- 1Center for Membrane and Water Science & Technology, Zhejiang University of Technology, Hangzhou, China

- 2Shanghai Radio Equipment Research Institute, Shanghai, China

- 3Navy Medical Centre, Shanghai, China

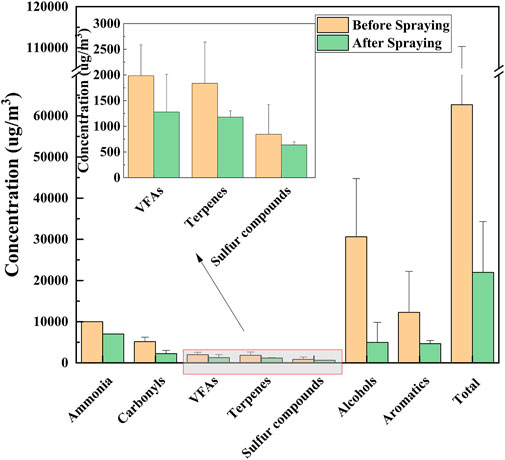

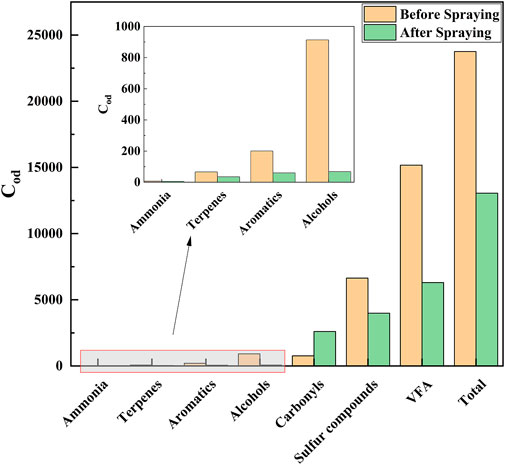

The composting process emits various volatile chemicals, including hydrocarbons, nitrogen compounds, sulfur compounds, and oxygenated compounds. These gases must be removed to avoid atmospheric pollution. Spraying extracted materials from plants, such as tea tree oil, onto the surface of a windrow is a novel odor-reduction technique for the treatment of gaseous emissions from composting facilities. In this study, a plant material-based deodorant from a mixture of coconut, lemon, and tea tree essential oils was sprayed directly onto the surface of a windrow with a spraying frequency of three times a day. Odorous compounds were measured before and after spraying to evaluate the performance of the plant material-based deodorant. After spraying, the ammonia concentration decreased from 10,000 to 7,000 μg/m3. There was a large decline in alcohols, aromatics, and carbonyls from 30,612, 12,270, and 5,138 μg/m3 to 4,965, 4,669, and 2,253 μg/m3, achieving efficiencies of 83%, 62%, and 56%, respectively. The removal efficiencies for terpenes, volatile fatty acids, sulfur compounds, and ammonia were lower than the former, falling within the range of 24%–36%. The theoretical total odor concentration was decreased from 23,757 μg/m3 at the beginning to 13,056 μg/m3 in the end, revealing that most of the bad smell had been eliminated.

1 Introduction

Solid waste management, particularly the organic fraction, is becoming a serious problem in developing countries. The common treatments include dumping, landfill, incineration, and composting, but each method has different negative impacts on the environment (Guo et al., 2021). Compared with these methods, composting is the most suitable treatment for organic waste. This technology uses microorganisms to transform organic waste into valuable fertilizer and soil amendment (Kundariya and Mohanty, 2021). Unfortunately, the composting process generates various volatile chemicals, including hydrocarbons, nitrogen compounds, sulfur compounds, and oxygenated compounds (Hwang et al., 2020). These gases have an irritating odor and are also hazardous to human health. Thus, they must be treated to avoid secondary atmospheric pollution (Gutiérrez, et al., 2015). Although the main objective of composting facilities is to reduce the environmental impact of organic solid wastes, there are unavoidable gaseous emissions and odor compounds responsible for nuisances and complaints (Tian, et al., 2013).

Odor abatement technologies are widely used and reliable methods for mitigating nuisance odors (Pillai et al., 2012; Alfonsín, 2015; Boraphech & Thiravetyan, 2015; Zaman & Rosli, 2015). The odor treatment technologies are classified mainly into hybrid (e.g., physical and chemical) and biological techniques. Physical and chemical methods have high abatement efficiency and robustness when operated and maintained correctly, low empty bed retention time, and rapid start-up. These techniques are often based on the transfer of odorants from the gas emission to either a solid (adsorption) or liquid (absorption) phase (Ren and Zhao, 2019). On the other hand, biological techniques constitute a more cost-effective and environmentally friendly alternative (Oliva et al., 2019), but they can present significant investment costs (Senatore et al., 2021). In recent decades, biological techniques have been increasingly widely used to efficiently treat pollutants with lower operating costs (Dubey and Shiwani, 2012; Taghizadeh et al., 2012).

In recent years, simple surface foam-spraying technology has been regarded as a promising method for physically suppressing odor and its subsequent degradation by bacteria. Bajagain uses durable surfactant foam, including bacteria that were sprayed on swine manure. The surfactant foam acted as a physical barrier, suppressing NH3 release, and the aqueous-phase bacteria formed after the foam breaking infiltrated the waste and degraded NH3 (Bajagain et al., 2022).

Furthermore, deodorant is an effective way to eliminate odor pollution. Using plant material-based products, extracted from plants such as acacia or bamboo, in odor abatement is an effective technique for treating gaseous emissions from composting facilities (Zhou et al., 2012). Deodorant is an end-of-pipe treatment technology that combines several deodorization principles. Through oxidation-reduction chemical reactions, decomposition reactions, neutralization reactions, etc., the deodorant transforms the fetid stench into an odorless gas, directly eliminates the odor, changes the adsorption odor molecule stereo configuration, weakens the molecular association bond, decreases the stability of odor molecules, or makes it easy to react with other molecules. For example, hydrogen sulfide reacts with deodorant to form sulfuric acid ions and water, while ammonia can form nitrogen and water (Dai et al., 2018; Yin and Lu, 2021). With the increasing awareness and demand for environmental protection, plant deodorants using plant extracts as the main ingredient have become a common theme in research. Zhou uses products derived from plants such as acacia or bamboo to eliminate odors from gas emissions from composting facilities (Zhou et al., 2012). Hu’s research shows that 10 kinds of plant-based deodorants have a removal effect on hydrogen sulfide, with the dilution of a more significant number of deodorants, mainly essential oils of plants, to remove the highest amount—the highest rate being 84%–87% (Hu, 2022). The active compounds in the extracted materials, such as tea polyphenols and tannins, can react with odorous gases and eliminate them (Pang and Yu, 2019).

Sprays or atomizing equipment are efficient devices to atomize the liquids, which can enhance the deodorant to infiltrate and decompose odor molecules. The active compound complex odor molecules destroy bonds of odor molecules, decompose odor molecules, and generate non-toxic and odorless products (Jin and Meng, 2019). This achieves the effect of eliminating odors and exterminating the source of odors, which is an essential difference from the products that use a fragrance to cover abnormal and unpleasant odors. The nanometer-level effective molecules infiltrate and destroy the cell walls of bacteria and viruses, thus collapsing their living environment to realize effective sterilization and disinfection. Through the effective absorption, decomposition, and neutralization of suspended particles and dust, the problem of dirty air is eliminated, and the air quality is improved (Nechifor and Cotorcea, 2021). The odor abatement method by spraying deodorant does not need an odor source sealing system and odor collection and transmission system to be installed; it only requires an odor treatment system. There is no need for civil works, collection systems, or overhead discharge pipelines, and there is no secondary pollution. The system is easy to install and use, without too much time and expense. It is not necessary to install any other accessories to handle the air (Zhang and Li, 2022). The system is easy to move, and the device can be moved and changed according to the odor source. The equipment for deodorizing natural plant extracts is simple and easy to use, requires no maintenance, and is fully automatic.

In this study, a composting facility was selected to observe the change in the odor gas concentration after applying the abatement method to evaluate the odor removal performance of plant extracts. The odorant removal efficiency was estimated by an on-site sampling campaign to observe the elimination or masking effect. The composting facility used in the study is located in a suburb of Shanghai, with the waste left there for 20 days for aerobic treatment after sorting. The plant extract was sprayed directly onto a windrow in the composting facility through pressure piping, with a spraying frequency of three times a day (9:00, 12:00, and 15:00). Each spray lasted for 15 min. Before and after the spraying trial, odor compounds were sampled in Tedlar® bags or cartridges close to the respiratory zone using four methods.

2 Materials and methods

2.1 Deodorant

The deodorant was self-formulated. It was based on a commercially available plant essential oil. It was a mixture of coconut, lemon, and tea tree essential oils (Shanghai Zhenfeng Environmental Protection Technology Co., Ltd., China) with trimethylene glycol as the solvent. The ratio of trimethylene glycol to plant essential oil was 10:1. After mixing evenly, a certain proportion of emulsifiers and additives were added, and the final product was prepared with deionized water, 0.6% compound essential oil, 6% trimethylene glycol, 1% β-cyclodextrin, and 3% Tween-80.

2.2 Site description and sampling location

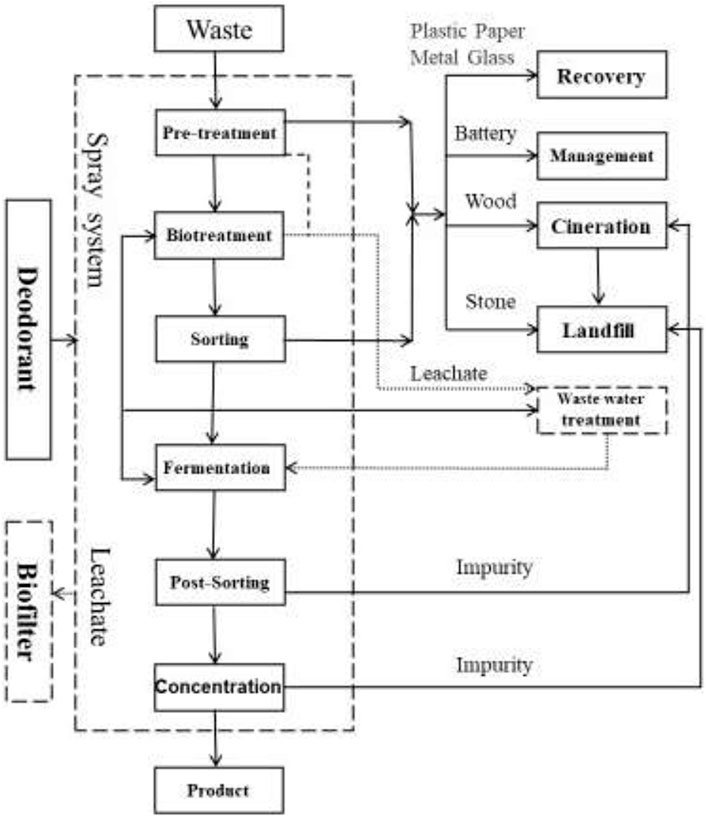

The treatment capacity of the composting plant was 1,200 t/d, with a working area of 20,000 m2, as shown in Figure 1. The waste was left in place for 20 days for aerobic treatment after sorting. Briefly, the municipal solid waste (MSW) was delivered to the facility, where the waste was sorted manually and then separated by sizes using trommel screens. The light fractions, such as plastics, were picked up by an air separator, and metals were picked up by a magnetic separator. After the pre-mechanical treatment, the waste was conveyed to the pre-biotreatment facility for 20 days of aerobic treatment. Next, the waste was sorted again in a post-mechanical treatment facility, after which undersized material was delivered to a post-biotreatment facility for another 30–60 days of aerobic treatment. The spraying deodorant system and atomizing nozzles were arranged in the pipeline above the windrow in the dotted rectangle area, and the leachate was collected from the bottom of the pile for treatment using a biofilter, as shown in Figure 2. The operation time of the spraying system was generally 2 min/h, of which 10 nozzles require about 0.4 L liquid per hour. The monthly cost of the deodorant is about 5,000 RMB (renminbi). Before the deodorant spraying trial, a sampling campaign was conducted as a control in the biotreatment and fermentation process in the facility at 9:00, 12:00, and 16:00, respectively. After spraying, the sampling campaign was repeated to detect the concentration to evaluate removal efficiencies. The campaign was completed within 1 day on September 19th, 2021.

2.3 Gas sampling and analyses

Five analytical methods were used to measure the odor pollutant concentration before and after spraying.

1) Colorimetric tubes to detect ammonia.

2) Gas chromatography flame ionization detection (GC-FID) is preceded by a cold trap concentration for aromatics, terpenes, and alcohols.

3) Gas chromatography-pulsed flame photometric detection (GC-PFPD) was preceded by the cold trap concentration for sulfur compounds.

4) Gas chromatography-flame ionization detection was preceded by a sorbent concentration to determine volatile fatty acids (VFAs).

5) High-performance liquid chromatography (HPLC) after the derivation by 2,4-dinitrophenylhydrazine (DNPH) to detect aldehydes.

2.3.1 Analyses of colorimetric tubes

Colorimetric tubes (Gastec., Japan) were used to detect ammonia in the field. A certain volume (1.5 L or 3 L) of gas was extracted with a hand pump attached to the tube. The tube color changed, and the length of the color change indicated the measured concentration.

2.3.2 Gas chromatography analyses after the cold pre-concentration method

Gas chromatography analysis after cold pre-concentration was determined for the most volatile compounds. Tedlar® bags were used to collect samples from the air. First, the bags were placed in a vacuum-generating container, then a vacuum pump was used to connect the container, and the samples were drawn directly into these bags via a Teflon tube. These samples were transported immediately (within 24 h) to the laboratory for analysis to minimize the loss of reduced sulfur compounds (RSCs) during storage. The pre-concentrated method was carried out by cryogenic liquid nitrogen according to the EPA TO-15 method. The experiment instrument was Entech 7100A (Entech Instruments Inc., United States), and the injection volume was 50–500 ml. The analysis conditions for GC-PFPD and GC-FID were reported by Fang et al. (2012, 2013).

2.3.3 Gas chromatography-flame ionization detection analysis after the sorbent concentration method

The sorbent concentration method was used to determine VFA concentrations in air samples. Commercial sorbent tubes (silica gel tube, SKC, United States) were used to collect the air samples. The airflow rate was 1,000 ml/min, and the collection time was 120 min. After sampling, the tubes were capped with end plugs and transported back to the laboratory for analysis. The silica gel was placed into a 5-ml volumetric flask and desorbed with 5 mL deionized water. After standing for 30 min in an ultrasonic instrument, the supernatant liquid was analyzed by GC-FID. The operating parameters for the FID detection system were the same as those described previously.

2.3.4 High-performance liquid chromatography analysis after derivation by DNPH

High-performance liquid chromatography after derivation by 2,4-dinitrophenylhydrazine (DNPH) was used to detect aldehydes. Commercial cartridges (Cleaner DNPH-Silica, Agela Technology, China) were used to collect air samples. The airflow rate was 1,000 ml/min, and the collection time was 30 min. After sampling, cartridges were connected to a clean syringe (Visiprep DL, Supelco Analytical, United States) and placed on a solid phase extraction (SPE) vacuum manifold (Visiprep, Supelco Analytical, United States). The compounds absorbed into the cartridges were then eluted into a 5-ml volumetric flask with 5 ml acetonitrile. The analytical column used was a C18 (4.6 mm ID × 25 cm; 5 μm) stainless steel tube (Venusil XBP, Agela Technology, China). The conditions of the method were reported by Fang et al. (2012, 2013).

2.4 Quality assurance and control

Five levels (50, 200, 500, 1,000, and 2,000 μg/m3) of standard gases (Air Liquid, France) were used to generate standard calibration curves. A good correlation (R2 > 0.93) was found in the range of 0–2,000 μg/m3. Instrumental detection limits were determined by linear extrapolation from the lowest standard in the calibration curve using the area of a peak having a signal-to-noise ratio of 3. The concentrations of blank samples were less than 1 μg/m3, which implied that no contamination of the samples occurred during collection, transportation, and storage processes. Ten replicate standard gases were used to evaluate the reproducibility, and the relative standard deviations were less than 6%. The standard recovery rate of these methods was 80%–112%.

2.5 Theoretical odor concentrations

The theoretical odor concentration (Cod) was used to evaluate the odor abatement effect. It was calculated from the ratio of the analytical concentration of each odor compound to its odor threshold, according to Eqs 1, 2 (Fang et al., 2012). This method can be used to compare the odor elimination effect of spraying activities.

where Ci is the analytical concentration of the ith compound (μg/m3), OTi is the odor threshold value of the ith compound (μg/m3), Cod,i is defined as the theoretical odor concentration (dimensionless), n is the total number of odorous compounds, and Cod represents the sum of the theoretical odor concentrations of n compounds.

3 Results

3.1 The change in concentration of each compound in the trial

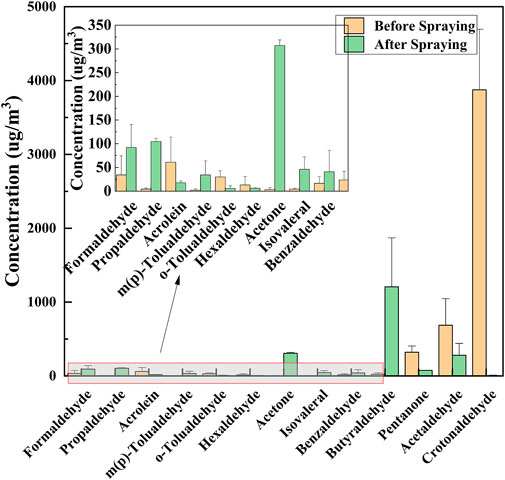

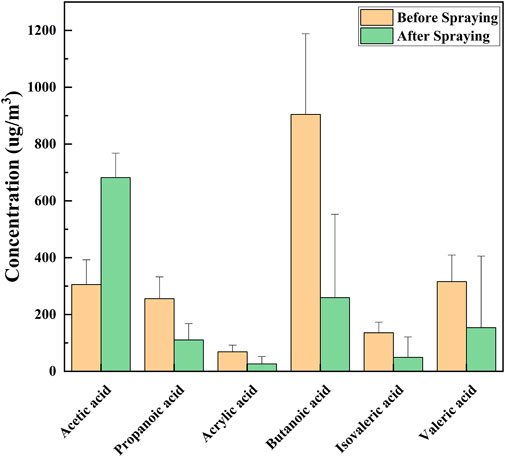

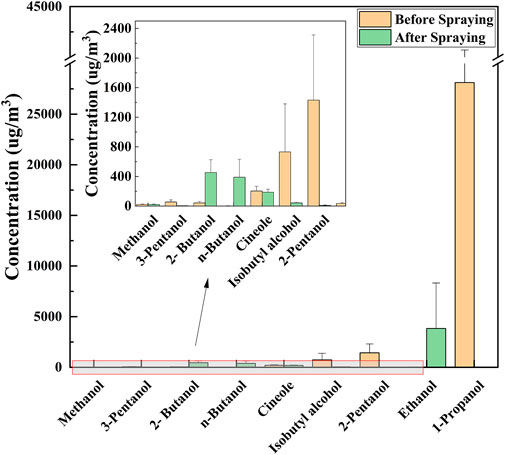

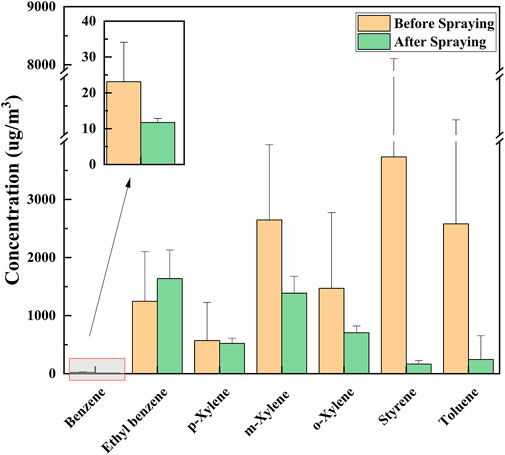

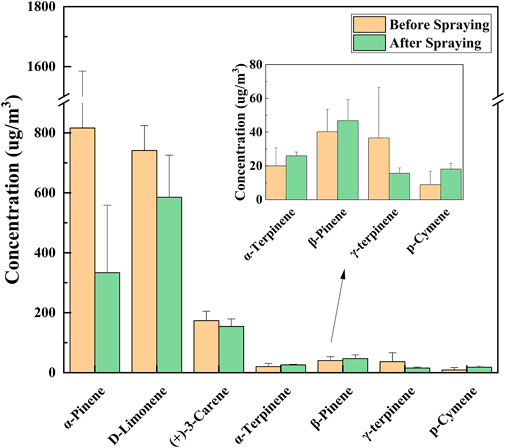

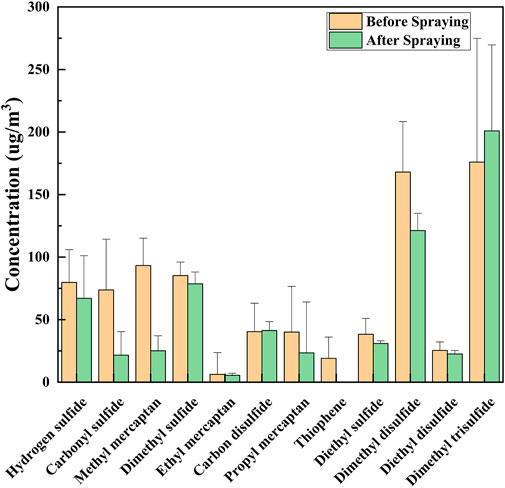

The concentration of every compound before and after spraying is shown in Figure 3–9, which show the average values of three measurements. In the carbonyl group, acetaldehyde, crotonaldehyde, and pentanone concentrations decreased, while the acetone and butyraldehyde concentrations increased to different degrees. There were no noticeable changes for the other compounds. For VFAs, the solution had only a slight effect on most compounds except acetic acid. The most effective removal was achieved for butanoic acid. Substantial changes in the concentrations of alcohols were observed in this trial, especially propanol, which fell from 28,115 to 23 μg/m3. This was followed by 2-pentanol, which dropped from 1,439 μg/m3 to 9 μg/m3. For the aromatics, the solution impacted toluene, m-xylene, and styrene. Their concentrations decreased from 2,850, 2,647, and 3,733 μg/m3 to 244, 1,385, and 164 μg/m3, respectively. For terpenes, the solution had a slight effect on α-pinene and d-limonene concentrations, with a decline from 816 and 741 μg/m3 to 333 and 585 μg/m3, respectively.

3.2 The purification efficiency

The changes in the concentrations of the seven groups and total compounds are shown in Figure 8; Table 1. The figure shows that the extraction had a good efficiency for the total. After spraying, the ammonia concentration decreased from 10,000 μg/m3 to 7,000 μg/m3. There was a significant decline in alcohols, aromatics, and carbonyls from 30,612, 12,270, and 5,138 μg/m3 to 4,965, 4,669, and 2,253 μg/m3, respectively. The removal efficiency of terpenes, VFAs, and sulfur compounds were not as good. A decline of 40,703 μg/m3 was observed for the total compounds, indicating that the plant material-based solution played an important role in eliminating the odorous gases.

The purification efficiency is shown in Table 1. The results showed that the solution could efficiently remove alcohols, aromatics, and carbonyls, achieving removal efficiencies of 83%, 62%, and 56%, respectively. The removal efficiencies of terpenes, VFAs, and sulfur compounds were lower at only 36% and 25%, respectively. After atomization by deodorization equipment, the natural plant extract formed a mist, with liquid droplets’ radius ≤0.04 mm. The droplets had a large specific surface area and large surface energy, with an average kinetic energy per mole of several tens of kcal. Energy levels of this magnitude are 1/3 to 1/2 of the bond energy of many elements (Kharat et al., 2020). Researchers found that monophenols, thymol, and carvacrol in essential oils exhibited odor-reducing activities (Nakasugi et al., 2017). The surface of the solution could, therefore, not only effectively adsorb odor molecules in the air but also change the three-dimensional configuration of the adsorbed odor molecules, weaken chemical bonds in odor molecules, and increase the instability of odor molecules.

3.3 The odor abatement effect

The odor abatement effect was evaluated by the theoretical odor concentration (Cod). The total Cod decreased from 23,757 at the beginning to 13,056 at the end, as shown in Figure 10. The decline order of Cod of gas groups was VFA > sulfur compounds > alcohols > aromatic hydrocarbons > terpenes > ammonia, showing that most of the foul smell had been eliminated. The Cod of carbonyls increased exceptionally, mainly due to the increase of n-butyraldehyde after spraying. The cause may be that the deodorant promotes the release of n-butyraldehyde, but it may also have been caused by the interference of aldehydes in the deodorant.

4 Discussion

The composition of plant essential oils is complex, and it is challenging to determine the components; for example Artemisia argyi has more than 100 components. The deodorant detected many compounds that are reactive and antibacterial; α-terpineol, dihydrolaurenol, α-hexyl cinnamaldehyde, hexyl salicylate, lily aldehyde, and citral are volatile chemical components that are commonly found in plant essential oils. Methyl dihydrojasmonate, existing in jasmine oil and black tea, has a deodorizing and refreshing effect (Zhang et al., 2019; Jaouadi and Hajjikasmi, 2020; Huang et al., 2022). α-Hexyl cinnamaldehyde is present in black tea and orchid; it can sterilize, act as an antiseptic, and deodorize, and can replace the traditional fungicide glutaraldehyde. Cedrylene methyl ketone is found in cedar, which is used in daily chemical, sanitary, and sanitary products such as disinfectants, cosmetics, and washing products in the healthcare industry. An active substance with an unsaturated structure in these plant essential oils reacted with the malodorous substances, turning them into odorless compounds, and the foul smell further reduced.

Plant material-based deodorants require the addition of surfactants for emulsification and form an oil-in-water structure that facilitates the hydration of plant active ingredients in scattered water (Jarzębski et al., 2020). Emulsifiers are divided into anionic surfactants, cationic surfactants, amphoteric surfactants, and non-ionic surfactants (Dammak et al., 2020). When anionic surfactants dissolve in water and ionize, they are connected with the lipophilic groups that are negatively charged, including carboxylate, sulfate and sulfonate groups, acid and phosphate anionic surfactants, and representative compounds, such as sodium dodecylbenzenesulfonate and stearic acid. Cationic surfactants dissolve in water and ionize; the hydrophilic base band is linked to lipophilic groups that are positively charged. The representative compounds are ammonium salts and quaternary ammonium salts, such as benzalkonium chloride and benzalkonium bromide. There are many types of amphoteric surfactants, for example, lecithin, amino acid type, and betaine. BS12 is a more common amphoteric surfactant. Non-ionic surfactants include fatty acid glycerides, AEO-7, OP-10, and Tween-80. Most of the ammonium and quaternary ammonium compounds are highly toxic and contain halogen elements; we do not consider the use of such surfactants. Tween-80 has good compatibility and stability; there are more hydrophilic groups in Tween-80 molecules (polycarbonate base), which have strong hydrophilicity and can emulsify and dissolve essential oils in water and improve the deodorizing capacity.

Due to the different sources of various odors, their components are also different. Using one of the chemical deodorants makes it challenging to meet the requirements of environmental deodorization. Many plant material-based deodorants are extracted from roots, stems, and leaves of plants. The extract protects the remaining natural bioactive components that can synergistically produce various effects on odor molecules. Research on the formulation of compound deodorants will be an important task in the future. The direction of development should receive more attention. The deodorant function of the deodorant designed by the formulation system could be enhanced, and the applications would therefore be expanded. The formulation of deodorant mainly focuses on systematic active ingredient selection, active ingredient dosage determination, and auxiliary and stabilizer choices. The identification of deodorant active ingredients is a technical challenge, requiring a variety of techniques to isolate and identify the active ingredient, mainly solvent extraction with gas chromatography or liquid phase mass spectrometry (Shin et al., 2020). In the future, we may analyze the composition of active substances, component structures, and efficacy relationships, etc. In-depth research studies to optimize formulations and reduce product development costs are needed.

The non-ionic surfactant Tween-80 was used in the formulation of this study. It can reduce surface tension, form smaller droplets, and increase the contact area with odor molecules. β-cyclodextrin and its derivatives are cyclic oligosaccharides with nanoscale porous molecular structures, the cavities of which can combine some small molecules and adsorb and release a variety of substances (Liu et al., 2020; Tian et al., 2021; Chodankar et al., 2022; Wang et al., 2022). A new adsorption-type deodorant is more and more widely used; β-cyclodextrin is added to the deodorant as an adsorptive modifier to enhance and improve the performance of the deodorant. Still, the amount of β-cyclodextrin should not be too much. Since the solubility of β-cyclodextrin in an aqueous solution is slight, adding too much will cause precipitation. It will affect the dispersion of the system. Further research is required on the compound system to enhance the solubility of β-cyclodextrin in the future.

In this study, plant essential oils were used as active ingredients. The deodorant contains highly reactive functional groups, which can effectively trap, quickly adsorb, and assimilate odorous substances, and can also interact with odorous molecules through a chemical reaction. Then, it will turn into an odorless substance to inhibit odors. This plant material-based deodorant can be sprayed in spaces to effectively clean odorous gases from composting facilities.

A plant material-based solution consisting of plant extracts was effective for removing toluene, xylene, styrene, α-pinene, d-limonene, propanol, pentanol, and butanoic acid from the air. Since the main odorants produced in the composting plant could be effectively removed by applying the solution, the odor reduction mode was removing odorous compounds rather than masking.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; Further inquiries can be directed to the corresponding author.

Author contributions

JW was responsible for interpreting results, updating reference lists, and creating “Summary of findings” tables. JY was responsible for writing the manuscript. JF was responsible for conducting the research. JW was responsible for screening potentially eligible studies and extracting and analyzing data. LF was responsible for extracting and analyzing data and interpreting results.

Funding

This work was financially supported by grants from the National Natural Science Foundation of China (No. 21507161), the Construction Project of Key Disciplines and Specialties in the 13th Five Year Plan (2020SZ06-13), the Shanghai Integration Project (HCXBCY-2021-006), the National Key R&D Program of China (No. 2018YFC0824300), and the Program of the Ministry of Industry and Information Technology of the P.R.C. (TC210H00L/43).

Acknowledgments

The authors thank Professor Pingjing He for suggesting the site used in the case study.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Alfonsín, C., Lebrero, R., Estrada, J. M., Munoz, R., Kraakman, N. B., Feijoo, G., et al. (2015). Selection of odour removal technologies in wastewater treatment plants: A guideline based on life cycle assessment. J. Environ. Manag. 149, 77–84. doi:10.1016/j.jenvman.2014.10.011

Bajagain, R., Gautam, P., Le, T. T. N., Dahal, R. H., Kim, J., and Jeong, S. W. (2022). Isolation and screening of odor-reducing microbes from swine manure and its role in reducing ammonia release in combination with surfactant foam. Appl. Sciences-Basel. 12 (4), 1806. doi:10.3390/app12041806

Boraphech, P., and Thiravetyan, P. (2015). Trimethylamine (fishy odor) adsorption by biomaterials: Effect of fatty acids, alkanes, and aromatic compounds in waxes. J. Hazard. Mater. 284, 269–277. doi:10.1016/j.jhazmat.2014.11.014

Chodankar, D., Vora, A., and Kanhed, A. (2022). β-Cyclodextrin and its derivatives: Application in wastewater treatment. Environ. Sci. Pollut. Res. Int. 29 (2), 1585–1604. doi:10.1007/s11356-021-17014-3

Dai, Z. N., Zeng, F. S., Liu, J., Yang, A. L., and Fu, H. Y. (2018). Application of deodorant in odor control of municipal solid waste. IOP Conf. Series-Earth Environ. Sci. 192, 012063. doi:10.1088/1755-1315/192/1/012063

Dammak, I., Sobral, P. J. D. A., Aquino, A., Neves, M. A. D., and Conte-Juniorand, C. A. (2020). Nanoemulsions: Using emulsifiers from natural sources replacing synthetic ones—a review. Compr. Rev. Food Sci. doi:10.1111/1541-4337.12606

Dubey, A., and Shiwani, S. (2012). Adsorption of lead using a new green material obtained from Portulaca plant. Int. J. Environ. Sci. &Technology 9 (15–20), 15–20. doi:10.1007/s13762-011-0012-8

Fang, J. J., Yang, N., Cen, D. Y., Shao, L. M., and He, P. J. (2012). Odor compounds from different sources of landfill: Characterization and source identification. Waste Manag. 32, 1401–1410. doi:10.1016/j.wasman.2012.02.013

Fang, J. J., Zhang, H., Yang, N., Shao, L. M., and He, P. J. (2013). Gaseous pollutants emitted from a mechanical biological treatment plant for municipal solid waste: Odor assessment and photochemical reactivity. J. Air & Waste Manag. Assoc. 63, 1287–1297. doi:10.1080/10962247.2013.822439

Guo, W., Xi, B. D., Huang, C. H., Li, J., Tang, Z., Li, W., et al. (2021). Solid waste management in China: Policy and driving factors in 2004-2019. Resour. Conservation Recycl. 173, 105727. doi:10.1016/j.resconrec.2021.105727

Gutiérrez, M. C., Martín, M. A., Serrano, A., and Chica, A. F. (2015). Monitoring of pile composting process of OFMSW at full scale and evaluation of odour emission impact. J. Environ. Manag. 151, 531–539. doi:10.1016/j.jenvman.2014.12.034

Hu, J. M. N. (2022). Study on the testing method of deodorization effect and influence factors of hydrogen sulfide remove effect by plant deodorizer. Environ. Sanit. Eng. 30 (02), 89–94.

Huang, P. M., Wang, Z. R., Shi, Y., Zhang, R., Feng, X., and Kan, J. (2022). Deodorizing effects of rosemary extract on silver carp (Hypophthalmichthys molitrix) and determination of its deodorizing components. J. Food Sci. 87 (2), 636–650. doi:10.1111/1750-3841.16023

Hwang, H. Y., Kim, S. H., Shim, J., and Park, S. J. (2020). Composting process and gas emissions during food waste composting under the effect of different additives. Sustainability 12 (18), 7811. doi:10.3390/su12187811

Jaouadi, T., Hajji, M., Kasmi, M., Kallel, A., Chatti, A., Hamzaoui, H., et al. (2020). Aloe sp. leaf gel and water glass for municipal wastewater sludge treatment and odour removal. Water Sci. Technol. 81-3, 479–490. doi:10.2166/wst.2020.123

Jarzębski, M., Siejak, P., Smułek, W., Fathordoobady, F., Guo, Y., Pawlicz, J., et al. (2020). Plant extracts containing saponins affects the stability and biological activity of hempseed oil emulsion system. Molecules 125 (11), 2696. doi:10.3390/molecules25112696

Jin, R. T., Meng, R., Zhang, H., Yang, X., and Wu, Z. (2019). Effects of different deodorising processes on the off-odour compounds and gel properties of common carp surimi. Int. J. Food Sci. Technol. 53 (9), 2045–2053. doi:10.1111/ijfs.13791

Kharat, M., Aberg, J., Dai, T., and McClements, D. J. (2020). Comparison of emulsion and nanoemulsion delivery systems: The chemical stability of curcumin decreases as oil droplet size decreases. J. Agric. Food Chem. 68 (34), 9205–9212. doi:10.1021/acs.jafc.0c01877

Kundariya, N., Mohanty, S. S., Varjani, S., Hao Ngo, H., W. C. Wong, J., Taherzadeh, M. J., et al. (2021). A review on integrated approaches for municipal solid waste for environmental and economical relevance: Monitoring tools, technologies, and strategic innovations. Bioresour. Technol. 342, 125982. doi:10.1016/j.biortech.2021.125982

Liu, Q., Zhou, Y., Lu, J., and Zhou, Y. (2020). Novel cyclodextrin-based adsorbents for removing pollutants from wastewater: A critical review. Chemosphere 241, 125043. doi:10.1016/j.chemosphere.2019.125043

Nakasugi, T., Murakawa, T., Shibuya, K., and Morimoto, M. (2017). Deodorizing substance in black cumin (<i>Nigella sativa</i> L.) seed oil. J. Oleo Sci. 66 (8), 877–882. doi:10.5650/jos.ess17001

Nechifor, A. C., Cotorcea, S., Bungau, C., Albu, P. C., Pașcu, D., Oprea, O., et al. (2021). Removing of the sulfur compounds by impregnated polypropylene fibers with silver nanoparticles-cellulose derivatives for air odor correction. Membranes 11 (4), 256. doi:10.3390/membranes11040256

Oliva, G., Ángeles, R., Rodríguez, E., Turiel, S., Naddeo, V., Zarra, T., et al. (2019). Comparative evaluation of a biotrickling filter and a tubular photobioreactor for the continuous abatement of toluene. J. Hazard. Mater. 380, 120860. doi:10.1016/j.jhazmat.2019.120860

Pang, X. L., Yu, W. S., Cao, C., Yuan, X., Qiu, J., Kong, F., et al. (2019). Comparison of potent odorants in raw and ripened Pu-erh tea infusions based on odor activity value calculation and multivariate analysis: Understanding the role of pile fermentation. J. Agric. Food Chem. 67 (47), 13139–13149. doi:10.1021/acs.jafc.9b05321

Pillai, S. M., Parcsi, G., Wang, X. G., and Stuetz, R. M. (2012). Odour abatement of poultry litter using odour control products. Chem. Eng. Trans. 30, 247–251.

Ren, B. M., Zhao, Y. Q., Lyczko, N., and Nzihou, A. (2019). Current status and outlook of odor removal technologies in wastewater treatment plant. Waste Biomass Valorization 10 (6), 1443–1458. doi:10.1007/s12649-018-0384-9

Senatore, V., Zarra, T., Galang, M. G., Oliva, G., Buonerba, A., Li, C. W., et al. (2021). Full-Scale odor abatement technologies in wastewater treatment plants (WWTPs): A review. Water 13 (24), 3503. doi:10.3390/w13243503

Shin, H., Jang, Y., Lim, M., Park, J. Y., Yang, W., and Lee, K. (2020). Characteristics of exposure factors and inhalation exposure to selected spray consumer products in Korean population. Regul. Toxicol. Pharmacol. 10, 104513. doi:10.1016/j.yrtph.2019.104513

Taghizadeh, T. A., Clough, T. J., Sherlock, R. R., and Condron, L. M. (2012). Biochar adsorbed ammonia is bioavailable. Plant Soil 350, 57–69. doi:10.1007/s11104-011-0870-3

Tian, B., Hua, S., Tian, Y., and Liu, J. (2021). Cyclodextrin-based adsorbents for the removal of pollutants from wastewater: A review. Environ. Sci. Pollut. Res. Int. 28 (2), 1317–1340. doi:10.1007/s11356-020-11168-2

Tian, H. Z., Gao, J. J., Hao, J. M., Lu, L., Zhu, C. Y., and Qiu, P. P. (2013). Atmospheric pollution problems and control proposals associated with solid waste management in China: A review. J. Hazard. Mater. 252-253, 142–154. doi:10.1016/j.jhazmat.2013.02.013

Wang, H., Liu, C., Ma, X., and Wang, Y. (2022). Porous multifunctional phenylcarbamoylated-β-cyclodextrin polymers for rapid removal of aromatic organic pollutants. Environ. Sci. Pollut. Res. Int. 29 (10), 13893–13904. doi:10.1007/s11356-021-16656-7

Yin, P. J., Lu, H. J., et al. (2021). Analysis of odor gas production and deodorization technology in domestic waste treatment facilities. China Resour. Compr. Util. 39 (03), 173–175.

Zaman, N. Q., and Rosli, Y. K. R. N. (2015). Trimethylamine (fishy odor) adsorption by biomaterials: Effect of fatty acids, alkanes, and aromatic compounds in waxes. J. Hazard. Mater. 284, 269–277. doi:10.1016/j.jhazmat.2014.11.014

Zhang, X., Li, J., Shao, L., Huan, H., Qin, F., Zhai, P., et al. (2022). Effects of manure removal frequencies and deodorants on ammonia and GHG concentrations in livestock house. Atmosphere 13 (7), 1033. doi:10.3390/atmos13071033

Zhang, X., Yuan, Y., Xu, Y. Q., and Shi, B. L. (2019). Research progress on extraction technology and bacteriostatic activity of active ingredients in plant extracts. Chin. J. Animal Nutr. 31-12, 5461–5467.

Keywords: deodorant, plant extracted, odor gas, composting plant, odor abatement

Citation: Wu J, Yang J, Wang J, Fang L and Fang J (2023) A field-scale evaluation of the removal of odorous gases by a plant material-based deodorant. Front. Environ. Sci. 10:1073835. doi: 10.3389/fenvs.2022.1073835

Received: 19 October 2022; Accepted: 22 December 2022;

Published: 09 January 2023.

Edited by:

Chuandong Wu, University of Science and Technology Beijing, ChinaReviewed by:

Rishikesh Bajagain, Korea University, South KoreaNuerla Ailijiang, Xinjiang University, China

Copyright © 2023 Wu, Yang, Wang, Fang and Fang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jingjing Fang, NTUyNDE3NzQ1QHFxLmNvbQ==

Jun Wu1

Jun Wu1 Jingjing Fang

Jingjing Fang