- 1School of Economics and Management, Northwest University, Xi’an, Shaanxi, China

- 2Institute of Quantitative Economics, Huaqiao University, Xiamen, Fujian, China

As an integration of artificial intelligence and advanced manufacturing technology, intelligent manufacturing has realized the innovation of manufacturing mode and created conditions for the green development of industry. After constructing a theoretical framework between intelligent manufacturing and industrial green total factor productivity, this paper uses panel data of 30 provinces in China from 2006 to 2020, and expresses the level of intelligent manufacturing with industrial robot density, to discuss the economic effects and mechanisms of intelligent manufacturing. The results show that intelligent manufacturing has a positive effect on industrial green total factor productivity, and the panel quantile regression model indicates that there is an increasing marginal effect. With the quantile points going from low to high, the coefficient and statistical significance become larger. Human capital is the mechanism for intelligent manufacturing to improve industrial green total factor productivity. Green technology innovation and producer service industry agglomeration have strengthened the positive effect. There is also heterogeneity in the effect, and the stronger the effect in regions launched local pilot schemes for carbon emissions trading and industrial green transformation development policy. In order to give full play to the technological dividend and empower sustainable industrial development, the paper argues that we need to accelerate the integration of artificial intelligence and manufacturing technology, thus improving the level of industrial intelligence and empowering green development.

1 Introduction

With the intensification of global warming, the conflict between energy consumption and ecological environment is becoming more and more obvious (Acemoglu et al., 2012). The concept of green growth is derived from the green economy, which emphasizes environmentally sustainable economic growth to promote low-carbon and socially inclusive development. China has always been an active practitioner of green growth, with CO2 emissions per unit of GDP declining by 34.4% and the share of coal in primary energy consumption falling from 68.5% to 56% in the last decade. While environmental pressures remain heavy. According to the Environmental Performance Index (EPI) 2022 report released by Yale University, China scored 28.4 points, ranking 160th worldwide. Industrialization has contributed a lot to China’s rapid economic growth. However, the industrial sector is also the largest production sector with highest energy consumption and pollution emission density (Greenstone and Hanna, 2014). Compared with developed countries, there are still gaps in green inputs, outputs and creation of industrial added value (Yang et al., 2021). To this end, the Chinese government puts forward to take advantage of the new generation of technological revolution, such as artificial intelligence (AI), to promote traditional industries upgrading such as iron and steel, non-ferrous metals, petrochemicals, chemicals, and building materials.

Intelligent manufacturing (IM) refers to the integration of AI and advanced manufacturing technology (Zhou et al., 2018; He and Bai, 2021). It combines the advantages of information technology and manufacturing technology and is a new manufacturing model (Zhong et al., 2017). With the penetration of AI, IM has rapidly become the main goal of developed countries and emerging economies to promote the redevelopment of manufacturing and compete in the global value chain. Such as the “Re-Industrialization” plan of the United States, Germany’s “Industry 4.0”, Japan’s “Innovation 25 Strategy”, China’s “the Made in China 2025 Initiative”, and India’s “National Advanced Manufacturing Strategy”. Given the integrated characteristics of IM, its architecture can be divided into five parts: resource layer, ubiquitous network layer, service platform layer, intelligent cloud service application layer, and safety management and standard specifications (Li et al., 2017). This architecture allows IM to penetrate the product life cycle, including design, production, management, and service. It also connects enterprises in the supply chain with technical advantages such as increasing flexibility, improving efficiency, and improving quality of products and services (Kusiak, 2017; Zhong et al., 2017). Due to the tightening of carbon emission reduction goals, rising labor costs, and the reshaping of the global value chains, there is an urgent need for the industry to leverage new achievements in IM to realize green growth. Green growth encapsulates the dual goals of economic and environmental performance. According to existing literature, we think that the key to green growth lies in the improvement of green total factor productivity (GTFP) (Chen and Golley, 2014; Zhao et al., 2022).

Although IM has been used long in practice, its impact on green economic growth is beginning to appear. Questions remain about what impact does IM have on industrial GTFP? Is it positive or negative? How does IM affect industrial GTFP? Answering these questions is crucial to achieve intelligent-driven green growth. We first construct a framework of this paper based on the endogenous growth theory to explain the impact of intelligent manufacturing on GTFP in theory. Then, using panel data of 30 provinces in China from 2006 to 2020, this paper discusses the effect of IM on industrial GTFP from empirical perspective through the interactive fixed effect model. We also discuss the mechanism of IM affecting GTFP by using mediation model and moderation model. The marginal contributions are mainly reflected in: 1) the theoretical framework for the impact of IM on GTFP is constructed, and the effects are explained by China’s provincial data; 2) the interactive fixed effect model and industrial variables are used to rule out possible endogeneity issues in the paper; and 3) identify the mediating role of human capital in the effect of IM on industrial GTFP, and the moderating role of GTI and producer services agglomeration, enriching the discussion on the mechanism of IM affecting industrial GTFP.

The rest of the paper is organized as follows: the second part is a literature review; In the third part, the theoretical framework for how IM improves industrial GTFP is constructed, and assumptions are put forward; The fourth part is research design; The fifth part makes an empirical analysis by using the data from China from 2006 to 2020; In the sixth part, the marginal effects, heterogeneity and the mechanisms are analyzed. The last part are the conclusion and discussion, and policy implications are put forward.

2 Literature review

Related literature has discussed the impact of AI and intelligence on GTFP, and the results can be summarized as “positive effect”, “negative effect”, and” non-linear effect".

The “positive effect” refers to the positive effect of intelligence on GTFP. According to Grossman and Krueger (1991), economic growth is closely related to technological progress. Intelligence has a technical effect when other conditions are constant. Technological progress brought about by intelligence will improve productivity, improve the efficiency of resource use and reduce the factor input per unit output; Intelligence will also replace heavily polluting technologies, reduce energy consumption and emissions, and promote green development. Nie et al. (2022), for instance, used a sample of hand-matched Chinese manufacturing enterprises from 2000–2013, and found that the use of industrial robots can promote green production. Zhang et al. (2022) used the data of industrial robots at manufacturing-level, and found that the use of industrial robots can encourage enterprises to produce cleaner products, which in turn can improve GTFP; due to the development path dependence, the positive effect of industrial robots on GTFP will be stronger in regions with clean industries. Intelligence is also considered to have a spatial spillover effect, which can not only improve the local green total factor energy efficiency (GTFEE), but also improve the GTFEE in neighboring areas (Wu et al., 2021). When it comes to how intelligence improves GTFP, Li et al. (2021) used panel data of 35 countries from 1993–2017, and found that the use of industrial robots can improve energy use efficiency in the production process through improving the spillover effect of technological innovation and optimizing the factor input structure, which in turn improves GTFP. Using provincial panel data of China’s manufacturing industry from 2008–2017, Zhang and Wu (2021) decomposed GTFP and found intelligence can improve GTFP, and they pointed out that the main channel is to improve green technical efficiency. Contrary to the research results of Zhang and Wu (2021), Zhou and Chen (2022) pointed out that AI improves GTFP mainly by promoting technological progress.

The “negative effect” holds that technological progress brought by AI has increased energy consumption, which has a negative impact on green development. At the macro level, according to the neoclassical economic growth theory, technological progress will increase per capita output, promote economic growth and increase energy consumption; At the micro level, according to the production theory, technological progress will improve efficiency, promote the downward shift of enterprise cost curve, promote enterprises to expand production scale, and increase energy consumption through the scale effect brought by technological progress. This is also what Grossman and Krueger emphasize, the scale effect of economic growth, which further affects the relationship between technology and environment. Part of the literature explains this such as Smulders and Di Maria (2012) found that technological progress has improved TFP, but the improvement of TFP has also improved the marginal productivity of all inputs, including pollution inputs. In other words, the higher the value of TFP, the higher the cost of reducing pollution. Therefore, technological progress has increased the marginal cost of reducing pollution emissions, which makes enterprises that carry out technological innovation with the goal of maximizing profits focus on labor and capital savings, expanding energy consumption and aggravating the negative impact on the environment. Moreover, technological progress brought by AI is also considered to have a rebound effect, and the scale of output expansion comes from the increase of energy consumption rather than the decrease (Zhang et al., 2022). For example, Hu et al. (2019) found that the output expansion caused by technological progress increased the demand of enterprises for energy consumption, and the increased pollution emissions offset the emission reduction effect of technological innovation, thus finally increased the total pollution.

Some views of the “non-linear effect” show that there is a “U-shaped” “inverted U-shaped” or other non-linear relationship between information technology and GTFP. The non-linear relationship between intelligence and green growth comes from the superposition of technology effect and scale effect as mentioned above (Liao and Ru, 2022). When the technology effect is greater, the effect of intelligence on green growth is positive; However, with the development of intelligence, the scale effect will become larger and larger, even exceeding the technology effect, and the impact of intelligence on the environment will be reduced or even negative (or vice versa). Zhao et al. (2022) constructed a mathematical model of AI and GTFP, and they found that there is an “inverted U-shaped” relationship between AI and GTFP; They further used provincial panel data of China from 2006 to 2019, and found that China’s AI is currently in a rapid development stage, and its influence on GTFP is in the first stage of the “inverted U-shaped”. Using data from forestry industry, Wu and Zhang (2020) found that the effect of internet on forestry GTFP is non-linear and there is a threshold effect.

It can be found from the above literature that scholars have paid attention to the relationship between IM and GTFP, but there is still room for our paper. First of all, most of the literature discussed the effect from national and regional levels, but few of them focused on industrial level, and a complete theoretical framework between the two has not yet been built. Secondly, some studies believe that IM can improve GTFP, some studies believe that IM, as a kind of technological progress, will have negative effects on GTFP, and some studies believe that there is a non-linear relationship between IM and GTFP. The results are inconsistent with each other. The reason lies in measurement methods of IM and GTFP. As for IM, some studies use the density of industrial robots at the provincial, municipal or industry level as a proxy variable, and some studies use text analysis methods such as ML to assess the degree of enterprises using AI. Similarly, the measurement methods of GTFP and the selected input and output indicators are different. The differences of measurement methods lead to the estimation effects showing great differences in the results. Another aspect of the inconsistent conclusions lies in the fact that endogeneity has not been well resolved. This paper holds that there are efficiency differences and development path dependence within industry. Therefore, it is necessary to solve endogenous problems. Thirdly, the path of IM affecting GTFP is still unclear. Some studies have tried to decompose GTFP, and through empirical research, it has been found that IM promotes GTFP by improving the efficiency of green technology, but the results are inconsistent. The mechanism of IM affecting GTFP is very complicated, and there is still a lack of testing of other mechanisms behind it.

3 Theoretical framework

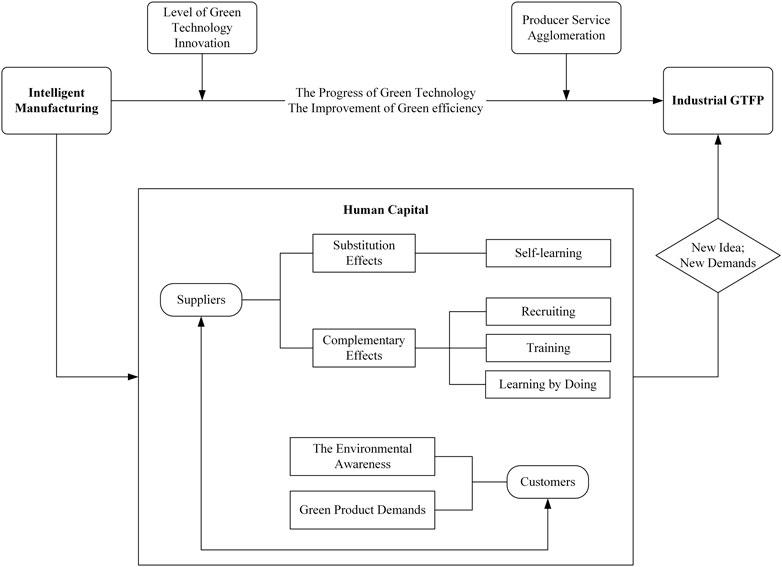

Unlike flexible and computer-integrated manufacturing, IM is characterized by self-awareness, self-determination, self-execution, self-adaptation, and self-learning. Through the industrial internet of things (IoT), cyber-physical systems (CPS), cloud computing (CC), large-scale data analysis (BDA), we can realize machine interconnection, even man-machine interconnection. With the application of these key technologies in manufacturing, the impact of IM on economic activities has been transmitted to all aspects. It may even redefine the economic functions of manufacturing. As an integrated technology, does IM affect industrial GTFP, and how does IM affect industrial GTFP? Based on the endogenous growth theory, this paper constructs the theoretical framework from three aspects: the direct and indirect effect, the mediating effect of human capital, and the moderating effect of the level of GTI and the agglomeration of the producer service industry. The framework of the paper is shown in Figure 1.

3.1 Direct mechanism

On the one hand, the improvement of GTFP stems from technological progress, and on the other hand, it is due to the improvement of technical efficiency, such as optimization of management and resource allocation efficiency (Zhao et al., 2022). Ghisetti and Quatraro (2017) pointed out that technological innovation can accelerate the application of technology in the production, and improve environmental productivity. IM, a major technological innovation in the era of Industry 4.0, has significantly influenced green technological progress and GTFP.

On the supply side, intelligence in the procurement process can help achieve source control of pollution emissions. With the help of blockchain and BDA technology, industrial enterprises can acquire and analyze energy market prices and supply in real-time, accurately use energy data, and optimize energy allocation. Industrial enterprises can reduce emissions in the process. Enterprises can directly improve existing production processes by using intelligent technologies into their production. For example, by promoting digitizing equipment, enterprises can enhance standard operations and visual control, and the energy consumption and pollution emissions generated during the production process can be observed and controlled in real-time (Magazzino et al., 2021). Enterprises can also innovate processes, combine AI with cleaner production technology, stimulate GTI, and enrich the application scenarios of AI, thus improving the effect of energy saving and emission in each link. In the digital era, transaction costs are decreasing, and various links in the industry chain continue to increase. GTI in one link will affect other industries through the industrial chain, which will generate a green technology spillover effect and structural effect of industrial structure upgrading, thus improving the GTFP of the whole industry. On the other hand, IM has connected the material supply, intelligent scheduling, production progress monitoring, quality control, product storage and transportation, logistics dynamics, and other production links. It can improve the efficiency of resource allocation, reduce the waste of resources caused by the inefficient connection of each production link, ultimately reduce the total energy consumption, thus improving the efficiency of energy utilization (Kusiak, 2017). Furthermore, enterprises with higher efficiency of energy utilization will gain competitive advantage, and green products will replace traditional resource-intensive products. Therefore, IM is conducive to eliminating high pollution and high energy consumption industries, and improving the GTFP.

From the demand side, the cost of green products is higher than that of traditional products. Under the traditional trading mode, the demand for green products is uncertain, so there are high innovation risks (Huang and Zhang, 2014). However, IM gives enterprises the potential to approach consumers. When making decisions, enterprises can predict demand more accurately to determine the best production scale by BDA. IM based on user value directly link demand with supply and realize on-demand production under mass production (Kohtamäki et al., 2019). It creates scale effect emphasized by improving TFP and reduces waste of resources. For example, enterprises can attract consumers to participate in value creation through technologies such as direct user connection manufacturing, user-generated content, co-creation, and virtual customer environment (VCEs). In addition, IM′ agility makes it possible to capture and analyze consumers’ preference accurately in real time (He and Bai, 2021). Enterprises can identify consumers’ demand for green products and meet it (Chang, 2011). Enterprises can also transform itself into cleaner production by improving environmental standards and product quality. High-quality products that meet environmental standards will win consumers’ preference, which will lead to an increase in output and the possibility of green production (Waldfogel, 2017), thus increasing GTFP. Accordingly, this paper puts forward the following hypothesis.

3.2 Indirect mechanism

From the technological architecture of IM, it is clear that Human-cyber-physical systems (HCPSs) are the technological mechanism that supports AI (Zhou et al., 2018). Human intelligence and machine intelligence grow up in a mutually enlightening way that inspires each other. Technological progress in AI has endowed AI with capabilities such as deep learning, cross-collaboration, human-computer intelligence, and swarm intelligence. Therefore, manufacturing become more intelligent, primarily cognitive and learning abilities. Machines can learn from past experiences or learn in real time. Therefore, AI can not only replace human beings in simple production tasks but also assist human beings in complex tasks (Acemoglu and Restrepo, 2019). It reduces the demand for a low-skilled labor force and, at the same time, increases the demand for a high-skilled labor force, thus improving the human capital of enterprises. Related literature, such as Salim et al. (2017), pointed out that the improvement of human capital can promote the innovation of energy-saving technologies and reduce energy consumption. Wang et al. (2021) also found that human capital is crucial to technological innovation, knowledge spillover, the upgrading of industrial structure, and awareness of environmental protection, thus improving GTFP.

From the perspective of producers, on the one hand, the substitution effect of IM on the labor engaged in simple production tasks can prompt workers to learn new technologies, improve their intellectual capital, promote the improvement of the human capital of the whole society, and provide more human capital and knowledge for GTI. On the other hand, employees need to be familiar with the manufacturing process and AI. This means that enterprises need to recruit more employees close to the technological Frontier. The increase of enterprise’s human capital is important to learning knowledge from the outside world, accelerating the penetration of AI and green technologies, thus promoting GTI. Employees and enterprises will gain experiences and skills from intelligence, and the learning effect of more imaginative “learning by doing” will promote cleaner production. The learning effect brought by more intelligent “learning by doing” will drive the cost curve of cleaner production to move to the left and reduce the average production cost by reducing the unit production cost. Secondly, IM′ self-adaptive and self-executing characteristics require machines to learn and train themselves. The main way of learning is to observe human decisions (Brynjolfsson and Mitchell, 2017). This encourages enterprises to increase the proportion of senior management and other tasks, recruit employees with rich management experience, and optimize the management process, thus improving the efficiency of green technology (Zhao et al., 2022).

The positive effect of human capital of IM is also reflected in the demand side. Goetz et al. (1998) found that human capital improves the environmental quality and that the more educated an individual is, the more environmentally conscious he or she is. Therefore, the increase in human capital in enterprise and society is conducive to stimulating consumers’ preference for green products and promoting them to adopt environmentally-friendly consumption behavior (Littledyke, 2008). This leads to a demand for green products, which drive enterprises to improve their environmental standards of their products. Accordingly, this paper puts forward the following hypothesis.

3.3 Moderating effect

3.3.1 Moderating effect of the level of GTI

Enterprises can make decisions according to a given level of GTI and choose whether to invest in AI. Related studies have showed that the stronger the effect of intelligence on GTFP in regions dominated by clean industries due to development path dependence (Zhang et al., 2022). Therefore, enterprises’ and industries’ GTI level is crucial to the relationship between IM and GTFP.

Compared with traditional technological innovation, GTI means higher costs, more complex innovation processes, and greener achievements (Ben Arfi et al., 2018). Although some enterprises have a high level of GTI, they still face large R&D costs. IM has dramatically reduced the cost, giving enterprises more incentives for green R&D. Enterprises can test the performance of cleaner production technology in virtual space (He and Bai, 2021). This improves the ability to analyze, predict and intervene in physical products and reduces the R&D cost of green technologies. Metcalfe’s Law of information technology enables some enterprises with a high level of GTI to quickly gain innovation cost advantage and improve the efficiency of green technology after using IM. Moreover, the fierce competition in AI makes the introduction cost decrease, so that enterprises can invest more in green technology R&D, promote GTI, and thus improving GTFP. Even small-scale enterprises have opportunities to approach the Frontier of IM technology (Acemoglu et al., 2007). According to Wu et al. (2022)’s study, the smaller the gap with advanced technology, the more beneficial it is for the innovation of enterprises to upgrade GTFP. Therefore, it also indirectly improves the GTI level of the industry. Finally, IM also realize the interconnection between intelligent systems, supply chains, and industrial chains through the platform, breaking the boundaries of production modules, enterprise, and even industry. Knowledge, labor and other factors needed for GTI will fully flow, thus promoting the integration of innovative resources. Even if some little enterprises can hardly turn knowledge into innovation output in a short time, they can “imitate” others to achieve incremental innovation and accelerate the adoption of Frontier green technology. Increasing the level of adoption of advanced green technologies can trigger a positive feedback loop of innovation, further increasing the use of technology, improving the green efficiency and promoting the improvement of GTFP. Therefore, a higher level of GTI can stimulate a positive feedback loop from IM to GTI and GTFP. This paper puts forward the following hypothesis.

3.3.2 Moderating effect of producer service industry agglomeration

Producer service industries are critical intermediate inputs of industry, and agglomeration of producer service industries has an essential impact on the promotion of GTFP. A study on Japanese manufacturing by Otsuka et al. (2014) found that agglomeration can significantly improve energy efficiency of manufacturing. Another study of the Chinese industrial sector also indicates that specialized and diversified agglomerations have a positive effect on industrial GTFP (Cheng and Jin, 2022). Agglomeration of producer services mainly affects industrial GTFP by scale effects, knowledge and technology spillover effects, and industrial structure upgrading effects.

Traditional agglomeration is based on geographical space, most of which are geographical agglomeration. Digital economy has given birth to new business models such as e-commerce, significantly reduced transaction costs, and choice constraints brought by distance have become less critical or even disappeared (Goldfarb and Tucker, 2019). The reduction of transaction costs leads to the agglomeration of producer services on the Internet. Internet-based agglomeration strengthens the connection of all links in the supply chain, turns the linear value chain into a network pattern, accelerates IM applications. The large-scale zero-distance agglomeration brought by the Internet has also formed a large-scale supply of traditional factors and new factors such as data. The final production sector has more choices that are no longer bound to the city or internal. They can purchase more environmentally intermediate goods at lower costs or specialized technologies, thereby promoting green production. Therefore, the higher the degree of agglomeration based on the Internet, the stronger the connection between industries and enterprises. The net-like value creation model will prompt the rapid penetration of AI into all industries, strengthening the positive effect of IM on GTFP.

Due to characteristics of AI and its requirements for digital infrastructure on which data computation, storage, and transmission depend, the development of digital economy has produced some specialized agglomerations of digital industries. For example, big data industry demonstration zones, digital economy industrial parks, industrial Internet platforms, and digital creative incubation platforms. In these regions with high degree of specialized agglomeration, the cost of introducing AI for enterprises will be lower. Introducing AI such as industrial robots can promote the integration and innovation of IM and cleaner production technologies. Diversified agglomeration also affects the effect of IM on GTFP. In regions with a higher degree of diversified agglomeration of producer services, the mobility of knowledge, technology, human capital, and other factors is higher. Enterprises can obtain more sources of knowledge, providing the foundation for the application and innovation of IM. In turn, intelligent products have the property of “a new division of labor” and the new property of “intelligent connection,” which can further produce large-scale, cross-border, highly integrated connections (Cao et al., 2022). This “intelligent connection” can generate large-scale, cross-border, and highly integrated connections, increasing the diversification and agglomeration of producer services. In regions with a high degree of diversification, the spillover effect of knowledge and technology will be rapidly transmitted to other industries, which will help inefficient and energy-intensive industries to improve their production patterns, thus enhancing industrial GTFP.

4 Research design

4.1 Variable selection

4.1.1 Explained variables

Industrial GTFP. Since the traditional Data Envelopment Analysis (DEA) requires input factors to grow simultaneously in a fixed proportion, it is difficult to measure marginal rate of technical substitution with significant variability among production factors due to different development environments and stages of development. In order to avoid statistical errors caused by traditional measurement methods as much as possible, this paper uses a non-radial and non-angle-based SBM directional distance function. It combines it with the GML index to measure GTFP. The advantage of this method is that the unexpected output and dynamic continuity can be considered more scientifically while the expected output is processed. The evaluation system of industrial GTFP contains three categories of inputs, desired outputs, and non-desired outputs. Regarding the input variables, this paper selects three variables: energy, labor, and capital, combined with the production function and data availability. Among them, labor is measured by the number of employees in urban industries; Capital is measured by the net fixed assets of industrial enterprises above scale; Energy is measured using industrial energy consumption (standard tons of coal). The gross industrial output value measures the expected output without intermediate inputs, and time output is converted by the price indices, with 2005 as the base year. Unexpected output is measured using industrial sulfur dioxide and industrial wastewater emissions.

4.1.2 Explanatory variables

IM (Rob). Some scholars take the density of industrial robot installation as a proxy variable for the level of IM or AI and believe that the number of industrial robots owned by unit labor reflects the level of IM in China (Chen et al., 2018; Lu and Zhu, 2021). Since 2006, the International Federation of Robotics (IFR) has published the number of industrial robots and installed stock in the old industries countries around the world. However, the published data are at national industry level, which does not meet the regional panel data needed for this paper. Regard of this, Xin et al. and Yan et al. first matched the 14 manufacturing classifications published by IFR with the 31 manufacturing industries in China (Yan et al., 2021; Wang et al., 2022). Then, the proportion of employed in urban units in each sub-sector to the total employed population in the country in each region in the past years is used as the weight, and finally, the industrial robot installation density at the manufacturing level in the United States in 2005 was introduced as an instrumental variable to construct the industrial robot installation density at the provincial level. The formula can be expressed as.

In Eq. 1, Rob denotes robot installation density, which is used to characterize IM;

4.1.3 Mechanism variables

Human capital (Hum). Currently, the mainstream method to measure human capital is to use local characteristics of individuals, such as literacy rate per year of education. However, this method ignores subjective and objective factors that affect human capital, such as vocational training, work experience, physical fitness, marketization process. So this method cannot provide a accurate picture of human capital (Li et al., 2014). Therefore, this paper selects the stock of human capital estimated by Human Capital Research Center of China Central University of Finance and Economics based on the Jorgenson-Fraumeni (J-F) lifetime income method, and combines it with the human capital Mincer model as the proxy variable of human capital. The stock of human capital measured by this method can more accurately reflect the role of long-term human capital investments such as education and health, and it is also comparable across regions (Fraumeni et al., 2019).

Green Technology Innovation (GTI). In 2010, the World Intellectual Property Organization (WIPO) launched an online tool to search for patent information related to environmentally-friendly technologies, namely the “Green List of International Patent Classification.” This search entry divides green patents into seven categories, such as waste management, energy saving, and alternative energy production. Based on the green technology categories published in the list, and the patent application data published by State Intellectual Property Office (SIPO), this paper defines whether patent has green attributes according to whether the international patent classification number accurately matches the list.

Aggregation of producer service industries (Agg). Industrial agglomeration can be divided into three modes: diversified agglomeration, specialized agglomeration and multi-industry synergistic agglomeration. This paper only discusses the economic and social effects of the two kinds of agglomeration behaviors. The reciprocal of the Herfindahl index is used to measure diversified agglomeration of producer service industries, which is calculated by

4.1.4 Control variables

Six variables are selected as control variables according to the work of Zhao et al. (2022), Zhang and Wu (2021), and Zhou and Chen (2022). Specifically: macro-control (Gov), the share of local general budget expenditure in GDP is chosen as a proxy variable; Population density (Pop), the ratio of total local resident population to regional administrative area is chosen as a proxy variable; Industrial structure (Ind), the share of value added in tertiary industry to value added in secondary industry is chosen as a proxy variable; Urbanization (Urban), the ratio of the number of urban population to the total population is chosen as a proxy variable. Economic development (PGDP), the per capita gross regional product (real GDP per capita in 2006 as the base period) is chosen as a proxy variable; Information technology (Tech), the length of long-distance fiber optic cable lines is chosen as a proxy variable.

4.2 Model construction

4.2.1 Benchmark model

In traditional panel data models, both individual effects and time effects are added to the model. The unobservable factors are differentiated by the methods of mean processing so as to control the individual effect that does not change with time, and the time effect that does not change with individual in the sample data, which can alleviate possible endogenous problem to some extent. However, shocks in time are often multi-dimensional. There is often heterogeneity in the economic effects caused by the same shock to different regions. Compared with traditional fixed effect model, the interactive fixed effect model fully considers the multidimensional impact of time in economic reality and the heterogeneous responses of different individuals to these impacts, which can better reflect the economic reality and effectively reduce the endogenous problems (Bai, 2009). Residual matrix obtained from the original equation is first estimated using OLS and treated as if N residuals exist, with one residual series for each individual. The interactive fixed effect model is assumed to

Where,

Embedding the common factors in a fixed effect model yields

Where,

In Eq. 5, the subscripts i and t denote province individuals and years, respectively, j denotes the number of control variables, Control denotes a series of control variables,

4.2.2 Intermediary effect

To test H2, a mediation model is used to test the mechanism, and the following set of equations is constructed on the basis of Eq. 6

In general, the specific ideas of the mediating effect test are: first, the total effect of IM affecting industrial GTFP is calculated by Eq. 5, and

4.2.3 Moderating effect

To test H3 and H4, the paper examines the interaction of moderating variables with IM, which leads to the construction of the following two econometric models

In Eqs 8, 9,

4.3 Data sources and descriptive statistics

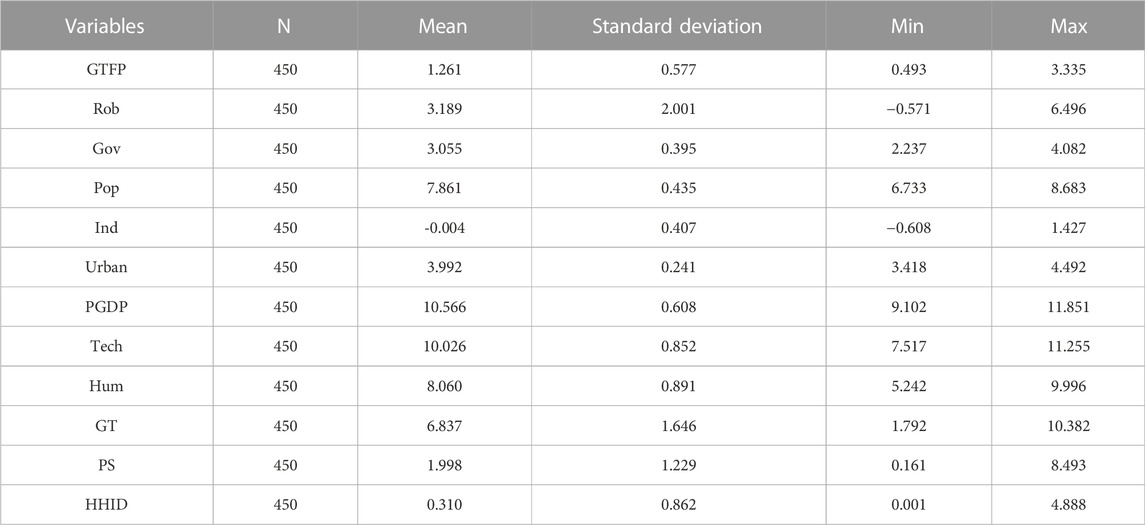

The panel data of 30 Chinese provinces (excluding Tibet and Hong Kong, Macao and Taiwan) from 2006 to 2020 are selected as the sample. The data of the indicators involved in industrial GTFP are mainly derived from the China Statistical Yearbook and the China Environmental Statistical Yearbook. The original data of IM comes from the China Labor Statistics Yearbook, the International Federation of Robotics (IFR), and U.S. Bureau of Economic Analysis. The data for human capital stocks comes from the China Human Capital Report (2020). The original data for control variables mainly come from the National Bureau of Statistics and the EPS database. For missing values, linear interpolation method is used in this paper. In the process of actual fitting calculation, variables, with relatively large values, are processed logarithmically. Descriptive statistical results of the processed variable data are shown in Table 1.

5 Empirical testing

5.1 Baseline regression

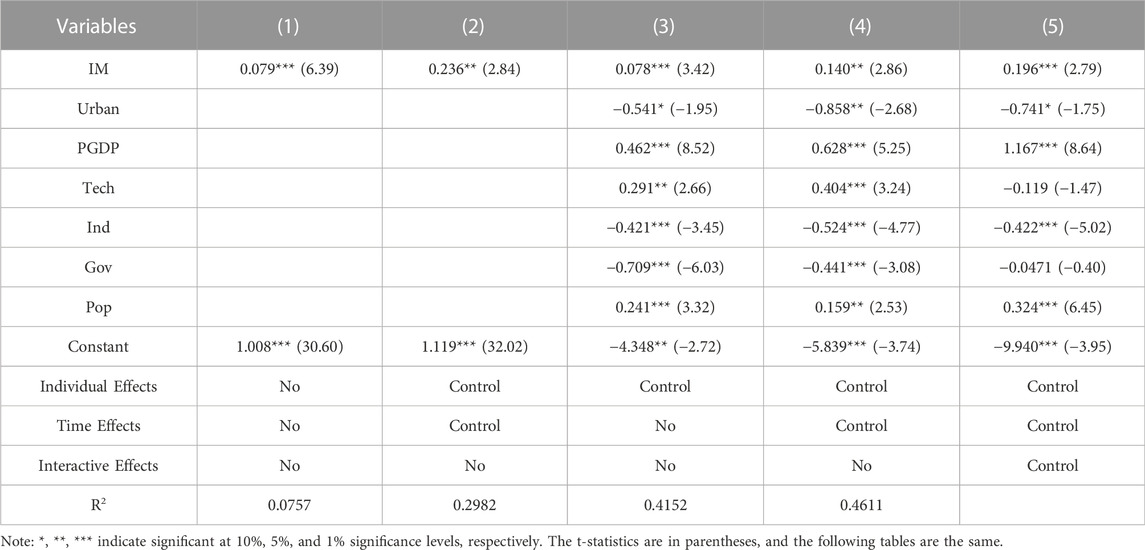

Table 2 shows the results of baseline regressions. We first report the results estimated by the traditional fixed effect model. Column (1) controls for individual effects only, and column (3) controls for time effects. Individual and time bivariate fixed effects are controlled in columns (2) and (4). Of these, column (2) contains estimates without any control variables, and column (4) contains all the control variables selected above. Column (5) shows the estimation results using the interactive fixed effect model presented in Eq. 6 above. From columns (2) and (4), it can be seen that IM promotes industrial GTFP improvement at least at the 5% significance level, regardless of whether control variables are included or not. It can be found that IM promotes industrial GTFP at 1% significance level. For every 1% increase in IM, industrial GTFP will increase by about 19.6%, which verifies H1. IM optimizes the traditional production process and improves the energy utilization efficiency of industrial enterprises. IM has also promoted the development of manufacturing industry, promoted the upgrading of industrial structure and further improved the industrial GTFP. The results are also consistent with the results of Zhao et al. (2022) on the impact of provincial industrial robot application on GTFP. Moreover, compared with their results, we have further identified this positive impact from an industrial perspective. Comparing the results estimated by the fixed effect model in column (4), it is found that the coefficients estimated by the interactive fixed effect model are larger and the significance level has been improved. It indicates that the interactive fixed effect model solves the endogeneity problem caused by the omitted unobservable factors to some extent, and the conclusion that there is a positive promotion effect of IM on industrial GTFP is valid.

5.2 Robustness test

5.2.1 Cross-sectional correlation

Although the influence caused by unobservable factors is reduced by interactive fixed effect model in benchmark regression, due to the panel type being short in this paper, conditional heteroscedasticity, autocorrelation with panel and cross-sectional correlation may exist in both time series and cross section, which makes the results biased. Although we have used the robust standard error of clustering to solve the problem of conditional heteroscedasticity and autocorrelation, a classical hypothesis is still unsolved. Driscoll and Kraay (1998) used SCC model to modify the finite element model so that it has more robust standard error, which can well overcome the threat that the panel data is short and difficult to meet the classical assumptions of econometrics. The results in column (1) of Table 3 show that IM still positively contributes to industrial GTFP at the 5% significance level, corroborating the robustness of the benchmark regression results.

5.2.2 Time lag effect

Although IM has made achievements in some industries, AI are still in the expansion stages (Brynjolfsson and Mitchell, 2017; Zhao et al., 2022). According to the law of penetration of generic technologies (Perez, 2010), the integration of AI with manufacturing technology and then the impact of IM on GTFP will be a long-term process, and industrial robots require a period of preparation from introduction, installation, equipment commissioning to production, so the impact of IM on industrial GTFP may have a time lag effect. To examine this time lag effect, the paper is re-fitted and calculated using the industrial GTFP with a one-period lag as the explanatory variable. Column (2) of Table 3 shows that after considering the lag effect, IM has a positive impact on industrial GTFP at the 5% significance level, which indicates that after considering the lag effect, the positive impact of IM on industrial GTFP is still valid. It is not disturbed by short-term time factors. According to Zhang et al. (2022), there is a technological path-dependence in the production of industrial enterprises. In order to maintain existing profits, industrial enterprises are often reluctant to adopt new technologies in a short time. Therefore, the process of improving the production process of enterprises through IM is slow.

5.2.3 Estimation method substitution

The traditional panel econometric models only consider the two-dimensional perspective of time and individuals but do not include the spatial linkages among individuals. As the economic trade between regions becomes closer and road access continues to increase, inter-regional policy behaviors or technological innovations often lead to imitation and interaction among neighboring regions, resulting in spatial game behavior. Therefore, it is necessary to control the economic linkage and geographic information among individuals. This paper uses the Spatial Durbin model to replace the classical panel fixed effect model to control the influence of potential spatial information. Column (3) of Table 3 shows a positive relationship between IM and industrial GTFP at the 5% significance level. Meanwhile, the Spatial Durbin model Spatial-rho statistic of −0.574 passed the 1% significance test, indicating that there is a spatial correlation between the effect of IM on GTFP, which is consistent with the results of Wu et al. (2021).

5.2.4 Endogenous analysis

The previous study argued efficiency differences and development path dependence among industries and enterprises within the industrial sector. The higher the GTFP, the more adaptive they are to the technological impact of IM. In these more efficient industries, the smaller the crowding-out effect of investing in IM on green technology R&D, the greater the positive effect of technology. Therefore, enterprises and industries with higher GTFP are usually more capable and willing to implement intelligent transformation and increase investment in IM. In other words, there may be bidirectional causality between IM and industrial GTFP. In addition, there may be endogeneity caused by omitted variables.

To address the possible endogeneity issue, drawing on Sun and Hou (2021), the long-distance fiber optic cable density of each province is used as the first instrumental variable. IM cannot be promoted without the support of information infrastructure. The density of optic cables affects the diffusion of the new generation of ICT on which IM relies. From the perspective of exclusivity, each province’s optic cable density has no direct impact on industrial GTFP. To prevent the problem of weak instrumental variables, this paper also draws on Bartik’s idea to construct a “Bartik Instrument” (Bartik, 2006), which is the product of the first-order differential terms of IM and IM in time with a lag of one order. The results show that the LM statistic is 100.994, which is significant at the 1% level and passes the instrumental variable non-identifiability test. The Wald F statistic is 64.648, which is greater than the 10% threshold of 19.93 and passes the weak instrumental variable validity test; The p-value of the Sargan statistic is 0.331, which does not reject the hypothesis that all instrumental variables are exogenous. The results of three tests show that the two industrial variables selected in this paper are effective, and there are no weak variables. As shown by the 2SLS results in Table 3, IM still contributes to industrial GTFP at the 10% significance level after solve the endogeneity issue.

Considering that it is very difficult to find a strictly exogenous industrial variable, this paper assumes that the above-mentioned industrial variables are slightly endogenous, and further uses the approximate exogenous tool variable method to estimate. The Bartik instrumental variable is used here as an example for testing.

As can be seen from the approximate exogenous IV results in Table 3, the coefficient of IM is 0.127, which has passed the test of 1% level. It confirms that the results confirmed in the benchmark regression again.

6 Further analysis

6.1 Non-linear analysis

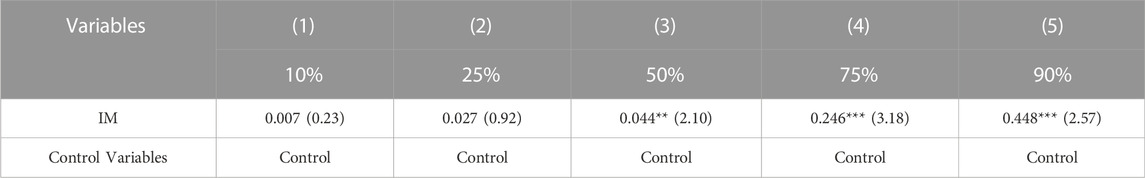

There are differences among industries regarding industry chain characteristics, production processes and procedures, products, and other dimensions. This makes the application of IM vary across industries. For example, the higher the degree of application of IM in industries such as computer, communication and other electronic equipment manufacturing, instrumentation manufacturing, and automobile manufacturing, the lower the degree of application of IM in industries with high dependence on natural resources such as petroleum processing, coking and nuclear fuel processing industries, and non-ferrous metal smelting and calendering industries (Zhao et al., 2021). However, the results of the benchmark regression only reflect the average effect of IM. This section uses a panel quantile regression model to explore the heterogeneous effects of different quantile locations. According to Zhang and Dai (2012), five quartiles of (0.1, 0.25, 0.5, 0.75, 0.9) are set.

As shown in Table 4, the effect of IM on industrial GTFP is positive but insignificant when the quantile is at the 10% and 25% quantile. As the quantile increases, the coefficient of IM gradually increases and the significance level increases. When at the 50% quantile, the coefficient of IM is 0.044, which is significant at the 5% level of significance; At the 75% quantile, the coefficient of IM is 0.246, which is significant at the 1% level of significance; and when at the 90% quantile, the coefficient of IM is 0.448, which is significant at the 1% level of significance. The results show a structural difference in the effect of IM on GTFP; the higher the level of industry GTFP, the more substantial the contribution of IM to industrial GTFP.

6.2 Heterogeneity analysis

Some of the literature found through empirical tests that there is industry and regional heterogeneity (Zhang and Wu, 2021; Zhao et al., 2022). However, these studies have ignored the role of government. According to Porter Hypothesis, environmental protection policies can improve the productivity of enterprises in the long run, offset the costs brought by environmental protection, promoting economic growth. The study of Jin et al. (2022) found that China’s SO2 emission trading schema pilot has a positive impact on industrial innovation. But Han et al. (2022) found that the effects of carbon trading mechanism on the green transformation of the economy will vary according to industry. To further identify the heterogeneity, this section discusses the heterogeneous effects of government industrial and environmental policies. We mainly discuss the impact of two policies, the policy of carbon emission trading mechanism and the policy of green transformation development of regional industry.

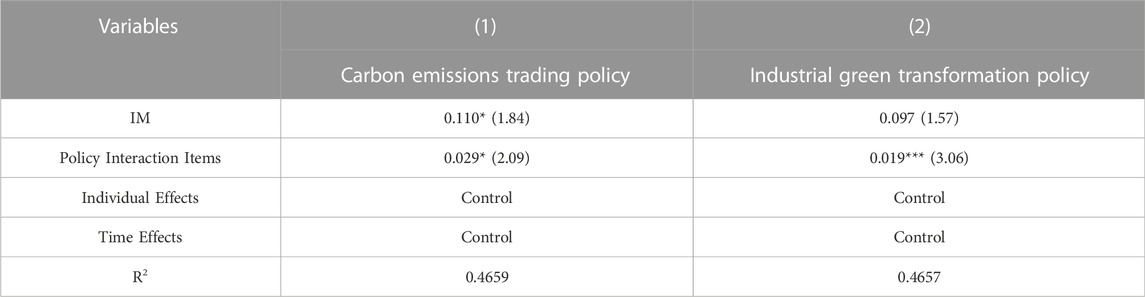

6.2.1 Policy of carbon emission trading

The clarification of carbon emission trading rights is conducive to promoting data flow and carbon market flow, strengthening industrial enterprises’ motivation to focus on laying out carbon assets and enhancing energy conservation and emission reduction. In October 2011, the Chinese government launched local pilot schemes for carbon emissions trading in Beijing, Tianjin, Shanghai, Chongqing, Hubei, Guangdong and Shenzhen. Here, these seven provinces are assigned a value of one and provinces without piloting are assigned a value of 0. After adding policy dummy variables, the estimated results are shown in column (1) of Table 5. As can be seen from column (1) of Table 5, the interaction term between IM and the pilot policy of the carbon emission trading is significant at the level of 10%, which means that in regions launched local pilot schemes for carbon emissions trading, enterprises have a stronger motivation to save energy and reduce emission, and IM has a more significant positive effect on industrial GTFP.

6.2.2 Policy of industrial green transformation development

In order to explore the green development path of industrialization and energy conservation and emission reduction that mutually promote each other, in June 2015, China’s Ministry of Industry and Information Technology started a pilot industrialization green transformation in 11 regions. The purpose is to promote energy conservation and emission reduction technology, cultivate energy conservation and environmental protection industry. Here, the provinces where these 11 regions are located are assigned a value of 1, and the provinces without piloting are assigned a value of 0. After introducing the policy dummy variables, the estimation results are shown in column (2) of Table 5. As shown in column (2) of Table 5, the interaction between IM and industrial green transformation development pilot policies is significant at the 1% level. It indicates that the improvement effect of IM on industrial GTFP is more robust in industrial green transformation development pilot areas.

6.3 Mechanism testing

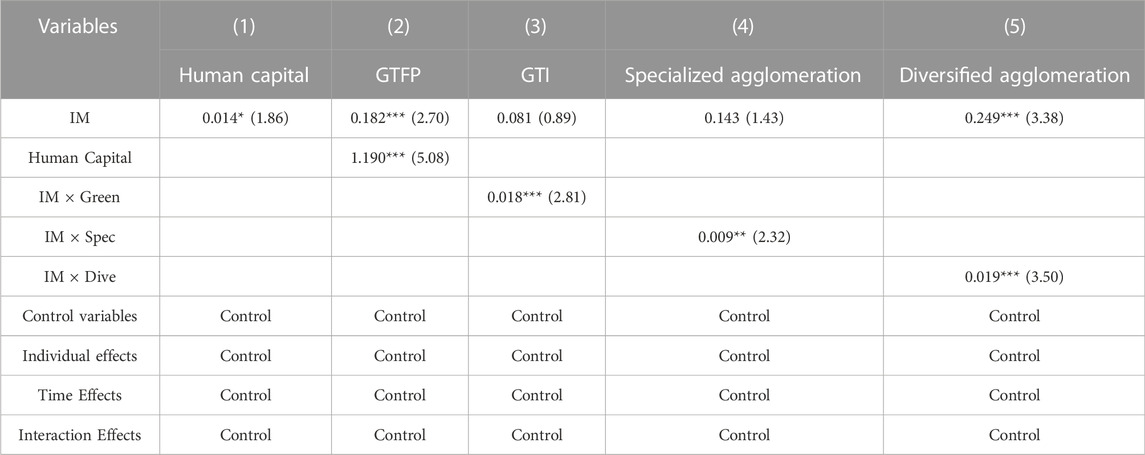

6.3.1 Mediating effect of human capital

Column (1) of Table 6 shows the results of Eq. 6; when human capital is used as a mediating variable, it can be found that IM improves human capital at a 10% significance level. Column (2) of Table 6 shows the results of Eq. 7 when human capital is used as a mediating variable. Column (2) shows that at the 1% significance level, IM has improved industrial GTFP by promoting human capital. There is a logic that IM affects GTFP by influencing human capital and thus GTFP. H2 is verified. In contrast to the results of Zhang and Wu (2018), and Zhou and Chen (2022), who proved the mediating effect of technological progress and technological efficiency, we proved the mediating effect of human capital from the perspective of endogenous technology, enriching the discussion of the mediating mechanism. On the one hand, IM puts forward new requirements on the human capital structure of enterprises, which will be forced to recruit workers with technical and management skills, to promote GTI. On the other hand, IM forces some low-skilled workers to improve their knowledge and skills to adapt to the intelligent society and improve the human capital of the whole society. When the level of human capital in society increases, people’s awareness of environmental protection will increase, which will increase green consumption behavior and thus have a positive impact on the industrial GTFP.

6.3.2 Moderating effect of GTI and productive service industry

Columns (3), (4), and (5) of Table 6 show the results of the moderating effects. As can be seen from column (3) of Table 6, when the interaction term between IM and the level of GTI is added to the baseline regression, the coefficient of the interaction term is positively significant at the 1% level. It shows that the level of GTI positively moderates the relationship between IM and industrial GTFP. The stronger the effect of IM on industrial GTFP in industries and enterprises with higher levels of GTI. H3 is verified. In regions and industries with higher levels of GTI, IM has a stronger effect on industrial GTFP. Consistent with Zhang et al. (2022) ‘s results, it shows that green economic growth does have technology path dependence.

From column (4) of Table 6, it can be seen that the interaction term between IM and specialized agglomeration is positively significant at the significance level of 5%, indicating that specialized agglomeration of producer services has positively moderated the relationship between IM and industrial GTFP. In regions with a high degree of specialized agglomeration, the spillover effect of knowledge and technology from IM will be rapidly transmitted to other industries, which will help inefficient and energy-intensive industries improve their production patterns, and further upgrade industrial structure, thus enhancing industrial GTFP. Diversified agglomeration has similar effects. Column (5) of Table 6 shows that the interaction term between IM and diversified agglomeration of producer services is significant at 1% significance level, indicating that diversified agglomeration of producer services positively moderates the relationship between IM and industrial GTFP. In regions with a higher degree of diversified agglomeration, knowledge, technology, labor and other factors flow fully, laying the foundation for GTI, thus the effect of IM on industrial GTFP is stronger. H4 is verified. Comparing the coefficients of the interaction terms of the two types of agglomeration, it can be seen that the coefficient of diversified agglomeration is significantly larger than that of specialized agglomeration, indicating that IM has a more severe impact on industrial green GTFP through the agglomeration knowledge spillovers and industrial linkages of various types of enterprises.

7 Conclusion and discussion

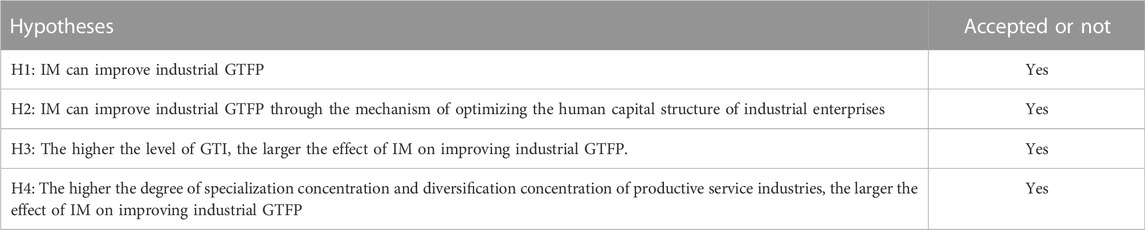

In this study, after discussing the impact of IM on industrial GTFP from theoretical level, we use panel data of 30 Chinese provinces from 2006 to 2020, and found that IM has improved industrial GTFP, and this result still holds after passing a series of robustness tests and using instrumental variables to rule out endogeneity. The effect of IM has an increasing marginal trend, and the higher the level of IM, the stronger its effect on GTFP. IM improves the level of industrial GTFP by improving human capital. The level of GTI and the agglomeration of producer service industries play moderating roles: the higher the level of GTI, the stronger the effect of IM on industrial GTFP; No matter specialized agglomeration or diversified agglomeration, producer service aggregation positively moderates the effect of IM on industrial GTFP. However, the moderating effect of diversified agglomeration is larger than that of specialized agglomeration. The results of heterogeneity analysis show that the environmental and industrial policies corresponding to the development of intelligence and greening also have significant impacts. In regions where carbon emission trading policy and industrial green transformation policy are implemented, IM has a greater impact on the improvement of GTFP. All results of this paper are shown in Table 7.

To better promote the green transformation of industrial enterprises, we proposed the following policy suggestions. Firstly, enrich the application scenarios of IM in industrial green production and energy saving, actively cultivate new business models, and create more opportunities for enterprises to develop and apply cleaner production technologies. Secondly, enterprises should pay attention to improve human capital to provide knowledge for enterprises’ intelligence and green transformation. While introducing high-end talents, enterprises should strengthen the training and management of existing employees and increase cooperation and innovation among industries, regions, and enterprises. Thirdly, guide the agglomeration of producer service industries in some areas with a low level of IM, and improve the IM level in these areas through the specialized agglomeration and diversified agglomeration of producer service industries.

Consistent with the studies of Zhang and Wu (2021); Li et al. (2021); Zhang et al. (2022), we found that IM represented by industrial robots has a positive effect on GTFP. In contrast to these studies, we focus our study on the industrial effect of IM rather than the macroeconomy, as the industrial sector is the main application field of IM (Zhong et al., 2017; Day, 2018). We believe it makes sense to focus on the industrial sector because of the differences in industry chain characteristics and technology needs of each industry (Zhao et al., 2021). Although studies by Hu et al. (2019); Zhang et al. (2022) pointed out that technological progress brought about by AI has scale effect, which will adversely affect green development through output expansion. However, through the non-linear analysis of IM, we found that at this stage IM has positive marginal effect on industrial GTFP. In other words, the intellectualization of China’s industrial sector is still at the stage of rapid development. The technological effect and structural effect will be greater than the scale effect to promote the improvement of industrial GTFP, which is also consistent with Zhao et al. (2022)’ study. After identifying that IM has a positive effect on industrial GTFP, we further discussed the multiple mechanisms. Different from the existing studies, for instance, Zhang and Wu (2021); Zhao et al. (2022), who decompose GTFP into technological progress and technological efficiency and then discuss the mechanism of IM, we further identified human capital as the mechanism by which IM affects industrial GTFP based on endogenous growth theory. We also found the moderating effect of green technological innovation level and producer services agglomeration. It enriches the research on the mechanism of IM affecting industrial GTFP.

Our study has the following limitations. First, as pointed out by Li et al. (2017), the technical architecture of IM is complex, so the mechanism of IM influencing industrial GTFP is also diverse. However, we have only identified the intermediary mechanism of human capital, but in fact there are still other mechanisms of IM affecting industrial GTFP, which needs further discussion. Second, we use industrial robots to express the level of IM, but the variable of industrial robots (Rob) was calculated through the application of robots at the industry level and cannot accurately reflect the actual level of industrial robots used in the industrial sector. Finally, the impact of IM on industrial GTFP is in fact different for different industries have different requirements for intelligence, but our results and discussion are very limited. These limitations will hopefully be addressed in future research.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

ZY wrote the introduction, literature review and theoretical analysis of this paper. The work of data search, calculation and empirical analysis was completed by YS. The abstract,conclusion and discussion settion, as well as the revision and proofreading of the paper,were jointly completed by ZY and YS.

Funding

This work was supported by the 2022 Natural Science Foundation of Fujian Province (Grant no. 2022J01320) and by the Fundamental Research Funds for the Central Universities in Huaqiao University.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Acemoglu, D., Aghion, P., Bursztyn, L., and Hemous, D. (2012). The environment and directed technical change. Am. Econ. Rev. 102 (1), 131–166. doi:10.1257/aer.102.1.131

Acemoglu, D., Aghion, P., Lelarge, C., Van Reenen, J., and Zilibotti, F. (2007). Technology, information, and the decentralization of the firm. Q. J. Econ. 122 (4), 1759–1799. doi:10.1162/qjec.2007.122.4.1759

Acemoglu, D., and Restrepo, P. (2019). Automation and new tasks: How technology displaces and reinstates labor. J. Econ. Perspect. 33 (2), 3–30. doi:10.1257/jep.33.2.3

Bai, J. (2009). Panel data models with interactive fixed effects. Econometrica 77 (4), 1229–1279. doi:10.3982/ECTA6135

Bartik, T. (2006). How do the effects of local growth on employment rates vary with initial labor market conditions? Kalamazoo,MI: Upjohn Institute Working Paper. No. 09-148). doi:10.2139/ssrn.1372814

Ben Arfi, W., Hikkerova, L., and Sahut, J. (2018). External knowledge sources, green innovation and performance. Technol. Forecast. Soc. Change 129, 210–220. doi:10.1016/j.techfore.2017.09.017

Brynjolfsson, E., and Mitchell, T. (2017). What can machine learning do? Workforce implications. Science 358 (6370), 1530–1534. doi:10.1126/science.aap8062

Cao, X., Ouyang, T., and Huang, J. (2022). Research on how smart connected products reshape enterprise boundaries: The case of xiaomi. J. Manag. World 38 (04), 125–142. doi:10.19744/j.cnki.11-1235/f.2022.0056

Chang, C. (2011). The influence of corporate environmental ethics on competitive advantage: The mediation role of green innovation. J. Bus. Ethics 104 (3), 361–370. doi:10.1007/s10551-011-0914-x

Chen, Q., Xu, D., and Zhou, Y. (2018). Labour substitution effect of artificial intelligence in the era of population aging: Evidence from panel data across countries and panel data at provincial level in China. Chin. J. Popul. Sci. (06), 30–42.

Chen, S., and Golley, J. (2014). ‘Green’ productivity growth in China's industrial economy. Energy Econ. 44, 89–98. doi:10.1016/j.eneco.2014.04.002

Cheng, Z., and Jin, W. (2022). Agglomeration economy and the growth of green total-factor productivity in Chinese industry. Socio-Economic Plan. Sci. 83, 101003. doi:10.1016/j.seps.2020.101003

Day, C. P. (2018). Robotics in industry—Their role in intelligent manufacturing. Engineering 4 (4), 440–445. doi:10.1016/j.eng.2018.07.012

Driscoll, J. C., and Kraay, A. C. (1998). Consistent covariance matrix estimation with spatially dependent panel data. Rev. Econ. Statistics 80 (4), 549–560. doi:10.1162/003465398557825

Fraumeni, B. M., He, J., Li, H., and Liu, Q. (2019). Regional distribution and dynamics of human capital in China 1985-2014. J. Comp. Econ. 47 (4), 853–866. doi:10.1016/j.jce.2019.06.003

Ghisetti, C., and Quatraro, F. (2017). Green technologies and environmental productivity: A cross-sectoral analysis of direct and indirect effects in Italian regions. Ecol. Econ. 132, 1–13. doi:10.1016/j.ecolecon.2016.10.003

Goetz, S. J., Debertin, D. L., and Pagoulatos, A. (1998). Human capital, income, and environmental quality: A state-level analysis. Agric. Resour. Econ. Rev. 27 (2), 200–208. doi:10.1017/S1068280500006511

Goldfarb, A., and Tucker, C. (2019). Digital economics. J. Econ. Literature 57 (1), 3–43. doi:10.1257/jel.20171452

Greenstone, M., and Hanna, R. (2014). Environmental regulations, air and water pollution, and infant mortality in India. Am. Econ. Rev. 104 (10), 3038–3072. doi:10.1257/aer.104.10.3038

Han, Y., Tan, S., Zhu, C., and Liu, Y. (2022). Research on the emission reduction effects of carbon trading mechanism on power industry: Plant-level evidence from China. doi:10.1108/IJCCSM-06-2022-0074Int. J. Clim. Change Strategies Manag.

He, B., and Bai, K. (2021). Digital twin-based sustainable intelligent manufacturing:A review. Adv. Manuf. 9 (1), 1–21. doi:10.1007/s40436-020-00302-5

Hu, D., Shen, H., and Liu, Z. (2019). Study on the spatial -temporal evolution and formation mechanism of energy eebound effect in Chinese cities. China Soft Sci. (11), 96–108.

Huang, Z., and Zhang, T. (2018). Analysis on enterprises’ green technology innovation and its obstruction factors. Studies in Dialectics of Nature 34 (8), 129–133. doi:10.19484/j.cnki.1000-8934.2018.08.019

Jin, C., Tsai, F. S., Gu, Q., and Wu, B. (2022). Does the porter hypothesis work well in the emission trading schema pilot? Exploring moderating effects of institutional settings. Res. Int. Bus. Finance 62, 101732. doi:10.1016/j.ribaf.2022.101732

Kohtamäki, M., Parida, V., Oghazi, P., Gebauer, H., and Baines, T. (2019). Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 104, 380–392. doi:10.1016/j.jbusres.2019.06.027

Kusiak, A. (2017). Smart manufacturing must embrace big data. Nature 544 (7648), 23–25. doi:10.1038/544023a

Li, B., Hou, B., Yu, W., Lu, X., and Yang, C. (2017). Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 18 (1), 86–96. doi:10.1631/FITEE.1601885

Li, H., Li, B., Qiu, Y., Guo, D., and Tang, T. (2014). China's human capital measurement: Method, results and applications. Journal of Central University of Finance & Economics, 69–78.05.

Li, Y., Yang, X., Ran, Q., Wu, H., Irfan, M., and Ahmad, M. (2021). Energy structure, digital economy, and carbon emissions: Evidence from China. Environ. Sci. Pollut. Res. 28 (45), 64606–64629. doi:10.1007/s11356-021-15304-4

Liao, Z., and Ru, S. (2022). Theoretical analysis and empirical test of the superposition effect of digital finance development on the increase and decrease of carbon dioxide emissions. Inq. into Econ. Issues (9), 117–132.

Littledyke, M. (2008). Science education for environmental awareness: Approaches to integrating cognitive and affective domains. Environ. Educ. Res. 14 (1), 1–17. doi:10.1080/13504620701843301

Lu, T., and Zhu, Z. (2021). Will AI reduce labor income share—a test based on fixed effect model and panel quantile model. J. Shanxi Univ. Finance Econ. 43 (11), 29–41. doi:10.13781/j.cnki.1007-9556.2021.11.003

Magazzino, C., Mele, M., and Schneider, N. (2021). A machine learning approach on the relationship among solar and wind energy production, coal consumption, GDP, and CO2 emissions. Renew. Energy 167, 99–115. doi:10.1016/j.renene.2020.11.050

Mengfan, Z., and Yunping, C. (2022). Research on the impact of artificial intelligence on green total factor productivity in manufacturing. Paper presented at the.

Nie, F., Hu, H., and Li, L. (2022). How can industrial robots promote green production? Evidence from Chinese micro-firms. Industrial Econ. Res. (04), 1–14. doi:10.13269/j.cnki.ier.2022.04.009

Otsuka, A., Goto, M., and Sueyoshi, T. (2014). Energy efficiency and agglomeration economies: The case of J apanese manufacturing industries. Reg. Sci. Policy Pract. 6 (2), 195–212. doi:10.1111/rsp3.12039

Perez, C. (2010). Technological revolutions and techno-economic paradigms. Camb. J. Econ. 34 (1), 185–202. doi:10.1093/cje/bep051

Salim, R., Yao, Y., and Chen, G. S. (2017). Does human capital matter for energy consumption in China? Energy Econ. 67, 49–59. doi:10.1016/j.eneco.2017.05.016

Smulders, S., and Di Maria, C. (2012). The cost of environmental policy under induced technical change. Munich, Germany: CESifo Working Paper Series No. 3886. doi:10.2139/ssrn.2112952

Sun, Z., and Hou, Y. (2021). The influence of artificial intelligence development on industrial total factor productivity -An empirical research based on manufacturing industries in China. Economist (01), 32–42. doi:10.16158/j.cnki.51-1312/f.2021.01.004

Waldfogel, J. (2017). How digitization has created a golden age of music, movies, books, and television. J. Econ. Perspect. 31 (3), 195–214. doi:10.1257/jep.31.3.195

Wang, M., Xu, M., and Ma, S. (2021). The effect of the spatial heterogeneity of human capital structure on regional green total factor productivity. Struct. Change Econ. Dyn. 59, 427–441. doi:10.1016/j.strueco.2021.09.018

Wang, X., Xie, Y., Peng, Y., and He, Q. (2022). AI's impact on employment and trend forecast: Based on data on the installation of industrial robots in Beijing. Hum. Resour. Dev. China 39 (01), 119–133. doi:10.16471/j.cnki.11-2822/c.2022.1.008

Wu, H., Hao, Y., Ren, S., Yang, X., and Xie, G. (2021). Does internet development improve green total factor energy efficiency? Evidence from China. Energy Policy 153, 112247. doi:10.1016/j.enpol.2021.112247

Wu, J., Xia, Q., and Li, Z. (2022). Green innovation and enterprise green total factor productivity at a micro level: A perspective of technical distance. J. Clean. Prod. 344, 131070. doi:10.1016/j.jclepro.2022.131070

Wu, L., and Zhang, Z. (2020). Impact and threshold effect of internet technology upgrade on forestry green total factor productivity: Evidence from China. J. Clean. Prod. 271, 122657. doi:10.1016/j.jclepro.2020.122657

Yan, X., Li, W., and Gao, R. (2021). Impact of artificial intelligence on China's labor market. Rev. Industrial Econ. (02), 65–77. doi:10.19313/j.cnki.cn10-1223/f.2021.02.006

Yang, T., Yi, X., Lu, S., Johansson, K. H., and Chai, T. (2021). Intelligent manufacturing for the process industry driven by industrial artificial intelligence. Engineering 7 (9), 1224–1230. doi:10.1016/j.eng.2021.04.023

Zhang, Q., Zhang, F., and Mai, Q. (2022). Robot adoption and green productivity: Curse or boon. Sustain. Prod. Consum. 34, 1–11. doi:10.1016/j.spc.2022.08.025

Zhang, X., and Dai, Y. (2012). Heterogeneity, fiscal decentralization and urban economic growth. J. Financial Res. (01), 103–115.

Zhang, Y., and Wu, Z. (2021). Intelligence and green total factor productivity based on China's province-level manufacturing data. Sustainability 13 (9), 4989. doi:10.3390/su13094989

Zhao, C., Wang, W., and Li, X. (2021). How does digital transformation affect the total factor productivity of enterprises?. Finance Trade Econ. 42 (07), 114–129. doi:10.19795/j.cnki.cn11-1166/f.20210705.001

Zhao, P., Gao, Y., and Sun, X. (2022). How does artificial intelligence affect green economic growth?—Evidence from China. Sci. Total Environ. 834, 155306. doi:10.1016/j.scitotenv.2022.155306

Zhong, R. Y., Xu, X., Klotz, E., and Newman, S. T. (2017). Intelligent manufacturing in the context of industry 4.0: A review. Engineering 3 (5), 616–630. doi:10.1016/J.ENG.2017.05.015

Zhou, M., and Chen, Y. (2022). “Research on the impact of artificial intelligence on green total factor productivity in manufacturing,” in International Conference on County Economic Development, Rural Revitalization and Social Sciences (ICCRS 2022), 47–50. doi:10.2991/aebmr.k.220402.010

Keywords: intelligent manufacturing, industry, green total factor productivity, panel quantile model, human capital

Citation: Yang Z and Shen Y (2023) The impact of intelligent manufacturing on industrial green total factor productivity and its multiple mechanisms. Front. Environ. Sci. 10:1058664. doi: 10.3389/fenvs.2022.1058664

Received: 30 September 2022; Accepted: 08 December 2022;

Published: 04 January 2023.

Edited by:

Mirela Panait, Petroleum & Gas University of Ploieşti, RomaniaReviewed by:

Abdul Majeed, Huanggang Normal University, ChinaEirini Aivazidou, International Hellenic University, Greece

Copyright © 2023 Yang and Shen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yang Shen, eWFuZ3M5OTZAZm94bWFpbC5jb20=

Zhihong Yang

Zhihong Yang Yang Shen

Yang Shen