- 1School of Economic Management and Law, Jiangxi Science and Technology Normal University, Nanchang, China

- 2School of Civil Engineering, Jiangxi Science and Technology Normal University, Nanchang, Jiangxi, China

- 3State Grid Jiangxi Electric power Co., Ltd., Nanchang, China

The steel industry is notable for its significant environmental impact, highlighting the pressing need to promote technological innovation within the sector in order to reduce carbon emissions. This paper utilizes a quadrilateral evolutionary game model to analyze the strategic behaviors of steel producers, construction companies, scrap steel recyclers, and the government throughout the entire steel production, consumption, and recycling processes and their impact on carbon emission reduction. The analysis and simulation of the model provide policy insights for these four key players. The study’s findings are as follows: (i) Government subsidies can effectively stimulate low-carbon production methods and encourage green consumer behavior. (ii) The strategic choices for technological innovation by steel manufacturers and scrap steel recyclers are primarily influenced by cost factors. Government subsidies for technological innovation play a crucial role in incentivizing a smooth transition to low-carbon production methods. (iii) For steel manufacturers, the carbon benefits derived from technological innovation are a critical factor influencing their engagement in such initiatives. If these manufacturers can benefit from environmental regulations, they are more likely to engage in technological innovation. (iv) The strategies of construction companies are influenced by production costs and carbon benefits associated with steel manufacturers, exhibiting threshold effects.

1 Introduction

In the context of global low-carbon development, addressing the ongoing environmental degradation is a significant challenge encountered by nations worldwide. In September 2020, China explicitly introduced the “dual-carbon” goals as a long-term strategy for reducing greenhouse gas emissions in the 21st century (Hao et al., 2022), showcasing China’s strong commitment to actively combatting climate change, embracing green and low-carbon development pathways, and fostering the collective advancement of humanity. As a pivotal industry with considerable potential for reducing carbon emissions, the iron and steel sector accounts for 5% of the world’s total energy consumption and contributes 6% of global anthropogenic CO2 emissions (Zhao et al., 2020). By 2021, China’s iron and steel industry is projected to represent approximately 16% of the nation’s overall carbon emissions, posing significant challenges to high-quality economic and social progress (Xu et al., 2022). Carbon emissions in the iron and steel production process primarily originate from fossil fuel combustion and chemical reactions during ironmaking, highlighting the pressing need for technological innovation in the sector to facilitate a transition towards low-carbon practices, a critical contemporary issue facing China.

Technological innovation stands as a pivotal strategy for the reduction of carbon emissions, offering the potential for significant cuts in CO2 output through the integration of sophisticated production methodologies and the adoption of cleaner manufacturing technologies. In light of the imperative to address contemporary climate change, the urgency is heightened for the development of transformative CO2 emission reduction technologies. Notably, the advancement of energy-saving technologies emerges as a paramount initiative in the quest for achieving carbon neutrality within the iron and steel sector (Wang et al., 2022). The enhancement of low-carbon technology innovation and its practical application is crucial for the iron and steel industry to meet its carbon reduction benchmarks. Scholars have illustrated that the expansion and utilization of high-temperature waste heat recovery technologies, coupled with the amalgamation of carbon capture and storage (CCS) methodologies, present a viable approach to diminishing CO2 emissions attributable to iron and steel manufacturing processes (Paltsev et al., 2021). Concurrently, the enhancement of energy efficiency and the optimization of industrial processes constitute an efficacious route for carbon reduction. This approach is capable of yielding substantial decreases in both energy usage and carbon emissions, attributable to systemic energy conservation and the refinement of operational procedures (Sundaramoorthy et al., 2023; Tang et al., 2024). Energy consumption within the iron and steel production sector is primarily concentrated in pivotal processes like blast furnace ironmaking, converter steelmaking, and steel rolling. Coke, serving as the principal raw material for blast furnace ironmaking, stands as the largest fossil fuel directly utilized by the iron and steel industry. The exploration and utilization of alternative fuels, such as hydrogen replacing conventional carbon-based fuels, present a promising avenue for reducing carbon dioxide (CO2) emissions during the iron and steel production process (Liu et al., 2021; Tang et al., 2020). Given hydrogen’s role as a reducing agent with iron ore, yielding water instead of carbon dioxide, it underscores the significance of hydrometallurgy as a clean and revolutionary technology in steel production.

As the world’s largest producer of steel, China accounts for half of the global output (Zhou and Yang, 2016). Within downstream industries, the construction sector remains the largest consumer of steel, representing 58.6% of direct steel consumption in China (Yang et al., 2023). This demand has remained stable, particularly as infrastructure development and urbanization progress are accelerated. However, regulatory policies in the real estate market in recent years have had a certain impact on the demand for construction steel (Yu et al., 2017). With the increasing demand from downstream industries for high-performance, eco-friendly steel materials, it is imperative for steel enterprises to intensify technological innovation and product upgrades. To address the various challenges of environmental pollution, both the steel industry and the construction sector are working together to promote the efficient use and recycling of steel materials through technological innovation and material development.

Achieving carbon emission reduction in the steel industry can be pursued through multiple avenues. The development of a circular economy, which enhances the recycling and utilization of scrap steel and thereby reduces the demand for new iron ore, constitutes an effective means of carbon emission reduction (Companero et al., 2021; Wuebbeke and Heroth, 2014). Driven by the momentum of scrap steel depreciation, there is a projected significant increase in the availability of scrap steel resources and the proportion of scrap steel used in the future (Xin et al., 2023). The construction sector generates a substantial amount of waste steel materials during demolition, maintenance, and construction processes. The recycling and utilization of this waste steel not only conserve iron ore resources and mitigate environmental degradation but also significantly reduce energy consumption and greenhouse gas emissions. Moreover, processed construction scrap steel can be repurposed as recycled steel materials in various sectors, including construction, transportation, and mechanical manufacturing, offering high recycling value. Currently, the scrap steel recycling and processing industry primarily employs advanced sorting technologies, sophisticated shredding techniques, and environmentally friendly treatment methods to achieve carbon emission reductions during the scrap steel processing. However, the application and promotion of these technologies face challenges related to technological maturity, economic costs, policy support, and market acceptance. A well-considered policy can offer substantial support for government regulation (Xu et al., 2024a). Consequently, boosting investment in technological innovation and enhancing policy incentives play a pivotal role in fostering technological innovation and mitigating carbon emissions across the entire iron and steel industry (Rissman, J. et al., 2020).

Carbon emission reduction in the steel industry involves numerous stakeholders, including downstream steel enterprises, scrap steel recyclers, and the government. Companies play a central role in the development of a low-carbon economy (Chang and Lo, 2022), and to encourage active corporate participation in low-carbon transitions, governmental policy support and stringent environmental regulation are essential. Governments worldwide have been implementing regulations and policies to mitigate climate change, aimed at fostering technological innovation for sustainable development (Dhayal et al., 2023). However, the enforcement of environmental policies often incurs substantial costs. To reduce the expenditure on environmental protection and management, governments increasingly rely on regulatory measures such as carbon taxes and subsidies to promote the widespread adoption of low-carbon technologies. To mitigate the environmental effects of pollutants, the government could enforce stringent regulations (Xu et al., 2024b). Some scholars argue that carbon taxes and subsidies positively influence manufacturers’ adoption of low-carbon strategies (Chen et al., 2022; Yang and Nie, 2022). Additionally, a well-constructed regulatory framework can effectively stimulate innovation and enhance productivity (Ahmed, 2020). Furthermore, subsidies for low-carbon consumption by the government can stimulate market demand, thereby driving green production on the supply side (Ma et al., 2021). The incentives for green product consumption implemented by governments, coupled with consumers’ growing positive attitudes towards these products, form the main driving force behind the growth of green product consumption (Hong et al., 2021). From the perspective of guiding social behavior, these subsidy policies not only offer economic rewards but, more importantly, they motivate economic actors to take proactive actions, thus promoting a harmonious coexistence between sustained economic growth and ecological and social wellbeing.

Currently, research on carbon emission reduction in the steel industry is quite extensive; however, most studies have focused on individual aspects, with few considering the integrated approach of production, consumption, and recycling. There is a scarcity of in-depth exploration into the interplay of strategies among different participants and the underlying mechanisms. This study zeroes in on four key players: steel manufacturers, construction companies, scrap steel recyclers, and the government. It examines the behavioral patterns and interactions among these parties under the incentive of government subsidies, aiming to provide practical guidance for technological innovation and carbon emission reduction in the steel industry. Nevertheless, achieving the optimal strategy selection and an ideal state for all parties involves a prolonged process of adjustment. By employing an evolutionary game model, this study aims to reveal the optimal strategies that each party should adopt to maximize the overall benefit of carbon emission reduction in the steel industry, thereby achieving a win-win outcome for technological advancement and environmental protection.

Therefore, this paper proposes a four-party evolutionary game model to investigate the following issues: (1) What are the strategic choices of stakeholders under the current state of insufficient technological innovation incentives in the steel industry, specifically in response to government subsidies for technological innovation and consumer subsidies? (2) What are the main factors influencing technological innovation in the steel industry? (3) How do the strategies of the parties in the game system influence each other? By addressing these questions, this paper aims to offer more flexible policy recommendations for the steel industry to achieve carbon emission reduction. The establishment of a multi-party evolutionary game model can reveal the true reactions of each participant in greater detail, better balance the interests of all parties, and on this basis, the paper attempts to provide practical and feasible suggestions for all stakeholders to promote the low-carbon development of the entire steel production, consumption, and recycling system. Additionally, this paper expands the application of evolutionary game theory by selecting four game entities to construct the model, providing a new perspective for future research on carbon emission issues in the steel industry using evolutionary game theory.

The remainder of this paper is structured as follows: In Chapter 2, a review and in-depth analysis of the relevant literature are conducted to demonstrate the innovation and practicality of this study. In Chapter 3, the research problem of this paper is described, and model assumptions are proposed. In Chapter 4, a stability analysis of the evolutionary game model is conducted, deriving the equilibrium conditions for system stability. Chapter 5 involves the valuation of the model and a sensitivity analysis to study the evolutionary trends of the parties in the system. In Chapter 6, the research findings are discussed, and policy implications for all stakeholders are presented. The final chapter summarizes the entire paper.

2 Literature review

The structure of this chapter is as follows: The initial section offers a comprehensive overview of the literature concerning the impact of technological innovation on carbon emissions, emphasizing the key role of innovation in steering the steel industry towards sustainability. The second section scrutinizes the multifaceted roles of stakeholders, including steel manufacturers, consumers, and policymakers, in the collective endeavor to reduce carbon emissions. The third section delves into the application of game-theoretic models, particularly evolutionary game theory, to analyze strategic interactions among stakeholders concerning carbon emissions. This section also discusses the novelty and potential contributions of the chosen model to the existing body of research.

2.1 Impact of technological innovation

The persistent global climate crisis has driven numerous countries to establish a comprehensive set of targets aimed at tackling and diminishing carbon emissions and a variety of other greenhouse gases. These targets can be effectively met by embracing and implementing technological innovations. Within the industrial sector, in particular, the role of technological innovation stands out as a potent force in reducing carbon emissions (Xu W. et al., 2023). With the ongoing expansion of the global economy and the heightened consciousness regarding environmental conservation, low-carbon manufacturing has progressively emerged as the prevailing trend in the evolution of new industries. It is widely acknowledged as a crucial pathway to attaining sustainable economic growth (Xiao et al., 2024). Low-carbon manufacturing is significantly driven by advancements in green technologies, which help to reduce carbon emissions during the production process by improving energy efficiency and adopting clean energy sources (Li et al., 2023). To address climate change and promote the transformation of the economy towards low-carbon development, it is crucial to encourage enterprises to adopt innovations in green and low-carbon technologies. Moreover, technological innovation must be achieved through appropriate low-carbon regulation to realize energy saving and emission reduction. The green technological innovation of enterprises is to some extent constrained by low-carbon regulatory policies, while also stimulating the role of these policies in enhancing green efficiency (Ding and Hu, 2022). An economic development model centered on green technological innovation is a key pathway to achieving the low-carbon transformation of the economy (Xu Y. et al., 2023). However, competition among local governments may suppress the positive effects of economic low-carbon transformation and green technological innovation. To foster innovation and application of low-carbon technologies, some scholars have proposed that, due to the limitations of research and development capabilities within a single industry, collaborative innovation involving industry, academia, research, and government (IURG) has become the most feasible solution for low-carbon technological innovation (Cui et al., 2020). Furthermore, several scholars have elucidated the intricate web of causality linking Foreign Direct Investment (FDI), green innovation, and CO2 emissions. Their findings offer crucial policy insights, guiding countries and regions on how to attain environmental sustainability through the lens of green innovation (Ali et al., 2022).

The low-carbon development of China’s steel industry can be achieved through four key actions: improving energy efficiency, shifting towards scrap steel or electric arc furnace routes, advancing material efficiency strategies, and deploying incentive-based innovative technologies (Lin et al., 2021). Low-carbon innovative technologies and revolutionary innovations are crucial for carbon emission reduction, significantly impacting low-carbon development by reducing CO2 emissions. Consequently, the government can stimulate the development of low-carbon technologies by formulating new policies and regulations related to the carbon market, thereby timely influencing the relationship between the carbon market and its participants (Sun et al., 2020). Although technological innovation is an effective way to address carbon emissions, different types of technological innovation may lead to varying environmental performance, and low-carbon technological innovation is key to achieving green production (Shi et al., 2021). Some scholars have found that energy consumption plays a significant mediating role in the impact of technological innovation on carbon emission reduction. The influence of technological innovation on carbon emissions is constrained by the level of energy consumption; low energy consumption significantly promotes the reduction of carbon emissions through technological innovation. However, once energy consumption exceeds a critical level, the facilitative effect of technological innovation on carbon emission reduction can turn into a suppressive one (Zhang et al., 2020). Additionally, other scholars have pointed out that digital technologies indirectly affect carbon emissions by influencing industry structure, technological innovation, and tax structure (Zeng and Yang, 2023; Lin and Ma, 2022).

The escalation of carbon emissions has accelerated low-carbon innovation in cities, with the type of low-carbon innovation exerting varying effects on its outcomes. Environmental awareness acts as an intermediary channel through which carbon emissions influence low-carbon innovation. With the assistance of media, government, and businesses, the growing volume of carbon emissions has heightened public environmental consciousness, altered consumer behavior, and spurred enterprises to quicken their pace of low-carbon innovation (Pan et al., 2021). Some scholars have also noted that the application of artificial intelligence technology has a positive impact on carbon reduction, where green technological innovation, green management innovation, and green product innovation play a moderating role, and corporate green innovation strengthens the impact of artificial intelligence on carbon reduction (Chen and Jin, 2023). Furthermore, government environmental regulation can effectively enhance corporate green innovation, with environmental investment serving as an intermediary. However, the development of environmental regulation in China is relatively lagging, and its positive incentive role remains to be further leveraged (Chen et al., 2023).

In summary, technological innovation plays a crucial role in promoting low-carbon manufacturing and sustainable economic development. Measures such as green technological innovation, inter-departmental collaboration, policy support, and raising environmental awareness can effectively facilitate industrial carbon reduction and achieve a green economic transition. How to achieve the low-carbon transformation of the socio-economic system through technological innovation is an important practical issue. At the same time, considering regional heterogeneity, governments need to formulate and implement region-specific technological innovation strategies for a certain period to promote global carbon reduction efforts.

2.2 Role of stakeholders in carbon emission reduction

The steel industry, as one of the primary sources of carbon emissions, is increasingly important in achieving carbon reduction targets (Wang and Lin, 2016). Steel manufacturers, as the main producers of steel products, directly impact the carbon footprint of the entire steel industry. It is estimated that the CO2 emission intensity of the steel industry is 2.33 tons (CO2/ton), with the production and manufacturing phase being the primary source of CO2 emissions, accounting for 89.84% of the total emissions in the steel’s entire lifecycle (Song et al., 2025). Under the current strategic goals of peak carbon and carbon neutrality, actively promoting energy-saving and low-carbon technologies and increasing the ratio of scrap steel to steelmaking aligns with the requirements of high-quality economic development. In traditional steel production processes, especially the blast furnace ironmaking method, high energy consumption and carbon emissions are significant (He et al., 2017). Therefore, manufacturers have tremendous potential and responsibility in technological innovation and optimization of the production process (Fu et al., 2014). For instance, they can optimize production processes to reduce the energy consumption and carbon emissions per unit of steel products by increasing the blast furnace pellet ratio and the electric furnace scrap rate (Na et al., 2024). They can also adopt advanced steelmaking technologies, utilizing green, pollution-free hydrogen energy, and using hydrogen plasma to reduce iron ore, thereby reducing CO2 emissions at the source (Gajdzik et al., 2023). In addition, steel manufacturers can employ technologies such as Direct Reduced Iron (DRI) to achieve carbon reduction, thus producing low-carbon, green steel products (Nduagu et al., 2022; Sharifi and Barati, 2010).

Construction companies, as major consumers of steel products (Kanyilmaz et al., 2023), have a profound impact on the carbon reduction of the entire industry through their material selection preferences. In the construction industry, material choices not only affect the quality and cost of buildings but also directly relate to their environmental impact, particularly carbon emissions (Xu et al., 2020). With the growing global concern over climate change, an increasing number of construction companies are focusing on steel manufacturers that employ low-carbon production technologies to reduce the carbon footprint of their construction projects (Chen et al., 2018). Initially, construction companies often consider suppliers’ environmental and carbon reduction policies when selecting material suppliers. Steel manufacturers committed to reducing carbon emissions typically adopt advanced production technologies and eco-friendly processes to decrease energy consumption and carbon emissions during production. These companies often highlight their environmental philosophies and carbon reduction measures in their promotional materials to attract construction companies with stronger environmental awareness. Subsequently, the construction industry is also actively exploring how to reduce steel material waste through technical means, thereby reducing carbon emissions (Nadoushani et al., 2018). Steel waste during construction is a serious issue in the construction industry, which not only increases project costs but also adversely affects the environment. Therefore, construction companies should not only focus on optimizing construction technology to reduce steel waste but also establish connections with recyclers to promote the recycling and reuse of scrap steel, as construction scrap steel indeed has significant potential value and environmental benefits (Czarnecki and Rudner, 2023).

Scrap steel recyclers play a crucial role in promoting the circular economy of the steel industry (Hu et al., 2020). In the production and consumption processes of steel, scrap steel, as a renewable resource, significantly contributes to reducing reliance on raw iron ore, saving energy, and lowering environmental pollution (Xuan and Yue, 2017). It is estimated that using scrap steel as raw material instead of iron ore to produce new steel can save a substantial amount of energy and reduce carbon emissions. Recycling 1 kg of scrap steel can reduce 1.5 kg of CO2 equivalent emissions, 13.4 MJ of primary energy, and 1.4 kg of iron ore (Broadbent, 2016). Moreover, scrap steel recyclers improve the quality and efficiency of scrap steel recycling by employing advanced sorting and processing technologies, including magnetic separation, crushing, cleaning, and packaging technologies (Rem et al., 2012; Ferreira Neto et al., 2021), ensuring the purity and consistency of scrap steel materials to meet the requirements of steelmaking processes. However, the efficiency of scrap steel recycling and utilization is influenced by various factors. For example, the construction of recycling channels (Berlin et al., 2022; Gu et al., 2021), scrap steel classification standards (Gao et al., 2023; Xu D. et al., 2023), market demand (Watari et al., 2023), and policy support all affect the recycling and utilization of scrap steel. Therefore, the government and the industry need to work together to improve the recycling rate of scrap steel through reasonable policies, financial support, strengthening technological research and development, and enhancing environmental awareness.

To promote the achievement of carbon reduction targets, the government can formulate clear carbon reduction targets (Bai et al., 2023), provide tax incentives (Tang et al., 2021), and R&D subsidies to encourage enterprises to reduce pollution and carbon emissions (Qi et al., 2023). For consumers, green consumption subsidies and green product certification are also effective ways to motivate green consumption behavior (Yang et al., 2022). Government regulation of firms, facilitated by the strategic implementation of subsidies, effectively enhances economic efficiency while simultaneously promoting environmental sustainability (Chen et al., 2024). Carbon reduction in the steel industry is a systematic project involving multiple industries and links. Steel manufacturers, construction companies, and scrap steel recyclers must work together to achieve carbon reduction through technological innovation and optimized management. At the same time, government policy support and the improvement of the market mechanism are also indispensable. Therefore, steel manufacturers, construction companies, and scrap steel recyclers each play different but interconnected roles, jointly promoting the development of the entire industry towards a lower-carbon and more sustainable direction. It is essential for industry players to leverage innovation and foster collaboration in order to mitigate risks and enhance their own development by capitalizing on the opportunities presented by the emerging market trends (Xiao and Xu, 2024). This paper will analyze these roles in detail and discuss how to more effectively achieve carbon reduction in the steel industry under government subsidies.

2.3 Applications of game theory

Game theory studies the decision-making processes of participants whose actions are interconnected and mutually influential, an analytical framework that has been widely applied across various fields (Eissa et al., 2021; Kaplinski and Tamosaitiene, 2010; Moretti and Vasilakos, 2010). Evolutionary game theory, a further development of game theory, is utilized to analyze and predict the strategic choices and evolutionary processes of individuals in long-term interactions (Estalaki et al., 2015).

Many scholars have conducted extensive research on carbon emission issues across various fields using game theory. To effectively understand the collaborative evolution mechanism among three stakeholders in carbon trading—government, emission reduction enterprises, and carbon control enterprises—Hu and Wang (2023) analyzed the selection mechanism of carbon trading participants’ game strategies through repeated dynamic equations and discussed the main factors affecting the evolution and stable outcomes of carbon trading through scenario simulation. Liu et al. (2022) constructed an evolutionary game model for local government cooperation in emission reduction, finding that the likelihood of the government choosing a cooperative emission reduction strategy increases at different rates based on the benefits and costs of cooperation. Additionally, carbon tax policies affect the likelihood of local governments choosing cooperative emission reduction, with different carbon tax scales having varying impacts on their willingness to cooperate. Cui et al. (2022) built a trilateral game model between enterprises and the government, concluding that carbon prices, additional green technology innovation benefits, and innovation incentives significantly impact corporate strategic choices, with different strategic selections made by enterprises with varying innovation input-output ratios under the same conditions. Li et al. (2022) simulated the evolutionary game path of government and corporate carbon reduction under the “Dual carbon” goals using carbon market transaction data, finding that increasing financial subsidies can improve the probability of high-pollution enterprises reducing carbon emissions, and intensifying carbon emission penalties helps high-pollution enterprises actively reduce emissions. Zhao and Liu (2019) established an evolutionary game framework between the government and enterprises to study the adoption of carbon capture and storage (CCS) technology from a micro perspective, which is significant for policy support, low-carbon power generation revenue, and reducing the cost of CCS adoption for power companies. To encourage enterprises to reduce carbon emissions, Li et al. (2024) constructed a three-party evolutionary game model to explore the interactive behavior between the government, enterprises, and customers, concluding that to encourage enterprises to reduce carbon emissions, it is necessary to guide customers to purchase low-carbon products. Moreover, customers are more sensitive to low-carbon consumption subsidies than to consumption taxes. Xue et al. (2022) studied the dynamic decision-making process of three stakeholders—manufacturing enterprises, government regulatory departments, and media investigation institutions—regarding stable strategies based on evolutionary game theory. The main factors affecting the stable strategies of the three stakeholders were identified as income, subsidies, costs, and losses.

In the steel industry, Liu et al. (2023) established a three-party evolutionary game model between steel enterprises, scrap steel enterprises, and the government and conducted simulation analysis, deriving three evolutionary stable strategies for the formation of scrap steel bases and determining that the optimal strategy is with the participation of steel and scrap steel enterprises and minimal government intervention. This provides unique insights and theoretical support for promoting the development of the scrap steel industry and helping to achieve peak carbon and carbon neutrality strategies. Duan et al. (2017) constructed a two-stage dynamic game model for China’s steel industry, incorporating factors such as carbon tax collection, product subsidies, and carbon capture and storage (CCS) into the emission reduction mechanism, studying the overall emission reduction effects and economic impact of the steel industry. Li et al. (2022) constructed a repeated dynamic game model that includes carbon trading policies and other mixed emission reduction policies, proposing that enterprises should comprehensively consider factors such as emission reduction policies, output adjustment policies, and carbon trading benchmarks to ensure that enterprises and the entire market do not fall into an unbalanced state. Zhang and Zhang (2022) established an evolutionary game model between steel enterprises under the government subsidy mechanism and introduced a carbon quota trading mechanism to determine the optimal collaborative atmospheric pollution management strategy between large and small steel enterprises under government subsidy policies. It was found that government subsidies and the input-output ratio are crucial for enterprises to cooperate in atmospheric pollution control investment, providing unique insights and theoretical support for steel enterprises to achieve carbon reduction.

According to existing research, although game theory has been widely used to analyze the impact of carbon emission policies in the steel industry, these studies have mostly focused on the interactions between the government and steel manufacturers, which are bilateral or trilateral. However, the steel industry is a complex system with multiple stakeholders, and current government subsidy policies tend to favor manufacturers and consumers, neglecting scrap steel recyclers who have significant potential for carbon reduction. This study expands the perspective to the entire steel industry, incorporating steel manufacturers, construction companies, scrap steel recyclers, and the government into an integrated system, to comprehensively analyze the coordinated dynamics and evolutionary trends of all parties in carbon reduction efforts. Through this multidimensional analytical framework, this study aims to reveal how different stakeholders interact, thereby providing a deeper insight into the green transformation of the steel industry. In the research of this paper, traditional game theory is not applicable because it is based on the assumption that participants have complete rationality and can obtain complete information. Obviously, such assumptions are unrealistic for the participants in this study. Enterprises and governments cannot fully grasp each other’s needs and specific situations. In contrast, Evolutionary Game Theory (EGT) provides a more realistic analytical framework, assuming that participants have limited rationality and are in an environment of asymmetric information (Wang et al., 2021). This theory is closer to reality and can better explain and predict the participants’ strategic choices and behavioral evolution under incomplete information.

3 Problem description and model assumptions

Through the introduction in Chapter 1 and the literature review in Chapter 2, we have gained an in-depth understanding of the current state of the steel industry and the issues related to carbon reduction. To better construct the model and draw innovative conclusions, the following sections will delve into the core issues of this study and provide a detailed introduction to the model’s construction and the basis of its assumptions. This process will offer us a more comprehensive analytical framework to reveal the new mechanisms of carbon reduction technology innovation in the steel industry. The assumptions are as follows.

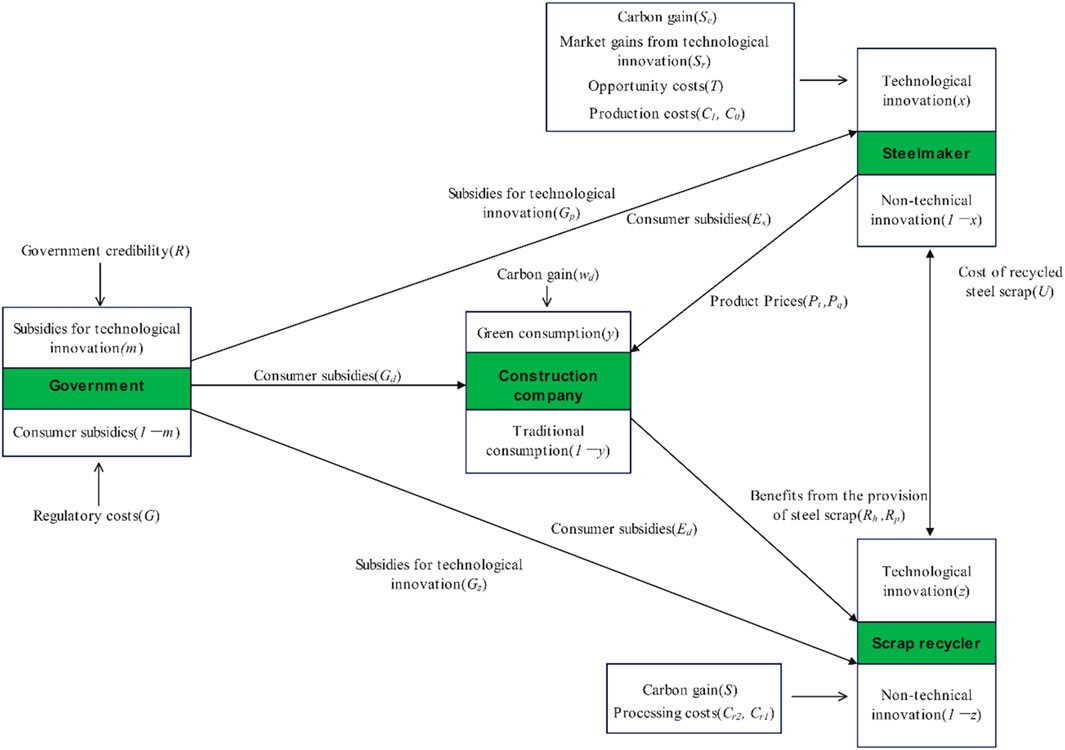

(1) This paper selects steelmaker, construction conpany, scrap recycler, and the government as the game players. The government, as an important player in the game, aims to promote technological innovation in steelmaker and scrap recycler through technological innovation subsidies; at the same time, it uses consumption subsidies to encourage green consumption by construction company. On the basis of maximizing the interests of all parties, the goal is to achieve carbon reduction targets in the production, consumption, and recycling processes of steel, promote the low-carbon transformation of the entire steel industry, and thus improve the level of sustainable environmental development. The strategies of the four parties are: the probability of steelmaker engaging in technological innovation is

(2) Assumptions for the strategies of steelmaker. Steelmaker that engage in technological innovation to produce green products will be favored by construction enterprises with stronger environmental awareness, thereby obtaining an additional market revenue

(3) Assumptions for the strategies of construction company. When construction enterprises choose green products, they will receive a certain carbon benefit

(4) Assumptions for the strategies of scrap recycler. Scrap steel recyclers engaging in technological innovation will obtain certain carbon benefits

(5) Assumptions for the strategies of the government. The government incentivizes firms to curb emissions by allocating rational green funds, thereby prompting them to lower their emissions (Chen and Li, 2023). In the model, the government adopts two different forms of subsidies, namely, technological innovation subsidies or consumption subsidies. The government should bear the corresponding costs

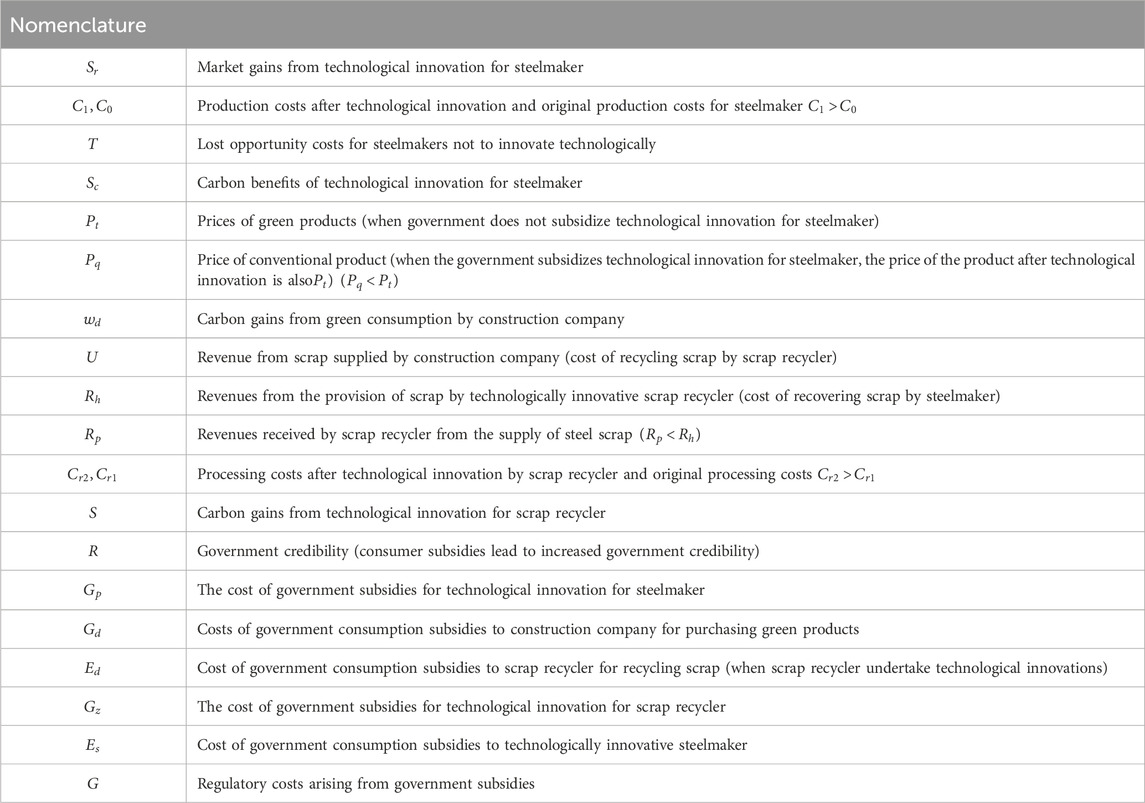

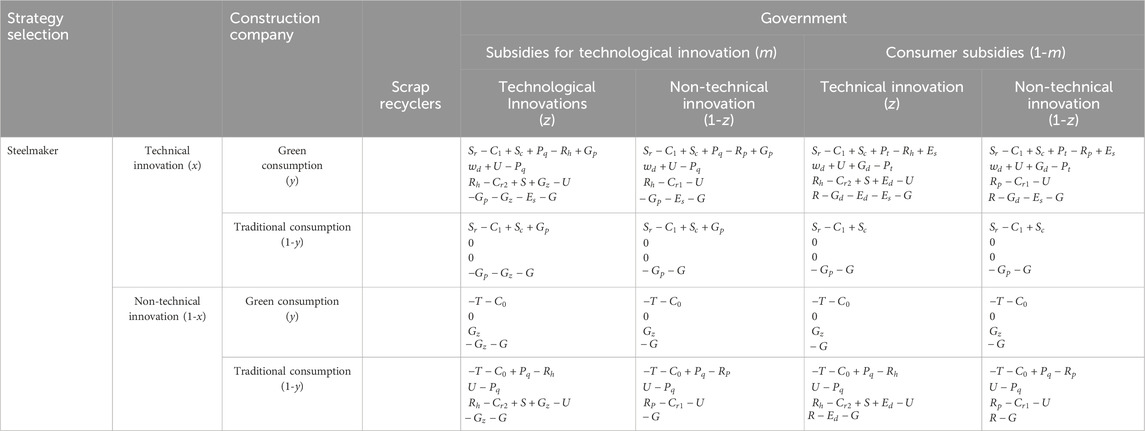

In summary, the game model relationship constructed in this paper is shown in Figure 1, the relevant model parameters are shown in Table 1, and the system’s four-party game payoff matrix is shown in Table 2.

4 Evolutionary game analysis

Based on the replicator dynamics equations of steelmaker, construction company, scrap recycler, and the government, a series of solutions for the replicator dynamics equations of each party are derived, and the stability of the four-party evolutionary game is analyzed.

4.1 Stability analysis of strategies for steelmaker

Steelmakers’ expected revenues under the innovative technological production model and the traditional production model are denoted as

From Equation 1, we can derive the replicator dynamics equation for steel manufacturers, which is:

Taking the first derivative of

Based on the stability theorem of differential equations, the probability that the strategy of steelmaker is in a stable state must satisfy the following formula:

Proof 1. Let

Proof 2.

(1) From Proof 1, it can be deduced that as the likelihood of green consumption by construction companies increases, it will lead steel manufacturers to transition from traditional production models to technologically innovative production models. Therefore, for the government, it is imperative to implement relevant policies and incentives to encourage construction companies to purchase green products, thereby promoting the low-carbon transition of steel manufacturers. In addition, the main factors influencing the strategic choices of steel manufacturers include product prices, carbon benefits from technological innovation, production costs after technological innovation, opportunity costs, original production costs, market revenue from technological innovation, the cost of reclaiming scrap steel, technological innovation subsidies, and scrap steel consumption subsidies.

(2) According to the conclusion of Proof 1, when

(3) Proof 2 shows that when steel manufacturers make technological innovations, they will bring certain market gains from technological innovations and carbon gains, and construction firms will be inclined to buy green products despite the increase in production costs and product prices. At the same time, if the government increases the subsidies for technological innovation for steel manufacturers and the consumption subsidies for steel scrap, construction companies will tend to buy green products, which will constitute a virtuous circle between low-carbon production and green consumption. In addition, the cost of steel manufacturers to recover scrap, the price of conventional products, the original production cost, and the lost opportunity cost will all contribute to the tendency of construction companies to purchase conventional products, which will ultimately affect the strategic choices of steel manufacturers to carry out technological innovation.

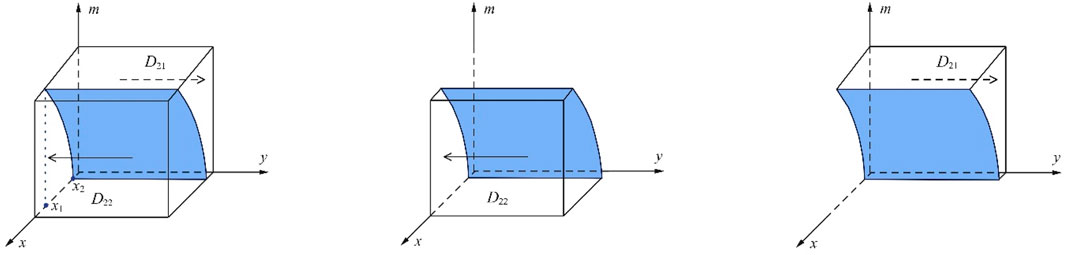

(4) The phase diagram chosen by the steelmaker’s strategy is determined by the relevant parameters, specifically, by

4.2 Stability analysis of strategies for construction company

The expected revenues of construction company under green and traditional consumption are

From (Equation 3), the equation for the replication dynamics of construction company can be obtained as:

Taking the first derivative of

According to the stability theorem of differential equations, the probability that a construction firm’s strategy is in a steady state must satisfy the following formulas:

Proof 3. Let

Proof 4.

(1) Proof 3 indicates that as

(2) According to Proof 3, when

(3) If the government focuses on implementing technological innovation subsidies, steel manufacturers will be attracted by the benefits of low-carbon production. Due to fierce competition, steel manufacturers will produce a large quantity of green products, leading to the phasing out of traditional products. Consequently, construction enterprises will be more inclined to purchase green products. Therefore, the government’s technological innovation subsidies have a crucial impact on both steel manufacturers and construction enterprises, compelling steel manufacturers to engage in low-carbon production. According to Proof 4, in the short term, the government should primarily increase consumption subsidies to encourage construction enterprises to buy green products. At the same time, the government should regulate the market prices of green products to prevent construction enterprises from favoring the purchase of traditional products. This approach will enhance the carbon benefits derived from green consumption.

(4) The phase diagram of the strategy choice of the construction enterprise is determined by the relevant parameters, specifically, by

4.3 Stability analysis of strategies for scrap recycler

The expected revenues of scrap recyclers under technological and non-technological innovations are

From (Equation 5), the equation for the replication dynamics of the scrap recycler can be obtained as:

Taking the first derivative of

According to the stability theorem of differential equations, the probability that the scrap recycler’s strategy is in a steady state must satisfy the following formulas:

Proof 5. Let

Proof 6.

(1) Derived from Proof 5, the strategy of the scrap steel recycler varies with the changes in the strategy of the construction enterprise, with

(2) Proof 5 demonstrates that when the inequality

(3) Proof 6 indicates that the technological innovation of scrap steel recyclers is related to the magnitude of government subsidies. If the government increases the consumption subsidies for scrap steel recyclers that undertake technological innovation, it will stimulate their enthusiasm. In addition, the size of the carbon benefits generated also has a positive effect on promoting technological innovation by scrap steel recyclers. It can be concluded that strengthening the economic support to scrap steel recyclers by the government can, to a certain extent, enhance the vitality of their technological innovation.

(4) The phase diagram of the strategic choices of scrap steel recyclers is determined by relevant parameters. According to the equation

4.4 Stability analysis of strategies for government

The government’s expected revenues under the implementation of technological innovation subsidies and consumption subsidies are

From (Equation 7), the government’s replication dynamic equation can be obtained as:

Taking the first derivative of

According to the stability theorem of differential equations, the probability that the government’s strategy is in a steady state must satisfy the following equations:

Proof 7. Let

Proof 8.

(1) According to Proof 7, the government’s strategy varies with the changes in the strategies of scrap steel recyclers, where

(2) Proof 7 shows that the government’s evolutionary stabilization strategy is to implement a technological innovation subsidy when

(3) According to Proof 8, whether the government increases the consumption subsidies for green consumption by construction enterprises or the technological innovation subsidies for scrap steel recyclers, it can enhance the enthusiasm of scrap steel recyclers for technological innovation. However, the increase in credibility due to government consumption subsidies, as well as the technological innovation subsidies to steel manufacturers and the consumption subsidies to scrap steel recyclers, have a dampening effect on the technological innovation by scrap steel recyclers. Therefore, for the government, it is crucial to strike a balance between consumption subsidies and technological innovation subsidies. Over a certain period, the government needs to establish reasonable subsidy levels based on feedback from various stakeholders and market research.

(4) The phase diagram chosen by the government strategy is determined by the relevant parameters, according to

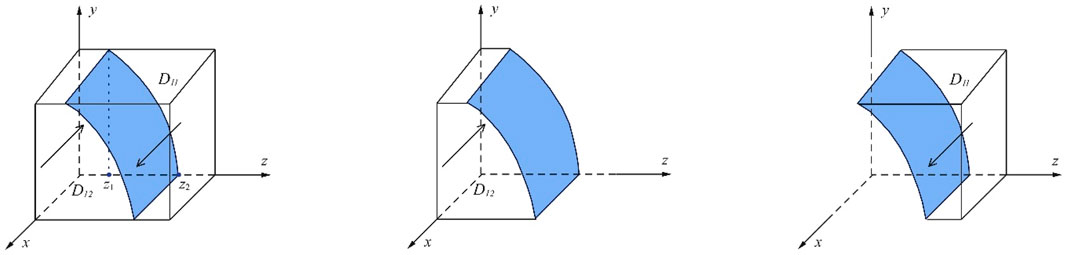

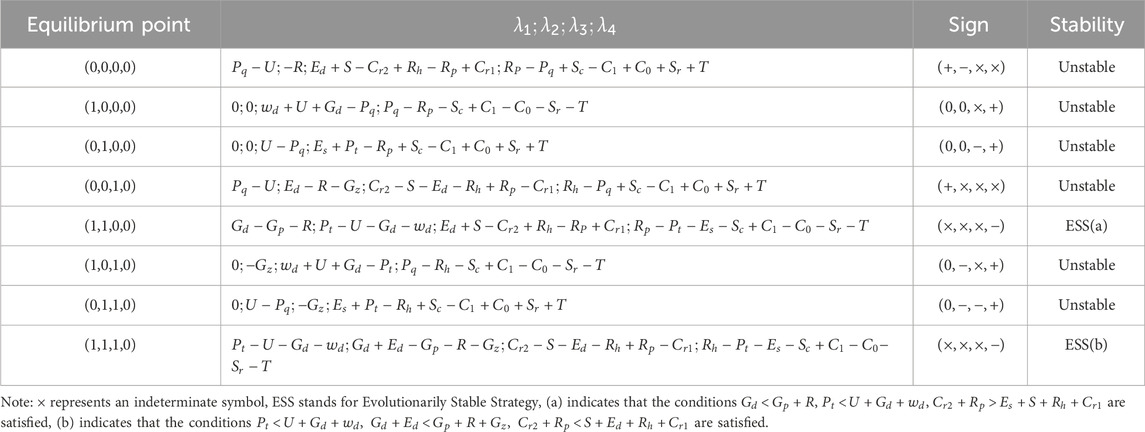

4.5 Stability analysis of the four-party strategy combination

The previous section mainly analyzes the evolutionary stability of each of the four parties, and the following section analyzes the evolutionary stability strategy and equilibrium point state under the joint action of the four parties.

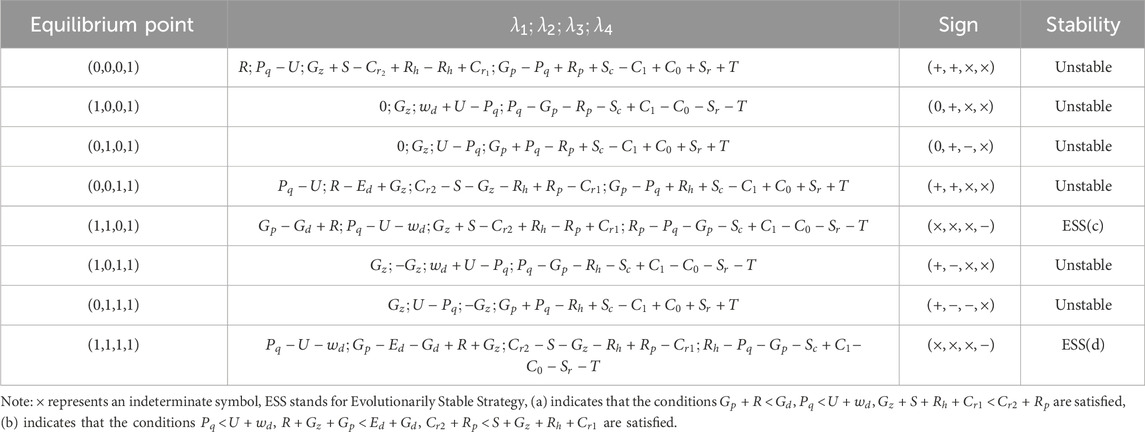

Based on the replicator dynamics equations of the four-player game system, the corresponding Jacobian matrix can be derived. The stability of strategies in the four-player game can be judged by the first Lyapunov method: if all the eigenvalues of the Jacobian matrix are negative, then the equilibrium point is an Evolutionarily Stable Strategy (ESS). If at least one of the eigenvalues of the Jacobian matrix is positive, then the equilibrium point is unstable. If all the eigenvalues of the Jacobian matrix are negative except for one that equals zero, then the equilibrium point is at a critical state, and its stability is uncertain. Moreover, the stable solution in a multi-population evolutionary game must be a strict Nash equilibrium, that is, a pure strategy equilibrium. Therefore, in the four-player evolutionary game, this paper attempts to analyze the stability of 16 pure strategy equilibrium points.

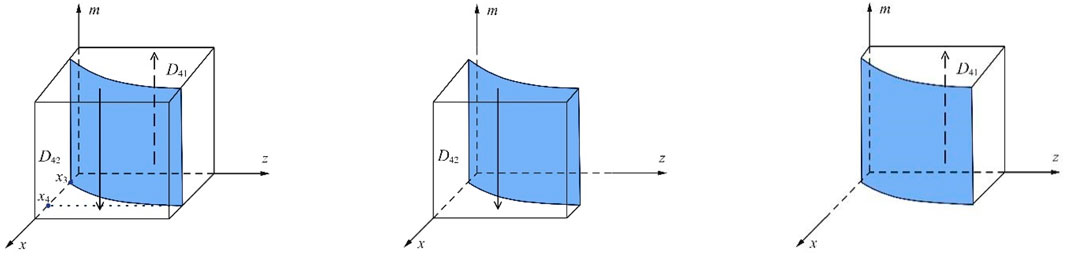

4.5.1 Stability analysis of strategy combination under consumption subsidy

The asymptotic stability analysis of the equilibrium point of this replicated dynamic system is shown in Table 3 when the government’s stabilization strategy is to implement consumption subsidies, i.e., when the condition

Table 3. Evolutionarily stable analysis of equilibrium points of replication dynamic system under consumption subsidies.

Table 3 indicates the existence of two possible stable strategies, namely, (1,1,0,0) and (1,1,1,0). The strategy (1,1,0,0) signifies that the steel manufacturer engages in technological innovation, the construction company adopts green consumption practices, the scrap steel recycler does not engage in technological innovation, and the government implements consumption subsidies. At this point, the conditions

The preceding analysis illustrates the necessity for the government to exert a guiding influence on the procurement of green products, while steel manufacturers must also manage product pricing judiciously. For scrap steel recyclers to be incentivized to undertake technological innovation, it is imperative that their overall revenue surpasses the differential in costs associated with innovation before and after its implementation, thereby integrating them into the transformation towards low-carbon steel production. Given the current landscape of the steel industry, technological innovation stands as a pivotal element for carbon emission reduction. However, there is a dearth of impetus for carbon reduction technological innovation at present. To facilitate the adoption of technologically innovative production paradigms by steel manufacturers, it is essential for the government to enact technological innovation subsidies as a priority. This strategic approach will foster an environment where engaging in technological innovation becomes a stable strategy for both the steel manufacturers and the scrap steel recyclers.

4.5.2 Stability analysis of strategy combination under technological innovation subsidies

When the government’s stable strategy is to provide subsidies for investment in technological innovation, specifically when the condition

Table 4. Evolutionarily stable analysis of equilibrium points of replication dynamic system under technological innovation subsidies.

Table 4 demonstrates that when the government implements technological innovation subsidies, there are two possible stable strategies: the points (1,1,0,1) and (1,1,1,1). The strategy (1,1,0,1) indicates that the steel manufacturer engages in technological innovation, the construction company practices green consumption, the scrap steel recycler does not engage in technological innovation, and the government provides subsidies for technological innovation. At this juncture, the conditions

As the net income of the scrap steel recycler increases, that is, when

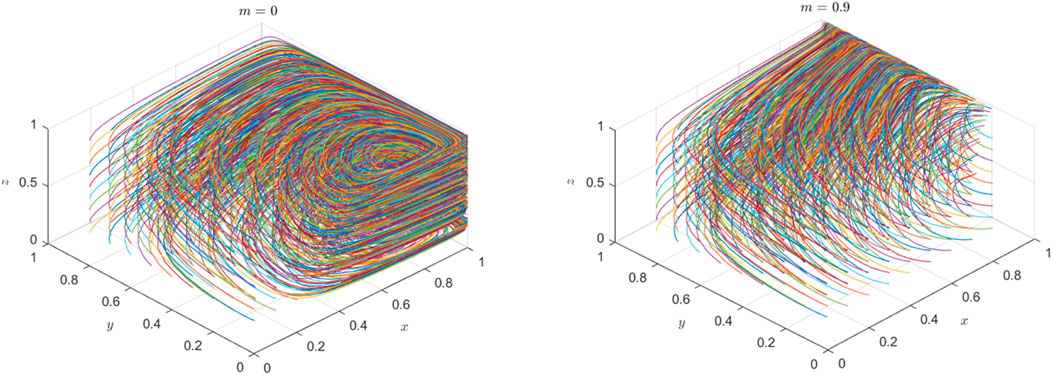

5 Numerical simulation and discussion

The analysis results presented earlier indicate that the strategies of the steel manufacturer, construction company, scrap steel recycler, and government are interdependent. To more intuitively demonstrate the impact of key elements in the replicator dynamics system on the evolutionary process and outcomes of the multi-party game, numerical simulations of the evolutionary trajectories of each game participant were conducted using MATLAB 2021b software.

The construction industry holds a major share of the demand in the steel market. Therefore, this paper selects the construction company as the downstream consumer of the steel manufacturer. Considering that the steel manufacturer offers a wide range of steel products with significant price differences, we chose the procurement and recycling prices of rebar steel as the data source for the numerical simulation. Through investigation, it was found that the monthly average price of rebar steel HS400E (20 mm) from 20 steel manufacturers in Jiangxi Province is 34.66 (yuan/100 tons). It was also learned that the average untaxed cost of rebar steel from 31 inland steel mills in mainland China is 33.49 (yuan/100 tons). In combination with the price of recycled steel rebar (thickness greater than 6 mm) from a certain environmental protection industry company in Jiangxi, which is 26.60 (yuan/100 tons) (Data sources:https://www.mysteel.com), the specific parameters for this paper are set as follows:

5.1 Impact of carbon benefits on system evolution for steelmaker

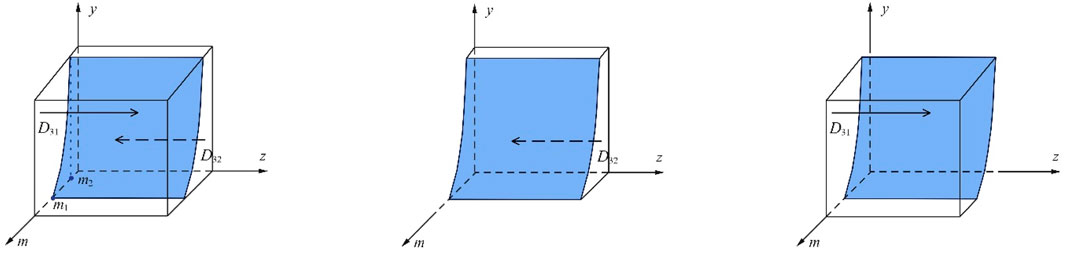

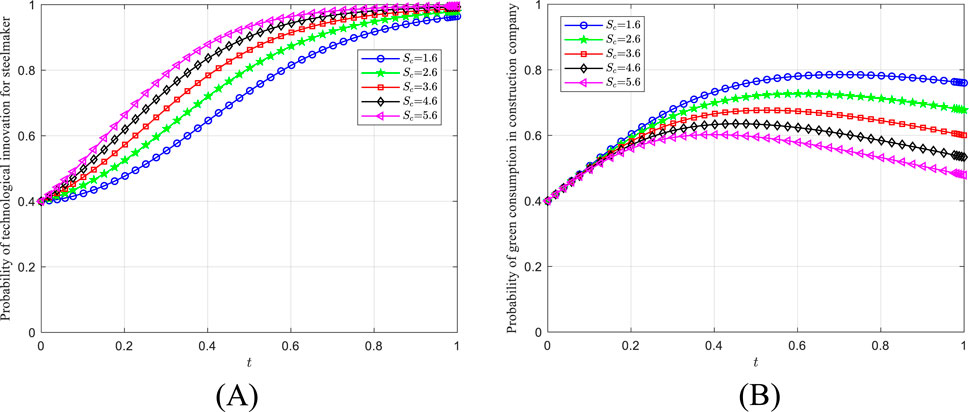

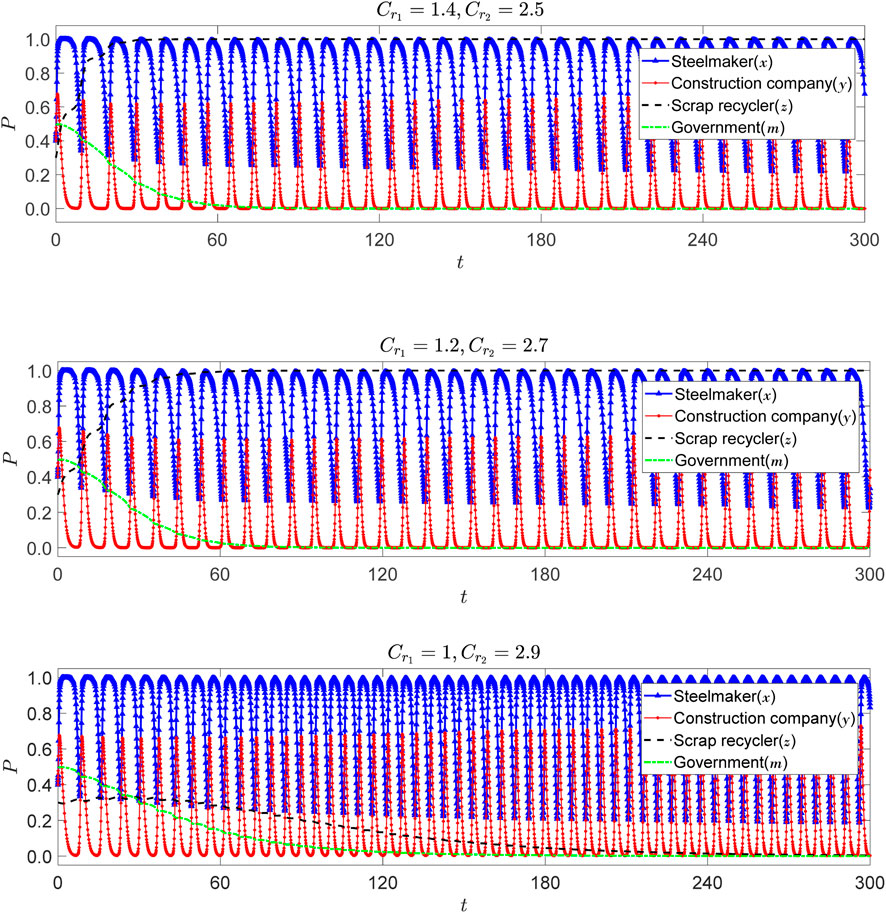

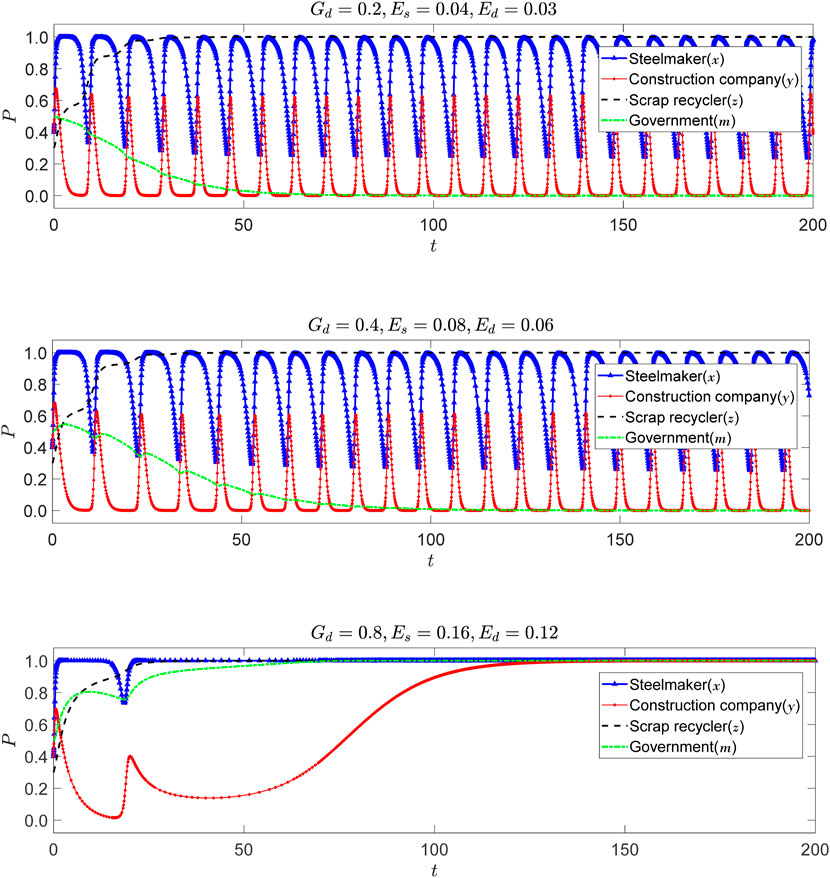

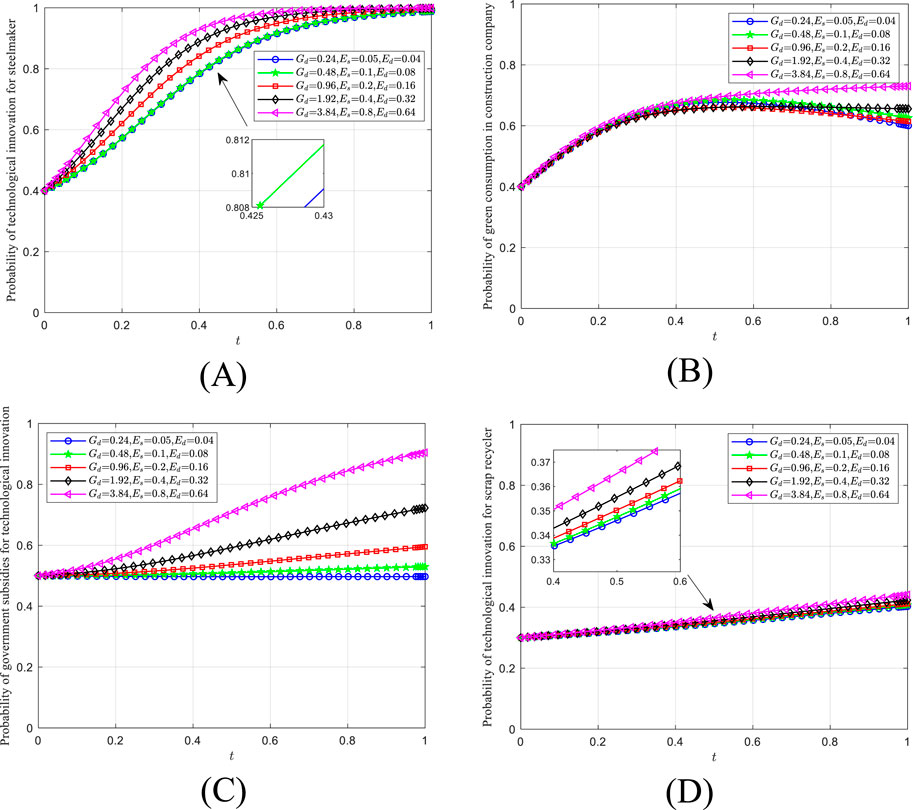

Figure 6 demonstrates that the carbon benefits derived from technological innovation in the steel manufacturing sector are a key determinant of the strategic evolutionary trends for both steel manufacturers and construction enterprises. Let the set

5.2 Impact of production costs of steelmaker on the evolution of the system

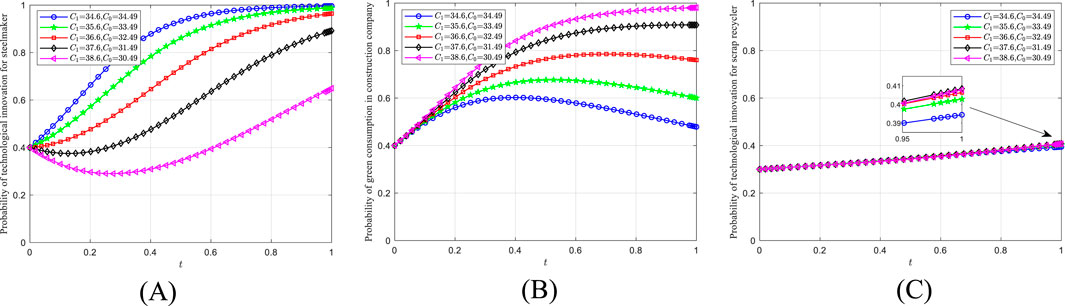

Figure 8 indicates that the production cost of steel manufacturers plays a crucial role in the evolution of strategies within the four-party game. Let

5.3 Impact of government credibility on system evolution

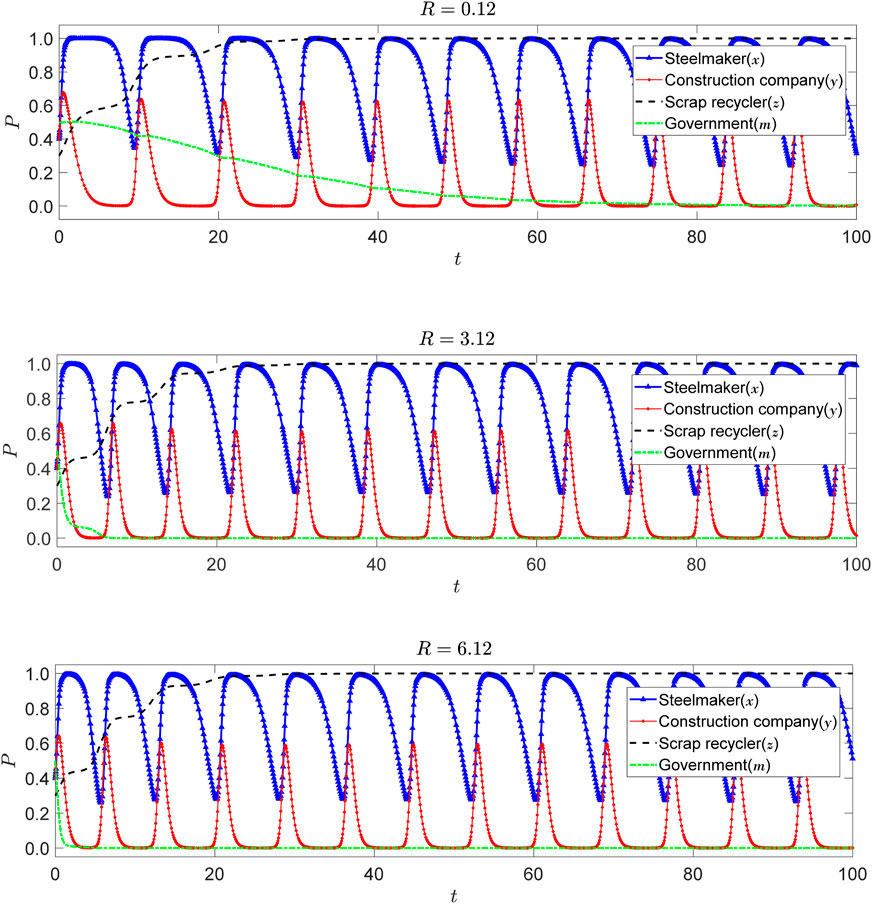

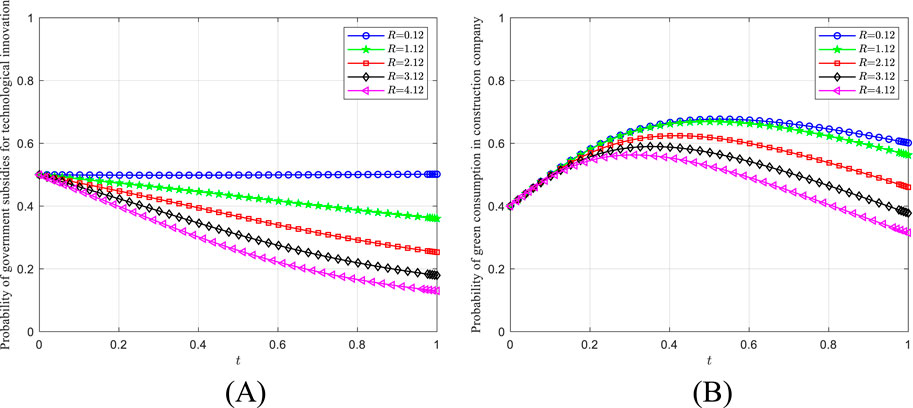

Figure 10 illustrates that the government’s credibility significantly influences the evolutionary process and outcomes of the strategies within the four-party game, with the most substantial impact on the strategic evolution trend of the government itself. Consequently, we define

Furthermore, Figure 11B discloses that the probability of green consumption by construction companies initially rises with an increase in

5.4 Impact of scrap recyclers’ processing costs on system evolution

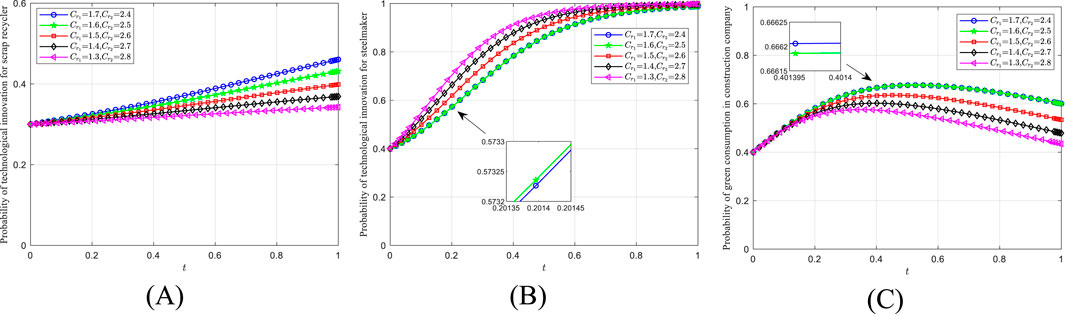

Figure 12 indicates that the processing costs of scrap steel recyclers exert a notable influence on the strategic evolution of the recyclers themselves, as well as that of steel manufacturers and construction companies. By examining the impact of the differential

Furthermore, Figure 13C reveals that the probability of green consumption by construction companies exhibits a downward trend in response to the differential

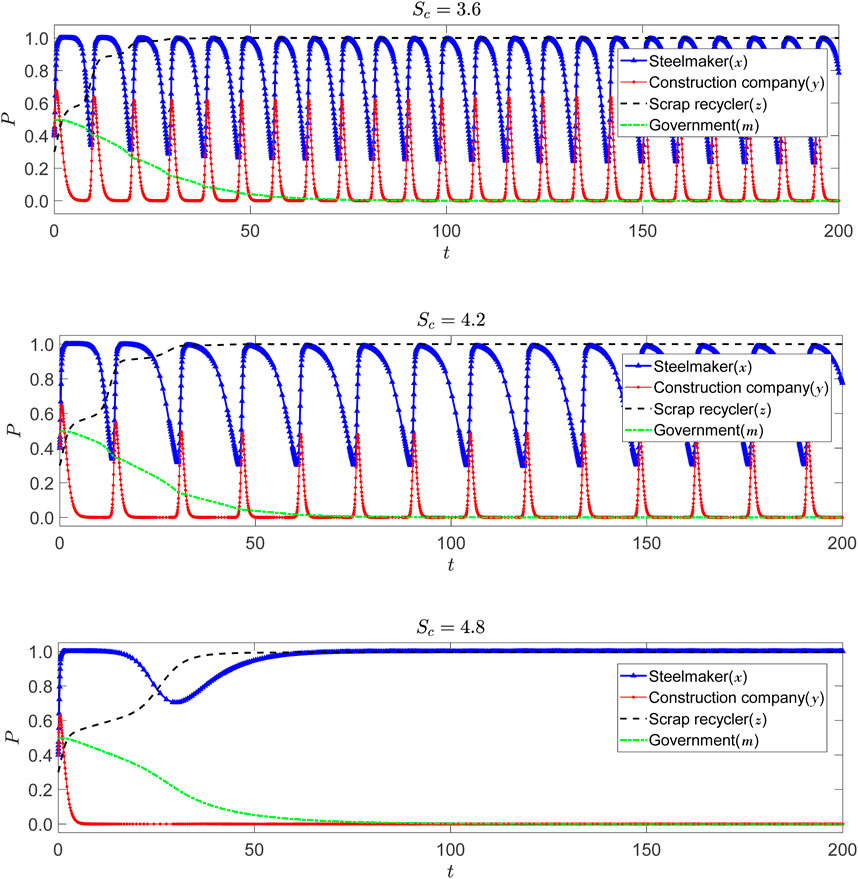

5.5 Impact of government subsidies for technological innovation on system evolution

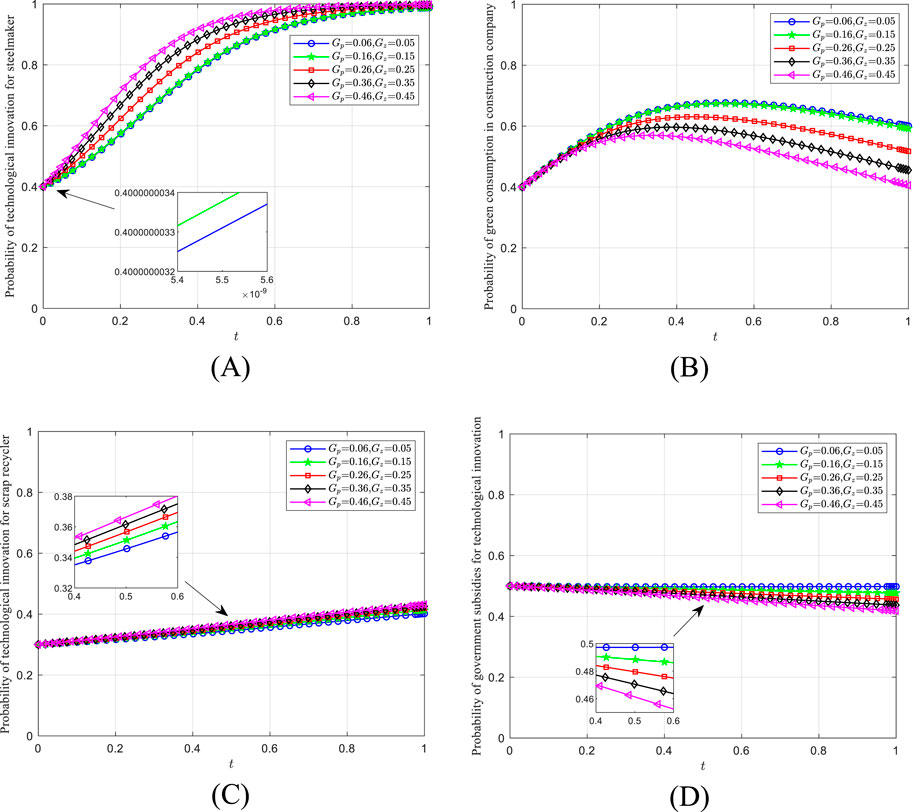

Figure 14 demonstrates that the government’s technological innovation subsidies exert a notable influence on the evolutionary dynamics of all four participants within the game system. In the context of sensitivity analysis, the parameters are adjusted as follows:

Furthermore, the probability of technological innovation by scrap steel recyclers also experiences a minor increase due to the marked enhancement in government subsidies. This indicates that there is a reciprocal influence among steel manufacturers, construction companies, and scrap steel recyclers, where the strategic choices of one can significantly sway the strategic propensities of the others. Considering the considerable costs associated with technological innovation subsidies, the government, prioritizing its own interests, is likely to transition from focusing on technological innovation subsidies to consumption subsidies over time. Figure 15D substantiates the finding that the likelihood of the government providing technological innovation subsidies diminishes with an increase in the subsidy amount.

5.6 Impact of government consumption subsidies on system evolution

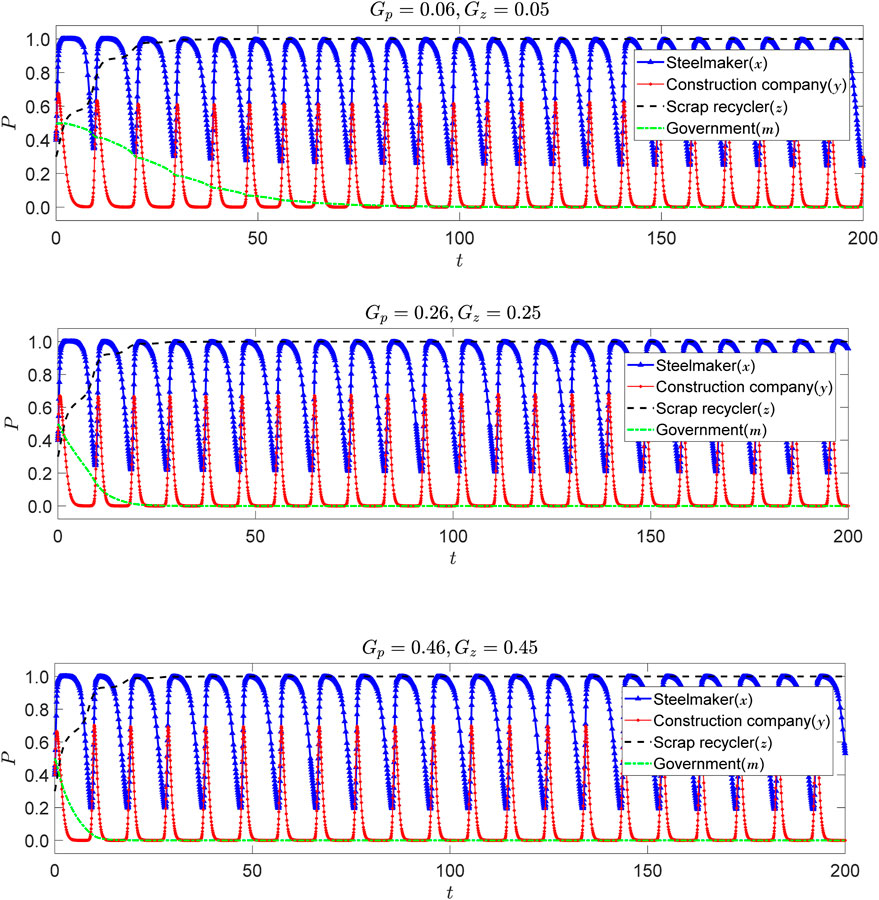

From Figure 16, it is evident that government consumption subsidies have a significant impact on the evolutionary trends of steel manufacturers, construction enterprises, and the government itself. To further investigate the influence of subsidy amounts, we have established the following sets:

5.7 Impact of government subsidy mechanisms

To further validate the feasibility and effectiveness of government subsidy mechanisms in promoting various stakeholders’ actions, we consider two states:

6 Discussion

This paper presents findings obtained by constructing and solving an evolutionary game model involving four parties. The discussion is divided into two parts: first, an introduction to the research results, followed by policy implications for stakeholders in steel production, consumption, and recycling. The aim is to foster technological innovation across the entire steel industry and facilitate a low-carbon transition, thereby contributing to the nation’s Dual-carbon goals.

6.1 Research findings

In this paper, we have constructed and theoretically analyzed a four-way evolutionary game model, demonstrating that it supports four Evolutionary Stable Strategies (ESS). The system’s optimal evolutionary stability point is identified as (1,1,1,1), with the necessary conditions for this stability being

(1) The paramount factor influencing carbon emission reduction across the steel production, sales, and recycling stages is the production cost of steel manufacturers. This cost differential

(2) The second most influential factor is the carbon returns

(3) The impact of government consumption subsidies ranks third in significance, with the probability of technological innovation by steel manufacturers and scrap recyclers being positively correlated with these subsidies. Generally, the likelihood of green consumption by construction firms is also positively correlated with consumption subsidies. The least influential factors, though still impactful to some degree, include subsidies for technological innovation, processing costs for steel scrap recyclers, and government credibility. Research has indicated that in the nascent stages of technological innovation, governments often extend incentive subsidies to manufacturers to foster innovation (Xu et al., 2024). Conversely, in the later stages, they tend to offer direct subsidies to consumers to promote market acceptance and widespread adoption of innovative products. Our study confirms that this pattern holds in the steel industry, where the potential benefits of both technological innovation subsidies and consumer subsidies influence the government’s subsidy decisions. As the government’s technological innovation subsidies escalate, there is a preference for implementing consumption subsidies, with the likelihood of offering technological innovation subsidies gradually diminishing. The government must rationally adjust the form of subsidies based on its interests. Moreover, as government credibility strengthens, the probability of green consumption by construction enterprises initially increases and then follows a decreasing trend, indicating a waning incentive effect of consumption subsidies over time.

(4) Lastly, the processing cost differential before and after technological innovation by scrap steel recyclers merits attention. While previous studies have established a tripartite evolutionary game model involving large steel enterprises, small and medium-sized steel enterprises, and the government to explore synergistic emission reduction (Tian et al., 2024), our study broadens this perspective by incorporating scrap recyclers into the game model, thereby enriching the research findings in this domain. We conclude that an increasing processing cost differential

6.2 Policy implications

Through comprehensive analysis, this study delineates the future trajectory for carbon reduction in the steel industry, which involves technological innovation by steel manufacturers and scrap steel recyclers, green consumption by downstream construction enterprises, and the implementation of technological innovation subsidies by the government. Building on the deductions from the previous text, this paper proposes policy recommendations for carbon reduction in the production, consumption, and recycling processes of steel.

To alleviate the pressure on steel manufacturers to transition to low-carbon practices, the government should provide reasonable subsidies to inject new momentum into their technological innovation. Green technological innovation is crucial for addressing environmental pollution and achieving sustainable development. However, steel manufacturers often face significant upfront costs and slow returns on investment when engaging in green technological innovation. Despite these challenges, such innovation is essential for the transformation and competitive edge of steel manufacturers. Therefore, the government must offer financial support through technological innovation subsidies to enhance their motivation for green technological innovation. As low-carbon metallurgical technologies advance, steel manufacturing processes will undergo revolutionary changes. Steel manufacturers need to recognize the situation, accelerate high-quality development, improve green technological innovation levels, and reduce pollutant emissions. They should intensify research and development in cutting-edge metallurgical technologies, adopt innovative development concepts, transform resources into valuable assets, enhance resource utilization, and gradually resolve environmental pollution issues.

Encouraging Green Consumption in Downstream Construction Enterprises. The consumption behavior of construction enterprises directly impacts the production methods of steel manufacturers. Their preference for green products can compel steel manufacturers to innovate technologically. The government should maintain a certain level of consumption subsidies to encourage construction enterprises to purchase green products. Additionally, relevant departments should leverage new media platforms to promote the concept of green consumption in the construction sector, gradually encouraging construction enterprises to prioritize green and low-carbon products. The government should strengthen regulation of enterprises, promote green certification of low-carbon products, and encourage the use of credible environmental labels to bolster the resolve of construction enterprises to purchase green products. For construction enterprises, it is advisable to use Building Information Modeling (BIM) technology in the design phase to optimize steel usage, reduce waste from over-purchasing and cutting. During construction, they should use high-precision cutting tools and technologies to ensure accurate steel cutting and minimize leftover waste. It is also essential to enhance on-site management to prevent waste and loss due to improper storage. Finally, establishing cooperative relationships with local scrap steel recyclers ensures that steel from construction waste can be effectively recycled and reused.

Enhancing the Viability and Competitiveness of Scrap Steel Recyclers. The strategic choices of scrap steel recyclers are influenced by their processing costs. While ensuring the normal profit margins of scrap steel recyclers, the government should provide technological innovation subsidies and consumption subsidies to foster healthy competition among recyclers. Large-scale recyclers, due to their substantial business volume, require significant capital, and government departments should increase financial support for scrap steel recyclers. Scrap steel recyclers themselves should gradually establish a comprehensive recycling supply network, promote the scaled and clustered development of the scrap steel industry, and continuously establish new types of scrap steel recycling bases that integrate collection, sorting, processing, and distribution in various regions. By leveraging scaled operations, they can enhance market competitiveness. Additionally, scrap steel recyclers should take advantage of government support to actively optimize production processes and equipment through technological innovation, improve the efficiency of scrap steel recovery and reprocessing, reduce the waste of materials and energy, and achieve the maximum carbon reduction goals at the recycling stage, contributing to the low-carbon and high-quality development of the economy and society.

Strengthening Coordination in Carbon Reduction Across the Steel Production, Consumption, and Recycling Processes. The government, with different interests in implementing technological innovation subsidies and consumption subsidies, has its strategic choices influenced by the strategies of steel manufacturers, construction enterprises, and scrap steel recyclers. As the linchpin of the system, the government should reasonably arrange subsidies and regulate the amount and timing of subsidies. Moreover, the government can also implement a dynamic subsidy system based on the state of social development and the different stages of the low-carbon transition of the steel industry. The study found that the carbon benefits from technological innovation by steel manufacturers are the second most sensitive factor. Therefore, it is crucial for the government to continuously improve carbon emission standards and quotas for the steel industry and integrate them into the legal and regulatory framework. This includes clearly defining the carbon emission requirements that steel manufacturers must adhere to during their production and operational processes, as well as the corresponding punitive measures and penalty mechanisms. Furthermore, the carbon emission quota trading mechanism in the steel industry is not yet mature, and the government must strengthen guidance to encourage voluntary emission reductions by steel manufacturers, enhancing the efficiency of carbon emission management and control. This will promote technological innovation and optimize production processes to reduce carbon emission levels.

7 Conclusion

This study, for the first time, introduces the four-player Evolutionary Game Theory (EGT) into the carbon reduction system of the steel industry, encompassing the cyclical processes of production, consumption, and recycling. The paper not only extends the application scope of EGT but also enriches existing research on carbon reduction in the steel industry, offering targeted policy recommendations for all stakeholders. Unlike previous studies, this paper focuses on finding an equilibrium of interests among the system’s entities under government subsidies, an aspect that has not been thoroughly considered in prior research. The main conclusions are as follows.

(1) This study affirms the critical role of government subsidies in fostering technological innovation among steel manufacturers. Well-targeted subsidies can catalyze low-carbon production processes, which are pivotal for steering the steel industry towards a sustainable and eco-friendly future. Consequently, it is imperative for the government to persist in refining and enhancing policies that subsidize technological innovation within the steel sector. This will not only stimulate technological advancement and innovation for low-carbon production but also ensure the industry’s long-term viability and competitiveness.

(2) The strategic decisions regarding technological innovation made by steel manufacturers and scrap recyclers are predominantly cost-driven. Subsidies aimed at technological innovation can mitigate a portion of these costs, thereby offering a compelling incentive for embracing low-carbon transformation. It is advisable for the government to contemplate offering increased financial assistance and tax relief to alleviate the financial strain associated with technological innovation. This approach would encourage the adoption of more environmentally conscious and efficient production methods.

(3) The carbon benefits derived from technological innovation for steel manufacturers are a significant motivating factor. If steel manufacturers stand to gain from environmental regulations, their likelihood of engaging in technological innovation is substantially heightened. This underscores the importance of refining the carbon trading mechanism within the steel industry. The government is encouraged to enhance this mechanism to motivate businesses to decrease carbon emissions through market-based strategies. Additionally, providing financial incentives or subsidies to businesses for carbon reduction efforts could foster a synergistic relationship between technological innovation and environmental regulation.

(4) The strategies employed by construction companies may be influenced by the production costs and carbon returns of steel manufacturers. There is a positive correlation between the carbon gains of steel manufacturers and the green purchasing tendencies of construction enterprises. When the disparity in production costs for steel manufacturers surpasses a certain threshold, construction enterprises tend to revert to traditional consumption patterns. Therefore, it is recommended that the government and industry bodies collaborate to boost demand for green building materials within the construction sector. Efforts should be made to incentivize construction firms to adopt green materials and low-carbon technologies through the establishment of green building standards and certification programs.

This paper endeavors to offer a set of constructive suggestions to address the complexities of carbon emission reduction in the iron and steel industry. However, it acknowledges its own limitations and suggests that further research is necessary to enhance the understanding of this intricate system. While this study has taken into account 21 factors, it has primarily focused on a subset of key parameters. The technological innovation within the broader context of carbon emission reduction is indeed a multifaceted issue, and there is scope for incorporating additional parameters to achieve a more holistic analysis. Considering the involvement of stakeholders such as the upstream companies of steel manufacturers in the carbon emission lifecycle of the steel industry, it would be beneficial to expand the scope of this research to include these entities. This would provide a more comprehensive view of the carbon emissions across the entire steel life cycle. Furthermore, given the close interconnection between scrap recyclers and steel manufacturers, exploring the potential of merging these two entities within the model could simplify the analysis while still capturing the essential dynamics. This approach merits consideration as a valuable direction for future studies aiming to refine and expand upon the current research.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

TX: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing. LS: Data curation, Formal Analysis, Software, Validation, Writing–original draft, Writing–review and editing. WGY: Writing–original draft, Writing–review and editing. WY: Writing–original draft, Writing–review and editing. MD: Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

First and foremost, we extend our deepest gratitude to everyone who has contributed to the crafting of this manuscript. Our sincere appreciation also goes to the Jiangxi Provincial Department of Education for their generous financial backing through the Science and Technology Research Project (Project No. GJJ2201327) and the Provincial Project on Teaching Reform Research in Higher Education Institutions in Jiangxi Province (Project No. JXJG-21-10-2). Lastly, we are immensely thankful to the esteemed readers who, amidst their hectic schedules, have taken the time to review this thesis. Their valuable insights are certain to significantly enhance our future academic endeavors.

Conflict of interest

Author WGY was employed by State Grid Jiangxi Electric power Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahmed, K. (2020). Environmental policy stringency, related technological change and emissions inventory in 20 OECD countries. J. Environ. Manag. 274, 111209. doi:10.1016/j.jenvman.2020.111209

Ali, N., Phoungthong, K., Techato, K., Ali, W., Abbas, S., Dhanraj, J. A., et al. (2022). FDI, green innovation and environmental quality nexus: new insights from BRICS economies. Sustainability 14, 2181. doi:10.3390/su14042181

Bai, T., Xu, D., Yang, Q., Piroska, V. D., David, L. D., and Zhu, K. (2023). Paths to low-carbon development in China: the role of government environmental target constraints. Oeconomia Copernic. 14, 1139–1173. doi:10.24136/oc.2023.034

Berlin, D., Feldmann, A., and Nuur, C. (2022). Supply network collaborations in a circular economy: a case study of Swedish steel recycling. Resour. Conservation Recycl. 179, 106112. doi:10.1016/j.resconrec.2021.106112

Broadbent, C. (2016). Steel's recyclability: demonstrating the benefits of recycling steel to achieve a circular economy. Int. J. Life Cycle Assess. 21, 1658–1665. doi:10.1007/s11367-016-1081-1

Chang, C.-H., and Lo, S.-F. (2022). Impact analysis of a national and corporate carbon emission reduction target on renewable electricity use: a review. Energies 15, 1794. doi:10.3390/en15051794

Chen, H., Zhu, H., Sun, T., Chen, X., Wang, T., and Li, W. (2023). Does environmental regulation promote corporate green innovation? Empirical evidence from Chinese carbon capture companies. Sustainability 15, 1640. doi:10.3390/su15021640

Chen, L., Bai, X., Chen, B., and Wang, J. (2022). Incentives for green and low-carbon technological innovation of enterprises under environmental regulation: from the perspective of evolutionary game. Front. Energy Res. 9. doi:10.3389/fenrg.2021.793667

Chen, M., and Wang, K. (2023). The combining and cooperative effects of carbon price and technological innovation on carbon emission reduction: evidence from China's industrial enterprises. J. Environ. Manag. 343, 118188. doi:10.1016/j.jenvman.2023.118188

Chen, Y., Chen, S., and Miao, J. (2024). Does smart city pilot improve urban green economic efficiency: accelerator or inhibitor. Environ. Impact Assess. Rev. 104, 107328. doi:10.1016/j.eiar.2023.107328

Chen, Y., and Jin, S. (2023). Artificial intelligence and carbon emissions in manufacturing firms: the moderating role of green innovation. Processes 11, 2705. doi:10.3390/pr11092705

Chen, Y., and Li, L. (2023). Differential game model of carbon emission reduction decisions with two types of government contracts: green funding and green technology. J. Clean. Prod. 389, 135847. doi:10.1016/j.jclepro.2023.135847

Chen, Y., Ng, S. T., and Hossain, M. U. (2018). Approach to establish carbon emission benchmarking for construction materials. Carbon Manag. 9, 587–604. doi:10.1080/17583004.2018.1522094

Companero, R. J., Feldmann, A., and Tilliander, A. (2021). Circular steel: how information and actor incentives impact the recyclability of scrap. J. Sustain. Metallurgy 7, 1654–1670. doi:10.1007/s40831-021-00436-1

Cui, B., Shui, Z., Yang, S., and Lei, T. (2022). Evolutionary game analysis of green technology innovation under the carbon emission trading mechanism. Front. Environ. Sci. 10. doi:10.3389/fenvs.2022.997724

Cui, H., Zhu, X., and Wang, H. (2020). Collaborative innovation of low-carbon technology from the triple helix perspective: exploring critical success factors based on DEMATEL-ISM. Pol. J. Environ. Stud. 29, 1579–1592. doi:10.15244/pjoes/109723

Czarnecki, S., and Rudner, M. (2023). Recycling of materials from renovation and demolition of building structures in the spirit of sustainable material engineering. Buildings 13, 1842. doi:10.3390/buildings13071842

Dhayal, K. S., Giri, A. K., Kumar, A., Samadhiya, A., Agrawal, S., and Agrawal, R. (2023). Can green finance facilitate Industry 5.0 transition to achieve sustainability? A systematic review with future research directions. Environ. Sci. Pollut. Res. 30, 102158–102180. doi:10.1007/s11356-023-29539-w

Ding, Y., and Hu, Y. (2022). Accelerating efficiency of green technology innovation on carbon mitigation under low-carbon regulation. Energy Rep. 8, 126–134. doi:10.1016/j.egyr.2022.10.039

Duan, Y., Li, N., Mu, H., and Gui, S. (2017). Research on CO2 emission reduction mechanism of China's iron and steel industry under various emission reduction policies. Energies 10, 2026. doi:10.3390/en10122026

Eissa, R., Eid, M. S., and Elbeltagi, E. (2021). Current applications of game theory in construction engineering and management research: a social network analysis approach. J. Constr. Eng. Manag. 147. doi:10.1061/(asce)co.1943-7862.0002085

Estalaki, S. M., Abed-Elmdoust, A., and Kerachian, R. (2015). Developing environmental penalty functions for river water quality management: application of evolutionary game theory. Environ. Earth Sci. 73, 4201–4213. doi:10.1007/s12665-014-3706-7

Fang, C., Wang, W., and Wang, W. (2023). The impact of carbon trading policy on breakthrough low-carbon technological innovation. Sustainability 15, 8277. doi:10.3390/su15108277

Ferreira Neto, W. A., Cavalcante, C. A. V., Santos, A. C. J., Araujo, L. H. C., Alberti, A. R., and Lima, H. B. V. (2021). An inspection policy for shredder equipment used in steel production lines considering buffer level and operating time. J. Manuf. Syst. 60, 640–651. doi:10.1016/j.jmsy.2021.06.013

Fu, J.-x., Tang, G.-h., Zhao, R.-j., and Hwang, W.-s. (2014). Carbon reduction programs and key technologies in global steel industry. J. Iron Steel Res. Int. 21, 275–281. doi:10.1016/s1006-706x(14)60042-x

Gajdzik, B., Wolniak, R., and Grebski, W. (2023). Process of transformation to net zero steelmaking: decarbonisation scenarios based on the analysis of the polish steel industry. Energies 16, 3384. doi:10.3390/en16083384

Gao, Z., Lu, H., Lei, J., Zhao, J., Guo, H., Shi, C., et al. (2023). An RGB-D-based thickness feature descriptor and its application on scrap steel grading. Ieee Trans. Instrum. Meas. 72, 1–14. doi:10.1109/tim.2023.3328089

Gu, W., Wang, C., Dai, S., Wei, L., and Chiang, I. R. (2021). Optimal strategies for reverse logistics network construction: a multi-criteria decision method for Chinese iron and steel industry. Resour. Policy 74, 101353. doi:10.1016/j.resourpol.2019.02.008

Hao, J., Chen, L., and Zhang, N. (2022). A statistical review of considerations on the implementation path of China's double carbon goal. Sustainability 14, 11274. doi:10.3390/su141811274

He, H., Guan, H., Zhu, X., and Lee, H. (2017). Assessment on the energy flow and carbon emissions of integrated steelmaking plants. Energy Rep. 3, 29–36. doi:10.1016/j.egyr.2017.01.001

Hong, I. H., Chiu, A. S. F., and Gandajaya, L. (2021). Impact of subsidy policies on green products with consideration of consumer behaviors: subsidy for firms or consumers? Resour. Conservation Recycl. 173, 105669. doi:10.1016/j.resconrec.2021.105669

Hu, J., and Wang, T. (2023). Strategies of participants in the carbon trading market-an analysis based on the evolutionary game. Sustainability 15, 10807. doi:10.3390/su151410807

Hu, X., Wang, C., Lim, M. K., and Koh, S. C. L. (2020). Characteristics and community evolution patterns of the international scrap metal trade. J. Clean. Prod. 243, 118576. doi:10.1016/j.jclepro.2019.118576

Jia, L., Zhang, X., Wang, X., Chen, X., Xu, X., and Song, M. (2024). Impact of carbon emission trading system on green technology innovation of energy enterprises in China. J. Environ. Manag. 360, 121229. doi:10.1016/j.jenvman.2024.121229

Kanyilmaz, A., Birhane, M., Fishwick, R., and del Castillo, C. (2023). Reuse of steel in the construction industry: challenges and opportunities. Int. J. Steel Struct. 23, 1399–1416. doi:10.1007/s13296-023-00778-4