94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

BRIEF RESEARCH REPORT article

Front. Environ. Health, 03 April 2025

Sec. Occupational Safety and Health Interventions

Volume 4 - 2025 | https://doi.org/10.3389/fenvh.2025.1557660

This article is part of the Research TopicEmerging Contaminants in Children: Exposure, Sources, and Health EffectsView all 3 articles

Objective: Playgrounds are essential for children's physical, social, and mental health. However, only 4.7% of playgrounds meet safety standards for wood chip surface depth around playground structures. This study aimed to quantify peak force attenuation at safety-compliant (9-inch) vs. non-compliant (5-inch) wood chip depths.

Methods: Wood chip layers of 5 inches and 9 inches were placed on a calibrated force platform. A 4.54-kg medicine ball was dropped from a consistent height onto the wood chips, and peak forces and time to peak force were measured.

Results: The 9-inch wood chip layer significantly reduced peak forces compared to the 5-inch layer, showing a 44% reduction (p < 0.001). No significant differences were observed in time to peak force between the two conditions (p = 0.46).

Discussion: Compliant wood chip surface depths reduce impact forces substantially, emphasizing the importance of routine inspection and maintenance of playground surfaces to safety standards. This practice can help minimize injuries in children resulting from playground falls.

What is already known on this topic – Wood chips are widely used to reduce injuries at playgrounds and are essential for fall impact attenuation.

What this study adds – This study quantifies a 44% reduction in peak force when wood chip surface depth meets safety standards, offering critical insights into their protective capacity.

How might this study affect research, practice, or policy – These findings highlight the significant impact of maintaining playground wood chips at safety-compliant depths, supporting the need for updated maintenance strategies and policies to enhance playground safety.

Playgrounds provide essential spaces for childhood physical, social, and mental development (1). As such, it is important for playgrounds to maintain the standards necessary to provide a safe environment for children, as accidents may occur. Studies indicate that only 4.7% of playgrounds comply with the 9-inch surface depth safety standards required for injury prevention (2). Inadequate surface compliance with safety standards, particularly regarding wood chip depth, has been linked to increased injury risks. Understanding the most effective ways to reduce injury risks to children may provide further evidence in persuading stakeholders to adhere to these safety standards.

The choice of playground materials surrounding structures affect impact attenuation. Concrete, for example, is a poor choice for playgrounds as impacts often result in childhood injuries. This is likely due to concrete increasing impulse by reducing the time component required to bring a child's downward velocity to zero. Other materials such as sand, wood chips, and rubber have been studied as safer alternatives for reducing playground injuries (2). Most studies have found that engineered wood chips are the best material for playgrounds, as they significantly reduce G-forces compared to other materials (3).

Extensive research has examined surface attenuation properties using metrics like peak deceleration and the Head Injury Criterion (HIC). Most studies report G-forces during impact on playground materials to reference HIC values to understand playground safety with respect to serious, if not fatal, injuries caused by head trauma (2, 4). However, it is currently not well understood how playground materials such as wood chips attenuate direct forces that a child may experience.

The purpose of this study is to investigate the attenuation of peak forces in playground impacts by comparing wood chip depths that meet safety standards to those below standard levels. We hypothesized that peak forces would be significantly reduced in wood chip levels that met standards compared to wood chip levels that were below standard levels. Understanding force attenuation will allow practitioners to evaluate injury risks associated with lower-level trauma, such as limb fractures, and guide safety interventions in playground design.

All drop-test trials were conducted at the University of Arizona, College of Health Sciences, Health Sciences Innovation Building. Vertical ground reaction forces were recorded at 500 Hz using a PASCO force plate (35 × 35 cm, Model PS-2141, PASCO, Roseville, CA, USA), calibrated prior to testing to ensure measurement accuracy. A 4.54-kg medicine ball (All in Motion, Minneapolis, MN, USA) was used as the projectile object to impact the force plate for testing impact forces. Two bags of playground wood chips were purchased from a local vendor (AcmeSand, Tucson, AZ). These wood chips were certified via the International Play Equipment Manufacturers Association and meet ASTM F2075 (5), ASTM F1292 (6), and ASTM F1951 (7) standards for impact attenuation, wood chip consistency, and Americans with Disabilities Act (ADA) compliance. IRB was not obtained for this study as no human or animal participants were recruited or placed under testing.

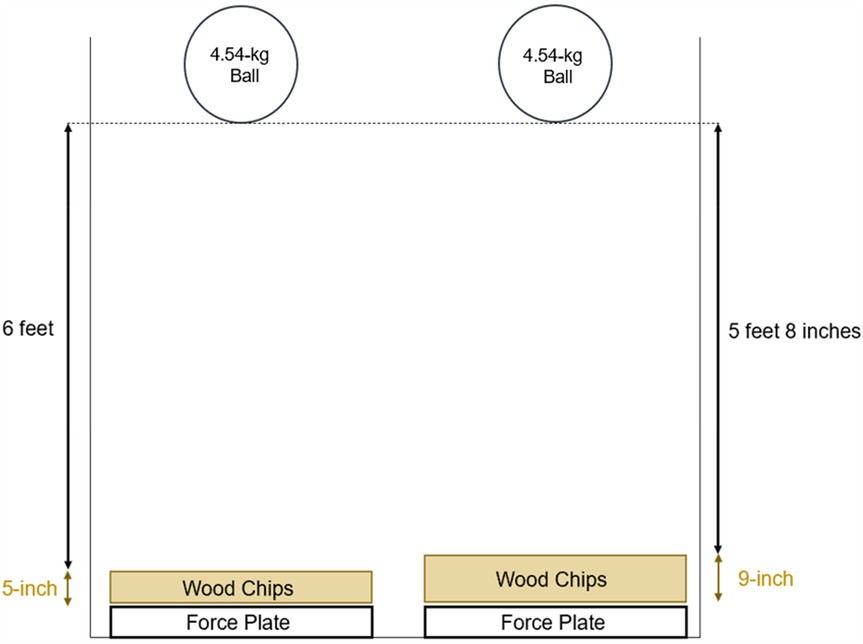

A 5-inch layer of engineered wood chips was placed on top of the force platform and measured to ensure uniformity. A height of 6 feet above the top of the wood chip layer was measured to determine the release point of the medicine ball. The selected height (6 feet) simulates a typical fall height for children aged 5–12, based on average playground equipment heights. The medicine ball was released and allowed to free-fall onto the center of the wood chip layer. After impact, the wood chips were restacked to the same height, measured for consistency, and the protocol was repeated three times (Figure 1).

Figure 1. Schematic of the experimental design. The 5-inch experiment is shown on the left side and the 9-inch experiment is shown on the right. The force plate is on the ground with the wood chip layer on top of the force plate. The medicine ball is dropped from the same height.

A 9-inch layer of engineered wood chips, representing the minimum surface depth required for playgrounds, was similarly tested. A height of 5 feet and 8 inches above the top of the 9-inch wood chip layer was measured for the release point. The same procedure of dropping the medicine ball and restacking the wood chips was repeated three times (Figure 1).

Peak forces for each trial were collected and averaged for the 5-inch and 9-inch wood chip layers, respectively. Additionally, the time from impact to peak force for each trial was recorded and averaged for both layers.

A one-tailed independent t-test was conducted to determine if the peak force was significantly lower in the 9-inch wood chip layer compared to the 5-inch layer. A two-tailed independent t-test was conducted to determine if there were any significant differences in the impulse between the two wood chip layers.

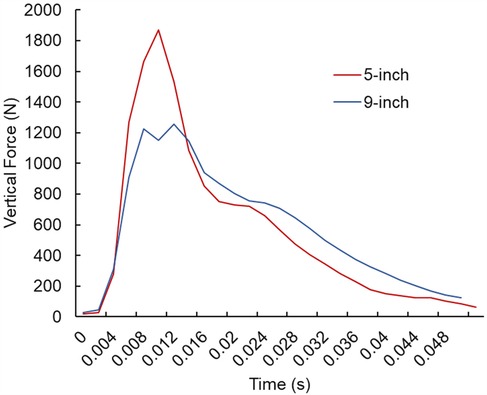

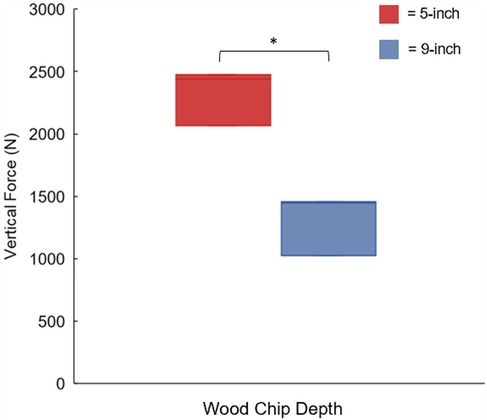

The peak force in the 9-inch wood chip layer was significantly lower than in the 5-inch layer (1,299 ± 236 vs. 2,325 ± 228 N, p < 0.001, Figures 2, 3). There was no significant difference in the time to peak force between the 9-inch and 5-inch layers (0.011 ± 0.003 vs. 0.009 ± 0.003 s, p = 0.46, Figures 2, 3).

Figure 2. A time-series comparison of the average vertical force (N) between the 9-inch (n = 3, blue line) and 5-inch layer (n = 3, red line) of wood chips during impact.

Figure 3. Box plots exhibit peak vertical force of the 5-inch wood chip layer (red) compared to the 9-inch wood chip layer (blue). *denotes significance at p < 0.001.

The purpose of this study was to investigate the attenuation of peak forces in playground impacts by comparing wood chip depths that meet safety standards to those below standard levels. In support of our hypothesis, the 9-inch wood chip layer significantly attenuated peak forces compared to the 5-inch layer. Additionally, no significant differences were observed in the time to peak force between the two layers.

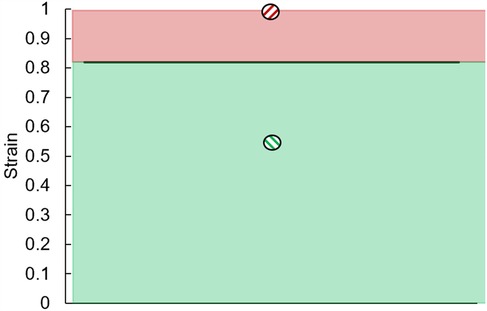

The wood chip surface depth plays a significant role in reducing peak forces and, consequently, injury risk. This study highlighted that meeting the 9-inch standard requirement for wood chip layers can reduce forces by 44% compared to a sub-standard 5-inch layer. To illustrate the impact and applicability of this study, a theoretical scenario is presented to highlight the importance of maintaining wood chips at the recommended depth. Consider a 6-year-old child weighing 24-kg who falls from a playground structure, landing with outstretched arms at a downward velocity of −4.0 m per second at impact. The total downward force exerted on the arms is calculated to be 1,966 N. Using the cortical area of the radius bone, the resulting radial stress is 49.16 MPa (8), and strain calculations yield a strain percentage of 0.984%. This strain can be compared to the established bone fracture threshold of 0.82% (9) to assess the likelihood of injury. If the child falls onto 5 inches of wood chips, the force attenuation would be lower than the 44% reduction observed in this study with a 9-inch depth. Applying this attenuation factor suggests that strain levels would decrease below the fracture threshold, reducing the risk of injury (Figure 4). These findings are particularly relevant in understanding thresholds of force that exceed the structural capacity of body parts such as the humerus (10), skull (11), and vertebrae (12), potentially leading to fractures. This type of analysis to understand the reduction of injuries due to maintaining wood chip depths require a biomechanical analyses of height drops, wood chip depths, body positioning, and factors that would affect the force application on the human body.

Figure 4. A graph showing the 0.82% strain threshold for fracture in a 6-year-old radius bone. The red shaded region (and above) indicates strain values that would cause fractures. The green shaded region indicates strain values that would not cause fractures. The strain on a radius bone (red) with 5-inches of wood chip depth compared to the strain on the radius bone (green) with 9-inches of wood chip depth.

The lack of significant differences in time to peak force suggests that the force attenuation observed cannot be attributed to changes in impulse through an extended time component. Instead, the attenuation is likely due to the wood chips dispersing energy downward and sideways from the vertical impact, with the 9-inch layer containing significantly more material to absorb the energy. The increased capacity for energy dissipation reduces the magnitude of force transmitted to the body, thereby lowering the risk of injury upon impact.

This study has several limitations. First, the wood chips were not compacted to standard requirements, as compacting them to such levels would have damaged the force platform. However, this limitation is mitigated by the observation that children often disturb wood chips through running, kicking, and digging during play, which results in less compacted layers. Secondly, the study only tested engineered wood chips and did not include alternative materials such as sand or rubber. Thirdly, this study only tested a standard 4.54-kg medicine ball and may not be applied to humans. However, projectile motion and impulse equations require three inputs to understand force: mass, velocity, and change in time. Effectively, the reduction in forces observed in the medicine ball can be directly applied to humans since the velocity and change in time are calculated, and only the mass needs to be adjusted. Finally, only two surface depths were evaluated, leaving gaps in understanding peak force amplification in layers thinner than 5 inches. While this study focused on two discrete depths, future research should evaluate whether force attenuation follows a linear relationship across a broader range of depths.

Playgrounds meeting the 9-inch wood chip safety standard are highly effective at reducing peak forces compared to surface depths below this standard, potentially lowering injury risks in children. Emphasizing compliance with the 9-inch standard is critical, as studies indicate that only 4.7% of playgrounds currently meet this requirement.

The raw data supporting the conclusions of this article will be made available, upon reasonable request to the corresponding author.

JL-C: Conceptualization, Data curation, Formal analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Visualization, Writing – original draft, Writing – review & editing.

The author(s) declare that no financial support was received for the research and/or publication of this article.

The author thanks Lila Wayman for her contribution in the data collection process.

JL-C is a majority stake-holder for a forensics company Verum Biomechanics.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

1. Schipperijn J, Madsen CD, Toftager M, Johansen DN, Lousen I, Amholt TT, et al. The role of playgrounds in promoting children’s health–a scoping review. Int J Behav Nutr Phys Act. (2024) 21:72. doi: 10.1186/s12966-024-01618-2

2. Gunatilaka AH, Sherker S, Ozanne-Smith J. Comparative performance of playground surfacing materials including conditions of extreme non-compliance. Inj Prev. (2004) 10:174–9. doi: 10.1136/ip.2003.004010

3. Lewis LM, Naunheim R, Standeven J, Naunheim KS. Quantitation of impact attenuation of different playground surfaces under various environmental conditions using a tri-axial accelerometer. J Trauma Acute Care Surg. (1993) 35:932–5. doi: 10.1097/00005373-199312000-00020

4. Himmelsbach JA, Shorten MR. Playground surfacing and playground injuries. Sport Surfaces Univ Calgary. (2003):71–88.

5. ASTM F2075-20. Standard Specification for Engineered Wood Fiber for Use as a Playground Safety Surface Under and Around Playground Equipment (n.d). doi: 10.1520/F2075-20

6. ASTM F1292-22. Standard Specification for Impact Attenuation of Surfacing Materials Within the Use Zone of Playground Equipment (n.d). doi: 10.1520/F1292-22

7. ASTM F1951-21. Standard Specification for Determination of Accessibility of Surface Systems Under and Around Playground Equipment (n.d). doi: 10.1520/F1951-21

8. Szabo E, Rimnac C. Biomechanics of immature human cortical bone: a systematic review. J Mech Behav Biomed Mater. (2022) 125:104889. doi: 10.1016/j.jmbbm.2021.104889

9. Vinz H. Change in the mechanical properties of human compact bone tissue upon aging. Polym Mech. (1975) 11:568–71. doi: 10.1007/BF00856785

10. Klenerman L. Experimental fractures of the adult humerus. Med Biol Eng. (1969) 7:357–64. doi: 10.1007/BF02551691

11. Coats B. Mechanics of head impact in infants (dissertation). University of Pennsylvania, Philadelphia (2007).

Keywords: playground, falls, children, injuries, wood chips, standards, safety, schools

Citation: Lee-Confer J (2025) The effect of wood chip surface depth on peak force during impacts. Front. Environ. Health 4:1557660. doi: 10.3389/fenvh.2025.1557660

Received: 8 January 2025; Accepted: 21 March 2025;

Published: 3 April 2025.

Edited by:

Shiming Song, Sun Yat-sen University, ChinaReviewed by:

Medani Bhandari, Akamai University, United StatesCopyright: © 2025 Lee-Confer. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Jonathan Lee-Confer, bGVlY29uZmVyQGFyaXpvbmEuZWR1

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.