- 1School of Civil and Resource Engineering, University of Science and Technology Beijing, Beijing, China

- 2Beijing Key Laboratory of Urban Underground Space Engineering, University of Science and Technology Beijing, Beijing, China

- 3CCCC-SHEC Third Highway Engineering Co., Ltd., Xi’an, China

- 4Hebei Academy of Building Research, Shijiazhuang, China

Tailings are one of the largest solid wastes in stock at present. In order to improve the comprehensive utilization rate of tailings, especially to solve the problems of fine-grained tailings treatment, the concrete composite admixture was prepared by using iron tailings powder and slag powder. In order to study the influence of iron tailings powder on the workability and long-term mechanical properties of concrete, C30 and C50 concrete with different iron tailings powder dosages were prepared, and the slump, expansion, flexural strength, splitting tensile strength, and compressive strength of concrete at different ages were tested. The results showed that the proper addition of iron tailing powder is beneficial to the working performance of concrete and can effectively reduce the time-loss of concrete fluidity. When the content of iron tailings powder in the composite admixture is 50%, the 1080d long age strength of C30 and C50 concrete can reach 50.3 and 80.7 MPa. Based on the 28d compressive strength, the relative strength-age prediction model of iron tailings powder concrete was established. The calculation and experimental results show that the model can accurately predict the compressive strength of micro-powder concrete of iron tailings at long age, and the error rate is less than 1%. The results lay a theoretical foundation for the utilization of iron tailings in concrete.

Introduction

With the continuous development of mineral resources, a large number of tailings have been formed after mineral dressing, and tailings is one of the most abundant solid wastes. The accumulation of tailings in tailings ponds not only pollutes groundwater and the surrounding environment but also threatens the safety of surrounding people and buildings (Pedro et al., 2019; Liu et al., 2020). Limited by science and technology, the overall utilization rate of tailings is not high at present; nearly 78% of the tailings are piled on the surface, resulting in a considerable waste of resources. The main use of tailings is to prepare filling materials and building materials, especially coarse-grained iron tailings can be used as an aggregate to prepare filling materials and concrete, iron tailings can be used as a kind of machine-made aggregate, and the performance of filling materials and concrete is good (Lv et al., 2019; Qi and Fourie, 2019; Protasio et al., 2020; Karthikeyan et al., 2021; Leong, 2021). Some tailings are used to prepare the concrete of mine pillars; the concrete has good mechanical properties by means of fiber reinforcement (Cao et al., 2020; Cao et al., 2021a; Cao et al., 2021b). However, with the continuous development of mineral processing technology, tailings become finer and finer, and the fine-grained tailings below 75 μm can reach more than 80% (Wu et al., 2020). Fine-grade tailings will lead to the increase of cementitive substances in filling materials and cannot be used as a concrete fine aggregate, which greatly increases the difficulty of tailings utilization. The fine-grained tailings need to be classified, and a large number of fine-grained tailings cannot be used, which results in a considerable waste of resources, reduces the overall utilization rate of tailings, and increases the treatment cost. To solve the problem of fine tailings treatment is the bottleneck to improve the comprehensive utilization rate of tailings.

On the other hand, a huge amount of concrete is consumed in infrastructure construction. The production and preparation of concrete lead to the shortage of many resources, especially high-quality mineral admixtures. Mineral admixtures are essential raw materials for the modern green high-performance concrete. Under the background of low carbon and environmental protection, more and more admixtures will replace cement in concrete, which will help reduce carbon emissions and form an environment-friendly cementitious material system (Miller, 2018; Li et al., 2020a; Li et al., 2020b; Habert et al., 2020). In some areas, there is a scarcity of high-quality mineral admixtures, such as fly ash and slag powder (Granulated blast furnace slag, S95 and S105). Therefore, it is imperative to make a rational and efficient use of all kinds of resources, especially waste resources. In order to supplement the shortage of traditional admixture resources such as fly ash and slag and to make a wider use of industrial solid waste, reuse of iron tailings powder as a mineral admixture of concrete should be considered. The content of fine powder below 75 μm in iron tailings is increasing. Because the iron tailings powder is mainly composed of SiO2, Al2O3, and other chemical components, it can be used as a kind of concrete admixture. At present, the research of iron tailings powder as a mineral admixture in concrete is mainly focused on the influence of iron tailings powder on the strength of concrete, as well as the activation and hydration of iron tailings powder. Research shows that when iron tailings powder is mixed with slag powder, concrete has relatively good mechanical properties (Wu and Liu, 2018; Han et al., 2019), and its hydration rate is very slow, which can effectively reduce the hydration heat of cement concrete (Han et al., 2017). It is found that the fineness of iron tailings powder has an important impact on the performance of concrete. Some scholars believe that iron tailings powder can promote the performance of concrete through effective activation and further grinding (Hou et al., 2019; Liu et al., 2019; Yang and Mao, 2020). Through the study on the influence of iron tailings powder as a concrete admixture on mechanical properties and microstructure, iron tailings powder can be completely used as a mineral admixture to prepare concrete materials (Song and Liu, 2017; Song et al., 2019; Wu et al., 2019; Song and Chen, 2020).

However, as an inactive mineral admixture of concrete, iron tailings powder needs to be mixed with highly active slag powder to become a compound admixture. The influence law of iron tailings powder and slag powder on concrete strength, especially the development law of long age strength, is urgently needed to be explored. In this article, different proportions of iron tailings powder and slag powder composite admixtures are designed to prepare two common grades of concrete, C30 and C50. The compressive strength, flexural strength, and splitting tensile strength of concrete are tested, and the long-term strength prediction model is established and verified. This study can fill the research blank of iron tailings powder concrete long-term mechanical properties, which provides a theoretical basis for the application of fine-grained tailings.

Raw Materials and Mix Proportion

Raw Materials

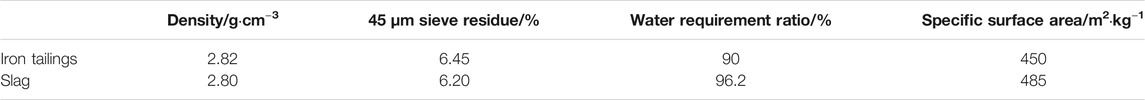

Iron tailings powder comes from Fujian, China. Iron tailings are collected from mines and become iron tailings powder after drying, dehydration, and grinding. Its specific performance indexes are shown in Table 1.

The main chemical composition of iron tailings powder is silica, which comprises metal elements such as iron, copper, and zinc, and the main chemical composition is shown in Table 2. Iron tailings are a kind of mineral rich in silica, so it can be used as a mineral admixture of concrete.

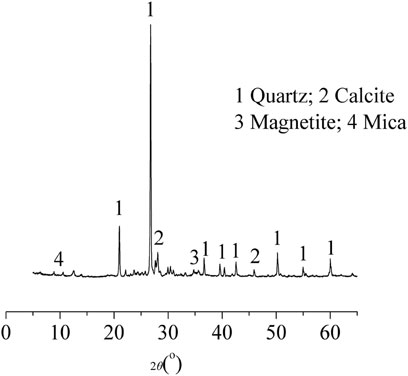

Figure 1 is the X-ray diffraction pattern of iron tailings powder, which is mainly composed of quartz, SiO2, and a small amount of calcite, mica, and other minerals.

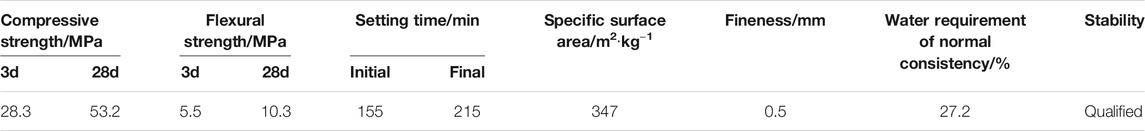

In order to eliminate the influence of other mineral admixtures in cement, the standard cement produced by the China Building Materials Institute, namely, pure Portland cement P.I 42.5, is selected for the test, and its basic performance indexes are shown in Table 3.

Water quenched slag powder is an important mineral admixture for concrete. S95 slag powder produced by a factory in Hebei Province is adopted in the test. The basic performance indexes are shown in Table 1.

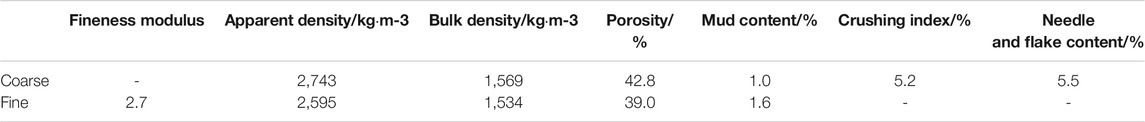

The coarse aggregate and fine aggregate used are in line with the national standard. In coarse aggregate, the particle size of large stone is 10–20 mm and that of small stone is 5–10 mm. The mass ratio of large stone and small stone is 8:2. The fine aggregate used in the test belongs to the medium sand of Ⅱ area. It meets the grade I aggregate requirements of JG/T568-2019 “High performance concrete aggregate”. See Table 4 for specific indicators.

Ordinary tap water is used to meet the requirements of mixing water. Polycarboxylate superplasticizer is used as a superplasticizer, and the solid content is about 20%.

Mix Proportion

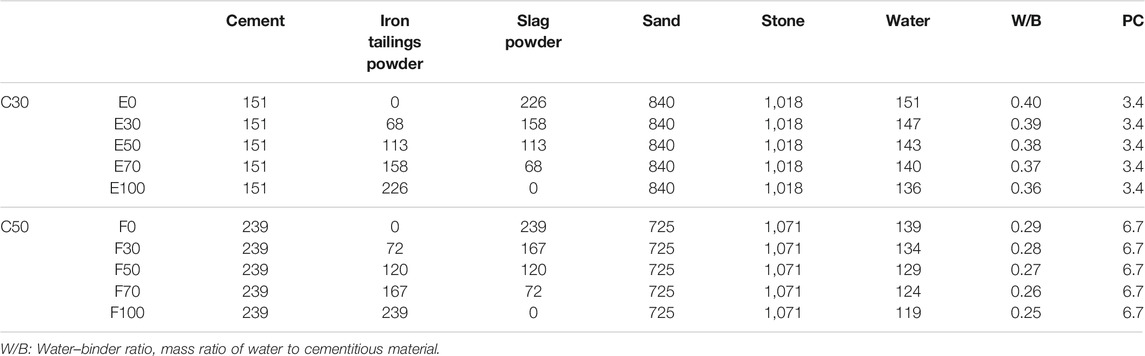

This article designs C30 and C50, two kinds of commonly used concrete. Due to environmental protection, concrete cementitious materials introduce solid waste, so the cement content should not be high. A low cement system is used in this experiment, and cement only accounts for 30 and 40% of the whole cementitious material system, respectively. After the preliminary test, the iron tailings powder belongs to an inactive admixture, so the water-binder is lower than that of concrete with common mineral admixtures. The water–binder ratio of C30 concrete is 0.40 and that of C50 concrete is 0.29. The composite admixture of iron tailings powder and slag powder is adopted, and the proportion of iron tailings powder in the composite admixture is 0, 30, 50, 70, and 100%, respectively. The influence of different proportion of iron tailings powder on the mechanical properties of concrete is studied. With the increase of iron tailings powder content, the water–binder ratio of concrete decreases to ensure that the strength can meet the requirements. Specific coordination is shown in Table 5.

In order to verify the relationship model between phase compressive strength and age of iron tailings micro-powder concrete, the verification group of concrete was prepared. The content of reference cement in C30 and C50 concrete accounted for 40 and 50% of the total cementing material, respectively, and the mixing ratio was shown in Table 6.

Results and Discussion

Influence of Iron Tailings Powder on Concrete Performance

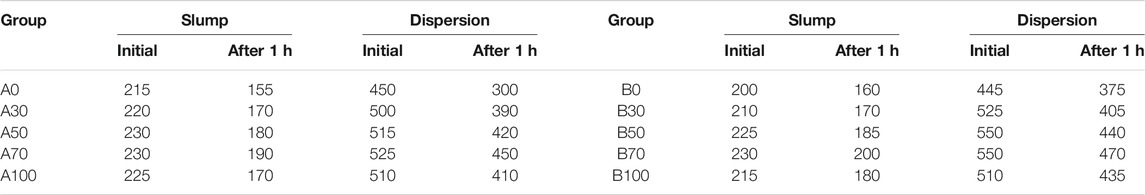

C30 and C50 concrete with different iron tailings powder contents were prepared according to the mix ratio, and the slump and dilatancy of each group of concrete at the time of discharge and 1 h after discharge were tested, respectively. The specific data are shown in Table 7.

The slump and expansion of C30 and C50 concrete mixed with iron tailings powder are greater than that of concrete mixed with slag powder alone. With the increase of iron tailings powder content, the slump and expansion of concrete first increase and then decrease. When iron tailings powder accounts for 70% of mineral admixtures (iron tailings powder and slag powder), the slump and expansion of concrete are the largest, with C30 concrete reaching 230 and 525 mm, and C50 concrete reaching 230 and 550 mm.

The slump and expansion of C30 and C50 concrete decreased in different degrees after 1 h out of the mixer. The slump and expansion of C50 concrete are higher than that of C30 concrete after 1 h. This is due to the low water–binder ratio and high viscosity of C50 concrete. With the passage of time, the concrete has a good water retention performance, while the water–binder ratio of C30 concrete is larger, and there is more free water in the concrete. The concrete will lose water with time, and even the phenomenon of mortar bone separation appears. Therefore, the working performance of C30 concrete is not as good as that of C50 concrete after 1 h. The slump loss rate and expansion loss rate of concrete with slag powder are the largest, and the loss rate of C30 concrete can reach 27.9 and 20.0%, respectively. The addition of iron tailing powder can effectively reduce the loss rate of slump and expansion of concrete after 1 h. When iron tailing powder accounts for 70% of mineral admixtures, the loss rate of slump and expansion is the lowest. Taking C30 as an example, it is 17.4 and 13.0%, respectively, which is 10.5 and 7.0% lower than that of concrete with slag powder alone.

In conclusion, the appropriate addition of iron tailings powder can effectively improve the particle size distribution of cement slag powder cementitious material system and make the particle distribution more uniform, thus increasing the workability of concrete. At the same time, it reduces the time loss of concrete slump and expansion, has good working performance, and ensures the smooth pumping and construction of concrete.

Flexural Strength and Splitting Tensile Strength of Concrete

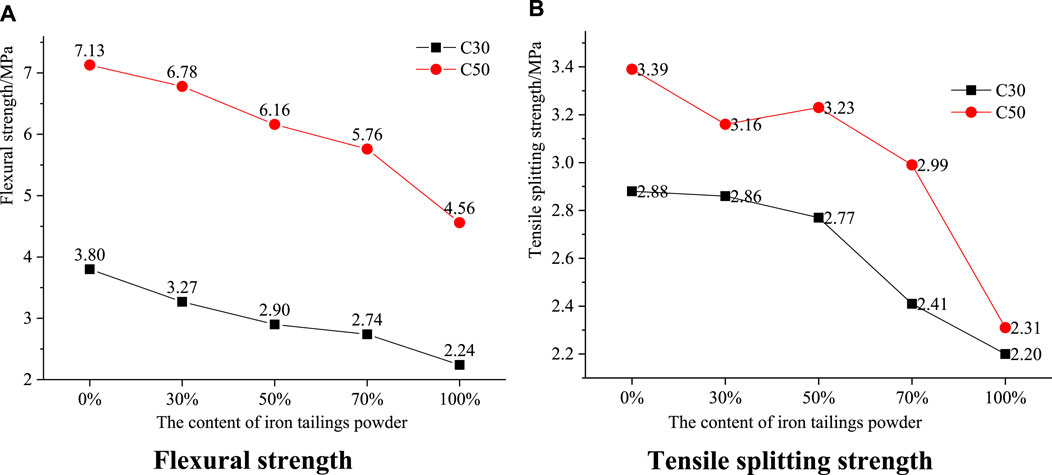

The flexural strength and splitting tensile strength of concrete after standard curing for 28d were respectively tested, and the results are shown in Figure 2.

The results show that the flexural strength and splitting tensile strength of concrete decrease with the increase of iron tailings powder content. The flexural strength and splitting tensile strength of A0 and B0 concrete with slag powder are the largest, which are 3.80, 7.13, 2.88, and 3.39 MPa, respectively. The A100 and B100 concrete with iron tailings powder is not suitable for single mixing. The bending strength and splitting tensile strength of A100 and B100 concrete with iron tailings powder is low, which is only 58–76% of that of concrete with single slag powder. When the ratio of iron tailings powder and slag powder is not more than 5:5, the flexural strength and splitting tensile strength of concrete are similar to those of concrete with slag powder alone. For example, when the proportion of iron tailings powder in a mineral admixture is 30%, the splitting tensile strength of C30 and C50 concrete is only 0.69 and 6.7% lower than that of concrete with single slag powder. In low-strength concrete (C30), the effect of iron tailings powder on flexural strength is greater, and the splitting tensile strength is less. In high-strength concrete (C50), the adverse effect of iron tailings powder on flexural strength is less than that of low-strength concrete, and the adverse effect on splitting tensile strength is greater than that of low-strength concrete. On the whole, the effect of iron tailings powder on the flexural strength of concrete is much greater than that on the tensile strength of concrete.

Long-Term Compressive Strength Law of Concrete

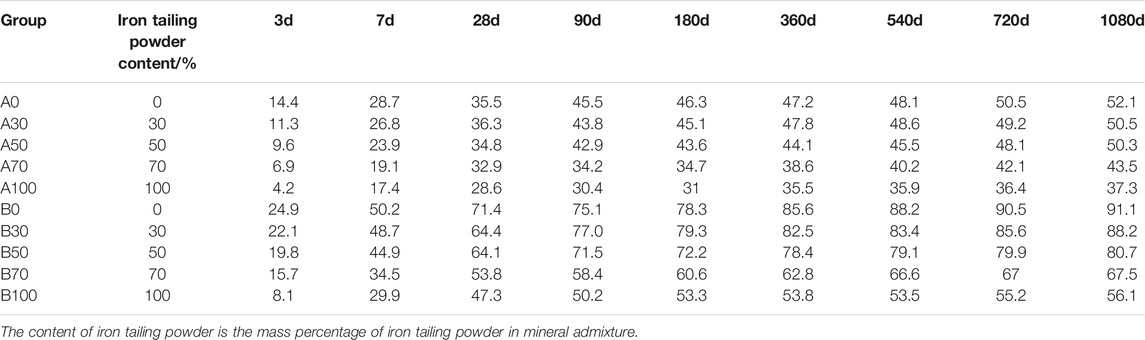

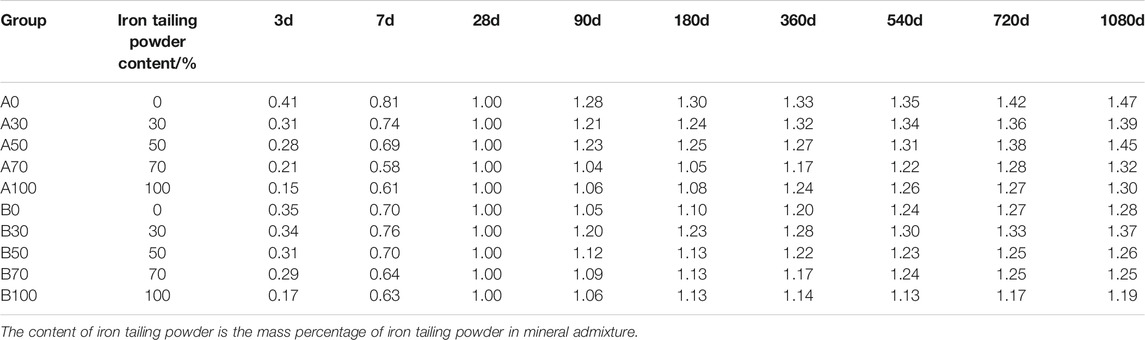

In order to explore the influence law of iron tailings powder on the long-term compressive strength of concrete, the 3, 7, 28, 90, 180, 270, 360, 540, 720, and 1080d compressive strength of C30 and C50 concrete were tested, respectively. The development law of concrete strength with age is shown in Table 8.

The results show that the strength of C30 and C50 concrete decreases with the increase of the iron tailings powder content. Iron tailings powder is a kind of non-active admixture, a very small amount of which can participate in the hydration reaction and produce less hydration products. Slag powder is a kind of mineral admixture with higher activity, which has a faster hydration reaction and can produce more hydration products, so it has higher strength. When the ratio of iron tailings powder to mineral admixtures (slag powder and iron tailings powder) is less than 50%, the compressive strength of concrete with different ages has little difference from that with single slag powder, The maximum reduction of compressive strength of C30 and C50 concrete at 28d was only 2.0 and 10.2% compared with that of the concrete with slag powder. When the proportion of iron tailings powder in a mineral admixture is more than 50%, the compressive strength of concrete at different ages decreases greatly compared with concrete mixed with slag powder alone. The maximum reduction ranges of 28d compressive strength are 19.4 and 33.8% compared with that of slag powder concrete. The content of iron tailing powder in concrete should not exceed 50% of the whole mineral admixture.

The influence of iron tailings powder on the strength of high-strength concrete (C50) is greater than that of low-strength concrete (C30). The reason is that high-strength concrete needs more cementitious materials, and the water–binder ratio is also relatively low. Although the addition of non-active admixtures can change the particle size distribution of cementitious materials to a certain extent, and the microaggregate effect can improve the performance of concrete, its effect is not as good as the hydration reaction of active admixtures. Therefore, the adverse effect of iron tailings powder on the strength of low-strength concrete is small, and the adverse effect of iron tailings powder on the strength of high-strength concrete is obvious. Therefore, in the design mix proportion of high-strength concrete, the amount of iron tailings powder should be reduced appropriately under the low clinker system. For example, when the proportion of iron tailings powder to a mineral admixture is 30%, the compressive strength of group B30 concrete is equivalent to that of group B0 concrete, even if at some age exceeds the strength of group B0. At the same time, the compressive strength of concrete can not only be based on the 28d compressive strength as the standard system in the case of introducing the non-active admixture iron tailings powder. The curing age should be extended so that the non-active admixture can give full play to its effect. For example, when the age reaches 90 days, the strength of concrete with iron tailings powder accounting for less than 50% of the mineral admixture is very close to that of concrete with slag powder alone; it is more suitable to evaluate the mechanical properties of concrete with inactive admixtures by the strength of longer age.

Relative Compressive Strength and the Age Prediction Model

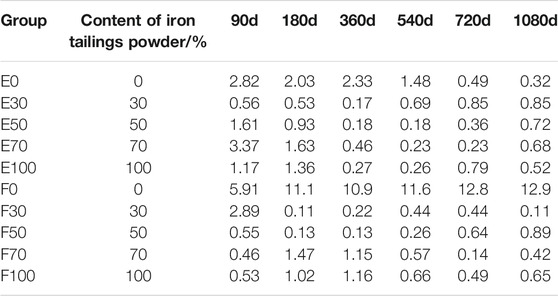

The 28d strength of concrete in each group was taken as the reference value 1, and the strength of other ages was divided by the 28d compressive strength to calculate the relative compressive strength of concrete at different ages, as shown in Table 9.

The addition of iron tailings powder is not conducive to the early strength of concrete, but the appropriate addition of iron tailings powder (30%) is conducive to the growth of long-term strength of concrete. From the point of view of long age, after 360 days, the strength development law of concrete with appropriate amount of iron tailings powder is similar to that of concrete with slag powder only. Taking 1080d strength as an example, the compressive strength of A50 group increased by 45% compared with 28d compressive strength.

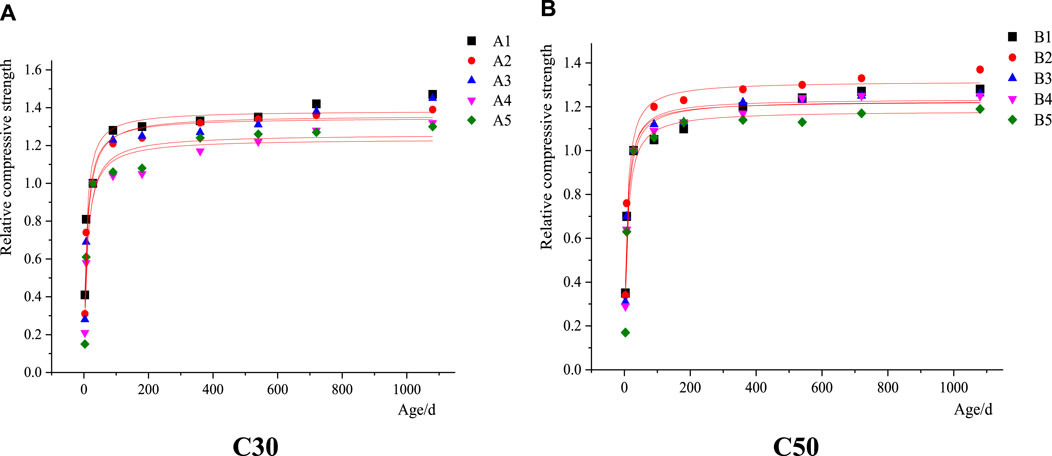

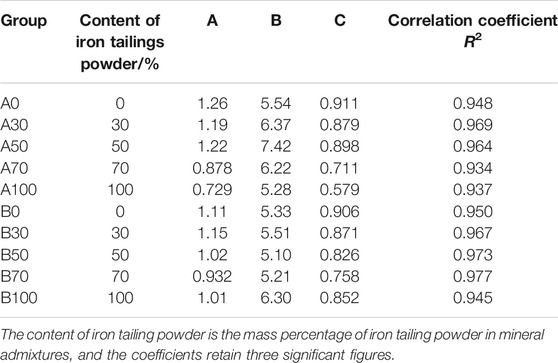

In order to study the relationship between compressive strength and age, the development model of compressive strength and age was established, which can provide theoretical basis for the prediction of long-term compressive strength of iron tailings powder concrete. By using the software to fit the curve of compressive strength and age of C30 and C50 concrete with different iron tailings powder contents, it is found that the regularity of single compressive strength and age is not strong, but the better regularity is found by using the relative compressive strength and age fitting of each age to 28d strength. The fitting curve is shown in Figure 3.

In order to more accurately determine the relationship between reaction intensity and age, three parameter equation is chosen as the fitting formula, and the fitting reliability is high. The formula is as follows:

In the formula, the fitting parameters of different concrete groups are shown in Table 10.

It can be seen from Table 10 that the range of parameters A, B, and C in the model of relative compressive strength and age relationship of iron tailings powder concrete is relatively concentrated, and the fitting correlation coefficient is also very high, all above 0.930, with a strong correlation, indicating that the model selection is more appropriate. Parameter A is related to the content of iron tailings powder. Parameter A increases with the increase of iron tailings powder contents. The A value of C30 concrete is between 0.7 and 1.3. The A value of group A5 with iron tailings powder is smaller and the dispersion is larger than that of the other four groups. The A value of C50 concrete is relatively concentrated, ranging from 0.9 to 1.2. It shows that the influence factor (parameter a) of non-active admixtures on the strength of iron tailings under the condition of low water–binder ratio is much smaller than that under the condition of high water binder ratio. The range of B value and C value in the model is relatively concentrated, except for the points with large individual dispersion, B value ranges from 5.10 to 6.30, and C value ranges from 0.711 to 0.911.

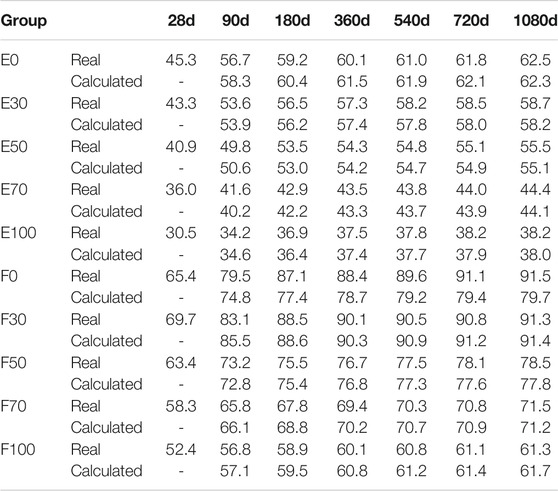

To verify the correctness of the prediction model, 30% of the original C30 concrete cement is increased to 40%, the original C50 concrete 40% cement content is increased to 50%, and the concrete is prepared according to the mix proportion shown in Table 9. Based on the measured value of 28d compressive strength, the compressive strength of different age is calculated according to the model, and compared with the measured value of the same age. The results are shown in Table 11.

In order to intuitively show the reliability of the relative compressive strength and age model, based on the experiment data of each age, the difference between the calculated value of the model and the real value is divided by the real value, and the error rate of strength predicted model is calculated, as shown in Table 12.

It can be seen from the above table that the prediction error of the relative compressive strength and age prediction model for E0 and F0 groups with single slag powder is relatively large, which indicates that the prediction effect of the concrete without iron tailings powder is general. However, the model has a good prediction effect on the strength of concrete mixed with iron tailings, and the prediction error of different proportion of iron tailings is relatively small. When the age is over 90 days, the error between the predicted value and the measured value is very small, and the error rate is basically within 1%. It shows that the model can effectively predict the long-term service strength of concrete based on the 28 days compressive strength, and the model has a good prediction effect on the long-term service performance of concrete.

This study has found out the influence of iron tailings powder and slag powder on the workability and long-term mechanical properties of concrete. The appropriate proportion of tailings powder and slag powder can increase the workability of concrete and contribute to the long-term strength. In the future research, we should pay attention to the long-term hydration mechanism of iron tailings powder and explore the hydration process of composite admixtures.

Conclusion

1) Appropriate addition of iron tailings powder is beneficial to the working performance of concrete and can effectively reduce the time loss of concrete fluidity.

2) When the content of iron tailings powder in the compound admixture is 50% or less, the mechanical properties of concrete are equivalent to that of the single slag powder concrete. The long-term strength of 1080d in C30 and C50 concrete can reach 50.3 and 80.7 MPa.

3) Based on the 28d compressive strength, the relative strength and age prediction model of iron tailings powder concrete is established. The calculation and experimental results show that the model can accurately predict the long-term compressive strength, and the error rate is less than 1%.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

LJ and WR conceived and designed the experiments; WR, CL, ZG, and ZY performed the experiments; SY contributed materials; WR and LJ wrote the article. All authors read and approved the manuscript.

Funding

This research was financially supported by the National Natural Science Foundation of China (No. 51834001) and Fundamental Research Funds for the Central Universities (FRF-BD-20-01B).

Conflict of Interest

SY was employed by CCCC-SHEC Third Highway Engineering Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Cao, S., Xue, G., Yilmaz, E., Yin, Z., and Yang, F. (2021b). Utilizing concrete Pillars as an Environmental Mining Practice in Underground Mines. J. Clean. Prod. 278, 123433. doi:10.1016/j.jclepro.2020.123433

Cao, S., Yilmaz, E., Yin, Z., Xue, G., Song, W., and Sun, L. (2021a). CT Scanning of Internal Crack Mechanism and Strength Behavior of Cement-Fiber-Tailings Matrix Composites. Cement and Concrete Composites 116, 103865. doi:10.1016/j.cemconcomp.2020.103865

Cao, S., Zheng, D., Yilmaz, E., Yin, Z., Xue, G., and Yang, F. (2020). Strength Development and Microstructure Characteristics of Artificial concrete Pillar Considering Fiber Type and Content Effects. Construction Building Mater. 256, 119408. doi:10.1016/j.conbuildmat.2020.119408

Habert, G., Miller, S. A., John, V. M., Provis, J. L., Favier, A., Horvath, A., et al. (2020). Environmental Impacts and Decarbonization Strategies in the Cement and concrete Industries. Nat. Rev. Earth Environ. 1 (11), 559–573. doi:10.1038/s43017-020-0093-3

Han, F., Li, L., Song, S., and Liu, J. (2017). Early-age Hydration Characteristics of Composite Binder Containing Iron Tailing Powder. Powder Techn. 315, 322–331. doi:10.1016/j.powtec.2017.04.022

Han, F., Song, S., Liu, J., and Huang, S. (2019). Properties of Steam-Cured Precast concrete Containing Iron Tailing Powder. Powder Techn. 345, 292–299. doi:10.1016/j.powtec.2019.01.007

Hou, Y. F., Liu, J. T., Zhao, S. R., and Peng, X. D. (2019). Effect Mechaniam of Iron Tailing Powder on Cement Mortar Properties. Joural Basic Sci. Eng. 27 (05), 1149–1157. doi:10.16058/j.issn.1005-0930.2019.05.018

Karthikeyan, B., Kathyayini, R., Aravindh Kumar, V., Uthra, V., and Senthil Kumaran, S. (2021). Effect of Dumped Iron Ore Tailing Waste as fine Aggregate with Steel and basalt Fibre in Improving the Performance of concrete. Mater. Today Proc. 2021. March. doi:10.1016/j.matpr.2021.01.906

Leong, Y.-K. (2021). Controlling the Rheology of Iron Ore Slurries and Tailings with Surface Chemistry for Enhanced Beneficiation Performance and Output, Reduced Pumping Cost and Safer Tailings Storage in Dam. Minerals Eng. 166, 106874. doi:10.1016/j.mineng.2021.106874

Li, J., Zhang, W., Li, C., and Monteiro, P. J. M. (2020a). Eco-friendly Mortar with High-Volume Diatomite and Fly Ash: Performance and Life-Cycle Assessment with Regional Variability. J. Clean. Prod. 261, 121224. doi:10.1016/j.jclepro.2020.121224

Li, J., Zhang, W., Xu, K., and Monteiro, P. J. M. (2020b). Fibrillar Calcium Silicate Hydrate Seeds from Hydrated Tricalcium Silicate Lower Cement Demand. Cement Concrete Res. 137, 106195. doi:10.1016/j.cemconres.2020.106195

Liu, W. B., Yao, H. Y., Wang, J. F., Chen, C. M., and Liu, Y. T. (2020). Current Situation of Comprehensive Utilization of Iron Tailings. Mater. Rep. 34 (Z1), 268–270.

Liu, Y. X., Li, X. G., Zhang, C. M., and Lv, B. N. (2019). Properties of Iron Tailing Sand Cement Based Grouting Material. J. Building Mater. 22 (04), 538–544. doi:10.3969/j.issn.1007-9629.2019.04.006

Lv, X., Shen, W., Wang, L., Dong, Y., Zhang, J., and Xie, Z. (2019). A Comparative Study on the Practical Utilization of Iron Tailings as a Complete Replacement of normal Aggregates in Dam concrete with Different Gradation. J. Clean. Prod. 211 (Nov), 704–715. doi:10.1016/j.jclepro.2018.11.107

Miller, S. A. (2018). Supplementary Cementitious Materials to Mitigate Greenhouse Gas Emissions from concrete: Can There Be Too Much of a Good Thing?. J. Clean. Prod. 178, 587–598. doi:10.1016/j.jclepro.2018.01.008

Pedro, D. D., Castro, G. B., Lima, M. M. F., and Lima, R. M. F. (2019). Characterisation and Magnetic Concentration of an Iron Ore Tailings. J. Mater. Res. Techn. 8 (1), 1052–1059. doi:10.1016/j.jmrt.2018.07.015

Protasio, F. N. M., Avillez, R. R., Letichevsky, S., and Silva, F. A. (2020). The Use of Iron Ore Tailings Obtained from the Germano Dam in the Production of a Sustainable concrete. J. Clean. Prod. 278, 123929. doi:10.1016/j.jclepro.2020.123929

Qi, C., and Fourie, A. (2019). Cemented Paste Backfill for mineral Tailings Management: Review and Future Perspectives. Minerals Eng. 144, 106025. doi:10.1016/j.mineng.2019.106025

Song, S. M., and Chen, H. Y. (2020). Influence of Iron Tailings Powder on Performance of Low Clinker Cementitious Material concrete. Bull. Chin. Ceram. Soc. 39 (08), 2557–2566. doi:10.16552/j.cnki.issn1001-1625.2020.08.026

Song, S. M., and Liu, X. D. (2017). Lnfluence of Iron Ore Tailings Powder on the Performance of High Fluidity concrete. Concrete 11, 77–80. doi:10.3969/j.issn.1002-3550.2017.11.018

Song, S. M., Zhang, L. Y., and Li, Z. Y. (2019). Effect of Iron Tailings Micropowder on Late-Property of Cement concrete. Concrete 01, 128–131+145. doi:10.3969/j.issn.1002-3550.2019.01.031

Wu, R. D., Zhang, G. T., and Wang, K. (2019). Study on Strength and Chloride Diffusion Coefficient of Iron Tailings Powder concrete. Construction Techn. 48 (03), 25–27+54. doi:10.7672/sgjs2019030025

Wu, R., and Liu, J. (2018). Experimental Study on the concrete with Compound Admixture of Iron Tailings and Slag Powder under Low Cement Clinker System. Adv. Mater. Sci. Eng. 2018, 1–7. 2018. doi:10.1155/2018/9816923

Wu, R., Liu, J., Zhang, G., Zhang, Y., and An, S. (2020). Research on Carbonation Characteristics and Frost Resistance of Iron Tailings Powder concrete under Low-Cement Clinker System. Adv. Mater. Sci. Eng. 2020, 1–11. doi:10.1155/2020/9192757

Keywords: iron tailings powder, slag, mechanical properties, workability, prediction model

Citation: Ruidong W, Yu S, Juanhong L, Linian C, Guangtian Z and Yueyue Z (2021) Effect of Iron Tailings and Slag Powders on Workability and Mechanical Properties of Concrete. Front. Mater. 8:723119. doi: 10.3389/fmats.2021.723119

Received: 10 June 2021; Accepted: 24 June 2021;

Published: 26 July 2021.

Edited by:

Lijie Guo, Beijing General Research Institute of Mining and Metallurgy, ChinaReviewed by:

Erol Yilmaz, Recep Tayyip Erdoğan University, TurkeyJiaqi Li, University of California, Berkeley, United States

Copyright © 2021 Ruidong, Yu, Juanhong, Linian, Guangtian and Yueyue. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Liu Juanhong, bGl1anVhbmhvbmc2NkAxMjYuY29t

Wu Ruidong

Wu Ruidong Shen Yu3

Shen Yu3 Cheng Linian

Cheng Linian