- 1Department of Mechanical Engineering, Faculty of Mechanical and Aeronautical Engineering, University of Engineering and Technology, Taxila, Pakistan

- 2Department of Mechanical Engineering, Universiti Teknologi PETRONAS, Seri Iskandar, Perak, Darul Ridzuan, Malaysia

- 3Tecnologico de Monterrey, Institute for the Future of Education, Monterrey, Mexico

Water contamination is a major problem nowadays which can not only be solved through technological innovations but also requires educational innovation. The contamination of water is caused by discharging harmful pollutants into the water. These harmful contaminants cause different diseases. The significance of water filtration has grown in recent years. The quality of water is affected majorly by residual waste, bacteria, and so on. Based upon these issues, the Six Sigma methodology is used in this research for the design of a portable filtration system. This methodology is based on five steps that align with the computational competencies involving abstraction, decomposition of problem, and algorithmic thinking. Initially, a questionnaire approach is used to identify the need for a portable water filter for potential users. The Quality Function Development (QFD) matrix is used to measure the user’s needs. Based on the user’s information, a decision matrix tool is being used in the Analyze stage. After this theoretical concept is generated, and selection is made among various options. The complete drawing was made in the design stage after several stages of concept generation and selection. Then a prototype is developed to conduct proof of concept testing. The hollow fiber membrane (HFM) that is being used is manufactured usually by melt spinning, dry spinning, and wet spinning. But usually, a wet spinning method is predominantly used for manufacturing hollow fiber membranes. Polymer liquid like polyvinyl chloride (PVC) is used for the manufacturing of membranes with other liquids in different ratios. The size of pores varies from 0.01 to 0.1 microns. The flux rate usually depends upon the volume, length, and size of the cartridge. Backwashing at regular intervals is done for the presentation of fooling due to the accumulation of solutes. This filtration system is also proficient in rejecting bacteria that are being found in water and soil. This is done by a coliform test that is being performed for bacteria. The porosity of the membrane is also affected by the concertation of polyvinyl chloride (PVC) as the concentration of polyethylene glycol increases the porosity of the membrane decreases. A Chemical Oxygen Demand test is also performed to check the presence of organic matter in water. After filtration, no organic matter was manifested in the water. Design for Six Sigma in a portable filtration system that uses membrane for filtration is a good start in looking for a new alternative concept. The implication of this research presents a multifaceted solution to water contamination issues, offering educational outreach programs, STEM education integration, community engagement, and innovative competitions as integral components for fostering awareness, sustainable practices, and creative solutions in the pursuit of clean water.

1 Introduction

The United Nations’ 2030 sustainable development agenda offers a blueprint for the betterment of both people and the planet, now and in the future. Sustainable development acknowledges that eliminating poverty and associated issues must go hand in hand with strategies to enhance healthcare and education, minimize inequality, enhance economic growth, address climate change, and work towards the preservation of our oceans and forests. The core of sustainable development highlights the critical significance of water and sanitation services, which are fundamental to the reduction of poverty, the promotion of economic advancement, and the preservation of environmental sustainability. These services form the foundation for efforts to build a sustainable and more environmentally aware world. Currently, over two million people face challenges in obtaining safe and well-managed drinking water (Othman et al., 2021). Climate change has contributed to the rise in natural disasters, including floods and droughts. Approximately 80% of the world’s wastewater is discharged back into the environment without proper treatment or reuse, leading to a substantial loss of freshwater species (Othman et al., 2021). Sustainable Development Goal 6, which focuses on water and sanitation, serves as a comprehensive plan to secure the availability and sustainable oversight of water and sanitation services to minimize health risks. Stakeholders who are deeply engaged in advancing sustainable development are catalysts for driving collective efforts within the framework, expediting progress toward water-related objectives and goals, in a concerted bid to confront the worldwide crisis. The frequency and severity of localized water crises have been on the rise, carrying serious concerns for public wellbeing, the preservation of our environment, as well as the stability of the food and energy sectors, and overall economic growth. Through national leadership and global partnership, a new version of water-related SDGs of the 2030 agenda is turning into a reality. Sustainable water solutions are not just based upon technological innovations, but they also require educational innovations because poor water quality can also directly influence educational performance, for example, Buajitti et al. (Buajitti et al., 2021) published research where the authors aim to explore the correlation between lead exposure in schools, identified through province-wide lead testing data from school drinking water systems, and educational outcomes in Ontario, Canada, during the school years 2008–09 to 2015–16, revealing that schools with lead exceedances are associated with increased risks of students failing to achieve provincial standards in math, reading, and writing assessments, indicating a potential link between environmental factors and educational performance.

The use of water filters for different aesthetic purposes by removing heavy metals, chlorine, and dour is essential to our everyday life. A portable water filter can be used for military personnel, and recreational that need to drink filtered water from untreated sources like lakes and rivers. The membrane has better performance in filtering water (Othman et al., 2021). Therefore, a comprehensive study is needed for a membrane-based water filtration system. Nanofiltration (NF) membranes have emerged as a highly promising technology that has observed great development and widespread commercialization. They excel in the separation of both neutral and charged solutes within aqueous solutions. A key feature that sets NF membranes apart is their molecular weight cut-off (MWCO), which positions them between the realms of ultrafiltration (UF) membranes and reverse osmosis (RO). This unique MWCO characteristic distinguishes NF membranes as a valuable tool for various applications.

Hollow fiber nanofiltration membrane is the next-generation nano filter polymeric membrane. Polymer membranes have gotten attention over the past 50 years. Nanofiltration membranes can provide a solution for the next-generation. Nanofiltration (NF) membranes have proven to be highly efficient when it comes to separating mixtures of organic molecules and salts. A notable characteristic of NF membranes is that the majority of them carry an electrical charge, either positive or negative, depending on the materials they are composed of. These properties make NF membranes well-suited for various applications. Furthermore, surfactants, which are organic chemicals, have found widespread use in products like soaps, laundry detergents, dishwashing liquids, and shampoos. Surfactants serve to lower the surface tension in water and other liquids, enhancing their effectiveness in cleaning and emulsifying tasks.

The overall design philosophy of Six Sigma is based on the following principles: continuous learning, leadership commitment, process excellence, data-driven decision-making, customer focus, and cross-functional collaboration. The ultimate goal of this approach is to drive long-term quality improvements, efficiency, and customer satisfaction. The integration of emerging technologies like big data analytics, machine learning, and artificial intelligence (AI) into conventional Six Sigma frameworks has been focused mainly on recent developments in the implementation of Six Sigma methodology. In order to find patterns, forecast future trends, and reveal hidden insights that might not be visible through conventional statistical analysis alone, AI and ML systems can evaluate large, complicated datasets. Furthermore, real-time monitoring of process parameters is made possible by developments in data collecting and sensor technologies using sigma methodology. This allows for the proactive detection and rectification of deviations before they become problems.

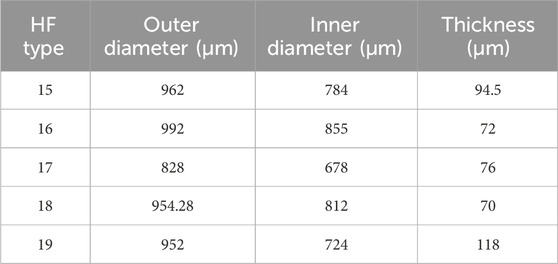

Figure 1 highlights the basic aspects of hollow fiber membranes as well as the fabrication techniques used for membranes and materials frequently used for membrane fabrication. This figure also highlights the major applications of membranes like water purification, CO2 capture, and gas separation. There are also emerging R&D applications of hollow fiber membranes like green materials and green modification (Lau et al., 2022). Figure 1 illustrates the general overview of hollow fiber membrane in which different subsections are related to the basic aspect, fabrication, types of hollow fiber membranes, applications in different areas, and emerging research and development.

Figure 1. Different aspects of hollow fiber membrane (Lau et al., 2022).

The integration of hollow fiber membrane (HFM) technology in water treatment processes represents a significant advancement in addressing critical environmental issues, particularly water scarcity and pollution. Hollow fiber membranes, characterized by their high surface-area-to-volume ratio and selective permeability, offer an efficient solution for removing contaminants, including microorganisms, heavy metals, and particulates from water sources (Chong et al., 2013). The environmental impact of water pollution is profound, affecting ecosystems, human health, and economic development (Schwarzenbach et al., 2010). HFMs are particularly relevant in regions where access to clean water is limited, providing a sustainable option for potable water production without the need for energy-intensive processes like traditional desalination (Peñate and García-Rodríguez, 2012). Moreover, the application of HFMs in wastewater treatment and recycling contributes to reducing the ecological footprint of industrial processes by minimizing the discharge of pollutants into natural water bodies (Hancock and Rhim, 2008). This technology aligns with the principles of circular economy and sustainable development, emphasizing resource recovery and the minimization of environmental impacts (Van der Bruggen, 2009). By advancing HFM technology and its applications, researchers and engineers can play a pivotal role in mitigating water-related environmental challenges, promoting water security, and supporting the United Nations Sustainable Development Goal 6 (Clean Water and Sanitation).

2 Current state-of-the-art and literature review

Norgren et al. (Norgren and Edlund, 2014) concentrate on the most latest developments in lignin’s physical chemistry. Developing patterns of lignin incorporation in favorable future applications, like the controlled release, carbon fibers, lignocellulose saccharification, bioplastics, composites, nanoparticles, adsorbents, and dispersants, are also discussed. We briefly discuss the lignin structure’s complexity, which affects how it behaves in solutions both as a colloid and a macromolecule, along with its potential to serve as a renewable precursor for the creation of high-value products. Ebrahimi et al. (Ebrahimi et al., 2015) studied that one of the main contributors to industrial water contamination is pulp and paper wastewater. In this study, ceramic tubular membrane technology was evaluated as a potential replacement for traditional wastewater treatment in the pulp and paper sector. In this particular scenario, ceramic membranes were specifically designed and implemented to address the reduction of chemical oxygen demand (COD) and the elimination of any remaining lignin from the effluent stream in the sulfite pulp production process. These membrane-based processes encompass a series of both batch and semi-batch procedures, which involve the use of microfiltration, ultrafiltration, and nanofiltration techniques. The aim is to effectively enhance the treatment and purification of the effluent, contributing to more sustainable and environmentally friendly sulfite pulp production.

Wang et al. (Wang et al., 2015) reveal that by removing lignin, laccase treatment was used to improve the nanofiltration process. The outcomes of the PHL filtration process demonstrated an enhancement in membrane filterability, as proved by the increased deionized water flux. An alternate method of using PHL’s hemicellulose sugars in an environmentally acceptable manner is the combined laccase-nanofiltration process. Bai et al. (Bai et al., 2020) presented the new techniques and design approaches required to create different kinds of “thin film composite (TFC) nanofiltration (NF) membranes” to get around the permeability-selectivity constraint and enhance the performance of desalination membranes. In this work, a simplified extra two-step method was used to create a modified TFC membrane with a surface layer and sandwiched layer. Zahir et al. (Zahir et al., 2017/07) developed mesoporous Al2O3 membranes on tubular Al2O3 substrates through the sol-gel technique. Notably, their study marked the first instance of conducting high-resolution transmission electron microscopy (HRTEM) characterization of the nanostructure, both before and after subjecting the membranes to hydrothermal treatment at 500°C. In another study by Hu et al. (Hu et al., 2018), an asymmetric graphene oxide/Al2O3 membrane was fabricated via a spin-coating process to achieve efficient salt rejection in saline solution treatment. Microstructure analysis revealed a multilayer structure, with graphene oxide uniformly coating the surface of the Al2O3 membrane interlayer. The membrane’s performance in terms of permeation flux and salt rejection was investigated across various aqueous salt solutions.

Yang et al. (Yang et al., 1998) prepared composite tubular membranes by applying zirconia particle suspensions to create separation top layers on two distinct porous α-alumina supports. These coated supports were then subjected to partial sintering of the top-layer particles. The study systematically explored the synthesis conditions of the ZrO2/α-Al2O3 membranes. Gestel et al. (Van Gestel et al., 2002) alumina and titania multilayer sol-gel-produced nanofiltration (NF) membranes chemical stability was investigated. Anatase-TiO2 fired at 300°C, anatase-TiO2 fired at 450°C, and -AlOOH fired at 400°C, respectively, making up the top layers of the membranes. The membranes’ solvent resilience was proved through a variety of stability tests using several types of organic solvents. A sequence of dynamic corrosion tests employing aqueous solutions at low pH (HNO3) and high pH (NaOH) was conducted to investigate the membrane performance, including PEG retention, molecular weight cut-off (MWCO), and permeability. These tests aimed to yield insights into the corrosion characteristics.

Xu et al. (Xu et al., 2013) by using a two-step process, composite films made of graphene oxide and particles have been effectively created with filtration capabilities. To start, sheets of a composite material made of graphene oxide and TiO2 that can create a stable dispersion in water are prepared. Graphene oxide-TiO2 films are then created by combining these composite sheets. The findings demonstrate that these graphene oxide-TiO2 films are not only capable of adsorbing these dyes but also of capturing extra amounts of dye molecules, suggesting potential uses in the field of water filtration. Zhu et al. (Zhu et al., 2022) have highlighted that graphene, a two-dimensional monoatomic-thick constituent of carbon allotropes, has garnered global attention as a groundbreaking material in the twenty-first century. This is due to its remarkable attributes encompassing charge transport, thermal conductivity, optical properties, and mechanical strength. Nearly all branches of science and engineering are now researching graphene and its sub-parts. The development of graphene-based materials has recently demonstrated its potential to significantly influence electrical and nanocomposites, chemical sensors, and optoelectronic devices. The primary goal of this review article is to offer a comprehensive and in-depth scientific assessment of the historical evolution of graphene and to gauge its prospective applications in the years ahead. We delve into an array of techniques employed in the production of single-layer graphene, graphene nanoribbons, chemically derived graphene, graphene-infused polymers, and the integration of graphene in composite materials with nanoparticles. Zhu et al. (Zhu et al., 2022) it is advantageous to produce graphene oxide with less acid to cut costs and the environmental impact, but it is still a difficult task. In this work, a reasonably straightforward, secure approach for significantly less acid (reduction of 40%)-based graphene oxide synthesis is provided. The temperature of a low acid reaction system can be effectively controlled with the help of heat absorbed from the environment and the reaction system. Several characterizations demonstrate that the yield and functional groups of the produced graphene oxide are comparable to those of the standard approach. With the help of this research, graphene oxide and its byproducts can be produced on a massive scale while being safe and environmentally acceptable. Lee et al. (Lee et al., 2015) work involved employing H2O as a reasonably priced absorbent at room temperature in a laboratory-scale gas-liquid membrane contacting technique for CO2 capture applications. To do this, phase inversion spinning and sintering techniques were used to create porous aluminum oxide (Al2O3) hollow fiber membranes. A fluoroalkyl silane (FAS) coating was employed to render the hydrophilic surface of the manufactured Al2O3 hollow fiber membrane without altering its physical characteristics. The relationships between water and gas flow rate and CO2 mass transfer through the modified hydrophobic Al2O3 hollow fiber membranes are given based on the experimental results. Also, a comparison of our modified hydrophobic aluminum oxide and conventional polymeric hollow fiber membrane was conducted.

Yanbing et al. (Zhu et al., 2022) It has been determined by several characterizations that the yield and functional groups of the synthesized graphene oxide are comparable to those of the conventional approach. With the help of this research, graphene oxide and its derivative materials can be produced on a massive scale while being safe and environmentally benign. Magnone et al. (Magnone et al., 2016) effectively showcased the utilization of room-temperature aqueous solutions containing monoethanolamide (MEA) to demonstrate the successful use of adapted inorganic hollow fiber membrane contactors for the efficient absorption of CO2 from gas mixtures, yielding impressive outcomes. With a high-symmetric distribution of morphological components, the fluoro alkyl salinized Al2O3 hollow fiber membrane contactors demonstrated enhanced CO2 permeability. 5.4*10–3 mol m2/s of CO2 are absorbed. In the process of CO2 absorption into MEA solutions, this achievement was realized using a single symmetric ceramic membrane, presenting a great performance compared to conventional polymeric membranes. Kim et al. (Kim et al., 2019) introduce an advanced hybrid method that integrates a fixed photocatalysis reactor featuring a TiO2 photocatalyst film applied to microstructured Al2O3 hollow fibers (AL-HF) with UV exposure. In this process, the zeolite-based adsorbent is fixed onto the AL-HF support. By using energy dispersive X-ray analysis, scanning electron microscopy (SEM), the Braeuer-Emmett-Teller (BET) method, and X-ray diffraction (XRD), and, the physicochemical parameters of both coated films were examined (EDX). The performance of the dual fixed-bed reactor was comprehensively assessed by employing a model solution that included the degradation of 20 ppm Methylene Blue (MB), 1 ppm Iron, and 0.04 ppm Arsenic. This model solution was utilized as a representative of complex aqueous solutions, encompassing both organic pollutants and the presence of heavy metals and toxic cations. Magnone et al. (Magnone et al., 2022) titanium dioxide functionalized Al2O3-based hollow fiber membranes were created and effectively used for effective heterogeneous photocatalytic NH3 gas degradation. Phase inversion was used to create Al2O3 hollow fiber membranes. Using thoroughly cleaned Al2O3-based hollow fiber membranes, nitrogen-doped titanium dioxide (N-TiO2) and titanium dioxide (TiO2) thin films were applied using a dip-coating process. All experiments on the heterogeneous photocatalytic breakdown of NH3 gas were carried out at room temperature using both UV and visible light irradiation.

Johra et al. (Johra et al., 2014) due to its intriguing features, graphene has gained more and more attention. Graphite was converted into graphene in this study using a quick and uncomplicated technique. The two-step technique entails oxidizing graphite to produce graphene oxide (GO), which is then reduced to produce graphene. Graphene and GO were produced, and their structures and characteristics were examined using X-ray photoelectron spectroscopy, UV-vis absorption, NMR, Raman, and X-ray diffraction methods. These products’ morphologies were examined using field emission scanning electron microscopy. Ciplak et al. (Çiplak et al., 2015) examined synthesis parameters which comprise the concentration of AgNO3 solution, the quantity of the reducing agent, and the concentration of the reducing agent solution. These parameters were systematically investigated for their influence on both the mean size and the distribution of particle sizes in Ag nanoparticles formed on graphene nanosheets. The evaluation of the resulting nanocomposites included the utilization of various analytical techniques such as Raman spectra, transmission electron microscopy (TEM), scanning electron microscopy (SEM), UV-visible spectra, and Fourier transform infrared spectrophotometry (FTIR), which collectively provided insights into the structure and morphology of the produced materials, based on experimental data. Shawon et al. (Shawon and Ur, 2019) describe a straightforward process for producing single-phase Al-Sb. Consolidation was then carried out to create a thermoelectrically applicable near single-phase very dense semiconductor. Also, this system’s thermoelectric characteristics are explained for the first time. The intermetallic compound’s mechanical attributes are also briefly examined for potential future applications. Tansel et al. (Tansel, 2012) conducted a comparative study on the permeability of various ions through a membrane during filtration, taking into account several of their physical and thermodynamic attributes. The properties under scrutiny included the Jones-Dole viscosity coefficient (B), hydration-free energy, hydrated radius, and ionic radius, and the investigation involved the examination of correlations between these ionic characteristics to elucidate the mechanisms governing specific ions’ ability to traverse the membrane. The passage of ions through thin film membranes is significantly influenced by the size and strength of their hydration shell when in a hydrated state. The hydration-free energy of ions plays a pivotal role in determining the selectivity of membrane-based processes.

Rokmana et al. (Rokmana et al., 2018) achieved the production of reduced graphene oxide (rGO) through a chemical process involving the conversion of graphite powder. This transformation was accomplished using a modified variant of Hummer’s method, specifically excluding NaNO3 from the reaction formula. The elimination of epoxy groups within the graphene oxide (GO) was carried out by employing a reduction consisting of 80-weight percent hydrazine hydrate. Results from FTIR and UV-Vis spectroscopy demonstrated the formation of graphene oxide (GO) as well as rGO. Our manufactured rGO was then used to spin coat the rGO/PEDOT: PSS composite thin film at room temperature. Tsai et al. (Tsai et al., 2023) present a multipass hollow fiber membrane to improve the thermal efficiency of the membrane distillation process. The performance is analyzed as a function of the length of each pass. The shell and multiple tube passes yield the highest flux. Imtiaz et al. (Imtiaz et al., 2023) have pioneered the development of membrane contactors to reduce the energy consumption and capital costs associated with CO2 absorption columns. Within these membrane contactors, the regeneration of CO2 occurs at temperatures below the boiling point, leading to a notable reduction in energy usage. Furthermore, they have also brought attention to the semi-commercial and commercial applications of these membrane contactors.

Yu et al. (Yu et al., 2023) use a new dip-coating approach for the preparation of hollow fiber membranes. This process involves cross-linking of polyamic acid precursor solution. The polyimide hollow fiber membrane exhibited superior separation performance when compared to a polyimide solution-coated membrane. Yan et al. (Yan et al., 2023) use an atomic layer deposition technique that provides a uniform coating layer. The deposition of TiO2 enhanced water permeability and fouling resistance of the membrane. Also increased the hydrophilicity and pore size reduction. Pang et al. (Pang et al., 2023) proposed a continuous and controlled photo-curing system for the fabrication of hydrophobic Polydimethylsiloxane (PDMS) hollow fiber membrane. The prepared PDMS HF membrane achieves outstanding separation performance and a high flux rate. Also, the feasibility of photo-cured fabrication of PDMS HF membrane was proved. Khan et al. (Khan et al., 2023) introduced an inclusive model designed to assess and forecast the potential failure modes of the Hollow Fiber Membrane-based NASA spacesuit Water Membrane Evaporator (SWME). This model is adaptable and can find application in other contexts using hollow-fiber membranes, including low-temperature separation processes.

Mandal et al. (Mandal and Mondal, 2023) develop low pressure-driven hollow fiber nanofiltration membrane via interfacial polymerization. The pure water permeate flux of the developed hollow fiber membrane was substantially improved through interfacial polymerization. Additionally, the characteristics of the hollow fiber membrane were examined using atomic force microscopy (AFM) and electron microscopy. Xie et al. (Xie et al., 2023) one-step-pyrolysis strategy proposed to achieve exceptional availability of catalytic sites. This integrated membrane system provides system engineering and catalytic membrane design for advanced water purification. Hou et al. (Hou et al., 2023) introduced a heat-stretching technique aimed at refining the structure of hollow fiber membranes, thereby augmenting their stability in the context of membrane desalination. This heat-stretching process led to a more compact and aligned chain arrangement, mitigating lengthwise shrinkage. Kumar et al. (Kumar et al., 2023) proposed a membrane for the removal of arsenic from water. The topology, membrane surface chemistry, and morphology of the fabricated membrane are estimated by thermogravimetric analysis, scanning electron microscopy, and atomic force microscopy. The study also involved an investigation into the mechanical properties, such as the tensile strength of the membrane.

Liu et al. (Liu et al., 2023) employed a one-step pressure-assisted cross-linking method to apply graphene oxide (GO) to the inner surface of a hollow fiber membrane. The orientation of the external force during the assembly of the GO selective layers played a vital role in shaping the nanochannel microstructure and determining the separation efficiency. The cross-linked graphene oxide (GO) hollow fiber membrane demonstrated exceptional performance. Wei et al. (Wei et al., 2023) generated efficient and portable photothermal material for freshwater supply. The one-step phase inversion method is used as well as a 3-D solar-driven steam evaporator fabricated via chemical vapor deposition. The HFM tree, with its great stability, good thermal management, and abundant light-harvesting demonstrated a high efficiency in purified water collecting. Biron et al. (da Silva Biron et al., 2023) use polyethersulfone (PES) for the preparation of mixed matrix polymeric membranes. The study focused on creating polymeric membranes by altering polymer ratios and then examining how these ratios influenced both membrane performance and specific physical characteristics. Choi et al. (Choi et al., 2023) developed a proton exchange membrane and its performance and durability are determined by different factors. Experiments are used to examine the water transport properties of membranes, and simulations allow for faster prediction and optimization of various operating circumstances.

Darmayanti et al. (Darmayanti et al., 2023) studied that the use of inorganic filler can improve antifouling characteristics and reduce membrane fouling. Also examines two alternative membrane fabrication approaches for the modification of hollow fiber membranes: dip coating and thermally induced phase separation (TIPS). Li et al. (Li et al., 2023) constructed a hollow fiber membrane and incorporated it in flow injection analysis to get ammonia separation from water. Parameters affecting the performance of the membrane were also investigated. The results showed that the system is free of the salinity effect and organic nitrogen compound interference. Raje et al. (Raje et al., 2023) use the metal extrusion method to fabricate membranes without the use of organic solvents. After post-treatment, the partially dense fibers are changed into porous fibers. Also proved that hollow fiber membranes for ultrafiltration could be produced via extrusion without the need for organic solvents. Zhang et al. (Zhang et al., 2023) conducted a series of ongoing investigations that revealed a significant correlation. It was observed that as the PH of the feed urine decreased, there was a noticeable decline in ammonia flux, accompanied by a substantial increase in membrane fouling tendencies. Microscale force analysis further elucidated that the absence of hydrodynamic drag forces related to water permeation made it challenging for foulants positioned at a considerable distance from the membrane to reach its surface, resulting in a notable reduction in membrane fouling.

Lau et al. (Lau et al., 2022) hollow fiber membranes emerge as the most promising among various membrane configurations, primarily attributed to their capacity for high packing density and the ease of module assembly. The research also presented significant discoveries regarding the application of hollow fiber membranes in diverse processes, including Membrane contactor technologies, membrane distillation, gas and vapor separation Pervaporation, Forward osmosis (FO), Reverse osmosis (RO), Nanofiltration (NF), Microfiltration (MF). Gao et al. (Ji et al., 2022) in study proposed that PVDF (polyvinylidene fluoride) is widely used as a membrane-forming polymer with strong processability and excellent thermal and chemical stability. The pore size, and porosity, improved significantly as PEG concentration increased, whereas the pressure of liquid entry and water contact angle decreased. Kim et al. (Zou et al., 2022) conducted an investigation into the modification of bore fluid and coating fluid compositions during the membrane spinning process, employing a triple spinneret configuration. This approach aimed to produce hollow fiber (HF) membranes characterized by robust mechanical strength and efficient water permeability through an environmentally friendly fabrication process. Impressively, the membrane exhibited remarkable stability, maintaining a rejection rate exceeding 99.99% even after 120 h of continuous operation. Franscis et al. (Im et al., 2022) employed commercially accessible microporous polypropylene hollow fibers in both air gap and water gap membrane distillation processes. In both configurations, the exterior surface of commercially available dense polypropylene hollow fibers served as the condensing surface for permeates. Ursino et al. (Ursino et al., 2020) innovatively utilized Polarclean, an environmentally friendly and sustainable solvent, for the first time in the preparation of Polyethersulfone (PES) hollow fiber membranes. This was achieved through the non-solvent-induced phase separation (NIPS) technique. The research encompassed a comprehensive examination of the fiber’s morphology, mechanical properties, porosity, pore size, and water permeability. Additionally, a cost-benefit analysis was conducted, taking into consideration the use of the eco-friendly solvent Polarclean.

Li et al. (Li et al., 2020) searched into the domain of Janus membranes, distinguished by their asymmetric surface wettability, and recognized as a promising solution for oil/water separation. While their potential is acknowledged, these membranes have faced limitations, such as their restricted size, dependence on dead-end filtration, reliance on batch-wise separation, limited disposal capacity, and a tendency to favor heavy oils. The study also underscored that the separation process, as well as the purity of the filtrates and feeds, fully conform to international purification standards. These findings shed light on the exciting practical applications of Janus membranes, particularly in the realm of separating oily wastewater, including surfactant-stabilized oil-in-water emulsions. Wu et al. (Wu et al., 2022) introduced a moderate chemical etching technique aimed at generating nano-scale pores on the basal plane of graphene oxide (GO) nanosheets. This innovative approach was employed to produce hollow fiber (HF) porous GO (PGO) membranes, enhancing water permeance and dye rejection capabilities. The research incorporated a range of characterization methods to monitor pore formation and assess structural and compositional changes in the synthesized PGO nanosheets. The study underscored the considerable potential of porous graphene oxide (PGO) membranes in the context of nanofiltration applications. Tasdemir et al. (Sengur-Tasdemir et al., 2021) designed and evaluated four distinct varieties of hollow fiber nanofiltration membranes. The extent of membrane fouling played a vital role in determining the quantity of permeate water obtained from these membranes. The research highlighted the practicality and potential of utilizing hollow fiber nanofiltration membranes for applications in surface water treatment.

The assessment of the literature revealed a research deficit for the creation of membrane-based filtration systems. By conducting a comprehensive literature review it is investigated that the use of the Six-Sigma approach for membrane filtration system is rare. Also, how the Six Sigma approach can be applied in the context of water treatment and filtration system design. Implementing Six Sigma in membrane filtration systems offers a unique opportunity to improve process efficiency and optimize filtration system performance. This can lead to cost-effective and reliable water treatment solutions. By incorporating sustainability principles into the design process, Six Sigma can be used to develop water treatment solutions with minimal environmental impact and resource utilization. It is uncommon to research to lengthen the membrane-based filtration system’s lifespan and improve the flow fate of the fluid flow after filtration. The portable water filter has its filtering capacity and flow rate increased without the usage of electricity. As filtration capacity is correlated with lifespan, this research utilized nanofiltration-based membranes to boost the filter capacity and to decrease the pipe diameters to increase flow rates, which increases the volume flow rate or velocity of the fluid that travels through the pipe.

In this study, dry/wet phase inversion techniques were used to create asymmetric nanofiltration membranes. This method, which was developed by Loeb and Sourirajan (Hołda and Vankelecom, 2015) is the one that is most frequently employed to create asymmetric membranes. In this method, the solution was poured onto a glass surface, submerged in water, and precipitated. Phase separation will occur in the film because the solvent in the casting solution is replaced with a non-solvent in the dry/wet phase inversion procedure. This research aims to design a membrane-based portable filtration using the Design for Six Sigma Methodology (DFSS). This method can be used for designing new products, services, and processes and is a powerful tool that can help maximize the success of a new product in the market. Most organizations have achieved a 4.5 Six Sigma level by implementing the Six Sigma approach. In this method, improved products are manufactured first time by focusing on the improved design of the products. This approach helps to save the time needed for improving the product to create these components, incorporating the applicable criteria that follow.

The main objectives of this research are to design a portable membrane-based filtration system using Six Sigma methodology. The development of a prototype (experimental setup) for the analysis and to ensure the improvement in production efficiency and quality control.

Regarding the educational outreach programs, STEM education integration, and community engagement in the broad sense, the research highlighted that it is the most significant challenge of sustainability and the United Nations’s twenty-thirteen agenda. Sustainable Development Goal 6 concerning water and sanitation emphasizes that clean water is crucial for poverty eradication, economic growth, and environmental conservation. The research findings can be used to develop impactful awareness campaigns to educate students, teachers, and the public at large, on the issues surrounding water contamination and the role played by the sophisticated water filtration technologies. In addition, this engagement not only provides information but also conveys a sense of responsibility for tackling water quality problems. The research is well aligned with the STEM education integration and it becomes important as the research focuses on the principles of science, technology, engineering, and mathematics. Teachers can incorporate the study into curricula and enable students to apply scientific methods in the real world, engineer designing, and problem-solving with innovations to create an environmentally conscious generation that is capable of solving global problems. The research can be used by community engagement initiatives to encourage collaboration between educators and the community on the adoption of sustainable water management practices. The research is not just an extension of theoretical frameworks, rather, it is an active participation of the communities in the search for community-based solutions to specific water quality problems. This can inspire new competitions where the participants have to come up with innovative solutions on ways of solving water pollution. Competitions can involve issues of developing efficient water filtration systems, incorporating new technology, or suggesting new water quality management strategies. Not only do these platforms enhance the flow of ideas but they also provide a good environment for cross-disciplinary collaboration. Essentially, research into portable water filtration systems using the Six Sigma methodology becomes an anchor for learning innovation, providing a holistic way to deal with problems of water contamination through the use of awareness, education, and public participation, alongside cutting-edge competitions. All these elements are an integrated approach to motivate people and communities to clean, and secure water for the future.

3 Methodology

In this research, a membrane-based portable filtration system is developed by using the Six Sigma methodology. This methodology is based upon the Design for Six Sigma (DFSS) by using DMADV eventually it fosters a computational thinking strategy too. Six Sigma and computational thinking share a fundamental relationship in their approach to solving complex problems, particularly in the context of process improvement and innovation. Six Sigma, a methodology aimed at reducing defects and improving quality, relies on a data-driven, systematic approach to problem solving, encapsulated in DMADV (Define, Measure, Analyze, Design, Verify) frameworks. These frameworks emphasize understanding the problem in detail, measuring and analyzing data, and then implementing and verifying solutions. This process mirrors the core principles of computational thinking, which involves abstraction (focusing on the important information only, ignoring irrelevant detail), algorithmic thinking (developing a step-by-step solution to the problem), decomposition (breaking down a complex problem into more manageable parts), and pattern recognition (identifying trends or patterns that can help solve the problem). The relationship between Six Sigma and computational thinking lies in their shared emphasis on systematic analysis and structured problem-solving methodologies. Computational thinking provides the foundational skills for problem decomposition, abstraction, and algorithmic development, which are critical in the Define, Measure, and Analyze phases of Six Sigma. It enables practitioners to conceptualize problems and solutions in ways that can be quantified, thus facilitating the precise measurement and analysis required in Six Sigma projects. Moreover, the iterative nature of computational thinking, where solutions are developed, tested, and refined, parallels the Improve and Control (or Design and Verify in DMADV) phases of Six Sigma, where solutions are implemented, evaluated, and optimized. This iterative process ensures that the solutions not only address the initial problem effectively but also remain adaptable and scalable over time.

3.1 Define-measure-analyze-design-verify (DMADV)

DMADV is a popular approach used commonly for membranes. The membrane acts like an obstacle for particles and chemicals to pass through. Utilizing membranes for water filtration is primarily employed to enhance the aesthetic quality of water, particularly by eliminating heavy metals like lead and eliminating chlorine to improve taste. The implementation of membrane-based water filtration systems is still in its early stages, as it necessitates the development of suitable filtration systems. The membrane usually separates two fluids. It acts like a barrier between two phases. Some components pass through the membrane while others are retained by it and accumulate in the stream. Membranes can also be of different thicknesses as well as various structures like homogeneous and heterogeneous structures. It usually depends upon the polymer that is being used for the preparation of the membrane. To design a portable water filtration system for water filtration, this study aims to formulate a design concept. For this, we use the Design for Six Sigma (DFSS) methodology. It is a process that is used for designing new products or services. In this method, the authors have correctly designed the product, services, or process that needs less time to improve the same. The quality of the Deming Cycle contributes to increasing the market share as well as the earnings and profitability’s is a complex mechanism that leads to maximizing the success of the new product. This is a concept-based analysis approach for the design of a product. The different critical parameters are analyzed using statistics. Further details are displayed in the subsequent sections.

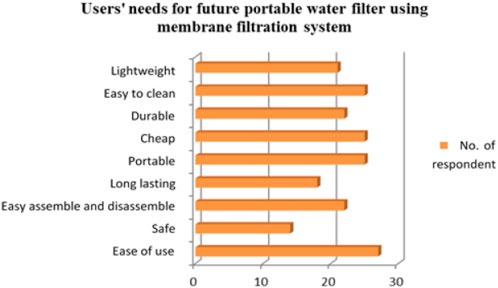

3.1.1 Define

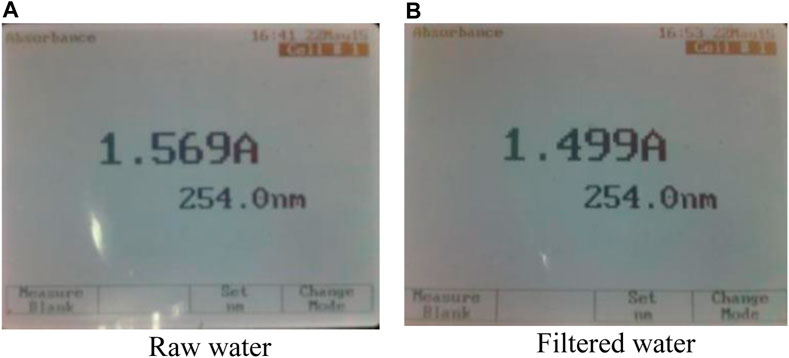

In the DFSS process, the first step is to define the goals and needs of the project or product. The user’s voice in proposing and telling the problem is identified. The information is being recorded for review. Based upon the collected information a questionnaire is developed. This questionnaire was developed by the survey form. A survey form is made to determine the effectiveness of the membrane filtration system. It includes specifications and future filter requirements. To better understand the requirements of users employing portable water filters, a survey was administered to 30 participants. Customized survey forms were crafted to assess the efficiency of currently available portable water filters in the market. Additionally, the aim was to gain insights into the specifications and preferences that users desire for future portable water filter designs. The outcomes of this survey are depicted in Figure 2.

Figure 2. Portable water filtration system development using membrane filtration technology to meet user needs (Hassan et al., 2017).

3.1.2 Measure

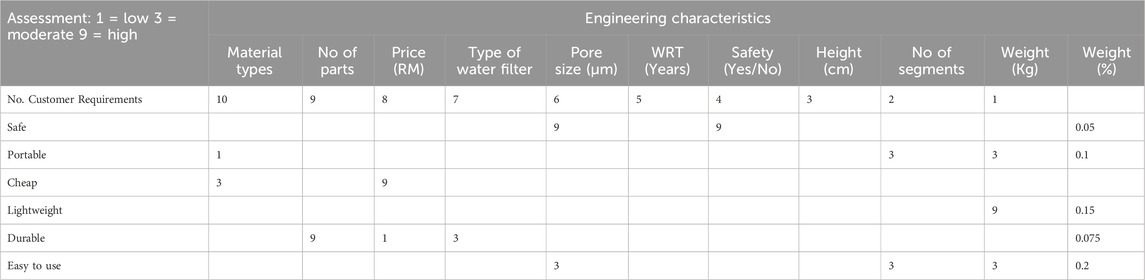

To tackle the structuring and advancement of information design challenges, the Quality Function Development (QFD) method proves to be a valuable tool. In the Design for Six Sigma (DFSS) process, the second critical step involves measurement, which is dedicated to assessing and identifying customer needs and specifications. These specifications are crucial as they provide a measurable definition of the product or service, enabling the collection of data for comparison against predetermined requirements. Quality function development (QFD) is a systematic approach integral to the structuring and development of information design issues. The process commences with the construction of the House of Quality (HOQ), wherein customer needs are initially defined, and the significance of these needs in the eyes of customers is determined. Subsequently, engineering characteristics are identified. Once this is accomplished, a correlation matrix between customer requirements and engineering characteristics is established in this study. An evaluation is carried out to compute scores based on the correlation matrix, which takes into account both customer requirements and their relative importance. Initially, engineering characteristics are defined, followed by the creation of the correlation matrix linking these characteristics to customer requirements. The resulting matrix is then used to calculate scores, contributing to a comprehensive assessment of the design process.

3.1.3 Analyze

Morphological analysis is presented to explore the relation in multidimensional problems. By determining the structure of the problem, the components can be synthesized to meet the desired function. In addition to compiling the results of the research, the analysis allows us to process the information. As part of the evaluation of the concept, a weighted decision matrix is being used. Components that are suitable for the product are determined. According to the market demand, this is done. The highest score option is become best and suitable. As a result, different criteria are assigned to the generated solutions in the previous stage to select the one with the most suitable characteristics. Based on the results the nano-filter-based alternative has the highest score and is selected for the next stage.

3.1.4 Design

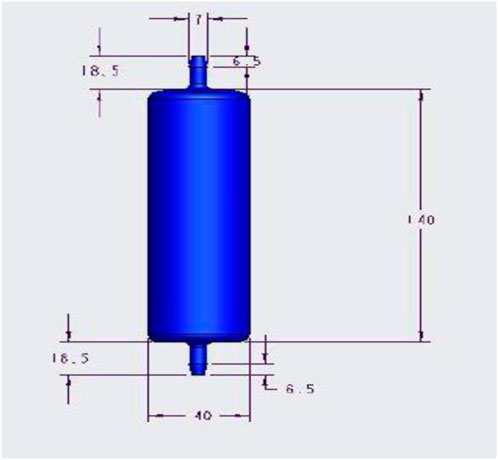

Solid Works (2016 × 64 Edition SPO2) software is being used for the designing of the 3D model for the portable water filter proposed concept in the previous stage. As part of this stage, 3D modeling was evaluated to determine whether the available components were suitable for the analysis or not. This phase is valuable as it involves the evaluation of 3D modeling to assess the compatibility of the available components and serves as a proof-of-concept test for the next stage. The illustrations comprise the actual dimensions of each part and component, along with a detailed assembly overview. The total length of this portable water filter is 19.9 cm with a width of 40 cm. The tip of the water filter (mini hose pump) has a height of 18.5 cm and a width of 7 cm while the overall length of the water filter bottle is 1.40 cm with a width of 40 cm. This 3D model is developed using Solid Works software and the prescribed dimensions presented in Figure 3.

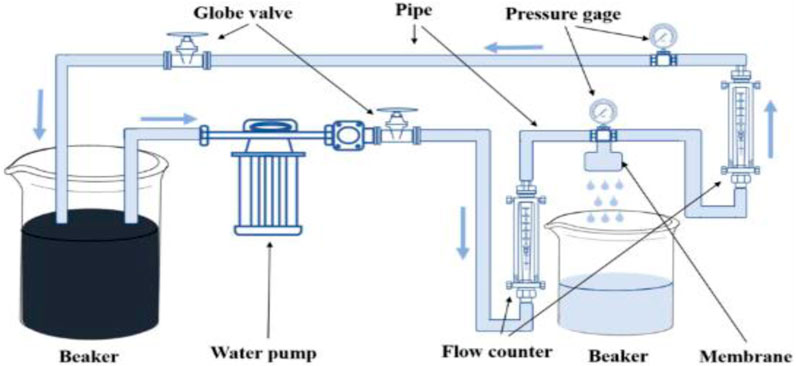

3.1.5 Verify

A portable water filter design is verified during the final stage. Because no design or concept has yet been made, the concept is critical. To develop a complete membrane-based filtration system prototype, different components are assembled as a whole. After the completion of the prototype, a bottle of dirty water is filled. This dirty water is being filtered by this membrane filtration system. After filtration of this water, the turbidity of filtered water is checked by the Spectrophotometer machine. The comparison of the filtered water with the original water is made in terms of turbidity.

3.2 Manufacturing of membrane

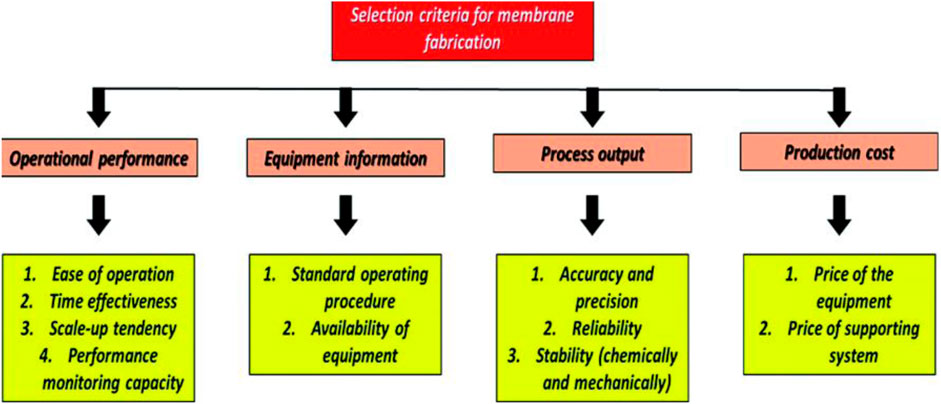

A membrane is a thin film that acts as an obstacle allowing some particles to pass. It is a separating structure rather than a barrier. The membrane can be of various thicknesses homogeneous and heterogeneous. The membrane can also be classified according to the diameter of the pores. It can be neutral or charged and particle transportation can be active as well as passive. Membrane application included water treatment, water recycling, separation as well as filtration. Mostly polymeric membrane is used which is a mixture of different polymers. Polyvinyl chloride polymer is used as a major component of membrane manufacturing. The phase inversion is done at different mass ratios. A membrane rejection rate is determined using a Sodium Chloride solution. Nanofiltration (NF) is emerged as the potential membrane-based separation process that uses asymmetric membranes. It has always been a focus to determine which membranes offer the highest rejection and water flux for better performance. The dope solution is stored in an insulated stainless-steel container for 1 day. Before entering the external coagulation bath, the dope solution is forced through the spinneret, creating an air gap. To complete the mass transfer between the solvent and non-solvent coagulant, the hollow fiber is dipped in tap water for 1 day after spinning. There is a reservoir for the hollow fiber. A membrane can be protected from damage or collapse by exchanging pore water with a solution with a lower surface tension. Lastly, air is used to dry the fibers. To achieve the performance and pore size requirements of specific applications, hollow fiber has to be produced with a desired pore size. Figure 4 presents the working of a hollow fiber membrane. Figure 5 presents the selection criteria for membrane fabrication.

Figure 4. Experimental schematic of hollow fiber membrane (Qiu and He, 2022).

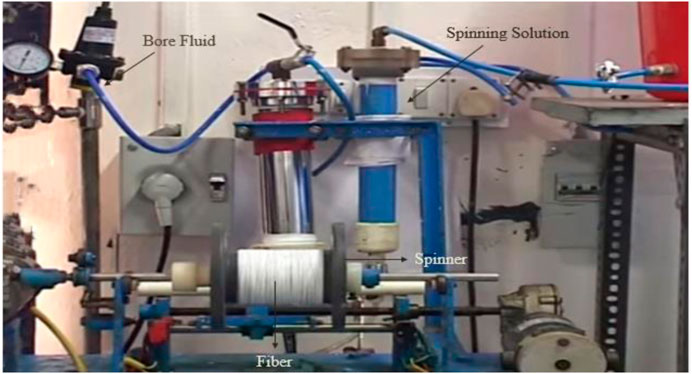

The manufacturing processes used for membranes are classified into three major types. There are three main techniques melt spinning, wet spinning, and dry spinning. The detail of hollow fiber nanofiltration membrane manufacturing includes the material selection as the first process. The membrane-forming polymer is Polyvinyl chloride (PVC) because of its durability, chemical resistance, and cost effectiveness. N, N-Dimethylacetamide (DMAc) is a solvent, and water is a non-solvent. Pore-forming agents can benefit from the addition of polymeric glycol. Tap water serves as the non-solvent in the pre-treatment procedure. The fiber module is potted using an epoxy potting compound. The new spinning formulation for hollow fiber fabrication consists of solvent, polymer additive, polymer, polymeric additive, and non-solvent. The newly designed dope solution consists of the material discussed earlier. The solution temperature was maintained at around 50°C.

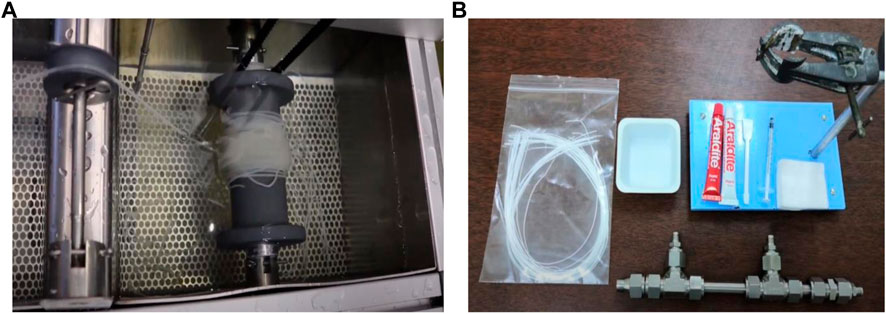

3.3 Experimental process

The experimental process includes dry or wet spinning used to create a polyvinyl chloride hollow fiber membrane for separation in the dry gap. Extrusion from the spinner went via a forced convection chamber that was cylindrical. At room temperature, the spinning solution was extruded through a spinner die to create a hollow fiber. The membrane underwent pre-treatment before the initial testing to achieve the desired membrane pore size. The fully formed fiber is dried at room temperature after the spinning process. HFM is potted into a bundle of 15 fibers that measures about 25 cm in length. The fiber was meticulously threaded through distilled water throughout the length of the tube sheet, serving as the benchmark for assessing pure water permeability. The feed solution was introduced into the shell side of the NF module, and the treated liquid was then extracted from the fibers. The flux was determined by averaging the results of three readings. A variety of ratios are also available. In the solution tank, they are kept in liquid form, and they are also called dopes. The experimental setup is presented in Figure 6.

4 Results

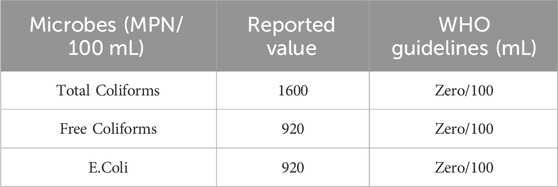

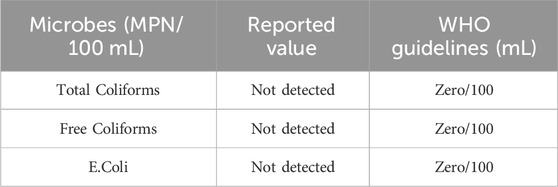

The membrane-based filtration system is presented successfully. The strength of this approach is the capability to guide a process of development systematically using DMADV: Define, Measure, Analyze, Design, and Verify. Several tools were used to comply with these five stages for their specific objective. The membrane filtration system is low cost and also lowers energy cost producing a great degree of purity and overall yield. A membrane filter does not result in filter cake (retaining particles on the filter during filtration) that effectively eliminates costs due to residue disposal. A membrane filter is an optimal solution because it does not require any chemical additives. Table 1 presents the house of quality for advance membrane filtration systems. A membrane physically eliminates pathogens and eliminates the need for chemicals such as chlorination. Wet-spinning phase inversion is used to prepare hollow fiber membranes. A measure is needed to implement the change of users’ needs into the engineering characteristics. The membrane has high thermal stability and high durability. Hydration of the membrane plays a vital role in uniform water content. Hollow fiber membrane also has highly compatible chemical properties which satisfy the bonding properties of the membrane. A morphological chart is being developed for the analysis stage. After this design is developed by Solid Works and 3-D modeling. Most of the membrane is developed by the wet spinning method. Membrane pore size varies from 0.01 nm to 0.1 nm. Pore size is an important factor in liquid filtration. Pore size plays a vital role in determining the flux of membranes. Small size pores are recommended for membranes because fouling from large particles can be controlled. Sieving is the same as blocking, whereby a particle is obstructed when the pore size is less than the particle’s size. The primary consequence of this phenomenon is fouling. Fouling transpires when impurities accumulate on the membrane’s surfaces or within its pores. These foulants retard the flow of water through the membrane, leading to heightened energy consumption and potential harm to the membrane and other system components. This effect should be minimized by backwashing. Backwashing is often used to remove fouling. During backwashing, the transmembrane pressure (TMP) is reversed, and permeate is used to wash away the accumulated fouling. More work is required to refine the selected design to improve the quality of the water. A microbiological examination of water is done to check the general sanitary condition of the water. Total coliforms and Fecal coliforms indicate the bacteria that are found in the soil and water influenced by these bacteria. According to WHO guidelines, coliform bacteria have no color, taste, or smell. According to the WHO, the absence of total coliforms or E. coli should be detected in every 100 mL of drinking water. When water undergoes testing for the presence of total coliforms and E. coli, and the results confirm its safety for drinking purposes, these findings can be presented in various ratios. The coliforms are not detected after the filtration of the water from this nanofiltration membrane which proves the good quality of the membrane. The different values of the original water are reported for different microbes across 100 mL. According to the WHO Guidelines, it should be zero/100 mL as illustrated in Table 2.

Table 1. A house of quality for advanced membrane filtration systems for portable water filters (Hassan et al., 2017).

Table 3 illustrates the reported value of water after the process of filtration. After the filtration process, the values of microbes are noted as zero/100 mL for the water and it lies perfectly on the WHO guidelines.

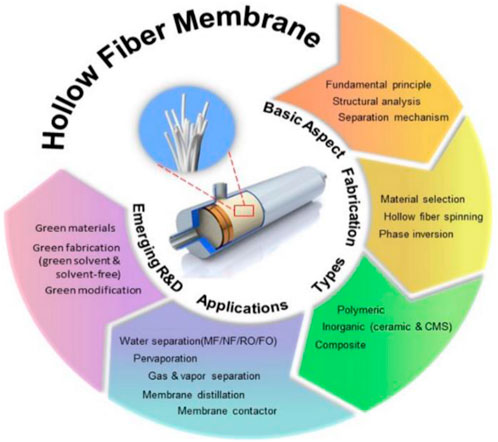

It is clear from Tables 2 and 3 that there is no evidence of the presence of bacteria and coliforms in filtered water. It is clear that filtered water has no presence of coliforms and it is according to the WHO guidelines. The measurement of water turbidity reading before and after the process of filtration is presented in Figure 7.

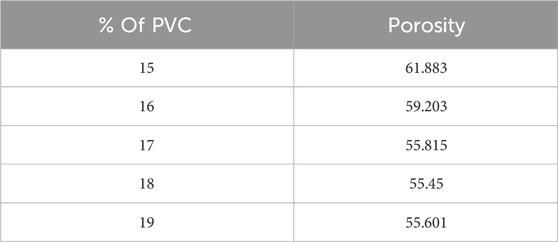

4.1 Effect of polymer concentration on the porosity of the membrane

Polymer concentration also influences the porosity of the membrane. As the concentration of the polymer increases, the porosity of the HF membrane decreases. A membrane’s porosity is determined by its solid content. HF membranes prepared with a lower concentration of PVC show greater porosity than those prepared with a higher concentration of PVC. HF membranes with PVC concentrations higher than 17 wt% showed a narrow range of pore sizes. Porosity is also dependent on the concentration of PVC in the dope solution. In phase-separated polymer solutions, solvents are not exchanged for non-solvents when the concentration of polymer solutions increases due to the polymer chains and polymer solutions’ higher viscosity. Table 4 morphological chart of component selection.

4.2 Effect of polymer concentration on hollow fiber dimensions

The effect of polymer concentration is a critical aspect of membrane fabrication. The polymer concentration can influence several key dimensions and properties of hollow fiber membranes. Depending upon HF dimensions all dimensions are constant, especially for outer diameter and thickness. It is concluded that the structure of the membrane depending upon HF dimensions is almost constant for all types of membrane noted at different dope concentrations.

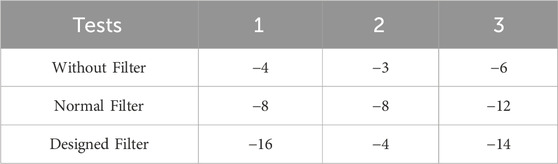

4.3 Chemical oxygen demand (COD) test

The Chemical Oxygen Demand test is often used as a measurement of pollutants in water, wastewater, and hazardous water. The COD test shows how many organics are present in the water. By calculating the amount of oxygen used to break down the organic matter, the COD is calculated (biodegradable or non-biodegradable). Since there should be no organic matter in the water, the COD value in drinking water should be 0 mg/L. Doing the test and finding a COD value indicates that the water includes organic matter that could be detrimental to us. It is clear from the outcome that all the COD values are negative values. A photometer is utilized to determine the COD. The porosity of hollow fiber membrane is displayed in Table 5. Chemical oxygen content demands in water is displayed in a Table 6.

5 Discussion

Polymer concentration has a direct relationship with porosity. As the concentration of the polymer increases, the porosity of the HF membrane decreases. This is because as the concentration of PVC in the dope solution increases, the relative proportion of solvent to non-solvent decreases. This reduction in solvent/nonsolvent exchange limits the kinetics of phase separation during the formation of membrane. With less nonsolvent available, the phase separation process becomes less efficient, leading to a denser membrane structure with reduced porosity. Other factors are decreased nucleation sites for pore formation and enhanced polymer-solvent interactions. A membrane’s porosity is determined by its solid content. HF membranes prepared with a lower concentration of Polyethylene glycol (PEG) show greater porosity than those prepared with a higher concentration of PEG. The effect of polymer concentration on hollow fiber dimensions is also noted. The findings indicated that the concentration does not have a significant impact on the dimensions of hollow fiber and it remains constant at various concentrations. Table 7 indicates the effects of polymer on hollow fiber dimensions.

The Chemical Oxygen Demand (COD) test is a crucial analytical technique employed in portable membrane filtration to assess the level of organic pollutants in water samples. This test measures the amount of oxygen required to chemically oxidize the organic and inorganic substances present in the water, providing a quantitative indicator of the water’s overall pollution load. In the context of portable membrane filtration, COD serves as a valuable tool for evaluating the effectiveness of the filtration system in removing organic contaminants. By quantifying the oxygen demand, operators can ascertain the efficiency of the membrane filtration process and ensure the production of purified water that meets regulatory standards. Additionally, COD testing aids in monitoring water quality over time, allowing for timely adjustments to filtration processes and facilitating the maintenance of portable filtration systems in various environmental settings. From the result, it can be noted that all the values of COD are negative. This shows that there is no content of organic matter in the water after the test is conducted. Moreover, the efficiency is increased by using the designed filter.

Water contamination is one of the major problems noted according to most of the researchers. It happens due to the pollutants in water bodies. Drinking water is gaining much attention as it contains a lot of bacteria, residual waste, and harmful contaminants. These contaminants cause different diseases. Recently significance of water filtration has increased so that’s why the objectives of this research deal with the design of a portable membrane-based filtration system using the Six Sigma methodology. Development of a Prototype (experimental setup) for the analysis and to ensure the improvement in production efficiency and quality control. Although the development of a membrane-based filtration system is key the study to increase the life span of the membrane-based filtration system and to increase the flow rate of the fluid flow after filtration is rare. This is still a research gap. We have to increase the filtration capacity as well as the flow rate of the portable water filter without the use of electricity. As filtration capacity is related to the life span to increase the filtration capacity and mass flow rate after filtration nano filtration-based membrane is used in this research which was a gap in literature studies. In this study by decreasing the diameter of the pipe, the volume flow rate or the velocity of the fluid which passes through the pipe increases. Moreover, it is also noted that increasing or decreasing the length of the pipe does not affect fluid velocity/flow. The significance of this research is discussed in terms of reliability, consistency, and operating costs which are important considerations in industrial-scale applications. Membrane filtration offers numerous advantages. A wide variety of feed products can be processed by membrane filtration, including those that have a high viscosity. Additionally, membrane filtration products are available in many different types, ensuring the right solution for every application. In addition to improving purity, membrane filtration increases yields and simplifies the processing steps. Additionally, there are no costs associated with removing and disposing of filter cakes since membrane filtration does not produce them. Increasing the design quality can increase customer value, resulting in larger market shares, earnings, higher margins, and profits, contributing to the Deming cycle’s quality as well as profitability.

To generate the correlation matrix between the requirements of customer and engineering characteristics the table of engineering characteristics is generated for the analysis. To synthesize the different components of the problem, a morphological chart is developed to meet the desired function. Furthermore, information can be processed by using morphological analysis to compile the findings of research. The wet spinning process is used in this research. The size of pores varies from 0.01 to 0.1 microns. The water filtration system is proficient in rejecting viruses, bacteria, and other contaminants between 0.01 and 0.1 microns to produce safe and healthy drinking water that is free of contaminants. Research on efficient water filtration is very vital task that should be done on a priority basis for the removal of harmful biological contaminants that affect human health badly. For this reason, turbidometry titration is recommended for quantifying water requirements based on this research. By interacting with particles, colloidal particles, or macromolecules on membrane pores or membrane surfaces, membrane fouling occurs when these particles, macromolecules, or colloidal particles are deposited or adsorbed onto the membrane pores, reducing their size or blocking their opening. Backwashing membranes involves reversing the transmembrane pressure (TMP) and using permeate to wash away build-up fouling, ensuring the membrane’s effectiveness and longevity. According to the WHO, the absence of total coliforms or E. coli should be detected in every 100 mL of drinking water. When water undergoes testing for the presence of total coliforms and E. coli, and the results confirm its safety for drinking purposes, these findings can be presented in various ratios. The coliforms are not detected after the filtration of the water from this nanofiltration membrane which proves the good quality of the membrane. Polymer concentration also influences the porosity of the membrane. Figure 8 presents the (a) raw water and (b) filtered water.

6 Conclusion

It is concluded from this research that the Six Sigma methodology is vital for designing the portable membrane-based filtration system by considering all the environmental, human, and industrial issues. In essence, computational thinking equips individuals with the analytical skills necessary to effectively implement Six Sigma methodologies. It fosters a mindset that is critical for identifying, analyzing, and solving problems in a structured and data-driven manner, thereby enhancing the effectiveness of Six Sigma projects in achieving quality improvement and innovation objectives. Then, a prototype is developed to conduct proof of concept testing. A wet spinning process is used at room temperature, the spinning solution was extruded through a spinner die to create a hollow fiber. Distilled water is used to characterize pure water permeability. Polymer liquid like polyvinyl chloride (PVC) is used for the manufacturing of membranes with other liquids in different ratios. The feed solution was pumped into the shell side of the NF module and premeditated liquid out from the fibers. Flux was calculated by taking the average of the three readings. The size of pores varies from 0.01 to 0.1 microns for the water filtration. It is noted that the COD test shows how many organics are present in the water. Moreover, this size of the membrane is proficient in rejecting various contaminates like bacteria and viruses. Also, the flux rate depends upon the volume, length, and size of the cartridge. Backwashing at regular intervals eliminated the fouling that occurs due to the accumulation of solutes. The current study is based on the use of a nanofiltration-based membrane system for filtration purposes. The membrane filtration involves separating particles from liquid solutions or gas mixtures using membranes. The main objectives include applying the Six Sigma methodology for the membrane-based filtration system. After this use spinning technology was used for the development of polymer-based hollow fiber membranes. The size of the membrane varies from 0.01 microns to 0.1 microns. Membrane typically utilizes a selectively permeable membrane to separate different molecular sizes. The advantage of using membrane is retained structural integrity and decreased laboratory waste. A microbiological examination of water is done to check the general sanitary condition of the water. Total coliforms and Fecal coliforms indicate the bacteria that are found in the soil and water influenced by these bacteria.

Polymer concentration also influences the porosity of the membrane. As the concentration of the polymer increases, the porosity of the Hollow fiber membrane decreases. A membrane’s porosity is determined by its solid content. The Chemical Oxygen Demand test is often used as a measurement of pollutants in water, wastewater, and hazardous water. The COD test shows how many organics are present in the water. This size of the membrane is proficient in rejecting various contaminants like bacteria and viruses. The filtering capacity as well as the flux rate is also being enhanced. The flux rate usually depends upon the module volume and size length. The fouling effect due to insoluble solutes can be minimized by backwashing after some time. If seawater is filtered with the above-mentioned membrane, marine salt is removed, and fresh water can be produced. In sewage management facilities water is purified by membrane and bacteria can be separated within compact installations. In low rainfall zones, drinkable water can be ensured even in drought times by using this membrane to desalinate water. Membrane technology is applied in many familiar aspects and it also contributes to ecology. There is a certain limitation for the membrane. Membrane is an expensive technology. Certain solvents can destroy the membrane permanently and quickly. Certain colloidals like graphite and residues can permanently foul the membrane surface. The scope of future membrane applications becomes wider, based on improving existing membrane materials and manufacturing processes as well as novel tailored tools for the fabrication of next-generation membranes for specific applications.

Although hollow fiber nanofiltration membranes exhibit good performance, several questions were raised during the analysis of results, so the following subjects need to be addressed in future studies. Apply Six Sigma tools to optimize costs associated with manufacturing, installation, and maintenance. Turbidometry titration is recommended for quantifying water requirements. Also investigate the advanced membrane materials with enhanced filtration properties, sustainability, and durability. There is a need to explore bio-inspired membranes for improved efficiency. Also, use recycling and reuse methods for membrane components. Conduct life cycle assessment to evaluate the environmental impact of membrane-based filtration system. Also, identify areas of improvement in terms of resource utilization and sustainability. Also made collaboration with industry partners, and organizations to share knowledge and innovation in sustainable water solutions. It is also recommended in the future to apply the six-sigma method on other filtration systems like humidification-dehumidification desalination (Tariq et al., 2018; Tariq et al., 2021) and compare the performance of both systems.

This research has tremendous importance for educational outreach programs. These findings present an opportunity to launch relevant public education programs that can provide valuable insights about the significance of water contamination, and the transformational influence of portable water filter apparatuses. Outreach should use research findings to create educational materials that would be able to engage schools, community centers, and public events with a deeper understanding of water quality issues. Such research can be used to educate pupils to have them become responsible for real issues in life and also how science and engineering contribute to solving those problems. This work provides a basis for educational outreach programs that can foster a wider understanding of water quality problems and their possible resolutions.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Ethics statement

Ethical review and approval was not required for the study on human participants in accordance with the local legislation and institutional requirements. Written informed consent from the [patients/ participants OR patients/participants legal guardian/next of kin] was not required to participate in this study in accordance with the national legislation and the institutional requirements.

Author contributions

AU: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Resources, Software, Validation, Visualization, Writing–original draft, Writing–review and editing. HK: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Writing–original draft, Writing–review and editing. RT: Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Supervision, Writing–review and editing. MA: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Software, Writing–original draft. AR: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Software, Writing–original draft, Writing–review and editing. MI: Conceptualization, Data curation, Formal Analysis, Investigation, Methodology, Project administration, Software, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Acknowledgments

The author is thankful to the Department of Mechanical Engineering, University of Engineering and Technology, Taxila-Pakistan, for their cooperation with this research project. The authors would like to thanks the financial support from Tecnologico de Monterrey through the “Challenge-Based Research Funding Program 2022”. Project ID # I003—IFE001—C2-T3–T.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Bai, L., Ding, J., Wang, H., Ren, N., Li, G., and Liang, H. (2020). High-performance nanofiltration membranes with a sandwiched layer and a surface layer for desalination and environmental pollutant removal. Sci. Total Environ. 743, 140766. doi:10.1016/j.scitotenv.2020.140766

Buajitti, E., Fazio, X., Lewis, J. A., and Rosella, L. C. (2021). Association between lead in school drinking water systems and educational outcomes in Ontario, Canada. Ann. Epidemiol. 55, 50–56.e1. doi:10.1016/j.annepidem.2020.09.011

Choi, Y., Nguyen, X. L., Choi, S., and Yu, S. (2023). 3D computational fluid dynamics-based analysis of water transfer characteristics of hollow fiber membrane for gas-to-gas membrane humidifier. Sustain. Energy Technol. Assessments 57, 103308. doi:10.1016/j.seta.2023.103308

Chong, M. N., Jin, B., Chow, C. W. K., and Saint, C. (2013). Recent developments in photocatalytic water treatment technology: a review. Water Res. 44 (10), 2997–3027. doi:10.1016/j.watres.2010.02.039

Çiplak, Z., Yildiz, N., and Çalimli, A. (2015). Investigation of graphene/Ag nanocomposites synthesis parameters for two different synthesis methods. Fullerenes, Nanotub. Carbon Nanostructures 23 (4), 361–370. doi:10.1080/1536383x.2014.894025

Darmayanti, R. F., Muharja, M., Widjaja, A., Widiastuti, N., Rachman, R. A., Widyanto, A. R., et al. (2023). Performance of modified hollow fiber membrane silver nanoparticles-zeolites Na–Y/PVDF composite used in membrane bioreactor for industrial wastewater treatment. Heliyon 9 (11), e21350. doi:10.1016/j.heliyon.2023.e21350

da Silva Biron, D., Espíndola, J. C., Subtil, E. L., and Mierzwa, J. C. (2023). A new approach to the development of hollow fiber membrane modules for water treatment: mixed polymer matrices. Membranes 13 (7), 613. doi:10.3390/membranes13070613

Ebrahimi, M., Busse, N., Kerker, S., Schmitz, O., Hilpert, M., and Czermak, P. (2015). Treatment of the bleaching effluent from sulfite pulp production by ceramic membrane filtration. Membranes 6 (1), 7. doi:10.3390/membranes6010007

Hancock, N. T., and Rhim, J.-W. (2008). Photocatalytic nanocomposite-fiber membranes for the degradation of organic contaminants in water. J. Membr. Sci. 313 (1-2), 170–181. doi:10.1016/j.memsci.2007.12.062

Hassan, M. F., et al. (2017). “Application of design for six sigma methodology on portable water filter that uses membrane filtration system: a preliminary study,” in IOP conference series: materials science and engineering (China: IOP Publishing), 243.

Hołda, A. K., and Vankelecom, I. F. (2015). Understanding and guiding the phase inversion process for synthesis of solvent resistant nanofiltration membranes. J. Appl. Polym. Sci. 132 (27). doi:10.1002/app.42130

Hou, C., Pang, Z., Xie, S., Wong, N. H., Sunarso, J., and Peng, Y. (2023). Enhanced permeability and stability of PVDF hollow fiber membrane in DCMD via heat-stretching treatment. Sep. Purif. Technol. 304, 122325. doi:10.1016/j.seppur.2022.122325

Hu, X., Yu, Y., Lin, N., Ren, S., Zhang, X., Wang, Y., et al. (2018). Graphene oxide/Al2O3 membrane with efficient salt rejection for water purification. Water Supply 18 (6), 2162–2169. doi:10.2166/ws.2018.037

Im, B.-G., Francis, L., Santosh, R., Kim, W.-S., Ghaffour, N., and Kim, Y.-D. (2022). Comprehensive insights into performance of water gap and air gap membrane distillation modules using hollow fiber membranes. Desalination 525, 115497. doi:10.1016/j.desal.2021.115497