- 1School of Accountancy, Guangzhou Xinhua University, Guangzhou, China

- 2Institute of Banking and Finance, Bahauddin Zakariya University, Multan, Pakistan

Introduction: In an increasingly competitive manufacturing sector, companies are adopting innovative approaches, such as the Lean Six Sigma methodology, to enhance their operations, competitiveness, and sustainability. This study explores the effect of Lean Six Sigma methodology and data-driven decision-making on sustainable manufacturing practices.

Methods: The study employs thematic analysis to clarify and identify principle nodes and themes, including Six Sigma, quality improvement, management approaches, and front-line worker perspectives. The analysis aims to deepen understanding of Lean Six Sigma principles and their implications for sustainable manufacturing practices.

Results: The analysis identifies employee motivation, balanced scorecards, company culture, Customer Relationship Management (CRM), and data-driven decision-making as key drivers of sustainable manufacturing practices. Evidence suggests that implementing Lean Six Sigma methodology, promoting data-driven decision-making, and nurturing a positive company culture enhances environmental performance in the manufacturing industry.

Discussion: The findings indicate that Lean Six Sigma, data-driven decision-making, and a positive company culture are effective strategies to enhance sustainability in manufacturing, offering valuable insights for companies seeking to improve sustainability while maintaining competitiveness. This study underlines the potential of Lean Six Sigma as a cornerstone of sustainable manufacturing practices.

1 Introduction

Sustainable manufacturing practices are no longer a mere option but a crucial necessity for our planet’s survival. They play a pivotal role in reducing the negative impact of industrial activities on the environment. Sustainable manufacturing practices have become increasingly important as concerns about climate change and environmental degradation have grown. The manufacturing sector significantly contributes to greenhouse gas emissions, resource depletion, and waste generation. Therefore, adopting sustainable manufacturing practices can help to reduce the negative impact of manufacturing on the environment and promote the efficient use of resources (Shen, 2014). These practices can include measures such as energy efficiency, waste reduction, recycling, and the use of renewable resources. By implementing sustainable manufacturing practices, companies can reduce their environmental footprint and improve their reputation, increase customer loyalty, and achieve cost savings through resource efficiency (Sarkis, Zhu, & Lai, 2011).

One approach that has gained attention in recent years for promoting sustainable manufacturing practices is Lean Six Sigma (LSS). LSS is a methodology combining Lean manufacturing principles and Six Sigma quality management to eliminate waste and defects in manufacturing processes (Tjahjono et al., 2010). Adopting LSS can significantly improve environmental performance, including reductions in energy consumption, emissions, and waste (Belhadi, Kamble, Zkik, Cherrafi, & Touriki, 2020). In addition, LSS has been found to contribute to cost savings, improved productivity, and enhanced customer satisfaction. For example, the company found that implementing LSS practices resulted in a reduction in energy consumption, a reduction in water usage, and a reduction in a waste generation (Tucci et al., 2021). These findings suggest that LSS can be a practical approach to promoting sustainable manufacturing practices and improving environmental performance.

Lean Six Sigma (LSS) combines Lean manufacturing principles and Six Sigma quality management to reduce waste and defects in business processes. The origins of LSS can be traced back to the Toyota Production System (TPS), which was developed in Japan in the 1950s to improve efficiency and eliminate waste in manufacturing processes (Womack, Jones, & Roos, 2007). Motorola later introduced Six Sigma in the 1980s as a statistical approach to quality control that focused on reducing variation and defects in manufacturing processes (Harry & Schroeder, 2006). LSS builds on the strengths of both approaches by emphasizing the importance of customer satisfaction, process improvement, and data-driven decision-making. The five principles of Lean manufacturing include defining customer value, identifying the value stream, creating flow, establishing pull, and pursuing perfection (Womack et al., 2007). The five phases of Six Sigma include Define, Measure, Analyze, Improve, and Control (DMAIC), which provide a structured approach to problem-solving and process improvement (Harry & Schroeder, 2006). LSS has been widely applied in various industries, including manufacturing, healthcare, finance, and service (Raja Sreedharan & Raju, 2016). For example, LSS has been used to improve product quality, reduce lead times, and increase efficiency in manufacturing processes (Trakulsunti, Antony, & Douglas, 2020). LSS has been used in healthcare to reduce medical errors, improve patient satisfaction, and increase productivity (Heckl, Moormann, & Rosemann, 2010; Yaduvanshi & Sharma, 2017). LSS has also been applied in service sectors, such as banking and insurance, to improve customer service, reduce errors, and increase profitability (Vashishth, Chakraborty, Antony, & Excellence, 2019; Gholami et al., 2021).

The manufacturing industry needs help to sustain competitiveness in an increasingly global market while attaining sustainable operations. While conventional industrial processes typically have severe environmental implications, there is an urgent need for novel solutions to increase operational efficiency and environmental performance. Even though Lean Six Sigma has become a popular solution for tackling these issues, how the methodology’s guiding principles and practises for data-driven decision-making promote sustainable manufacturing is still being determined. This knowledge gap limits the industry’s capacity to fully realize the promise of Lean Six Sigma to promote sustainable practices and enhance environmental performance. As a result, this research aims to look into the relationship between data-driven decision-making, Lean Six Sigma concepts, and sustainable manufacturing practices to provide valuable insights for manufacturing companies looking to improve their environmental performance while remaining competitive.

This study analyzed the relationship between Lean Six Sigma (LSS) principles, data-driven decision-making, and environmental performance within the broader context of sustainable manufacturing. Sustainable manufacturing is producing goods that minimize adverse environmental impacts, conserve energy and natural resources, and enhances the wellbeing of employees and communities. The main research question was: “What was the impact of Lean Six Sigma on environmental performance in sustainable manufacturing?” The study focused on identifying the key factors contributing to the successful implementation of LSS, promoting sustainable manufacturing practices, and enhancing environmental performance. A literature review of existing research on LSS and sustainable manufacturing practices, case studies of manufacturing companies implementing LSS principles for environmental performance improvement, and survey data collection from manufacturing companies were employed to achieve this objective. The scope of the study was limited to analyzing LSS principles and their impact on environmental performance within the sustainable manufacturing context, excluding other aspects such as renewable energy or waste reduction outside of LSS principles. Additionally, the study concentrated on manufacturing industries, not covering other sectors like healthcare or service industries.

2 Literature review

The role of Lean Six Sigma (LSS) in promoting sustainable manufacturing practices and improving environmental performance has gained increasing attention in recent years (Zhang, Luo, & Skitmore, 2015; Ganjavi & Fazlollahtabar, 2021). LSS is a methodology combining Lean manufacturing principles and Six Sigma quality management to reduce waste and defects in business processes. On the other hand, sustainable manufacturing practices aim to reduce the negative impact of manufacturing on the environment through measures such as energy efficiency, waste reduction, and the use of renewable resources (Antony, Snee, Hoerl, & Management, 2017). This literature review aims to analyze the relationship between LSS principles, data-driven decision-making, and environmental performance in the context of sustainable manufacturing practices. To gather a broad range of literature on the topic, relevant keywords and search terms such as “Lean Six Sigma,” “sustainable manufacturing,” “environmental performance,” and “data-driven decision making” were used to search scholarly databases and other sources the review will synthesize and analyze the literature to identify the key factors that contribute to the successful implementation of LSS in promoting sustainable manufacturing practices and improving environmental performance. By examining the existing research on this topic, the review aims to provide insights and recommendations for manufacturing companies seeking to improve their environmental sustainability while maintaining operational efficiency and profitability.

The first theme in the article is the history and principles of LSS. This theme includes sources that provide an overview of LSS, its origins, and the principles underpinning it (Stankalla, Koval, & Chromjakova, 2018). The second theme is the relationship between LSS and sustainable manufacturing practices. This theme includes sources that examine how LSS can be applied to promote sustainability in manufacturing and the challenges and benefits of doing so (Pereira, Silva, Domingues, & Sá, 2019). The third and final theme is the impact of LSS on environmental performance. This theme includes sources that analyze the effect of LSS on various environmental performance metrics, such as energy consumption, waste reduction, and carbon emissions. The theoretical and empirical literature, case studies, and best practices in the field are included to ensure a comprehensive review. By organizing the literature by these themes and topics, the review provides a structured and systematic analysis of the relationship between LSS principles, data-driven decision-making, and environmental performance in sustainable manufacturing practices.

After synthesizing and analyzing the literature, it is essential to critically evaluate the findings and provide a personal perspective on the topic. One of the strengths of the literature is the growing body of research that highlights the potential benefits of using LSS principles to promote sustainable manufacturing practices and improve environmental performance (Antony, Gijo, Kumar, Ghadge, & Management, 2016; Mohan, Rathi, Kaswan, & Nain, 2022; Nagadi & Engineering, 2022). Another strength is the availability of case studies and best practices demonstrating the successful implementation of LSS in various manufacturing industries (Yadav, Desai, & Management, 2017). However, a weakness of the literature is the need for more focus on the implementation challenges of LSS in the context of sustainable manufacturing practices. While some studies identify the barriers and limitations of LSS implementation in general (Willis, 2008; Shamsi & Alam, 2018; Ali et al., 2020), few studies have addressed the unique challenges of implementing LSS in sustainable manufacturing practices.

Researchers have been interested in the potential benefits of integrating data-driven methodologies into Lean Six Sigma. Six Sigma Lean has shown that cutting waste and boosting efficiency can boost profitability and encourage the growth of creative businesses (Atmaca and Girenes, 2013). A study examined how the Dutch financial services sector may benefit from integrating data science into Lean Six Sigma. They suggested changes to the sector’s organizational structure, employee training, and DMAIC roadmap (Zwetsloot, Kuiper, Akkerhuis, & de Koning, 2018). Lean Six Sigma has proven to be a possible answer to the healthcare industry’s issues by lowering variation, making mistakes, and spending more while raising overall quality (Van den Heuvel, Does, De Koning, & Advantage, 2006). When Lean/Kaizen and Six Sigma are combined, the outcomes are better for cutting waste and rework while generating a smooth production flow (Smith, 2003). The University of Central Florida’s successful application of Lean Six Sigma in a course on total quality improvement shows how effective the technique is for enhancing academic processes (Coowar et al., 2006). Lean Six Sigma 4.0 was promoted as a workable method to raise healthcare supply chain efficiency and lower unnecessary spending by highlighting the need for precise, current data (Arcidiacono, Pieroni, & Technology, 2018). The ability of Lean Six Sigma to enhance environmental performance across sectors is emphasized in the literature. An Indian producer of automotive components successfully applied the Lean Six Sigma methodology while taking environmental considerations, which reduced internal flaws and negative environmental consequences (Ruben, Vinodh, & Asokan, 2018). A recent comprehensive literature analysis shed light on incorporating these technologies into Green Lean Six Sigma (GLSS), a collection of approaches enterprises use to enhance their environmental performance. Lean, Six Sigma, and Lean Six Sigma are valuable tools for minimizing waste and emissions, two of the main contributors to climate change (Chugani, Kumar, Garza-Reyes, Rocha-Lona, & Upadhyay, 2017; Farrukh, Mathrani, & Sajjad, 2021). Nevertheless, study found that the Malaysian automotive industry’s adoption of ISO 14001 certification had no appreciable effect on the link between Lean Six Sigma and organizational performance (Habidin & Yusof, 2012). The most crucial factors for environmental efficacy were TPM and JIT, as opposed to autonomation and VSM (Garza-Reyes, Kumar, Chaikittisilp, & Tan, 2018). Researchers found that firms that embraced lean manufacturing techniques performed better regarding the environment using data from 17,499 enterprises in the United States (King, Lenox, & management, 2001). Lean management is associated with lower volatile organic compound air emissions, according to research by Rothenberg et al. on how lean manufacturing practices impact environmental performance in the vehicle sector.

Existing research on LSS in sustainable manufacturing practices and how it affects how well the environment works gives us valuable information and case studies. However, we need to learn more about the unique problems that come up when LSS is used in the context of sustainable manufacturing. In the literature, the potential problems and limits of using LSS for sustainable manufacturing have yet to be discussed as much as the benefits and successful uses of LSS. Also, few studies examine how LSS principles and data-driven techniques work together to improve environmental performance. Even though some studies have looked at how data science fits into LSS and how it affects different industries, there needs to be more research on how data-driven decision-making can make LSS better at promoting sustainable manufacturing practices and environmental performance. In the future, researchers could look into the unique problems that arise when LSS is used in environmentally friendly production and how they could be solved. Studying how data-driven methods and LSS principles work together to improve environmental performance across different industries would be beneficial. This would help us learn more about the topic and give people in the field the tools they need to improve sustainable manufacturing practices.

3 Methodology

The present study employed a qualitative research methodology to investigate the impact of Lean Six Sigma (LSS) as a culture-focused, continuous philosophy on environmental economics and management, employee-centric approach, intensity, and customer focus. The ethnographic method was employed for data collection, requiring researchers to deeply understand the Culture surrounding the data and immerse themselves in the community from which the data is sourced. In this study, the authors analyzed the public discourse on websites such as blogs, tweets, and Facebook comments, with a particular focus on communities from South Asia, as the researcher belongs to this region (Kozinets, 2002). The authors have investigated the specific Facebook communities that contributed to the data source, ensuring a comprehensive understanding of the context. This method reduces bias and increases comprehension of social and corporate challenges, providing valuable insights into the research topic (Ekblom, 2018).

3.1 Data collection

In this study, the selection of Facebook comments was carried out through a systematic process to ensure their quality and relevance. Criteria for inclusion encompassed the comments’ genuineness and their content being informative and well-thought-out. Comments containing emoticons, graphics, or merely three to four words and brief remarks were excluded, as they were deemed insufficient for our analysis (Hellerstein, 2008). This meticulous selection ensured that only high-quality, relevant comments were considered for the study. The careful selection of Facebook comments based on relevance and genuineness in this study provides several benefits. Firstly, it ensures that the data collected is of high quality and accurately reflects the attitudes and opinions of the stakeholders. Secondly, it reduces the potential for bias in the data by excluding comments with emoticons or graphics, which may not provide valuable insights into the research topic. Thirdly, excluding comments with three to four words or quick remarks ensures that the data analyzed is sufficiently detailed and informative, which is crucial for drawing valid and reliable conclusions. Previous research has also highlighted the importance of careful data selection and cleaning in qualitative research (Kozinets, 2002; Harper & Thompson, 2011; White, Oelke, & Friesen, 2012).

3.2 Data analysis and reporting

Content analysis techniques were used to evaluate qualitative data. Content analysis techniques were used to analyze the data, a reliable and systematic approach to analyzing text-based data (Braun & Clarke, 2006). The researchers carefully selected the comments based on their relevance and genuineness and excluded comments with emoticons or graphics, as well as quick remarks, to ensure the validity and reliability of the data (Brandão, 2015). This rigorous data collection and analysis approach ensures that the study’s findings are valid and reliable and accurately reflect the attitudes and opinions of the stakeholders in question. Content analysis is typically implemented in several stages, and it is crucial to explain these stages for a comprehensive understanding. This study employed the QSR NVivo 11 software for qualitative data analysis, using the top-down paradigm for qualitative data coding theme analysis (Saldaña, 2021). This widely recognized and user-friendly software offers efficient data management and organization, essential for handling large datasets and intricate research projects. Advanced analytical tools, such as the word frequency cloud function, help swiftly identify patterns and trends in data (Ford, 2004). NVivo’s coding and analysis features facilitate detailed and rigorous qualitative data analyses while ensuring accuracy and reliability (Singh & Smith, 2004). By utilizing NVivo in this study, we illustrate the advantages of incorporating advanced software tools in qualitative data analysis, ultimately bolstering the rigour and credibility of research findings.

The study presents the nodes and parent nodes that emerged from the dataset in manufacturing companies. First, the nodes were identified and then grouped similar nodes into central nodes. Identifying nodes and parent nodes using content analysis techniques is a widely accepted method in qualitative research. Content analysis involves identifying and categorizing patterns in textual data, such as themes or topics. This process typically involves several steps, including coding, categorizing, and analyzing the data to identify meaningful patterns and themes (Liberatore & Nydick, 2008). Once the nodes have been identified, researchers may group them into principle nodes based on their similarities. This approach is often used in thematic analysis, which involves identifying and analyzing patterns of meaning across a dataset (Ford, 2004). Thematic analysis can be a powerful tool for identifying and exploring complex and nuanced themes within qualitative data. The findings are presented both in tabular form and paragraph form. Overall, the approach taken in this study to identify nodes and principle nodes from the data using content analysis techniques is in line with best practices in qualitative research. Using thematic analysis to group similar nodes into principle nodes is a reliable and systematic approach to analyzing textual data and can provide valuable insights into complex research questions.

Last, the interrelationship digraph techniques were applied to the parent nodes to find the possible cause-and-effect relationship between the parent nodes for better decision-making. Applying interrelationship digraph techniques can be valuable for identifying and analyzing the potential relationships between parent nodes in a complex system. One key benefit of this technique is that it allows researchers to visually map out the potential causal relationships between different variables or concepts, providing a more intuitive understanding of how these components interact (Thomas et al., 2014). This can be especially useful in Lean Six Sigma and sustainable manufacturing practices, where many factors can often impact organizational performance and environmental sustainability. Another benefit of interrelationship digraph techniques is that they can highlight potential focus areas for further research or intervention. By identifying the most significant relationships between parent nodes, researchers can prioritize which areas of the system to target for improvement or investigation (Ahi & Searcy, 2015). This can be especially useful in sustainable manufacturing practices. Organizations may need to focus on specific areas such as employee motivation, company culture, or data-driven decision-making to achieve sustainability goals. Overall, using interrelationship digraph techniques can help researchers better understand the complex relationships between different variables in the context of Lean Six Sigma and sustainable manufacturing practices. By identifying these relationships, researchers can develop more effective strategies for improving organizational performance and promoting sustainability in manufacturing practices.

4 Results and discussion

4.1 Word frequency

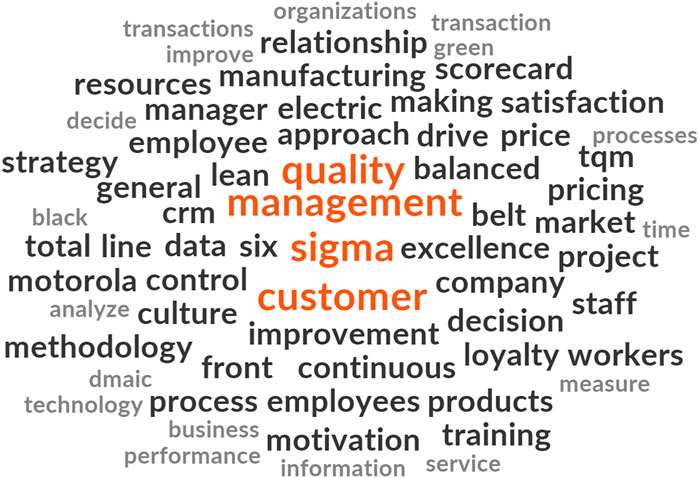

To better understand the studied variables, the authors utilized frequency tables and diagrams to analyze the frequency of certain words in the data set. As shown in Figure 1, the most frequently used words in the study, highlighted in red, included “quality management” and “Six Sigma.” Other frequently used words, written in bold, included “scoreboard,” “satisfaction,” “employees,” “workers,” “employers,” and “training.” In contrast, words written in grey, such as “information,” “service,” “time,” and “transaction,” were less frequently used in the study. By analyzing the frequency of these words, the authors could better understand the studied variables and determine which factors were most relevant to their research.

4.2 Nodes using NVivo

The current study used NVivo QSR to analyze the vast qualitative data collected. Nodes, essentially subcategories of the data, were generated and organized into their corresponding parent nodes. The thematic analysis involved extracting various themes from the dataset, such as the benefits of Lean Six Sigma (LSS) and the different implementation procedures for LSS across various geographical regions. As per the data, the LSS implementation procedures vary depending on the region and the organization’s level of adoption. While some organizations have implemented LSS at the departmental level, others have implemented it at the organizational level. Moreover, the study highlighted that the research on LSS is still in its initial stages and has shifted from manufacturing to service. In emerging nations, LSS implementation was initially limited to the manufacturing sector, while in developing nations, the focus has shifted to high-tech industries and the service sector.

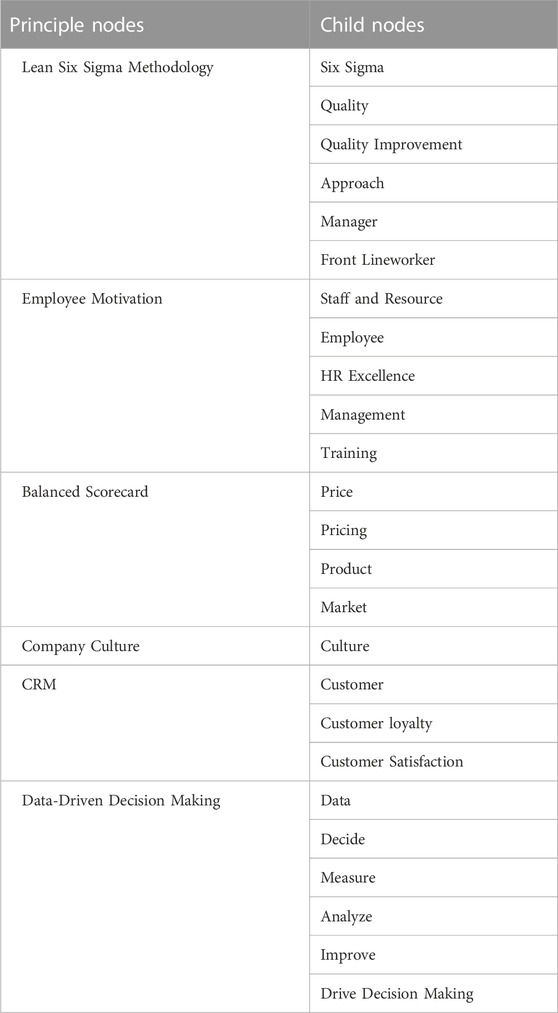

The principle nodes represent the overarching themes from the data analysis, and the child nodes represent the specific topics or themes that fall under each principle node. By organizing the nodes in this way, the researchers could identify and categorize the key themes and patterns that emerged from the qualitative data, providing a comprehensive and nuanced understanding of the manufacturing industry. Table 1 presents the outcome of the thematic analysis conducted in the study, which aimed to investigate the impact of Lean Six Sigma methodology on environmental economics and management, employee-centric approach, intensity, and customer focus in the manufacturing industry. The table displays the six principle nodes that emerged from the data analysis and their respective child nodes. The first principle node, Lean Six Sigma Methodology, includes six child nodes: Six Sigma, Quality, Quality Improvement, Approach, Manager, and Front Lineworker. In this context, the “Approach” node refers to the systematic and structured methods used in implementing Lean Six Sigma principles, focusing on continuous improvement and waste reduction. This principle node suggests that applying the Lean Six Sigma methodology in manufacturing companies can lead to enhanced quality and efficiency and increased involvement and motivation of both managers and front-line workers through the adoption of these systematic approaches. The second principle node, Employee Motivation, includes five child nodes: Staff and Resource, Employee, HR Excellence, Management, and Training. This principle node suggests that employee motivation is a crucial factor in the success of Lean Six Sigma implementation. Companies must invest in training and HR excellence to create a motivated and engaged workforce.

4.3 Lean Six Sigma Methodology

Thematic analysis of the data in this study identified Lean Six Sigma Methodology as a critical principle node with several child nodes, including Six Sigma, Quality, Quality Improvement, Approach, Manager, and Front Lineworker. These findings are consistent with previous research that has demonstrated the positive impact of the Lean Six Sigma methodology on environmental economics and management in the manufacturing industry (Womack & Jones, 1997). Lean Six Sigma methodology emphasizes continuous improvement and eliminating waste in production, which can lead to significant environmental benefits such as reduced energy consumption, waste generation, and emissions (Seuring & Müller, 2008). By focusing on improving quality and efficiency, the Lean Six Sigma methodology can also help companies to reduce costs and increase profitability while minimizing their environmental impact (Ching, Ghobakhloo, Iranmanesh, Maroufkhani, & Asadi, 2022). Moreover, the child nodes identified under Lean Six Sigma Methodology, such as Six Sigma, Quality, Quality Improvement, and Approach, are all critical components of the methodology that can lead to improvements in environmental economics and management. For example, Six Sigma is a data-driven approach to quality improvement that can help companies to reduce defects and waste. At the same time, the Quality Improvement Approach emphasizes the need for continuous improvement in all aspects of the production process (Cherrafi, Elfezazi, Chiarini, Mokhlis, & Benhida, 2016). Overall, the thematic analysis conducted in this study provides valuable insights into the impact of Lean Six Sigma methodology on environmental economics and management in the manufacturing industry and highlights the importance of specific components of the methodology such as Six Sigma, Quality, Quality Improvement, and Approach. These findings can inform the development of strategies and practices to support sustainable manufacturing and improve the environmental performance of manufacturing companies.

4.4 Employee motivation

One of the principle nodes that emerged from the thematic analysis in this study was employee motivation, which included five child nodes: Staff and Resource, Employee, HR Excellence, Management, and Training. This principle node suggests that employee motivation is critical in successfully implementing the Lean Six Sigma methodology in manufacturing. The importance of employee motivation in the context of Lean Six Sigma implementation is supported by previous research, showing that engaged and motivated employees are more likely to embrace change and take ownership of continuous improvement initiatives (Antony, McDermott, Powell, & Sony, 2022). Effective HR practices, such as training and development, can significantly promote employee motivation and engagement in implementing the Lean Six Sigma methodology (Wu, Wu, Chen, & Goh, 2014). Effective management and leadership practices can also create a positive organizational culture that supports continuous improvement and employee engagement (Walker, Seuring, Sarkis, Klassen, & Management, 2014). By focusing on employee motivation through HR excellence, management, and training, manufacturing companies can create a culture of continuous improvement that can positively impact environmental economics and management and other aspects of the business.

Overall, the thematic analysis in this study highlights the importance of employee motivation as a critical factor in successfully implementing the Lean Six Sigma methodology in the manufacturing industry. By investing in HR excellence, effective management practices, and training, manufacturing companies can create a culture of continuous improvement and engagement that can positively impact various aspects of the business.

4.5 Balanced scorecard

The principle node of the Balanced Scorecard emerged as an essential theme in the thematic analysis of the impact of Lean Six Sigma methodology on different aspects of environmental economics and management in the manufacturing industry. The child nodes under this principle node, including Price, Pricing, Product, and Market, suggest that companies must balance their focus on various aspects to successfully implement the Lean Six Sigma methodology. The study’s findings align with previous research emphasizing the importance of balancing different business operations to improve overall performance. For example, a balanced scorecard approach can help companies to align their business strategies with their goals and objectives and to measure their performance in a comprehensive and balanced way (Chugani et al., 2017). Similarly, a balanced approach to quality management, focusing on customer satisfaction, employee involvement, and financial performance, can improve organizational performance (Sodhi, Singh, Singh, & Advantage, 2019). In the context of the present study, the findings suggest that companies must consider a balanced approach that includes factors such as pricing, product quality, and market positioning to successfully implement the Lean Six Sigma methodology. By focusing on a balanced scorecard approach, companies can ensure that their Lean Six Sigma initiatives are aligned with their business goals and objectives and that they are measuring their performance comprehensively and rationally. Overall, the thematic analysis of the impact of Lean Six Sigma methodology on different aspects of environmental economics and management in the manufacturing industry highlights the importance of balancing different aspects of business operations to achieve success. The study’s findings provide valuable insights into the factors that can influence the success of Lean Six Sigma implementation in manufacturing companies and can inform future research and practice in this area.

4.6 Company culture

The thematic analysis conducted in this study revealed that company culture is a crucial factor in successfully implementing Lean Six Sigma methodology in the manufacturing industry. The principle node of Company Culture included a single child node, Culture, which highlights the importance of creating a culture that supports continuous improvement and employee engagement. Research suggests that a strong culture that emphasizes continuous improvement and employee engagement can positively impact the effectiveness of Lean Six Sigma implementation (Yadav et al., 2017). Companies that prioritize creating a culture of continuous improvement and employee engagement can see improvements in quality, efficiency, and customer satisfaction, among other factors. However, creating a culture supporting Lean Six Sigma implementation can be challenging and requires buy-in and commitment from top-level management and front-line workers. This requires a focus on training and development, as well as effective communication and leadership (Ahire & Dreyfus, 2000). Overall, the findings of this study suggest that company culture plays a crucial role in the success of Lean Six Sigma implementation in the manufacturing industry. Companies prioritizing creating a culture of continuous improvement and employee engagement can see significant benefits in quality, efficiency, and customer satisfaction.

4.7 Customer relationship management

The results of the thematic analysis conducted in this study suggest that customer relationship management (CRM) is a critical factor in successfully implementing the Lean Six Sigma methodology in the manufacturing industry. The central node of CRM includes three child nodes: Customer, Customer loyalty, and Customer Satisfaction. The findings indicate that companies need to prioritize customer needs and satisfaction to implement Lean Six Sigma and achieve the desired outcomes effectively. Several studies have highlighted the importance of customer satisfaction and loyalty in Lean Six Sigma implementation. For instance, Lean Six Sigma implementation can enhance customer satisfaction and loyalty, leading to improved business performance (Galvão, de Carvalho, Oliveira, Medeiros, & Marketing, 2018). Similarly, Lean Six Sigma can improve customer satisfaction by reducing defects and improving product and service quality (Bag, Kilbourn, & Pisa, 2023).

In addition, using CRM can help companies better understand their customers’ needs and preferences and tailor their products and services accordingly. CRM can help companies identify and target profitable customer segments and develop more effective marketing strategies (Govindan & Soleimani, 2017). Furthermore, CRM can help companies build strong customer relationships, increasing loyalty and retention. Overall, the findings from this study suggest that the effective use of CRM is a crucial factor in the successful implementation of Lean Six Sigma methodology in the manufacturing industry. By prioritizing customer needs and satisfaction and using CRM to understand better and target customer segments, companies can achieve the desired outcomes of improved environmental economics and management, employee-centric approach, intensity, and customer focus.

4.8 Data-driven decision making

The data-driven decision-making principle node that emerged from the thematic analysis of this study suggests that data analysis and decision-making should be at the core of Lean Six Sigma implementation in the manufacturing industry. The child nodes under this principle node, including Data, Decide, Measure, Analyze, Improve, and Drive Decision Making, indicate the various steps in making data-driven decisions. The use of data-driven decision-making processes in Lean Six Sigma implementation can significantly impact environmental economics and management in manufacturing companies. For example, by analyzing energy usage and waste management data, companies can identify opportunities to reduce environmental impact and optimize resource usage. Additionally, by using data to monitor and track key performance indicators, companies can identify areas for improvement and implement strategies to increase their efficiency and reduce costs.

Previous research has also highlighted the importance of data-driven decision-making in Lean Six Sigma implementation. For instance, data analysis and decision-making should be at the core of Lean Six Sigma methodology, and companies should use data to guide their continuous improvement efforts (Thakur, 2022). Similarly, data analysis in identifying and addressing environmental sustainability challenges is essential in manufacturing companies (Garza-Reyes et al., 2018). In conclusion, the thematic analysis conducted in this study highlights the importance of data-driven decision-making in Lean Six Sigma implementation in the manufacturing industry. By using data to guide their decision-making processes, companies can identify areas for improvement and optimize their resource usage, leading to economic and environmental benefits.

4.9 Employees are an essential element of focus of an organization

Employees are the lifeblood of an organization, and their impact on a company’s performance cannot be overstated. Qualitative analysis has revealed that lean six sigma programs in companies focus on employees as a central element. The contribution of a company’s personnel is directly proportional to its productivity, and establishing organizational success is only possible with a highly competitive labour force. To understand the employee’s role more comprehensively, they are classified into front-line, middle-line, or managers, and each contributes to the overall success of their task force. Employees are the organization’s interface and are crucial in administrating a company’s brand. Employees’ performance directly impacts the company’s operation, and their services convey the brand’s image and value (Raval, Kant, & Shankar, 2019). Motivated and engaged employees are valuable assets to an organization, and continuous learning significantly impacts individuals’ contextual performance, leading to improved organizational performance (Tensay & Singh, 2020). According to Barney’s resource-based perspective (2001), the same holds for resources, making the personnel of any firm critical to the corporation’s overall performance. In summary, the Resource-Based View accurately outlines employees’ role in organizational progress and productivity. A motivated and engaged workforce can significantly modify a company’s overall performance, and it is vital to recognize the vital function employees play in administrating a company’s brand.

4.10 The outcome of the interrelationship diagraph of the parent nodes

The following relationship occurs between the parent nodes due to building an interrelationship digraph in the context of lean Six Sigma and the sustainability of the manufacturing organizations.

• Employee motivation can influence the success of the balanced Scorecard by driving staff and resource allocation toward critical metrics.

• Company culture can impact employee motivation and customer relationship management (CRM) by creating a positive and customer-focused work environment that motivates employees to engage with customers.

• Data-driven decision-making can support balanced Scorecard and CRM by providing insights into key performance indicators and customer behaviour.

• The balanced Scorecard and CRM can interact to provide data-driven insights into customer behaviour and preferences, which can then inform decisions about resource allocation and marketing strategies.

These interrelationships are complex and can have multiple causal factors. However, by understanding these relationships, organizations can develop more effective strategies for employee motivation, implementing the balanced Scorecard, managing company culture, improving CRM, and driving data-driven decision-making. The interrelationships between employee motivation, balanced scorecards, company culture, CRM, and data-driven decision-making in the context of Lean Six Sigma and sustainable manufacturing practices have been the subject of extensive research. Studies have found that employee motivation is a critical factor in achieving success with the balanced Scorecard, as it drives staff and resource allocation toward key metrics (Liou, Chuang, Zavadskas, & Tzeng, 2019). Similarly, company culture has been shown to impact employee motivation and CRM by creating a positive and customer-focused work environment that motivates employees to engage with customers (Tjahjono et al., 2010). Data-driven decision-making has also been a crucial component in the success of the balanced Scorecard and CRM, as it provides insights into key performance indicators and customer behaviour (Masri & Jaaron, 2017). This information can then inform decisions about resource allocation and marketing strategies as the balanced Scorecard and CRM interact to provide data-driven insights into customer behaviour and preferences (Ahi & Searcy, 2013).

5 Conclusion

The study conducted a thematic qualitative data analysis to explore the relationship between Lean Six Sigma methodology, data-driven decision-making, and sustainable manufacturing practices. Six principle nodes emerged from the analysis: Lean Six Sigma Methodology, Employee Motivation, Balanced Scorecard, Company Culture, Customer Relationship Management (CRM), and Data-Driven Decision Making. The results indicate that implementing the Lean Six Sigma methodology can lead to improved quality and efficiency in manufacturing and increased involvement and motivation of both managers and front-line workers. Employee motivation was crucial for successful Lean Six Sigma implementation, with companies needing to invest in HR excellence, management, and training to create a motivated workforce. A balanced scorecard approach, focusing on various business aspects, is essential for successful Lean Six Sigma implementation, ensuring alignment with company goals and objectives. Company culture plays a crucial role in Lean Six Sigma’s success, emphasizing the importance of creating a culture that supports continuous improvement and employee engagement. CRM is vital in prioritizing customer needs and satisfaction for effective Lean Six Sigma implementation, leading to improved business performance. Data-driven decision-making is at the core of Lean Six Sigma. Companies should use data to guide their continuous improvement efforts, which can lead to economic and environmental benefits.

The Lean Six Sigma Methodology principle node and its child nodes, such as Six Sigma, Quality, and Quality Improvement, are crucial in enhancing environmental performance. By focusing on continuous improvement and waste reduction, the methodology can minimize environmental impact, reduce costs, and increase profitability. Employee Motivation plays a significant role in the success of Lean Six Sigma implementation. A motivated workforce can lead to more efficient use of resources and improved environmental performance. The Employee Motivation principle node and its child nodes, such as Staff and Resources, Employee, HR Excellence, and Training, emphasize the importance of investing in human resources to foster a culture of continuous improvement. The Balanced Scorecard principle node and its child nodes, such as Price, Pricing, Product, and Market, suggest that companies must adopt a balanced approach to implement Lean Six Sigma successfully. Companies can enhance their environmental performance by aligning their business strategies with environmental goals and considering factors like pricing and product quality. Company Culture is essential in supporting the Lean Six Sigma methodology, as a culture that promotes continuous improvement and employee engagement is more likely to achieve environmental objectives. The single-child node, Culture, emphasizes fostering a supportive organizational culture. The CRM principle node and its child nodes, Customer, Customer loyalty, and Customer Satisfaction, highlight the need to prioritize customer needs and satisfaction. Lean Six Sigma can improve customer satisfaction by reducing defects and enhancing product and service quality, leading to better environmental performance. Lastly, the Data-Driven Decision Making principle node and its child nodes, such as Data, Decide, Measure, Analyze, Improve, and Drive Decision Making, emphasize the importance of using data to guide decision-making processes. By analyzing data related to environmental performance, companies can identify opportunities for improvement and optimize their resource usage.

This study’s primary contribution is an examination of the factors that influence the successful implementation of Lean Six Sigma in environmentally responsible manufacturing processes, which ultimately leads to improved environmental performance. The thematic analysis permits the identification of six primary nodes: the Lean Six Sigma Methodology, Employee Motivation, Balanced Scorecard, Corporate Culture, Customer Relationship Management, and Data-Driven Decision Making. The study provides valuable insights for organizations seeking to maximize resource utilization, boost customer satisfaction, and foster continuous improvement, ultimately resulting in more sustainable manufacturing and enhanced environmental performance. This can be accomplished by investigating these factors and their interrelationships, which are the subject of the study.

Our findings are consistent with previous research highlighting the importance of Lean Six Sigma and data-driven decision-making in driving sustainable manufacturing practices (Flor Vallejo, Antony, Douglas, Alexander, & Sony, 2020; Duggan, Cormican, & McDermott, 2023). Furthermore, our findings regarding the importance of employee motivation, company culture, and customer relationship management in Lean Six Sigma are consistent with prior research that has highlighted the role of these factors in promoting sustainable practices (Flores-Sigüenza, Marmolejo-Saucedo, Niembro-Garcia, Lopez-Sanchez, & Engineering, 2021; McDermott et al., 2022; Duggan et al., 2023). Overall, our findings add to the growing literature on the importance of Lean Six Sigma, data-driven decision-making, and organizational Culture in promoting sustainable manufacturing practices. By understanding the interrelationships between these factors, organizations can develop more effective strategies for improving their environmental performance and achieving their sustainability goals.

While much is still to be learned about the complex relationships between these different factors, our analysis suggests that organizations can benefit from a holistic approach that integrates Lean Six Sigma principles with data-driven decision-making, employee motivation, and strong company culture. By focusing on these critical areas, organizations can promote sustainability in manufacturing practices and achieve various other benefits, including improved operational efficiency, enhanced customer loyalty, and increased profitability. Our analysis underscores the importance of continuous improvement and ongoing evaluation in pursuing sustainable manufacturing practices. Through further research and experimentation, organizations can continue to refine their approaches and build more sustainable, environmentally friendly operations that benefit both their bottom line and the planet.

The findings of our analysis have significant implications for a range of stakeholders, including industrial managers, policymakers, and theoretical researchers. From an industrial perspective, our findings suggest that organizations can benefit from adopting a holistic approach that integrates Lean Six Sigma principles with data-driven decision-making, employee motivation, and strong company culture. Organizations can prioritize these key areas to improve operational efficiency, enhance customer loyalty, and drive long-term sustainability. The study’s findings emphasize the importance of incorporating Lean Six Sigma methodology, data-driven decision-making, and fostering a supportive company culture to enhance environmental performance in the manufacturing industry. Managers should invest in employee training, implement balanced scorecards, and cultivate a culture that promotes sustainability and continuous improvement. Emphasizing customer relationship management can also lead to more sustainable product and service choices. By embracing these strategies, manufacturing companies can improve their environmental performance while maintaining a competitive edge in the market. From a theoretical perspective, our findings contribute to the ongoing discussion about the role of Lean Six Sigma methodology in promoting sustainable manufacturing practices. By identifying key factors that can influence the success of sustainability initiatives, our analysis provides a foundation for future research on this topic. Finally, from a policy perspective, our findings underscore the importance of promoting sustainability in manufacturing practices through adopting data-driven decision-making and using balanced scorecards. Policymakers can support these efforts by providing incentives and resources to encourage organizations to adopt more sustainable practices and by promoting education and awareness around the importance of sustainability in manufacturing. Our analysis highlights the importance of collaboration and continuous improvement in promoting sustainable manufacturing practices that benefit organizations and the environment.

Our analysis has identified several potential research directions for further quantitative research in Lean Six Sigma and sustainable manufacturing practices. These research directions include investigating the relationship between Lean Six Sigma principles and quality improvement in manufacturing and exploring employee motivation’s impact on HR excellence in a manufacturing organization. Additionally, our analysis suggests that further research could be conducted on the relationship between balanced scorecard metrics and product pricing in a competitive market, as well as on the effect of company culture on customer loyalty and satisfaction in the service industry. Finally, we recommend investigating the implementation of data-driven decision-making in improving operational performance in a manufacturing organization. By exploring these research directions, future studies can build upon our findings and deepen our understanding of the complex relationships between Lean Six Sigma, sustainability, and organizational performance. This can help organizations develop more effective strategies for promoting sustainability in manufacturing practices, driving business growth and innovation. Ultimately, the pursuit of sustainable manufacturing practices is an ongoing process that requires ongoing research and evaluation, and we hope that our analysis will inspire further research in this critical area.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

The research idea was conceived by MI and RS, who also collected the data. MI and RS performed data analysis. The initial draft was written by RS, SF, and MI wrote the final draft. JH provided pivotal contributions to this study. Her role was instrumental in conducting the data analysis and data curation, ensuring the validity and accuracy of the results presented. Beyond these technical contributions, JH also secured the necessary funding for the research, playing a key role in facilitating the resources needed to bring the study to fruition. Additionally, she took an active role in the preparation of the final draft of the manuscript, ensuring that the research findings were accurately and compellingly communicated. Her multifaceted contributions added significant value to the entire research process, from inception to publication. All authors contributed to the article and approved the submitted version.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahi, P., and Searcy, C. J. A. M. M. (2015). Assessing sustainability in the supply chain: A triple bottom line approach. A triple bottom line approach 39 (10-11), 2882–2896. doi:10.1016/j.apm.2014.10.055

Ahi, P., and Searcy, C. J. J. o. c. p. (2013). A comparative literature analysis of definitions for green and sustainable supply chain management. supply chain Manag. 52, 329–341. doi:10.1016/j.jclepro.2013.02.018

Ahire, S. L., and Dreyfus, P. J. J. o. o. m. (2000). The impact of design management and process management on quality: An empirical investigation. Manag. Qual. Empir. investigation 18 (5), 549–575. doi:10.1016/s0272-6963(00)00029-2

Ali, S. M., Hossen, M. A., Mahtab, Z., Kabir, G., Paul, S. K. J. C., and Adnan, Z. u. H. (2020). Barriers to lean six sigma implementation in the supply chain: An ISM model. An ISM Model. 149, 106843. doi:10.1016/j.cie.2020.106843

Antony, J., Gijo, E., Kumar, V., Ghadge, A. J. I. J. o. Q., and Management, R. (2016). A multiple case study analysis of six sigma practices in indian manufacturing companies. Int. J. Qual. Reliab. Manag. 33.

Antony, J., McDermott, O., Powell, D., and Sony, M. J. T. T. J. (2022). The evolution and future of lean Six Sigma 4.0. TQM J. 35.(ahead-of-print).

Antony, J., Snee, R., Hoerl, R. J. I. J. o. Q., and Management, R. (2017). Lean six sigma: Yesterday, today and tomorrow. today tomorrow 34 (7), 1073–1093. doi:10.1108/ijqrm-03-2016-0035

Arcidiacono, G., and Pieroni, A. J. I. J. o. A. S. (2018). The revolution lean six sigma 4.0. Int. J. Adv. Sci. Eng. Inf. Technol. 8 (1), 141–149. doi:10.18517/ijaseit.8.1.4593

Atmaca, E., and Girenes, S. S. (2013). Lean six sigma methodology and application. Qual. Quant., 47, 2107–2127.

Bag, S., Kilbourn, P., and Pisa, N. J. T. T. J. (2023). Guest editorial: Data-driven quality management systems for improving supply chain management performance. TQM J. 35 (1), 1–4. doi:10.1108/tqm-11-2021-315

Belhadi, A., Kamble, S. S., Zkik, K., Cherrafi, A., and Touriki, F. E. J. J. o. C. P. (2020). The integrated effect of big data analytics, lean six sigma and green manufacturing on the environmental performance of manufacturing companies: The case of north africa. Lean Six Sigma Green Manuf. Environ. Perform. Manuf. Co. case North Afr. 252, 119903. doi:10.1016/j.jclepro.2019.119903

Brandão, C., Bazeley, P., and Jackson, K. (2015). Qualitative data analysis with Nvivo (2013). London, UK: Taylor & Francis.Sage

Braun, V., and Clarke, V. J. Q. r. i. p. (2006). Using thematic analysis in psychology. Using Themat. analysis Psychol. 3 (2), 77–101. doi:10.1191/1478088706qp063oa

Cherrafi, A., Elfezazi, S., Chiarini, A., Mokhlis, A., and Benhida, K. J. J. o. C. P. (2016). The integration of lean manufacturing, six sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 139, 828–846. doi:10.1016/j.jclepro.2016.08.101

Ching, N. T., Ghobakhloo, M., Iranmanesh, M., Maroufkhani, P., and Asadi, S. J. J. o. C. P. (2022). Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 334, 130133.

Chugani, N., Kumar, V., Garza-Reyes, J. A., Rocha-Lona, L., and Upadhyay, A. J. I. J. o. L. S. S. (2017). Investigating the green impact of lean, six sigma and lean six sigma. A Syst. lit. Rev. 8 (1), 7–32. doi:10.1108/ijlss-11-2015-0043

Coowar, R., Furterer, S., Akinrefon, T., Ferreras, A., Gibson, K., Lakkoju, R., et al. “Lean Six Sigma as an improvement tool in academia,” in Annual Conference & Exposition, Las Vegas, NV, USA, June, 2006.Paper presented at the 2006

Duggan, J., Cormican, K., and McDermott, O. J. I. J. o. L. S. S. (2023). Lean implementation: Analysis of individual-level factors in a biopharmaceutical organisation. Int. J. Lean Six Sigma 14 (2), 309–334. doi:10.1108/ijlss-10-2021-0184

Ekblom, A. C. (2018). Facebook groups for dissemination of EU-funded projects: An exploratory study of knowledge sharing in communities of interest in social media. International Master’s Programme in IT & Learning (Report no: HT18-2920-006-PDA699), Second Cycle, Autumn term 2018. Gothenburg University. Available at: https://gupea.ub.gu.se/bitstream/handle/2077/58008/gupea_2077_58008_1.pdf?sequence=1&isAllowed=y.

Farrukh, A., Mathrani, S., and Sajjad, A. “A DMAIC approach to investigate the green lean six sigma tools for improving environmental performance,” in IEEE Asia-Pacific Conference on Computer Science and Data Engineering (CSDE), Queensland, Austria, December, 2021.Paper presented at the 2021

Flor Vallejo, V., Antony, J., Douglas, J. A., Alexander, P., and Sony, M. J. T. T. J. (2020). Development of a roadmap for Lean Six Sigma implementation and sustainability in a Scottish packing company. Dev. a roadmap Lean Six Sigma Implement. Sustain. a Scott. Pack. Co. 32 (6), 1263–1284. doi:10.1108/tqm-02-2020-0036

Flores-Sigüenza, P., Marmolejo-Saucedo, J. A., Niembro-Garcia, J., and Lopez-Sanchez, V. M. J. M. B. (2021). A systematic literature review of quantitative models for sustainable supply chain management. supply chain Manag. 18 (3), 2206–2229. doi:10.3934/mbe.2021111

Ford, J. M. J. P. P. (2004). Content analysis: An introduction to its methodology. Newbury Park, CA, USA: SAGE Publications.57(4), 1110.

Galvão, M. B., de Carvalho, R. C., Oliveira, L. A. B. d., Medeiros, D. D. d. J. J. o. B., and Marketing, I. (2018). Customer loyalty approach based on CRM for SMEs. CRM SMEs 33 (5), 706–716. doi:10.1108/jbim-07-2017-0166

Ganjavi, N., and Fazlollahtabar, H. J. I. T. o. E. M. (2021). Integrated sustainable production value measurement model based on Lean and Six sigma in Industry 4.0 context. IEEE Trans. Eng. Manag. 70.

Garza-Reyes, J. A., Kumar, V., Chaikittisilp, S., and Tan, K. H. J. I. J. o. P. E. (2018). The effect of lean methods and tools on the environmental performance of manufacturing organisations. Int. J. Prod. Econ. 200, 170–180.

Gholami, H., Jamil, N., Mat Saman, M. Z., Streimikiene, D., Sharif, S., Zakuan, N. J. B. S., et al. (2021). The application of green lean six sigma. Bus. Strategy Environ. 30 (4), 1913–1931. doi:10.1002/bse.2724

Govindan, K., and Soleimani, H. J. J. o. c. p. (2017). A review of reverse logistics and closed-loop supply chains: A journal of cleaner production focus. A J. Clean. Prod. focus 142, 371–384. doi:10.1016/j.jclepro.2016.03.126

Habidin, N., and Yusof, S. M. J. I. J. o. A. T. (2012). Relationship between lean six sigma, environmental management systems, and organizational performance in the Malaysian automotive industry. Environ. Manag. Syst. Organ. Perform. Malays. Automot. industry 13, 1119–1125. doi:10.1007/s12239-012-0114-4

Harper, D., and Thompson, A. R. (2011). Qualitative research methods in mental health and psychotherapy: A guide for students and practitioners. Hoboken, NJ, USA: John Wiley & Sons.

Harry, M., and Schroeder, R. (2006). Six sigma: The breakthrough management strategy revolutionizing the world's top corporations: Currency. New York, NY, USA: Bantam Doubleday Dell Audio Pub.

Heckl, D., Moormann, J., and Rosemann, M. J. B. p. m. j. (2010). Uptake and success factors of six sigma in the financial services industry. Bus. Process Manag. J. 16.

Hellerstein, J. M. J. U. N. E. C. f. E. (2008). Quantitative data cleaning for large databases, 25. Geneva, Switzerland: United Nations Economic Commission for Europe. 1-42.

Kozinets, R. V. J. J. o. m. r. (2002). The field behind the screen: Using netnography for marketing research in online communities. Using Netnogr. Mark. Res. online communities 39 (1), 61–72. doi:10.1509/jmkr.39.1.61.18935

Liberatore, M. J., and Nydick, R. L. J. E. J. o. O. R. (2008). The analytic hierarchy process in medical and health care decision making: A literature review. A lit. Rev. 189 (1), 194–207. doi:10.1016/j.ejor.2007.05.001

Liou, J. J., Chuang, Y.-C., Zavadskas, E. K., and Tzeng, G.-H. J. J. o. C. P. (2019). Data-driven hybrid multiple attribute decision-making model for green supplier evaluation and performance improvement. J. Clean. Prod. 241, 118321. doi:10.1016/j.jclepro.2019.118321

Masri, H. A., and Jaaron, A. A. J. J. o. c. p. (2017). Assessing green human resources management practices in Palestinian manufacturing context: An empirical study. An Empir. study 143, 474–489. doi:10.1016/j.jclepro.2016.12.087

McDermott, O., Antony, J., Bhat, S., Jayaraman, R., Rosa, A., Marolla, G., et al. (2022). Lean six sigma in healthcare: A systematic literature review on challenges, organisational readiness and critical success factors. Organ. readiness Crit. success factors 10 (10), 1945. doi:10.3390/pr10101945

Mohan, J., Rathi, R., Kaswan, M. S., and Nain, S. S. J. M. T. P. (2022). Green lean six sigma journey: Conceptualization and realization. Mater. Today Proc. 50, 1991–1998.

Nagadi, K. J. I. J. o. P. M. (2022). Implementation of green, lean and six sigma operations for sustainable manufacturing. A Rev. 10 (2), 159–171. doi:10.4995/ijpme.2022.16958

Pereira, A. M., Silva, M. R., Domingues, M. A., and Sá, J. C. J. Q. I. P. (2019). Lean six sigma approach to improve the production process in the mould industry: A case study. A case study 23 (3), 103–121. doi:10.12776/qip.v23i3.1334

Raja Sreedharan, V., and Raju, R. J. I. J. o. L. S. S. (2016). A systematic literature review of Lean Six Sigma in different industries. Int. J. Lean Six Sigma 7 (4), 430–466. doi:10.1108/ijlss-12-2015-0050

Raval, S. J., Kant, R., and Shankar, R. J. B. A. I. J. (2019). Benchmarking the lean six sigma performance measures: A balanced score card approach. Benchmarking An Int. J. 26 (6), 1921–1947. doi:10.1108/bij-06-2018-0160

Ruben, R. B., Vinodh, S., and Asokan, P. J. T. I. J. o. A. M. T. (2018). Lean six sigma with environmental focus: Review and framework. Int. J. Adv. Manuf. Technol. 94, 4023–4037. doi:10.1007/s00170-017-1148-6

Saldaña, J. J. T. c. m. f. q. r. (2021). The coding manual for qualitative researchers. Newbury Park, CA, USA: SAGE, 1–440.

Sarkis, J., Zhu, Q., and Lai, K.-h. J. I. j. o. p. e. (2011). An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 130 (1), 1–15. doi:10.1016/j.ijpe.2010.11.010

Seuring, S., and Müller, M. J. J. o. c. p. (2008). From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 16 (15), 1699–1710. doi:10.1016/j.jclepro.2008.04.020

Shamsi, M. A., and Alam, A. J. I. J. o. L. S. S. (2018). Exploring lean six sigma implementation barriers in information technology industry. Int. J. Lean Six Sigma 9 (4), 523–542. doi:10.1108/ijlss-06-2017-0054

Shen, B. J. S. (2014). Sustainable fashion supply chain: Lessons from H&M. Lessons H&M 6 (9), 6236–6249. doi:10.3390/su6096236

Singh, P. J., and Smith, A. J. J. J. o. M. T. M. (2004). Relationship between TQM and innovation: An empirical study. J. Manuf. Technol. Manag. 15 (5), 394–401. doi:10.1108/17410380410540381

Sodhi, H. S., Singh, D., Singh, B. J. J. I. J. o. S. S., and Advantage, C. (2019). An empirical analysis of critical success factors of Lean Six Sigma in Indian SMEs. Int. J. Six Sigma Compet. Advant. 11 (4), 227–252. doi:10.1504/ijssca.2019.103556

Stankalla, R., Koval, O., and Chromjakova, F. J. Q. E. (2018). A review of critical success factors for the successful implementation of Lean Six Sigma and Six Sigma in manufacturing small and medium sized enterprises. Qual. Eng. 30 (3), 453–468. doi:10.1080/08982112.2018.1448933

Tensay, A. T., and Singh, M. J. H. (2020). The nexus between HRM, employee engagement and organizational performance of federal public service organizations in Ethiopia. Heliyon 6 (6), e04094. doi:10.1016/j.heliyon.2020.e04094

Thakur, A. J. A. o. M. S. J. (2022). Employee branding for marketing brand: A brand positioning strategy through aligning culture and hrm practices. Acad. Mark. Stud. J. (AMSJ) 26 (5).

Thomas, A. J., Ringwald, K., Parfitt, S., Davies, A., John, E. J. I. J. o. Q., and Management, R. (2014). An empirical analysis of Lean Six Sigma implementation in SMEs–a migratory perspective. Int. J. Qual. Reliab. Manag. 31 (8), 888–905. doi:10.1108/ijqrm-04-2013-0070

Tjahjono, B., Ball, P., Vitanov, V. I., Scorzafave, C., Nogueira, J., Calleja, J., et al. (2010). Six sigma: A literature review. Six. Sigma a Lit. Rev. 1 (3), 216–233. doi:10.1108/20401461011075017

Trakulsunti, Y., Antony, J., and Douglas, J. A. J. T. T. J. (2020). Lean Six Sigma implementation and sustainability roadmap for reducing medication errors in hospitals. TQM J. 33 (1), 33–55. doi:10.1108/tqm-03-2020-0063

Tucci, H. N. P., de Oliveira Neto, G. C., Rodrigues, F. L., Giannetti, B. F., de Almeida, C. M. V. B. J. R., and Reviews, S. E. (2021). Six sigma with the blue economy fundamentals to assess the economic and environmental performance in the aircraft refueling process. Renew. Sustain. Energy Rev. 150, 111424. doi:10.1016/j.rser.2021.111424

Van den Heuvel, J., Does, R. J., De Koning, H. J. I. J. o. S. S., and Advantage, C. (2006). Lean six sigma in a hospital. Lean Six Sigma a Hosp. 2 (4), 377–388. doi:10.1504/ijssca.2006.011566

Vashishth, A., Chakraborty, A., Antony, J. J. T. Q. M., and Excellence, B. (2019). Lean six sigma in financial services industry: A systematic review and agenda for future research. Total Qual. Manag. Bus. Excell. 30 (3-4), 447–465. doi:10.1080/14783363.2017.1308820

Walker, P. H., Seuring, P. S., Sarkis, P. J., Klassen, P. R. J. I. J. o. O., and Management, P. (2014). Sustainable operations management: Recent trends and future directions. Int. J. Operations Prod. Manag. 34 (5). doi:10.1108/ijopm-12-2013-0557

White, D. E., Oelke, N. D., and Friesen, S. J. I. j. o. q. m. (2012). Management of a large qualitative data set: Establishing trustworthiness of the data. Establishing Trust. data 11 (3), 244–258. doi:10.1177/160940691201100305

Willis, J. W. (2008). Qualitative research methods in education and educational technology. Newbury Park, CA, USA: SAGE.

Womack, J. P., and Jones, D. T. J. J. o. t. O. R. S. (1997). Lean thinking—Banish waste and create wealth in your corporation. J. Oper. Res. Soc. 48 (11), 1148. doi:10.1038/sj.jors.2600967

Womack, J. P., Jones, D. T., and Roos, D. (2007). The machine that changed the world: The story of lean production--Toyota's secret weapon in the global car wars that is now revolutionizing world industry. New York, NY, USA: Simon & Schuster.

Wu, T., Wu, Y.-C. J., Chen, Y. J., and Goh, M. J. I. J. o. P. E. (2014). Aligning supply chain strategy with corporate environmental strategy: A contingency approach. Int. J. Prod. Econ. 147, 220–229. doi:10.1016/j.ijpe.2013.02.027

Yadav, G., Desai, T. N. J. I. J. o. Q., and Management, R. (2017). A fuzzy ahp approach to prioritize the barriers of integrated lean six sigma. Int. J. Qual. Reliab. Manag. 34.

Yaduvanshi, D., and Sharma, A. J. J. o. H. M. (2017). Lean six sigma in health operations: Challenges and opportunities—‘Nirvana for operational efficiency in hospitals in a resource limited settings. J. Health Manag. 19 (2), 203–213. doi:10.1177/0972063417699665

Zhang, X., Luo, L., and Skitmore, M. J. J. o. C. P. (2015). Household carbon emission research: An analytical review of measurement, influencing factors and mitigation prospects. J. Clean. Prod. 103, 873–883. doi:10.1016/j.jclepro.2015.04.024

Keywords: manufacturing industry, Lean Six Sigma methodology, environmental performance, data-driven decision-making, sustainable manufacturing practices, thematic analysis, company culture, competitive marketplace

Citation: Huang J, Irfan M, Fatima SS and Shahid RM (2023) The role of lean six sigma in driving sustainable manufacturing practices: an analysis of the relationship between lean six sigma principles, data-driven decision making, and environmental performance. Front. Environ. Sci. 11:1184488. doi: 10.3389/fenvs.2023.1184488

Received: 11 March 2023; Accepted: 15 May 2023;

Published: 01 June 2023.

Edited by:

Rongrong Li, China University of Petroleum, ChinaReviewed by:

Sarina Abdul Halim-Lim, Putra Malaysia University, MalaysiaHamed Fazlollahtabar, Damghan University, Iran

Copyright © 2023 Huang, Irfan, Fatima and Shahid. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Muhammad Irfan, ZHIubWlyZmFuQGJ6dS5lZHUucGs=

Jing Huang1

Jing Huang1 Muhammad Irfan

Muhammad Irfan Syeda Saman Fatima

Syeda Saman Fatima Rao Muhammad Shahid

Rao Muhammad Shahid