95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

REVIEW article

Front. Mater. , 24 February 2022

Sec. Smart Materials

Volume 9 - 2022 | https://doi.org/10.3389/fmats.2022.812984

This article is part of the Research Topic Horizons in Materials View all 10 articles

Ni-Mn-In-based magnetic shape memory alloys have promising applications in numerous state-of-the-art technologies, such as solid-state refrigeration and smart sensing, resulting from the magnetic field-induced inverse martensitic transformation. This paper aims at presenting a comprehensive review of the recent research progress of Ni-Mn-In-based alloys. First, the crystallographic characterization of these compounds that strongly affects functional behaviors, including the crystal structure of modulated martensite, the self-organization of martensite variants and the strain path during martensitic transformation, are reviewed. Second, the current research progress in functional behaviors, including magnetic shape memory, magnetocaloric and elastocaloric effects, are summarized. Finally, the main bottlenecks hindering the technical development and some possible solutions to overcome these difficulties are discussed. This review is expected to provide some useful insights for the design of novel advanced magnetic shape memory alloys.

In 1996, a large magnetic-field-induced strain, i.e., 0.2% under a magnetic field of 0.8 T realized by the rearrangement of martensite variants driven by the magnetocrystalline anisotropy energy, was first reported in the stoichiometric Heusler-type Ni2MnGa alloys by K. Ullakko and collaborators (Ullakko et al., 1996). Compared with the magnetostrictive materials, such as Terfenol-D, and conventional shape memory alloys, such as Ni-Ti, the magnetic-field-induced strain in Ni2MnGa has both fast responsive frequency and large output strain, and thus is considered to have huge potential in the fields of smart actuators and sensors. From then on, the Heusler-type NiMnGa alloy has aroused widespread attention (Zheludev et al., 1996; Mañosa et al., 1997; Planes et al., 1997; Ullakko et al., 1997; Brown et al., 1999). About 10 years later, Y. Sutou and R. Kainuma et al. fabricated a series of nonstoichiometric Ni(Co)MnZ (Z = In, Sn and Sb) Heusler-type alloys by the replacement of the p-block type Ga by Z (Z = In, Sn or Sb) (Sutou et al., 2004a). Although Ga (4s2p1) and In (5s2p1) belong to the same main-group elements (IIIA) and their positions in the elemental periodic table are adjacent, the magnetic properties and the resultant functional behaviors of NiMnGa and NiMnIn are significantly different.

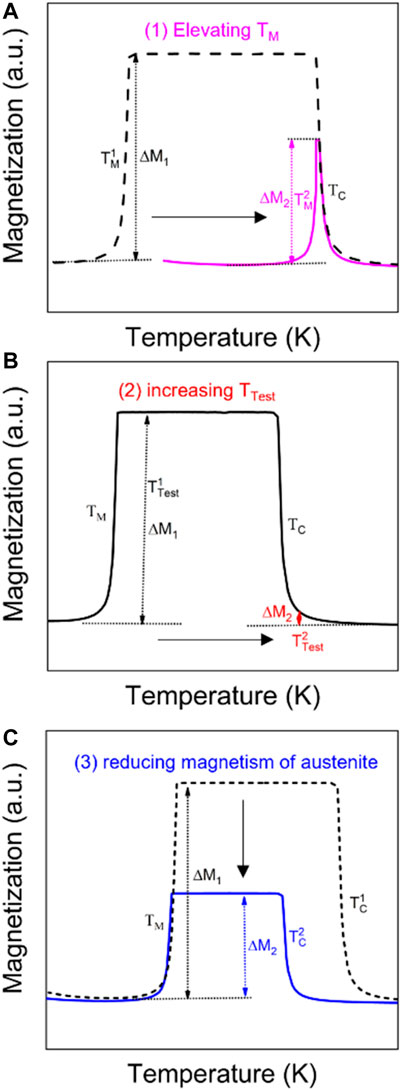

Specifically, the magnetization of martensite and austenite are similar in NiMnGa, while the magnetization of martensite in the NiMnIn is much weaker than that of austenite, as shown in Figure 1. In other words, for the NiMnIn-based alloys, there is a significant change in magnetism during the martensitic transformation, and thus this transition is also termed the magnetostructural transition. As a result, the Zeeman energy (

If a pre-strain is applied to the martensite before the application of a magnetic field, during the magnetic-field-induced inverse martensite transformation, the sample tends to recover its original shape, which is termed as the metamagnetic shape-memory effect (Kainuma et al., 2006). Different from NiMnGa, in which the output stress (a few MPa) is limited by the magnetocrystalline anisotropy energy, the output stress of Ni(Co)MnIn can reach a large value (∼100 MPa) since the Zeeman energy continues to increase with the elevated magnetic field (Karaca et al., 2006; Karaca et al., 2009). In addition, since the total entropy and the electric resistance of austenite and martensite have great differences, when an external magnetic field is applied, a huge change of total entropy (termed as the magnetocaloric effect) and electric resistance (termed as the magnetoresistance effect) may occur during the magnetic-field-induced inverse martensite transformation. Thus, the Ni(Co)MnIn alloys possess excellent magnetoresponsive performances (Han et al., 2006; Han et al., 2008; Kustov et al., 2009; Liu et al., 2012; Kihara et al., 2014), including magnetocaloric, magnetoresistance, and exchange bias effects. Besides, like the conventional shape memory alloy in which the martensitic transformation can be driven by thermal and mechanical fields, the Ni(Co)MnIn alloys also exhibit the thermal-induced shape memory, superelasticity, and elastocaloric effects (Mañosa et al., 2010; Lu et al., 2014; Moya et al., 2014; Liu et al., 2017; Manosa and Planes, 2017; Kabirifar et al., 2019).

During the past 15 years, scientists from all over the world have conducted continuous and in-depth research on NiMnIn-based alloys (Kainuma et al., 2008; Hu et al., 2013; Bachaga et al., 2019). Numerous systematic and in-depth research results covering crystal structure, morphological and crystallographic features of microstructure, martensitic transformation, multifunctional behaviors, etc., have been reported in the literature. Therefore, a systematical overview of the current findings is of great significance to the development of this compound. To date, the metamagnetic shape memory, magnetocaloric, and elastocaloric effects of NiMnIn alloy have been briefly summarized and compared with other competitors in different review papers, such as the review paper about magnetic shape memory alloy by Kainuma et al. (2008), the paper focused on caloric materials by Moya et al. (2014), the review about mechanocaloric effect by Manosa and Planes (2017) and the paper focused on magnetic elastocaloric materials by Liu et al. (2017), and the review about magnetic refrigeration materials by Gottschall et al. (2019). Nevertheless, to the best of the authors’ knowledge, there is still a lack of review articles focusing on the NiMnIn-based alloy in the literature.

This paper aims at presenting a comprehensive review of the research progress of Ni-Mn-In-based alloys. First, the crystallographic characterizations, including the crystal structure of austenite and modulated martensite (Section 2), the self-organization microstructure of modulated martensite (Section 3), and the transformation strain path of martensitic transformation (Section 4), are reviewed. Then, the current research progress in functional behaviors, including magnetic shape memory (Section 5), magnetocaloric (Section 6), and mechanocaloric (Section 7) effects, are summarized. For each topic, the main bottlenecks hindering the technical development and some possible solutions for overcoming these difficulties are discussed.

The crystal structure is one of the most fundamental information of crystalline materials. In general, the determination of crystal structure is the first step to understanding the physical or mechanical properties of materials (Ravel et al., 2002b). Since the magnetostructural transition was discovered in the NiMnIn-based alloys, many state-of-the-art modern characterization techniques, such as X-ray diffraction (XRD) (Liu et al., 2008; Feng et al., 2009; Zhang et al., 2014; Crouigneau et al., 2015; Paramanik and Das, 2016), synchrotron high-energy XRD (Karaca et al., 2009; Huang et al., 2016), neutron diffraction (Yan et al., 2015), high-resolution transmission electron microscope (HRTEM) (Yan et al., 2016c), selected area electron diffraction (SAED) (Ito et al., 2007; Ito et al., 2008; Liu et al., 2009a), high angle annular dark-field (HAADF) imaging of spherical aberration-corrected high-resolution scanning transmission electron microscope (Yang et al., 2020), have been used to characterize crystal structure of the compounds.

NiMnIn-based alloys belong to the Heusler-type alloys. The austenite phase of this compound has a typical structure of 2:1:1 full Heusler alloy, that is, a highly ordered cubic Cu2MnAl-type L21 structure (space group:

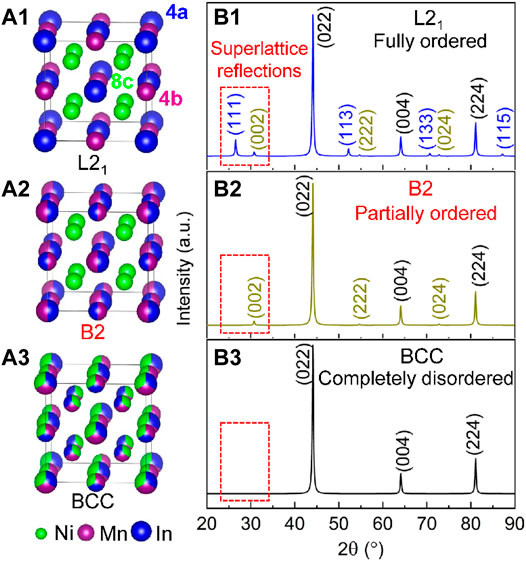

FIGURE 2. Illustration of crystal structural models of L21 (A1), B2 (A2), and BCC (A3) of NiMnIn alloy and their corresponding Cu Kα-radiation X-ray diffraction patterns (B1–B3). To keep consistency with the L21 structure (A1), for the B2 (A2) and the BCC (A3) structures, the superstructural models containing 8 unit cells are illustrated. The main reflections in (B1–B3) are labeled with the black indices, while the superlattice reflections generated due to the B2 and the L21 types of stacking order of Ni, Mn, and In atoms are highlighted in olive and blue, respectively.

As is known, the ordering degree of crystal structure significantly affects both mechanical and functional properties in the Heusler-type alloy (Ravel et al., 2002a; Raphael et al., 2002; Harris and Chen, 2015). For the NiMn-based alloys, the order degree of austenite is sensitive to the fabrication process and chemical composition (Krenke et al., 2006). When the alloy is quenched from a high temperature with a high cooling rate (such as melt-spinning technique), the austenite of NiMnIn alloy could exhibit the B2 type structure, as illustrated in Figure 2A2. The difference between the L21 and the B2 structures is that In and Mn atoms are orderly located at 4a and 4b sites in the former, whereas these two elements occupy the 4a and 4b sites randomly in the latter. Owing to the reduction of ordering degree, as shown in Figure 2B2, the number of satellite reflections decreases from 7 (the L21 structure) to 3 (the B2 structure), i.e., (002), (222), and (024). When the ordering degree further decreases, the B2 structure may turn to be the body-centered cubic (BCC) type. In this case, as shown in Figure 2A3, all Ni, Mn, and In atoms randomly occupy the 4a, 4b, and 8c sites. For the XRD spectrum, the fully random occupations of Ni, Mn, and In atoms lead to the disappearance of all satellite diffraction peaks (Figure 2B3). Generally, the ordering degree of the austenite of the NiMnIn-based alloys can be evaluated by examining the number of satellite reflections at 2θ ranging from 25° to 35° (Cu Kα-radiation), as indicated in the red dashed boxes in Figures 2A1–A3. Two (Figure 2A1), one (Figure 2A2), or zero (Figure 2A3) reflections suggest the austenite has the L21, the B2, or the BCC structure.

First-principles calculations showed that the exchange energy for In (4a) and Mn (4b) is around 70 meV/atom (Liu et al., 2020), which is smaller than that for Ni (8c) and Mn (4b) (around 85 meV/atom) (Liang et al., 2021). This result implies that the possibility of the occurrence of 4a-4b disorder should be larger than that of 4a (4b)-8c disorder, which explains the experimental results that the B2 structure is observed easier than the BCC structure. Moreover, from Figures 2A1–A3, it is seen that even though the L21 structure is usually classified to be the face-centered cubic (FCC) structure from the point of view of crystallographic symmetry (Yan et al., 2016a; Lin et al., 2016), the atom stacking manner of the NiMnIn-based alloys mostly follows the characteristics of the BCC structure (with a different degree of ordering) rather than FCC. Thus, the typical structure characteristic parameters of the NiMnIn-based alloy, such as close-packed crystal plane, close-packed crystal direction, stacking density, coordination number, are the same as those of the BCC structure.

Unlike the NiMnGa alloys, where the stoichiometric case, i.e., Ni2MnGa, undergoes a displacive structural transition at around 210 K (Wirth et al., 1997; Brown et al., 2002), the stoichiometric Ni2MnIn is thermodynamically stable even when the temperature drops toward 0 K (Kurfiß et al., 2005; Krenke et al., 2006). Thus, the investigations on the NiMnIn-based alloys are mostly focused on the nonstoichiometric compositions, especially the Mn-enriched Ni2Mn(In, Mn) systems. Rietveld refinement of the high-resolution neutron diffraction data (Yan et al., 2015) showed that the extra-Mn prefers to directly substitute In at the 4a site. For the NiMnIn-based alloys, the magnetoresponsive behaviors are originated from the magnetic-field induced inverse martensitic transformation owing to the significant change of magnetization between austenite (ferromagnetism) and martensite (antiferromagnetism). Numerous studies suggested that the antiferromagnetism comes from the first-neighbored Mn (4a)-Mn(4b) coupling (Şaşıoğlu et al., 2004; Liu et al., 2006), which can be easily realized in the Mn-enriched Ni2Mn(In, Mn) system since the extra-Mn tends to occupy the 4a sites while the normal Mn is located at the 4b sites (Figure 2A2). This could be the reason why the fruitful magnetoresponsive behaviors of the NiMnIn-based alloys mostly exist in the Mn-enriched systems. By using the first-principles calculations, it is revealed that at the 4b site, the extra-Mn atoms prefer to be dispersed from one another (Yan et al., 2015).

For the martensite of the NiMnIn-based alloys, numerous studies showed that there exist two kinds of crystal structures, i.e., the non-modulated (NM) martensite and modulated martensite (Krenke et al., 2006). Note that even though the partial substitution of Co for Ni can significantly enhance the ferromagnetism of the NiMn-based alloys and thus improve their magnetoresponsive performances, this substitution will not change the type of crystal structure. Moreover, with the addition of Co, it is difficult to obtain a pure single-phase martensite powder sample, even if the testing temperature is far below the finishing temperature of martensitic transformation Mf measured by the DSC technique (Abematsu et al., 2014; Yan et al., 2015; Yan et al., 2016b). The reason could be attributed to the large specific surface area of the powder sample, which tends to stabilize the austenite and suppress the occurrence of martensitic transformation (Yan et al., 2021a). Thus, it is more convenient to determine the crystal structure of martensite with Co-free NiMnIn samples. X-ray diffraction studies showed that for the ternary Mn-enriched Ni50Mn50–xInx (0 ≤ x ≤ 25) alloys, the NM martensite structure exists in the alloys with a relatively low In content (x ≤ 10) (Yang et al., 2016). When 10 < x ≤ 16, the martensite has a modulated structure. When the content of In continues to increase, the martensite transformation is arrested (Sutou et al., 2004b).

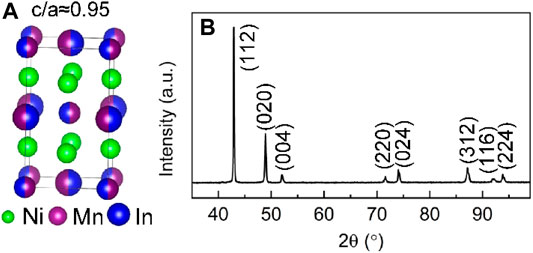

For the Ni50Mn50–xInx alloys with a relatively low In content, it can be considered as In doped NiMn alloys. Actually, the crystal structure of the martensite of the Ni50Mn50–xInx (x ≤ 10) alloys is indeed the same as that of the stochiometric NiMn (Yang et al., 2016), i.e., the tetragonally distorted B2 structure. Nevertheless, to keep consistency with the L21 structure of austenite, as an equivalent structural model of the distorted B2 structure, the double L10 tetragonal cell proposed by J. Pons and coworkers (Pons et al., 2000) was extensively used in the literature to describe the non-modulated structure of martensite, as shown in Figure 3A. The space group of the double L10 tetragonal structure is I4/mmm (group number: 139). The atomic fractional coordinates of the different constituent elements in the NiMnIn alloys are as follows: Ni: 4d (0, 0.5, 0.25); Mn and In: 2a (0, 0, 0) and 2b (0, 0, 0.5). The typical X-ray diffraction pattern of the non-modulated martensite is displayed in Figure 3B. Note that in this figure, the reflections are indexed based on the double L10 structural model rather than the distorted B2 model.

FIGURE 3. Double L10 tetragonal structural model (A) and typical X-ray diffraction pattern (B) of the non-modulated martensite of the NiMnIn-based alloys.

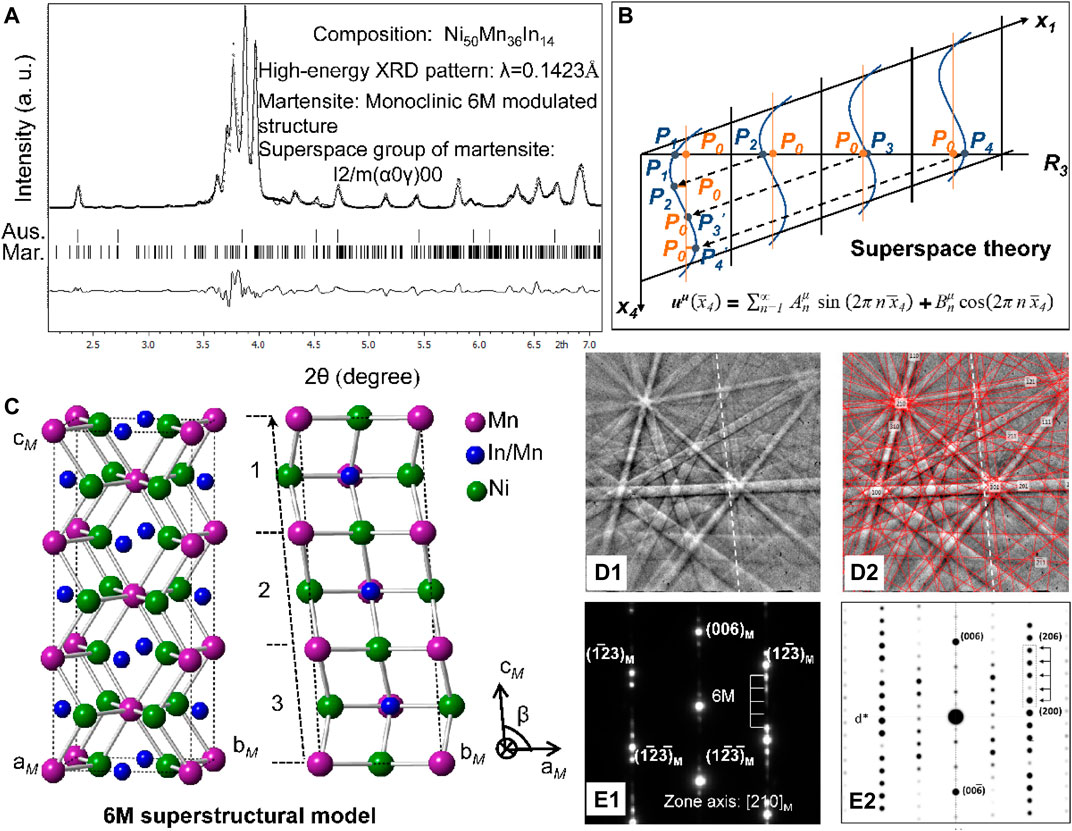

With the increase of In content in the Ni50Mn50–xInx alloys, the crystal structure of martensite no longer follows the structure of NiMn (non-modulated double L10 tetragonal structure) and exhibits a long periodic layered modulated structure (Yang et al., 2016). For the NiMnIn-based alloys, the excellent magnetoresponsive performance mainly exists in the alloy systems with a modulated structure. Therefore, the accurate determination of the crystal structure for the modulated martensite is of significant importance for understanding and optimizing magnetoresponsive behaviors. Measured by neutron diffraction and synchrotron high-energy X-ray diffraction, and analyzed using the (3+1) dimensional superspace theory in combination with the Rietveld full-profile fitting method, the crystal structure of the modulated martensite of the NiMnIn alloys was determined with the Ni50Mn36In14 alloy as a model material (Yan et al., 2015), as shown in Figure 4A. The basic idea of superspace theory is that by increasing the dimension of space, as shown in Figure 4B, the aperiodic structure can be mathematically transformed into a periodic one (Van Smaalen, 1995). Then, a unit cell can be defined in a higher-dimensional space and can thus be determined by fitting the diffraction data.

FIGURE 4. (A) Rietveld full-profile refinement of high-energy synchrotron XRD pattern of the Ni50Mn36In14 alloy by using the (3 + 1)-dimensional theory (Yan et al., 2015). (B) Basic idea of superspace theory, i.e., mathematically transforming the aperiodic structure to a periodic representation by increasing the dimension of space (x4). (C) Established the three-dimensional 6M superstructural model with three consecutive averaging cells along the c axis. Measured (D1,E1) and simulated (D2,E2) SEM/EBSD Kikuchi and TEM selected area electron diffraction patterns (Yan et al., 2015). Reproduced with the permission of Elsevier Publisher.

The determination process in Ref. (Yan et al., 2015) is as follows: 1) Construct the average crystal structure model of modulated martensite (ignoring atomic position modulation). Based on the crystal structure of austenite, combined with the splitting characteristics of neutron diffraction peaks during the martensitic transformation, the space group, the lattice constants, and the atom occupation information of the average crystal structure of the modulated martensite were determined. 2) Estimate the modulation wave vector q representing the modulation periodicity using the peak position of the satellite reflections caused by the periodic modulation of atom position. 3) Refine all structure information, including the coefficients of atom position modulation function, the lattice parameters, etc., with the high energy synchrotron X-ray diffraction pattern by means of the Rietveld method in the frame of the (3+1) dimensional superspace theory. 4) Analyze the rationality of the determined crystal structure information. 5) Build a three-dimensional superstructure model. A three-dimensional periodic superstructure model was established to approximately represent the determined modulated structure since many theoretical and experimental studies require the crystal structure information in the three-dimensional space.

Refinement showed that the modulated martensite has a monoclinic 6M modulated crystal structure and the space group is I2/m(α0γ)00, the lattice parameters of the average 1crystal structure are a = 4.3919 (4) Å, b = 5.6202 (1) Å, c = 4.3315 (7) Å, and β = 93.044 (1)°, and the modulation wave vector q = 0.343 (7) c* (Yan et al., 2015). Since the coefficient of modulation wave vector q [0.343 (7)] is irrational, the structure should be incommensurate. The modulation wave vector can be described as q = 1/3(1+δ)c*, where δ (0.0312) represents the incommensurability. As δ is very small, the determined incommensurable 6M modulated structure can be approximately described using a superstructural model containing three average crystal structure cells along the c axis, as shown in Figure 4C. The space group of the established superstructural model is P2/m, and the lattice constants are a = 4.3919 (4) Å, b = 5.6202 (1) Å, c = 12.9947 (1) Å and β = 93.044 (1)°. For the detailed atomic occupation information, the readers can refer to Ref. (Yan et al., 2015). It is seen from Figure 4C that the shuffling character of the atomic layers is the same as that of the

Recently, by means of synchrotron and neutron diffraction, using the (3+1) dimensional superspace theory, P. Devi et al. also reported that the Ni2Mn1.4In0.6 alloy possesses a 6M incommensurate structure (Devi et al., 2018). It is worth emphasizing that the type of modulated martensite in the NiMn-based alloy is very sensitive to external stress and the sample state. Based on the TEM SAED method, 5M, 7M, and 8M modulated structures (Ito et al., 2007; Liu et al., 2008; Karaca et al., 2009; Erkartal et al., 2012; Huang et al., 2016; Paramanik and Das, 2016) were also observed in the NiMnIn-based alloys. Nevertheless, for the stress-free powder sample investigated by neutron and X-ray diffraction, so far, only the 6M modulated martensite has been evidenced in the Ni(Co)MnIn based alloys.

(1) The formation mechanism of modulated martensite is still unclear. For the Ni2Mn1+xIn1-x alloy, the martensite has a non-modulated double L10 structure when the In content is low, while the structure of martensite transforms into a complex long periodic layered 6M modulated structure when the In content is high. Moreover, the NiMnGa-based alloys have 5M and 7M structures, and NiMnSn and NiMnSb alloys possess 4O structure, but only 6M structure is observed in the NiMnIn-based alloys at the stress-free state. As mentioned above, structural modulation often brings excellent magnetoresponsive properties. However, so far, the formation mechanism of modulated structure is still an open issue.

(2) The relationship between the modulated martensite and the functional properties in the NiMn-based alloy is not clear yet. The excellent magnetoresponsive performances of the NiMn-based alloys often only exist in alloys with a modulated martensite structure. However, the quantitative relationship between the modulated structure and the properties has yet to be established.

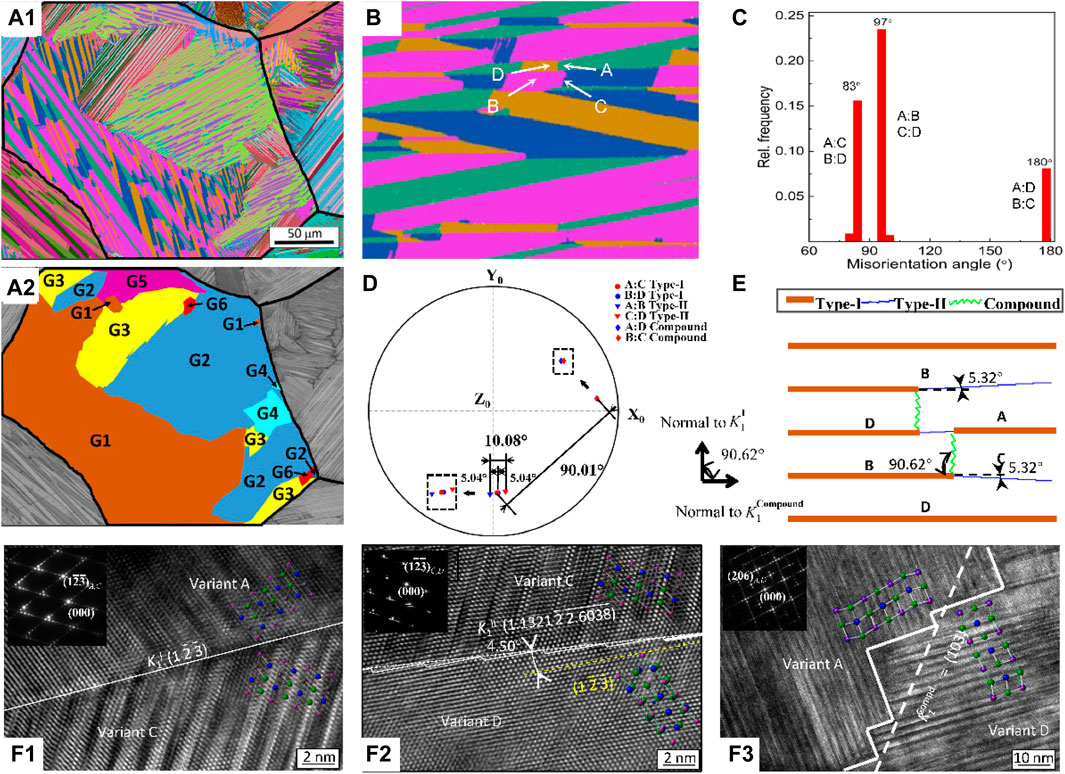

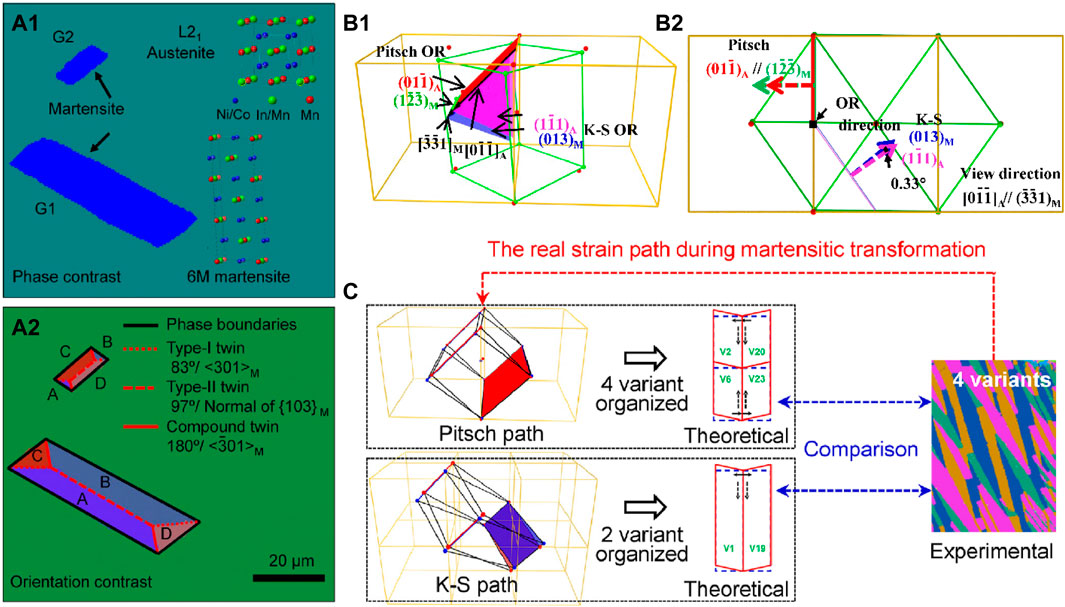

Based on the established superstructural model (Figure 4C), by using the SEM/EBSD technique combined with the orientation analysis method, the morphological and the crystallographic characters of the 6M modulated martensite microstructure of the NiMnIn alloys were characterized in detail (Yan et al., 2015; Yan et al., 2016b; Yan et al., 2016c; Yan et al., 2021b). Experiments showed that the 6M modulated martensite is in a plate shape and self-organized in colonies, as shown in Figure 5A1. Within one initial austenite grain, a maximum of 6 orientation-independent variant colonies (Figure 5A2) and a total of 24 orientation-independent variants can be generated. The formation mechanism of the microstructure will be discussed with the transformation strain path in Section 4. In each martensite colony, as shown in Figure 5B, there are four orientation variants, i.e., A, B, C, and D.

FIGURE 5. Crystallographic orientation (A1) and variant-group distribution (A2) maps of the 6M modulated martensite of the NiMnIn-based alloys at room temperature measured using SEM/EBSD. The bold black line represents the initial austenite grain. (B) Variant organization within the martensite variant group. (C) Minimum misorientation angles of different variant pairs. (D) Stereographic projections of twinning plane K1 of different variant pairs. (E) 2D illustration of variant organization. High-resolution TEM images of the type-I (F1), the type-II (F2), and the compound (F3) twin interfaces (Yan et al., 2016b). Reproduced with the permission of Elsevier Publisher.

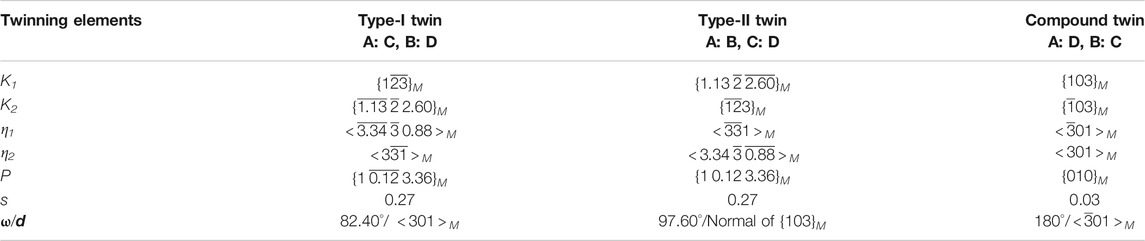

Misorientation examinations showed that the four variants within the martensite colony are twin-related. In total, there exist three types of twins, i.e., type-I (A: C and B: D), type-II (A: B and C: D), and compound (A: D and B: C) twins (Yan et al., 2016b). The twinning elements of K1, K2, η1, η2, s, and P for different types of twins, determined with the method proposed by Zhang et al. (2010), are listed in Table 1. It is seen that the shear magnitudes of the type-I and the type-II twins are the same (0.27), which is around one order of magnitude larger than that of the compound twin (0.03). Misorientation calculations showed that for the 6M NiMnIn modulated martensite, the theoretical angle/axis pair (ω/d) for the type-I, the type-II, and the compound twins are 82.4°/

TABLE 1. Twining elements of the type-I, the type-II, and the compound twins for the 6M modulated martensite of the NiMnIn alloys (Yan et al., 2016a). K1, K2, η1, η2, s, and P represent the twinning plane, the conjugate twinning plane, the twinning direction, the conjugate twinning direction, the shear magnitude and the shear plane, respectively. ω/d indicates the minimum misorientation angle/the corresponding rotation axis, respectively. Reproduced with permission of the International Union of Crystallography.

Twin boundary is a key material parameter that significantly affects both the physical and mechanical properties of materials. For the 6M modulated martensite of the NiMnIn alloys, using the indirect two-trace method (Zhang et al., 2007), the interface indices between different variants within the martensite colony are found to coincide with their twinning plane K1 in the mesoscale (Yan et al., 2016a). Within one martensite colony, as shown in Figure 5D, there is only one kind of type-I (indicated by the solid circle) and compound twin (indicated by the solid diamond) boundaries. In other words, the two boundaries between the type-I twin related variants A: C and B: D (or the compound twin related variants A: D and B: C) are parallel to each other. In addition, the interface between the type-I twin related variants is almost perpendicular to the interface between the compound twin related variants. In contrast, the two boundaries between the type-II twin related variants (indicated by the inverted triangle), i.e., the interfaces between A: B and C: D, are separated. It is seen from Figure 5D that the two kinds of type-II twin interfaces are distributed on the two sides of the type-I twin interfaces with an angle of around 5°. The orientation characters of various interfaces within one martensite colony are illustrated in Figure 5E.

High-resolution TEM characterization showed that at the atomic scale, the type-I twin interface possesses a straight boundary, whereas the type-II twin boundary has a “stepped” interface (Yan, et al., 2016a). This difference leads to much smaller detwinning stress of the type-II twin with respect to that of the type-I twin, although the shear magnitudes of these two twins are exactly the same. For the compound twin, even though its twinning plane is rational, i.e., {103}M, it also has a “stepped” interface at the atomic scale. Compared with the type-II twin, the step of the compound twin is much larger and shows an irregular distribution feature. The irregularly stepped interface structure and the small shear of the compound twin account for its high mobility (Yan et al., 2016a).

The reason for the difference in detwining stress of different twin systems is still unclear. For the modulated martensite, there are huge differences in the detwining stresses for type-I, type-II, and compound twin systems. At present, we can only speculate that this phenomenon is related to the magnitude of the shear and the structure of the interface. However, the underlying physical mechanism still needs to be explored.

The magnetoresponsive behaviors of the NiMnIn-based alloys are closely related to the magnetic field-induced inverse martensitic transformation. It is thus greatly meaningful to clarify the crystallographic characteristics of martensitic transformation, including transformation orientation relationship (OR), transformation strain path, etc., to understand the formation mechanism of microstructure and magnetoresponsive behaviors.

Transformation OR describes the geometrical relation between the crystal lattices of austenite and martensite. Generally, the transformation OR is represented by plane and in-plane direction correspondences, i.e., {hkl}A//{hkl}M and <uvw>A//<uvw>M where the subscript “A” and “M” represent austenite and martensite, respectively. By composition design, a dual-phase Ni45Co5Mn36.8In13.2 alloy at room temperature was fabricated, and the accurate crystallographic orientations of the two coexisting phases were measured by using the SEM/EBSD technique (Yan et al., 2021a), as shown in Figure 6A. With the orientation information of the co-existing austenite and martensite, the reported ORs in the literature, including the Bain (Bain and Dunkirk, 1924), the Nishiyama-Wassermann (N-W) (Nishiyama, 1934), the Kurdjumov-Sachs (K-S) (Kurfib and Schultz, 1930), and the Pitsch (Pitsch, 1962) ORs were examined one by one. Results showed that the deviations of the measured misorientation between austenite and martensite Δgexp from the theoretical ΔgOR of the Bain, the N-W, the K-S, and the Pitsch ORs are 3.73°, 1.27°, 0.70°, and 0.63° (Yan et al., 2021a), respectively.

FIGURE 6. Phase contrast (A1) and crystallographic orientation (A2) maps of the dual-phase Ni45Co5Mn36.8In13.2 alloy measured by using the SEM/EBSD technique at room temperature. (B1) Geometrical relation between the K-S and the Pitsch orientation relationships (ORs). (B2) is the projection of (B1) along the OR direction. (C) Basic idea of determining transformation strain path based on the variant organization of martensite variants. Reproduced with the permission of Elsevier Publisher.

For the Bain and the N-W ORs, the deviation angles are the largest (>1°), and thus these two ORs can be excluded. In contrast, for both the K-S and the Pitsch OR, the deviation angles are both the smallest and are close to the angular resolution of current EBSD technology (±0.5°). Thus, it is difficult to discriminate which is the valid OR or to determine that both are valid. It is worth emphasizing that such a dual OR occasion is not a unique occurrence in the studied Ni45Co5Mn36.8In13.2 alloy nor in the NiMnIn-based alloys. This dual-OR phenomenon widely exists in many other NiMn-based ferromagnetic shape memory alloys with modulated martensite, such as Ni50Mn30Ga20 (Li Z. B. et al., 2011) with 7M modulated martensite, Ni50Mn28Ga22 (Li Z. et al., 2011) with 5M modulated martensite and Ni50Mn38Sb12 (Zhang et al., 2016) alloy with 4O modulated martensite.

In order to reveal the difference between the K-S and the Pitsch OR in the NiMnIn-based alloys, the correspondent crystalline planes and crystalline directions of these two ORs are outlined in the austenite (orange) and the martensite (green) lattices that strictly obey the Pitsch OR, as shown in Figure 6B1. It is seen that the OR directions of the K-S and the Pitsch relations are exactly the same. The difference between these two ORs lies in the OR planes. For the K-S relation, the OR plane pair is

By definition, the transformation OR of martensitic transformation describes the geometric relation between the crystal lattices of austenite and martensite. Nevertheless, considering that the martensitic transformation involves a shear process and the atomic displacement during this process is far less than one atomic spacing, the OR plane {hkl}A and OR direction vector [uvw]A of austenite should not rotate (distortion is allowed) during the lattice distortion of phase transformation. Thus, OR can be used to describe the transformation strain path of martensitic transformation, that is, the OR plane {hkl}A of austenite shears along the OR direction <uvw>A. It is worth emphasizing that the OR plane of austenite {hkl}A is not the so-called habit plane since both rotation and distortion are not allowed for the habit plane, but only rotation is forbidden for the OR plane. During the lattice distortion of martensitic transformation, the OR plane {hkl} and the OR direction <uvw> can be distorted to realize the change of crystal structure.

Normally, the transformation strain path can be easily obtained from the transformation OR. However, for the NiMnIn-based alloys, both the K-S and the Pitsch ORs can be approximately satisfied. Thus, the commonly utilized method to determine the transformation strain path through the relevant orientation relationship is no longer applicable. For the NiMnIn-based alloys, from the viewpoint of transformation OR, the conclusion that can be drawn is that the two transformation strain paths, i.e., the K-S type {1

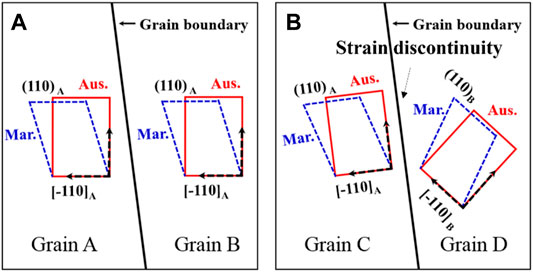

Usually, the resultant behaviors of phase transition are greatly affected by the transformation process. Thus, one can assume that the microstructure characters of martensite produced by different transformation strain paths are likely to be different. Based on this assumption, a strategy of determining the transformation strain path was proposed, i.e., deducing the transformation strain path according to the microstructural features of martensite (Yan et al., 2021b). With this strategy, the transformation strain path of NiMnIn alloy was determined successfully. To satisfy the criterion of the minimum interface and elastic strain energies, combined with the stress and the strain compatibility conditions, theoretically, the K−S path produces two variants as a self-accommodated variant group, whereas the Pitsch path produces four variants as a self-accommodated variant group, as shown in Figure 6C. The details are referred to Ref. (Yan et al., 2021a). For the NiMnIn-based alloy, as shown in Figure 5B and Figure 6A, the self-accommodated variant group is composed of 4 orientation variants. Thus, the Pitsch strain path, {01

Moreover, it is found that the 4 self-accommodated martensite variants within the variant group are transformed on the same transformation plane {01

The underlying physical mechanism why the K-S and the Pitsch transformation orientation relations are almost simultaneously satisfied in the NiMn-based alloys is still unclear. The shuffling path of the different (001)M atomic layers during the martensitic transformation is still unclear. The Pitsch-type transformation strain path can only reveal the shear mode of the average lattice of modulated martensite. However, in addition to the Pitsch-type lattice distortion, the shuffling of the (001)M atomic layer is also needed to form the modulated martensite. The physical mechanism of this process is still unclear.

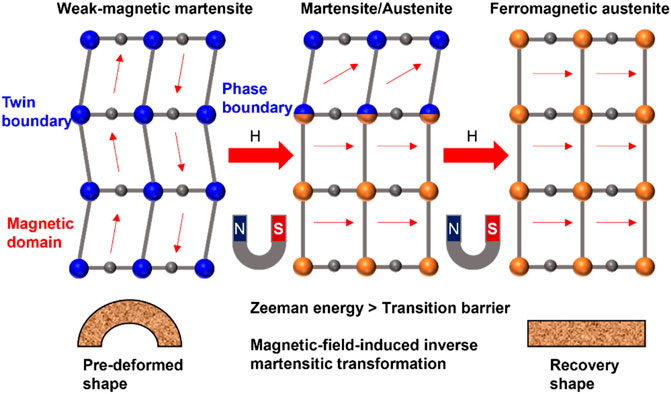

NiMnIn-based alloys can achieve the shape memory effect via the magnetic-field-induced inverse martensitic transformation from the weak-magnetic martensite to the ferromagnetic austenite, which is called the magnetic shape memory effect (MSME). The mechanism of MSME of the NiMnIn-based alloys is illustrated in Figure 7. When the pre-deformed martensite of a NiMnIn alloy is exposed in a magnetic field, at the condition that the driving force for the inverse martensitic transformation (the Zeeman energy difference, μ0HΔM) exceeds the energy barrier of structural transition, the new phase of austenite nucleates and grows, and thus resulting in the shape recovery (Karaca et al., 2007). Compared with the conventional thermally-induced SME that is limited by the low heat conduction rate, the MSME of the NiMnIn-based alloys shows the advantages of fast response, easy control, and high stability. Moreover, different from NiMnGa in which the magnetic output work (magneto-stress) is limited by the magnetocrystalline anisotropy energy (Karaca et al., 2006; Karaca et al., 2007), the magneto-stress of the NiMnIn-based alloys continuously increases with the strength of magnetic field as there is no limit for the Zeeman Energy (Karaca et al., 2009; Turabi et al., 2016).

FIGURE 7. Schematic diagram of magnetic shape memory effect (MSME) from the weak-magnetic martensite to the strong-magnetic austenite.

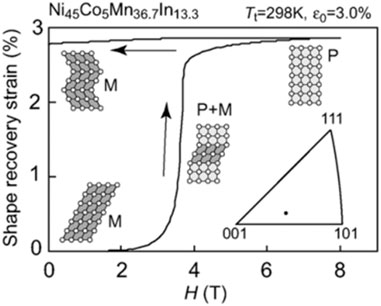

In 2006, for the first time, R. Kainuma et al. reported the MSME in a Co-doped Ni45Co5Mn36.7In13.3 single-crystalline sample (Kainuma et al., 2006). They observed that a pre-strain of 3% can almost be recovered by the magnetic field-induced inverse martensitic transformation in the Ni45Co5Mn36.7In13.3 single-crystalline sample, as shown in Figure 8. Based on the Clausius–Clapeyron relation, the output magneto-stress generated during the transformation was estimated to be about 108 MPa under a magnetic field of 7 T (Kainuma et al., 2006), which is about 50 times larger than that of NiMnGa (2 MPa) (Murray et al., 2000). Later, under a pulsed magnetic field of 70 kOe, a 3% recoverable strain was obtained in the Ni45Co5Mn36.7In13.3 single-crystalline sample at room temperature (Sakon et al., 2007). Since then, the MSME of the NiMnIn-based alloys has attracted more and more attention.

FIGURE 8. Magnetic shape memory effect (MSME) in the single-crystalline Ni45Co5Mn36.7In13.3 alloy measured at room temperature (Kainuma et al., 2008). Reproduced with the permission of Royal Society of Chemistry Publisher.

For the MSME, in view of practical applications, a large magnetic-field-induced strain (MFIS) is desirable (Jiang et al., 2013; Barua et al., 2018). For the NiMnIn-based alloys, owing to the high energy barrier, the magnitude of MFIS is closely associated with the transformed volume under an external magnetic field, which is greatly affected by the sensitivity of transformation temperature to the magnetic field, i.e., ∆T/∆H. Normally, under a given magnetic field, a large ∆T/∆H tends to increase the transformed volume and thus the magnitude of the MFIS. Besides, a large ∆T/∆H can expand the operating temperature window of the MSME. Based on the Clausius–Clapeyron relation (Eq. 1),

where ∆M and ∆S represent the magnetization difference and the entropy change during the martensitic transformation, respectively, it is clear that a large ΔM value is favorable to promote a high magnetic-field sensitivity of transformation temperature (∆T/∆H). So far, for the NiMnIn-based alloys, the most successful strategy of increasing ΔM is the partial substitution of Co for Ni. Thus, the MSME of the Co-doped NiCoMnIn alloys has been intensively studied (Karaca et al., 2009; Monroe et al., 2012; Turabi et al., 2016; Bruno et al., 2017).

Like the conventional shape memory alloy, for the single crystal sample, since the counteraction of transformation strains generated by different austenite grains with distinct orientations is avoided, the transformation strain is much larger than that of the polycrystalline sample. Thus, studies on the MFIS in the NiMnIn-based alloys were first focused on single crystals. Under a magnetic field of 18 T and bias stress of 125 MPa, J.A. Monroe and cooperators observed a fully recoverable transformation strain of 3.1% in the <100> oriented Ni45Co5Mn36.5In13.5 single crystal (Monroe et al., 2012). For this sample, an output work of 1 MJ m−3 T−1 (Karaca et al., 2009) and a magneto-stress of 71 MPa at a magnetic field of 9 T (Turabi et al., 2016) were obtained. Both of them are one order of magnitude higher than those in NiMnGa. The theoretical magneto-stress along [100], [123], [011], and [111] were 26.5, 42.2, 50.4, 143.4 MPa T−1, respectively, which are much larger than the corresponding values in NiMnGa (2–5 MPa T−1). Along the [111] direction, a transformation strain of ∼1.2% was observed. N. M. Bruno et al. found that the magneto-mechanical training can significantly reduce the critical magnetic field required for the inverse martensitic transformation from 8.3 T to 1.3 T in the single-crystalline Ni45Co5Mn36.6In13.4 alloy (Bruno et al., 2017). After the magneto-mechanical training, under a magnetic field of 3 T, an MFIS of 5.6% was obtained.

Apart from single crystals, owing to the simple preparation process and the low cost, the MSME of the NiMnIn-based polycrystalline alloys were also studied (Krenke et al., 2007; Liu et al., 2009a; Sharma et al., 2010a; Li et al., 2010; Acet et al., 2011; Yu et al., 2014; Yu et al., 2016), although the magnitude of the MFIS of polycrystalline sample is generally smaller than those of single crystals. In 2007, by using in-situ X-ray diffraction technology, Y. D. Wang et al. evidenced the occurrence of magnetic-field-induced reversible martensitic transformation in the Ni45Co5Mn36.6In13.4 polycrystalline sample under a uniaxial compressive stress of 50 MPa and a magnetic field of 5 T (Wang et al., 2007). In 2009, J. Liu et al. studied the MFIS of the textured Ni45.2Mn36.7In13Co5.1 polycrystalline sample during two magnetic-field cycles at 310 K (Liu et al., 2009b). They found that magnetic training was able to enhance the magnitude of magnetostrain from 0.2% (the first magnetic cycle) to 0.25% (the second magnetic cycle). After the magnetic training, the critical magnetic field of transformation is reduced from 1.6 T to 1.2 T. In 2010, Z. Li et al. found that the non-prestrained Ni45Co5Mn37In13 polycrystalline alloy possesses a reversible MFIS of 0.4% and exhibits a large two-way MSME without applying a pre-strain (Li et al., 2010). Moreover, the two-way MSME was still reproducible even after three magnetic-field cycles at 320 K.

Apart from the Co-doped NiCoMnIn, the MSME of undoped (Krenke et al., 2007), Cu-doped (Sharma et al., 2010b), Sb-doped (Yu et al., 2014), and Ga-doped (Yu et al., 2016) NiMnIn-based polycrystalline samples were also studied. In 2007, T. Krenke and collaborators obtained an MFIS of 0.12% under a magnetic field of 5 T in the ternary Ni50Mn34In16 polycrystalline sample (Krenke et al., 2007). Later, S. Y. Yu et al. found that the transformation strain increases rapidly with the doping by Sb (Yu et al., 2014). Under a magnetic field of 10 T, an MFIS of 1.7% was obtained in the non-prestrained Ni50Mn36In8Sb6 alloy (Yu et al., 2014). Unfortunately, the critical magnetic field in this alloy is as large as ∼ 6 T, and there is almost no shape recovery after removing the magnetic field. Besides, by using the directional solidification technique, S. Y. Yu et al. obtained an MFIS of −0.28% along (and 0.49% perpendicular to) the solidification direction in the polycrystalline Ni50Mn33In13Ga4 alloy (Yu et al., 2016).

For the NiMnIn-based alloys, both the single-crystal and the polycrystalline samples have excellent MSME, which makes this compound a potential candidate for smart sensors and actuators. However, in view of commercial application, there are still some thorny problems that need to be solved:

High critical magnetic field required to drive reversible transformation. Usually, the critical magnetic field required to drive a completely reversible transformation in the NiMnIn-based alloys is as large as ∼ 3 T (Kainuma et al., 2006; Li et al., 2010; Huang et al., 2021), which greatly limits the application range of this compound. For instance, the critical magnetic fields for the inverse martensitic transformation in the Ni45Co5Mn37In13 alloy at 320 K and 310 K are as large as 5 T and 7 T, respectively (Li et al., 2010).

Large thermal hysteresis ΔThys and transition interval ΔTint during martensitic transformation. The large thermal hysteresis ΔThys and transition interval ΔTint may lead to the retain of partial austenite after removing the magnetic field and ultimately reduce the transformed volume fraction. For instance, due to the existence of thermal hysteresis, the value of MFIS in the Ni50Mn36In8Sb6 alloy becomes irreversible after removing the magnetic field (Yu et al., 2014).

Based on the previous studies, for the NiMnIn-based alloys, the critical magnetic field, thermal hysteresis, and transition interval could be optimized in the following ways:

a) External field training to reduce the critical magnetic field. The external field training methods, such as mechanical, magnetic, and thermo-mechanical training, can reduce the number of martensite variants. After that, the number of unfavorable variants is reduced by the process of detwinning (Yan et al., 2016a), and thus the critical magnetic field driving the inverse martensitic transformation can be reduced.

b) Applying mechanical or thermal field to reduce thermal hysteresis and critical magnetic field. Generally speaking, for the NiMnIn-based alloys, the mechanical field stabilizes the martensite, and the thermal field stabilizes the austenite. Applying the mechanical or the thermal field reasonably to assist transformation can reduce the thermal hysteresis and the critical magnetic field of MSME.

c) Increasing geometrical compatibility between austenite and martensite to reduce thermal hysteresis. Adjusting the lattice parameters of austenite and martensite by tailoring the chemical composition to increase the geometric compatibility between austenite and martensite can reduce the thermal hysteresis.

d) Tailoring microstructural features to control thermal hysteresis. The microstructure characteristics, including grain boundary, point defect, and phase constituent, play important roles in the nucleation and growth of martensite. Thus, the hysteresis can also be tuned by microstructure modification.

Reasonably utilizing the above-mentioned strategies, it is possible to significantly improve the MSME of the NiMnIn-based alloys and thus promote the practical application of this compound in the field of smart sensors and actuators.

The magnetocaloric effect (MCE) refers to the temperature change ∆T of a material when exposed to an external magnetic field (Wiedemann, 1889; Moya et al., 2014). Nowadays, the magnetocaloric refrigeration technique has been successfully applied in the low and extremely low-temperature refrigeration fields, such as physical property measurement, superconducting environment, and cryogenic physics, and shows the potential of entering the conventional room-temperature refrigeration market (Yu et al., 2010; Kitanovski and Egolf, 2009), such as conditioner, refrigerator, and food freezer. Generally, the MCE is characterized by the isothermal magnetic entropy change ∆SM or the adiabatic temperature change ∆Tad. The mechanism of MCE in the conventional materials is shown in Figure 9. When a magnetic material is exposed to a magnetic field, the magnetic moment tends to be parallel to the direction of the applied magnetic field, resulting in a decrease in magnetic entropy and thus a rise in temperature. By heat exchange, the heat of the MCE material releases into the environment. When the magnetic field is removed, the magnetic moments of magnetic atoms tend to be disordered again due to the thermal vibration, resulting in an increase in magnetic entropy and a decrease in temperature. In 1933, by using the thermal-magnetic cycle illustrated in Figure 9, W. F. Giauque and D. P. Macdougall successfully realized an ultra-low temperature of 0.25 K by using the paramagnetic salt Gd2(SO4)3·8H2O (Giauque and Macdougall, 1933). Subsequently, a variety of excellent low-temperature magnetic refrigerants have been discovered, such as Gd2(SO4)3·8H2O (Giauque and Macdougall, 1933), GGG (Gd3Ga5O12) (McMichael et al., 1993), and RAl2 (R = Er, Ho, Dy, Dy0.5Ho0.5, DyxEr1−x, Gd and Pd) (Hashimoto et al., 1987). After the development of the low-temperature magnetic refrigerants for half a century, in 1976, G. V. Brown observed a room-temperature MCE effect in Gd (Brown, 1976). At this time, both the low-temperature and the room-temperature MCE effects were realized at around the temperature of the second-order Cuire magnetic transition.

A breakthrough came in 1997. In this year, V. K. Pecharsky and K. A. Gschneidner et al. reported a first-order phase transition related room-temperature magnetocaloric material Gd5Si2Ge2 (Pecharsky and Gschneidner, 1997). In this material, a giant ∆SM of about 18 J kg−1 K−1 under a magnetic field of 5 T was obtained at 280 K, which is about twice larger than that of Gd. Further investigations showed that this large ∆SM comes from the magnetic-field-induced transformation from the paramagnetic monoclinic phase to the ferromagnetic orthorhombic phase. From then on, the magnetocaloric materials associated with the first-order phase transition attracted great attention based on this work.

For the NiMnIn-based alloys, as mentioned above, the martensitic transformation is accompanied by significant changes in magnetism, which is similar to the case of Gd5Si2Ge2 (Pecharsky and Gschneidner, 1997). Thus, since the discovery of NiMnIn alloy, the magnetocaloric effect of this compound has attracted increasing attention. By the Maxwell relation, R. Kainuma et al. found that the Ni45Co5Mn36.7In13.3 single-crystal exhibits a large ∆SM of 28.4 J kg−1 K−1 at 292 K under a magnetic field of 7 T (Kainuma et al., 2006). This value of ∆SM is comparable to the famous room-temperature rare-earth-based MCE refrigerant, such as Gd5Si2Ge2, MnAsSb, and La(Fe, Si)13. Besides, since the critical temperature of first-order martensitic transformation can be easily tailored by composition modification, the NiMnIn-based alloy has adjustable refrigeration working temperature, as well as relatively low cost, compared with the second-order Cuire transition associated rare-earth-based MCE materials, such as Gd, RAl2 (R = Er, Ho, Dy, Dy0.5Ho0.5, DyxEr1−x, Gd and Pd), RE-TM (RE = Nd, Ho, Er, and Tm; TM = Zn and Ga) and RETMX (RE = Tb, Dy, Ho, and Er; TM = Fe, Co, and Pt; X = Al, Mg, and C) (Luo and Wang, 2009; Nirmala et al., 2015; Li and Yan, 2020). Moreover, different from the conventional MCE refrigerants in which the temperature is increased upon the application of magnetic field, the temperature of the NiMnIn-based alloys is decreased when a magnetic field is applied. For the NiMnIn-based alloys, when a magnetic field is applied, the heat absorbed from the structural transition from the low-entropy martensite phase to high-entropy austenite is larger than the heat released from the alignment of magnetic moments during the process of the inverse martensitic transformation. Therefore, the temperature of the sample decreases during the process of the magnetic-field induced inverse martensitic transformation. Clearly, the MCE in the NiMnIn-based alloys is different from the above-mentioned conventional magnetocaloric effect, which thus is termed as the inverse magnetocaloric effect (Tegus et al., 2002; Krenke et al., 2005).

For the MCE refrigerant, the following requirements should be satisfied: 1) the value of isothermal magnetic entropy change ∆SM (or adiabatic temperature change ∆Tad) should be as large as possible as it directly decides the refrigeration efficiency; 2) the transition thermal hysteresis ΔThys accompanied with the magnetostructural transformation should be as small as possible since the existence of large thermal hysteresis will greatly reduce the cooling efficiency and may further cause the functional fatigue after several cycles; 3) the refrigeration temperature window δTFWHM should be as wide as possible. Aimed at improving the above-mentioned three parameters, the MCE of the NiMnIn-based alloys has been extensively studied during the past 15 years. Next, the main progress related to the improvement of ∆SM (or ∆Tad), ΔThys, and δTFWHM in the NiMnIn-based alloys will be briefly reviewed.

As mentioned above, the isothermal magnetic entropy change ∆SM (or adiabatic temperature change ∆Tad) is the key parameter to decide the refrigeration capacity for the MCE refrigerants. Thus, to improve ∆SM or ∆Tad, several strategies, including increasing transformed volume fraction via enlarging the driving force of magnetic-field-induced inverse martensitic transformation, reducing the negative contribution of magnetic entropy change ∆Smag to transformation entropy change ∆Str and exploiting multicaloric effect, have been proposed.

a) Increasing transformed volume fraction via increasing the driving force of magnetic-field-induced inverse martensitic transformation. For the NiMnIn-based alloys, one of the critical issues is the high magnetic field requirement to induce a completely inverse martensitic transformation. This results in a limited volume of inverse martensitic transformation under a relatively low magnetic field. In this case, the corresponding MCE performance is significantly reduced compared with that of a complete transformation. This is why the reported MCEs of the NiMnIn-based alloys in the literature were mostly measured with high magnetic field strength, usually 5T (Liu et al., 2009b; Wang et al., 2020; Yang et al., 2020; Bai et al., 2021). It is known that the maximum magnetic field produced by the ordinary permanent magnets is around 2T. This value is much lower than the magnetic field required to induce a complete inverse martensitic transformation in the NiMnIn alloys. Thus, increasing transformed volume under a relatively low magnetic field should be the most efficient method to increase the MCE refrigeration efficiency.

For the NiMnIn-based alloys, the driving force of magnetic-field induced inverse martensitic transformation comes from the giant magnetization difference between austenite and martensite, i.e., Zeeman energy, μ0HΔM. Thus, under a constant magnetic field, increasing the magnetization difference between austenite and martensite ∆M can greatly elevate the Zeeman energy and thus increase the transformed volume. For the NiMnIn-based alloys, the magnetization of martensite is very small, and thus ∆M is mainly decided by the magnetization of austenite. Therefore, the most effective method to increase ΔM is to enhance the magnetism of austenite.

So far, the most successful method of enhancing the magnetism of austenite in the NiMnIn alloys is the partial substitution of Co for Ni (Kainuma et al., 2006; Liu Z. H. et al., 2009; Pathak et al., 2010; Guillou et al., 2012; Li et al., 2018; Wang et al., 2020; Yang et al., 2020; Bai et al., 2021). In the Co-doped Ni45.2Mn36.7In13Co5.1 alloy, J. Liu et al. realized a ∆Tad of −6.2 K under a relatively low magnetic field of 1.9 T at 317 K (Liu et al., 2012). Besides, by using a pulsed magnetic field of 15 T, T. Kihara and collaborators realized a giant ∆Tad of −12.8 K in the Ni45Co5Mn36.7In13.3 alloy (Kihara et al., 2014). Apart from the doping with Co, Z. H. Liu et al. reported that the addition of Sb can also enhance the ferromagnetism of austenite, thus improving ΔT/ΔH (Liu et al., 2009b). In the Ni48.3Mn36.1In10.1Sb5.5 alloy, an ∆SM of 21 J kg−1 K−1 was obtained at a magnetic field of 5 T (Liu et al., 2009a). Different from the strategy of increasing magnetism of austenite, V. Sánchez-Alarcos reported that the magnetization of martensite can be reduced with the addition of Ti, which further results in an enhancement of MCE (Sánchez-Alarcos et al., 2015).

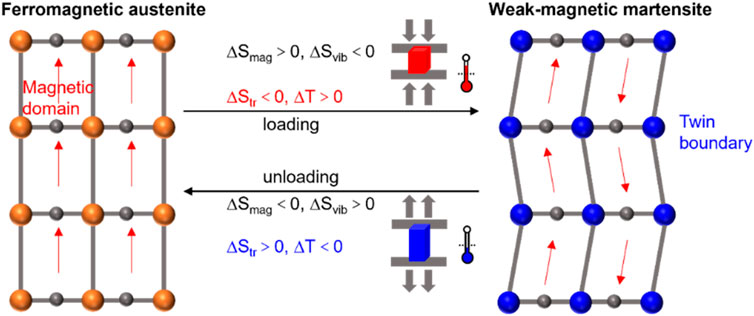

b) Reducing the negative contribution of magnetic entropy change during the magnetostructural transition. For the MCE associated with the first-order phase transition, the upper-limit of the isothermal magnetic entropy change ∆SM is the transformation entropy change ∆Str during phase transition. Thus, a large ∆Str is a prerequisite to realizing a significant MCE performance. Theoretically, the transformation entropy change ∆Str comes from three contributions, i.e., the lattice vibration entropy change ∆Svib, the magnetic entropy change ∆Smag and the electronic entropy change ∆Selec (Recarte et al., 2010; Recarte et al., 2012; Wang et al., 2017). For the NiMnIn-based alloys, during the process of magnetic-field induced inverse martensitic transformation from low-entropy martensite to high-entropy austenite, the lattice vibration entropy change ∆Svib is increased. This term makes the highest contribution to ∆Str. Nevertheless, since the austenite has a highly ordered magnetic structure while martensite has a disordered magnetic structure, ∆Smag is decreased during the process of magnetic-field induced inverse martensitic transformation. Clearly, the sign of ∆Smag is opposite to ∆Svib and ∆Str. Thus, in the NiMnIn-based alloy, ∆Smag plays a negative contribution to ∆Str. For the contribution of electronic structure change on ∆Str, since both austenite and martensite exhibit the conductivity of metal in the reported NiMnIn alloys, ∆Selec usually makes a negligible contribution to ∆Str. For example, ∆Str of the Ni45Co5Mn36.5In13.5 alloy was determined to be ∼23 J kg−1 K−1, where ∆Svib, ∆Smag, and ∆Selec were about 51, −29, and 1.2 J kg−1 K−1, respectively (Kihara et al., 2014). From the above analyses, under the condition of constant ∆Svib, decreasing the negative contribution of ∆Smag should be the most effective method to improve ∆Str and then ∆SM (or ∆Tad).

Intuitively, the most direct way to decrease the negative contribution of ∆Smag is to reduce the magnetization difference between austenite and martensite ∆M. However, as discussed in the first half of this section, a remarkable ∆M, directly related to the Zeeman energy (μ0HΔM), is the prerequisite of the occurrence of magnetic-field induced martensitic transformation. Therefore, from the perspective of the MCE performance, a moderate ∆M is appropriate. In experiments, the most utilized strategy to reduce ∆Smag is to reduce the temperature distance between the magnetostructural transition TM and the Curie temperature of austenite

Different from mechanical properties that are strongly dependent on microstructure, TM belongs to the inherent property of materials and thus is mainly determined by the chemical composition. Aimed at reducing ∆Smag by tailoring TM, for the ternary NiMnIn alloys, several alloying methods including changing relative contents of different elements of the alloy and adding the fourth alien elements, such as Cu (Li et al., 2019a; Yan et al., 2021a; Huang et al., 2021), Cr (Sharma et al., 2010a; Sharma et al., 2011), Fe (Chen et al., 2012; Feng et al., 2012), Ga (Paramanik and Das, 2016) and Pd (Li et al., 2015), have been utilized. For instance, under the guidance of valence electron concentration (e/a) criteria of TM, i.e., a larger e/a corresponds to a higher TM (Wei et al., 2016), Feng et al. elevated TM of Ni50Mn34In16 from 250 K to 303 K via the partial substitution of a low valence electron number (VEN) element of In (5s2p1, VEN = 3) by a high VEN element of Fe (3d64s2, VEN = 8) (Feng et al., 2012). In the Fe-doped Ni50Mn34In14Fe2 alloy, TM almost coincides with

For the Co-doped NiCoMnIn alloys, compared with ternary NiMnIn alloys, the negative contribution of ∆Smag to ΔStr is more pronounced as the addition of Co greatly enhances the magnetism of austenite and then the value of ∆M (Li et al., 2019a; Yang et al., 2020). The strategy of weakening ∆Smag in the NiCoMnIn alloy is the same as that of NiMnIn, i.e., elevating TM to make it close to

c) Utilizing multicaloric effect. As discussed above, the incompleteness of magnetic field-induced inverse martensitic transformation due to the high critical magnetic field required for a full transformation is a critical issue that restricts the MCE performance of the NiMnIn-based alloys. Inspired by the fact that apart from the magnetic field, the martensitic transformation of NiMnIn alloy can also be triggered by mechanical field, an idea of improving MCE by simultaneously or sequentially applying mechanical and magnetic fields was proposed. Owing to the existence of multiple stimuli, the caloric effect generated in this process is termed as the multicaloric effect (Stern-Taulats et al., 2018). Compared with the caloric response when subjected to a single stimulus, the multicaloric effect generally has a much higher refrigeration capacity (Gràcia-Condal et al., 2020). In the Ni50Mn35.5In14.5 alloy, by applying a magnetic field of 4 T and a mechanical field of 40 MPa, a multicaloric effect with an entropy change of 25.2 J kg−1 K−1 and an adiabatic temperature change of 5.9 K was realized at room temperature. These values obviously exceed that of single magnetocaloric and elastocaloric effects.

In application, to realize a real MCE refrigeration, the magnetic field needs to be repeatedly applied to the MCE refrigerant (around 107 times), which requires that the MCE effect possess a good cyclability. Unfortunately, different from MCE around the second-order Curie transition, MCE originated from the first-order magnetostructural transition is inevitably accompanied with the transitional thermal hysteresis ΔTHys. Theoretically, ΔTHys caused by the energy barrier between austenite and martensite is closely related to the transitional stress layer between the two phases. During the cyclic transformation, the stress in the transitional layer could induce certain irreversible processes, such as the formation of dislocations and the nucleation of microcracks, which further lead to functional degradation and failure (Song et al., 2013). Thus, for the practical applications, it is greatly meaningful to reduce ΔTHys and improve the reversibility of magnetostructural transition of the NiMnIn alloys. Until now, several strategies have been proposed, aimed at reducing ΔTHys, such as improving geometric compatibility between austenite and martensite, applying extra stimuli, etc.

a) Enhancing geometrical compatibility between austenite and martensite: As mentioned above, the degradation of cyclability is associated with the transitional stress layer between austenite and martensite. Thus, reducing the transition layer will be able to fundamentally decrease ΔTHys and improve the functional stability. According to the crystallographic theory of martensitic transformation (Nishiyama, 1978; Christian, 2002), the transitional stress layer is closely related to the geometrical compatibility between austenite and martensite, which can be described quantitatively by the middle eigenvalue of transformation stretch tensor λ2 and the more strict cofactor condition (Chen et al., 2013; Song et al., 2013; Della Porta, 2019). A thinner transitional layer corresponds to better geometrical compatibility. For the geometrical compatibility between austenite and martensite, it is purely determined by the lattice parameters of these two phases, which can be adjusted by tailoring the chemical composition of the alloy. This provides an effective method to reduce ΔTHys.

For the ternary NiMnIn alloys, it is reported that the substitution of Cu for Mn is a valid method to improve the geometrical compatibility and thus decreases ΔTHys (Zhao et al., 2017a). For instance, D. W. Zhao et al. achieved a small ∆THys of 3K and an excellent phase transition stability over 105 magnetic field cycles in the Cu-doped Ni50Mn31.5In16Cu2.5 alloy (Zhao et al., 2017b). They attributed the low ∆THys and the exceptional cyclic stability to the fact that in this compound, λ2 (0.99281) is fairly close to 1 and the (011) type-I/II twins, together with the (100) compound twins, closely satisfy the co-factor conditions simultaneously (Zhao et al., 2017a).

For the NiCoMnIn alloys, even though the addition of Co can enhance the magnetism of austenite and further significantly improve the magnetoresponsive behaviors, unfortunately, this alloying leads to a significant increase in hysteresis and phase transition irreversibility. For example, ∆Thys of the ternary NiMnIn alloys is around 5–12 K, while with the addition of Co the value of ∆Thys abruptly elevates to 10–30 K (Yan et al., 2021a). Thus, for the NiCoMnIn alloys, the harm caused by the thermal hysteresis and the irreversibility of phase transition is more severe compared with that in the ternary NiMnIn alloys. Until now, apart from Co, several fifth alloying elements were co-added to the NiMnIn alloys aimed at optimizing the hysteresis behavior, such as Co & Fe (Chen et al., 2012), Co & Si (Li et al., 2019b), Co & Cu (Li et al., 2019c; Yan et al., 2021b; Huang et al., 2021). Z. B. Li et al. reported that the Cu substitution for Mn can effectively reduce ΔTHys of the NiCoMnIn alloys from 17.5 K (Ni46Co3Mn36Cu1In14) to 9 K (Ni46Co3Mn34Cu3In14) (Li et al., 2019a). In the Co and Cu co-doped Ni46Co3Mn35Cu2In14 alloy, they achieved a reversible ∆SM of 16.4 J kg−1 K−1 under a magnetic field of 5 T and a reversible ∆Tad of 2.5 K under a magnetic field of 1.5 T (Li et al., 2019b).

Nevertheless, this alloying strategy of Cu, i.e., replacing Mn, will inevitably lead to the reduction of magnetism, since the magnetic moment of the Ni–Mn-based alloys is mainly provided by Mn (∼85%) (Yan et al., 2020a; Yan et al., 2020b). To avoid the negative influence on magnetism caused by Cu doping, the co-alloying strategy with Cu replacing In and Co replacing Mn was studied (Yan et al., 2021a). In the Ni45Co5Mn36In13.3Cu0.7 alloy, a reversible isothermal magnetic entropy change of 13.8 J kg−1 K−1 and a refrigeration capacity of 270.2 J kg−1 were obtained. Moreover, when the geometrical compatibility between austenite and martensite is improved by adjusting lattice parameters via tailoring the chemical composition, the volume variation ratio ∆V/V0 during the transition that is closely related to the transformation entropy change will inevitably be changed. The alloying strategy of improving geometrical compatibility and keeping remarkable ∆V/V0 meanwhile is still an open issue.

b) Applying extra stimulus fields: For the NiMnIn based alloys, owing to the strong coupling between magnetism and crystal lattice, the magnetostructural transformation is sensitive to both magnetic field and stress/strain field. This provides another way to tailor the hysteresis behavior of MCE, i.e., the stress/strain-assisted transformation. J. Liu et al. reported that the application of bias stress can greatly reduce or even eliminate the magnetic hysteresis during the cycle of the magnetic field-induced inverse martensitic transformation (Liu et al., 2012; Zhao et al., 2017a). They observed that if the sample is magnetized without bias stress but is demagnetized under a low external hydrostatic pressure of 1.3 kbar, the isothermal magnetization and demagnetization curves of the NiCoMnIn alloy almost coincide (Liu et al., 2012).

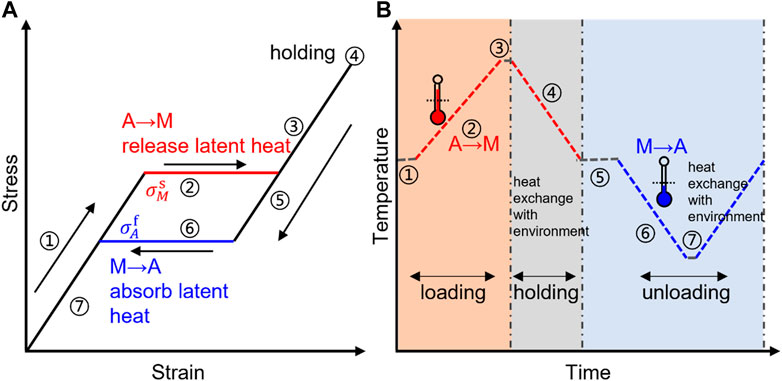

By utilizing the bias stress, T. Gottschall et al. proposed a multicaloric cooling cycle to eliminate the negative influence of hysteresis on the reversibility of phase transition (Gottschall et al., 2018). The key idea of this method is to apply uniaxial stress to assist the transformation of the ferromagnetic austenite phase locked by large hysteresis into the martensite phase. The caloric effect is expected to be reproducible under the following sequence: 1) a decrease in temperature when the NiMnIn-based alloys are adiabatically magnetized; 2) the reverse transition does not happen due to the existence of thermal hysteresis during demagnetization; 3) absorbing heat from surroundings in the absence of a magnetic field; 4) applying uniaxial stress to assist the transformation from austenite to martensite; 5) removing stress; 6) expelling heat to the surroundings. By alternately applying a magnetic field (1.8T) and a stress field (80 MPa), they obtained a reversible ∆Tad of −1.2 K in the Ni49.6Mn35.6In14.8 alloy (Gottschall et al., 2018).

Apart from bias stress, Z. Z. Li et al. reported that the existence of the internal stress introduced by the pre-deformation can also improve the MCE cyclability (Li et al., 2018). They found that by applying pre-deformation, the reversible ∆Tad of the Ni45.3Co5.1Mn36.1In13.5 alloy increases to 1.1 K from 0.8 K (the stress-free state). Besides, Y.-Y. Gong et al. reported that the strain-assisted transformation can also effectively tailor the hysteresis behavior of the NiCoMnIn alloy (Gong et al., 2015). They found that the strain generated by the PMN-PT piezoelectric ceramics can decrease ΔTHys from 25.5 to 21.6 K with an electric field varying from 0 to 8 kV cm−1.

c) Other methods: Apart from tailoring geometrical compatibility and applying external stress/strain stimuli, the microstructure of MCE refrigerant was also reported to have an important influence on hysteresis. J. Liu et al. found that for the Ni45Mn37In13Co5 ribbons sample, the annealing can reduce the thermal hysteresis from 25 K to 20 K (Liu et al., 2009b). They attributed the reduction of ∆Tad to the increased grain size and decreased defect density. Besides, T. Gottschall et al. proposed that the transformation performed in a minor loop instead of a complete transformation can improve the MCE stability (Gottschall et al., 2015). With this method, they obtained a cyclic ∆Tad of −3 K at the magnetic field of 1.95 T in the Ni45.7Mn36.6In13.5Co4.2 alloy (Gottschall et al., 2015).

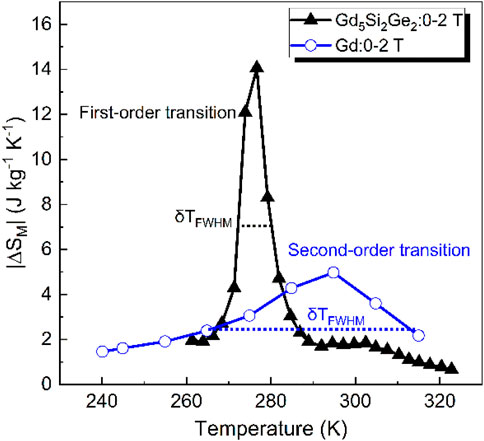

For the NiMnIn-based alloys, different from the conventional giant MCE which occurs around the second-order Curie transition, the excellent MCE in these compounds is originated from the first-order magnetostructural transition. During the second-order Curie transition, the order parameter, i.e., magnetization, experiences a continuous transition in a relatively wide temperature change (40–50 K). In contrast, the first-order martensitic transformation occurs in a burst manner at speed close to that of the sound. The difference in the transformation speed of the first-order and the second-order phase transition results in a large difference in the operating temperature window of the corresponding MCE. An example comparing the MCE operating temperature window widths of the first-order and second-order transitions is illustrated in Figure 10. It is seen that the operating temperature range δTFWHM defined as the full width at half maximum of ∆SM(T) curve of Gd (second-order Curie transition) is around 47 K, which is about 6 times wider than that of Gd5Si2Ge2 (first-order magnetostructural transition) (Pecharsky and Gschneidner, 1997). For the MCE, the refrigeration capacity (RC) is determined by the product of isothermal magnetic entropy change ΔSM and the operating temperature window δTFWHM. Thus, a narrow δTFWHM will lead to a significant reduction in refrigeration capacity. So far, numerous strategies have been proposed to expand the operating temperature window of the MCE, such as enhancing the magnetic field sensitivity of magnetostructural transition temperature TM, preparing composite material containing the MCE refrigerants with different TM, and combining different caloric responses (magnetocaloric and elastocaloric).

a) Enhancing the magnetic field sensitivity of magnetostructural transition temperature ∆T/∆H: Fundamentally, for the MCE associated with the first-order magnetostructural transition, the width of the operating temperature window is decided by the magnetic field sensitivity of magnetostructural transition temperature ∆T/∆H. Under a certain magnetic field, a higher ∆T/∆H value will lead to a larger shift of magnetostructural transition temperature, further resulting in a wider operating temperature window δTFWHM. Based on the Clausius-Clapeyron equation, as discussed previously, the ∆T/∆H value can be increased by enlarging the magnetization difference between austenite and martensite ∆M, which can be achieved by the partial substitution of Co for Ni. For instance, by introducing Co, the value of δTFWHM increases from 24 K (Mn50Ni39In9Co2) to 32 K (Mn50Ni37In9Co4) (Yang et al., 2020). However, as mentioned earlier, the substitution of Co will increase ∆Thys. To weaken the negative effect on ∆Thys, L. M. Wang proposed a low content of Co alloying method aiming at simultaneously realizing a wide ∆T/∆H and low ∆Thys (Wang et al., 2020). In the Ni48Co1Mn37In14 alloy, a working temperature range of 34 K and an effective refrigeration capacity of 284 J kg−1 were realized under a magnetic field of 5 T.

b) Combining different caloric responses: For the NiMnIn-based alloys, apart from the inverse MCE associated with the first-order magnetostructural transition, it also exhibits the elastocaloric effect (see details in Section 7) and the conventional MCE around the second-order Curie transition of austenite. As is known, the magnetic field tends to stabilize the phase with strong magnetism, i.e., austenite, while the mechanical field stabilizes martensite preferentially. Therefore, the transitional temperature of martensitic transformation TM tends to shift towards an opposite direction when the magnetic field and the stress field are applied, respectively. As a result, although both inverse MCE and elastocaloric effects are associated with martensitic transformation, typically, the working temperature ranges for the inverse MCE and the elastocaloric effect are, respectively, lower and higher than TM. This characteristic of the NiMnIn-based alloys provides a novel route to widen the working temperature range, i.e., combining the different caloric responses with adjacent temperature ranges. Moreover, by composition design, MCE associated with the second-order Curie temperature can also be adjusted near the magnetostructural transition. In this situation, the inverse MCE, the elastocaloric effect, and the conventional MCE can be combined and further expand the refrigeration temperature region.

FIGURE 10. Isothermal magnetic entropy change of the Gd5Si2Ge2 between 240 and 325 K for a magnetic field change from 0 to 2 T, compared with that of pure Gd as determined from magnetization measurement (Pecharsky and Gschneidner Jr., 1997).

In 2017, Y. Hu et al. proposed the method of widening the operating temperature window by combining elastocaloric and MCE effects. By using this method, they realized a broad refrigeration temperature region of around 120 K in the Ni49.5Mn28Ga22.5 alloy (Hu et al., 2017). In the Ni50Mn35In15 alloy, Z. B. Li et al. realized a broad refrigeration temperature region ranging from 270 K to 380 K via the combination of successive MCE and elastocaloric effects (Li et al., 2020). Recently, P. T. Cheng et al. realized a refrigeration temperature range of 250–340 K in the Ni45Co5Mn37In13 alloy by using the same strategy (Cheng et al., 2021).

c) Utilizing the intermediate martensitic transformation: In some NiMnIn-based alloys, an intermediate martensitic transformation has been observed, i.e., the martensitic transformation occurs in multiple stages. By using the multi-stage phase transition characteristics, the operating temperature window of MCE can be extended if different stages of martensite transformation occur in an adjacent temperature range. For example, S. Dwevedi et al. reported a two-step martensitic transformation in the Sn-doped Ni–Mn–In-based alloys, which leads to the double peak behavior of ∆SM and widens the operating temperature range (Dwevedi and Tiwari, 2012). With a two-step martensitic transformation, an operating temperature window δTFWHM of around 46.5 K was realized in the Ni50Mn34In8Sn8 alloy that greatly exceeds the typical δTFWHM value of the single-stage martensitic transformation (∼10 K at a magnetic field of 2 T).

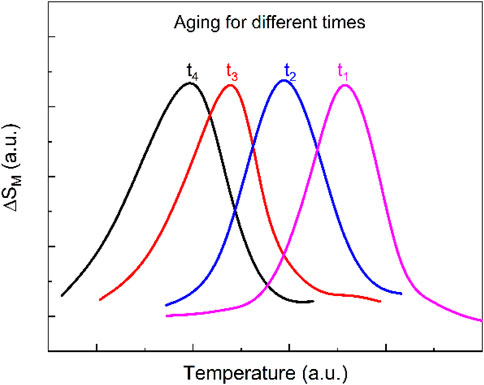

d) Fabricating composite material containing the MCE refrigerants with different TM: For the MCE associated with the first-order magnetostructural transition, the operating temperature is around the temperature of magnetostructural transition. Thus, fabricating a series of MCE refrigerants with different TM and compositing them will allow to greatly expand the operating temperature range. Using this strategy, J. Liu et al. proposed a method of stacking a series of alloys with different annealing times to successfully expand the operating temperature window of the NiCoMnIn alloy(Liu et al., 2012). For the NiCoMnIn alloys, with the prolongation of aging time, the martensitic transformation is gradually shifted to the lower temperatures, whereas the transformation entropy change remains unchanged. Thus, for the composite containing a series of alloys aged at different times, the operating temperature window is greatly enlarged, as illustrated in Figure 11. Later, J.-P. Camarillo et al. reported that a reversible ∆SM of 7.5 J kg−1 K−1 was obtained over a broad temperature range of 30 K by assembling a composite specimen in a NiMnInCu alloy (Camarillo et al., 2016).

FIGURE 11. Realizing a wide operating temperature window by combining various samples with different aging times.

From the above discussion, the high magnetic moment of austenite, which usually brings about a large magnetization difference ∆M between austenite and martensite, is a double-edged sword for the MCE performance. On the one hand, a remarkable ∆M is a prerequisite for the magnetic field-induced inverse martensitic transformation. On the other hand, a higher ∆M makes a larger negative contribution of ∆Smag to ∆Str. Thus, for the optimized MCE performance, ∆M should be neither too big nor too small. For the multicaloric effect, it is indeed possible to improve refrigeration efficiency. Unfortunately, compared with the single stimulus, the multiple stimuli significantly increase the complexity of machine construction and equipment cost. More efforts focused on optimizing the structure of the equipment are required. Apart from the above-mentioned strategies, in our opinion, the methods of improving lattice vibration entropy change ∆Svib and electronic entropy change ∆Selec may open new ways to improve the MCE performance. Since ∆Str is mainly decided by ∆Svib, the method of enlarging ∆Svib could greatly improve the MCE performance. In addition, even though in the known NiMnIn-based alloys, ∆Selec plays a negligible positive role on ∆Str, it might be possible to obtain a large ∆Selec by tailoring the electronic structure of martensite from metal to semiconductor state. The semiconducting state is not uncommon in the 2:1:1 type Heusler alloys. Recently, J. C. Lin et al. found that ∆Selec plays a key role on ∆Str in the Ni1-xFexS alloy during the study of barocaloric effect (Lin et al., 2020), which evidenced that it is feasible to utilize ∆Selec to improve ∆Str.

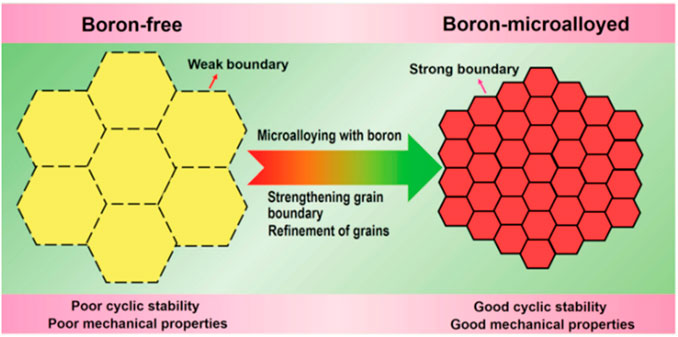

Through the above-mentioned strategies, the thermal/magnetic hysteresis of the Ni(Co)MnIn alloys has been greatly optimized. However, the cyclic stability of the MCE performance of the Ni(Co)MnIn alloys yet cannot meet the needs for practical applications. For instance, in the state-of-the-art Co and Cu co-doped Ni46Co3Mn35Cu2In14 alloy, the maximum ΔTad is up to −4.8 K under the magnetic field of 1.5 T at the first cycle, while this value rapidly drops to −2.5 K at the second cycle (Li et al., 2019c). So far, there is still a lack of satisfactory alloying methods, which can substantially improve the geometrical compatibility of the alloy without degrading other parameters required for MCE. One of the difficulties is that the geometrical compatibility rule is a posteriori criterion. Specifically, the geometrical compatibility factors can only be calculated with the measured lattice parameters of austenite and martensite after the alloy is fabricated. This method is inefficient and cannot be directly used to guide the design of alloy composition. So far, the direct relation between alloy composition and geometrical compatibility is unknown. High throughput experimental or computational methods and machine learning may provide a feasible way to find the correlation and then promote the design of low-hysteresis NiMnIn alloys.