- 1Belt and Road Initiative Center for Chinese-European Studies (BRICCES), Guangdong University of Petrochemical Technology, Maoming, China

- 2Department of Mining Engineering and Education, Dnipro University of Technology, Dnipro, Ukraine

- 3Department of Surface Mining, Dnipro University of Technology, Dnipro, Ukraine

Introduction: Complex mineral mining leads to critical earth’s surface disturbance and environmental pollution from industrial waste. This research aims to comprehensively study, assess and show the current scale of the earth’s surface disturbances in the largest mining region of Ukraine – the Kryvyi Rih. Iron-ore Basin and suggests ways to improve the situation based on backfill technologies for the earth’s surface rehabilitation and industrial waste utilization.

Methods: To identify the forms of surface disturbance, their parameters, and spatial location, satellite images of the region, government statistical data, and a geographic information system software suite were studied. An analysis of the effectiveness of existing reclamation measures for technogenic voids in the region was carried out, and a new concept of surface restoration was proposed using beneficiation tailings, which are difficult to utilize in the region.

Results: It has been determined that the contribution of the Kryvyi Rih Iron-ore Basin to waste generation is 92.08% of the total volume of waste accumulations in Dnipropetrovsk Oblast and 65.5% in Ukraine as a whole, amounting to 10.7 billion tons. It is determined that 65.25% of the total disturbed land area is industrial waste, 34.76% – quarry cavities and mine failure zones, occupying 49% of the Kryvyi Rih city area. An analysis of waste accumulation density in allotted areas shows that per 1 m2 of land area, on average, 183.5 tons of dump waste rocks and 73.5 tons of beneficiation tailings are placed. Disposal of beneficiation tailings is recognized as a priority, because their utilization is slower, occupy the largest area, creating a risk of dams breaching and intense dusting from tailings dams surface, threatening the environment and public health. For the first time in Ukraine, a concept for the earth’s surface rehabilitation for various industrial purposes has been developed based on paste backfill technologies.

Discussion: Paste backfill technology implementation is prioritized in the central and northern parts of the city, which can dispose of at least 65–70 million tons of waste in cavities and reclaim about 200 ha of land. The research results are valuable for the development of strategies or programs to overcome the technogenic-ecological crisis in the city. The rehabilitated earth’s surface can be usefully involved in various infrastructure projects for the development of the industrial and economic potential of an industrial city such as Kryvyi Rih.

1 Introduction

The rapid growth of the world’s population increasingly requires the consumption of mineral resources to provide raw materials for a wide variety of economic sectors, resulting in intensive mining of minerals in many countries of the world (Henckens, 2021; Maja and Ayano, 2021; Khan et al., 2021). On the one hand, mining of mineral resources is dictated by economic vectors of development, accounting for an important part of the country’s budget revenues. On the other hand, the mining industry has a negative impact on the natural environment. It is known and thoroughly studied that mining industry facilities pollute and cause significant damage to air, soils and the upper earth’s crust layer, as well as to groundwater and surface water resources, flora and fauna, safety and health of the population (Vinayagam et al., 2024; Batur and Babii, 2022; Yu et al., 2024; Mardonova and Han, 2023; Petlovanyi et al., 2023a). Some of the important sources of environmental pollution are: large-scale drilling-and-blasting operations in quarries, emissions from mine shafts, pumping of mine and quarry waters with subsequent formation of settling ponds и сбрасывание в поверхностные водоемы, and accumulated large-tonnage industrial waste (Farjana et al., 2019; Shehu et al., 2023; Andrade et al., 2015; Novitskyi et al., 2023).

The influence of the mining industry on the earth’s surface state deserves special attention. Significant land areas are allotted for mining sites of quarries, mines and mining dumps, which are very difficult and slow to return to their original state after the completion of mining operations (Maus et al., 2022; Ashimova et al., 2022). Stripping operations in quarries cause damage to valuable fertile soils, depress natural ecosystems, and disrupt the natural balance of geological and hydrological environment due to the formation of significant cavities in the subsoil, creating the risk of landslide phenomena (Marchelli et al., 2023; Bo et al., 2019). Underground mining operations result in complex geomechanical processes of the earth’s surface subsidence, which leads to a rise in groundwater table and waterlogging of territories, followed by soil salinization. Hazardous processes are the occurrence of deep failures in the earth’s surface, which have unpredictable consequences and lead to the destruction of infrastructure and even the resettlement of people (Morrison et al., 2019; Sakhno et al., 2023; Asgari et al., 2024). Significant areas are allotted for waste storage, such as waste rock dumps and tailings dams, which create technogenic landscapes and depress the population. There is a risk of shear phenomena on dumps and breaches of tailings dams (Shengo, 2021; Vallero and Blight, 2019).

The situation is aggravated by the fact that mining facilities and the consequences of their activities are located near settlements and civil infrastructure, which causes social tensions and a threat to public safety. Often there are conflicts with state authorities and business owners regarding harmful enterprise activities. Therefore, at the present stage of human development, the importance of environmental protection technologies in the complex mining of mineral resources in the world, along with population growth, should become a priority (Malashkevych et al., 2022; Hrinov et al., 2019; Mashifana and Sithole, 2021; Bondarenko et al., 2023).

During open-pit mining operations, a reclamation complex is performed aimed at bringing disturbed lands to a state suitable for their use for agricultural, forestry, fishery, recreational and other purposes. Reclamation usually consists of technical and biological stages (Favas et al., 2018; Tymchuk et al., 2020). The problem of restoring the earth’s surface for industrial purposes is especially acute when the scale of the formed quarry cavities is significant. The difficulty of filling the mined-out quarry spaces with overburden and hard rocks is that this can be done if there are sufficient volumes of such rocks when the quarry or other dumps in the immediate vicinity are in operation. Therefore, in industrial regions, the potential of lands disturbed by mining activities is usually lost (Shang et al., 2022). During underground mining, to extract valuable types of minerals, for the prevention of land subsidence and industrial waste management, especially in regions with developed industrial and civil infrastructure, technologies of backfilling the mined-out space are used (Xue et al., 2023; Kuzmenko et al., 2023; Petlovanyi M. V. et al., 2020; Udd, 2021). Nevertheless, despite these circumstances, the mining industry is an important sector of economic development in many developed and developing countries, including Ukraine, providing a significant number of jobs.

Ukraine is a country rich in mineral resources. In the interior of Ukraine, more than 20 thousand deposits and occurrences with 117 types of mineral raw materials have been identified, of which more than 8,949 deposits have industrial significance and are included in the State Balance of Mineral Reserves, while more than 2,800 deposits of 100 types of mineral resources have been industrially developed (Mineral Resources of Ukraine, 2021). There are 2,868 deposits involved in industrial development, where more than two thousand mining and processing enterprises operate. The total estimate of their value is in the range of $8–12 trillion (Post-war Recovery of Ukraine’s Economy, 2022). The most developed in terms of mining volumes are deposits of iron ore, coal, natural gas, oil, manganese and titanium-zirconium ores, as well as deposits of construction raw materials (granites, limestones, sands, kaolins, clays, etc.) (Mineral Resources of Ukraine, 2021; Petlovanyi M. et al., 2020; Lozhnikov et al., 2022).

The iron-ore industry in the Ukrainian economy is the leader in foreign exchange earnings to the State budget of Ukraine in terms of product exports among all types of minerals. The resource potential of the iron-ore industry is reflected in product exports from Ukraine. For example, a record volume of 44.46 million tons of ores, agglomerated and non-agglomerated iron concentrates were exported in 2021 (with a profit of US$6.9 billion) (Extractive Industries Transparency Initiative EITI in Ukraine 2021, 2023). Since 2022, due to the armed aggression of the russian federation, the productivity of the iron-ore industry has also undergone significant changes due to logistical difficulties, reduced demand and rising production costs, forcing major mining companies to temporarily stop iron ore mining. Iron-ore mining and production of iron-ore products by various companies have declined by 40%–75%.

The greatest irreparable damage to the surrounding natural environment, especially to the earth’s surface, is caused precisely by complex mining of iron ores, the reserves of which are concentrated in five iron-ore basins (Mineral Resources of Ukraine, 2021; Extractive Industries Transparency Initiative EITI in Ukraine 2021, 2023; Hromozdova et al., 2021; Kurylo and Plotnikov, 2020). The Kryvyi Rih Iron-ore Basin deserves special attention, where the main iron-ore balance reserves (48.6%) are concentrated. In this basin there is a significant density of mining and processing enterprises (quarries, mining-processing plants, mines, metallurgical plant) and wastes from their operation (overburden and mine rock dumps, tailings dams, metallurgical slag dumps), which occupy and disturb a significant earth’s surface area, creating depressive anthropogenic landscapes. At open-pit method of iron ore mining, per 1 million tons of mineral raw materials, the loss of land is 14–640 ha, and with at underground mining method, per 1 million tons, about 4 ha of land are lost for dumps and surface deformations (Syvyi et al., 2013). Most of the Kryvyi Rih Iron-ore Basin is occupied by the city of Kryvyi Rih, and these mining facilities are located around the city and even in the city itself, which entails a significant threat to the health and safety of the population. Iron ore mines extract ore without backfilling the mined-out space, which has caused severe earth’s surface subsidence with the formation of failure craters in the western outskirts of the city and the destruction of infrastructure facilities (Bazaluk et al., 2021a; Pysmennyi et al., 2023; Azaryan et al., 2018). Thus, a large-scale technogenic-environmental catastrophe has arisen in the Kryvyi Rih Iron-ore Basin, requiring an urgent solution. Similar technogenic-environmental problems in the regions of different countries around the world, where iron ores are mined, have been repeatedly noted in scientific papers (Syvyj et al., 2023; Yadransky et al., 2021). Similar technogenic-environmental problems have been repeatedly noted in various regions around the world where iron ores are mined. For example, in northern Spain, the stability of abandoned siderite mines has posed significant challenges. In the case of the Bodovalle mine, severe surface subsidence occurred due to the collapse of over-exploited rib pillars, resulting in large surface craters. This issue was documented in the study (Trigueros et al., 2021) which used advanced numerical methods to review and address the stability of the mine. Additionally, another study (Trigueros et al., 2024) assessed the effectiveness of backfilling in mitigating subsidence risks. The study found that backfilling could be an effective countermeasure to maintain stability and prevent further subsidence.

Many scientific papers are devoted to the study and solution of environmental problems of the Kryvyi Rih region. Special attention should be paid to scientific papers related to the study of the disturbed earth’s surface state. Thus, the works (Koptieva and Denysyk, 2020; Nazaruk and Ostroushko, 2021; Paranko et al., 2015) conducted a study of existing mining-industrial landscapes of the Kryvyi Rih region (quarries, failure zones, accumulated wastes) and compiled their classification, but did not provide characteristics and parameters of specific objects. The work (Rudenko, 2017) indicates quarries suitable for development, typological groups of buildings and structures that can be used for renovation, formulates principles and methods for the architectural-planning organization of public buildings and structures on the territory of quarries. In the course of research (Rudko and Yakovlev, 2018; Dovhyi et al., 2021), the authors assess the role of natural and technogenic factors entailing the disturbance of the primary natural state of the upper earth’s crust layer, hydrosphere, and landscape sphere of the Kryvyi Rih Basin. However, they provided only a general, but not detailed, assessment of the earth’s surface state. Many information sources constantly contain data (mostly outdated) on the general earth’s surface disturbance without detailing and grading for specific objects. There is also a lack of information in scientific and information sources on studying the parameters of failure craters formed from the influence of underground mining operations. A comprehensive current state analysis of the disturbed earth’s surface in the Kryvyi Rih Basin has not been conducted in open sources, and this has not been given sufficient attention. These studies today need to be clarified, systematized and presented in more detail, especially in terms of the forms of disturbances. Despite significant developments, the study of the above-mentioned issues is relevant at present, since the issues of studying, systematizing and identifying specific forms of the earth’s surface disturbances require further research and development of effective ways to improve the situation, which is very relevant for the region today. Effective ways of improvement should be to develop the earth’s surface rehabilitation technologies specifically for deep forms of the earth’s surface disturbances, such as inactive quarries and failure zones, by moving away from traditional backfill technology towards monolithic backfill types. This will make it possible to create a stable earth’s surface and use it wisely for the benefit of the region development, utilize a wider industrial waste range, thereby reducing social tensions.

Addressing these issues is of paramount importance as Ukraine moves steadily towards gaining membership in the European Union in the near future. In connection with the rapid development of European integration processes, Ukraine has adopted a gradual policy of substantially reducing waste generation and its recycling in accordance with the principles of 2006/21/EC, 2008/98/EC Directives, which regulate the principles of waste management and handling (including mining industry), as well as rehabilitation of disturbed lands.

The presented research aims to study and show the current scale of the earth’s surface disturbances in the largest mining region of Ukraine. The research identifies the main forms of the earth’s surface disturbances and analyzes, generalizes and systematizes their parameters and characteristics, revealing an idea of the scale of the growing technogenic-environmental catastrophe. Attention is drawn to possible ways of solving problems and restoring the earth’s surface. To improve the environmental state and Ukraine’s post-war rehabilitation, the need for land areas for the construction of new industrial, energy, defense and civil infrastructure facilities will gain significant importance.

2 Research background

2.1 Research object

An important task is to substantiate the choice of the Kryvyi Rih iron-ore region for a comprehensive analysis of the state of the earth’s surface disturbances. To do this, attention is given to the following aspects: iron ore production volumes, disturbed land area and the population living in the region.

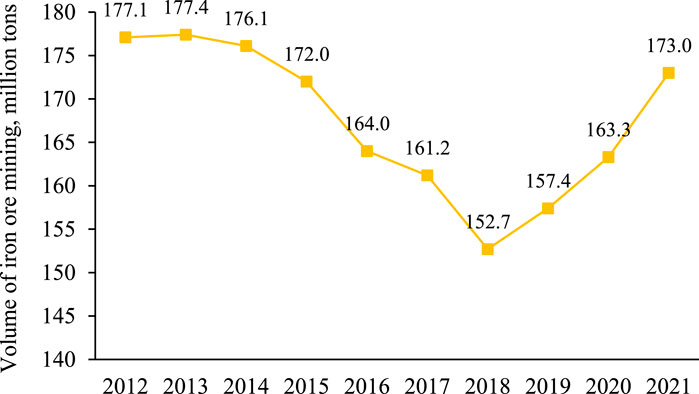

As of today, iron ores are mined in three out of five iron-ore basins available in Ukraine – Kryvyi Rih, Kremenchuk and Bilozers’k. The Kerch Iron-ore Basin is located in the russian federation-occupied Autonomous Republic of Crimea. The Pryazovskyi Iron-ore Basin is in reserve, no mining is performed. The dynamics of iron ore mining for the latest period 2012–2021 is shown in Figure 1 (Mineral Resources of Ukraine, 2021; Extractive Industries Transparency Initiative EITI in Ukraine 2021, 2023).

Thus, for the period shown in Figure 1 mining ranges within 153–177 million tons. The share of the underground mining method is within 10%–15%, the other is the open-pit mining method. The highest figures are typical for the period when mining was carried out in four out of five iron-ore basins (2012–2014).

The period of 2016–2018 is characterized by a global decline in demand for steel and consequently iron ore, which has led to a rapid fall in market prices and forced mining enterprises to reduce the scale of mining. Since 2018, there has been a positive trend and in 2021, Ukraine’s iron ore mining has almost reached the record levels of a decade ago. There is no iron ore mining data for 2022, which is probably due to the military law in the country. However, information resources indicate a 50% decline in mining due to shelling, power outages, damage to infrastructure and the significant part of industry’s employees recruited into the Ukrainian Armed Forces. Figure 2 shows the distribution of iron ore mining volumes by Ukrainian regions.

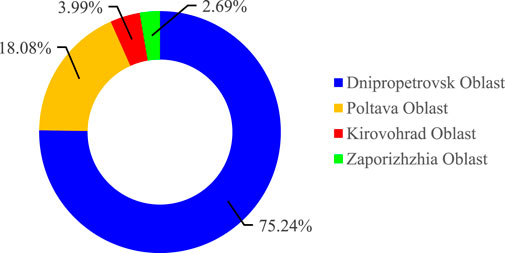

Data on the distribution of iron ore mining volumes by regions are known for 2020. According to Figure 2 in 2020, the largest volumes of iron ores were mined in the Dnipropetrovsk Oblast (75.24% or 122.87 million tons), where most of the Kryvyi Rih Iron-ore Basin is located. In the Poltava Oblast (Kremenchuk Basin) 18.08% or 29.53 million tons were mined, in the Kirovohrad Oblast (smaller part of the Kryvyi Rih Basin) – 3.99% or 6.52 million tons, and in the Zaporizhzhia Oblast (Bilozers’k Basin) – 2.69% or 4.39 million tons. Thus, the Kryvyi Rih Iron-ore Basin concentrates the largest iron ore production in Ukraine (Extractive Industries Transparency Initiative EITI in Ukraine 2021, 2023).

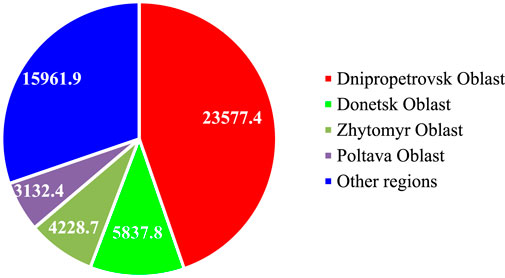

Today, deposits in Ukraine are mined mainly by open-pit mining, which has the greatest impact on the earth’s surface and the environmental state. According to the State GeoCadastre data, the total amount of disturbed land area in Ukraine is estimated at 142.7 thousand hectares, among which the following oblasts are the leaders: Dnipropetrovsk Oblast – 37.7 thousand hectares, Donetsk Oblast – 25.3 thousand hectares, Lviv Oblast – 10.7 thousand hectares, and Luhansk Oblast – 10.3 thousand hectares (National Report on the State of the Natural Environment in Ukraine in 2021, 2022). It is obvious that the mining industry, widely developed in these areas, has the greatest influence. The reclamation level is quite low and was only 17.35 ha in 2021. According to the National Report on the State of the Environment, data on the land areas occupied by mining enterprises are known, which are illustrated in Figure 3.

Figure 3. Distribution of land areas occupied by mining industry enterprises (mines, quarries) by regions, (ha).

An analysis of the state of lands allotted for mining industry shows (Figure 3) that the leader is also the Dnipropetrovsk Oblast (44.7%), where the most of the Kryvyi Rih Iron-ore Basin and a complex of mining facilities are located (Pysmennyi et al., 2022; Kalinichenko et al., 2020; Stupnik et al., 2023).

The iron-ore industry has the greatest influence on the generation of industrial waste volumes that accumulate on the earth’s surface as a result of iron ore mining and beneficiation, thereby disturbing the earth’s surface. This is well illustrated by the data of the State Statistics of Ukraine, which provides detailed information on the generated waste volumes by categories (Ukrstat, 2021). Analysis of industrial waste categories makes it possible to identify the following types of waste that belong to the iron-ore industry: 1310.2.3.01 – “iron ore sludge and beneficiation tailings”; 1310.2.3.04 – “residues (dust, powder, etc.) from the iron-ore agglomerate production”; 1310.2.9.01 – “waste from iron ore quarrying”; 1310.3.1.01 – “iron-ore blast-furnace unconditioned agglomerate”; 1310.3.1.10 – “other iron-ore wastes.” Thus, of the 0.462 billion tons generated in 2020, the volume of the above-mentioned types of iron-ore industry waste is 0.357 billion tons or 77.2%. The total mining industry waste is 0.391 billion tons, meaning that the difference of 0.034 billion tons of waste is waste from mining of other minerals. The above information data indicate a significant contribution of the iron-ore industry to the total industrial waste generation in Ukraine.

Further, based on Dnipropetrovsk Oblast regional statistics data (Environment, 2023), the contribution to the industrial waste accumulation from mining enterprises of the largest Kryvyi Rih Iron-ore Basin, the area of which includes the city of Kryvyi Rih, is analyzed and compared with the accumulated waste of the Dnipropetrovsk Oblast and Ukraine. A comparison is illustrated in Figure 4.

Analysis of Figure 4 shows that in 2020, the volume of waste generated from the iron-ore industry in the city of Kryvyi Rih is 0.256 billion tons, which is 92.08% of the total waste accumulation in the Dnipropetrovsk Oblast and 65.5% of the whole Ukraine. This demonstrates the powerful importance of the city of Kryvyi Rih and the Kryvyi Rih Iron-ore Basin as a whole in the generation of large-tonnage industrial waste both in the Dnipropetrovsk Oblast and in Ukraine.

Thus, an analysis of the population living within the iron-ore basins, where iron ore is mined, includes Kryvyi Rih – 1170.9 thousand, Kremenchuk – about 60 thousand, and Bilozers’k – about six thousand. Given the fact that the Kryvyi Rih Basin is more densely populated, the main city of Kryvyi Rih is gradually being rebuilt and expanded, so the research focuses specifically on the Kryvyi Rih Iron-ore Basin. A dangerous technogenic landscape has been created on its area, affecting the state of the environment, safety, health, and socio-economic sentiments in society. Therefore, the objective of this research is to determine in detail and reveal the degree of influence that the activity of the mining-metallurgical complex enterprises of the Kryvyi Rih Iron-ore Basin have had on the earth’s surface state and propose effective ways to improve the situation.

2.2 Characteristics and importance of the Kryvyi Rih Iron-ore Basin

As of early 2021, the Kryvyi Rih Iron-ore Basin concentrated the largest iron-ore balance reserves of 8.78 billion tons or 48.6%, where 123 million tons (75.2%) of Ukraine’s iron ore is mined. A strip of ferruginous rocks, ranging from 2 to 7 km wide, extends from south to north for more than 100 km, where the city of Kryvyi Rih (Dnipropetrovsk Oblast) occupies the main part of the basin. The area of the Kryvyi Rih Iron-ore Basin is estimated at 300 km2. The Kremenchuk Iron-ore Basin (Poltava Oblast) is a continuation of the Kryvyi Rih Iron-ore Basin to the north (Paranko et al., 2015; Dovhyi et al., 2019).

In the Kryvyi Rih Iron-ore Basin, high-grade ores are mined mainly by underground methods, and ferruginous quartzites are mined mainly by open-pit and partially underground methods. Iron ore has been mined since 1885. Today, a number of powerful mining companies are mining iron ore: “YUZHNIY GOK” Mining and Processing Plant (1 active iron-ore quarry), JSC Inhuletskyy Hirnycho-Zbahachuvalnyy Kombinat (1 active iron-ore quarry), PJSC Northern Iron Ore Enrichment Works (2 iron-ore quarries), PJSC ArcelorMittal Kryvyi Rih (2 active iron-ore quarries, 1 quarry at the stage of filling, 1 iron-ore mine), PJSC Central Iron Ore Enrichment Works (3 active iron-ore quarries, 1 quarry at the stage of filling, 1 iron-ore mine), PJSC Kryvyi Rih Iron Ore Plant (4 iron-ore mines), PJSC Suha Balka (2 iron-ore mines), Rudomine LLC (1 active iron-ore quarry), LLC Ukrainian Mining Company (1 active iron-ore quarry), BLASTCO MS. Ltd. (1 granite quarry). In addition to these enterprises, there are also five closed old quarries in the region.

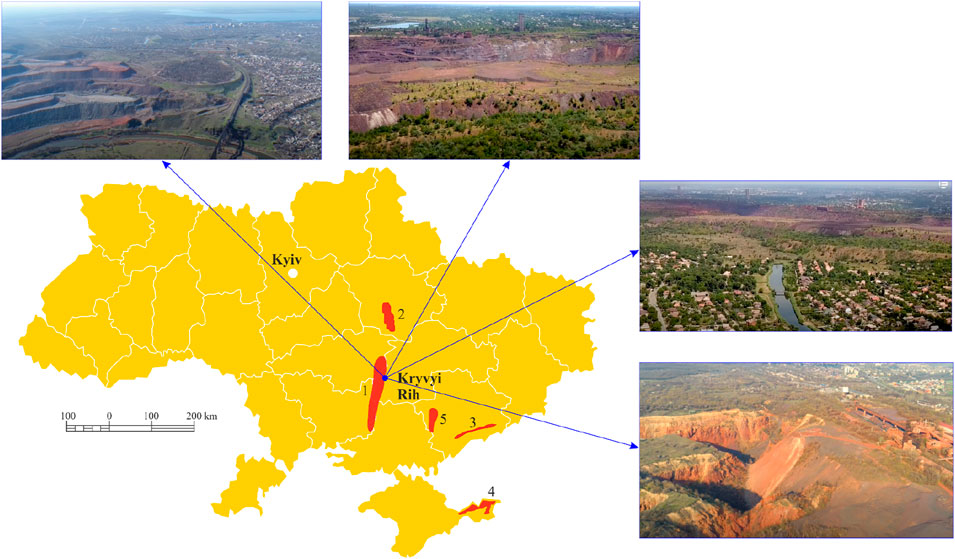

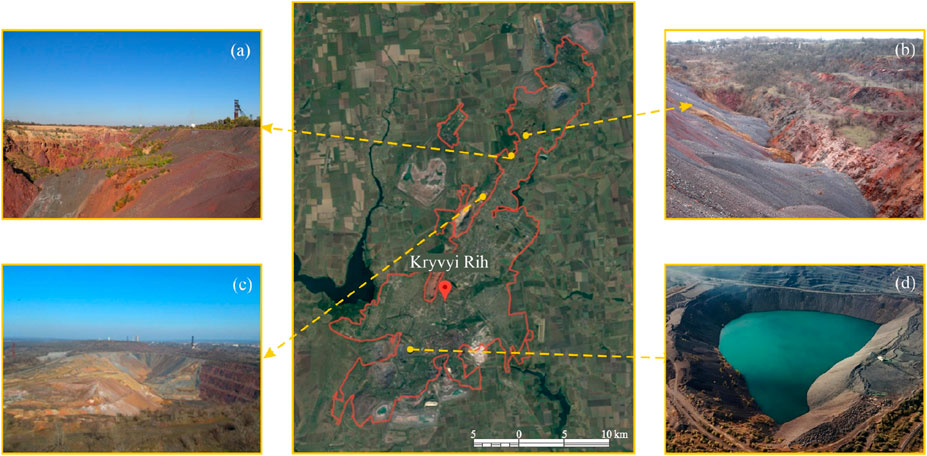

As a result of intensive mining of iron-ore reserves over almost a 150-year period, a large-scale transformation of natural landscapes into mining-technogenic landscapes occurred in the Kryvyi Rih Iron-ore Basin, illustrated in Figure 5.

Figure 5. Illustrative presentation of technogenic landscape around the city of Kryvyi Rih: 1 – Kryvyi Rih iron-ore basin; 2 – Kremenchuk iron-ore area; 3 – Pryazoviia iron-ore area; 4 – Kerch iron-ore basin; 5 – Bilozerka iron-ore area (landscape screenshots are made from open video resources: http://www.youtube.com/@user-vl7vn6vg9y, http://www.youtube.com/@MrJeshko).

Kryvyi Rih industrial region plays a leading role in the economy of Ukraine and is the main raw material base for the development of ferrous metallurgy, is of strategic importance for the economic independence and security of the state. In the total gross domestic product of Ukraine, the share of Kryvyi Rih is 9%, national exports – 8%, total industrial production of the Dnipropetrovsk Oblast – 42.3% (Investment Passport of Kryvyi Rih, 2021; Stupnik and Shatokha, 2021).

The paper draws special attention to the Kryvyi Rih iron-ore region, because around and in the city of Kryvyi Rih with a population of 650 thousand there is the largest concentration of mining facilities in Ukraine, the amount of lands disturbed by mining operations, the amount of industrial waste generated per one inhabitant and the most serious environmental problems of global scale. Despite the strong industrial development around the city of Kryvyi Rih, the environmental state in this region needs to be urgently addressed, especially the earth’s surface state.

3 Methodology

The research focuses on the study and systematization of the following forms of the earth’s surface disturbances in the Kryvyi Rih Iron-ore Basin (Dnipropetrovsk Oblast): quarry cavities, mine failure zones are formed and waste from the mining-metallurgical complex is accumulated (overburden and mine rock dumps, tailings dams, metallurgical slag dumps). When studying all forms of the earth’s surface disturbances, theoretical methods are used, such as collection and analysis of analytical information data, generalization and systematization.

To determine the geospatial location and identify the mined-out spaces of active and closed quarries, the information-analytical map of valid and invalid special permits for subsoil use from the State Geology and Subsoil Service of Ukraine is studied. Based on the annual productivity of active quarries and the volumes of balance reserves, they are graded according to the projected period of their operation (Extractive Industries Transparency Initiative EITI in Ukraine 2021, 2023; Ukrainian Geological Survey, 2024). To determine the geographical location and identify potential shear zones and failure craters within allotted areas of deposits for mining, the earth’s surface state is studied using the Google Earth satellite program on the area of mine land allotments.

The geospatial location and industrial waste accumulations of the mining-metallurgical complex are identified on the basis of the study of the State register of waste disposal sites in Dnipropetrovsk Oblast for 2021 (Register of Waste Disposal Sites in the Dnipropetrovsk Oblast, 2021). Each enterprise annually reports to local and government authorities on the generated waste volumes for the calendar year and in general. Then, annual registers of waste disposal sites are formed, indicating their characteristics for regions of Ukraine. Additionally, environmental passports and regional reports on the environmental state for Dnipropetrovsk Oblast are studied, as well as a number of reports and scientific-informational resources of the mining industry (Environmental Passport of the Dnipropetrovsk Oblast for 2022, 2023; Regional Report on the State of the Natural Environment in the Dnipropetrovsk Oblast for 2022, 2023).

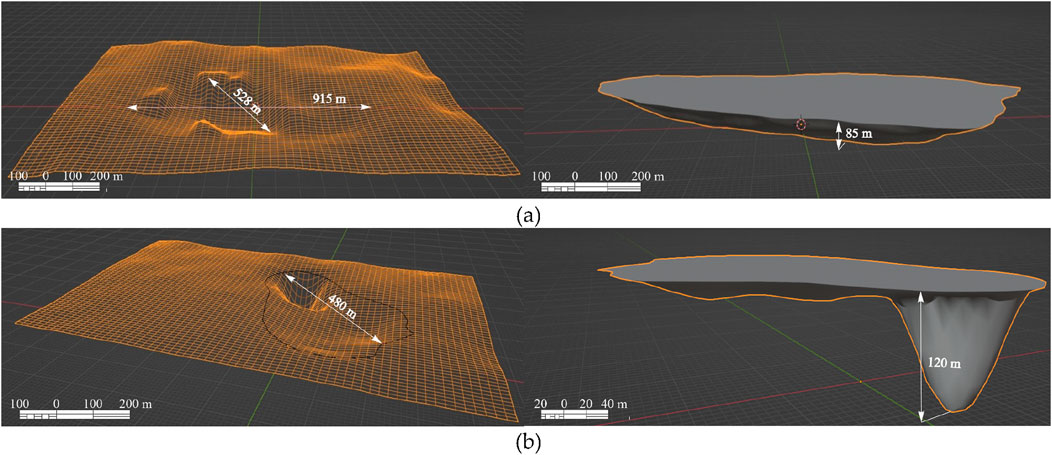

After determining the geospatial location of the formed quarry cavities and mine failure zones in the subsoil, using the BlenderGIS software package, 3D-models (example, Figure 6) have been developed with the determination of geometric parameters – area of the earth’s surface disturbance along the contour (ha), depth of the cavities (m), predicted volume of cavities formed (million m3).

Figure 6. Illustration of the 3D-model of the earth’s surface disturbance objects of the Kryvyi Rih Iron-ore Basin: (A) quarry cavities; (B) failure cavities.

The accuracy of the method has been verified, and if Google Earth geospatial data is adequately displayed, the accuracy is at least 90%. If the accuracy of Google Earth is unacceptable, an analytical method is used to determine the mined-out quarry space volume. The volume of resulting quarry and failure cavities is determined from the position of restoring the earth’s surface level: from the bottom to the imaginary horizontal area along the quarry surface at the lowest absolute elevation of the quarry contour. Based on the identification and study of the parameters and characteristics of the earth’s surface disturbance objects, an information-analytical map of their location in the city of Kryvyi Rih has been created.

To understand the environmental protection activities implemented in the region and their direct effectiveness in restoring the earth’s surface state, the activities and results of state, regional and city programs of the city of Kryvyi Rih have been analyzed with relevant conclusions being made.

4 Results and discussion

4.1 The state of the earth’s surface disturbances in the Kryvyi Rih Iron-ore Basin

4.1.1 Identification of mining-technogenic earth’s surface disturbance objects

In accordance with the research methodology, the main facilities of the mining, processing and metallurgical industries were studied and identified, the operation of which resulted in significant earth’s surface disturbances in the Kryvyi Rih city area and the environment in general. There are two large iron-ore quarries with five waste rock dumps located 25 km north-west of the northern outskirts of the city of Kryvyi Rih, mining the reserves in the northern part of the Kryvyi Rih Iron-ore Basin, which have no direct impact on the city of Kryvyi Rih. The research focuses on the main part of the Kryvyi Rih Iron-ore Basin, the facilities of which are located directly around the city of Kryvyi Rih.

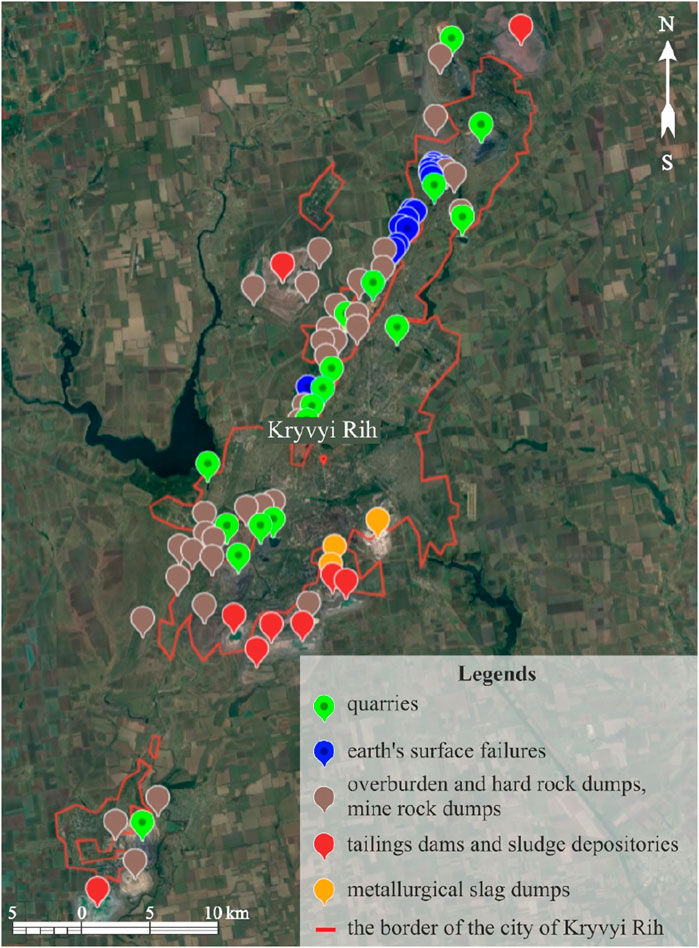

Thus, as of today, 17 major large quarries have been identified in the Kryvyi Rih city area, including 13 quarries for iron ore and quartzite mining (11 active, 2 closed) and 3 quarries for granite mining (1 active, 2 closed). Underground mining is currently carried out by 8 iron-ore mines. It should be noted that over 120 years of iron ore mining in the Kryvyi Rih Iron-ore Basin, there are a number of small too old quarries, the identification of which is difficult (Figure 7).

The area of such quarries in terms of occupied earth’s surface ranges within 1.5–3 ha. Similarly, the region has a significant number of shallow old abandoned mines, of which there are about 15. Thirty-seven large overburden and hard rock dumps from quarries and mine dumps have been identified. It should be noted that the State register identifies only 20 dumps, which is probably due to the fact that the rest of the dumps are closed and rehabilitated, but still occupy land areas. The indicated group of dumps is also analyzed in this research. Nine tailings dams and three metallurgical slag dumps have been identified. Thus, having identified the earth’s surface disturbance objects and their geospatial location, a schematic map has been compiled (Figure 7).

Further attention is given to a detailed study of the earth’s surface disturbances and their parameters for each form in the Kryvyi Rih city area, which forms the major part of the Kryvyi Rih Iron-ore Basin. Attention is paid to forms of the earth’s surface disturbances specifically from iron ore mining and processing operations. Storage ponds and industrial sites of mines and quarries are not taken into account, as mine and quarry water pumping is an additional technological process, and land allotment is a temporary phenomenon, and will be returned to economic use after exploitation of deposits.

4.1.2 Formation of quarry cavities

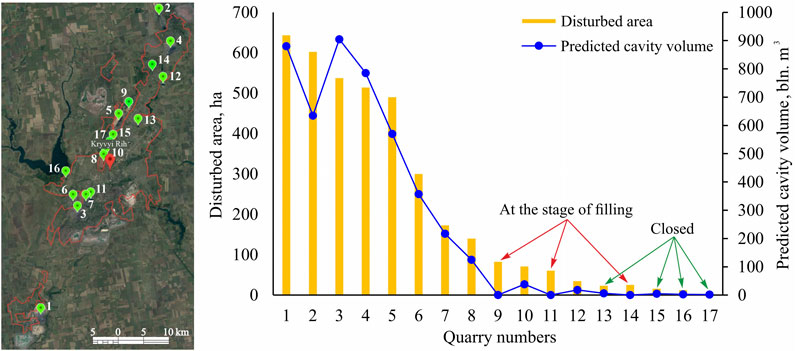

As a result of long-term open-pit iron ore mining in the Kryvyi Rih Iron-ore Basin, quarry cavities of different scales have been created in the subsoil, which are the objects of the deep technogenic landscape. A gradation of identified main 17 quarry cavities has been compiled based on the occupied areas, and predicted volumes of the formed quarry cavities have been determined, given in Figure 8.

Figure 8 data analysis shows a significant variation in the parameters of the resulting quarry cavities. Thus, the occupied quarry surface area ranges from 12 to 643 ha, and the total earth’s surface area disturbed by quarrying is 3,750 ha. The volumes of resulting quarry cavities are in the range of 2.5–900 million m3, and the total volume of cavities is estimated at more than 4.5 billion m3. The maximum quarry depth in the region reaches the 400 m level. Of the 16 quarries in the basin, 7 quarries are inactive, of which 3 iron-ore quarries are at the stage of filling with waste rocks during the mining-technical reclamation stage, 2 closed granite quarries are flooded, where artificial water bodies are created, and 2 iron ore quarries are reclaimed for forestry purposes.

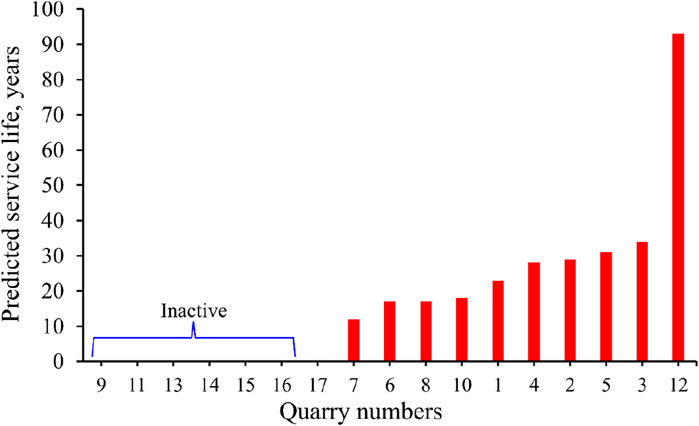

Based on a comparison of current productivity of quarries and available balance reserves within the deposits, a predictive gradation of their service life has been compiled (Figure 9).

Figure 9 shows that seven quarries are currently inactive, covering approximately 220 ha of land area, for which it is imperative to explore the possibility of complete earth’s surface rehabilitation. In three inactive quarries today this is already applied by filling waste rocks in their mined-out space. In the next 10–20 years, four more quarries, where about 680 ha of land surface have been disturbed, can be expected to complete their operational life. It should be understood that the compiled gradation is predictive, since the economic situation may change over time. This is conditioned by fluctuations in the level of annual productivity of quarries, as well as the possibility of premature completion of mining operations with the write-off of their reserves due to proof of inexpediency of further mining the reserves for technical and economic reasons. In this way, it has been found that the total earth’s surface area disturbed by quarrying is 8.7% of the Kryvyi Rih city area.

4.1.3 Earth’s surface failures

Long-term underground mining of high-grade iron ores of the Kryvyi Rih Iron-ore Basin has had a powerful destructive impact on the earth’s surface state. The form of the earth’s surface deformations from the impact of underground mining operations in the Kryvyi Rih Iron-ore Basin is represented by two types of deformations: shear and failure zones, which are also objects of deep technogenic landscape. To determine the total area undermined by mining operations with the earth’s surface subsidence, it is necessary to conduct a complex specialized survey of the territory. Thus, according to scientists and the SE State Institute for Design of mining enterprises “Krivbassproekt”, the area of the earth’s surface subsidence (shear and failure zones) near the city of Kryvyi Rih is estimated at 4,000 ha, which is gradually increasing. Thus, the total area of shear zones increased by 2,400 ha compared to 1955, and the average depth of failure craters also increased from 60.0 m to 120.0 m.

Our research focuses specifically on identifying critical zones of the earth’s surface subsidence – failure craters with the determination of their basic parameters, such as disturbed land area and volumes. Significant earth’s surface deformations are caused by the use of ore reserve mining systems with caving of overlying rocks and blast-hole stoping systems of mining without backfilling the mined-out space. InSAR satellite remote sensing technologies based on interferometric radar have become widespread today to study the dynamics of the formation of failure craters or zones of smooth earth’s surface subsidence under the influence of mining operations (Zhao et al., 2023; Xu et al., 2024; Baltiyeva et al., 2023; Blachowski and Ellefmo, 2023). In future research, it is advisable to predict, based on the studies of dynamics of surface subsidence processes, an increase in the area of failure zones, whether they will reach adjacent infrastructure and what area of valuable soils may be damaged.

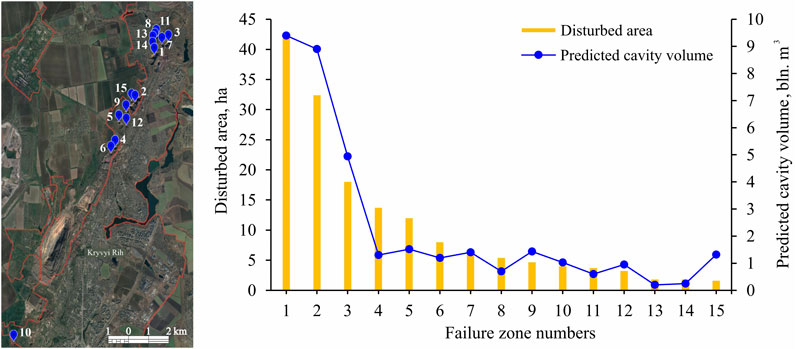

Based on the study of the earth’s surface state in the Google Earth program, 15 main failure zones formed on the western outskirts of the city of Kryvyi Rih have been identified and their parameters have been determined. A gradation of identified main failure zones has been compiled based on the disturbed land areas and predicted volumes of the resulting failure cavities, illustrated in Figure 10. These identified failure zones are located within the mining allotments of the Ternivska mine, Kolachevsky mine, Kozatska Mine, Yuvileina Mine, and Artem-1 Mine. The above mines have annual iron ore production in the range of 0.6–1.5 million tons, the mining depth ranges within 680–1,570 m, and the depth of explored reserves reaches 1,200–2,060 m. The horizontal thickness of ore deposits in different mines varies from 10 to 180 m, and their length along the strike is from 600 to 1,700 m. There are two mining methods used to mine iron ore reserves: the sublevel caving method and the sublevel stoping method, with some mines applying these methods separately, and some mines using both methods in a 50/50 or 70/30 ratio. In most mines, stopes and blocks are placed along the strike of the ore deposit, and their averaged parameters are as follows: the level height is 70–95 m, the width depends on the deposit capacity, and the length is 20–45 m.

Figure 10 data analysis also shows a significant variation in the parameters of the resulting failure cavities. Thus, the disturbed earth’s surface area within the craters ranges from 1.5 to 43 ha, and the total disturbed earth’s surface area due to the formation of failure zones is 180 ha. The volumes of quarry cavities formed are in the range of 0.3–9 million m3, and the total volume of cavities is estimated at over 35 million m3. The average depth of failure zones varies within 30–100 m, and the largest failure formed in the region in depth reached the level of 285 m (failure No. 12), named as “Queen of Craters.”

Thus, it has been determined that the earth’s surface area disturbed by the resulting failure zones is 180 ha, and the shear zone area of 3,600 ha, which is 8.4% of the area of the city of Kryvyi Rih.

The failure zones have created a real technogenic-ecological crisis in the city of Kryvyi Rih, which is associated with the following aspects:

– failure zones have reached residential areas of the city’s private sector, resulting in the resettlement of some residents;

– industrial and transport infrastructure facilities (buildings, roads) are destroyed;

– over time, the surface of the craters gradually expands under the action of climatic and geomechanical factors, resulting in the development of erosion processes on the failure slopes and the degradation of valuable soils;

– the occurrence of failure zones is sudden and poses a threat to the life and health of the population and natural ecosystems.

The mentioned problems and threats of failure zones require a complete immediate urgent solution, however, apart from filling them with waste rocks, no effective solution has been found. A conducted comprehensive analysis of the earth’s surface state in the Kryvyi Rih Iron-ore Basin, disturbed by large-scale mining of iron ore reserves from the subsoil by open-pit and underground methods, shows the urgent need to rehabilitate the territories to achieve environmental and socio-economic balance in the region.

4.1.4 Accumulation of industrial waste from the mining-metallurgical complex

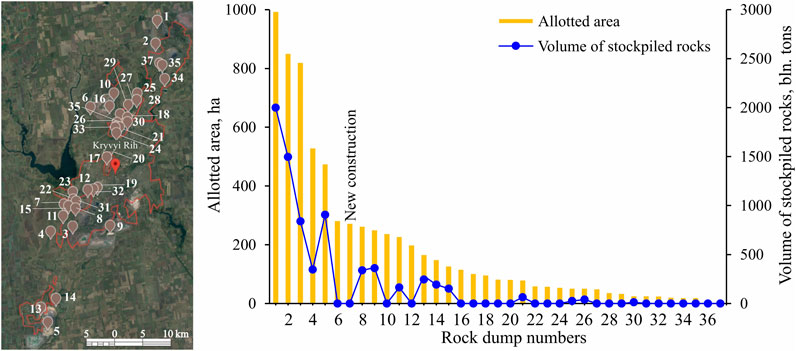

An integral part of the technological mining and processing cycle of iron ores mining in the Kryvyi Rih Iron-ore Basin is the formation of overburden and hard rock dumps in quarries, waste mine rock dumps at mines, and tailings dams with ore beneficiation waste at processing plants. The mentioned objects represent a high-altitude technogenic landscape. By type of waste disposal site, rock dumps are open, surface, and bulk objects. The region also has a metallurgical plant for the production of rolled steel, where blast-furnace and steelmaking slag dumps have been created in the process of the technological cycle of iron and steel smelting. A gradation of 37 identified generated quarry and mine waste rock dumps has been compiled based on the allotted area and known value of the accumulated rock volumes, as shown in Figure 11. The volumes of waste rock stockpiled in only 14 out of 37 dumps can be identified from government open sources.

Figure 11. Gradation of quarry and mine waste rock dumps according to the allotted area and accumulated rock volumes.

Figure 11 data analysis shows a variable distribution of quarry and mine waste rock dumps by area and rock volumes. Thus, the area occupied by waste dumps is in the range of 6–990 ha, and the total earth’s surface area disturbed by waste rock dumps is 6,900 ha. The amount of rocks stockpiled in the identified rock dumps is 13–2,000 million tons. The volume of stockpiled rock in the 14 identified dumps is 7.2 billion tons, and the total volume for 37 dumps is projected to be 7.5–8.0 billion tons. The bulk density of waste rock stockpiled in dumps varies in the range of 2.5–2.8 t/m3, which makes it possible to estimate the volumetric parameters of these types of mining-technogenic relief. It should be noted that of the 37 existing waste rock dumps, 1 new dump is under construction. It has been determined that the total earth’s surface area disturbed by the formed quarry and mine waste rock dumps is 16.05% of the Kryvyi Rih city area.

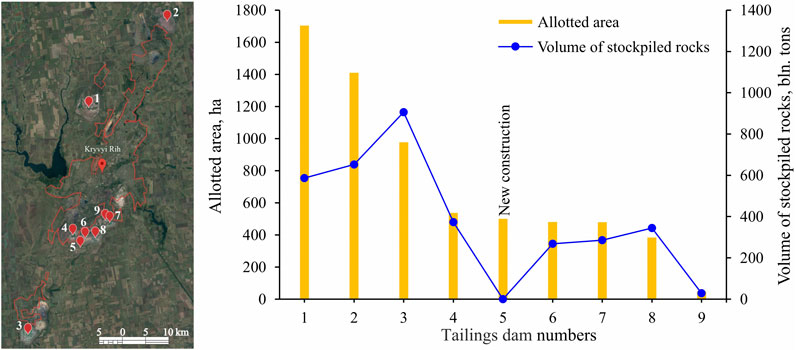

Due to the fact that predominantly low-grade iron ores, represented by magnetite oxidized quartzite, are mined in the region by open-pit method, the quality of iron ore concentrates is brought to an iron content of 65%–67% at the processing plants, while significant waste volumes – tailings and beneficiation sludge – are generated and stockpiled in tailings dams. By type of waste disposal site (tailings dams), there are open, surface and bulk objects. A gradation of the nine identified generated tailings dams has been compiled based on the allotted land area and the volume of accumulated sludge, which is illustrated in Figure 12.

Figure 12. Gradation of tailings dams according to the allotted land area and the volume of accumulated iron ore beneficiation tailings.

Figure 12 data analysis shows that tailings dams in the region occupy significant land areas. Thus, the area occupied by tailings dams is in the range of 50–1705 ha, and the total earth’s surface area disturbed by waste rock dumps is 6,530 ha. The amount of tailings stockpiled in tailings dams is 3.45 billion tons. The bulk density of beneficiation tailings stockpiled in tailings dams varies in the range of 1.55–1.65 t/m3, which makes it possible to estimate the volumetric parameters of these types of mining-technogenic relief. It should be noted that of the nine identified tailings dams, one new tailings dam is under construction. It has been determined that the total earth’s surface area disturbed by the formed tailings dams is 15.2% of the Kryvyi Rih city area.

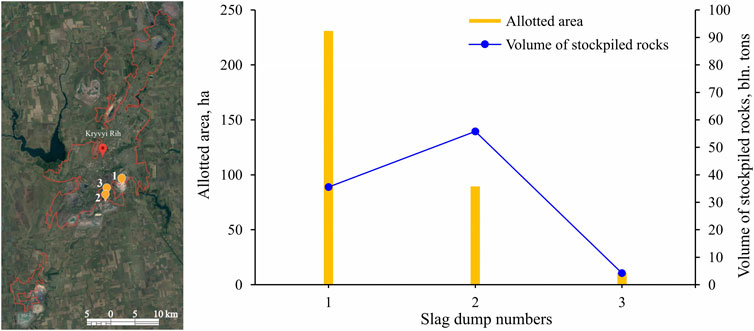

In addition to the mining-technogenic landscape objects, three metallurgical slag dumps of a large metallurgical plant have been created in the region: dump of steel-smelting, open-hearth and converter slags, blast-furnace waste and blast-furnace granulated slags. A gradation of the identified slag dumps has been compiled based on the allotted land area and the known value of the accumulated slag amount, illustrated in Figure 13.

Figure 13. Gradation of slag dumps according to the allotted land area and the volume of accumulated metallurgical slag.

Figure 13 data analysis shows that the land area occupied by slag dumps is in the range of 11–231 ha, and the total earth’s surface area disturbed by slag dumps is 332 ha. The amount of slags stockpiled in dumps is 97.3 million tons. The bulk density of metallurgical slags stockpiled in dumps, depending on their types, varies in the range of 1.3–1.75 t/m3, which makes it possible to estimate the volumetric parameters of these types of accumulations. It has been determined that the total earth’s surface area disturbed by the formed metallurgical slag dumps is 0.8% of the Kryvyi Rih city area.

The conducted comprehensive analysis of the identified objects of industrial waste accumulations from the mining-metallurgical complex, disturbing the earth’s surface, shows that a significant mineral-raw material base of waste of natural and technogenic origin, accumulated in the Kryvyi Rih Iron-ore Basin, should be considered as potential backfill materials. It is important that the generated industrial waste according to the class of environmental hazard (toxicity and radioactivity) based on the legislation of Ukraine belongs to class IV (low-hazard) and can be considered for backfilling mined-out spaces. Given the significant volumes of resulting surface technogenic cavities and the reserves of potential backfill materials, the development of backfill directions to rehabilitate a geomechanically stable earth’s surface is timely and appropriate.

4.1.5 General assessment of the structure of the earth’s surface disturbances

The conducted comprehensive analysis of the forms of the earth’s surface disturbances by mining-metallurgical complex enterprises functioning in the main part of the Kryvyi Rih Iron-ore Basin (the city of Kryvyi Rih) makes it possible to present the current general situation infographically. The structure of the earth’s surface disturbances is presented in Figure 14.

Figure 14. Structure of the earth’s surface disturbances in the Kryvyi Rih Iron-ore Basin: (A) general distribution; (B) distribution in relation to the city of Kryvyi Rih.

Figure 14 data analysis shows that 65.25% of the total disturbed land area consists precisely of accumulated industrial waste – quarry and mine waste rock dumps, tailings dams of iron ore beneficiation wastes, metallurgical slag dumps, while 34.76% is disturbed by quarrying, shear and failure zones of mines. If to compare the land area disturbed by mining operations around and in the city of Kryvyi Rih and the area directly in Kryvyi Rih (Figure 14B), it becomes obvious that there is a critical technogenic-environmental situation in the region, as the earth’s surface disturbances account for 49% of the city area. Given the industrial potential of the city of Kryvyi Rih, intensive reclamation of disturbed territories with rehabilitation of geomechanically stable earth’s surface level is an important and necessary direction, which will improve the state of the environment in the region and use the territories for the construction of various infrastructure facilities contributing to the socio-economic development of the region.

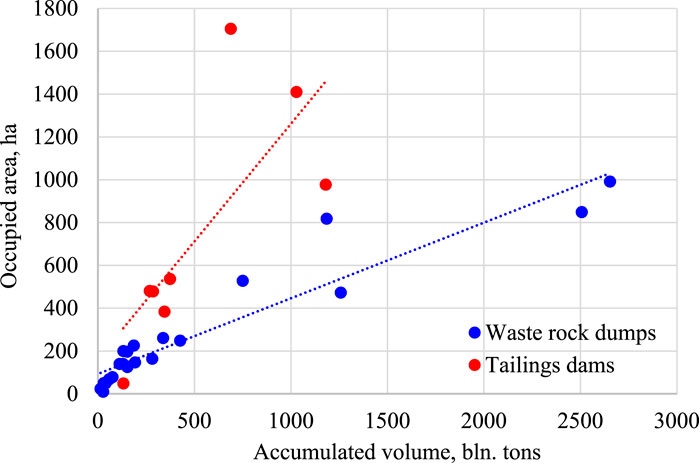

Since waste rock dumps and tailings dams contribute to the greatest earth’s surface disturbances (Figure 14A), the parameters of allotted land areas of all these identified objects in the Kryvyi Rih Iron-ore Basin have been compared. There is a linear relationship between the occupied land area and accumulated waste volumes, which is illustrated in Figure 15.

Figure 15. Relationship between allotted land areas and accumulated waste volumes in waste rock dumps and tailings dams.

Figure 15 data analysis shows that there is a significant difference between the land areas allotted for dumps and tailings dams. Thus, by increasing the volume of waste rocks stockpiled in dumps in the range of 0–2.6 billion tons, the allotted area increases by 5 times, and an increase in beneficiation tailings in tailings dams in the range of 0–1.0 billion tons leads to an increase in occupied land areas up to 14 times. If we look at the density of these waste accumulations, then on average 183.5 tons of waste rocks and 73.5 tons of beneficiation tailings are placed per 1 m2 of land area. Thus, land areas for placing iron-ore beneficiation tailings are used less efficiently than for waste rock dumps. This is a problem and attention today should be directed specifically to finding ways to utilize beneficiation tailings. The threat of tailings dams is the risk of breaching their dams, resulting in technical water leakage and pollution, as well as significant dust generation in the dry areas of alluviation of beneficiation tailings.

The exhaustion of the projected size of some waste dumps and tailings dams is also becoming a gradual problem, resulting in the need to construct new facilities. Thus, as of 2022, PJSC ArcelorMittal Kryvyi Rih began construction of a new waste rock dump Stepovyi-2 (Figure 11, No. 7). The area occupied by the facility will be 271 ha, and the total capacity is designed for 51.38 million m3 of stockpiled rocks. In addition, PJSC ArcelorMittal Kryvyi Rih has received permission and is building a new tailings dam, Tretya Karta (Figure 12, No. 5). Active tailings dams, such as Myrolyubiv and Obiednane, are planned to be closed after the commissioning of a new tailings dam. The tailings dam projected volume is planned to be 280 million m3, as more than 500 ha of land area is allotted.

The construction of new facilities for the placement of mining waste creates social tension in the region, causes constant indignation of residents and environmental organizations. According to the authors, a significant improvement in existing large-scale technogenic-environmental situation can be achieved by developing technologies for backfilling surface technogenic cavities in the region, which will gradually rehabilitate the earth’s surface level with the achievement of geomechanical stability and utilize part of the accumulated waste of the mining-metallurgical complex. To date, this conceptual approach has received insufficient attention in the region.

The general supply of the region with reserves of mineral-raw material base of backfill materials and the predicted volume of cavities formed in the subsoil allow us to assert the existing positive balance.

4.2 Directions for improving the earth’s surface ecological state

4.2.1 Mechanisms available for reducing the influence of the mining industry on the earth’s surface

The severe technogenic-environmental situation, developed in the Kryvyi Rih Iron-ore Basin, has not gone unnoticed by the central and local authorities. To improve the environmental situation in the Kryvyi Rih Iron-ore Basin, various programs have been developed and are being implemented at the state, regional and district levels with the participation of polluting enterprises with the implementation of a set of measures in the period 2000–2026. These programs focus on specific measures and effective mechanisms for improving the state of atmospheric air, water resources, disturbed lands, waste management, as well as protection of natural reserve fund objects, environmental monitoring and public environmental consciousness. Since the research purpose is to analyze the state of the earth’s surface influenced by mining operations, existing measures for the rehabilitation of disturbed lands and industrial waste management are studied.

Based on the results of implementation of the first Program on overcoming the ecological crisis of the city of Kryvyi Rih at the city level in the field of improving the land condition for the period from 2000 to 2010, 223.1 ha of land disturbed by mining operations have been rehabilitated in the Kryvyi Rih region (Gov, 2011). The implementation of the developed concept of the State Program on prevention of technogenic catastrophe in the city of Kryvyi Rih for 2013–2016 was not successful, as the Program was not adopted due to the savings in state funds in connection with the occupation of the Crimean Peninsula by the russian federation and the beginning of the occupation of the eastern part of Ukraine in 2014 (Author Anonymous, 2013). To continue solving specific environmental problems at the regional level, a long-term two-stage Program has been adopted to address environmental problems of the Kryvyi Rih Iron-ore Basin for 2011–2022 (Author Anonymous, 2011). To accelerate and promptly resolve problems at a more effective local level, in 2016 the City Program for solving environmental problems of Kryvbas and improving the state of the natural environment for 2016–2025 was approved (Author Anonymous, 2016). Given that the long-term Regional Program gradually lost its relevance, the City Program for 2016–2025 was adopted instead. The second stage of the Program has not been developed, and during the first stage of the Program, the Kryvyi Rih mining enterprises have utilized 179 million tons of industrial waste. In order to avoid duplication of measures of the above Programs, the long-term Program for the period 2011–2022 has been cancelled. Thus, as of today, the City Program for solving environmental problems in Kryvbas is being implemented, and its completion is scheduled for 2025. The implementation of this long-term Environmental Program has made positive changes in industrial waste management at various levels.

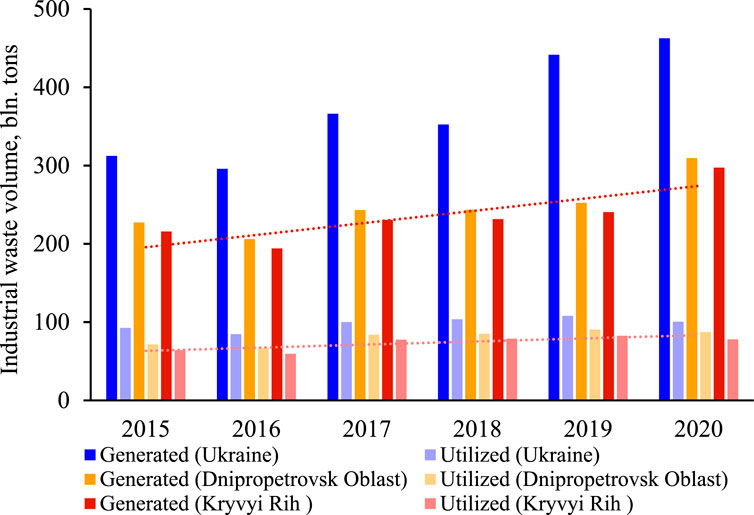

The dynamics of volumes of industrial waste generation and utilization, the main part of which are mining industry wastes for 2015–2020 in Ukraine, the Dnipropetrovsk Oblast and the city of Kryvyi Rih well illustrate the trends in their change (Figure 16). Due to the martial law in Ukraine, caused by the aggression of the russian federation, the State Statistical Service of Ukraine has restricted public access to information, therefore data for 2021 and 2022 are not given.

Figure 16. Volumes of industrial waste generation and utilization in Ukraine, the Dnipropetrovsk Oblast and the city of Kryvyi Rih.

Figure 16 analysis shows the significant importance of the city of Kryvyi Rih in the total volume of both generation and utilization of industrial waste. During this period, when intensive implementation of the Environmental Program measures to improve the state of the environment began, the city of Kryvyi Rih saw a positive trend towards increasing level of mining waste utilization (60–80 million tons/year). However, the tendency to increased intensity of these waste generation is still much stronger than its utilization, which stimulates the search for new utilization methods.

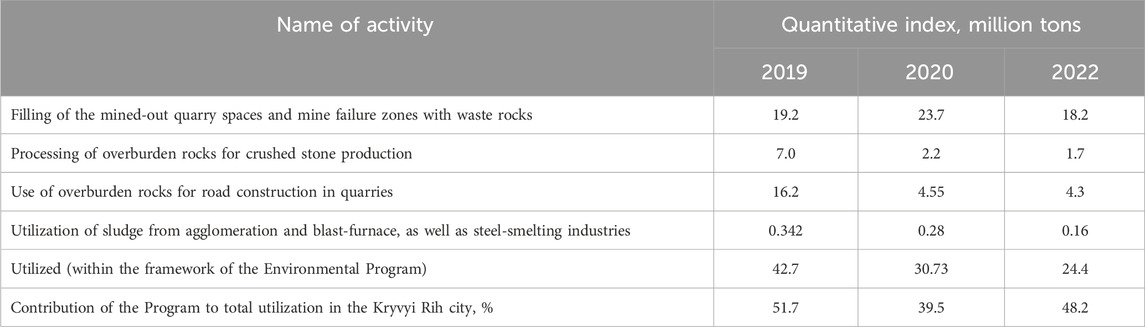

Quantitative indices of Environmental Program measures were identified and analysed according to known reports data (2019, 2020, 2022) related to the improvement of the earth’s surface state disturbed by mining operations (quarries, mine failures), resulting in the achieved quantitative indices, which are summarized and given in Table 1. It should be noted that the contribution of existing environmentally-oriented activities of the Environmental Program to the efficiency of the overall industrial waste utilization, according to data from Program implementation reports published in the public domain, averages 40%–50%.

Table 1. List of environmentally-oriented activities implemented in the Kryvyi Rih Iron-ore Basin within the framework of the Environmental Program.

As can be seen from the data in Table 1, the implementation of environmental programs has been successful and their contribution to waste management is about 50%. During the implementation period of environmental programs, there is an annual fluctuation in the annual rates of environmental improvement measures, due to a number of social, economic and political factors. The main influencing factors were: aggression of the russian federation in 2014 and the implementation of the anti-terrorist operation, global crisis and falling iron ore prices 2015–2017, aggression of the russian federation and full-scale war in 2022. This led to fluctuating levels of financing of environmental programs by the state and mining enterprises.

In addition to the participation of polluting enterprises in the environmental program activities (Table 1), other directions of industrial waste utilization are also used, which in combination allows achieving utilization rates in the range of 60–80 million tons/year. Thus, depending on the need, mining and processing plants in the region also use overburden rocks and beneficiation tailings for the construction of tailings dams to build dams, thus increasing their capacity without allotting new areas. In 2021, for the first time in Ukraine, a tailings thickening complex was commissioned at “YUZHNIY GOK” Mining and Processing Plant, which made it possible to reduce the volume of tailings slurry pumped into the tailings dam, reduce the volume of technical water, electricity supply and the area for placing tailings. In 2004, PJSC Central Iron Ore Enrichment Works developed and implemented a technology for processing beneficiation tailings to extract iron-ore concentrate. However, the technology does not fully process the re-extracted material and about 80% of the minerals are returned to the tailings dam (Vilkul et al., 2018). For example, in 2015, 6.4 million tons of beneficiation sludge were used to produce 852 thousand tons of concentrate.

The highest level of industrial waste utilization is achieved in the region precisely when handling waste rocks from quarries and mines. Figure 17 illustrates the processes of filling up the failure zones and old inactive quarries in the region.

Figure 17. Illustration of the existing methods for the earth’s surface rehabilitation in the city of Kryvyi Rih: (A) filling with mine waste rocks of the Yuvileina Mine failure zone; (B) filling with mine waste rocks of the old Lenin quarry No. 1; (C) filling of quarry No. 2, PJSC Central Iron Ore Enrichment Works, with dump waste rocks; (D) filling of quarry No. 1, Novokryvorizky GZK, with dump waste rocks [images (A–C) by Dmytro Antonov; image d from open online resource: https://kryvyi-rih.name/ru/nezvychajni-pryrodni-misczya-kryvogo-rogu].

Noteworthy is the filling of shear zones and the earth’s surface failures during underground mining of iron ores occurring in the Kryvyi Rih iron-ore region. As a result of mining, failure zones have formed in the mining allotments of almost all mines. For example, in the Yuvileina Mine mining allotment, mining-technical reclamation of the failure zone is performed by filling it with mine waste rocks using bulldozers and dump trucks (Figure 17A). In the region, various mines are gradually filling up five failure craters. The situation is paradoxical, since if there were no failure zones on the earth’s surface, mine waste rocks would be stockpiled in dumps and occupy land areas. It is important to note that from a geomechanical point of view, the issues of how filling of waste rocks will affect the failure crater state have not been studied.

Backfilling of mined-out quarry cavities is also used in the region (Figures 17B–D). Mine waste rocks (Figure 17B) and overburden hard rocks from adjacent active quarries (Figures 17C, D) are used as a reclamation material. The type of mechanization used are bulldozers, draglines and dump trucks (Bazaluk et al., 2023). After rehabilitation of the earth’s surface level, enterprises plan to use the areas for new dumps without returning them to economic use. It should be noted that filling of quarries is generally used when backfill material is close to the site. When announcing intentions to construct new waste rock dumps, mining enterprises are often criticized by environmental organizations and residents for allocating new land areas without further intensive use of rocks for reclamation of already existing technogenic cavities in the region to accelerate the earth’s surface level rehabilitation.

These reclamation methods for quarry and failure cavities are characterized by simplicity and lower economic costs for enterprises. However, in surface technogenic cavities, a loose rock mass is formed, characterized by inhomogeneous filling of material, significant hollowness and high filtration properties (Villain et al., 2013; Petlovanyi et al., 2021; Wickland et al., 2010), which does not guarantee the effective and safe use of the rehabilitated earth’s surface for the possible future construction of various infrastructure facilities and is risky. In addition, waste rock filling operations result in dust generation during both the delivery of the backfill material and during the backfilling process.

The conducted analysis shows that the region pays more attention to the utilization of quarry and mine waste rocks, but the utilization of beneficiation tailings is slower. This is mainly the reuse of beneficiation tailings for the reconstruction of existing tailings dams. In addition to the fact that tailings dams in the Kryvyi Rih region occupy the largest area of disturbed land, there are risks of their dams breaching, and they are also a significant source of environmental pollution. The state of the surrounding air during tailings storage is affected by the drying beaches of the tailings dam alluviation during periods of dry and windy weather. Thus, according to the environmental impact assessment of one of the tailings dams (Figure 11, No. 4), the volume of emissions of fine particles only from an area of 45 ha of dry beaches will be 9.5 tons/year (Environmental Impact Assessment Report, 2021).

Thus, in the Kryvyi Rih Iron-ore Basin, there is an urgent need to utilize the accumulated iron ore beneficiation tailings and to develop effective mechanisms for their rational use, which will significantly reduce the allotment of land areas for new tailings dams and improve the environmental state.

4.2.2 A promising direction for restoring the disturbed earth’s surface

The high availability of significant reserves of mineral-raw material base of industrial wastes and the resulting volumes of technogenic cavities in the Kryvyi Rih Iron-ore Basin makes it possible to consider the prospect for development of technologies for their backfilling. A return to technologies of backfilling underground cavities in iron-ore mines today is ineffective and probable, since for more than 40 years, the iron-ore reserves has been mined using mining systems with caving of overlying rocks and blast-hole stoping without backfilling the mined-out space with a specific weight of 50% of each and today has reached a depth of 1,500 m (Bazaluk et al., 2021b). Consideration of backfill technologies at mining depths of 1,500 m is doubtful, since significant volumes of cavities and caved loosened mass have been formed in the subsoil above the level of mining operations, which have already led to the formation of a rock mass shear troughs. Technologies for forming the backfill mass are no longer capable of solving the problems of the earth’s surface deformation and will probably be very expensive.

The high availability of significant reserves of mineral-raw material base of industrial wastes and the resulting volumes of technogenic cavities in the Kryvyi Rih Iron-ore Basin makes it possible to consider the prospect for development of technologies for their backfilling. A return to technologies of backfilling underground cavities in iron-ore mines today is ineffective and probable, since for more than 40 years, the iron-ore reserves has been mined using mining systems with caving of overlying rocks and blast-hole stoping without backfilling the mined-out space with a specific weight of 50% of each and today has reached a depth of 1,500 m (Bazaluk et al., 2023). Consideration of backfill technologies at mining depths of 1,500 m is doubtful, since significant volumes of cavities and caved loosened mass have been formed in the subsoil above the level of mining operations, which have already led to the formation of a rock mass shear troughs. Technologies for forming the backfill mass are no longer capable of solving the problems of the earth’s surface deformation and will probably be very expensive.

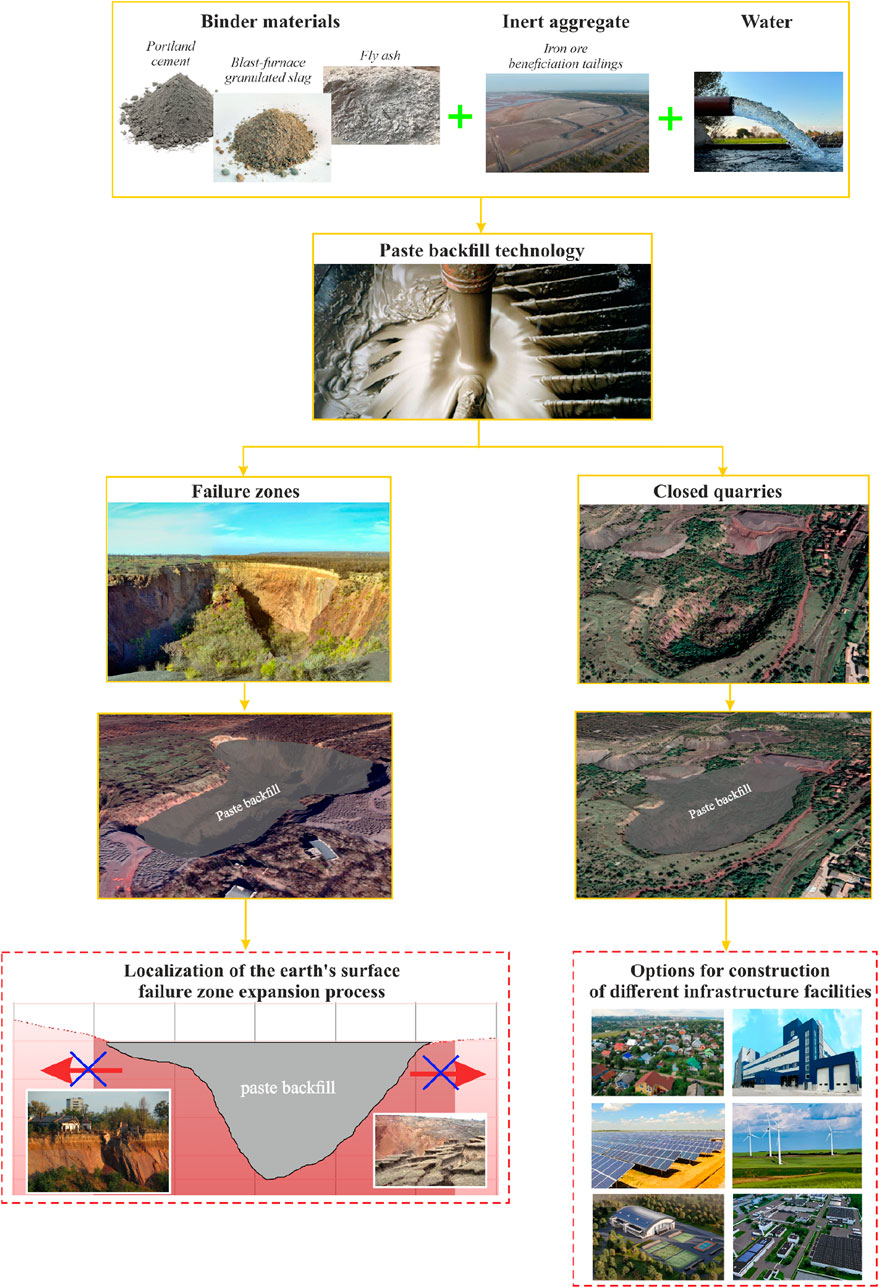

Given the need to achieve geomechanical backfill mass stability, environmental difficulties with significant volumes of accumulated iron-ore beneficiation tailings, the low level of their utilization and the potential supply of the region with binder materials, for the first time for the conditions of the Kryvyi Rih Iron-ore Basin and Ukraine, it is proposed to develop and implement the paste technology for backfilling the formed surface technogenic cavities – inactive quarries and mine failure zones. The region has created favorable conditions for the implementation of paste backfill technology: significant volumes of accumulated beneficiation tailings and the availability of reserves of potential binder materials (cement plant, blast-furnace slag dumps, and dry fly ash from thermal power plants). These aspects are also confirmed in the previous research results of the authors (Petlovanyi et al., 2023b), where the “quarry cavities - backfill material” systems in the Kryvyi Rih region are recognized as priority for the development of backfill directions for the purpose of the earth’s surface rehabilitation.

Cement paste backfill technologies have become widespread in mines and quarries of various countries around the world as a significant environmental protection method. When backfilling underground cavities with paste, the earth’s surface continuity is preserved, large-scale utilization of beneficiation tailings, waste from metallurgy and thermal power plants is achieved, and the formation of new dangerous tailings dams is prevented (Yang et al., 2021; Bek et al., 2022; Behera et al., 2021).

In addition, the pipeline transport of paste backfill mixture makes it possible to create a widely developed mobile network of backfill pipelines for the purpose of delivering it to quarries and mine failures. This will make it more environmentally friendly to transport the backfill mixture than, for example, the delivery of dump waste rocks to quarries and failure zones, which is accompanied by intense dusting and pollution of the air and adjacent soils. In the conditions of the densely populated city of Kryvyi Rih and a significant number of industrial and civil buildings, pipeline transport for paste backfill mixture is a feasible technical solution. As an alternative to paste backfilling, cemented rockfill should be mentioned (Kuzmenko et al., 2014; Petlovanyi and Mamaikin, 2019). However, the main disadvantages will be the expected high wear of pipelines during transportation of the mixture, longer setting time of the mixture and segregation of coarse fractions with subsequent heterogeneity of the mass when filling quarry cavities and mine failure zones.

Extensive long-term experience in using paste backfill technology allows us to highlight its following advantages: lower pipeline wear, low filtration coefficient of artificial mass, no segregation of inert aggregate, no mixture stratification during transportation, minimal degree of shrinkage, low amount of water in technological processes, high degree of compaction and homogeneity of the mass. This makes this type of backfilling the most technologically convenient and environmentally friendly. With sufficient isolation and sealing of the bottoms of quarry cavities and failure zones, due to the colloidal water-holding capacity of the paste, very little free water is expected for possible leachate formation, thus reducing groundwater contamination (Cheng et al., 2020). The concept of the paste backfill idea for the Kryvyi Rih Iron-ore Basin is shown in Figure 18.

Figure 18. Concept of restoring the disturbed earth’s surface in the Kryvyi Rih Iron-ore Basin (Image “paste backfill” from CEC Mining Systems: https://cecminingsystems.com/mining-solutions/paste-backfill-solutions/).

The ultimate goal of implementing the paste backfill concept should be the complete rehabilitation of a geomechanically stable earth’s surface level for its further use in various infrastructure projects to develop the region’s economic potential. These may include energy facilities, sports facilities, industrial workshops and warehouses, private residential buildings, etc.

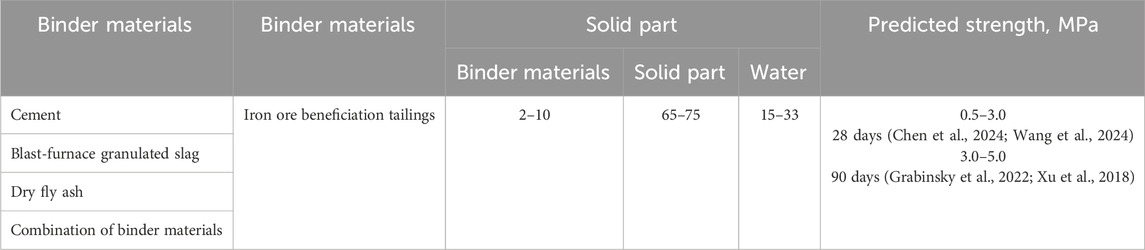

The world practice of using paste backfill mixture shows a wide variation in possible its formulations and achieved physical-mechanical properties. Therefore, for the conditions of the Kryvyi Rih Iron-ore Basin, it is recommended to consider options for the characteristics of paste backfill mixtures given in Table 2.

To prepare the paste backfill mixture, it is possible to use different types of binder materials or their combination of Kryvyi Rih region. It should be noted that at a distance of about 55 km in the south-eastern direction from the city of Kryvyi Rih, there is an ash and slag dump of the Kryvyi Rih Thermal Power Plant, connected by railway to the city of Kryvyi Rih. The ash and slag dump has accumulated 82.4 million tons of fuel slag and fly ash, which can be considered as a component for paste backfilling.

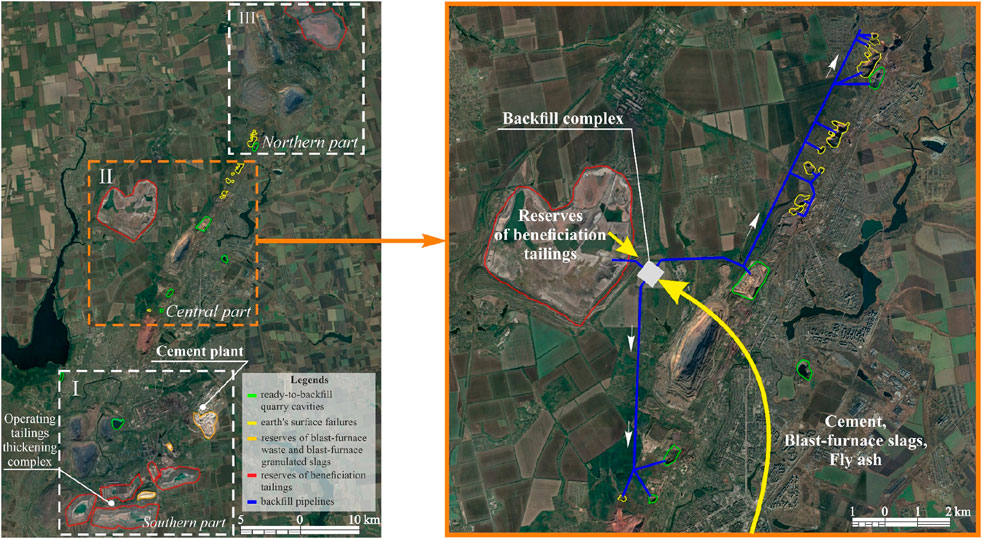

Given the location of major mining and processing facilities in the southern, western and northern parts of the city of Kryvyi Rih, further prospects and options for using paste backfilling are discussed separately for these areas (Figure 19).

Figure 19. Prospects for the development of technologies for paste backfilling of technogenic cavities in the Kryvyi Rih Iron-ore Basin.

In the southern part of the city of Kryvyi Rih (Figure 19, I), the basis for iron ore mining is formed by the enterprises of the “YUZHNIY GOK” Mining and Processing Plant (1 quarry) and PJSC ArcelorMittal Kryvyi Rih (2 active quarries, 1 at the stage of filling), which in the process of their beneficiation have formed a number of tailings dams. Prospects for the development of paste backfill technologies in the near future, despite the availability of tailings thickening complex and binder materials reserves, are assessed as low, since the completion of mining the deposits by quarries and the availability of ready-to-backfill cavities are not expected before 12–15 years.

Theoretically, attention can be drawn to the flooded quarry, which is located 5–6 km in the north-western direction from the tailings dams and is in the process of being filled with dump waste rocks. However, this is likely to lead to technological difficulties and significant costs, as the quarry flooding depth reaches 100 m, and waste rocks are gradually filled into the mined-out space by excavators from the quarry walls using inclined ways, which causes the long-term presence of a water bowl in the bottom of the quarry. While the quarry bottom is filled with water, paste backfilling cannot be used, even with quarry water pumping systems, due to the too high cost of auxiliary processes. The system for transporting the paste mixture from the thickening complex to the technogenic cavities in the central part of the city will probably be difficult due to the dense presence of infrastructure facilities and transportation distances.

In the northern part of the city of Kryvyi Rih (Figure 19, III), there is PJSC Northern Iron Ore Enrichment Works with two large quarries and one tailings dam, and there are also two iron ore mines in operation. The service life of these two large quarries is estimated at 30 years, but there are other technogenic cavities. This group of ready-to-backfill technogenic cavities is located in the south-western part of the northern area of the city of Kryvyi Rih. At the ready-to-backfill stage, it is advisable to consider five failure craters near 2 mines, as well as 1 quarry, which is at the stage of filling, but can be additionally backfilled with paste. The distance of the backfill pipeline route from the tailings dam to the cavities is about 11–12 km. In 2023, PJSC Northern Iron Ore Enrichment Works planned to begin construction of the region’s second tailings pulp thickening complex, but it has been postponed due to martial law reasons. The option of developing a paste backfilling has a right to exist, but the energy consumption for transportation can be high.

In our opinion, the central part of the city of Kryvyi Rih has the most favorable conditions for the introduction of paste backfill technology in the Kryvyi Rih Iron-ore Basin (Figure 19, II). PJSC Central Iron Ore Enrichment Works operates here with one large quarry and one tailings dam, one quarry at the stage of filling and six iron ore mines. The ready-to-backfill cavities can be eight formed failure craters, additional backfilling of a quarry that is at the stage of filling and two long-closed water-free quarries. Favorable conditions are explained by the presence of these ready-to-backfill cavities in the closest proximity to the tailings dam and the possible location of the backfill complex for preparing paste backfill mixture. The transportation distance to the nearest technogenic cavities will be 4–5 km and even 11.0 km to the technogenic cavities, which are conditionally referred to the northern part of the city of Kryvyi Rih (Figure 19, III). Reserves of binder materials (slag dumps, cement plant) are located at a distance of about 30–40 km and can be delivered to the backfill complex warehouse by railway transport. It is also less promising to consider the accumulation of fly ash in the ash and slag dump of Kryvyi Rih Thermal Power Plant, but the railway transportation distance will be 85 km. A technologically convenient aspect is that the resulting technogenic cavities are in dry conditions. Atmospheric precipitation is filtered into the mine space through caved rocks at the failure bottoms, and closed quarries are drained by the influence of depression cones of large quarries located nearby. If to conduct backfilling simultaneously in the central and northern parts of the city (Figure 19 II, III), significant success can be achieved in intensifying the earth’s surface rehabilitation along the western outskirts of the city of Kryvyi Rih. Initially, it is recommended to implement pilot projects on paste backfilling of the failure zones and quarries nearest to the backfill complex and draw technical-economic conclusions about the effectiveness of the mentioned measure. In addition, the construction of a tailings thickening complex at PJSC Central Iron Ore Enrichment Works can be sufficiently effective to save the area of the existing tailings dam, technical water and utilize significant volumes of beneficiation tailings using paste backfill technology for backfilling technogenic cavities.

The use of paste backfill technology in the central and possibly northern part of the city will make it possible to utilize at least 65–70 million tons of accumulated beneficiation tailings, 4.5 million tons of blast-furnace granulated and dump slags or fly ash, thereby reclaiming 200 ha of land. The speed of filling technogenic cavities using paste backfill technology and, accordingly, reclaiming the earth’s surface level will depend on a number of factors, but first of all: the productivity of the mixer of the paste backfill components, which is a bottleneck today, the number of backfill complexes and the climatic conditions of the region, which affect the mode of conducting backfill operations. It is possible to consider the options for simultaneous paste backfilling of several cavities and individually, depending on the available productivity for the production of paste backfill mixture. In the practice of paste backfilling of mines, mixers with a capacity of 50–300 m3/h are used, which is sufficient to fill underground cavities. However, large-scale projects as filling surface technogenic cavities with paste backfill mixtures and intensifying the earth’s surface rehabilitation require the design of higher-performance mixers. It may also be possible to form a combined backfill mass from layers of paste and rock backfill, which is due to the change in climatic conditions during the year.

The layout of the facility for the preparation of the paste backfill mixture should contain the following: point for loading moistened tailings in the designated part of the tailings dam, conveyor line for transporting tailings from the tailings dam to the backfill complex, drying chamber (if necessary), receiving hoppers, feeder conveyors, silos with storage of binder materials, a warehouse and a binder materials grinding point (for blast-furnace slag), dosing units, mixer, pumping systems and installed pipeline systems. The issue of forming a backfill mass using paste backfill mixture in failures and quarries has not been sufficiently studied. Today, there are some studies in the world where paste backfill technologies are considered for surface technogenic cavities from mining activities (quarries, failure zones) (Sun et al., 2018; Zhang et al., 2021; Chen et al., 2023). In Wang et al. (2024), the authors propose a similar approach to paste backfilling a metal mine failure zones, and it is proposed to add waste rocks to the paste before it is fed into the cavity in order to improve the backfill mass properties. Also, some scientists conducted research on the impact of a paste-backfilled quarry on underground mining operations using numerical modeling. However, no information is provided on the processes and parameters of the backfill mass formation. The influence of water released into a quarry filled using paste backfilling is studied, but the technological aspects of backfilling are not discussed in the paper.