiority of the VGG16 convolutional neural network in the recognition of magnetic fluid seal, other convolutional network models, including NIN, GooLeNet, and ResNet50, are also used for comparative experiments.

The experimental samples were high-order cumulant grayscale images, including 500 samples in each of the three sealed states: no leakage (NL), micro leakage (ML), and complete leakage (CL). The three types of samples were randomly divided into training and testing in a ratio of 4:1, i.e., 400 training samples and 100 testing samples were included respectively. Among them, the validation set is divided into the training set of each category according to the ratio of 1: 9, which is used to evaluate the accuracy of the current model after the completion of each epoch, while the testing set is used for the final model evaluation.

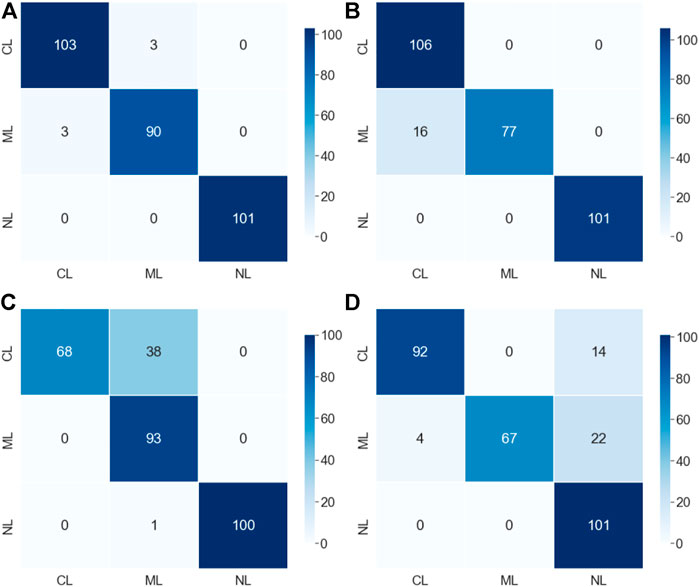

After the samples were divided, they were input into four convolutional neural network models (VGG16, NIN, GooLeNet, and ResNet50) for training and testing. The gray image is processed by multi-channel to adapt to the original image input format of the model. The cross-entropy loss function was adopted in the training process, the optimization algorithm was Adam (Adaptive Moment), the learning rate was set as 0.0001, and the confusion matrix was introduced to visualize the testing results. Figure 5 is the comparison diagram of the confusion matrix of the testing recognition results of different CNN models.

FIGURE 5. Confusion matrix charts of the seal state identification results obtained by different CNN models. (A) VGG16, (B) NIN, (C) GooLeNet, (D) ResNet50.

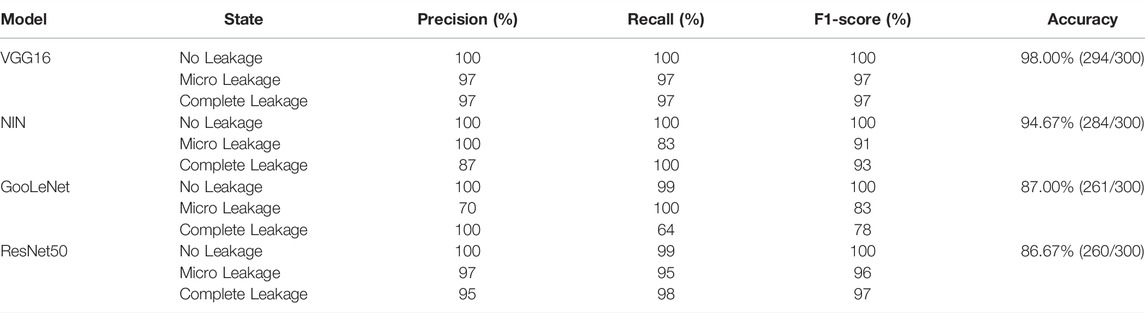

In the confusion matrix, the row corresponds to the prediction class, the column corresponds to the real class, the diagonal unit corresponds to correct classification, and the non-diagonal unit corresponds to wrong classification. The number is displayed in each cell. It can be seen from the confusion matrix in Figure 5 that the four convolutional neural network models, VGG16, NIN, GooLeNet, and ResNet50, all have good recognition effects on the grayscale image samples in this experiment. To verify the superiority of the VGG16 model in the recognition of magnetic fluid seal status, evaluation indexes such as

Where,

Where,

TABLE 1. Comparison table of the comprehensive evaluation of experimental results of different CNN models.

It can be seen from the experimental results that the VGG16 model has a recognition rate of 98.67%, which is significantly higher than the NIN, GooLeNet, and ResNet50 convolutional network models. In addition, the comprehensive evaluation index of the VGG16 model for all kinds of samples is above 97%, indicating that the model is stable for the identification of samples with different magnetic fluid seal states.

In this paper, a method based on a high-order cumulant image and VGG16 convolution neural network is proposed to identify the magnetic fluid seal state. The main innovations of this study are as follows:

1) The signal acquisition experiment of magnetic fluid seal status adopts the acoustic emission technology, which minimizes the damage to the seals to the greatest extent and realizes the nondestructive testing of the magnetic fluid seal components.

2) High-order cumulant image processing is carried out on the acoustic signals collected in the experiment. One-dimensional acoustic signals are transformed into two-dimensional high-order cumulant images, which retain the original signal characteristics to the maximum extent and suppress Gaussian-colored noise.

3) The comparison experiment proves that the VGG16 model can effectively recognize the high-order cumulant image of the magnetic fluid seal state, providing a new method for the recognition of the magnetic fluid seal state.

In the next step, based on the characteristics of magnetic fluid seal status, the VGG16 convolutional neural network model will be improved to further enhance the recognition accuracy of seal status and the generalization of the model. In addition, the universality of the identification method of magnetic fluid seal status in this study can be explored and improved through repeated experiments on seals with different structures and working conditions.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

AD contributed to paper writing. AD and YX contributed to the entire revision process. DL and JX performed the experiment.

The study was supported by the National Natural Science Foundation of China (grant number 51735006), the National Natural Science Foundation of China (grant number U1837206), the National Natural Science Foundation of China (grant number 51927810), and the Beijing Municipal Natural Science Foundation (grant number 3182013).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alzubaidi, L., Zhang, J., Humaidi, A. J., Al-Dujaili, A., Duan, Y., Al-Shamma, O., et al. (2021). Review of Deep Learning: Concepts, CNN Architectures, Challenges, Applications, Future Directions. J. Big Data 8 (1), 53. doi:10.1186/s40537-021-00444-8

Chen, Y., Li, D., Zhang, Y., Li, Z., and Zhou, H. (2020). The Influence of the Temperature Rise on the Sealing Performance of the Rotating Magnetic Fluid Seal. IEEE Trans. Magn. 56 (11), 1–10. doi:10.1109/TMAG.2020.3023018

Chen, Z., Li, C., and Sanchez, R. V. (2015). Gearbox Fault Identification and Classification with Convolutional Neural Networks. Shock Vib. 2015, 1–10. doi:10.1155/2015/390134

Delgado-Arredondo, P. A., Morinigo-Sotelo, D., Osornio-Rios, R. A., Avina-Cervantes, J. G., Rostro-Gonzalez, H., Romero-Troncoso, R. d. J., et al. (2017). Methodology for Fault Detection in Induction Motors Via Sound and Vibration Signals. Mech. Syst. Signal Process. 83, 568–589. doi:10.1016/j.ymssp.2016.06.032

Gao, W. (2014). Research on the seal design and properties of magnetic fluid in the space environment. [master’s thesis]. [Beijing: Beijing Jiaotong University.

Glowacz, A. (2019). Acoustic Fault Analysis of Three Commutator Motors. Mech. Syst. Signal Process. 133, 106226. doi:10.1016/j.ymssp.2019.07.007

Han, T., Tian, Z., Yin, Z., and Tan, A. C. C. (2020). Bearing Fault Identification Based on Convolutional Neural Network by Different Input Modes. J. Braz. Soc. Mech. Sci. Eng. 42 (9), 474. doi:10.1007/s40430-020-02561-6

Hasegawa, N., Yoshioka, H., and Shinno, H. (2016). Noncontact Gravity Compensator with Magnetic Fluid Seals. J. Adv. Mech. Des. Syst. Manuf. 10 (5), JAMDSM0078. doi:10.1299/jamdsm.2016jamdsm0078

Liu, B., Zhang, X., Gao, Z., and Chen, L. (2018). “Weld Defect Images Classification With VGG16-Based Neural Network,” in Digital TV and wireless multimedia communication. Editors G. Zhai, J. Zhou, and X. Yang (Springer Singapore), 215–223.

Mitamura, Y., and Durst, C. A. (2017). Miniature Magnetic Fluid Seal Working In Liquid Environments. J. Magn. Magn. Mater. 431, 285–288. doi:10.1016/j.jmmm.2016.09.032

Parmar, S., Ramani, V., Upadhyay, R. V., and Parekh, K. (2020). Two Stage Magnetic Fluid Vacuum Seal for Variable Radial Clearance. Vacuum 172, 109087. doi:10.1016/j.vacuum.2019.109087

Qassim, H., Verma, A., and Feinzimer, D. (2018). “Compressed Residual-VGG16 CNN Model for Big Data Places Image Recognition,” in The Proceedings of 2018 IEEE 8th Annual Computing and Communication Workshop and Conference (CCWC) (Piscataway: IEEE), 169–175.

Shao, R., Huang, X., Liu, H., and Xu, Y. (2008). Fault Detection and Diagnosis of Gear System Based on Higher Order Cumulants. J. Mech. Eng. 6, 161. doi:10.3901/jme.2008.06.161

Shi, W., Fan, X., and Zhang, C. (2018). Armored Vehicle Classification Based on Spectral Dynamic Feature and Cuckoo Search-Support Vector Machine. J. Comput. Appl. 38 (S1), 44–47.

Simonyan, K., and Zisserman, A. (2008). Very Deep Convolutional Networks for Large-Scale Image Recognition [Preprint]. Available at: https://arxiv.org/abs/1409.1556 (Accessed March 15, 2022).

Theckedath, D., and Sedamkar, R. R. (2020). Detecting Affect States Using VGG16, ResNet50 and SE-ResNet50 Networks. SN Comput. Sci. 1 (2), 79. doi:10.1007/s42979-020-0114-9

Wang, Y., Fan, J., and Yao, Y. (2014). Online Monitoring of Multivariate Processes Using Higher-Order Cumulants Analysis. Ind. Eng. Chem. Res. 53 (11), 4328–4338. doi:10.1021/ie401834e

Wang, Z. (2018). The study of sealing liquid with magnetic fluid. [dissertation]. [Beijing]: Beijing Jiaotong University.

Zhang, D., Stewart, E., Entezami, M., Roberts, C., and Yu, D. (2020). Intelligent Acoustic-Based Fault Diagnosis of Roller Bearings Using A Deep Graph Convolutional Network. Measurement 156, 107585. doi:10.1016/j.measurement.2020.107585

Keywords: magnetic fluid seal, high-order cumulant image, state recognition, convolution neural network (CNN), VGG16

Citation: Dai A, Xiao Y, Li D and Xue J (2022) Status Recognition of Magnetic Fluid Seal Based on High-Order Cumulant Image and VGG16. Front. Mater. 9:929795. doi: 10.3389/fmats.2022.929795

Received: 27 April 2022; Accepted: 06 June 2022;

Published: 19 August 2022.

Edited by:

Miao Yu, Chongqing University, ChinaReviewed by:

U. Ubaidillah, Sebelas Maret University, IndonesiaCopyright © 2022 Dai, Xiao, Li and Xue. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yancai Xiao, eWN4aWFvQGJqdHUuZWR1LmNu

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.