94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Environ. Sci., 10 August 2022

Sec. Water and Wastewater Management

Volume 10 - 2022 | https://doi.org/10.3389/fenvs.2022.960639

Paper mills generate large quantities of wastewater and sludge waste depending on the type of paper making processes employed. This poses several problems regarding wastewater treatment, discharge, and sludge disposal. Whenever wastewater is generated, it should be treated in wastewater treatment plants prior to being released to the environment since it can be polluting and dangerous. A study was conducted at Star Paper Mills Ltd. Saharanpur, UP to demonstrate the existing and advanced technologies for wastewater treatment. The mill uses woody raw materials such as eucalyptus, poplar, and veener chips to manufacture a wide range of industrial and cultural grade papers, such as absorbent kraft, maplitho, azure lay, and copier. We observed that the most common excess back water is from paper machines, bleach plant effluent, floor cleaning, and other sources of wastewater. High chemical oxygen demand (COD), biochemical oxygen demand (BOD), and low biodegradability are all characteristics of pulp and paper wastewater. Approximately 85–90% of the fresh water utilized is wasted. We examined the wastewater collected and evaluated from the paper mill by Central Pulp and Paper Research Institute (CPPRI). The Effluent treatment plant (ETP) at Star Paper Mills Ltd. is sufficient to facilitate satisfactory removal of suspended matter in clarifiers and oxidation of biodegradable organic matter in aeration tank. As a matter of fact, if the ETP is operated under optimal conditions, the aeration capacity is sufficient to effectively treat even higher BOD loads than the existing load.

1. The pulp and paper industry has long been regarded as one of the most significant consumers of natural resources, energy, and a major polluter of the environment. It generates a huge number of pollutants because of pulping and manufacturing paper goods, the composition of which varies depending on the manufacturing method. In terms of wastewater generation, the pulp and paper industry ranks third (Liu et al., 2008; Ashrafi et al., 2015; Xu et al., 2022). Water is produced throughout the manufacturing process because of numerous activities such as wood preparation, pulping, pulp washing, bleaching, and coating processes. Figure 1 depicts the pulp and paper industry’s production flow chart. These industries require a large number of lignocellulosic plant components and utilize chemicals during the manufacturing process, and they are often considered polluting industries due to the large amount of waste material that enters the environment. Increased economic concerns and tight environmental rules arose as a result of the growing demand for freshwater. This exercise emphasizes the use of water and appropriate wastewater treatment procedures in the pulp and paper sector (Irfan et al., 2022; Ali et al., 2021; Zhang et al., 2022; Khan et al., 2022; Dagar et al., 2021c; Dagar et al., 2022). Only when wastewater is adequately treated, it can be successfully reused, reducing the amount of freshwater utilized. As a result, the amount of wastewater emitted into the atmosphere will be reduced (Liu et al., 2011; Fang et al., 2021; Zhang et al., 2022). Water recovery and reuse, on the other hand, can raise organic and inorganic concentrations, which can impact paper formation, increase the bacterial load, or cause corrosion and stink. As a result, an appropriate advanced wastewater treatment system must be adopted to solve this (Chiavola et al., 2014; Bai et al., 2019; Chen et al., 2022).

For instance, the process of pulping involves the separation the fibers and creation of a fiber suspension in water. Mechanical, thermal, and chemical energy, in various amounts, can be used to achieve this separation (Ge et al., 2019; Lin et al., 2021; Dai et al., 2022). The most significant sources of contamination from various stages of the process are: wood preparation, pulping, pulp washing, screening, bleaching, papermaking, and coating operations, depending on the method. The type of wood, the type of operation, the amount of water that the mill can circulate, the technology utilized, and the management techniques adopted all influence the properties of the waste liquid to be treated (Chauhan et al., 2021; Bhardwaj M. et al., 2022; Shaikh et al., 2021; Tillaguango et al., 2022; Islam et al., 2022). Untreated waste fluids might have significant biological oxygen demand (BOD), chemical oxygen demand (COD), suspended particles (primarily fibers), fatty acids, tannins, resin acids, lignin, and its derivatives, depending on the raw material and the procedure involved (Kamali and Khodaparast, 2015). Some are naturally occurring contaminants, while others are xenobiotics created during the pulp and paper production process. Some compounds resist biological decomposition and are harmful to aquatic organisms (Liu et al., 2020; Guan et al., 2021; Ge et al., 2022). It is reported that pulp and paper wastewater contains around 700 organic and inorganic chemicals, including adsorbable organic halogens (AOX), colour, and phenolic compounds (Karrasch et al., 2006). Some bleaching methods produce bioaccumulative chemicals.

In a recent study, researchers have reported that bleaching effluents have high BOD and COD levels, as well as a lot of suspended particles, fatty acids, tannins, resin acids, and lignin and its derivatives (Singh et al., 2019). These suspended solids, organic substances, chromophoric compounds, inorganic compounds, and salts are all characteristics of high yield pulping wastewaters (Yuan et al., 2022; Wen et al., 2022; Zakari et al., 2022; Bhardwaj et al., 2022). In addition to the foregoing, semi-chemical procedures use lignosulfonates. Solids dissolved organics, and chromophoric chemicals are all measured in the Kraft process wastewaters. If Kraft pulps are bleached with chlorine chemicals, organochlorine compounds may be present (Achoka, 2002). Table 1 shows examples of beginning COD for high yield pulping and Kraft pulping. Furthermore, there is a variation in the physiochemical characteristics among the size of paper mills i.e., small and large paper mills. Table 2 summarizes the physio-chemical characteristics of small and large paper mills (Murshed et al., 2021a; Dagar et al., 2020b; Cao et al., 2022).

Thus it has become a significant task to understand the physio-chemical characteristics of wastewater from the pulp and paper making process.

Color, odour, temperature, and solids content are the most important physical features of wastewater (Ammary, 2004).

Because of considerable bacterial breakdown, wastewater appears dark grey or black in colour, indicating that it is septic. Under anaerobic septic conditions, sulphides such as ferrous sulphide, hydrogen sulphide, and the creation of divalent metal irons increase the colour of the effluent.

Fresh wastewater has a pleasant odour, but when it is digested biologically under anaerobic conditions for 3–4 h, odorous chemicals are emitted. As a result, hydrogen sulphide and other sulphur compounds are released, increasing the odour.

Temperature measurement is critical because most wastewater treatment plans contain temperature-sensitive biological processes. The temperature of wastewater varies depending on the season and geographic region. Temperatures in colder places will range from 7 to 18°C, while temperatures in warmer regions will range from 13 to 24°C.

Insoluble or suspended solids, as well as soluble chemicals dissolved in water, make up total solids in wastewater. The suspended solids concentration is determined by drying and weighing the residue left after the sample has been filtered (Islam et al., 2021; Tillaguango et al., 2021; Murshed et al., 2021b). Proteins, carbohydrates, and lipids make up the majority of organic matter.

Turbidity is the cloudiness or haziness of fluids with suspended solid matter, which is made up of particles of various sizes; it is caused by suspended and colloidal particles in wastewater. Due to the growth of algae, the anaerobic process, and gas production noted by Pavanelli and Bigi, it will rise (Pavanelli and Bigi, 2005; Işık, 2013; Işık et al., 2022). A nephlometer with a light source and one or more photoelectric detectors read out mechanism at right angles to the stream of light can be used to measure it.

For reusing treated wastewater, inorganic phosphorus, chloride, sulphate, pH, and alkalinity are being evaluated. The growth of aquatic plants is fueled by nitrogen and phosphorus. Heavy metals that are not consistently determined as trace elements must be considered for biological wastewater treatment. The growth of organisms in water requires trace elements such as cobalt, copper, iron, and zinc [Işık et al., 2020; Ahmad et al., 2021; Irfan et al., 2021; Işık et al., 2021]. However, if the number of heavy metals in the environment exceeds a certain level, it might be harmful. As a result, characterization of treated effluent and settling sludge is critical.

The biodegradability of the organic matter contained in the wastewater is measured by BOD. It is reflected by the microorganism’s consumption of oxygen to oxidize the waste present in the wastewater at a specific period (Işık et al., 2021; Rehman et al., 2021; Murshed et al., 2021a; Alvarado et al., 2021; Fahad et al., 2022). A high BOD level in wastewater indicates a considerable amount of degradable organic matter. The amount of oxygen required for the full breakdown of organic matter is also represented by COD. COD produces dissolved raw materials, chemicals to aid the pulping process, and substances generated during the pulping process, all of which have major environmental consequences. The COD value in pulp and paper mill effluent is determined by the paper making process (Thompson et al., 2005). The BOD/COD ratio is a critical statistic for determining the biodegradability of a contaminant in wastewater. When the ratio is larger than 0.5, the organic pollutant contained in the wastewater has a high biodegradability, while when it is less than 0.3, it has a low biodegradability.

The total quantity of carbon in organic compounds such as suspended particulate matter, colloidal particles, BOD, and COD is referred to as TOC. It is feasible to relate and identify the BOD and COD values using the TOC value to determine the typical wastewater.

The alarming issue regarding the use of freshwater, vis-a-vis stringent environmental regulations calls for the need for water use and efficient wastewater treatment in the pulp-and-paper industry. Thus, the recycling and reuse of the generated wastewater after its proper treatment is the key to reducing freshwater use. This approach will in turn minimize effluent discharge to the environment and at the same time conserve the environment by reducing freshwater use. There are several wastewater treatment technologies whose major goal is to eliminate contaminants by combining physio-chemical, biological, and sophisticated treatment processes that encompass primary, secondary, and tertiary treatment.

Primary treatment in the pulp and paper industry is accomplished through various unit operations such as screening, mixing, sedimentation, filtration, dissolved air floatation, and sedimentation, all of which remove a small amount of organic material in the form of suspended solids. At surface loading rates of up to 1.4 m3/m2 h, it removes around 80% of suspended particles from wastewater. Drying, incineration, freezing, dialysis, osmosis, and adsorption are all part of the process.

Aerated lagoons, aerobic reactors, and anaerobic reactors are used to treat pulp and paper mill effluent. The activated sludge technique is the most frequent biological treatment method (ASP). For the removal of COD, BOD, TSS, and AOX in pulp and paper mill effluent, it consists of an aeration tank with complete mixing followed by a secondary clarifier. The aerobic bacteria’ oxygen needs are met by distributed aerators or a shaft mechanical aeration system. According to Bajpai and Bajpai (Bajpai and Bajpai, 1994), the removal of AOX ranges from 15 to 65%, while the elimination of specific chlorinated organics such as chlorinated phenols, catechols, guaiacols, and vanillins can range from 20 to 100%. The ASP that treats wastewater from paper mills appears to be particularly prone to thickening. It contributes to sludge’s low settleability, resulting in poor wastewater quality. Hydraulic variation, organic load variation, and filamentous bulking all have a negative impact on depollution operations in pulp and paper wastewater treatment plants (Clauss et al., 1999). It improves the removal of particles in the wastewater in the form of suspended dissolved solids (Işık et al., 2021a; Işık et al., 2021b; Mohamed et al., 2019).

Membrane processes, ultra-filtration, coagulation, metal salt precipitation, and advanced oxidation processes are some of the tertiary treatment methods used in the pulp and paper industry to remove residual COD, toxicity, total solids, and colour (Murshed et al., 2021a; Dagar et al., 2020a; Saroha et al., 2021; Khan et al., 2022a; Khan et al., 2022b). In order to comply with stricter restrictions regarding the quality of wastewater entering bodies of water. In many sectors, tertiary treatment is an option. It is done based on the wastewater’s quality. The goal of tertiary treatment is to eliminate contaminants from wastewater and ensure that effluent is safely discharged into the environment. Pollution in water bodies is reduced by internal reuse, recycling, and recovery of by-products. Chemical coagulation-flocculation followed by sedimentation is a widely used procedure for SS removal that can be used as a tertiary treatment for pulp and paper effluents (Pokhrel and Viraraghavan, 2004; Mainardis et al., 2020).

Microorganisms are used in biological treatment to break down the organic materials in wastewater. Adjusting pH in biological treatment of pulp mill wastewater utilising sequential batch reactors does not result in a substantial improvement in COD removal (Dubeski et al., 2001). Based on their oxygen requirements, bacteria are classified as aerobic, anaerobic, or facultative. The bacteria make contact with the organics and use it as food for their growth in order to eliminate the trash from the wastewater. The secondary biological treatment coagulates and removes both organic and inorganic non-settling colloidal particles that could not be eliminated in the main treatment unit. Biological treatment is used to stabilize the dissolved organic matter that remains in the effluents after basic treatment.

The removal of dissolved and fine colloidal organic materials necessitates biological wastewater treatment. The decomposition can be either slow or fast, depending on the type of dehydrogenation. Biological treatment can be categorized into the following types.

The organic stuff is consumed by aerobic microorganisms. Bacteria, algae, fungus, protozoa, rotifers, and other organisms make up active biomass. In the presence of oxygen, these organisms convert biodegradable organic matter into non-biodegradable compounds such as CO2 and H2O. Contact beds, ASPs, and trickling filters are examples of aerobic treatment methods. Biodegradable organic matter, oxygen nutrients, the absence of hazardous matter, and favourable environmental variables such as pH, temperature, hydraulic retention durations, and solids retention times are all basic prerequisites for any aerobic biological treatment.

The designed methanogenic anaerobic breakdown of organic matter with diverse species of anaerobic bacteria is defined as the anaerobic treatment process. In the absence of dissolved oxygen, anaerobic microbes transform organic substrates into stable compounds such as carbon dioxide, methane, and water. Up-flow anaerobic sludge blanket reactors, anaerobic sludge digestion, and rotating biological contractors are examples of anaerobic treatment technologies. Another study discovered that excessive viscosity is an issue in the anaerobic digestion of pulp and paper mills for biogas production (Morgan-Sagastume et al., 2014). The advantage of the anaerobic treatment is that it produces biogas based on the substrate’s characteristics, but it requires more maintenance, has a longer startup time, and is difficult to manage biomass (Mahat et al., 2021).

Biological processes are categorized into suspended growth systems and attached growth systems based on the status of biomass in the reactor. The microorganisms in suspended growth systems are suspended in mid-air while treating wastes. Organic elimination, nitrification, and denitrification are all part of this process. Anaerobic digestion, anaerobic contact method based on the suspended growth process, ASP, aerated lagoons, Sequencing Batch Reactor (SBR), ASP. Microorganisms linked to the media in the reactor treat the wastes during the wastewater treatment process. The wastes that are being treated pass through the media. This method is utilized for organics removal, nitrification, and denitrification. The associated growth process operates trickling filters, roughing filters, rotating biological contractors, packed bed anaerobic filter, and extended bed. Table 3 compares the advantages of these two processes for a better understanding of the process benefits (Razali et al., 2012).

Both organic and inorganic dissolved solids are removed. A variety of strategies for removing inorganic components from wastewater have been researched. Ion exchange, electrodialysis, and reverse osmosis are three technologies that are widely used in advanced waste treatment. Adsorption on activated carbon is the most popular method for removing soluble organics from wastewater. Solvent extraction is also utilized to recover certain organic compounds from industrial waste fluids, such as phenol and amines.

Hardness, iron, and manganese salts have all been removed from drinking water supplies using this method. It is also been used to remove certain pollutants from industrial waste and recover important trace metals like chromium, nickel, copper, lead, and cadmium. The method takes advantage of certain natural and manufactured materials’ ability to exchange one of their ions. Ion exchange characteristics can be found in a variety of naturally occurring minerals. The aluminium silicate minerals known as zeolites are among the most remarkable. Sodium silicate and sodium aluminate solutions were used to make synthetic zeolites. Synthetic ion-exchange resins made of organic polymers with connected functional groups, such as—COO—3 –SO H + H+ (weakly acidic cation exchange resins), or—N+(CH3)3OH (strongly basic anion exchange resins) can also be employed. Hardness-producing components like calcium and magnesium are replaced by sodium ions during the water softening process (Dagar et al., 2021b; Wei et al., 2022; Xiang et al., 2022). A sodium-based cation exchange resin is typically utilized. When sodium ions in the resin are exchanged for calcium ions in solution, cation exchange has the power to soften water. De-mineralization water is created by driving water through semipermeable membranes at high pressure in the reverse osmosis process. When a vessel is divided by a semipermeable membrane (one that is permeable to water but not to dissolved material) and one compartment is filled with water and the other with concentrated salt solution, water diffuses through the membrane towards the compartment containing salt solution until the difference in water levels on the two sides of the membrane creates enough pressure to counteract the original water flow (Khan et al., 2022; Dagar et al., 2021a; Tang et al., 2022). The osmotic pressure of the fluid is represented by the difference in levels.

RO can be used to treat industrial wastewater. Some of the industries that employ the RO method are as follows:

1) Colorings-containing outflows are treated, with the possibility of their recovery.

2) Treatment of oily emulsions, latex, and electrophoretic paints in outflows.

3) Treatment of metal-finishing industrial effluents with the recovery of concentrated metal salt solutions and reuse of water for cleaning

4) Treatment of organic chemical wastewater in the organic chemical and pharmaceutical sectors

The use of RO for wastewater treatment differs greatly from the use of the technology for general process water purification (Figure 2). This is owing to the fact that wastewater typically contains larger amounts of pollutants and a wider variety of toxins. Furthermore, there is a lot of variation in industrial wastewaters. Wastewaters differ from one industry to the next, and they might alter from 1 h to the next at any one plant. The protection against organic fouling, mineral scaling, and chemical degradation is the most significant component in treating industrial wastewater with RO. Before considering RO, a full cation/anion balance is essential, as well as the identification of possible flocculants. Calcium, iron, aluminum, and other insoluble heavy metals are all potential inorganic foulants and sealants for RO membranes. Surfactants, colour bodies, flocculants, and bacteria are all examples of organic foulants. Membrane fouling can also be caused by high BOD and COD levels. Pretreatment methods come in a variety of shapes and sizes. Rinse-waters from fabrication operations are generally cleaned to remove heavy metals and subsequently released to the sewer, particularly in the metal finishing, printed circuit board, and microelectronics industries. Total dissolved solids in wastewater discharged to sewers typically range from 200 to 10,000 parts per million (ppm) (TDS). This wastewater can be treated and recycled with the right pretreatment technology and RO. The RO product water can be further polished with ion exchange treatment, making it ideal for all rinses. Because the pH, oxidizing potential, and concentration of soluble salts in wastewater effluents frequently exceed the working limitations of RO systems, it is vital to examine each unique application in order to build a successful and cost-effective system (Krishnan and Dagar, 2022; Basantwani et al., 2021; Xie et al., 2022; Weimin et al., 2022; Javed et al., 2022). After completing a thorough analysis of the wastewater, decide the optimal preconditioning chemical and choose the best pretreatment technology for the application. The reverse osmosis process produces a waste stream with a high TDS content. Feedwater will yield approximately 25–40% of waste rejects with high TDS concentrations. To concentrate and remove organic pollutants from this waste, it must be evaporated in forced evaporation systems.

Microorganisms play a vital role in the degradation of pollutants present in the wastewater. The most important ones include bacteria, fungus, algae, protozoa and rotifers. Bacterial species of Bacillus, Pseudomonas, Acinetobacter, Achromobacter and fungal species of Fusarium, Phanero chaetechrysosporium, Corious versicolor, Ralstonia, Streptomyces are also proved to be efficient fungal groups that evidenced degradation pollutants (Lacey et al., 2012). These microorganisms treat the wastewater mainly by enzyme action and biosorption (Othman et al., 2013).

Biokinetics plays a vital role in the operation of aerobic wastewater treatment systems, based on the biochemistry and microbiology of the aerobic treatment. The process of biokinetics is essential for the rational design and operation, predicting system stability, effluent quality and waste stability. The performance of biological processes used for wastewater treatment depends on the dynamics of substrate utilization and microbial growth. Effective design and operation of such system require an understanding of the biological reactions occurring and an understanding of the basic principles governing the growth of microorganisms (Abdullah et al., 2005). Jacques Monod proposed an equation to relate microbial growth rates in an aqueous environment to the concentration of a limiting nutrient. It is a mathematical model equation for the growth of microorganisms involved in the wastewater treatment (Dagar et al., 2020c; Singh et al., 2021; Zakari et al., 2021; Shahzad et al., 2022). The empirical coefficient of the equation differs from species to species and based on the environmental conditions.

The Monod equation

where μ is the specific growth rate.

μmax is the maximum specific growth rate.

S is the concentration substrate.

Ks is the half-velocity constant.

The proportionality constants obtained from the kinetics equations derived for the above rates are known as biokinetic constants or growth constants. The objectives of the biokinetics study are as follows.

1) To describe the development of microbes within the bioreactor.

2) To predict the effluent microbes and substrate concentrations by developing suitable mathematical models.

3) To study the effect of biokinetics on the process design, performance and stability of treatment process

Several types of research have been conducted to assess and analyze the characteristics of effluents and their composition in wastewater. A study showed that the chemical oxygen demand (COD) levels of greater than 10,000 mg/L and total suspended solids as the primary contaminants in PPW (TSS) (Liang et al., 2021). Some researchers demonstrated that the pulp and paper industry is infamous for consuming large amounts of fresh water and producing harmful effluents (Singh and Chandra, 2019). Another study showed high chemical oxygen demand (COD), large biological oxygen demand (BOD), and low biodegradability (reported as BOD/COD ratio) in pulp and paper wastewater (Kamali and Khodaparast, 2015). A study on Bleaching effluents having high BOD and COD levels, as well as a lot of suspended particles (primarily fibres), fatty acids, tannins, resin acids, and lignin and its derivatives is also reported (Singh et al., 2019). Some researchers from the USA demonstrated that the direct reaction (promoted by ozone itself) and the indirect response of OH radicals produced during ozonation treatment are both involved in ozone application (McBride et al., 2019). In another research work, a group of researchers from China and New Zealand studied on the pulp and paper black liquor treatment, ozonation alone and combination UV/ozonation, process efficiency analysis utilizing various operating parameters, and data regression (Li et al., 2019). Two Indian researchers demonstrated that lignin, hemicelluloses, benzoic acid, phenylacetic acid, hexadecenoic acid, octadecanoic acid, phenol, p-cresol, benzophenone, diethyl phtanlate, and alkyl halides are all components of PPW pollutants, and they are resistant to degradation and removal (Yadav and Chandra, 2018). It is learnt that the physicochemical mechanisms for PPW pollutant removal are very well understood, however there are fewer information on biological pollutant elimination pathways (Wilks and Scholes, 2018). Furthermore, a study showed that the pulp and paper wastewater (PPW) make for 42% of the three billion tons of industrial wastewater produced worldwide (Toczyłowska-Mamińska, 2017). It is aloso reported that ozonation is useful for eliminating color and oxidizing refractory organics, especially in industrial wastewater treatment, but also in effluent disinfection (Lazarova et al., 2013).

Keeping the above discussion in view, the objective of our study is set.

In our study, we aim to evaluate the efficacy of existing ETPs for treating wastewater generated by the pulp and paper making process in a selected paper mill in India. The study is based on Central Pulp and Paper Research Institute (CPPRI)’s pollutant load assessment and information provided by the paper mill regarding its current maximum working capacity.

Duncan Goenka Group’s flagship company, Star Paper Mills Ltd., is an integrated pulp and paper plant in Saharanpur, Uttar Pradesh (Figure 3). The mill uses woody raw materials such as eucalyptus, poplar, and veener chips to manufacture a wide range of industrial and cultural grade papers, such as absorbent kraft, maplitho, azure lay, and copier. The mill has four paper machines with a 300 tpd installed capacity. Even though the mill uses traditional chlorine bleaching technology, it also uses an oxidative extraction stage that involves oxygen and peroxide. CEOPHH is the actual bleaching sequence. Furthermore, the mill has implemented Oxygen Delignification prior to bleaching to reduce the consumption of bleach chemical requirements in following pulp bleaching through bleaching sequence and overall pollution load reduction.

Water is used extensively in the papermaking process. The amount of freshwater consumed is determined by the raw material utilized, the procedure performed, and the quality of the final product. Freshwater (groundwater) is first abstracted at Star Paper Mills Ltd. via borewell. The total number of borewells is ten, but only five are operational at any given time. The remaining five borewells are maintained on standby and gathered in a reservoir before being transferred to different areas of the mill as needed (Figure 4). A flow meter is installed in the borewell. The usage of freshwater by section is shown in Table 4. It is observed that paper machine and stock preparation consumes the highest (3,500 m3/day) amount of water compared to other processes which is followed by the pulping process i.e. 2850 m3/day.

The layout of the existing ETP at the paper mill is shown in Figure 5. The current ETP is based on the traditional activated sludge process and comprises mostly of a primary clarifier, an aeration tank, and a secondary clarifier. A belt press is also installed at the mill for dewatering primary and secondary sludge. After screening through a bar screen, the mill effluent is fed into a primary clarifier to remove suspended solids (Figure 6). To reduce pollution load, the primary clarifier overflow is pumped into the aeration tank for biological treatment (Figure 7). The aeration tank is equipped with 12 surface aerators (each with 50 HP) and a 50 HP blower to provide distributed aeration to maintain the dissolved oxygen level essential for appropriate microbial metabolic activity. The vital nutrient is introduced to the aeration tank to aid in the growth of microorganisms. Using a sludge filter press, the primary clarifier’s underflow is further dewatered to around 30% consistency (Figure 8). Sludge that has been dewatered is sold to board mills. The secondary clarifier’s (Figure 9) underflow is recycled back into the aeration tank to maintain the MLSS level (3,000 mg/L), and the rest is dewatered using the Volute Press (Figure 10). The treated wastewater is released into the Hindon River at a distance of roughly 3 km via a concrete underground drain. The mill has placed an OCEMS at the final output to monitor the quality of treated effluent 24 h a day, 7 days a week (Figure 11).

FIGURE 7. The aeration tank overflow is processed further with a secondary clarifier to remove suspended active biomass.

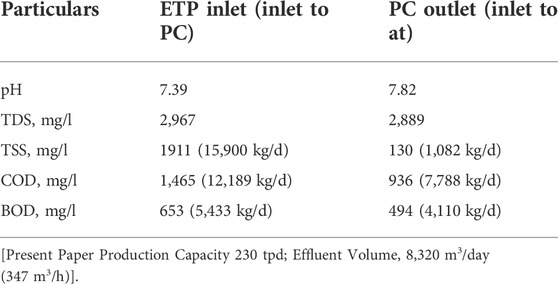

Excess backwater from paper machines, bleach plant effluent, floor cleaning, and other sources of wastewater are the most common. Approximately 85–90% of the freshwater utilized is wasted. Table 5 shows the average parameters of wastewater collected following composite sampling and evaluated at CPPRI.

TABLE 5. Average characteristics of wastewater collected and pollution load generated at star paper mills Ltd.

The adequacy of the various units of the existing ETP at Star Paper Mills Ltd. was assessed based on influent retention time in each unit, surface overflow rate in primary and secondary clarifiers, volumetric loading rate, and estimation of oxygenation capacity of existing aerators in the aeration tank for oxidation/degradation of BOD load available. Table 6 summarizes the assessment of ETP adequacy.

To achieve the designed performance from ETP, it is necessary to operate it under optimum conditions to meet the environmental discharge standards. Following are the suggested measures, the mill should adopt for proper and optimum operation of ETP:

1) Ensure proper and optimum conditions as per the designed specification and manufacturer’s instruction.

2) Ensure proper addition of nutrients in aeration tank as per thumb rule BOD: N: P - 100:5:1 to facilitate the growth of microbes and maintain an adequate level of MLSS.

3) Maintain the required level of MLSS concentration (2,500–3,000 mg/L) in the aeration tank by ensuring proper microbial growth.

4) Maintain desired level of DO in the aeration tank (1–2 mg/L).

5) Ensure periodic and timely withdrawal of sludge from the clarifiers.

6) Proper maintenance of electric motors and pumps etc.

7) Use of coagulant and effective settling of suspended solids in the primary clarifier.

8) In addition to the above, routine testing of major pollution parameters viz pH, TSS, COD, BOD is essential on daily basis to maintain the desired performance of ETP. The parameters of concern and the frequency of their analyses advised are as under.

The information on pH, TSS, TDS, COD, BOD, and color were recorded by CPPRI for the month of September 2021 (Table 7). Based on the studies conducted to assess the adequacy of the Effluent Treatment plant (ETP) at Star Paper Mills Ltd., Saharanpur, CPPRI has the following observations to make:

1) The retention time available in the primary clarifier, aeration tank and secondary clarifier are sufficient to facilitate satisfactory removal of suspended matter in clarifiers and oxidation of biodegradable organic matter in the aeration tank. More than 50% of TDS is removed from the primary clarifier outlet to the secondary clarifier outlet As per the information received (September 2021), the secondary clarifier was able to significantly reduce the TSS from 123 mg/L to 53 mg/L.

2) The number of surface aerators provided in ETP i.e., 11 × 50 HP = 550 HP, 1 × 30 HP = 30 HP and 1 × 50 HP air blower are adequate to provide sufficient oxygen for oxidation of biodegradable organic matter. In fact, the aeration capacity is adequate to treat an even higher BOD load than the existing BOD load provided the ETP is operated under optimum conditions. BOD is lowered from 356 mg/L at the outlet of primary clarifier to a sufficiently lower amount of 26 mg/L. Likewise, COD reduced from 894 mg/L to 252 mg/L.

3) The mill has significantly reduced its water consumption with the adoption of modern fiber line technologies like oxygen delignification, new pulp washers as well as optimization of process operations and water requirement process-wise, good housekeeping practices.

The most important step in developing a successful wastewater treatment technology is site characterization, which aids in determining the most appropriate and feasible method. Various technologies, such as ion-exchange methods to remove dissolved materials, are used in the process to assist in clean wastewater. Nonetheless, they can be employed in a regulated manner to remediate a wide spectrum of contaminants. Despite significant technological improvements and achievements, wastewater treatment remains a critical issue internationally.

In this paper, we studied the WWTP in Star Paper Mills Ltd. Saharanpur, Uttar Pradesh, India. The paper mill comprises of an ETP which is based on the conventional activated sludge process. The ETP have a primary clarifier, an aeration tank, and a secondary clarifier. The following conclusions result from our study.

1) Primary clarifier, and secondary clarifier reduces all suspended matter in clarifiers

2) The aeration tank not only oxidises the biodegradable organic matter but also is capable to treat significantly higher BOD than rated value.

3) Adoption of technologies such as oxygen delignification and pulp washers helped the mill reduce water consumption

Due to its flexible design, operation, and cost-effectiveness, ETP appears to be the most frequent technology for removing heavy metals in wastewater among many wastewater treatment procedures. To make wastewater usable for other purposes, to eliminate pollutants and toxicants, to preserve the water quality of natural water resources, and to make wastewater useable for other reasons, advanced WWTP techniques in paper mills is required.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

SD Experiment and writing, SS supervision, MK proofreading.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abdullah, A. L., Idris, A., Ahmadun, F. R., Baharin, B. S., Emby, F., Noor, M. M. M., et al. (2005). A kinetic study of a membrane anaerobic reactor (MAR) for treatment of sewage sludge. Desalination 183 (1-3), 439–445. doi:10.1016/j.desal.2005.03.044

Achoka, J. D. (2002). The efficiency of oxidation ponds at the Kraft pulp and paper mill at Webuye in Kenya. Water Res. 36 (5), 1203–1212. doi:10.1016/s0043-1354(01)00325-6

Ahmad, M., Akhtar, N., Jabeen, G., Irfan, M., Khalid Anser, M., Wu, H., et al. (2021). Intention-based critical factors affecting willingness to adopt Novel Coronavirus prevention in Pakistan: Implications for future pandemics. Int. J. Environ. Res. Public Health 18 (11), 6167. doi:10.3390/ijerph18116167

Ali, S., Yan, Q., Hussain, M. S., Irfan, M., Ahmad, M., Razzaq, A., et al. (2021). Evaluating green technology strategies for the sustainable development of solar power projects: Evidence from Pakistan. Sustainability (Switzerland) 13 (23), 12997–29. doi:10.3390/su132312997

Alvarado, R., Tillaguango, B., Cuesta, L., Pinzon, S., Alvarado-Lopez, M. R., Işık, C., et al. (2022). Biocapacity convergence clubs in latin america: An analysis of their determining factors using quantile regressions. Environ. Sci. Pollut. Res. Int., 1–17. doi:10.1007/s11356-022-20567-6

Alvarado, R., Tillaguango, B., Dagar, V., Ahmad, M., Işık, C., Méndez, P., et al. (2021). Ecological footprint, economic complexity and natural resources rents in Latin America: Empirical evidence using quantile regressions. Journal of Cleaner Production 318, 128585. doi:10.1016/j.jclepro.2021.128585

Ammary, B. Y. (2004). Nutrients requirements in biological industrial wastewater treatment. Afr. J. Biotechnol. 3 (4), 236–238. doi:10.5897/ajb2004.000-2042

Ashrafi, O., Yerushalmi, L., and Haghighat, F. (2015). Wastewater treatment in the pulp-and-paper industry: A review of treatment processes and the associated greenhouse gas emission. J. Environ. Manag. 158, 146–157. doi:10.1016/j.jenvman.2015.05.010

Bai, B., Rao, D., Chang, T., and Guo, Z. (2019). A nonlinear attachment-detachment model with adsorption hysteresis for suspension-colloidal transport in porous media. J. Hydrol. (Amsterdam) 578, 124080. doi:10.1016/j.jhydrol.2019.124080

Bajpai, P., and Bajpai, P. K. (1994). Biological colour removal of pulp and paper mill wastewaters. J. Biotechnol. 33 (3), 211–220. doi:10.1016/0168-1656(94)90069-8

Basantwani, L. V., Sharma, S., Dagar, V., and Kharinta, K. (2021). Impact of national income and public expenditure on employment and its public-private sector composition in indian economy. International Journal of Agricultural and Statistical Sciences 17 (1), 213–222.

Bhardwaj, A., Dagar, V., Khan, M. O., Aggarwal, A., Alvarado, R., Kumar, M., et al. (2022). Smart IoT and machine learning-based framework for water quality assessment and device component monitoring. Environ. Sci. Pollut. Res. 29, 46018–46036. doi:10.1007/s11356-022-19014-3

Bhardwaj, M., Kumar, P., Kumar, S., Dagar, V., and Kumar, A. (2022). A district-level analysis for measuring the effects of climate change on production of agricultural crops, i.e., wheat and paddy: Evidence from india. Environ. Sci. Pollut. Res. 29 (21), 31861–31885. doi:10.1007/s11356-021-17994-2

Cao, H., Khan, M. K., Rehman, A., Dagar, V., Oryani, B., and Tanveer, A. (2022). Impact of globalization, institutional quality, economic growth, electricity and renewable energy consumption on carbon dioxide emission in OECD countries. Environ. Sci. Pollut. Res. 29 (16), 24191–24202. doi:10.1007/s11356-021-17076-3

Chauhan, S., Banerjee, R., and Dagar, V. (2021). Analysis of impulse buying behaviour of consumer during COVID-19: An empirical study. Millennial Asia, 097639962110412. doi:10.1177/09763996211041215

Chen, F., Aqeel, M., Maqsood, M. F., Khalid, N., Irshad, M. K., Ibrahim, M., et al. (2022). Mitigation of lead toxicity in vigna radiata genotypes by silver nanoparticles. Environ. Pollut. 308, 119606. doi:10.1016/j.envpol.2022.119606

Chiavola, A., Farabegoli, G., and Antonetti, F. (2014). Biological treatment of olive mill wastewater in a sequencing batch reactor. Biochem. Eng. J. 85, 71–78. doi:10.1016/j.bej.2014.02.004

Clauss, F., Balavoine, C., Hélaine, D., and Martin, G. (1999). Controlling the settling of activated sludge in pulp and paper wastewater treatment plants. Water Sci. Technol. 40 (11-12), 223–229. doi:10.2166/wst.1999.0716

Dagar, V., Ahmed, F., Waheed, F., Bojnec, Š., Khan, M. K., and Shaikh, S. (2022). Testing the pollution haven hypothesis with the role of foreign direct investments and total energy consumption. Energies 15 (11), 4046. doi:10.3390/en15114046

Dagar, V., Bansal, E., Murshed, M., Mishra, V., Alvarado, R., Kumar, A., et al. (2020). Stochastic frontier analysis to measure technical efficiency: Evidence from skilled and unskilled agricultural labour in india. Inter. J. Agricul. Stat. Sci. 16 (2), 647–657.

Dagar, V., Bhattacharjee, M., Ahmad, F., Charan, A., and Jit, P. (2020). A comparative stochastic frontier analysis for technical efficiency of irrigation in Haryana. Inter. J. Agricul. Stat. Sci. 16 (1), 199–209. doi:10.6084/m9.figshare.12949706.v1

Dagar, V., Jit, P., Bhattacharjee, M., Ahmad, F., and Pawariya, V. (2020). Stochastic frontier analysis for measuring technical efficiency of neem coated urea : Evidence from north India. Int. J. Agricult. Stat. Sci. 16 (1), 361–371.

Dagar, V., Khan, M. K., Alvarado, R., Rehman, A., Irfan, M., Adekoya, O. B., et al. (2021). Impact of renewable energy consumption, financial development and natural resources on environmental degradation in OECD countries with dynamic panel data. Environ. Sci. Pollut. Res. 29, 18202–18212. doi:10.1007/s11356-021-16861-4

Dagar, V., Khan, M. K., Alvarado, R., Usman, M., Zakari, A., Rehman, A., Murshed, M., et al. (2021). Variations in technical efficiency of farmers with distinct land size across agro-climatic zones: Evidence from India. J. Cleaner Prod. 315 (June), 128109. doi:10.1016/j.jclepro.2021.128109

Dagar, V., Tiwari, A. K., Mishra, S., Mahajan, V., Singh, S., Jit, P., et al. (2021). Covid 19 - risk management and technical efficiency of farmers post migration of agricultural labour in India. nt. J. Agricult. Stat. Sci 16, 965–977.

Dai, L., Wang, Z., Guo, T., Hu, L., Chen, Y., Chen, C., et al. (2022). Pollution characteristics and source analysis of microplastics in the Qiantang River in southeastern China. Chemosphere Oxf. 293, 133576. doi:10.1016/j.chemosphere.2022.133576

Dubeski, C. V., Branion, R. M., and Lo, K. V. (2001). Biological treatment of pulp mill wastewater using sequencing batch reactors. J. Environ. Sci. Health A 36 (7), 1245–1255. doi:10.1081/ese-100104875

Fahad, S., Bai, D., Liu, L., and Dagar, V. (2022). Comprehending the environmental regulation, biased policies and OFDI reverse technology spillover effects: A contingent and dynamic perspective. Environ. Sci. Pollut. Res. 29 (22), 33167–33179. doi:10.1007/s11356-021-17450-1

Fang, X., Wang, Q., Wang, J., Xiang, Y., Wu, Y., and Zhang, Y. (2021). Employing extreme value theory to establish nutrient criteria in bay waters: A case study of xiangshan bay. J. Hydrol. 603, 127146. doi:10.1016/j.jhydrol.2021.127146

Ge, D., Wu, W., Li, G., Wang, Y., Li, G., Dong, Y., et al. (2022). Application of CaO2-enhanced peroxone process to adjust waste activated sludge characteristics for dewaterability amelioration: Molecular transformation of dissolved organic matters and realized mechanism of deep-dewatering. Chem. Eng. J. 437, 135306. doi:10.1016/j.cej.2022.135306

Ge, D., Yuan, H., Xiao, J., and Zhu, N. (2019). Insight into the enhanced sludge dewaterability by tannic acid conditioning and pH regulation. Sci. Total Environ. 679, 298–306. doi:10.1016/j.scitotenv.2019.05.060

Guan, Q., Zeng, G., Song, J., Liu, C., Wang, Z., and Wu, S. (2021). Ultrasonic power combined with seed materials for recovery of phosphorus from swine wastewater via struvite crystallization process. J. Environ. Manag. 293, 112961. doi:10.1016/j.jenvman.2021.112961

Irfan, M., Sultan Salem, M. A., Acevedo-Duque, Á., Abbasi, K. R., Ahmad, F., Razzaq, A., et al. (2021). Interventions for the current COVID-19 pandemic: Frontline workers' intention to use personal protective equipment. Front. Public Health 9, 793642. doi:10.3389/fpubh.2021.793642

Irfan, M., Elavarasan, R. M., Ahmad, M., Mohsin, M., Dagar, V., and Hao, Y. (2022). Prioritizing and overcoming biomass energy barriers: Application of AHP and G-TOPSIS approaches. Technol. Forecasting Social Change 177, 121524. doi:10.1016/j.techfore.2022.121524

Işık, C., Ahmad, M., Ongan, S., Ozdemir, D., Irfan, M., Alvarado, R., et al. (2021a). Convergence analysis of the ecological footprint: Theory and empirical evidence from the USMCA countries. Environ. Sci. Pollut. Res. 28 (25), 32648–32659. doi:10.1007/s11356-021-12993-9

Işık, C., Ongan, S., Bulut, U., Karakaya, S., Irfan, M., Alvarado, R., et al. (2022). Reinvestigating the Environmental Kuznets Curve (EKC) hypothesis by a composite model constructed on the Armey curve hypothesis with government spending for the US States. Environ. Sci. Pollut. Res. 29 (11), 16472–16483. doi:10.1007/s11356-021-16720-2

Işık, C., Ongan, S., Ozdemir, D., Ahmad, M., Irfan, M., Alvarado, R., et al. (2021b). The increases and decreases of the environment Kuznets curve (EKC) for 8 OECD countries. Environ. Sci. Pollut. Res. 28 (22), 28535–28543. doi:10.1007/s11356-021-12637-y

Işık, C., Sirakaya-Turk, E., and Ongan, S. (2020). Testing the efficacy of the economic policy uncertainty index on tourism demand in USMCA: Theory and evidence. Tour. Econ. 26 (8), 1344–1357. doi:10.1177/1354816619888346

Işık, C. (2013). The importance of creating a competitive advantage and investing in information technology for modern economies: An ARDL test approach from Turkey. J. Knowl. Econ. 4 (4), 387–405. doi:10.1007/s13132-011-0075-2

Islam, M. M., Ali, M. I., Ceh, B., Singh, S., Khan, M. K., and Dagar, V. (2022). Renewable and non-renewable energy consumption driven sustainable development in ASEAN countries: Do financial development and institutional quality matter?. Environ. Sci. Pollut. Res. 29 (23), 34231–34247. doi:10.1007/s11356-021-18488-x

Islam, M. M., Khan, M. K., Tareque, M., Jehan, N., and Dagar, V. (2021). Impact of globalization, foreign direct investment, and energy consumption on CO2 emissions in Bangladesh: Does institutional quality matter?. Environ. Sci. Pollut. Res. 28 (35), 48851–48871. doi:10.1007/s11356-021-13441-4

Javed, H., Irfan, M., Shehzad, M., Abdul Muqeet, H., Akhter, J., Dagar, V., et al. (2022). Recent trends, challenges, and future aspects of P2P energy trading platforms in electrical-based networks considering blockchain technology: A roadmap toward environmental sustainability. Front. Energy Res. 10. doi:10.3389/fenrg.2022.810395

Kamali, M., and Khodaparast, Z. (2015). Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 114, 326–342. doi:10.1016/j.ecoenv.2014.05.005

Karrasch, B., Parra, O., Cid, H., Mehrens, M., Pacheco, P., Urrutia, R., et al. (2006). Effects of pulp and paper mill effluents on the microplankton and microbial self-purification capabilities of the Biobio River, Chile. Sci. Total Environ. 359 (1-3), 194–208. doi:10.1016/j.scitotenv.2005.03.029

Khan, I., Zakari, A., Zhang, J., Dagar, V., and Singh, S. (2022). A study of trilemma energy balance, clean energy transitions, and economic expansion in the midst of environmental sustainability: New insights from three trilemma leadership. Energy 248, 123619. doi:10.1016/j.energy.2022.123619

Khan, I., Zakari, A., Dagar, V., and Singh, S. (2022). World energy trilemma and transformative energy developments as determinants of economic growth amid environmental sustainability. Ener. Econ. 108, 105884. doi:10.1016/j.eneco.2022.105884

Khan, M. K., Babar, S. F., Oryani, B., Dagar, V., Rehman, A., Zakari, A., et al. (2022). Role of financial development, environmental-related technologies, research and development, energy intensity, natural resource depletion, and temperature in sustainable environment in canada. Environ. Sci. Pollut. Res. 29 (1), 622–638. doi:10.1007/s11356-021-15421-0

Krishnan, D., and Dagar, V. (2022). Exchange rate and stock markets during trade conflicts in the USA, China, and India. Glob. J. Emerg. Mark. Econ. 14 (2), 185–203. doi:10.1177/09749101221082724

Lacey, C., Basha, S., Morrissey, A., and Tobin, J. M. (2012). Occurrence of pharmaceutical compounds in wastewater process streams in Dublin, Ireland. Environ. Monit. Assess. 184 (2), 1049–1062. doi:10.1007/s10661-011-2020-z

Li, B., Boiarkina, I., Yu, W., Huang, H. M., Munir, T., Wang, G. Q., et al. (2019). Phosphorous recovery through struvite crystallization: Challenges for future design. Sci. Total Environ. 648, 1244–1256. doi:10.1016/j.scitotenv.2018.07.166

Liang, J., Mai, W., Wang, J., Li, X., Su, M., Du, J., et al. (2021). Performance and microbial communities of a novel integrated industrial-scale pulp and paper wastewater treatment plant. J. Clean. Prod. 278, 123896. doi:10.1016/j.jclepro.2020.123896

Lin, X., Lu, K., Hardison, A. K., Liu, Z., Xu, X., Gao, D., et al. (2021). Membrane inlet mass spectrometry method (REOX/MIMS) to measure 15N-nitrate in isotope-enrichment experiments. Ecol. Indic. 126, 107639. doi:10.1016/j.ecolind.2021.107639

Liu, W., Huang, F., Liao, Y., Zhang, J., Ren, G., Zhuang, Z., et al. (2008). Treatment of CrVI-containing Mg(OH)2 nanowaste. Angew. Chem. Int. Ed. 47 (30), 5619–5622. doi:10.1002/anie.200800172

Liu, W., Huang, F., Wang, Y., Zou, T., Zheng, J., and Lin, Z. (2011). Recycling Mg(OH)2 nanoadsorbent during treating the low concentration of CrVI. Environ. Sci. Technol. 45 (5), 1955–1961. doi:10.1021/es1035199

Liu, W., Li, J., Zheng, J., Song, Y., Shi, Z., Lin, Z., et al. (2020). Different pathways for Cr(III) oxidation: Implications for Cr(VI) reoccurrence in reduced chromite ore processing residue. Environ. Sci. Technol. 54 (19), 11971–11979. doi:10.1021/acs.est.0c01855

Mahat, S. B., Omar, R., Man, H. C., Idris, A. M., Kamal, S. M., Abdullah, L. C., et al. (2021). Dynamic anaerobic membrane bioreactor (DAnMBR) with phase separation for food processing wastewater treatment at mesophilic temperature: Characterization of cake layer. J. Environ. Chem. Eng. 9 (4), 105718. doi:10.1016/j.jece.2021.105718

Mainardis, M., Buttazzoni, M., De Bortoli, N., Mion, M., and Goi, D. (2020). Evaluation of ozonation applicability to pulp and paper streams for a sustainable wastewater treatment. J. Clean. Prod. 258, 120781. doi:10.1016/j.jclepro.2020.120781

Murshed, M., Ahmed, Z., Alam, M. S., Mahmood, H., Rehman, A., and Dagar, V. (2021). Reinvigorating the role of clean energy transition for achieving a low-carbon economy: Evidence from Bangladesh. Environ. Sci. Pollut. Res. 28, 67689–67710. doi:10.1007/s11356-021-15352-w

Murshed, M., Rahman, M. A., Alam, M. S., Ahmad, P., and Dagar, V. (2021a). The nexus between environmental regulations, economic growth, and environmental sustainability: linking environmental patents to ecological footprint reduction in South Asia. Environ. Sci. Pollut. Res. 28 (36), 49967–49988. doi:10.1007/s11356-021-13381-z

Murshed, M., Rahman, M. A., Alam, M. S., Ahmad, P., and Dagar, V. (2021b). The nexus between environmental regulations, economic growth, and environmental sustainability: linking environmental patents to ecological footprint reduction in South Asia. Environ. Sci. Pollut. Res. 28 (36), 49967–49988. doi:10.1007/s11356-021-13381-z

Murshed, M., Rashid, S., Ulucak, R., Dagar, V., Rehman, A., Alvarado, R., et al. (2022). Mitigating energy production-based carbon dioxide emissions in argentina: The roles of renewable energy and economic globalization. Environ. Sci. Pollut. Res. 29 (12), 16939–16958. doi:10.1007/s11356-021-16867-y

McBride, E. M., Mach, P. M., Dhummakupt, E. S., Dowling, S., Carmany, D. O., Demond, P. S., et al. (2019). Paper spray ionization: Applications and perspectives. TrAC Trends Anal. Chem. 118, 722–730. doi:10.1016/j.trac.2019.06.028

Mohamed, N., Al-Jaroodi, J., and Lazarova-Molnar, S. (2019). Leveraging the capabilities of industry 4.0 for improving energy efficiency in smart factories. IEEE Access 7, 18008–18020. doi:10.1109/access.2019.2897045

Morgan-Sagastume, F., Valentino, F., Hjort, M., Cirne, D., Karabegovic, L., Gerardin, F., et al. (2014). Polyhydroxyalkanoate (PHA) production from sludge and municipal wastewater treatment. Water Sci. Technol. 69 (1), 177–184. doi:10.2166/wst.2013.643

Othman, I., Anuar, A. N., Ujang, Z., Rosman, N. H., Harun, H., Chelliapan, S., et al. (2013). Livestock wastewater treatment using aerobic granular sludge. Bioresour. Technol. 133, 630–634. doi:10.1016/j.biortech.2013.01.149

Pavanelli, D., and Bigi, A. (2005). Indirect methods to estimate suspended sediment concentration: Reliability and relationship of turbidity and settleable solids. Biosyst. Eng. 90 (1), 75–83. doi:10.1016/j.biosystemseng.2004.09.001

Pokhrel, D., and Viraraghavan, T. (2004). Treatment of pulp and paper mill wastewater—A review. Sci. total Environ. 333 (1-3), 37–58. doi:10.1016/j.scitotenv.2004.05.017

Razali, M. A. A., Ahmad, Z., and Ariffin, A. (2012). Treatment of pulp and paper mill wastewater with various molecular weight of PolyDADMAC induced flocculation with polyacrylamide in the hybrid system. Adv. Chem. Eng. Sci. 2 (04), 490–503. doi:10.4236/aces.2012.24060

Rehman, A., Radulescu, M., Ma, H., Dagar, V., Hussain, I., and Khan, M. K. (2021). The impact of globalization, energy use, and trade on ecological footprint in Pakistan: Does environmental sustainability exist?. Energies 14 (17), 5234. doi:10.3390/en14175234

Saroha, K., Dagar, V., Jit, P., Alvarado, R., Mishra, V., Pahwa, N., et al. (2021). COVID-19: Trend analysis for market arrival of green gram in India. Inter. J. Agricul. Stat. Sci. 16, 1017–1031.

Shahzad, U., Madaleno, M., Dagar, V., Ghosh, S., and Doğan, B. (2022). Exploring the role of export product quality and economic complexity for economic progress of developed economies: Does institutional quality matter?. Structural Change and Economic Dynamics 62, 40–51. doi:10.1016/j.strueco.2022.04.003

Shaikh, E., Mishra, V., Ahmed, F., Krishnan, D., and Dagar, V. (2021). Exchange rate, stock price and trade volume in US-China trade war during COVID-19: An empirical study. Stud. Appl. Econ. 39 (8). doi:10.25115/eea.v39i8.5327

Singh, A. K., and Chandra, R. (2019). Pollutants released from the pulp paper industry: Aquatic toxicity and their health hazards. Aquat. Toxicol. 211, 202–216. doi:10.1016/j.aquatox.2019.04.007

Singh, G., Kaur, S., Khatri, M., and Arya, S. K. (2019). Biobleaching for pulp and paper industry in India: Emerging enzyme technology. Biocatal. Agric. Biotechnol. 17, 558–565. doi:10.1016/j.bcab.2019.01.019

Singh, S., Kumar, S., Dagar, V., Saxena, M., and Rashid, S. (2021). India’s agricultural food processing and industry specific trade pattern with EU and ASEAN. International Journal of Agricultural and Statistical Sciences 17 (1), 39–51.

Tang, C., Irfan, M., Razzaq, A., and Dagar, V. (2022). Natural resources and financial development: Role of business regulations in testing the resource-curse hypothesis in ASEAN countries. Res. Pol. 76, 102612. doi:10.1016/j.resourpol.2022.102612

Tillaguango, B., Alvarado, R., Dagar, V., Murshed, M., Pinzón, Y., and Méndez, P. (2021). Convergence of the ecological footprint in Latin America: the role of the productive structure. Environ. Sci. Pollut. Res. 28, 59771–59783. doi:10.1007/s11356-021-14745-1

Thompson, A., Griffin, P., Stuetz, R., and Cartmell, E. (2005). The fate and removal of triclosan during wastewater treatment. Water Environ. Res. 77 (1), 63–67. doi:10.2175/106143005x41636

Toczyłowska-Mamińska, R. (2017). Limits and perspectives of pulp and paper industry wastewater treatment–A review. Renew. Sustain. Energy Rev. 78, 764–772. doi:10.1016/j.rser.2017.05.021

Wei, R., Ayub, B., and Dagar, V. (2022). Environmental benefits from carbon tax in the Chinese carbon market: A roadmap to energy efficiency in the Post-COVID-19 Era. Front. Ener. Res. 10, 1–11. doi:10.3389/fenrg.2022.832578

Weimin, Z., Sibt-e-Ali, M., Tariq, M., Dagar, V., and Khan, M. K. (2022). Globalization toward environmental sustainability and electricity consumption to environmental degradation: does EKC inverted U-shaped hypothesis exist between squared economic growth and CO2 emissions in top globalized economies. Environ. Sci. Pollut. Res. Int.. doi:10.1007/s11356-022-20192-3

Wen, C., Akram, R., Irfan, M., Iqbal, W., Dagar, V., Acevedo-Duqued, Á., et al. (2022). The asymmetric nexus between air pollution and COVID-19: Evidence from a non-linear panel autoregressive distributed lag model. Environ. Res. 209, 112848. doi:10.1016/j.envres.2022.112848

Wilks, R., and Scholes, E. (2018). DNA sequencing of pulp and paper wastewater treatment systems to inform process analysis. Appita Technol. Innov. Manuf. Environ. 71 (2), 157–164. doi:10.3316/informit.645420249448252

Xiang, H., Chau, K. Y., Iqbal, W., Irfan, M., and Dagar, V. (2022). Determinants of social commerce usage and online impulse purchase: Implications for business and digital revolution. Front. Psychol. 13, 837042–13. doi:10.3389/fpsyg.2022.837042

Xie, M., Irfan, M., Razzaq, A., and Dagar, V. (2022). Forest and mineral volatility and economic performance: Evidence from frequency domain causality approach for global data. Resour. Pol. 76, 102685. doi:10.1016/j.resourpol.2022.102685

Yuan, B., Leiling, W., Saydaliev, H. B., Dagar, V., and Acevedo-Duque, Á. (2022). Testing the impact of fiscal policies for economic recovery: does monetary policy act as catalytic tool for economic Survival. Econ. Chan. Restruct., 0123456789. doi:10.1007/s10644-022-09383-7

Xu, D., Liu, J., Ma, T., Zhao, X., Ma, H., and Li, J. (2022). Coupling of sponge fillers and two-zone clarifiers for granular sludge in an integrated oxidation ditch. Environ. Technol. Innovation 26, 102264. doi:10.1016/j.eti.2021.102264

Yadav, S., and Chandra, R. (2018). Detection and assessment of the phytotoxicity of residual organic pollutants in sediment contaminated with pulp and paper mill effluent. Environ. Monit. Assess. 190 (10), 581. doi:10.1007/s10661-018-6947-1

Zakari, A., Khan, I., Tan, D., Alvarado, R., and Dagar, V. (2022). Energy efficiency and sustainable development goals (SDGs). Energy 239, 122365. doi:10.1016/j.energy.2021.122365

Zakari, A., Toplak, J., Ibtissem, M., Dagar, V., and Khan, M. K. (2021). Impact of Nigeria’s industrial sector on level of inefficiency for energy consumption: Fisher ideal index decomposition analysis. Heliyon 7 (5), e06952. doi:10.1016/j.heliyon.2021.e06952

Zhang, C., Khan, I., Dagar, V., Saeed, A., and Zafar, M. W. (2022). Environmental impact of information and communication technology: Unveiling the role of education in developing countries. Technol. Forecast. Social Chan. 178, 121570. doi:10.1016/j.techfore.2022.121570

Keywords: wastewater treatment plant, chemical oxygen demand, biochemical oxygen demand, adsorbable organic halogens, suspended solids, effluent treatment plant

Citation: Dagar S, Singh SK and Gupta MK (2022) Economics of advanced technologies for wastewater treatment: Evidence from pulp and paper industry. Front. Environ. Sci. 10:960639. doi: 10.3389/fenvs.2022.960639

Received: 06 June 2022; Accepted: 27 June 2022;

Published: 10 August 2022.

Edited by:

Cem Işık, Anadolu University, TurkeyReviewed by:

Rafael Alvarado, National University of Loja, EcuadorCopyright © 2022 Dagar, Singh and Gupta. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Sumit Dagar, ZGFnYXJzdW1pdDk1QGdtYWlsLmNvbQ==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.