- 1School of Artificial Intelligence and Big Data, Henan University of Technology, Zhengzhou, Henan, China

- 2College of Information Science and Engineering, Henan University of Technology, Zhengzhou, Henan, China

- 3School of Art and Design, Changzhou Institute of Technology, Changzhou, Jiangsu, China

- 4Research Institute of Science and Technology, Tokyo University of Science, Tokyo, Japan

The advent of Industry 4.0 and the emerging Industry 5.0 have fundamentally transformed manufacturing systems, introducing unprecedented levels of complexity in production scheduling. This complexity is further amplified by the integration of cyber-physical systems, Internet of Things, Artificial Intelligence, and human-centric approaches, necessitating more sophisticated optimization methods. This paper aims to provide a more comprehensive perspective on the application of metaheuristic algorithms in shop scheduling problems within the context of Industry 4.0 and Industry 5.0. Through a systematic review of recent literature (2015–2024), we analyze and categorize various metaheuristic approaches, including Evolutionary Algorithms (EAs), swarm intelligence, and hybrid methods, that have been applied to address complex scheduling challenges in smart manufacturing environments. We specifically examine how these algorithms handle multiple competing objectives such as makespan minimization, energy efficiency, production costs, and human-machine collaboration, which are crucial in modern industrial settings. Our survey reveals several key findings: 1) hybrid metaheuristics demonstrate superior performance in handling multi-objective optimization compared to standalone algorithms; 2) bio-inspired algorithms show promising results in addressing complex scheduling and multi-objective manufacturing environments; 3) tri-objective and higher-order multi-objective optimization problems warrant further in-depth exploration; and 4) there is an emerging trend towards incorporating human factors and sustainability objectives in scheduling optimization, aligned with Industry 5.0 principles. Additionally, we identify research gaps and propose future research directions, particularly in areas such as real-time scheduling adaptation, human-centric optimization, and sustainability-aware scheduling algorithms. This comprehensive review provides insights for researchers and practitioners in the field of industrial scheduling, offering a structured understanding of current methodologies and future challenges in the evolution from Industry 4.0 to 5.0.

1 Introduction

The manufacturing industry is undergoing a profound transformation, characterized by rapidly expanding production scales and intensifying global competition. Traditional manufacturing approaches, heavily dependent on manual labor, are becoming increasingly inadequate in meeting the demands of modern industrial production. In response to these challenges, the emergence of cutting-edge technologies, including the Internet of Things (IoT), Artificial Intelligence (AI), and advanced automation systems, has provided unprecedented opportunities for manufacturing transformation (Mourtzis, 2020a; Mourtzis, 2022). These technological innovations have not only revolutionized production processes through enhanced automation and intelligence but have also optimized resource allocation, reduced operational costs, and significantly improved both efficiency and quality of products.

Shop scheduling represents a fundamental challenge in manufacturing systems and has been extensively studied in the literature. The core objective of scheduling is to optimally allocate limited production resources (e.g., machines, workers, materials) to various tasks while satisfying multiple constraints and objectives. While traditional scheduling approaches, based on human expertise and simplified mathematical models, have served well historically, they prove inadequate in addressing the complexity and dynamism of contemporary manufacturing environments characterized by volatile demand patterns and high uncertainty. Consequently, the integration of advanced information technologies and intelligent algorithms for scheduling optimization has emerged as a critical research focus.

In the evolution of industrial paradigms, Industry 4.0 emphasizes the comprehensive integration of information and communication technologies with cyberspace virtual systems, encompassing IoT, Cyber-Physical Systems, smart factories, and cloud computing, to enhance manufacturing automation and intelligence (Mourtzis, 2020b; Jain et al., 2022). Within the Industry 4.0 framework, shop scheduling faces both new opportunities and challenges (Ferreira et al., 2023). Data-driven scheduling optimization, intelligent decision support, and flexible production models have transformed production processes into more efficient and controllable systems. The vast amount of production data collected through IoT infrastructure enables the development of more accurate scheduling models. Furthermore, the integration of big data analytics and machine learning algorithms facilitates data-driven optimization, while smart factories and autonomous decision-making systems enable real-time production adjustments and anomaly detection, significantly enhancing system adaptability and efficiency.

With the continued advancement of Industry 4.0, it has become increasingly evident that, while technological progress has significantly enhanced productivity, achieving more comprehensive and sustainable industrial development requires greater consideration of human factors, environmental sustainability, and system resilience. Consequently, Industry 5.0 has emerged as an extension of Industry 4.0, adopting a more holistic approach that emphasizes human-centricity, sustainability, and resilience. This shift represents not merely a technological upgrade but a profound reevaluation and transformation of industrial production paradigms, aiming to establish a more harmonious, green, and flexible industrial ecosystem.

In this context, shop scheduling must evolve beyond technical optimization to incorporate human factors and social responsibility (Destouet et al., 2023). The human-centric manufacturing paradigm prioritizes worker wellbeing and satisfaction through smart wearable devices and health monitoring systems. Sustainable production practices focus on minimizing resource consumption and environmental impact through green manufacturing and circular economy principles. Additionally, resilient production systems are designed to withstand disruptions through flexible production networks and robust supply chain architectures. These emerging requirements have significantly increased the complexity of scheduling problems, necessitating the consideration of multiple objectives which often competing.

Metaheuristic algorithms have emerged as powerful tools for addressing these complex multi-objective scheduling challenges. These algorithms demonstrate remarkable effectiveness in handling large-scale problems with multiple competing objectives, offering flexible and efficient solutions that can adapt to varying production scenarios. Their success in solving complex and dynamic shop scheduling problems, coupled with their ability to balance multiple objectives across different production scales, has led to their increased adoption in manufacturing applications. Moreover, the integration of metaheuristics with Industry 4.0 and 5.0 technologies has opened new avenues for scheduling optimization, enabling more sophisticated approaches to improving production efficiency and quality. Compared to previous studies, this paper aims to provide a more comprehensive perspective on the application of metaheuristic algorithms in shop scheduling problems within the context of Industry 4.0 and Industry 5.0, making the following contributions:

(1) This paper focuses on the application of metaheuristic algorithms in multi-objective scheduling problems from 2015 to 2024, systematically evaluating the advantages and disadvantages of single algorithms and hybrid algorithms found in the existing literature.

(2) By conducting an in-depth analysis of the number of objectives across various studies, this paper explores scheduling goals in the context of Industry 5.0 and Industry 4.0, distilling the current scale of research objectives and the trends for future research goals.

(3) This paper provides an overview of the research progress on metaheuristic algorithms combined with Reinforcement Learning (RL) methods in scheduling problems, assesses the advantages of these combined approaches, and suggests potential directions for future research.

(4) Addressing the classification of scheduling problems, this paper summarizes and examines the current trends in scheduling issues from the perspectives of flow-shop and job-shop scheduling problems.

This comprehensive survey examines the application of metaheuristic algorithms in multi-objective shop scheduling within the Industry 4.0 and 5.0 frameworks. The paper is structured as follows: Section 2 provides an overview of multi-objective optimization concepts and methodologies. Section 3 presents a systematic classification of scheduling objectives in modern manufacturing environments. Sections 4, 5 analyze the application of metaheuristics in flow-shop and job-shop scheduling problems, respectively, including their variants. Section 6 explores the integration of metaheuristics with RL and other advanced techniques. Finally, Section 7 summarizes key findings and identifies promising directions for future research.

2 Multi-objective optimization

In contemporary manufacturing processes, multiple objectives often conflict with each other, such as product quality versus production cost, or production efficiency versus energy consumption. The complexity of modern manufacturing systems, particularly in the context of Industry 4.0 and 5.0, necessitates simultaneous optimization of multiple objectives, making multi-objective optimization a crucial research focus.

2.1 The essence of multi-objective optimization

Multi-objective optimization problems are characterized by the presence of multiple, often conflicting objectives where the optimization of one objective typically results in the degradation of others. This inherent trade-off necessitates finding solutions that achieve an acceptable balance among all objectives. The mathematical formulation of a Multi-objective Optimization Problem (MOP) can be expressed as follows:

Definition 1. MOP (Coello, 2007) (Equation 1):

where

Definition 2. Pareto Dominance Relationship:

For two solutions

Definition 3. Pareto Optimal Solution (POS):

A solution

In the context of Multi-objective Evolutionary Algorithms (MOEA), the goal is to identify a set of Pareto optimal solutions, formally defined as (Equation 2):

Definition 4. Pareto-optimal Front (POF) (Equation 3):

Depending on the evolutionary mechanism, MOEA can be divided into three categories: decomposition-based MOEA, dominance relationship-based MOEA, and indicator-based MOEA.

2.1.1 Decomposition based multi-objective evolutionary algorithm

The core idea of the decomposition-based MOEA algorithm is to decompose a multi-objective problem into a set of single-objective optimization problems, and approximate the solution set of the multi-objective problem by solving the subproblems simultaneously. Among them, the commonly used decomposition methods include the following three: weighted sum approach, Tchebycheff approach and penalty-based boundary intersection approach.

The weighted sum approach was proposed by Hillermeier (2001) and it is a commonly used linear multi-objective aggregation method. The aggregation function of this method can be expressed as (Equation 4):

where

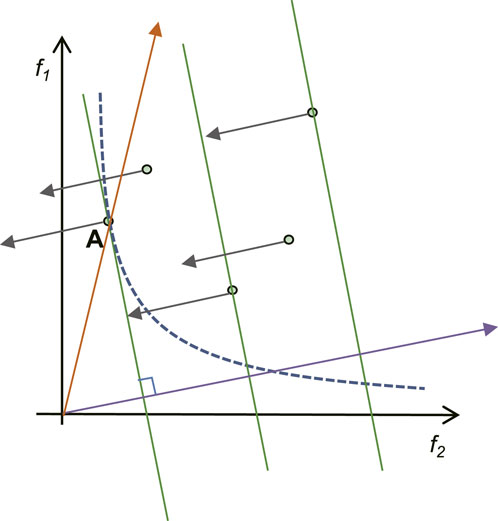

As shown in Figure 1, take two objective values as an example, when the real Pareto front is convex, purple is the weight vector, the green solid line perpendicular to the purple weight vector is the contour line. Connecting the objective point and the origin in the objective space constitutes a vector, and the purpose of the aggregation function is to multiply this vector with the pair of weight vectors point by point. When the weight vector is unchanged, minimizing/maximizing the length value is optimizing the vector.

Tchebycheff approach is a nonlinear multi-objective aggregation method, proposed by the aggregation function is defined as (Equation 5):

The Tchebycheff approach continuously forces individuals to approach a predetermined ideal point when transforming a multi-objective problem into a single-objective optimization by means of an aggregation function, which ultimately results in a Pareto optimal solution under the constraints. As shown in Figure 2, by definition the contour of each function in this method is a straight line parallel to that function, respectively; moreover, the intersection of two objective contours lies in the direction of the weight vector. In order to solve the problem that the solutions obtained by the standard Tchebycheff approach are not homogeneous, Qi et al. (2014) proposed the conversion of the reference vector into

The penalty-based boundary intersection approach was proposed by Zhang and Li (2007) which combines the Tchebycheff method and the penalty mechanism, which allows the solution to deviate from the direction of the weight vector, but a penalty will be imposed on the deviated solution. During the process of multi-objective optimization, the convergence and distribution of the solution can be controlled by adjusting the penalty parameter, so that the solution evolves directly along the direction of the weight vector, which is defined as follows:

Equation 6 give the calculation of the method. Where

2.1.2 Pareto dominance based multi-objective evolutionary algorithm

Schaffer extended the simple Genetic Algorithm (GA) and proposed the Vector Evaluation Genetic Algorithm (Schaffer, 1985) (VEGA) in 1985, but the method cannot make trade-offs according to the attributes of each sub-objective, and it can only find the extreme points on the optimality boundary. In addition, the non-dominated solutions produced by VEGA are not necessarily globally non-dominated individuals. Fonseca and Fleming made use of the idea of sorting and proposed a kind of Multi-Objective Genetic Algorithm (MOGA) (Fonseca and Fleming, 1993), which determine the classification order of individuals based on the dominance relationship between them. Subsequently, Goldberg et al. (1993) proposed a dominance relationship-based MOEA method, which mainly uses a Pareto-based fitness allocation strategy to find all non-dominated individuals in an evolving population.

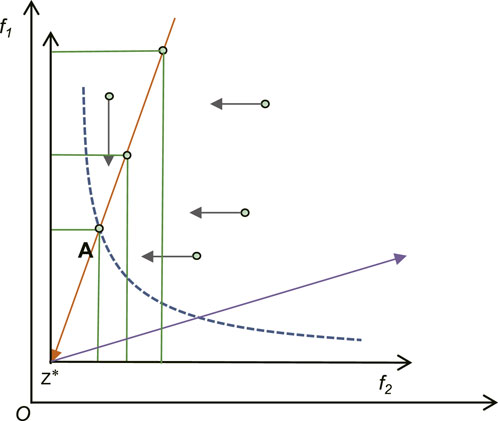

Currently, there is a great number of MOEA problems that use dominance relationship methods. The Non-dominated Sorting Genetic Algorithm (NSGA) proposed by Srinivas and Deb (1994) uses Goldberg’s idea directly. This algorithm is an improvement of the selection of the next-generation of sub-populations method based on GA, which stratifies each individual according to their dominance and non-dominance relationship before screening, which in turn makes the algorithm get the satisfactory results as possible on multiple objectives. Non-dominated Sorting Genetic Algorithm-II (NSGA-II) proposed by Deb et al. (2002), they uses fast non-dominated sorting on the basis of NSGA, which reduces the complexity of the algorithm and improves the running speed of the algorithm. Subsequently Jain and Deb (2014) proposed Non-dominated Sorting Genetic Algorithm-III (NSGA-III), which uses reference point based non-dominated sorting based on NSGA-II, this approach helps to identify the non-dominated solutions better in high dimensional objective space, NSGA-III is more suitable for the case where the number of objectives to be optimized is large. Zhang et al. (2014) employed a Pareto dominance-based strategy, proposed a hybrid sampling approach that combines VEGA with a fitness function grounded in novel Pareto dominance relationships, to balance the distribution and convergence of solutions. In addition, Gen et al. (2008) provided a comprehensive analysis of the advantages and applications of the GA. Figure 3 illustrates the development of MOEA based on dominance relationships.

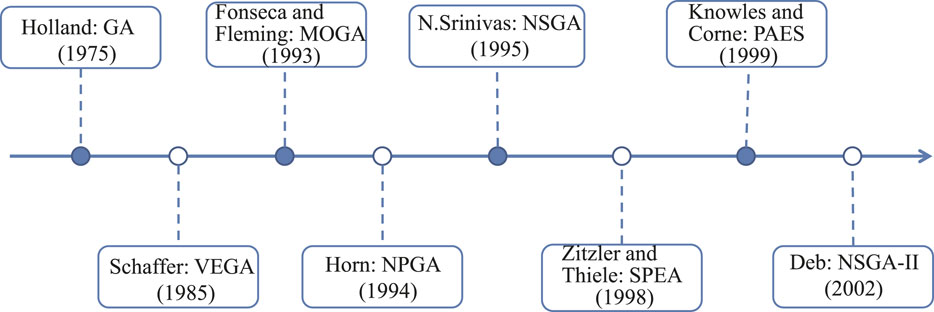

In the MOEA based on dominance relationship, the evolutionary population is divided into several layers according to the dominance relationship. The first layer is the set of non-dominated individuals of the evolutionary population, the second layer is the set of non-dominated individuals after removing the first layer of individuals in the evolutionary population, the third layer is the set of non-dominated individuals after removing the first and second layer of individuals in the evolutionary population, and so on. When making the selection, the first layer of the non-dominated set is considered first, and individuals are selected from the first layer according to a certain strategy, and then individuals are considered to be selected sequentially in the other layers until the size requirement of the new evolutionary population is met. Figure 4 illustrates this process in detail.

2.1.3 Indicator based multi-objective evolutionary algorithm

Indicator based MOEA refers to the use of performance evaluation indictor in optimization algorithms to guide the search selection process of solutions. Based on the decision-making approach, MOEA can be classified into three categories: pre-decision techniques, interactive decision techniques and post-decision techniques.

Pre-decision techniques are those in which the decision maker has specified the preferences and objective weights of the problem before the optimization process begin. These preferences and weights are fixed during the optimization process and the algorithm searches based on these fixed preferences and weights. The advantage of pre-decision techniques is their simplicity and clarity, but the disadvantage is that some potential high-quality solutions may be ignored. The common pre-decision techniques are weighted sum method,

Interactive decision-making techniques are those in which the decision maker interacts with the algorithm during the optimization process, adjusting preferences and objective weights step by step. This technique allows the decision maker to dynamically adjust the objectives during the optimization process to find a solution that better meets the practical requirements. Common interactive decision-making techniques are: stepwise preference adjustment, interactive multi-objective optimization and dynamic preference adjustment.

The post-decision technique means that at the end of the optimization process, the algorithm generates a set of Pareto optimal solutions from which the decision maker chooses the most satisfactory solution. The advantage of this technique is that the decision maker can make a decision after seeing all possible solutions, but the disadvantage is that it may need to deal with a large set of solutions. Some common post-decision techniques are: non-dominated sorting method, MOGA, Multi-Objective Particle Swarm Optimization (MOPSO) algorithm, Multi-Objective Differential Evolutionary algorithm.

Pre-decision techniques optimize with fixed objective weights and constraints, with the advantage of simplicity and clarity and ease of implementation, but may ignore potential high-quality solutions. Interactive decision-making techniques dynamically adjust preferences during the optimization process by providing real-time feedback and adjusting objective weights, which improves flexibility and adaptability, but may increase time costs. Post-decision techniques generate a set of Pareto optimal solutions after optimization, from which the most satisfactory solutions are selected, ensuring diversity and quality of solutions, but may need to deal with a large set of solutions, increasing the difficulty of decision-making. Depending on the size of the problem, these techniques can be applied in different methods.

3 Classification of scheduling optimization objectives

The selection of optimization objectives in shop scheduling problems fundamentally determines the effectiveness and practical applicability of scheduling solutions. This section presents a systematic classification and analysis of common scheduling objectives, which can be formalized as follows:

3.1 Time-based objectives

Makespan Minimization: The most fundamental objective in shop scheduling, defined as (Equation 7):

where

Total Weighted Completion Time: Considers job priorities through weights (Equation 8):

where

3.2 Resource-based objectives

Energy Consumption: Modern scheduling increasingly emphasizes energy efficiency (Equation 9):

where:

Worker-related Objectives: Incorporating human factors (Equation 10):

where

3.3 Quality-based objectives

Tardiness-related (Equation 11):

where

Fuzzy Objectives: For uncertain environments (Equation 12):

where

Analysis of the literature reveals several key trends in scheduling optimization objectives:

(1) Objective Prevalence: makespan minimization and energy consumption remain the most frequently studied objectives, reflecting their fundamental importance in production efficiency and sustainability.

(2) Multi-objective Complexity: the majority of studies focus on bi-objective optimization, with fewer addressing three or more objectives simultaneously. This trend reflects the inherent complexity of handling multiple competing objectives.

(3) Emerging Objectives: recent research shows increasing attention to: sustainability metrics (energy, emissions) and human factors (workload, fatigue).

(4) Integration Trends: modern studies increasingly combine traditional time-based objectives with resource and quality considerations, reflecting the complex requirements of contemporary manufacturing environments.

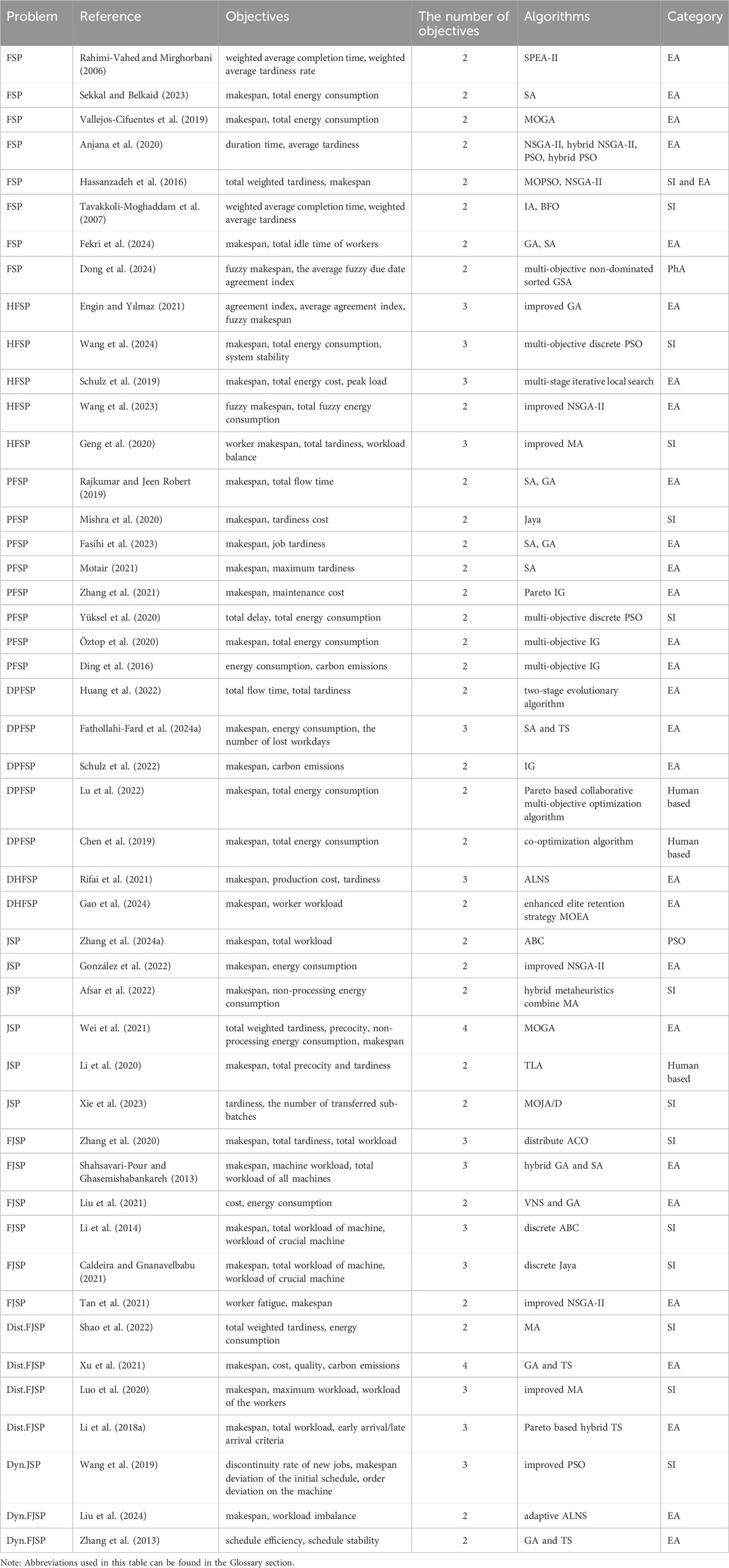

Table 1 summarise the studies related to each objective in detail. This classification demonstrates the evolution of scheduling objectives from simple time-based metrics to comprehensive multi-dimensional optimization problems that better reflect real world manufacturing challenges.

4 Metaheuristic algorithm in flow-shop scheduling problems

Metaheuristic optimization algorithms have emerged as powerful tools for solving complex global optimization problems, particularly in production scheduling. These algorithms excel in generating high-quality solutions within reasonable computational timeframes, making them especially valuable for planning, scheduling, and engineering design applications. Based on their underlying principles, metaheuristics can be broadly categorized into evolutionary mechanisms, physical principles, and swarm intelligence approaches.

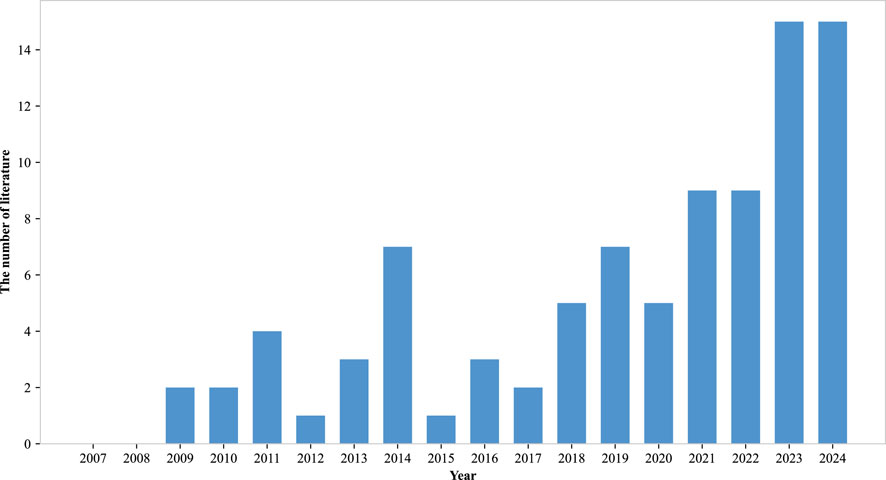

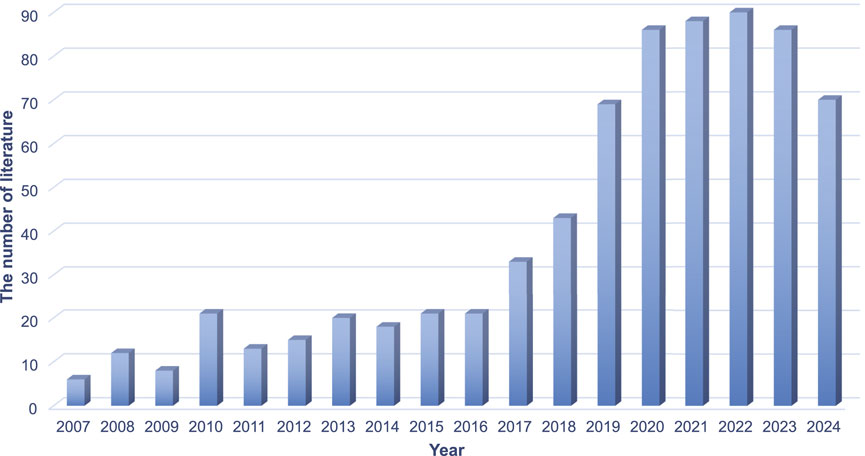

To comprehensively analyze the research landscape, we conducted a systematic literature review using Web of Science from 2000 to 2024, focusing on metaheuristic algorithms in multi-objective Flow-shop Scheduling Problem (FSP) from 2015 to 2024.1

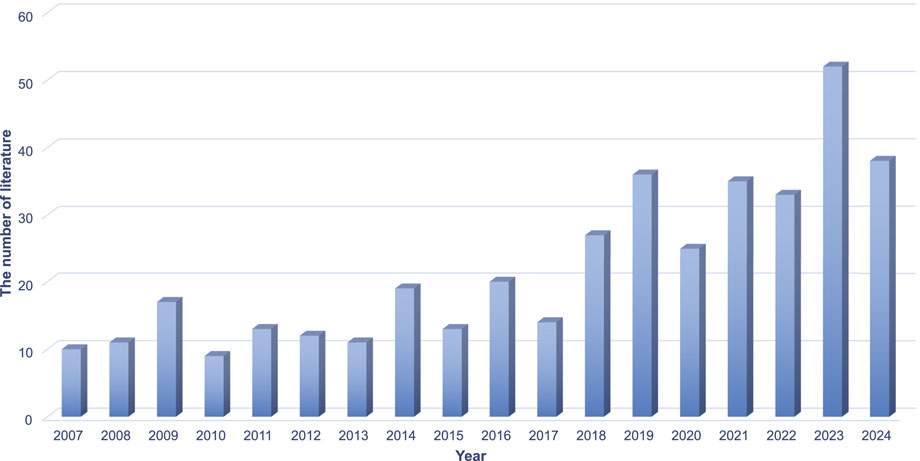

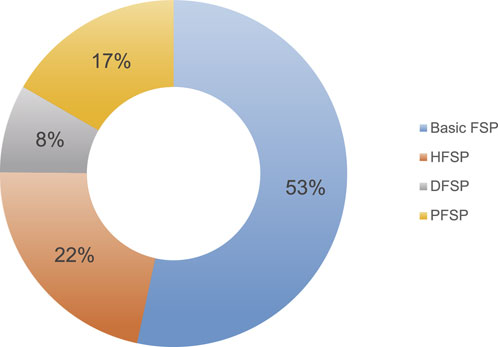

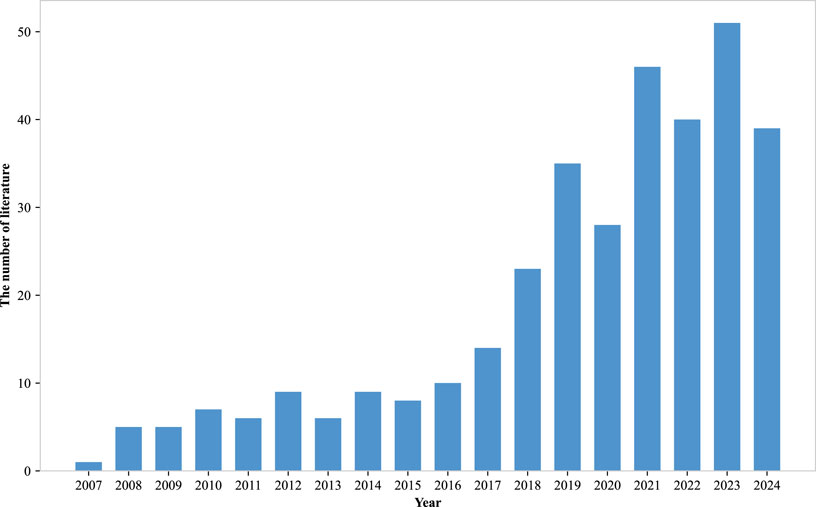

As illustrated in Figure 5, research activity in FSP reached its peak during 2019–2023, with 2023 recording over 50 publications. The trend analysis reveals a significant increase in academic attention since 2011, with particular intensity after 2020. Figure 6 further demonstrates that, beyond basic FSP, Hybrid Flow-shop Scheduling Problem (HFSP) and Permutation Flow-shop Scheduling Problem (PFSP) have garnered substantial scholarly interest.

Figure 5. Statistics on the number of metaheuristic algorithms solving muti-objective FSP and variant problems.

Figure 6. Proportion of metaheuristic algorithms solving muti-objective FSP and variant problems posted.

4.1 Flow-shop scheduling

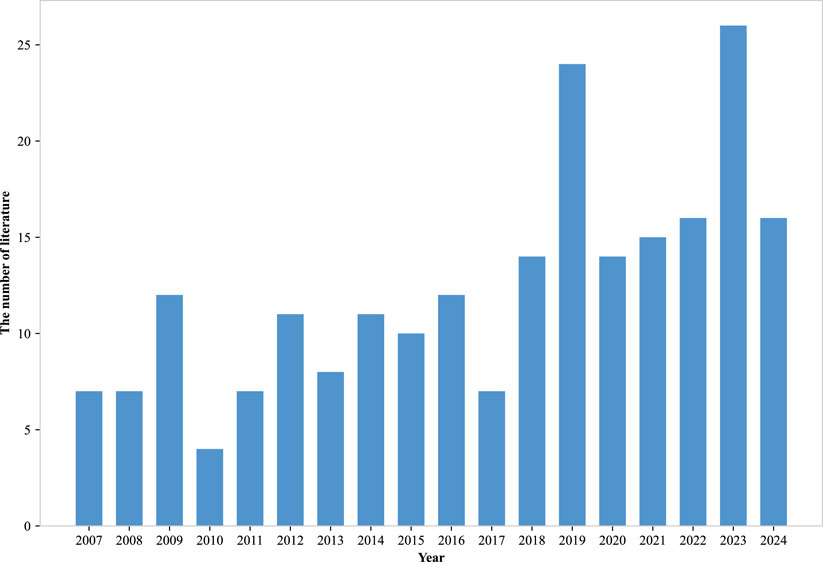

FSP represents a fundamental challenge in production scheduling, where the primary goal is to optimize the processing sequence of multiple jobs across a series of sequentially connected machines. As illustrated in Figure 7, research interest in multi-objective FSP has shown significant growth since 2019, reflecting the increasing complexity of modern manufacturing requirements.

Figure 7. The number of literature on metaheuristic algorithms solving muti-objective FSP and variant problems over the years.

4.1.1 Problem model

The problem can be formally defined as follows: Let

(1) Each machine can process only one job at a time;

(2) Each job can be processed on only one machine at a time;

(3) The processing sequence is identical for all jobs;

(4) No preemption is allowed.

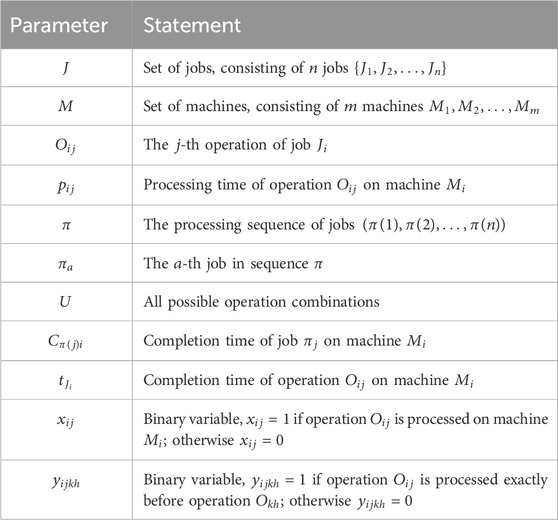

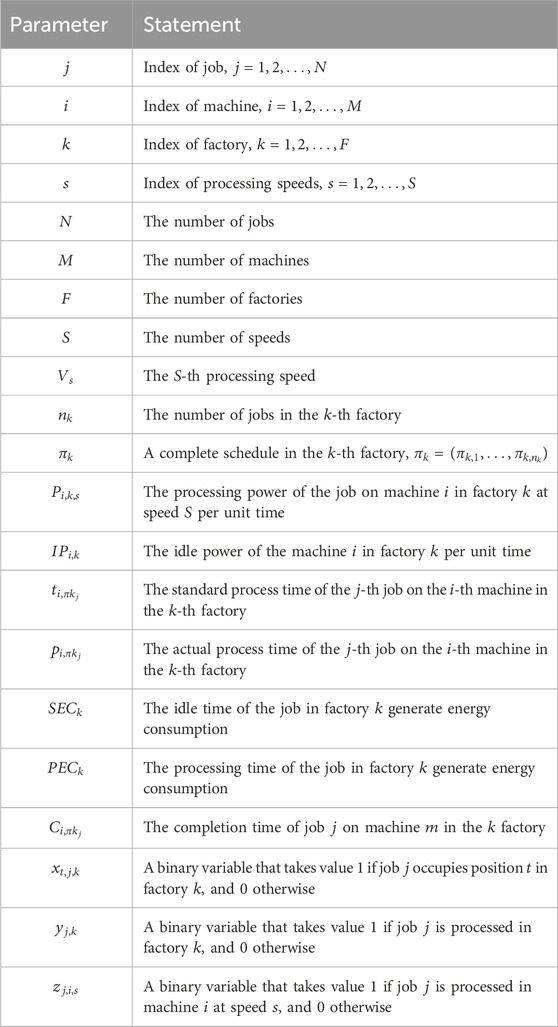

This chapter aims to construct a basic FSP model with the objectives of minimizing makespan and total flow time. Table 2 illustrates the parameter definitions for this problem.

Equations 15–18 represents the completion time of each job, while Equation 19 defines the processing sequence on each machine. Equation 20 ensures the feasibility of the operation sequence, and Equation 21 imposes constraints on job uniqueness. Similarly, Equation 22 enforces machine uniqueness, and Equations 23–25 specify non-negativity conditions. The optimization objectives of this model are defined in Equation 13, 14. Among these, Equation 13 represents the minimization of the makespan. As derived from Equations 15–18, the makespan is determined by

4.1.2 Solution algorithm

The evolution of FSP research can be categorized into three main phases: classical optimization phase (pre-2010), modern manufacturing transition phase (2010–2020) and industry 5.0 and sustainability phase (2020-present).

Classical Optimization Phase (Pre-2010): Early research focused on fundamental scheduling objectives. Rahimi-Vahed and Mirghorbani (2006) designed an effective MOPSO considering minimizing the average weighted completion time and weighted average tardiness, which finds the local Pareto frontiers of the problem by employing ideal points to specify the position vectors of the dominant particles in the swarm. Tavakkoli-Moghaddam et al. (2007) in order to minimize the weighted average completion time and weighted average tardiness time, proposed a hybrid multi-objective algorithm based on Immune Algorithm (IA) and Bacterial Foraging Optimization Algorithm.

Modern Manufacturing Transition Phase (2010–2020): This period witnessed the convergence of various modern manufacturing constraints, integrating technological advancements. Rossit et al. (2022) proposed a decomposition-based MOEA to solve the multi-objective FSP with missing operations. The method employs a structured approach to decompose the solution space, ensuring diversity among initial solutions. Hassanzadeh et al. (2016) considered an multi-objective integrated production-distribution FSP with the objective of minimizing the total weighted tardiness and the makespan as the first objective function, and minimizing the sum of total weighted early completion times, total weighted number of late jobs, inventory cost and total delivery cost as the second objective function. Hao et al. (2017) proposed a Multi-objective Estimation of Distribution Algorithm to address stochastic JSP with uncertain processing times. The algorithm effectively balances the trade-off between expected mean completion time and total tardiness. By employing probabilistic model updates and Monte Carlo sampling, it ensures scheduling quality while enhancing computational efficiency. Branda et al. (2021) examined two metaheuristic algorithms combining GA and Harmony Search for solving the bi-objective problem of FSP. Anjana et al. (2020) considered a sequence-dependent setup time FSP with the objective of minimizing duration and average tardiness.

Industry 5.0 and Sustainability Phase (2020-Present): Current research emphasizes human-centric manufacturing and environmental considerations. Key developments include: energy efficiency and worker-centric optimization. Vallejos-Cifuentes et al. (2019) considered achieving energy savings without compromising the productivity of the manufacturing system and proposed an energy-aware FSP with process speed as the main energy related decision variable for a problem that targets production goals with energy efficiency. Boufellouh and Belkaid (2023) investigated the problem of energy saving FSP in the presence of blocking and collision-free transport constraints. For a manufacturing system with a sequential dependent setup times, Automatic Guided Vehicles (AGV), transport speed control and battery management constraints, an enhanced multi-objective Ant Colony Optimization (ACO) was developed for the scheduling problem. With the objective of simultaneously minimizing makespan and total energy consumption, the algorithm proposes a novel high-resolution search strategy, a heuristic AGV scheduling strategy and a critical path based energy saving improvement strategy. Sekkal and Belkaid (2023) considered the learning effect of workers and proposed FSP with learning efficiency. They developed a metaheuristic algorithm based on multi-objective Simulate Anneal (SA) with the minimisation of makespan and energy consumption as two objective functions, in which the search for solutions is enhanced by local search. Focusing on the multi-skilled characteristics of the workers, Fekri et al. (2024) proposed a GA and a SA with the objective of minimizing makespan and the total idle time of workers, and used a special Taguchi method for the parameter adjustment. It is finally concluded that the GA has better performance and efficiency than the SA for the multi-skill resource constrained FSP, but SA is superior to GA in terms of solution time. Dong et al. (2024) solved the multi-objective fuzzy block FSP based on learning and fatigue effects by combining the characteristics of the workers with the background of the FSP scheduling of the prefabricated pods modular cells. They used the objective of minimizing the fuzzy makespan and maximize the average fuzzy due-date agreement index, a multi-objective non-dominated Sorted Gravitational Search Algorithm (GSA) is proposed.

The evolution of FSP research reflects the field’s adaptation to emerging manufacturing paradigms, with increasing emphasis on sustainability, worker wellbeing, and system flexibility. Future research opportunities lie in integrating advanced technologies while maintaining computational efficiency and practical applicability.

4.2 Permutation flow-shop scheduling

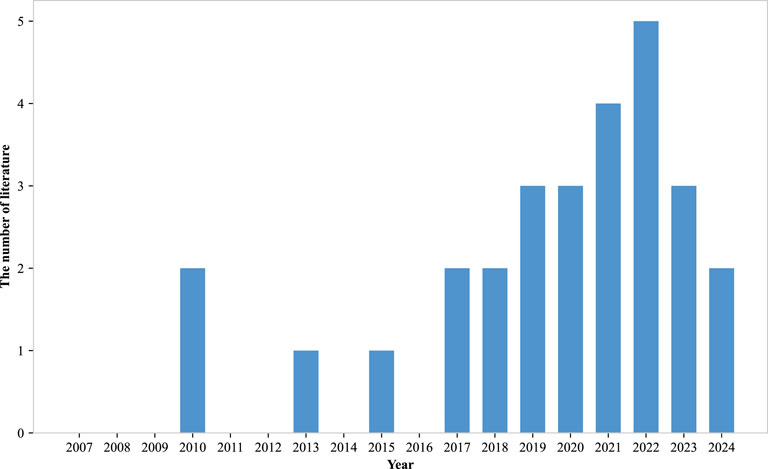

As shown in Figure 8, research interest in PFSP has exhibited significant volatility between 2007 and 2024, with notable peaks in 2019 and 2022.

Figure 8. The number of literature on metaheuristic algorithms solving muti-objective PFSP over the years.

4.2.1 Problem model

The PFSP can be described as follows: a set of

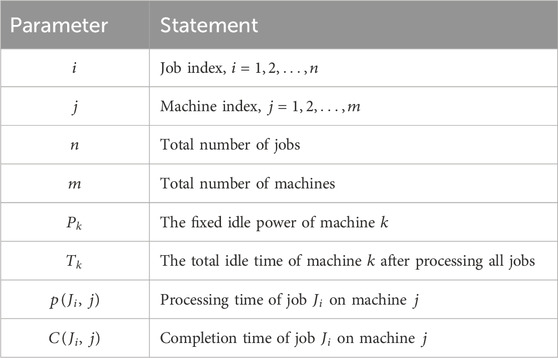

Equations 26–28 define the objective functions of this model. Specifically, Equation 26 represents the first objective, which is the minimization of makespan. Equation 27 presents the second objective. The total energy consumption is calculated as the sum of the products of the idle time and the corresponding idle power for all machines. Equation 28 defines the computation of machine idle times. Equation 29 calculates the completion time of the first job on the first machine. Equation 30 computes the completion time of job

4.2.2 Solution algorithm

Tajbakhsh et al. (2014) focused on a three-phase manufacturing system including machining, assembly and batch processing with the objective of minimizing makespan and the sum of early-to-delay costs. Based on the formulation of PFSP as a mixed integer mathematical model, a hybrid algorithm was designed to achieve efficient exploration of the solution space using a metaheuristic approach that combines the advantages of GA and Particle Swarm Optimization (PSO). Rajkumar and Jeen Robert (2019) proposed a hybrid multi-objective optimization algorithm based on GA and SA in order to solve the PFSP problem with the objective of minimizing makespan and the total flow time. The algorithm determines the near-optimal solution by assigning weights to each objective function.

The Jaya algorithm has also been used by scholars to study PFSP due to its advantages of simplicity, efficiency and scalability, Mishra et al. (2020) used the Jaya algorithm with the objective of minimizing makespan and tardiness cost to solve the PFSP problem. The algorithm converts the job preference vector into job ranking vector using maximum order value rule after randomly assigning priority to each job. In order to solve multi-objective, it uses a multi-attribute model based on Apriori method, and after comparing with SA. Zhang et al. (2021) considered preventive and corrective maintenance in manufacturing activities, and with the objective of minimizing makespan and maintenance cost, they designed a restarted iterative Pareto greedy algorithm. During the search process, the algorithm develops a restart mechanism to generate a new initial solution to prevent the algorithm from falling into a local optimum. Fasihi et al. (2023) proposed a two-step procedure by considering the reentrant PFSP with the objective of minimizing makespan and maximizing delay. The first step divides the population into sub-populations and applies GA in each sub-population to obtain the set of approximate Pareto frontier solutions. The second step unifies all the Pareto solution sets into a whole, using a multi-objective hybrid metaheuristic algorithm based on dominance relations.

Considering energy consumption and environmental constraints on manufacturing, Yüksel et al. (2020) proposed a new multi-objective discrete Artificial Bee Colony Algorithm (ABC) with the objective of minimizing both total delay and total energy consumption. By comparing it with metaheuristic algorithms such as traditional MOGA, variations of MOGA with local search, the algorithm is able to adapt to idle free FSP, blocking FSP, and Job-shop Scheduling Problem (JSP), or other higher level integrated manufacturing problems. Öztop et al. (2020) with the objective of minimizing makespan and total energy consumption, developed an enhanced

Ding et al. (2016) concerned about the direct relationship between energy consumption and carbon emissions, with the aim of improving the carbon efficiency of industrial factories and thus reducing the energy cost in the production process. Designed an optimization algorithm for the PFSP with the objective of minimizing the total carbon emissions and the makespan as the objective of the optimization algorithm. The algorithm is based on an extended Nawaz-Enscore-Ham (NEH) insertion procedure, and a multi-objective NEH algorithm and an improved multi-objective IG are designed to solve the problem. Wu and Che (2020) investigated the energy efficient no-waiting PFSP problem, and designed an adaptive multi-objective Variable Neighborhood Search (VNS) with the objective of minimizing makespan and total energy consumption. The algorithm designs two VNS structures to generate neighbours through insertion and swapping operations, and uses an adaptive mechanism to dynamically select the appropriate structure to handle the evolutionary direction of the current solution. Xin et al. (2021) designed an improved discrete Whale Optimization Algorithm (WOA) for PFSP with sequential dependence on setup time, considering that the energy consumption is related to the time of the job transfer process. The algorithm aims to minimize makespan and total energy consumption, and combines Differential Evolution (DE) and enhanced search strategy to improve the performance of the algorithm.

Recent research developments can be categorized into three main streams:

• Manufacturing System Integration: recent studies have expanded PFSP to incorporate real-world manufacturing complexities.

• Advanced Hybrid Approaches: modern PFSP solutions employ sophisticated hybrid algorithms. Such as hybrid GA and SA, Jaya algorithm and hybrid PSO and so on.

• Energy and Environmental Considerations: recent research has increasingly focused on sustainability objectives. For example, carbon emissions, energy consumption and machine availability and so on.

The evolution of PFSP research reflects increasing emphasis on practical manufacturing constraints and environmental considerations. This progression suggests a trend toward more comprehensive and sustainable scheduling solutions that balance traditional performance metrics with modern manufacturing requirements.

4.3 Hybrid flow-shop scheduling

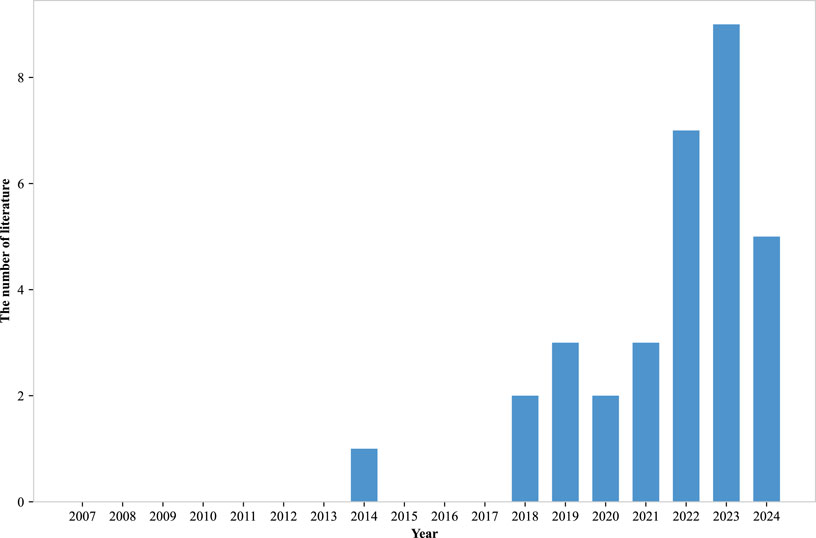

As illustrated in Figure 9, research interest in HFSP has shown significant growth since 2020, reaching unprecedented levels in recent years. This surge reflects the increasing complexity and practical relevance of HFSP in modern manufacturing.

Figure 9. The number of literature on metaheuristic algorithms solving muti-objective HFSP and variant problems over the years.

4.3.1 Problem model

This chapter takes the HFSP with worker constraints as an example to establish a mathematical model. The problem can be described as follows: there are

(1) Sequencing all operations based on operational constraints;

(2) Assigning machines to process the jobs;

(3) Allocating workers to operate the assigned machines.

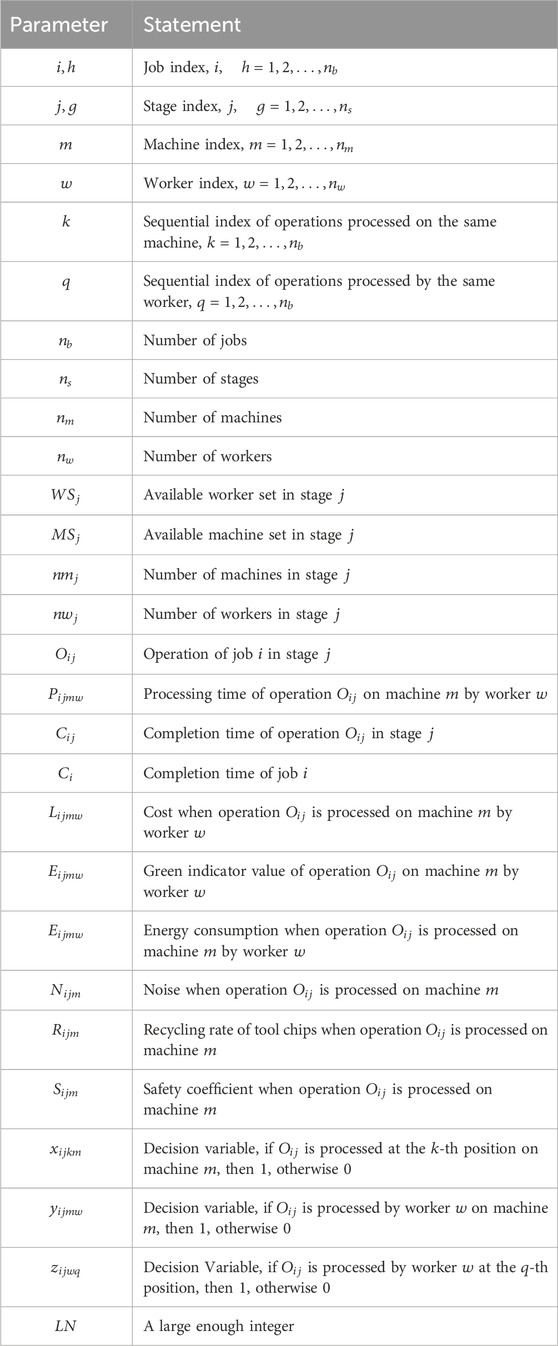

Table 4 summarizes the parameters and their descriptions for this problem.

The model aims to minimize the makespan and the total worker cost, as formulated in Equations 34, 35. Equation 36 ensures the precedence constraints for operations. Equation 37 enforces the sequencing constraints for operations on the same machine. Equation 38 ensures the sequencing constraints for operations assigned to the same worker. Equation 39 guarantees that each operation is processed by only one machine at any given time. Equation 40 ensures that each machine processes at most one operation at any given time. Equation 41 prevents gaps in the sequence of operations on the same machine, ensuring that no position is left empty before a position is fully occupied. Equation 42 ensures that each operation is handled by only one worker at any given time. Equation 43 guarantees that each worker handles at most one operation at any given time. Equation 44 prevents gaps in the sequence of operations assigned to the same worker, ensuring that no position is left empty before a position is fully occupied. Equation 45 ensures that each operation is performed by only one worker on one machine at a time. Equation 46 allows each worker to perform multiple operations on the same machine.

4.3.2 Solution algorithm

Behnamian et al. (2009) proposed a multi-objective HFSP with sequence-dependent setup times, focusing on minimizing makespan and the sum of job advance and delay times. Their approach consists of three stages: first, they use a random-keyed GA to approximate the Pareto front; second, they unify non-dominated solutions and enhance the front with a local search; and third, they apply an

In real production process, energy consumption is one of the concerns of managers, Li et al. (2018b) proposed an energy-aware multi-objective optimization algorithm to solve the HFSP problem, which considers both minimizing makespan and energy consumption. This metaheuristic algorithm two vectors are used to represent the solution using machine assignment priority and scheduling, and four types of decoding methods are used to consider the two objectives simultaneously. Eight types of neighbourhood structures and an adaptive neighbourhood selection method are designed to speed up the search for a solution, effectively balancing the capabilities of global and local search through deep exploitation and exploration strategies. Hosseini (2017) focused on the difference between the manufacturing and assembly phases of a product and proposed a two phase HFSP, where they assumed the first phase to be a HFSP with the same parallel machines and the second phase was treated as assembly. The algorithm uses a two-stage MOGA to solve this problem with the objective of minimizing makespan and the sum of early and late arrivals of jobs. For the uncertain time manufacturing process, Wang et al. (2024) proposed the green HFSP in the case of emergency batch insertion. The problem adopts a multi-objective discrete ABC with the objectives of minimizing makespan, total energy consumption and system stability. The algorithm is able to significantly reduce the cost and substantially improve the accuracy and efficiency by testing and comparing it on small and large scale problems.

Schulz et al. (2019) focused on the importance of energy-aware scheduling and developed a new multi-stage iterative local search algorithm for energy-aware HFSP. The algorithm incorporates three energy saving strategies of reducing energy consumption, reducing energy cost using different energy prices and considering load balancing with the objective of minimizing makespan, total energy cost and peak load. The algorithm incorporates a tabu list, several time and energy dependent list scheduling algorithms, a right shift procedure and a reference point based fitness function to improve the quality of the solution. Chen et al. (2020) used a multi-objective mixed-integer planning model with the objective of minimizing makespan and power consumption. The algorithm uses a GA to obtain the Pareto solution set, and uses a multi-objective energy-efficient scheduling algorithm to compute the fitness value of each chromosome in GA. Wang et al. (2023) added variable machine speed constraints to the energy-efficient HFSP problem and proposed an energy-efficient fuzzy HFSP considering variable machine speeds, for which an extended NSGA-II was designed. The algorithm aims to minimize both fuzzy makespan and total fuzzy energy consumption, and generates an initial population through inverse learning, and a new strategy based on historical information to produce high-quality solutions.

In addition to the consideration of energy consumption, many scholars have also focused on human-centred manufacturing in the context of Industry 5.0. Geng et al. (2020) investigated multi-objective HFSP with dual resource constraints considering the dual flexibility characteristics of machines and workers. The problem was formulated with the objective of minimizing worker makespan, total tardiness and workload balance, and proposed an improved multi-objective Memetic Algorithm (MA) with parameters set by Taguchi method. This method significantly outperforms other algorithms in terms of convergence, diversity, and dominance of non-dominated solutions. Han et al. (2021) proposed a MOEA with seven heuristic decodings for HFSP considering workers constraints. The algorithm combines machine worker allocation priority rules with the optimization objective of minimizing makespan and total delay. It is demonstrated through numerical experiments that the algorithm enables the solution to achieve a balance between exploration and exploitation, and can reasonably solve the manufacturing problem.

Recent research has focused on several key aspects of HFSP: setup time considerations, energy-aware scheduling, human-centered manufacturing and uncertainty management. The evolution of HFSP research reflects a growing emphasis on practical manufacturing constraints while maintaining computational efficiency. Future research opportunities lie in integrating emerging technologies and addressing increasingly complex real-world scenarios, particularly in the context of smart manufacturing and Industry 5.0 requirements.

4.4 Distributed flow-shop scheduling

Distributed flow-shop scheduling problems encompasses three main variants: Distributed Flow-shop Problem (DFSP), Distributed Permutation Flow-shop Problem (DPFSP), and Distributed Hybrid Flow-shop Problem (DHFSP). In a DFSP system with

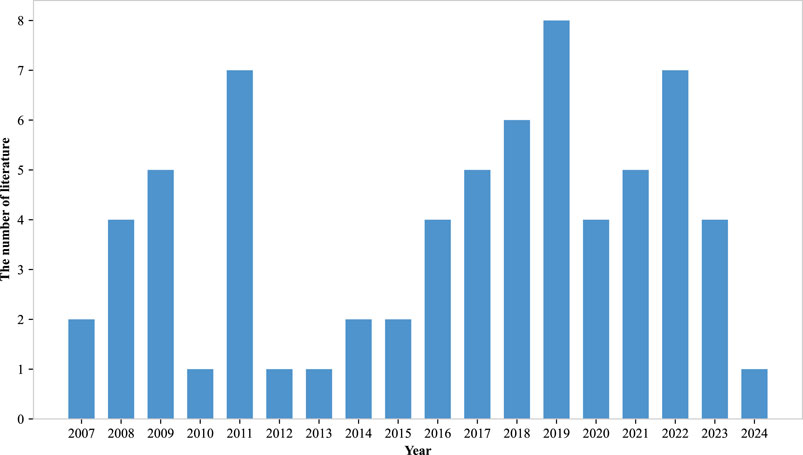

As shown in Figure 10, research interest in distributed scheduling systems has grown significantly in recent years, which may be related to the expansion of manufacturing operations.

Figure 10. The number of literature on metaheuristic algorithms solving muti-objective DFSP and variant problems over the years.

4.4.1 Problem model

The DFSP can be described in detail as follows. It involves

Equations 47, 48 represent the minimization of the two objectives. Equations 49, 50 ensure that each job is accurately assigned to one factory and exists only once within that factory. Equations 51, 53 indicate that each job can potentially be a predecessor or successor within the assigned factory, while avoiding priority conflicts. Equation 52 explains that all jobs should have the possibility of being assigned to the

4.4.2 Solution algorithm

Rifai et al. (2021) proposed an improved multi-objective Adaptive Large Neighborhood Search (ALNS) for the DPFSP by considering the effect of sequence-dependent setup time for the first time. The algorithm achieves an effective use of balancing and exploration by introducing new destruction and repair heuristics, optimizing the solution acceptance criterion and the non-dominated set update mechanism. Cai et al. (2018) proposed an improved NSGA-II for the DPFSP with transport and qualification constraints aiming to optimize the three objectives of fabrication time, maximum delay, and total cost (including transport and installation cost) simultaneously. The algorithm introduces a new solution representation, a population initialisation strategy, efficient crossover and mutation operators, and local search techniques.

Huang et al. (2022) proposed a two-stage evolutionary algorithm with the objective of minimizing the total flow time and total tardiness time. A two-stage structure is used, in the first stage of this algorithm to increase the population diversity through two constructive heuristics and four crossover and two mutation operators designed. In the second stage the first two populations are integrated to improve the performance of the algorithm by using the normalised objective function and two new crossover operators to extend the solution to the Pareto frontier. Fathollahi-Fard et al. (2024a) redefined the sustainable DPFSP using an online mixed-integer programming model. With the objective of minimizing makespan, energy consumption, and reducing the number of lost workdays, SA and Tabu Search (TS) were designed for the large scale problem. Fathollahi-Fard et al. (2024b) also proposed an ALNS for the sustainable DPFSP. The algorithm considers different modes of operation in which machines can run from manual to automatic, taking into account energy consumption, number of operators required and number of working days lost to training. In addition, the algorithm considers uncertainty problems including machine failures, variable processing times and the random arrival of new jobs.

Since carbon emissions will have a direct impact on the environment, Schulz et al. (2022) designed an IG for the DPFSP under large-scale instances in order to minimize makespan while reducing carbon emissions. Lu et al. (2022) investigated energy efficient scheduling for DPFSP with a finite buffer, aiming to minimize both the manufacturing time and the total energy consumption. They proposed a Pareto based collaborative multi-objective optimization algorithm. The algorithm reduces the total energy consumption through a speed scaling strategy, generates a high quality initial population using a collaborative initialisation strategy, and exploits the properties of the problem to develop a collaborative search operator and a knowledge based local search operator. Chen et al. (2019) investigated the energy efficient DPFSP with idle-free aiming to minimize both makespan and total energy consumption. For this problem, they designed a co-optimization algorithm. The algorithm uses two metaheuristics for population initialisation together to ensure the quality and diversity of the initial solutions. Multiple search operations are designed to collaborate in a competitive manner to enhance the exploration capability. Wang et al. (2022) proposed a method combining a multi-objective mixed integer programming model and a multi-objective WOA to solve the DFSP considering energy consumption. The method has the objective of minimizing the total energy consumption and makespan. For the base WOA, a new initialisation method, update operator and local search strategy are designed for this particular problem. When dealing with large scale problems, this combined approach is able to strike a good balance between computational cost and the quality of the solution.

Zhao et al. (2024) considered the problem of energy efficient DFSP with blocking, and proposed a multi-objective discrete DE with the objective of minimizing makespan and total energy consumption. The algorithm employs a local search strategy based on the knowledge of five operators is introduced to enhance the utilisation of the algorithm, and a non-critical path energy saving strategy is used to reduce energy consumption. In order to cope with environmental problems and to meet the demand of customised production, Yu F. et al. (2024) proposed a mixed integer linear programming model and a multi-objective MA for the study of DHFSP. The method simultaneously aims at minimizing the total delay and total energy consumption. The quality of the initial solution is improved by introducing a speed dependent decoding method, an initialisation strategy based on the problem characteristics, and a search strategy that enhances the local search capability, which guides the population to achieve effective exploration in the solution space. As the worker resources also affect the efficiency of scheduling in the actual production manufacturing process, Gao et al. (2024) studied the DHFSP with assembly to minimize the degree of imbalance between makespan and worker workload. To address the problem, a variation based local search method and an elite search method were proposed, and a MOEA with an enhanced elite retention strategy was developed. Xin et al. (2015) proposed an adaptive binary PSO in the process of solving the multi-skilled worker assignment problem in a complex assembly system in order to achieve a balance between assembly station and process workloads and to minimize the man cost.

Recent research has addressed various practical aspects: sequence-dependent setup time, energy efficiency, sustainability considerations, worker resource management and algorithmic innovations. These developments reflect the field’s evolution toward more comprehensive and practical scheduling solutions, incorporating environmental, worker-related, and efficiency considerations. Future research opportunities lie in addressing emerging challenges in distributed manufacturing environments, particularly in areas of real-time adaptation and system resilience.

The evolution of FSP and variant problems research reflects four key trends: Industry 4.0 integration, sustainability considerations, the development of hybrid algorithms and human-centered manufacturing. These developments reflect the field of evolution toward more comprehensive and practical scheduling solutions, incorporating environmental, worker-related, and efficiency considerations. Future research opportunities lie in addressing emerging challenges in smart manufacturing environments, particularly in areas of real-time adaptation and system resilience.

5 Metaheuristic algorithm in job-shop scheduling problems

Job-shop scheduling problems has established itself as a cornerstone of modern manufacturing, particularly valued for its flexibility and customization capabilities. Its applications span diverse industrial sectors, including precision machinery, aerospace manufacturing, and foundry operations (Tan et al., 2021; Wu et al., 2018; Gong et al., 2020). However, this versatility introduces significant complexity in resource utilization and productivity optimization, making it a focal point for academic research.

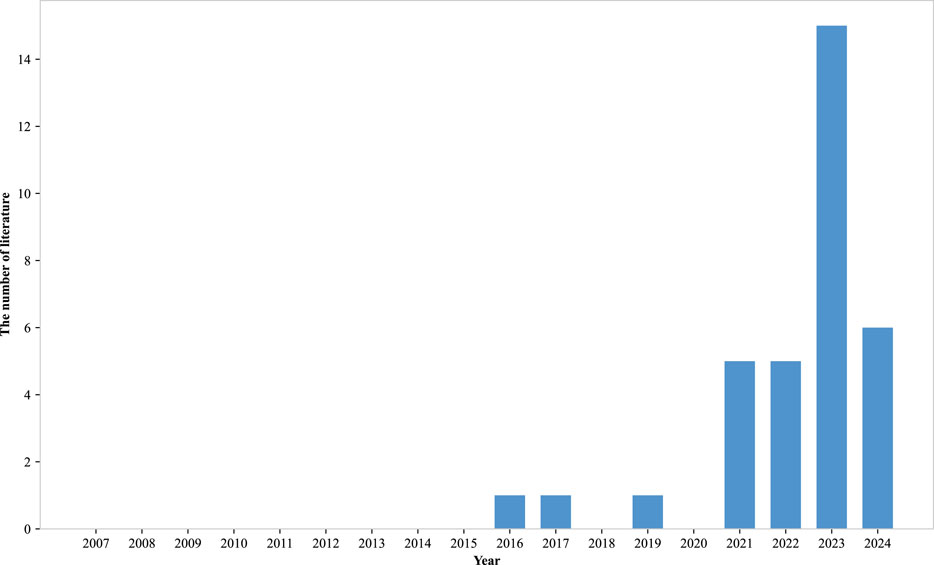

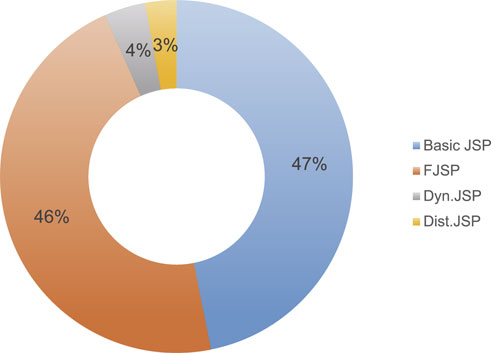

To comprehensively analyze the research landscape, we conducted a systematic literature review using Web of Science from 2000 to 2024, focusing on metaheuristic algorithms in multi-objective job-shop scheduling problems from 2015 to 2024.2

The analysis reveals several significant trends in job-shop scheduling problems research. As illustrated in Figure 11, there has been a marked increase in research activity since 2021, with sustained growth in publications across various JSP variants. Figure 12 demonstrates that Flexible Job-shop Scheduling Problem (FJSP) and Distributed Job-shop Scheduling Problem (Dist.JSP) have emerged as dominant research areas, likely due to their enhanced adaptability to modern production environments characterized by increasing complexity and variability.

Figure 11. Statistics on the number of metaheuristic algorithms solving muti-objective JSP and variants problems.

Figure 12. Proportion of metaheuristic algorithms solving muti-objective JSP and variant problems posted.

5.1 Job-shop scheduling

JSP, classified as NP-hard, finds widespread application in various industrial contexts, from automotive assembly to airport operations. As illustrated in Figure 13, research interest in JSP has shown significant growth since 2016, peaking in 2021, with continued momentum expected in this field.

Figure 13. The number of metaheuristic algorithms solving muti-objective JSP literature over the years.

5.1.1 Problem model

To address the JSP, the following factors are typically considered:

(1) Processing sequence of jobs: each job must be processed on different machines in a specific order;

(2) Machine availability: some machines may be unavailable at specific times, which affects the scheduling of jobs;

(3) Job arrival time: certain jobs may not arrive at the workshop simultaneously, and their arrival times can influence the scheduling plan;

(4) Priority: some jobs may have higher priority than others, requiring preferential scheduling.

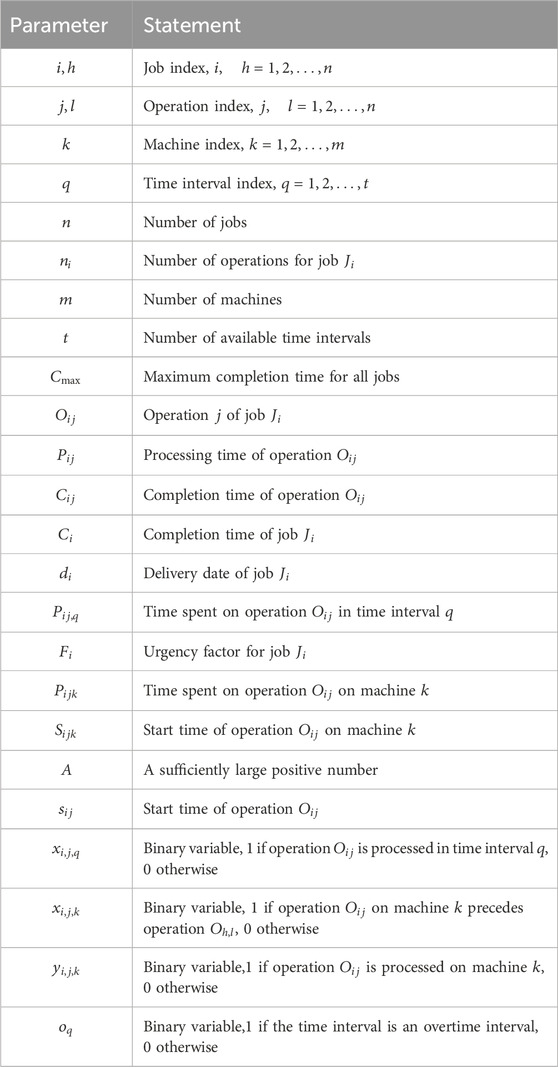

This chapter establishes a mathematical model with the objectives of minimizing makespan and total overtime. Table 6 presents the parameters and variables of the model.

Among them, Equations 65, 66 represent the two objective functions, which are minimizing the total overtime and minimizing the makespan, respectively. Equation 67 defines the no-tardiness constraint. Equations 68, 69 constrain that an operation of a job can only start after its immediately preceding operation has been completed, and its start time must be no earlier than time zero. Equation 70 ensures that an operation cannot be interrupted once it starts. Equations 71, 72 indicate that an operation can be processed within one or more time intervals, with its processing time equal to the total time spent across these intervals. Equations 73, 74 constrain that each operation can be processed on only one machine, and each machine can process only one operation at a time.

5.1.2 Solution algorithm

GA have been extensively applied to address the challenges of the classical JSP (Cheng et al., 1996; Cheng et al., 1999). Davis proposed using GA to solve the classical JSP (Davis, 2014). Gonçalves et al. (2005) introduced a hybrid GA to tackle JSP. This method utilizes a chromosome representation based on random keys, where schedules are constructed according to priorities derived from GA. To enhance solution quality, parameterized active schedules are first generated, followed by the application of a local search heuristic for further optimization. Momenikorbekandi and Abbod (2023) proposed a metaheuristic hybrid Parthenogenetic Algorithm (PGA) for traditional JSP with the objective of minimizing makespan and delay time. The algorithm combines with ethnic selection GA and PGA to improve the search efficiency and the quality of the solution by introducing a racial selection mechanism and multiple selection operators. The parthenogenetic algorithm employs exchange, inversion, and insertion operators, while population selection utilizes four different selection operators: random selection, roulette wheel selection, sexual selection, and aging selection. Abedi et al. (2020) concerned with the fact that the speed of the machine has an impact on the productivity, considered JSP that carry out the necessary maintenance activities during the scheduling process. The problem with the objective of minimizing the total weighted delay time and the total energy consumption also determines the appropriate speed of the machine and the location of the maintenance activities. They proposed a multi-cluster, multi-objective MA. The algorithm assigns solutions to different sub-populations, and to better cover the solution space, the algorithm combines local search and advanced goal-oriented local search methods. In addition, an efficient non-dominated sorting method is developed for multi-objective optimization. For variable batch JSP, Xie et al. (2023) designed a decomposition-based multi-objective Jaya algorithm. The algorithm aims to achieve minimize tardiness and the least number of transferred sub-batches, based on which it combines forward and backward decoding strategies, problem-specific Jaya updating mechanisms, and local search strategies in order to better balance the exploration and exploitation of solutions. With the development of AI, robots provide new ideas to further improve the productivity of factories. Li et al. (2020) discussed JSP in a robotic cell, where the transport of jobs is handled by robots and the jobs need to be completed within a time window. They used a mixed integer planning model to formulate the problem and proposed a Teaching-based Learning Algorithm (TLA). The algorithm is able to simultaneously determine the operation assignments, the robot assignments to be used for the transport operations, and the robot movement order, aiming to minimize makespan and the overall early arrival and delay rates.

Nowadays, with the growing impact of the Industry 5.0 trend on the manufacturing industry, more and more scholars are exploring the constraints of environmental protection and worker scheduling in JSP as well. González et al. (2022) investigated the problem of minimizing both makespan and energy consumption in classical JSP. The energy model considered allows the machine to be in five states, i.e., off, standby, idle, setup, and processing. They proposed an NSGA-II based evolutionary algorithm combining local and heuristic search. Wei et al. (2021) investigated the problem of simultaneously minimizing makespan, total weighted tardiness and precocity, and non-processing energy consumption in JSP by proposing a algorithm based on unified NSGA. The algorithm incorporates a heuristic that incorporates MinMax and NEH for population initialisation. The algorithm is capable of generating a set of Pareto optimal solutions that enable production managers to select appropriate scheduling schemes based on priorities. González-Rodríguez et al. (2020) solved the fuzzy JSP by referencing fuzzy sets to deal with processing time uncertainty with the objective of minimizing makespan and total non-processing energy. They used a NSGA-II based approach combined with heuristic decoding operators that improves the robustness and applicability of the algorithm in practical applications. Since the processing and handling time of a job is affected by a number of uncertainties in the actual production process, Afsar et al. (2022) proposed a new hybrid metaheuristic approach with the objective of minimizing makespan and minimizing non-processing energy consumption. The method combines the design principles of MA, including an evolutionary component based on explicitness, a forbidden search for makespan and a heuristic search for non-processing energy, as well as a post-processing optimization based on linear programming. The collaborate of multiple algorithms is used to achieve reduced energy consumption and improved environmental sustainability without compromising service levels.

Zhang et al. (2024a) investigated a multi-objective JSP for manual loading and unloading tasks considering the human factor, and proposed a grid-based ABC with the goal of minimizing makespan and total workload. The algorithm combines the artificial bee colony algorithm and the grid technique to reduce the complexity of the problem using a decomposition method with earliest and shortest scheduling rule, and divides the target space into multiple cells by constructing a grid coordinate system to facilitate the localisation and evaluation of individuals. The algorithm also designed to generate observer bees based on a mathematical formulation of priority weights to improve information utilisation and algorithm exploration and development. Efficiency in the manufacturing process is also limited by worker’s ability to operate the machine, his work capacity, and the worker’s fatigue level, etc. Rodríguez-Espinosa et al. (2024) investigated multi-objective JSP considering overtime work in a make to order manufacturing company, aiming to minimize the total tardiness and overtime costs. They proposed an enhanced NSGA-II. To accelerate convergence, a problem-specific two-stage decoding scheme was designed and an adaptive mechanism was employed to maintain the stability of global convergence. In addition, a local search procedure is introduced to enhance solution exploration.

Recent advances in JSP research have addressed various practical considerations. These developments reflect the evolving nature of JSP research, incorporating increasingly complex real-world constraints while maintaining computational efficiency and practical applicability.

5.2 Flexible job-shop scheduling

FJSP represents a complex manufacturing scenario where each job comprises a sequence of operations with specific processing constraints. The defining characteristic of FJSP is its dual-layer decision making requirement: machine selection and process sequencing. Operations must follow sequential constraints and are non-preemptable, while each operation can be processed on multiple capable machines.

As shown in Figure 14, research interest in FJSP has grown significantly since 2019, indicating its continued relevance in modern manufacturing systems.

Figure 14. The number of literature on metaheuristic algorithms solving muti-objective FJSP over the years.

5.2.1 Problem model

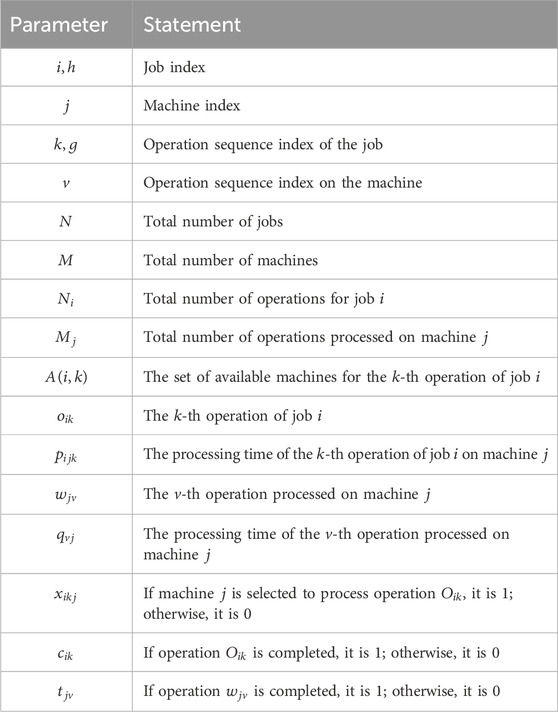

Addressing FJSP requires not only determining the sequence of jobs but also assigning each operation to an appropriate processing machine, resulting in a complex set of constraints. This section presents a mathematical model formulated with the dual objectives of minimizing the makespan and the total machine delay time. Table 7 provides a detailed definition of the parameters for this problem.

Equation 75, 76 represents the objective function for minimizing the makespan and the total machine delay time. In Equation 76, if a solution assigns only one operation to machine

5.2.2 Solution algorithm

Gao et al. (2008) developed a hybrid GA to solve the FJSP with three objectives: minimizing the makespan, minimizing the maximum machine workload, and minimizing the total workload. Pezzella et al. (2008) introduced an integrated approach to tackle the FJSP, which combines various strategies for initial population generation, individual selection for reproduction, and the creation of new offspring. Shahsavari-Pour and Ghasemishabankareh (2013) proposed a hybrid algorithm combining the advantages of GA and SA for solving the multi-objective function optimization problem in FJSP. The algorithm directly deals with three objectives through a Pareto optimal solution approach: minimizing makespan, minimizing machine workload, and minimizing the total workload of all machines. The hybrid algorithm is able to provide higher quality solutions than existing methods in solving multi-objective problems while reducing computation time. Zhang et al. (2020) investigated FJSP with two neighbouring work areas for a problem involving the production of basic parts and subsequent assembly operations. In order to minimize makespan, total tardiness time and total workload, a distributed ACO is proposed to explore the Pareto frontier. In addition, the method was successfully applied to different scenarios of the ball valve production scheduling problem. Liu et al. (2021) provided a new algorithm which combine with VNS and GA for solving FJSP. The algorithm aims to improve productivity, reduce cost and energy consumption, and it proposes several improvement measures for the problems of slow convergence and low accuracy of traditional GA in solving FJSP. These include a mutation operator based on PSO, a hybrid heuristic initialisation strategy, a VNS based on an improved multilevel neighbourhood structure, and a real-number based chromosome representation, encoding, decoding and crossover method. These improvements improve the convergence performance and solution accuracy of the algorithm.

Li et al. (2014) proposed a novel discrete ABC in solving a multi-objective FJSP containing maintenance activities. The algorithm aims to optimize three main performance metrics: minimizing makespan, total machine workload and critical machine workload. The algorithm employs a unique problem solution representation, the application of TS for local search, an efficient initialisation scheme, an adaptive strategy to enhance the exploratory capabilities of the algorithm, and a specially designed decoding method to handle maintenance activities. An external Pareto archive set is employed for recording all the non-dominated solutions found. Kacem et al. (2002) proposed a Pareto-based hybrid approach combining fuzzy logic and EAs to address the FJSP. This method leverages the knowledge representation capability of fuzzy logic and the adaptability of EAs to optimize three objectives: minimizing the makespan, the total machine workload, and the workload of the most heavily utilized machine. Basiri et al. (2020) designed a hybrid intelligent algorithm for FJSP dealing with fuzzy time. The algorithm is optimized based on the Pareto solution set, considering constraints such as the number of un-predetermined parallel machines, sequence-dependent setup times, re-entrant workflows and fuzzy variables, and combines a simple weighted sum method and a technology preference method.

Industry 5.0 further extends the beautiful vision of Industry 4.0 for energy saving by focusing on sustainable development and environmental responsibility while emphasising on human-centred production methods. Luan et al. (2023) developed an enhanced NSGA-II for multi-objective energy-saving FJSP with the objective of minimizing makespan, total delay time and total energy consumption. This algorithm improves the accuracy of the current solution by performing different neighbourhood search procedures in the sparse solution space by performing different neighbourhood search procedures to increase the diversity of the population of children in the local search, thus improving the accuracy of the current solution. In addition, a weighted approach is used to select the desired compromise solution from the set of Pareto solutions in order to achieve a balance between multiple objectives. Burmeister et al. (2023) focused on FJSP with dynamic energy costs and proposed a multi-objective modelling algorithm based on NSGA-II. The algorithm aims to minimize makespan and energy cost, and bridges the gap in the existing literature that is limited to coarse-grained time periods by taking into account frequently changing real-time energy tariffs. He et al. (2022) focusing on FJSP with dual resource constraints of machines and workers, constructed a model considering both machine and worker constraints, with the aim of minimizing makespan and total delay. They developed an improved African Vultures Optimization Algorithm. A neighbourhood search operation was designed to further minimize makespan and total delay. Zhang et al. (2023b) focused on the post processing shop for parallel disassembly/reassembly workstations and FJSP, which needs to decide on the assignment and sequence of disassembly/reassembly jobs, the as well as the sequence of operations and workstation assignments for reprocessing operations. An enhanced Grey Wolf Optimizer is proposed to address the multi-objective FJSP in remanufacturing systems, aiming to minimize both makespan and energy consumption. The algorithm improves accuracy, computational efficiency, solution stability, and convergence performance by incorporating multiple local neighborhood search strategies, stochastic interference methods, and weighted distance updating mechanisms.

Tan et al. (2021) proposed an optimization model considering worker fatigue for FJSP with dual resource constraints, aiming to simultaneously reduce worker fatigue and increase productivity through joint scheduling of machines and workers. The model aims at minimizing maximum worker fatigue and makespan. This research not only provides practical scheduling tools for decision makers, but also brings fatigue awareness to machine and worker constrained flexible manufacturing systems, facilitating both worker health and productivity. Vital-Soto et al. (2023) developed an elite NSGA-II with innovative operators for a dual resource constrained FJSP considering machine and worker allocation and sorting. The algorithm is able to provide a set of Pareto optimal solutions that help the decision maker to evaluate the trade-offs between different objectives. The algorithm demonstrates its advantages in defining daily schedules, adjusting schedules, priority management, on-time delivery and balancing worker workloads.

With the advent of Industry 5.0, the field of FJSP is increasingly oriented toward energy efficiency and sustainable development. Researchers are placing greater emphasis on integrating factors such as energy consumption, worker fatigue, and environmental responsibility into the scheduling process, aiming to achieve sustainability objectives alongside enhanced production efficiency. Current studies employ various hybrid algorithms designed to address the limitations of traditional methods, thereby improving convergence speed and solution accuracy. This trend indicates that future research will place greater importance on the synergy between algorithmic innovation and practical applications, underscoring the necessity of developing efficient and environmentally friendly scheduling solutions in complex dynamic environments.

5.3 Dynamic job-shop scheduling

Manufacturing environments inherently contain uncertainties, making dynamic scheduling a crucial research direction that closely aligns with real-world production scenarios. Dynamic events in manufacturing can be categorized into four main types: job-related events, operations-related events, machine-related events and other operational events.

Within this domain, the Dynamic Flexible Job-shop Scheduling Problem (Dyn.FJSP) emerged as an extension of Dynamic Job-shop Scheduling Problem (Dyn.JSP), incorporating machine selection flexibility.

As illustrated in Figure 15, research interest in dynamic scheduling problems shows an upward trend, reflecting their increasing practical significance. The ability to respond rapidly to environmental changes while generating optimal scheduling solutions is paramount in this context.

Figure 15. The number of literature on metaheuristic algorithms solving muti-objective Dyn.JSP and variant problems over the years.

5.3.1 Problem model

The Dyn.FJSP with new job insertion considered in this chapter can be defined in detail as follows. There are

This chapter establishes a mathematical model with the objectives of simultaneously minimizing the total weighted tardiness and maximizing the average machine utilization. Table 8 presents the detailed parameters of this model.

Equation 85 represents the total weighted tardiness of all jobs, where urgency is used as the weight factor (i.e., the penalty factor) for delays. Equation 86 represents the reciprocal of the average machine utilization. Equation 87 indicates that the completion time of each operation must be non-negative. Equation 88 ensures that each operation can only be processed on one available machine. Equation 89 ensures that a job can only be processed after its arrival time. Equation 90 guarantees precedence constraints. Equation 91 ensures capacity constraints are satisfied.

5.3.2 Solution algorithm

When solving scheduling problems under the influence of dynamic events, it is particularly important to design algorithms that can respond quickly to changes in the environment and generate reasonable scheduling schemes in immediately. Chryssolouris and Subramaniam (2001) designed a GA for the Dyn.JSP with the objectives of average job tardiness and average job cost. In scheduling considering dynamic events, most scholars use rescheduling method, i.e., the newly inserted jobs are merged with the existing jobs to reschedule, this scheduling method will make the new scheduling scheme completely different from the old scheduling scheme. In addition, this rescheduling method may lead to stability degradation. Rangsaritratsamee et al. (2004) in order to improve the stability degradation caused by rescheduling and other problems, they proposed a multi-objective rescheduling method based on GA and local search algorithm. The method adopts stability as an additional performance measure based on the objective of minimizing makespan and delay, aiming to balance efficiency and stability. Random job arrivals are the most common class of dynamic events in the dynamic scheduling. Wang et al. (2019) proposed a rescheduling method that combines performance and stability considerations to address this type of Dyn.JSP. The method aims to minimize the discontinuity rate of new jobs, makespan deviation of the initial schedule and order deviation on the machine. Four matching strategies are modified to determine the rescheduling range. An improved PSO is proposed, which consists of a decoding scheme that considers machine unavailability constraints, a population initialisation method based on a new transformation mechanism, and a particle movement method that introduces positional variations and random inertia weights.

Compared to Dyn.JSP, Dyn.FJSP is more challenging in that it needs to consider not only the impact of dynamic events in the manufacturing process, but also the flexibility that jobs can be assigned to multiple machines for processing. Fattahi and Fallahi (2010) proposed a multi-objective mathematical model and a metaheuristic algorithm based on GA to address Dyn.FJSP, aiming at balancing the efficiency and stability of the schedule. Zhang et al. (2013) proposed a rescheduling approach based on hybrid GA and TS to solve Dyn.FJSP. They introduced a simulator to deal with the complexity of real-time events and the difficulty of representing them accurately in a mathematical model. Liu et al. (2024) proposed a multi-objective ALNS for the Dyn.FJSP of self-driving transportation in smart factories. The algorithm adopts a proactive responsive approach to cope with the dynamic interference of new job insertion. The algorithm formulates a two stage multi-objective mixed-integer planning model: the first stage aims to minimize makespan and workload imbalance; the second stage introduces instability minimisation to deal with the effects of disturbances.

From the above research, it can be concluded that in the field of dynamic scheduling, the design of algorithms that can quickly respond to dynamic events is particularly important, as it directly impacts the efficiency and stability of manufacturing environments. Researchers are focusing on employing rescheduling strategies to balance efficiency and stability, particularly in the context of multi-objective optimization, where the goal is to simultaneously enhance scheduling efficiency and robustness. The trend towards the adoption of hybrid algorithms and innovative strategies underscores the critical role of algorithmic innovation in improving scheduling performance.

5.4 Distributed job-shop scheduling

Modern manufacturing systems have evolved into complex networks of multiple interconnected job-shop scheduling problems, each characterized by distinct equipment, process capabilities, and resources. This evolution has exposed the limitations of traditional centralized scheduling approaches, highlighting the growing importance of distributed scheduling solutions. The field encompasses two main variants: Dist.JSP and its flexible counterpart, Distributed Flexible Job-shop Scheduling Problem (Dist.FJSP), distinguished by machine optionality.

As illustrated in Figure 16, research interest in Dist.JSP has shown a consistent upward trend, driven by industry demands for enhanced productivity and resource optimization. This trajectory suggests continued growth in this research domain.

Figure 16. The number of literature on metaheuristic algorithms solving muti-objective Dist.JSP and variant problems over the years.

5.4.1 Problem model

In production and manufacturing systems, flexible scheduling strategies play a critical role in adapting to dynamic market demands and enhancing production flexibility. As a representative problem of multi-factory scheduling, Dist.FJSP is characterized by allowing each sub-factory to operate as an independent flexible job shop, responsible for processing specific parts of the overall production tasks. The resolution of Dist.FJSP involves addressing three key subproblems:

(1) The allocation of parts to processing factories;

(2) The matching of operations to processing machines;

(3) The optimization of operation scheduling within individual factories.

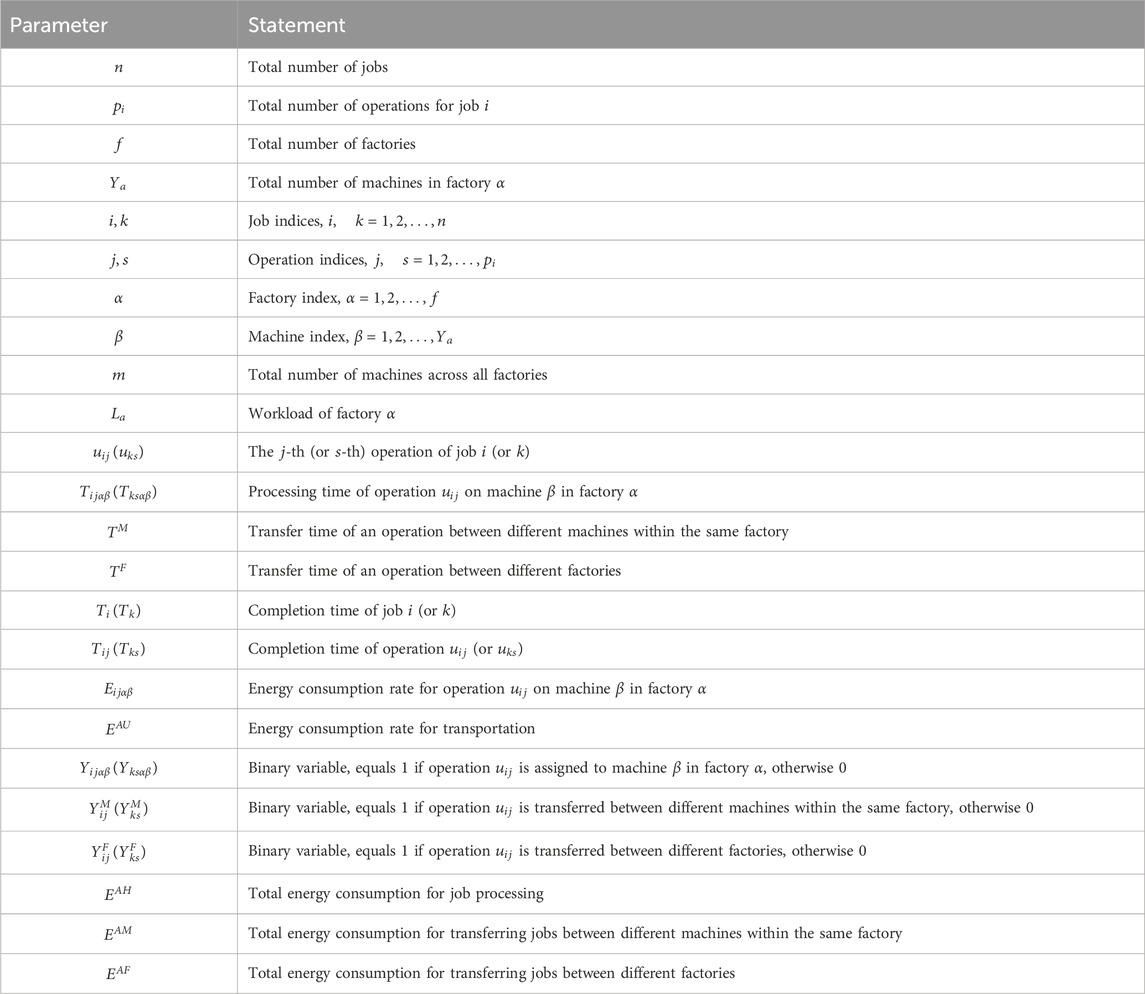

This chapter uses Dist.FJSP as an example to formulate a mathematical model aimed at minimizing makespan and total energy consumption. Table 9 presents the detailed parameters of this model.

Equations 92, 93 define the optimization objectives of the problem, which are minimizing the makespan and total energy consumption, respectively. Equation 94 ensures that each operation satisfies the precedence constraints. Equation 95 guarantees that each machine processes at most one operation at a time. Equation 96 ensures that each operation is processed on one machine in a single factory only once. Equation 97 restricts each operation to undergo only one transportation, either within or between factories.

5.4.2 Solution algorithm