- 1Louisiana State University, Center for Energy Studies, Baton Rouge, LA, United States

- 2National Renewable Energy Laboratory, Biosciences Center, Golden, CO, United States

Biohydrogen (bioH2) production in rural regions of the United States leveraged from existing biomass waste streams serves two extant needs: rural energy resiliency and decarbonization of heavy industry, including the production of ammonia and other H2-dependent nitrogenous products. We consider bioH2 production using two different strategies: (1) dark fermentation (DF) and (2) anaerobic digestion followed by steam methane reforming of the biogas (AD-SMR). Production of bioH2 from biomass waste streams is a potentially ‘greener’ pathway in comparison to natural gas-steam methane reforming (NG-SMR), especially as fugitive emissions from these wastes are avoided. It also provides a decarbonizing potential not found in water-splitting technologies. Based on literature on DF and AD of crop residues, woody biomass residues from forestry wastes, and wastewaters containing fats, oils, and grease (FOG), we outline scenarios for bioH2 production and displacement of fossil fuel derived methane. Finally, we compare the costs and carbon intensity (CI) of bioH2 production with those of other H2 production pathways.

1 Introduction

H2 production through renewables could play a major role in combating the effects of climate change via applications in industrial, transportation and utility/microgrid-scale electricity, provided the cost of production can be reduced. The Hydrogen Earthshot initiative (EERE, 2021) targets production of clean hydrogen at a cost of $1 per kg in 1 decade (“111”). Around 70 million metric tons (MMT) of H2 are produced annually, 10 MMT/year in the U.S., with 95% produced by steam methane reforming of natural gas (NG-SMR) at high temperatures and pressures, i.e., ‘grey H2’. The remainder is produced by gasification of coal and oil (Ferraren-De Cagalitan and Abundo, 2021). Process emissions and the use of natural gas as a precursor has led to interest in cleaner technologies and feedstocks for H2 production. While ‘green H2’ (produced using renewable energy, usually via electrolysis of water) has lower emissions than NG-SMR and gasification, those from biohydrogen (bioH2) can be even lower.

Ideally, bioH2 production leverages an integrated biorefinery where biomass collection, transport, separations of components, followed by valorization of intermediates through process streams, and complete utilization of the feedstock is achieved. BioH2 refineries can produce H2 from waste biomass either directly through dark fermentation (DF) or through anaerobic digestion followed by biogas SMR, among others. An ideal bioH2 refinery would, therefore, utilize process waste biomass residues that are locally available and produce H2 for use either as a source of fuel for electricity, or a feedstock for the manufacture of chemicals – allowing for industrial decarbonization.

For context in production cost and GHG emission, grey H2 has the lowest cost ~$1/kg H2, but also generates high greenhouse gas (GHG) emissions (Majumdar et al., 2021). It was estimated that median CO2 emissions from NG-SMR facilities in the US was ~9 kg CO2/kg H2 (or ~75 g CO2/MJ) (Sun et al., 2019). Cho, et. al (Cho et al., 2022). found that H2 production using NG-SMR led to direct GHG emissions of 9.35 kg CO2e/kg H2 (and 11.2 kg CO2e/kg H2 when upstream emissions of H2 production were included). This analysis further found that replacing fossil-derived CH4 with landfill gas and AD-derived biomethane (using animal manure) as feedstocks reduced the GHG potential by 68% and 54%, respectively. Other studies have found similar improvements to the life cycle carbon emissions of H2 production using vegetable oils (Marquevich et al., 2002) and biomass gasification (Susmozas et al., 2013), among others.

Several biological pathways exist to produce H2 as described here. Using water molecules (H2O) as the starting feedstock, biophotolysis (BP) uses sunlight to dissociate H2O into oxygen (O2) and hydrogen (H2) by photosynthetic organisms (Kamran, 2021). H2 can also be generated through photo-fermentation (PF) and dark fermentation (DF) using organic compounds as the starting feedstock. For photo-fermentation, specialized photosynthetic organisms (e.g., purple non-sulfur bacteria) use light energy to convert volatile fatty acids such as acetate, butyrate, lactate among others to H2 and CO2 without oxygen (Yin and Wang, 2022), whereas for dark fermentation, H2 is typically produced from carbohydrates (e.g., glucose, or more commonly known as “sugars”) anaerobically without light input (Kamran, 2021). Two-stage processes integrating PF and DF have also been explored. Amongst these processes, BP suffers low light conversion efficiency (Oh et al., 2013) and high oxygen sensitivity of hydrogenase that are specialized enzymes catalyzing the biosynthesis of H2 from protons (H+) and electrons (e-) (Ghirardi, 2015). While PF can achieve higher H2 yield than DF, growth rates of the photo-fermenting bacteria without oxygen are much lower and the H2 productivity of these bacteria is about two orders of magnitude lower than that of DF (Zhang and Zhang, 2018). In addition, high cost in feedstock pretreatment and enzymatic hydrolysis of lignocellulosic biomass that may be required for photo-fermentative H2 production renders it economically unfavorable. Taking these together, H2 production from DF remains compelling and favorable among biological processes. In-depth description of these processes is beyond the scope of this paper, but we point to relevant articles that discuss these (Manish and Banerjee, 2008). The term bioH2 herein refers to H2 produced using microbial pathways and those using biomass-based feedstocks.

BioH2 via DF using thermophilic bacteria offers sustainable H2 generation pathways with lower GHG emissions. Utilizing waste biomass sources (such as crop residues, municipal solid wastes, seafood industry wastes, etc.) for H2 production using DF can improve process economics due to reduced feedstock costs. An advantage of fermentative biological H2 production is reduced electricity demand—a current study estimated over 50% reduction in electricity requirement by DF-integrated with microbial electrolysis cell (MEC) compared with clean H2 produced by water electrolysis (Liu et al., 2022a). One of the challenges, however, is incomplete feedstock utilization by the microbial systems due to biomass recalcitrance and low accessibility to the sugars embedded in the biomass. Recent research has shown increased H2 production using Clostridium thermocellum engineered to co-utilize both cellulose and hemicellulose in waste plant biomass (i.e., lignocellulose) through consolidated bioprocessing (CBP) (Xiong et al., 2018; Chou et al., 2024).

Waste streams high in fats, oils, and grease (FOG), such as fish and seafood processing wastewaters, have the highest biogas potential, but also tend to adsorb to sludge and inhibit microbial activity (Holohan et al., 2022), particularly that of methanogens (Nges et al., 2012). Anaerobic co-digestion of various wet wastes with lignocellulosic feedstocks such as sugarcane bagasse, rice husks, corn stover, etc., which are rich in cellulose and hemicelluloses, is known to increase biogas and H2 production (Carver et al., 2011; Li et al., 2013; Bohutskyi et al., 2018; Adarme et al., 2019; Fernando Herrera Adarme et al., 2022). Anaerobic co-digestion of FOG with high fiber feedstocks can improve biomethane potential (BMP), dilute toxins, improve nutrient balance, and allow for increasing the load of biodegradable organic matter (Shah et al., 2015). Blending carbohydrate-rich crop residues could be reasonably expected to enhance bioH2 production from seafood industry wastes and wastewaters through added minerals and nutrients as well as diluting inhibitory compounds.

Sparging to lower the partial pressure of H2 in the reactor can also enhance H2 production (Kim et al., 2023). Biogas CH4 is separated from CO2 and trace gases such as H2S, NH3, CO, etc. using processes such as temperature and pressure swing adsorption, pressurized water scrubbing, membrane separations, etc (Chen et al., 2015). Due to their lower installation and operational costs, membranes represent a cost-effective solution for recovery of biomethane in high purity. Biogas can be upgraded through multiple reforming processes (Kumar et al., 2022), resulting in H2 production with lower GHG emissions compared to NG-SMR. Siloxanes, sulfur species, and other gases should be removed to increase reaction specificity and reduce energy consumption (Zhao et al., 2020). Biogas reforming can also overcome the theoretical Thauer limit of DF processes (4 mol H2 per mol glucose).

2 Technoeconomics and emissions associated with H2 production

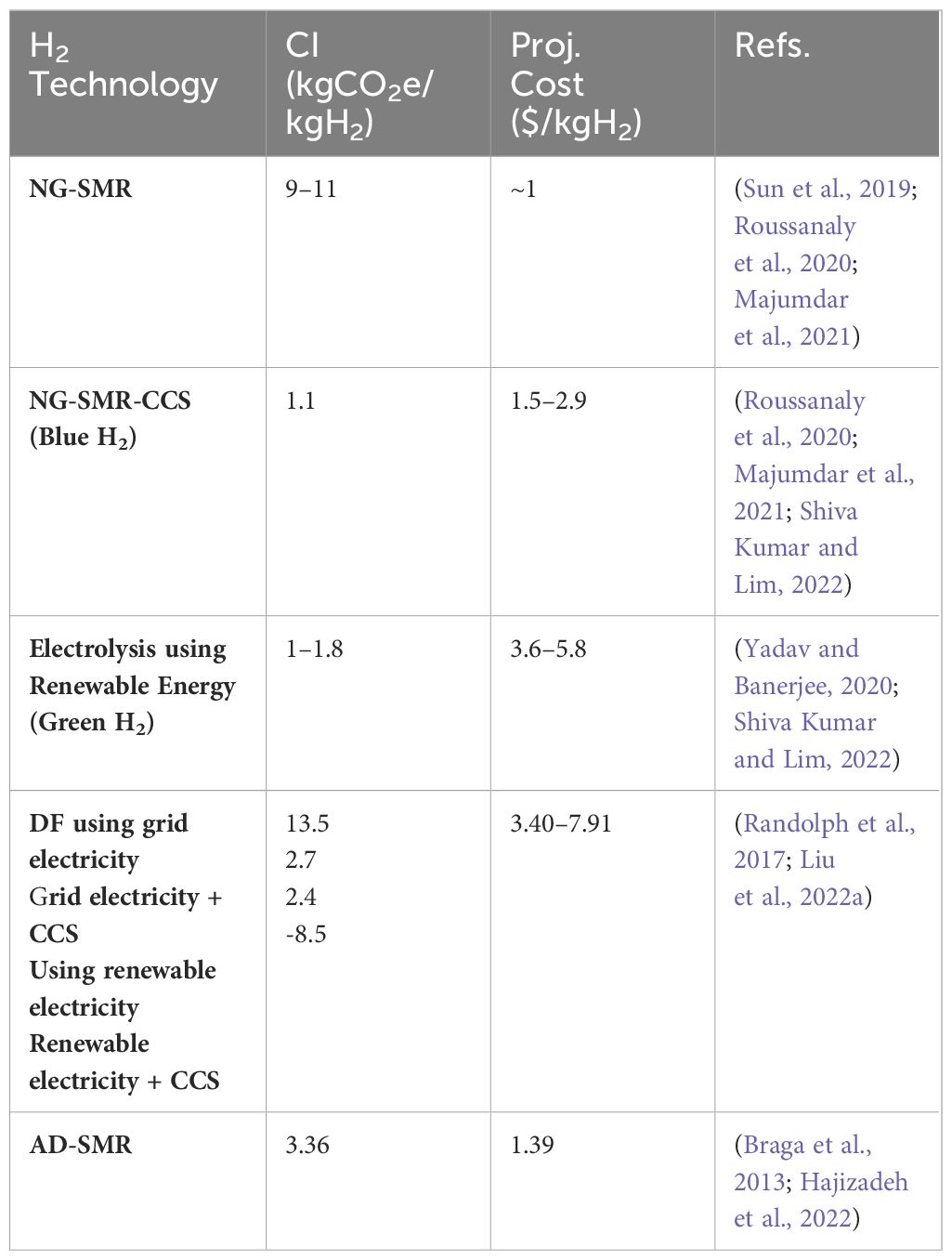

The net energy ratio (NER) for three different bioH2 production technologies was calculated, and it was found that gasification of forest residues via the Gas Technology Institute (GTI) gasifier resulted in the highest NER (of 9.3) with GHG emissions ranging between 1.2 to 8.1 kgCO2e/kgH2 (Kabir and Kumar, 2011). Manish and Banerjee (2008) compare the efficiency and emissions from several biohydrogen production processes with those of NG-SMR. DF was compared with PF, a two-stage process combining DF and PF, and bio-catalyzed electrolysis, and it was found that efficiencies of the fermentative approaches improved in comparison to NG-SMR when removal and utilization of by-products from the former was considered. Carbon capture and storage (CCS) is another aspect of H2 production that can reduce emissions. It can potentially add to the costs or offsets cost through decarbonizing tax credits (e.g., IRA 45Q). Modeling scenarios project that up to 80% of CO2 emissions in NG-SMR can be inexpensively abated, whereas the remainder of the 20% are expensive to avoid (Pruvost et al., 2022). Table 1 shows a compilation of some of the reported findings on emissions from various H2 production pathways. In general, the source of electricity plays a key role in carbon intensity. As exemplified by DF, CI is substantially lower when renewable electricity is utilized compared to grid electricity. When renewable electricity is utilized for bioH2 production followed by CCS, there is a removal of CO2 per kilogram H2 generated (Table 1), providing a decarbonization potential not associated with H2 production from water-splitting technologies. In essence, not only can biological H2 displace energy demands currently filled by fossil-derived energies, concentrated streams of CO2 co-released during the oxidation of organic compounds for the production of bioH2 from DF can be removed (Lou et al., 2023) through point-source carbon capture rather than direct air capture (DAC), with the latter generally understood to be more energy intensive.

Based on recent technoeconomic analysis for H2 production via dark fermentation through consolidated bioprocessing (CBP) configuration (van Zyl et al., 2007), top drivers for the production cost are capital expenses (CAPEX) in the bioreactor and cost associated with the feedstock (Randolph et al., 2017). As the cost of the bioreactor directly correlates with bioreactor footprint, economic DF must operate at high loadings of lignocellulosic biomass at high H2 yield for a given amount of feedstock while minimizing bioreactor footprint. Efficient feedstock deconstruction, utilization, and conversion to H2 in this condition is therefore a priority for ongoing research and development through which novel chassis organisms and bioprocess designs are pursued.

3 BioH2 in rural energy resiliency

BioH2 can impact energy resiliency where access to reliable energy is a concern. Disaster recovery and energy resilience are not equitably distributed—rural areas witness disproportionate impacts and have been shown to be less energy-resilient than urban regions (Mitsova et al., 2018). Grid susceptibility is likely to worsen due to the projected increased frequency of tropical storms as a result of climate change in combination with aging grid infrastructure (Casey et al., 2020). Existing power systems that are reliable under ‘normal conditions’ are not necessarily resilient under high-impact events (Panteli and Mancarella, 2015; Hussain et al., 2019). Emergency diesel generators (EDGs) are the main source for backup power during extended power outages (Phillips et al., 2016) and can be unreliable (Marqusee and Jenket, 2020), contribute to greenhouse gas emissions (Jakhrani et al., 2012), require expensive transported fuel, and have negative human health impacts due to exhaust exposure (Gilmore et al., 2006; Gilmore et al., 2010). Microgrids (groups of interconnected loads and distributed energy resources that act as singular entities and have the ability to operate in either grid-connected or island modes) are increasingly suggested as alternatives to EDGs for reliable backup power during disasters (Callaway et al., 2014). The benefit of microgrids during power disruptions is that they can avail local energy assets to improve costs and reliability, particularly for rural areas (NREL, 2023). Solar photovoltaics (PV) and wind energy have been typical microgrid candidates, however, the stochastic nature of these requires the inclusion of backup power sources, historically fossil fuel-based (Singh et al., 2016). Utilizing biomass resources such as those generated from agricultural operations or the vision of utilizing renewable carbons sourced from biogenic waste streams (Langholtz, 2024) for backup power can reduce the carbon footprint of microgrids and improve their life cycle emissions (Aberilla et al., 2019), while improving energy resiliency.

BioH2 production can be leveraged for energy resiliency as microgrids, either by combustion for power or through the deployment of H2 fuel cells, the latter having the advantage of instantaneous deployment. Rural microgrids have been evaluated as hybrid systems based on solar photovoltaic (PV) or other renewable energy technologies in combination with biomass-based energy. Many of these analyses have been conducted for other nations and typically involve thermochemical biomass conversion (combustion or gasification) (Mazzola et al., 2016; Kaur et al., 2020; Ribó-Pérez et al., 2021; Singh and Basak, 2022). Similarly, H2 fuel cells have been evaluated as potential electrification devices in rural and remote areas (Cotrell and Pratt, 2003; Munuswamy et al., 2011). Taking this further, there is the potential for bioH2 to play key roles in rural electrification and energy resiliency (especially in the aftermath of emergencies) in the form of microgrids or fuel cells, especially when incorporating biomass waste residues generated in these communities.

4 BioH2 in chemical manufacturing

Of the three waves of clean H2 adoption proposed in the 2023 DOE National Clean Hydrogen Strategy and Roadmap (DOE, 2023), NH3 production was identified as the second-largest captive market following refining, and was suggested to provide a stable market for clean H2. Current consumption of H2 produced from NG-SMR is primarily due to chemical manufacturing of NH3. Due to its high energy density and ease of shipping internationally, NH3 is considered an energy carrier and has applications as a direct fuel source in the electricity, transportation, and heating sectors (Nayak-Luke et al., 2018; Joseph Sekhar et al., 2024). Approximately 80% of industrial NH3 production is used for fertilizer, indicating bioH2 for NH3 production could play a major role in decarbonizing agriculture (Yüzbaşıoğlu et al., 2022). Each ton of NH3 produced via NG-SMR and tertiary reactions generates 2.6 tons of GHG emissions over its life cycle (Liu et al., 2020) (or 114.4 g CO2e/MJ (Busch et al., 2023)); NH3 production can be attributed to 2% of worldwide fossil fuel consumption, resulting in 420 million tons of CO2 emissions each year (Liu et al., 2020). In a life cycle assessment study (Singh et al., 2018) comparing several pathways for NH3 production, it was found that NG-SMR and coal gasification led to the greatest carbon intensity (CI) of 3.85 kg CO2e/kg NH3, whereas biomass gasification led to the lowest CI of 0.38 kg CO2e/kg NH3. Local production of bioH2 as a feedstock for this NH3 production capacity can aid in emissions reductions and, therefore, decarbonize a hard-to-abate sector. ‘Green NH3’, produced from bioH2, can reduce the GHG burdens and CI associated with the fossil fuel based SMR process.

5 Impact on energy equity for rural, disadvantaged communities

Applications of bioenergy (including biofuels) in a rural perspective have previously been explored (Hiloidhari et al., 2020), leveraging particularly the agroforestry industries in these regions (Dubois and Kristensen, 2018). A Hungarian study found that rural ethanol-producing biorefineries can stimulate employment and drive rural development (Heijman et al., 2019). Stöhr et al. developed a rural-centric outline to establish a bioH2 value chain comprised of 7 steps that differentiate rural needs from urban. This study incorporated distinctions between urban and rural environments by focusing on a central supply chain (hub concept) versus a distributed/decentralized supply chain, with pros and cons for each type. They also suggest that community engagement between population, industry, and stakeholders is critical when it comes to acceptance and sustainability of hydrogen production technologies in rural regions (Stöhr et al., 2024). As conventional H2 production is energy intensive, bioH2 also provides more opportunities for energy-poor areas as it only requires organic waste and water for production (Goria et al., 2022). An interesting recent development is technology to convert diesel engines to run on H2 or diesel/H2 blends (Liu et al., 2022b). In addition to multiple efforts in developing rural H2 from electrolysis with renewable energy, efforts are underway to transition rural communities to bioH2, including transitioning from diesel to dual fuel to H2 powered generators (ABB in Australia) (ABB, 2023) and exploring bioH2 from biogas (European Biogas Association) (EBA, 2024).

6 Discussion

Biohydrogen represents a clean, renewable, low-carbon energy source for industrial and flexible-scale use. The potential of producing bioH2 from waste biomass material provides production options that do not rely on sunlight or wind and can be bolted on or adapted to existing waste digestors. Rural communities particularly stand to benefit from this approach as they tend to be spatially more distributed (compared to urban areas), have existing waste and agricultural feedstocks available, and are subject to elevated energy cost and limited supply chain due to transportation costs and logistics of bringing in outside fuels and power. As part of a biorefinery, bioH2 production can deliver localized energy security to communities, especially during disruptive weather or natural disasters, while enabling other fuels, chemicals, and bioproducts to be produced locally. Depending on the local energy needs and resources, bioH2 could be augmented with H2 from electrolysis when excess renewable electricity is available from wind or solar. Advances in converting diesel engines to run on H2 or H2/diesel blends makes bioH2 even more attractive as a locally produced, renewable fuel, especially during energy disruptions in rural areas reliant on generators.

There is a substantial knowledge gap on operational data and performance pertaining to not only commercial-scale but also pilot-scale bioH2 systems, a fact underscored by uncertainties associated with scaleup (Zhang et al., 2024). To our knowledge, there are few commercial-scale projects that have been announced globally. A project based in the United Kingdom integrates AD with DF to produce bioH2 and NH3 from feedstock such as chicken litter (EcoScience, A, 2024). An operation based in Czechia supplies modular units ranging between 40 to 120 Nm3/h H2 to produce bioH2 via AD-SMR (Mega, 2024). The nascent stage of current implementation of bioH2 is evidence for greater R&D efforts in this area—the realization of a bioH2 economy will require persistent R&D with concerted effort in genome editing to produce robust microbial consortia which can metabolize seasonally-varying organic waste streams (e.g., changes in feedstock quality due to prevailing weather, or introduction of new feedstock blends depending on availability, etc.). Addressing the production cost of hydrogen and efforts to bring it within parity of costs associated with NG-SMR will require innovative solutions, particularly strategies which can integrate bioH2 production methods, such as DF and PF, and with other co-products which can improve energy recovery compared to a single-stage H2 production process (Brar et al., 2022). Technoeconomic assessments of niche applications of bioH2 as a source of energy (as discussed in Section 4) are needed in scenarios where the lack of access to reliable energy can lead to loss of life; such studies can incentivize bioH2 even if it is not currently cost-competitive against the current grid mix. Along with the applications of H2 as a fuel source, it would be prudent to explore additional applications, including H2 utilization in biomass/crude oil upgrading, production of synthetic fuels and chemicals, reduction of iron in steelmaking, and finally, NH3 production, which was briefly discussed in Section 5 (Elgowainy et al., 2020). We suggest that concerted efforts in laboratory and pilot-scale R&D, technoeconomic, life-cycle, and regio-specific sociological are necessary to realize the true potential of a bioH2 economy.

Author contributions

AM: Writing – original draft, Writing – review & editing. KC: Writing – original draft, Writing – review & editing. SD: Writing – original draft, Writing – review & editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This work was authored by the National Renewable Energy Laboratory (NREL), operated by Alliance for Sustainable Energy, LLC, for the U.S. Department of Energy (DOE) under Contract No. DE-AC36-08GO28308. Funding was provided by DOE Hydrogen and Fuel Cell Technologies Office (HFTO).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declared that they were an editorial board member of Frontiers, at the time of submission. This had no impact on the peer review process and the final decision.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

ABB (2023) A vision for green hydrogen powering remote regions (ABB). Available online at: https://new.abb.com/news/detail/107646/a-vision-for-green-hydrogen-powering-remote-regions (Accessed 9 April 2024).

Aberilla J. M., Gallego-Schmid A., Azapagic A. (2019). Environmental sustainability of small-scale biomass power technologies for agricultural communities in developing countries. Renewable Energy 141, 493–506. doi: 10.1016/j.renene.2019.04.036

Adarme O. F. H., Baeta B. E. L., Filho J. B. G., Gurgel L. V. A., Aquino S. F. (2019). Use of anaerobic co-digestion as an alternative to add value to sugarcane biorefinery wastes. Bioresour Technol. 287, 121443. doi: 10.1016/j.biortech.2019.121443

Bohutskyi P., Phan D., Kopachevsky A. M., Chow S., Bouwer E. J., Betenbaugh M. J. (2018). Synergistic co-digestion of wastewater grown algae-bacteria polyculture biomass and cellulose to optimize carbon-to-nitrogen ratio and application of kinetic models to predict anaerobic digestion energy balance. Bioresour Technol. 269, 210–220. doi: 10.1016/j.biortech.2018.08.085

Braga L. B., Silveira J. L., da Silva M. E., Tuna C. E., Machin E. B., Pedroso D. T. (2013). Hydrogen production by biogas steam reforming: A technical, economic and ecological analysis. Renewable Sustain. Energy Rev. 28, 166–173. doi: 10.1016/j.rser.2013.07.060

Brar K. K., Cortez A. A., Pellegrini V. O. A., Amulya K., Polikarpov I., Magdouli S., et al. (2022). An overview on progress, advances, and future outlook for biohydrogen production technology. Int. J. Hydrogen Energy 47, 37264–37281. doi: 10.1016/j.ijhydene.2022.01.156

Busch P., Kendall A., Lipman T. (2023). A systematic review of life cycle greenhouse gas intensity values for hydrogen production pathways. Renewable Sustain. Energy Rev. 184, 113588. doi: 10.1016/j.rser.2023.113588

Callaway D. W., Noste E., McCahill P. W., Rossman A. J., Lempereur D., Kaney K., et al. (2014). Time for a revolution: smart energy and microgrid use in disaster response. Disaster Med. Public Health Preparedness 8, 252–259. doi: 10.1017/dmp.2014.39

Carver S. M., Hulatt C. J., Thomas D. N., Tuovinen O. H. (2011). Thermophilic, anaerobic co-digestion of microalgal biomass and cellulose for H2 production. Biodegradation 22, 805–814. doi: 10.1007/s10532-010-9419-z

Casey J. A., Fukurai M., Hernández D., Balsari S., Kiang M. V. (2020). Power outages and community health: a narrative review. Curr. Environ. Health Rep. 7, 371–383. doi: 10.1007/s40572-020-00295-0

Chen X. Y., Vinh-Thang H., Ramirez A. A., Rodrigue D., Kaliaguine S. (2015). Membrane gas separation technologies for biogas upgrading. RSC Adv. 5, 24399–24448. doi: 10.1039/C5RA00666J

Cho H. H., Strezov V., Evans T. J. (2022). Environmental impact assessment of hydrogen production via steam methane reforming based on emissions data. Energy Rep. 8, 13585–13595. doi: 10.1016/j.egyr.2022.10.053

Chou K. J., Croft T., Hebdon S. D., Magnusson L. R., Xiong W., Reyes L. H., et al. (2024). Engineering the cellulolytic bacterium, Clostridium thermocellum, to co-utilize hemicellulose. Metab. Eng. 83, 193–205. doi: 10.1016/j.ymben.2024.03.008

Cotrell J., Pratt W. (2003). Modeling the feasibility of using fuel cells and hydrogen internal combustion engines in remote renewable energy systems (Golden, CO (United States: National Renewable Energy Lab.(NREL).

DOE (2023). U.S. National clean hydrogen strategy and roadmap (Washington, DC: Taylor & Francis). Available at: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/us-national-clean-hydrogen-strategy-roadmap.pdf.

Dubois A., Kristensen I. (2018). “The role of biorefineries in the revitalisation of (old) industrial rural regions,” in Strategic approaches to regional development(Routledge: Taylor & Francis), 125–142.

EBA (2024) Biohydrogen’s take into the net-zero equation (European Biogas Association). Available online at: https://www.europeanbiogas.eu/biohydrogens-take-into-the-net-zero-equation (Accessed 9 April 2024).

EcoScience, A (2024) ALPS Ecoscience and Ixora Energy Pave the Way for a new era of Sustainable Energy with Biohydrogen Commercialisation. Available online at: https://www.alpsecoscience.co.uk/biohydrogen-commercialisation.

EERE (2021). Hydrogen shot (Washington, DC: US department of energy). Available at: https://www.energy.gov/eere/fuelcells/hydrogen-shot.

Elgowainy A., Mintz M., Lee U., Stephens T., Sun P., Reddi K., et al. (2020). Assessment of potential future demands for hydrogen in the United States (Argonne, IL (United States: Argonne National Lab.(ANL).

Fernando Herrera Adarme O., Eduardo Lobo Baeta B., Cardoso Torres M., Camilo Otalora Tapiero F., Vinicius Alves Gurgel L., de Queiroz Silva S., et al. (2022). Biogas production by anaerobic co-digestion of sugarcane biorefinery byproducts: Comparative analyses of performance and microbial community in novel single-and two-stage systems. Bioresour Technol. 354, 127185. doi: 10.1016/j.biortech.2022.127185

Ferraren-De Cagalitan D. D. T., Abundo M. L. S. A. (2021). review of biohydrogen production technology for application towards hydrogen fuel cells. Renewable Sustain. Energy Rev. 151, 111413. doi: 10.1016/j.rser.2021.111413

Ghirardi M. L. (2015). Implementation of photobiological H2 production: the O2 sensitivity of hydrogenases. Photosynthesis Res. 125, 383–393. doi: 10.1007/s11120-015-0158-1

Gilmore E. A., Adams P. J., Lave L. B. (2010). Using backup generators for meeting peak electricity demand: A sensitivity analysis on emission controls, location, and health endpoints. J. Air Waste Manage. Assoc. 60, 523–531. doi: 10.3155/1047-3289.60.5.523

Gilmore E. A., Lave L. B., Adams P. J. (2006). The costs, air quality, and human health effects of meeting peak electricity demand with installed backup generators. Environ. Sci. Technol. 40, 6887–6893. doi: 10.1021/es061151q

Goria K., Kothari R., Singh H. M., Singh A., Tyagi V. V. (2022). “Chapter 20 - Biohydrogen: potential applications, approaches, and hurdles to overcome,” in Handbook of biofuels. Ed. Sahay S. (Cambridge, MA: Academic Press), 399–418.

Hajizadeh A., Mohamadi-Baghmolaei M., Cata Saady N. M., Zendehboudi S. (2022). Hydrogen production from biomass through integration of anaerobic digestion and biogas dry reforming. Appl. Energy 309, 118442. doi: 10.1016/j.apenergy.2021.118442

Heijman W., Szabó Z., Veldhuizen E. (2019). The contribution of biorefineries to rural development: the case of employment in Hungary. Stud. Agric. Economics 121, 1–13. doi: 10.7896/issn.2063-0476

Hiloidhari M., Bhuyan N., Gogoi N., Seth D., Garg A., Singh A., et al. (2020). “16 - Agroindustry wastes: biofuels and biomaterials feedstocks for sustainable rural development,” in Refining biomass residues for sustainable energy and bioproducts. Eds. Kumar R. P., Gnansounou E., Raman J. K., Baskar G. (Cambridge, MA: Academic Press), 357–388.

Holohan B. C., Duarte M. S., Szabo-Corbacho M. A., Cavaleiro A. J., Salvador A. F., Pereira M. A., et al. (2022). Principles, advances, and perspectives of anaerobic digestion of lipids. Environ. Sci. Technol. 56, 4749–4775. doi: 10.1021/acs.est.1c08722

Hussain A., Bui V.-H., Kim H.-M. (2019). Microgrids as a resilience resource and strategies used by microgrids for enhancing resilience. Appl. Energy 240, 56–72. doi: 10.1016/j.apenergy.2019.02.055

Jakhrani A. Q., Rigit A. R. H., Othman A. K., Samo S. R., Kamboh S. A. (2012). “Estimation of carbon footprints from diesel generator emissions,” 2012 International Conference on Green and Ubiquitous Technology, Bandung, Indonesia, pp. 78–81. doi: 10.1109/GUT.2012.6344193

Joseph Sekhar S., Samuel M. S., Glivin G., Le T. G., Mathimani T. (2024). Production and utilization of green ammonia for decarbonizing the energy sector with a discrete focus on Sustainable Development Goals and environmental impact and technical hurdles. Fuel 360, 130626. doi: 10.1016/j.fuel.2023.130626

Kabir R., Kumar A. (2011). Development of net energy ratio and emission factor for biohydrogen production pathways. Bioresour. Technol. 102 (19), 8972–8985. doi: 10.1016/j.biortech.2011.06.093

Kamran M. (2021). “Chapter 8 - bioenergy,” in Renewable energy conversion systems. Eds. Kamran M., Fazal M. R. (Cambridge, MA: Academic Press), 243–264.

Kaur M., Dhundhara S., Verma Y. P., Chauhan S. (2020). Techno-economic analysis of photovoltaic-biomass-based microgrid system for reliable rural electrification. Int. Trans. Electrical Energy Syst. 30, e12347. doi: 10.1002/2050-7038.12347

Kim C., Wolf I., Dou C., Magnusson L., Maness P.-C., Chou K. J., et al. (2023). Coupling gas purging with inorganic carbon supply to enhance biohydrogen production with Clostridium thermocellum. Chem. Eng. J. 456, 141028. doi: 10.1016/j.cej.2022.141028

Kumar R., Kumar A., Pal A. (2022). Overview of hydrogen production from biogas reforming: Technological advancement. Int. J. Hydrogen Energy 47, 34831–34855. doi: 10.1016/j.ijhydene.2022.08.059

Li Y., Zhang R., Chen C., Liu G., He Y., Liu X. (2013). Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour Technol. 149, 406–412. doi: 10.1016/j.biortech.2013.09.091

Liu X., Bafana A., Sun P., Elgowainy A., Chou K. J., Beliaev A., et al. (2022a). “Techno-economic analysis and life cycle assessment of bio-based hydrogen production from integrated dark-fermentation and microbial electrolysis cells,” in 2022 AIChE Annual Meeting. AIChE.

Liu X., Elgowainy A., Wang M. (2020). Life cycle energy use and greenhouse gas emissions of ammonia production from renewable resources and industrial by-products. Green Chem. 22, 5751–5761. doi: 10.1039/D0GC02301A

Liu X., Seberry G., Kook S., Chan Q. N., Hawkes E. R. (2022b). Direct injection of hydrogen main fuel and diesel pilot fuel in a retrofitted single-cylinder compression ignition engine. Int. J. Hydrogen Energy 47, 35864–35876. doi: 10.1016/j.ijhydene.2022.08.149

Lou Y., Fan Z., Friedmann J., Corbeau A.-S., Agarwal M., Khatri A. (2023). The potential role of biohydrogen in creating a net-zero world: the production and applications of carbon-negative hydrogen (New York, NY: Columbia University). Available at: https://www.energypolicy.columbia.edu/wp-content/uploads/2023/01/Biohydrogen-report-designed-12.21.22-with-Jan-update-1.5.23.pdf.

Majumdar A., Deutch J. M., Prasher R. S., Griffin T. P. (2021). A framework for a hydrogen economy. Joule 5, 1905–1908. doi: 10.1016/j.joule.2021.07.007

Manish S., Banerjee R. (2008). Comparison of biohydrogen production processes. Int. J. Hydrogen Energy 33, 279–286. doi: 10.1016/j.ijhydene.2007.07.026

Marquevich M., Sonnemann G. W., Castells F., Montané D. (2002). Life cycle inventory analysis of hydrogen production by the steam-reforming process: comparison between vegetable oils and fossil fuels as feedstock. Green Chem. 4, 414–423. doi: 10.1039/B203742B

Marqusee J., Jenket D. (2020). Reliability of emergency and standby diesel generators: Impact on energy resiliency solutions. Appl. Energy 268, 114918. doi: 10.1016/j.apenergy.2020.114918

Mazzola S., Astolfi M., Macchi E. (2016). The potential role of solid biomass for rural electrification: A techno economic analysis for a hybrid microgrid in India. Appl. Energy 169, 370–383. doi: 10.1016/j.apenergy.2016.02.051

Mega (2024) Biohydroge production from biomethane. Available online at: https://www.mega.cz/biohydrogen/#mega-biohydrogen.

Mitsova D., Esnard A.-M., Sapat A., Lai B. S. (2018). Socioeconomic vulnerability and electric power restoration timelines in Florida: the case of Hurricane Irma. Natural Hazards 94, 689–709. doi: 10.1007/s11069-018-3413-x

Munuswamy S., Nakamura K., Katta A. (2011). Comparing the cost of electricity sourced from a fuel cell-based renewable energy system and the national grid to electrify a rural health centre in India: A case study. Renewable Energy 36, 2978–2983. doi: 10.1016/j.renene.2011.03.041

Nayak-Luke R., Bañares-Alcántara R., Wilkinson I. (2018). Green” ammonia: impact of renewable energy intermittency on plant sizing and levelized cost of ammonia. Ind. Eng. Chem. Res. 57, 14607–14616. doi: 10.1021/acs.iecr.8b02447

Nges I. A., Mbatia B., Björnsson L. (2012). Improved utilization of fish waste by anaerobic digestion following omega-3 fatty acids extraction. J. Environ. Manage. 110, 159–165. doi: 10.1016/j.jenvman.2012.06.011

NREL (2023). Microgrids (Golden, CO: National renewable energy laboratory). Available at: https://www.nrel.gov/grid/microgrids.html.

Oh Y.-K., Raj S. M., Jung G. Y., Park S. (2013). “Chapter 3 - metabolic engineering of microorganisms for biohydrogen production,” in Biohydrogen. Eds. Pandey A., Chang J.-S., Hallenbecka P. C., Larroche C. (Burlington, MA: Elsevier), 45–65.

Panteli M., Mancarella P. (2015). Influence of extreme weather and climate change on the resilience of power systems: Impacts and possible mitigation strategies. Electric Power Syst. Res. 127, 259–270. doi: 10.1016/j.epsr.2015.06.012

Phillips J. A., Wallace K. E., Kudo T. Y., Eto J. H. (2016). Onsite and electric power backup capabilities at critical infrastructure facilities in the United States. Argonne Natl. Laboratory April 10, 1–58.

Pruvost F., Cloete S., Arnaiz del Pozo C., Zaabout A. (2022). Blue, green, and turquoise pathways for minimizing hydrogen production costs from steam methane reforming with CO2 capture. Energy Conversion Manage. 274, 116458. doi: 10.1016/j.enconman.2022.116458

Randolph K., Studer S., Liu H., Beliaev A., Holladay J. (2017). Hydrogen production cost from fermentation. DOE Hydrogen and Fuel Cells Program Record 16016. Available at: https://www.hydrogen.energy.gov/docs/hydrogenprogramlibraries/pdfs/16016_h2_production_cost_fermentation.pdf?Status=Master.

Ribó-Pérez D., Herraiz-Cañete Á., Alfonso-Solar D., Vargas-Salgado C., Gómez-Navarro T. (2021). Modelling biomass gasifiers in hybrid renewable energy microgrids; a complete procedure for enabling gasifiers simulation in HOMER. Renewable Energy 174, 501–512. doi: 10.1016/j.renene.2021.04.083

Roussanaly S., Anantharaman R., Fu C. (2020). Low-carbon footprint hydrogen production from natural gas: A techno-economic analysis of carbon capture and storage from steam-methane reforming. Chem. Eng. Trans. 81, 1015–1020. doi: 10.3303/CET2081170

Shah F. A., Mahmood Q., Rashid N., Pervez A., Raja I. A., Shah M. M. (2015). Co-digestion, pretreatment and digester design for enhanced methanogenesis. Renewable Sustain. Energy Rev. 42, 627–642. doi: 10.1016/j.rser.2014.10.053

Shiva Kumar S., Lim H. (2022). An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 8, 13793–13813. doi: 10.1016/j.egyr.2022.10.127

Singh A., Basak P. (2022). Conceptualization and techno-economic evaluation of municipal solid waste based microgrid. Energy 238, 121711. doi: 10.1016/j.energy.2021.121711

Singh V., Dincer I., Rosen M. A. (2018). “Chapter 4.2 - life cycle assessment of ammonia production methods,” in Exergetic, energetic and environmental dimensions. Eds. Dincer I., Colpan C. O., Kizilkan O. (Cambridge, MA: Academic Press), 935–959.

Singh S., Singh M., Kaushik S. C. (2016). Feasibility study of an islanded microgrid in rural area consisting of PV, wind, biomass and battery energy storage system. Energy Conversion Manage. 128, 178–190. doi: 10.1016/j.enconman.2016.09.046

Stöhr T., Wohlmuth B., Kutz J., Lesemann L., Pletz S., Zimmermann F., et al. (2024). Analysis and installation of H2 value chains in rural areas. Int. J. Hydrogen Energy 49, 530–537. doi: 10.1016/j.ijhydene.2023.09.209

Sun P., Young B., Elgowainy A., Lu Z., Wang M., Morelli B., et al. (2019). Criteria air pollutants and greenhouse gas emissions from hydrogen production in U.S. Steam methane reforming facilities. Environ. Sci. Technol. 53, 7103–7113. doi: 10.1021/acs.est.8b06197

Susmozas A., Iribarren D., Dufour J. (2013). Life-cycle performance of indirect biomass gasification as a green alternative to steam methane reforming for hydrogen production. Int. J. Hydrogen Energy 38, 9961–9972. doi: 10.1016/j.ijhydene.2013.06.012

van Zyl W. H., Lynd L. R., den Haan R., McBride J. E. (2007). Consolidated bioprocessing for bioethanol production using Saccharomyces cerevisiae. Adv. Biochem. Eng. Biotechnol. 108, 205–235. doi: 10.1007/10_2007_061

Xiong W., Reyes L. H., Michener W. E., Maness P.-C., Chou K. J. (2018). Engineering cellulolytic bacterium Clostridium thermocellum to co-ferment cellulose- and hemicellulose-derived sugars simultaneously. Biotechnol. Bioengineering 115, 1755–1763. doi: 10.1002/bit.26590

Yadav D., Banerjee R. (2020). Net energy and carbon footprint analysis of solar hydrogen production from the high-temperature electrolysis process. Appl. Energy 262, 114503. doi: 10.1016/j.apenergy.2020.114503

Yin Y., Wang J. (2022). “Chapter 8 - production of biohydrogen,” in Biofuels and biorefining. Eds. Gómez Castro F. I., Gutiérrez-Antonio C. (Amsterdam, Netherlands: Elsevier), pp 283–pp 337.

Yüzbaşıoğlu A. E., Avşar C., Gezerman A. O. (2022). The current situation in the use of ammonia as a sustainable energy source and its industrial potential. Curr. Res. Green Sustain. Chem. 5, 100307. doi: 10.1016/j.crgsc.2022.100307

Zhang Q., Jiao Y., He C., Ruan R., Hu J., Ren J., et al. (2024). Biological fermentation pilot-scale systems and evaluation for commercial viability towards sustainable biohydrogen production. Nat. Commun. 15, 4539. doi: 10.1038/s41467-024-48790-4

Zhang Q., Zhang Z. (2018). “Chapter four - biological hydrogen production from renewable resources by photofermentation,” in Advances in bioenergy, vol. 3 . Eds. Li Y., Ge X. (Cambridge, MA: Elsevier), 137–160.

Keywords: biorefinery, biohydrogen, biogas, dark fermentation, anaerobic digestion, energy resiliency

Citation: Mandalika AS, Chou KJ and Decker SR (2024) Biohydrogen: prospects for industrial utilization and energy resiliency in rural communities. Front. Ind. Microbiol. 2:1428686. doi: 10.3389/finmi.2024.1428686

Received: 06 May 2024; Accepted: 30 May 2024;

Published: 14 June 2024.

Edited by:

Shuchi Singh, University of Illinois at Urbana-Champaign, United StatesReviewed by:

Divya Ramchandran, Amyris, United StatesChandan Mahata, University of Illinois at Urbana-Champaign, United States

Copyright © 2024 Mandalika, Chou and Decker. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Anurag S. Mandalika, YW1hbmRhNkBsc3UuZWR1

Anurag S. Mandalika

Anurag S. Mandalika Katherine J. Chou

Katherine J. Chou Stephen R. Decker

Stephen R. Decker