95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

EDITORIAL article

Front. Mater. , 24 March 2022

Sec. Structural Materials

Volume 9 - 2022 | https://doi.org/10.3389/fmats.2022.874556

This article is part of the Research Topic Fundamentals and Challenges of Advanced Amorphous and High-entropy Alloys View all 5 articles

Editorial on the Research Topic

Fundamentals and Challenges of Advanced Amorphous and High-Entropy Alloys

In recent years, high-entropy alloys and amorphous alloys have attracted much attention due to their respective structural features and performance advantages. In the development history of amorphous alloys, the concept of “entropy” has been widely studied as one of the important factors affecting the glass-forming ability. To develop bulk amorphous alloys with high glass-forming ability, Greer (1993) and Inoue (2000) proposed the “Confusion principle” and “Three empirical principles,” respectively. Therefore, the multi-component mixing mode is usually adopted to promote the formation of the amorphous phase. On the other hand, to break through the single principal component design concept of traditional metal alloys, the multiple-principal component concept was also introduced into the composition design of metal alloys and then the concept of the high-entropy alloys was proposed (Cantor, et al., 2004; Yeh, et al., 2004). Soon afterward, people realized that the design concept of high-entropy alloy also provides a broad composition design space for finding new bulk amorphous alloys.

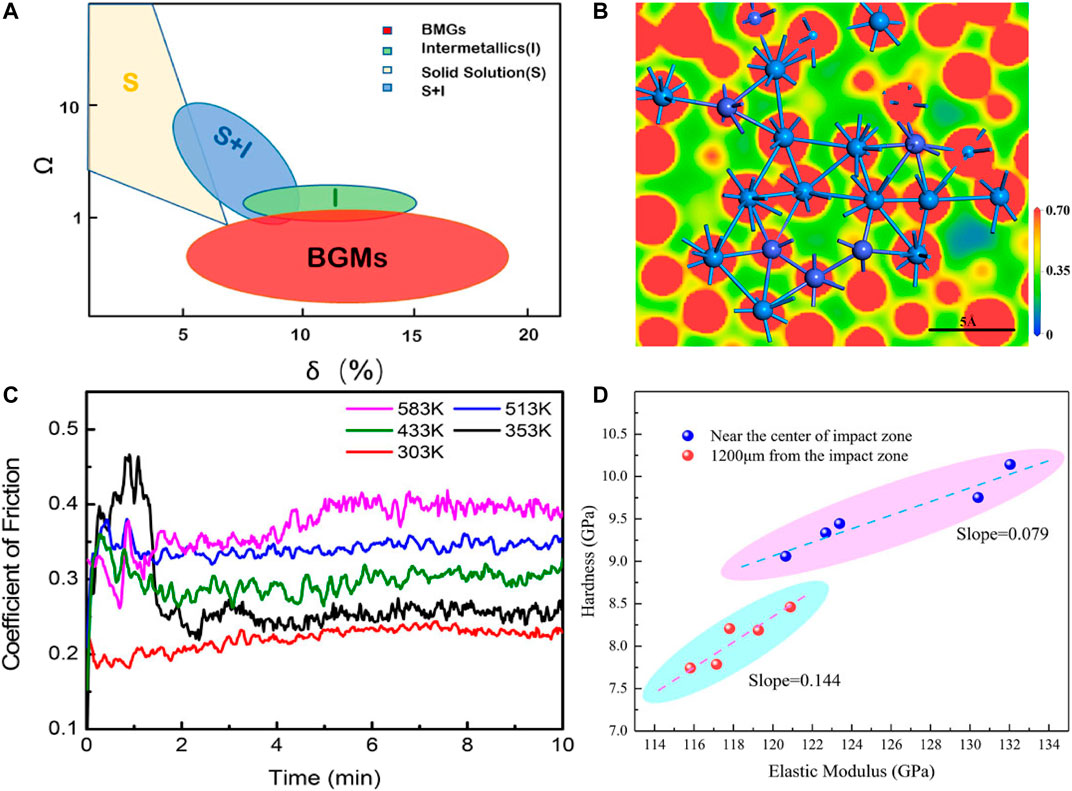

The goal of the present research topic is to collect articles mainly concerning the frontiers of research in amorphous and high-entropy alloys. In this topic, four papers were finally published, which were about the local structure, 3D balanced growth theory, and mechanical properties of bulk amorphous alloys. Zhang et al. summarized the development of amorphous alloys, high-entropy alloys, and high-entropy amorphous alloys (Figure 1A) and addressed that the production and development of bulk amorphous alloys have a bright future. Sun et al. investigated the local structures of glass-forming melts and found that two sub-peaks in the first peaks of the total pair distribution function can be attributed to two kinds of U-centered clusters. According to simulation results, not only topological but also chemical structural heterogeneities also appear in amorphous alloys (Figure 1B). Furthermore, Huang et al. and Zhang et al. investigated the mechanical properties of multi-principal amorphous alloys (Figures 1C,D). These observations may shed more insights into the deformation mechanism of amorphous alloys and promote their future industrial applications.

FIGURE 1. (A) Relationship between the parameters Ω and δ of multicomponent alloys and the amorphous phase region, (B) the slice map of electron density of U-Co melts, (C) the coefficient of friction of the Ti-based BMG sample tested at different temperatures with an applied load of 3.5 N, and (D) the hardness as a function of the elastic modulus of samples after laser shock peanning.

KS: Investigation, Formal analysis, Writing-original draft, Writing-review and editing; YH: Formal analysis, Writing-review and editing; RL: Formal analysis, Writing-review and editing; JQ: Formal analysis, Writing-review and editing; ZW: Formal analysis, Writing-review and editing; KP: Formal analysis, Writing-review and editing; DS: Formal analysis, Writing-review and editing.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The author is grateful to Dr. Yu Wang for technical assistance.

Cantor, B., Chang, I. T. H., Knight, P., and Vincent, A. J. B. (2004). Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 375-377, 213–218. doi:10.1016/j.msea.2003.10.257

Inoue, A. (2000). Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys. Acta Materialia 48, 279–306. doi:10.1016/S1359-6454(99)00300-6

Keywords: amorphous alloys, high-entropy alloys, liquid structure, mechanical properties, deformation mechanism

Citation: Song K, Huang Y, Li R, Qiao J, Wang Z, Prashanth KG and Sopu D (2022) Editorial: Fundamentals and Challenges of Advanced Amorphous and High-Entropy Alloys. Front. Mater. 9:874556. doi: 10.3389/fmats.2022.874556

Received: 12 February 2022; Accepted: 24 February 2022;

Published: 24 March 2022.

Edited and reviewed by:

John L. Provis, The University of Sheffield, United KingdomCopyright © 2022 Song, Huang, Li, Qiao, Wang, Prashanth and Sopu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Kaikai Song, c29uZ2thaWthaTgyOTdAZ21haWwuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.