94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

CORRECTION article

Front. Mater., 18 September 2020

Sec. Structural Materials

Volume 7 - 2020 | https://doi.org/10.3389/fmats.2020.594883

This article is part of the Research TopicDual-phase Materials in the Medium and High Entropy Alloy Systems Al-Cr-Fe-Ni and Al-Co-Cr-Fe-NiView all 13 articles

This article is a correction to:

Laser Metal Deposition of Ultra-Fine Duplex AlCrFe2Ni2-Based High-Entropy Alloy

A Corrigendum on

Laser Metal Deposition of Ultra-fine Duplex AlCrFe2Ni2-based High-Entropy Alloy

by Molina, V. R., Weisheit, A., Gein, S., Hecht, U., and Vogiatzief, D. (2020). Front. Mater. 7:275. doi: 10.3389/fmats.2020.00275

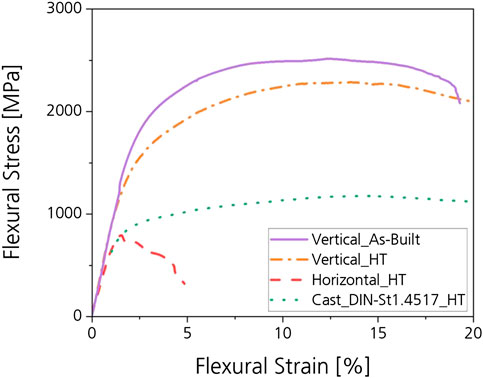

In the original article, there was a mistake in Figure 10 as published. The legend colors did not match to the depicted lines, which confuses the reader. The corrected Figure 10 appears below.

FIGURE 10. Bending test trendlines–stress (MPa) vs. strain (%) for laser material deposition fabricated B samples in as-built and heat-treated condition in a vertical build orientation (Vertical_As-Built, Vertical_HT), heat treated in a horizontal build orientation (Horizontal_HT), and a reference heat-treated DIN St.1.4517 cast sample material (Cast_DIN-St1.4517_HT).

The authors apologize for this error and state that this does not change the scientific conclusions of the article in any way. The original article has been updated.

Keywords: laser meterial deposition, high-entropy alloy, AlCrFeNi alloy, duplex microstructure, additive manufacturing

Citation: Molina VR, Weisheit A, Gein S, Hecht U and Vogiatzief D (2020) Corrigendum: Laser Metal Deposition of Ultra-Fine Duplex AlCrFe2Ni2-Based High-Entropy Alloy. Front. Mater. 7:594883. doi: 10.3389/fmats.2020.594883

Received: 14 August 2020; Accepted: 31 August 2020;

Published: 18 September 2020.

Approved by:

Frontiers Editorial Office, Frontiers Media SA, SwitzerlandCopyright © 2020 Molina, Weisheit, Gein, Hecht and Vogiatzief. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Veronica Rocio Molina, dmVyb25pY2EubW9saW5hQGlsdC5mcmF1bmhvZmVyLmRl

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.