- Idaho National Laboratory, Idaho, ID, United States

Digital engineering and digital twins are increasingly being used in nuclear energy projects with important impacts. At Idaho National Laboratory, these approaches have been applied in a variety of nuclear energy research, development, and demonstration projects, with key lessons and evolutions occurring for each. In this paper, we describe the use of digital engineering and digital twins in the Versatile Test Reactor design, National Reactor Innovation Center test beds, and nonproliferation analysis of the AGN-201 reactor design. We share key lessons learned for these projects related to tool selection, adoption and training, and working with existing assets versus beginning at the design phase. We also share highlights of future potential uses of digital twins and digital engineering, including using artificial intelligence to perform repetitive design tasks and digital twins to move towards semiautonomous nuclear power plant operations.

1 Introduction

Digital engineering (DE) and digital twins (DT) can radically change the design, construction, operation, and lifecycle of nuclear energy assets. By providing a single source of truth for multidisciplinary teams, and by equipping asset owners and operators with a digital replica of the system, DE and DTs combined with artificial intelligence (AI) and machine learning (ML) can improve outcomes during construction and can enable predictive maintenance, advanced operational modes like remote and autonomous control, and the development of advanced security and safeguards. This technology has enabled enormous cost reductions in other industries and can bring the same benefits to nuclear energy, unlocking a capacity to scale nuclear energy so that its energy, security, and environmental benefits can be fully realized. At Idaho National Laboratory (INL), we have applied DE to a number of nuclear energy projects to varying degrees and have learned key lessons. The purpose of this article is to share the authors’ perspectives on the present and future value of digital engineering for nuclear energy and nuclear nonproliferation and to highlight experiences with three projects: the Versatile Test Reactor, the National Reactor Innovation Center (NRIC) test beds, and a DT for the nonproliferation analysis of the AGN-201 reactor.

2 Digital twins and digital engineering

DE is a data-driven approach in which legacy paper-based engineering practices are replaced by a selection of design-, engineering-, procurement-, construction-, management-, and operation-related digital tools. These tools are connected and used in an integrated digital thread to support dynamic synchronization across traditionally siloed domains while maintaining an accurate virtual replica of the product. A DT is a living virtual model that leverages both data from the digital thread and real-time feedback from an operating asset to mimic its behavior in ways that are important to the user (Grieves, 2014).

This approach improves accuracy and efficiency across engineering and management disciplines, results in better cost and performance outcomes, and unlocks potential advanced uses of digital tools, including predictive capabilities, AI/ML, remote operation, and customized uses such as safeguards development (Basher, 2003; Wood, 2004; Upadhyaya et al., 2007; Tuegel et al., 2011; Li et al., 2017; Rajesh et al., 2019; Ritter et al., 2022a; Wang et al., 2022; Javaid et al., 2023; Tao et al., 2019). For a more comprehensive description of the benefits of DTs, see Javaid et al. (2023).

DE has been prioritized in the U.S. Department of Defense, real estate, and aerospace industries, as examples (DoD, 2023; Attaran and Celik, 2023; Grosse, 2019; Dang et al., 2018; Bazilevs et al., 2015; Glaessgen and Stargel, 2012; Seshadri and Krishnamurthy, 2017; Li et al., 2017; Tuegel et al., 2011). Increasingly, DE is being used in biotechnology, medicine, agriculture, nuclear energy, and other fields (Cai et al., 2017; Bruynseels et al., 2018; Rassolkin et al., 2019; Kochunas and Huan, 2021; Crowder et al., 2022; Prantikos et al., 2022; Attaran and Celik, 2023; Javaid et al., 2023; Sandhu et al., 2023; Plachinda et al., 2021; Yadav et al., 2021; Soori et al., 2023).

3 Digital engineering opportunities for nuclear energy

The existing U.S. nuclear energy industry has not routinely exercised many DE tools. The landscape has changed dramatically, however, in the past 10–15 years, with dozens of new companies, new designs, several demonstration projects, and an influx of talent from other high-tech industries like aerospace, oil and gas, automotive, and computing.

The opportunities to use DE and DTs in nuclear energy are diverse. A 2021 report by INL, Oak Ridge National Laboratory, and the U.S. Nuclear Regulatory Commission evaluated potential uses of DTs in the nuclear industry (U.S. NRC, 2021). Here, we highlight several key opportunities.

• The high capital cost of nuclear energy has long been a key impediment to its increased use (Joskow and Parsons, 2009). DE has reduced costs in other complex engineering projects (Osborn, 2020; General Electric, 2024). Its potential to reduce the cost of nuclear design, engineering, and construction is perhaps the most consequential opportunity in using DE for nuclear energy (Ritter and Rhoades, 2023).

• By using DTs, it would be possible to streamline and improve the training of nuclear operators and inspectors, as well as ensure state-of-the-art training over time, with updates to the DT (Martínez-Gutiérrez et al., 2023).

• DTs are being used to test and improve the use of remote operation and autonomy in fields ranging from production and construction to transportation and surgery (Basher, 2003; Wood, 2004; Upadhyaya et al., 2007; Laaki et al., 2019; Isto et al., 2020; Stączek et al., 2021). This application could be important in an expansion of nuclear energy. Remote and autonomous operations can enable smaller remote reactors for important energy security or energy access needs, as well as other flexible operating approaches.

• DTs could be used to reduce proliferation and security risks, by facilitating the development of safeguards and security strategies during design and operation by providing a platform to identify and train on suspicious system behaviors. Remote monitoring could enable the scalable and advanced safeguards and security of reactors and fuel cycle facilities, which is largely accomplished today through direct inspections by individuals (Ritter et al., 2022a; Stewart et al., 2023).

• The use of DE and DTs enables incorporating AI/ML for predictive maintenance, autonomy, and many other purposes. The uses of AI/ML are just beginning to be widely understood and appreciated; by using DE approaches, we enable the current and future application of those tools (Tao et al., 2018; Daniel et al., 2024; da Silva Mendonça, 2022).

• Finally, while product lifecycle management (PLM) has value in many applications, it is especially beneficial in nuclear energy, where decommissioning is a major undertaking and an important part of integrated planning.

At INL, in partnership with others and in collaboration with the Digital Innovation Center of Excellence (DICE), DE is being applied to many nuclear energy projects, with varying intensity of scope and at varying stages of the technology lifecycle. In Sections 4–6, we provide insights from implementing DE in three representative projects.

4 Digital engineering for the Versatile Test Reactor

The Versatile Test Reactor (VTR) program was established to build an advanced, fast flux test reactor in the United States for research and development needs. The design effort was a collaboration across six national laboratories, ten universities, and over 15 industry partners and was concentrated between 2017 and 2021. The VTR program implemented elements of the Department of Defense Digital Engineering Strategy (DoD, 2023) through the use of data-driven tools, a digital thread, cloud computing, and close collaboration with the Digital Innovation Center of Excellence (Ritter et al., 2022b). These tools were implemented through design and procurement, with the intent to continue their use during construction and operation.

To transition towards a fully connected digital thread, VTR leadership invested in an ecosystem of data-driven tools, which was novel for a large nuclear reactor program. Prior to the VTR, most requirements were developed within Microsoft Office documents and then published in pdf format to document management repositories. The VTR project implemented a capability to natively develop and maintain requirements within commercial off the shelf (COTS) requirement management software. Similarly, building information modeling (BIM) and the capture of structured data were emphasized over purely geometric computer-aided design artifacts. These BIM models were used to generate fly-through videos of the plant, providing a marketing capability and ensuring all engineering teams were aware of changes to the design. Most VTR organizations used local instances of scheduling software, but to increase collaboration, the VTR program deployed a centralized platform to manage the schedule across organizations.

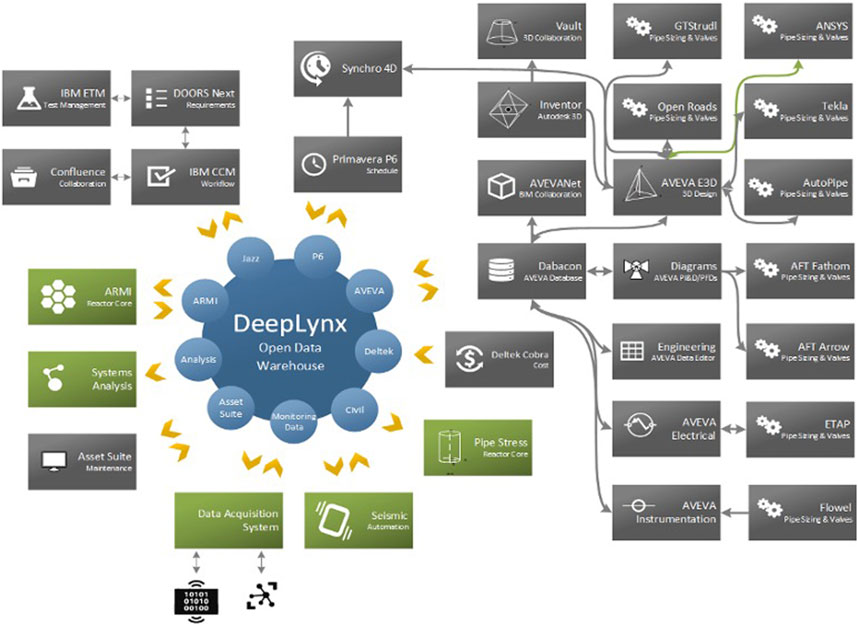

To connect these new sources of data, the VTR program developed a novel open-source digital thread platform, DeepLynx, now in use across dozens of nuclear, national security, and renewable energy projects. At its core, DeepLynx uses an ontological model to organize data within a graph-like structure. The ontological model includes classes, their properties, and relationship (relations) pairs to organize data across a graph. The graph for the VTR included information such as individual requirements, pieces of plant equipment, or schedule activities that needed to be completed on the project. These objects were then related through relationship pairs. DeepLynx’s graph structure is linked to external COTS tools through custom-built software pipelines using available application programming interfaces. The VTR program developed these pipelines for the majority of COTS software deployed in the cloud environment. Since the VTR program, many other projects have expanded this ecosystem, illustrated in Figure 1, to other application domains and software platforms.

To host this vast quantity of data and the digital thread, the VTR was the first project at INL and one of the first in the nuclear industry to use cloud computing. Most of the VTR ecosystem of tools were deployed centrally to a Microsoft Azure for Government cloud. Each laboratory and industry partner could authenticate with their home organization credentials and instantly collaborate within the same databases. The COTS requirements tool was natively designed for cloud computing and allowed for near real-time synchronization of requirements data across the project.

The use of a strong DE ecosystem for the VTR project enabled collaboration across national laboratories, universities, and private companies. The VTR program was able to meet key milestones on schedule despite the challenges of the COVID-19 pandemic; the team credits DE with making major contributions to this success (Ritter et al., 2022b). The DE implementation in the project was not without its challenges, however. At deployment, the COTS BIM tools proved mature for engineering and drafting, but the team experienced rendering and deployment issues with the cloud collaboration tools available in 2019. One of the tools was chosen not based on its suitability to meet the needs of the project but for its prior use by partner organizations, and its implementation was never successful. Cultural and workforce adoption was slow, and multiple trainings, guides, and other resources were developed to increase end-user acceptance. If the VTR program is reinitiated, the use of DE will pay dividends, because it will be straightforward to restore access to program documents and data for team members.

5 Digital engineering for the National Reactor Innovation Center test beds

NRIC is establishing two demonstration test beds in which industry will demonstrate their reactors or perform experiments as part of its mission to accelerate the demonstration of advanced reactors. The two test beds addressed here are the Demonstration of Microreactor Experiments and the Laboratory for Operation and Testing in the United States test beds.

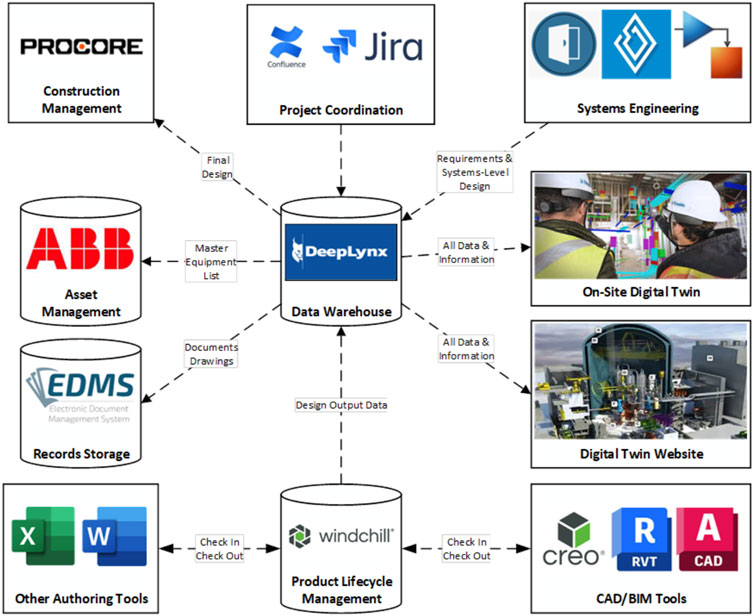

For both these test beds, NRIC anticipated the need to interface with industry partners on many design details. The test beds provide various support infrastructure, electrical supply, control systems, cooling, and other opportunities for the industry reactors to utilize the existing physical plant. To support timely engineering execution and a smooth integration between the test bed and reactor, NRIC incorporated DE tools from the outset of both test bed projects. These tools included those implemented in the VTR program, as well as more complex domains such as model-based systems engineering, PLM, model-based definition, and mixed reality (MR). The NRIC DE ecosystem is illustrated in Figure 2.

For the NRIC test beds, DE was established as the expected approach for all team members, and training was provided to enable its effective use. Before developing a physical architecture for the test bed, there was a strong focus on functional requirements and the concept of operations for the facility. Requirements were managed in a model-based system, and systems and functions in the design were traced back to requirements, whether based on project needs or Department of Energy requirements. This DE approach to verifying the ways in which the design addresses each requirement is novel and enhanced the regulatory review process. The PLM and model-based definition implementation allowed tables and pdfs to be exported from the model, avoiding manual, error-prone tabulation. Upon design approval, data created in the PLM is automatically transferred to INL’s electronic document management system, reducing labor in developing those documents while ensuring an accurate transfer.

While the VTR project developed some fly-through videos for marketing and team review, the NRIC test bed projects took this farther, using the DE environment to develop imagery viewed through MR headsets that are valuable for design reviews, walkdowns, and tours.

Benefits of DE in working with industry have been marked. The ability to share requirements and design details in real time, with all changes propagating through the system immediately, has led to improved collaboration and design optimization for both test beds. Working in a single environment with numerous project participants from laboratories and industry creates a single source of truth for project documentation, alleviating the emailing of documentation and enabling access control. Several potential users are currently collaborating with NRIC to design microreactor experiments, and the use of DE tools has led to efficiencies and improved communication, as well as the ability to partner with multiple potential users. The physics-based modeling of the facility that simulates how the test bed will perform can connect to a demonstrator’s models and simulations.

A key challenge in implementing DE for the test beds was the acceptance of tools and training for new users. Some external partners who have their own tools do not want to learn a new tool for collaboration, but it can be necessary. Different types of training also work better for different people, so offering both self-study and guided options is important. Tools need to be as simple as possible to begin with, and training, guides, and procedures need to be provided to promote adopting new ways of performing project functions.

The NRIC team has conceptualized a facility-scale DT and plans to develop that DT in the future to enable operational predictions.

6 Digital twin of the AGN-201 reactor

In a partnership between Idaho State University and INL, a multidisciplinary team developed a DT of the 5 W AGN-201 reactor at Idaho State University. The DT is used to simulate proliferation activities and methods of detection and to inform researchers and practitioners on safeguards innovation with DTs, as well as to potentially serve as a training platform. The AGN-201 DT project was a 1 year project to leverage prior research to deliver the first nuclear reactor DT. The team initially invested in four primary areas: digitalization of the reactor data acquisition (DAQ), development of real time (5 s) DAQ streaming to DeepLynx, reactor physics model development, and anomaly detection models. After the streaming technology was operational, the team collected data over a series of reactor runs to train and tune models for a red-team, blue-team test.

The DAQ system connected AGN-201 sensors directly to LabView. A new ingestion system, Jester, watches for LabView changes and uploads these changes to DeepLynx. After the VTR program, DeepLynx was modified to add time series support to collect real-time operating information alongside an ontological graph model, allowing for near-real-time DTs.

A high-fidelity reactor physics model was developed using the Serpent Monte Carlo code. A mathematical surrogate model was developed with Gaussian process regression to run alongside the operating reactor in real time.

DeepLynx included a processing loop to communicate with both a surrogate physics model and machine model in real time. The red team developed a reactor operation plan to evaluate the performance of the two AI models. Prior to the experiment, the blue team developed a software platform with these two AI models to detect proliferation. During the experiment, the models are automatically run based on reactor operations data to evaluate the probability of proliferation. After the experiment, a presentation from the blue team was presented to the red team to evaluate model performance. The use of two models proved successful, and some of these results will be discussed in an upcoming paper “Autonomous Anomaly Detection of Proliferation in the AGN-201 Nuclear Reactor Digital Twin.”

This project developed a DT of an already-operating asset, which is challenging because there were no digital artifacts from the design and build process to inform the twin. Further, the reactor could only be accessed during scheduled times, which complicated development. These challenges would likely be greater for a commercial asset.

Based on experience with the AGN-201 DT, future efforts could include developing a DT of a novel design to facilitate incorporating safeguards during the development phase. A DT of an existing reactor can be created to enhance understanding of possible proliferation-related activities and to provide a training platform.

7 Future directions

We see several promising future uses for DE and DTs and highlight two here.

• AI for plant design: Even with digital tools, there are repetitive, time-consuming steps in the engineering process that could potentially be automated using AI. These include building three-dimensional models in drafting software from conceptual sketches or meetings and verbal communication; building the corresponding analytical model used to validate architectural or design models; generating documents that summarize work performed in modeling and simulation platforms; elements of performing a design review, obtaining feedback, and incorporating feedback into the design; and matching up design requirements with design output documentation during design reviews and verification stages.

• Semiautonomous operation for nuclear energy: With DE tools and DTs, a research microreactor could be designed and built with autonomy in mind, with a goal of testing and implementing autonomy for specific tasks in the plant. This could be an important step forward for nuclear power research and development and for future autonomous operations of single plants or fleets of plants.

8 Discussion

DE tools were implemented at different levels in each of the three projects described here. In the case of VTR, DE tools benefitted design collaboration and schedule success. Lessons included the importance of identifying tools based on the needs of the project, rather than user preferences. Implementing DE tools at the earliest possible point in a project can save a lot of rework in migration of data between tools.

In contrast with VTR’s project-level DE, for the NRIC test bed projects, INL began deploying model-based tools as an enterprise capability and making the use of DE tools an expectation among teams across INL. DE tools have been valuable in enabling collaboration with potential test bed users. Visualization tools used in the VTR project were improved for the test beds to use MR to have greater value in design. Further, in the test bed implementation, tools were chosen carefully for their ability to meet project needs, which improved implementation.

The AGN-201 project demonstrated that a DT can be used to evaluate proliferation risks. Building upon this work, in the future, a DT could be used to enable safeguards improvements in design and provide a training platform for inspectors.

The open-source DeepLynx tool developed at INL has evolved over the course of these and other projects, and the team has plans for improving and extending it, including implementing AI features to perform repetitive tasks.

DE and DTs are already improving the way we approach nuclear design and demonstration, and they have the potential to revolutionize how nuclear energy is built, operated, safeguarded, and decommissioned in the future, resulting in lower costs and higher performance.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

AF: Conceptualization, Methodology, Supervision, Writing–original draft, Writing–review and editing. CR: Methodology, Supervision, Writing–original draft, Writing–review and editing. PS: Methodology, Visualization, Writing–original draft, Writing–review and editing. AM: Methodology, Visualization, Writing–original draft, Writing–review and editing.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. Funding sources included the U.S. Department of Energy Office of Nuclear Energy and the U.S. Department of Energy National Nuclear Security Administration, including the Defense Nuclear Nonproliferation Research and Development Data Science Portfolio.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Attaran, M., and Celik, B. G. (2023). Digital twin: benefits, use cases, challenges, and opportunities. Decis. Anal. J. 6, 100165. doi:10.1016/j.dajour.2023.100165

Basher, H. (2003). Autonomous control of nuclear power plants. Washington, DC, USA: United States Department of Energy. Technical Report ORNL/TM-2003/252, 885601.

Bazilevs, Y., Deng, X., Korobenko, A., Lanza di Scalea, F., Todd, M. D., and Taylor, S. G. (2015). Isogeometric fatigue damage prediction in large-scale composite structures driven by dynamic sensor data. J. Appl. Mech. 82. doi:10.1115/1.4030795

Bruynseels, K., Santoni de Sio, F., and van den Hoven, J. (2018). Digital twins in health care: ethical implications of an emerging engineering paradigm. Front. Genet. 9, 31. doi:10.3389/fgene.2018.00031

Cai, Y., Starly, B., Cohen, P., and Lee, Y. S. (2017). Sensor data and information fusion to construct digital-twins virtual machine tools for cyber-physical manufacturing. Procedia Manuf. 10, 1031–1042. doi:10.1016/j.promfg.2017.07.094

Crowder, N., Lee, J., Gupta, A., Han, K., Bodda, S., and Ritter, C. (2022). Digital engineering for integrated modeling and simulation for building-piping systems through interoperability solutions. Nucl. Sci. Eng.Vol. 196, 260–277. doi:10.1080/00295639.2022.2055705

Dang, N., Kang, H., Lon, S., and Shim, C. (2018). “3D digital twin models for bridge maintenance,” in Proceedings of the 10th international conference on short and medium span bridges, Canada), 31 July–3 August 2018.

Daniel, C., Gehin, J., Laurin-Kovitz, K., Morreale, B., Stevens, R., and Tumas, W. (2024). Advanced research directions on AI for energy. ANL-23/69. Argonne National Laboratory. doi:10.2172/2340139

da Silva Mendonça, R., Sidney de Oliveira, L., Iury Valente de, B., and Ferreira de Lucena, V. (2022). Digital Twin Applications: A Survey of Recent Advances and Challenges. Processes. 10, (4): 744. doi:10.3390/pr10040744

DoD Instruction 5000.97 (2023). Digital engineering. Department of Defense. Available at: https://www.esd.whs.mil/Portals/54/Documents/DD/issuances/dodi/500097p.PDF?ver=bePIqKXaLUTK_Iu5iTNREw%3D%3D.

General Electric (2024). Industrial digital twins: real products driving $1B in loss avoidance. Available at: https://www.ge.com/digital/blog/industrial-digital-twins-real-products-driving-1b-loss-avoidance (Accessed May 25, 2024).

Glaessgen, E., and Stargel, D. (2012). “The digital twin paradigm for future NASA and U.S. Air force vehicles,” in Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference (Honolulu, HI, USA, 23 April 2012, American Institute of Aeronautics and Astronautics).

Grieves, M. (2014). Digital twin: manufacturing excellence through virtual factory replication. White Pap. 1, 1–7.

Grosse, C. U. (2019). “Monitoring and inspection techniques supporting a digital twin concept in civil engineering,” in Proceedings of the 5th international conference on sustainable construction materials and technologies (SCMT5): in honour of professor christian Grosse (London, UK, 15–17 July 2019, Kingston University).

Isto, P., Heikkilä, T., Mämmelä, A., Uitto, M., Seppälä, T., and Ahola, J. (2020). 5G based machine remote operation development utilizing digital twin. Open Eng. 10 (Issue 1), 265–272. doi:10.1515/eng-2020-0039

Joskow, P. L., and Parsons, J. E. (2009). The economic future of nuclear power. Daedalus 138 (4), 45–59. doi:10.1162/daed.2009.138.4.45

Javaid, M., Haleem, A., and Suman, R. (2023). Digital twin applications toward industry 4.0: A review. Cognitive Robotics 3, 71–92. doi:10.1016/j.cogr.2023.04.003

Kochunas, B., and Huan, X. (2021). Digital twin concepts with uncertainty for nuclear power applications. Energies 14, 4235. doi:10.3390/en14144235

Laaki, H., Miche, Y., and Tammi, K. (2019). Prototyping a digital twin for real time remote control over mobile networks: application of remote surgery. IEEE Access 7, 20325–20336. doi:10.1109/ACCESS.2019.2897018

Li, C., Mahadevan, S., Ling, Y., Choze, S., and Wang, L. (2017). Dynamic bayesian network for aircraft wing health monitoring digital twin. AIAA J. 55, 930–941. doi:10.2514/1.j055201

Martínez-Gutiérrez, A., Díez-González, J., Verde, P., and Perez, H. (2023). Convergence of Virtual Reality and Digital Twin technologies to enhance digital operators’ training in industry 4.0. Int. J. Human-Computer Stud. 180, 103136. doi:10.1016/j.ijhcs.2023.103136

Osborn, K. (2020). Air Force flies 6th-gen stealth fighter – ‘super fast’ with digital engineering. Fox News. Available at: https://www.foxnews.com/tech/air-force-flies-6th-gen-stealth-fighter-super-fast-with-digital-engineering. [Accessed May 25, 2024.]

Plachinda, P., Ritter, C. S., and Sabharwall, P. (2021) “Digital engineering sensor architectures for future microreactor builds,”. Idaho National Laboratory. INL/EXT-21-63631-Rev000. doi:10.2172/1827623

Prantikos, K., Tsoukalas, L. H., and Heifetz, A. (2022). Physics-informed neural network solution of point kinetics equations for a nuclear reactor digital twin. Energies 15, 7697. doi:10.3390/en15207697

Rajesh, P., Manikandan, N., Ramshankar, C., Vishwanathan, T., and Sathishkumar, C. (2019). Digital twin of an automotive brake pad for predictive maintenance. Procedia Comput. Sci. 165, 18–24. doi:10.1016/j.procs.2020.01.061

Rassolkin, A., Vaimann, T., Kallaste, A., and Kuts, V. (2019). “Digital twin for propulsion drive of autonomous electric vehicle,” in Proceedings of the 2019 IEEE 60th international scientific conference on power and electrical engineering of riga technical university (RTUCON) (Riga, Latvia, 7–9 October 2019, IEEE), 1–4.

Ritter, C., Browning, J., Suyderhoud, P., Hays, R., Marshall, A. M., Han, H., et al. (2022b). Versatile test reactor open digital engineering ecosystem. Insight 25 (1), 56–60. doi:10.1002/inst.12374

Ritter, C., Hays, R., Browning, J., Stewart, R., Bays, S., Reyes, G., et al. (2022a). Digital twin to detect nuclear proliferation: a case study. J. Energy Resour. Technol. 144 (10), 102108. doi:10.1115/1.4053979

Ritter, C., and Rhoades, M. (2023). Incorporating digital twins in early research and development of megaprojects to reduce cost and schedule risk. INCOSE. Insight. 26 (3), 57–65. doi:10.1002/inst.12457

Sandhu, H., Srikanth, S., and Gupta, A. (2023). A future with machine learning: review of condition assessment of structures and mechanical systems in nuclear facilities. Energies 16, 2628. doi:10.3390/en16062628

Seshadri, B. R., and Krishnamurthy, T. (2017). “Structural health management of damaged aircraft structures using digital twin concept,” in Proceedings of the 25th AIAA/AHS adaptive structures conference USA, 9–13 January 2017, Grapevine, TX, 1675.

Soori, M., Arezoo, B., and Dastres, R. (2023). Digital twin for smart manufacturing, A review. Sustain. Manuf. Serv. Econ. 2, 100017. doi:10.1016/j.smse.2023.100017

Stączek, P., Pizoń, J., Danilczuk, W., and Gola, A. (2021). A digital twin approach for the improvement of an autonomous mobile robots (AMR’s) operating environment—a case study. Sensors 21 (Issue 23), 7830. doi:10.3390/s21237830

Stewart, R., Shields, A., Pope, C., Darrington, J., Wilsdon, K., Bays, S., et al. (2023). A digital twin of the AGN-201 reactor to simulate nuclear proliferation. Inst. Nucl. Mater. Manag. Available at: https://resources.inmm.org/sites/default/files/2023-07/finalpaper_209_0513112751.pdf.

Tao, F., Zhang, H., Liu, A., and Nee, A. Y. C. (2019). Digital twin in industry: state-of-the-art. IEEE Trans. Ind. Inf. 15, 2405–2415. doi:10.1109/TII.2018.2873186

Tao, F., Zhang, M., Liu, Y., and Nee, A. Y. C. (2018). Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 67 (1), 169–172. doi:10.1016/j.cirp.2018.04.055

Tuegel, E. J., Ingraffea, A. R., Eason, T. G., and Spottswood, S. M. (2011). Reengineering aircraft structural life prediction using a digital twin. Int. J. Aerosp. Eng. 2011, 1–14. doi:10.1155/2011/154798

Upadhyaya, B. R., Zhao, K., Perillo, S. R., Xu, X., and Na, M. G. (2007). Autonomous control of space reactor systems. Knoxville, TN, USA: University of Tennessee.

U.S. DoD (2018). Digital engineering Strategy. U.S. Department of Defense. Tech. Rep. Available at: https://man.fas.org/eprint/digeng-2018.pdf.

U.S. NRC (2021). The state of technology of application of digital twins. U. S. Nucl. Regul. Comm. TLR/RES-DE-REB-2021-01. Available at: https://www.nrc.gov/docs/ML2116/ML21160A074.pdf.

Wang, L., Lin, L., and Dinh, N. (2022). Data coverage assessment on neural network based digital twins for autonomous control system. Ann. Nucl. Energy 182, 109568. doi:10.1016/j.anucene.2022.109568

Wood, R. T. (2004) “Autonomous control for generation IV nuclear plants,” in Proceedings of the 14th pacific basin nuclear conference Honolulu, HI, USA. 21–25 March 2004.

Yadav, V., Agarwal, V., Gribok, A. V., Hays, R. D., Pluth, A. J., Ritter, C., et al. (2021) “Technical challenges and gaps in digital-twin-enabling technologies for nuclear reactor applications,”. U.S. Nuclear Regulatory Commission. Available at: https://www.nrc.gov/docs/ML2136/ML21361A261.pdf.

Keywords: digital twin, digital engineering, nuclear energy, nonproliferation, model-based, advanced reactors

Citation: Finan AE, Ritter CS, Suyderhoud PA and Marshall A (2024) Digital engineering implementation in nuclear demonstration and nonproliferation projects at Idaho National Laboratory. Front. Energy Res. 12:1443896. doi: 10.3389/fenrg.2024.1443896

Received: 04 June 2024; Accepted: 26 June 2024;

Published: 14 August 2024.

Edited by:

Prashant K. Jain, Oak Ridge National Laboratory (DOE), United StatesReviewed by:

Bożena Gajdzik, Silesian University of Technology, PolandCopyright © 2024 Finan, Ritter, Suyderhoud and Marshall. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ashley E. Finan, QXNobGV5LkZpbmFuQGlubC5nb3Y=

Ashley E. Finan

Ashley E. Finan Christopher S. Ritter

Christopher S. Ritter