- 1China-UK Low Carbon College, Shanghai Jiao Tong University, Shanghai, China

- 2Drilling Technology Research Institute of SINOPEC, Shengli Oilfield Service Corporation, Dongying, China

- 3School of Petroleum Engineering, China University of Petroleum (East China), Qingdao, China

CO2, used as an environmentally friendly fracturing fluid, has encountered a bottleneck in development in recent years. Despite great efforts in research work, limited progress has been made in field applications. In this study, an extensive literature review of research work and field cases was performed to summarize the technical issues and challenges of CO2 fracturing. The key issues of CO2 fracturing were analyzed to reveal the gap between fundamental research and field operations. The effects of CO2 properties on fracture creation and proppant transport were synthetically analyzed to extract new common research orientations, with the aim of improving the efficiency of CO2 injection. The hydraulic parameters of CO2 fracturing were compared with those of water-based fracturing fluids, which revealed a theory-practice gap. By studying the developing trends and successful experiences of conventional fluids, new strategies for CO2 fracturing were proposed. We identified that the major theory-practice gap in CO2 fracturing exists in pump rate and operation scale. Consequently, the friction reducer, effects of flow loss (due to leak-off) and distribution (within fracture networks), and shear viscosity of thickened CO2 are key factors in improving both fracture propagation and proppant transport. By increasing the scale of injected CO2, the CO2 fracturing technique can be enhanced, making it an essential option for carbon capture, utilization, and storage (CCUS) to reduce carbon emissions and mitigate climate change.

1 Introduction

Carbon capture, utilization, and storage (CCUS) is an essential technique for achieving the goals set forth in the Paris Agreement, particularly the target of limiting global warming to 1.5°C (Zheng et al., 2022a; Shen et al., 2022; Zhao et al., 2022; Zhu et al., 2022). It plays a crucial role in mitigating greenhouse gas emissions and reducing the concentration of carbon dioxide (CO2) in the atmosphere (Lab, 2022; Hou et al., 2024a). CCUS enables the capture of CO2 emissions from various industrial processes, such as power generation, cement production, and steel manufacturing, and then stores the CO2 underground or utilizes it in other applications (Sharifzadeh et al., 2019; Zhang et al., 2020). This allows for the continued utilization of these traditional assets while simultaneously reducing their carbon footprint. Among all the approaches to carbon sinks, geological storage of CO2 can permanently remove the largest amount of carbon in a short time compared to other methods such as afforestation, agricultural practices, and chemical applications, among others (Busch et al., 2008; Tao and Clarens, 2013; Godec et al., 2014; Levine et al., 2016).

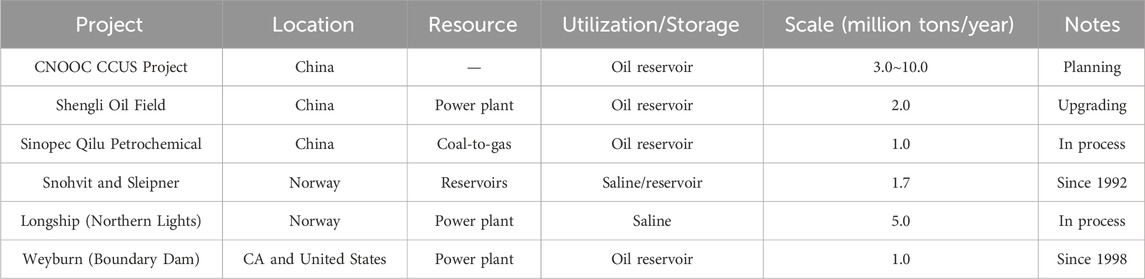

The ideal underground reservoirs for CO2 storage primarily include oil and gas reservoirs, saline formations, and salt caverns (Rutqvist et al., 2008; Gilfillan et al., 2009; Jia et al., 2019). In this study, we specifically focus on oil and gas reservoirs due to their well-known geological conditions and well-constructed infrastructures. These factors significantly improve the efficiency, economy, and safety of CO2 injection and storage (Tayari et al., 2015). The utilization of CO2 in oil fields has a long history, particularly in the context of enhanced oil recovery (EOR) techniques since the 1950s (Crawford et al., 1963; Lillies and King, 1982). The injection of CO2 drives and displaces in situ oil and gas, especially the heavier components, by reducing their viscosity and increasing their mobility. This process enhances the ultimate recovery of oil and gas. The remarkable performance of CO2 injection in both the oil and gas industry and as a carbon sink has drawn worldwide attention. Currently, approximately 80% of the CCUS projects worldwide inject CO2 into oil and gas formations for EOR, as illustrated in Table 1 (Institute, 2021).

However, CCUS in oil fields is facing several technical and environmental challenges. One of the most significant issues is the efficiency of CO2 storage through the EOR process, which has been reported as low as 20% in previous studies (Zhang R.-H. et al., 2021). In other words, approximately 80% of the injected CO2 is reproduced along with the extracted oil and gas, necessitating the separation and reinjection of CO2. Additionally, the migration of CO2 over geological timescales is currently difficult to predict. Extensive monitoring devices are installed from the surface to track the movement of injected CO2 in representative CCUS sites, such as the Weyburn project. The continuous movement of CO2 is monitored over time and injections. This is primarily due to the interconnected pore system in the rock matrix, which provides a pathway through which the mature oil and gas migrate from the source rock into the geological structure, reflecting the nature of a conventional oil and gas reservoir (Goodman et al., 2020).

The CO2 fracturing technique is an alternative approach to CO2 storage, distinct from EOR, and is typically employed in unconventional formations characterized by extremely low permeability and water sensitivity (Hou et al., 2024b). As a relatively new technique, CO2 has demonstrated its efficiency as a working fluid in reducing the breakdown pressure of the formation and increasing the stimulated volume following hydraulic injection (Hou et al., 2021). Extensive laboratory research has been conducted to elucidate the rock-mechanical and flow-dynamical characteristics of CO2 fracturing (Xiangzeng et al., 2014; Wang H. et al., 2019). Corresponding chemical additives have also been developed to enhance the performance of CO2. Field trials have indicated that the flowback rate of CO2 after hydraulic injection is significantly lower compared to that after EOR (Yiyu et al., 2021; Honglei et al., 2022). However, the CO2 fracturing technique is still in the field-trial stage compared to CO2 EOR. It injects CO2 at much higher pressures and rates than in EOR injections, resulting in increased investment and challenges (Jing et al., 2022). Furthermore, there exists a gap between previous laboratory-scale efforts and practical field applications at a larger scale.

This study focuses on identifying the disparity and deficiencies between the theory and practice of CO2 fracturing, with the aim of bridging this gap. Firstly, CO2 fracturing is redefined and limited to supercritical CO2 (SC-CO2) fracturing, which presents a more environmentally friendly solution for CCUS in the oil and gas industry. Secondly, an extensive literature review is carried out to summarize the performances of fracture creation and proppant transport by CO2—the major tasks of a hydraulic fracturing fluid. By conducting a systematic analysis of research findings and field trials related to CO2 fracturing, we propose several promising research directions that can advance the field and enhance the efficiency of CO2 fracturing in practical applications. Through these efforts, we anticipate the CO2 fracturing technique to become an essential supplement and approach for CCUS in oil and gas reservoirs.

2 History and restricted definition of CO2 fracturing

The history of CO2 fracturing can be traced back to the 1970s when it was first experimented with as a method for enhancing oil recovery. Initial trials focused on using CO2 as a miscible fluid to displace oil from reservoirs, with CO2 being injected as a liquid from the wellhead. In order to enhance the performance of CO2 fracturing and flooding, CO2 was combined with foam-based fracturing techniques, leading to the development of CO2 foam fracturing in the early 2000s (Martin and Taber, 1992; Yost et al., 1993). The use of foam in CO2 fracturing offers several advantages over traditional hydraulic fracturing methods. Firstly, the foam acts as a carrier for the CO2, reducing the amount of CO2 required to achieve the desired fracturing effect. Secondly, the viscosity of CO2 foam is significantly improved, enhancing the transport capacity of proppants (Lv et al., 2017). However, the behavior and stability of CO2 foam under formation conditions present challenges due to the phase change of CO2 from a gaseous to a supercritical phase. The quality of the foam plays a crucial role in fracture generation, propagation, and production enhancement. Moreover, the use of water in CO2 foam is inevitable, which can lead to permeability and conductivity losses in water-sensitive formations.

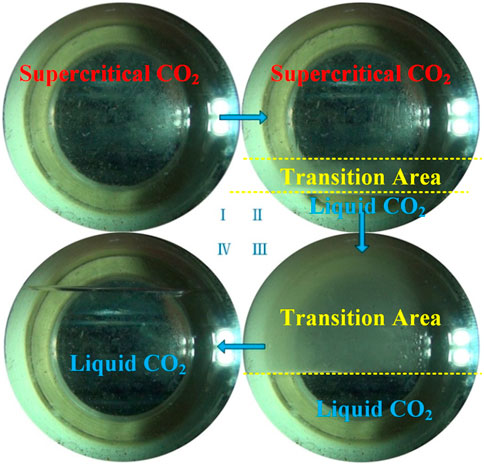

With the revolution of unconventional oil and gas, a more specific definition of CO2 fracturing has emerged - supercritical CO2 (SC-CO2) fracturing, also known as water-free fracturing (Middleton et al., 2015; Sanguinito et al., 2018; Wang et al., 2019). This technique utilizes 100% CO2 as the primary fracturing fluid to prevent damage caused by water in unconventional formations. In reservoirs buried approximately 800 m deeper, the injected CO2 undergoes a transition into a supercritical phase state, characterized by temperatures and pressures above the critical point (7.3 MPa, 31°C). The phase state transition of CO2 (from supercritical state to liquid state) has been observed and illustrated in Figure 1. In the process of supercritical CO2 fracturing, CO2 is initially pressurized and heated to reach its supercritical state at the surface. This supercritical CO2 is then mixed with proppant and injected into the wellbore to fracture the targeted reservoir zone. Supercritical CO2 exhibits high density, low viscosity, low surface tension, high diffusion coefficient, and excellent heat and mass transfer properties (Hou et al., 2021). As a fracturing fluid, it does not harm the reservoir, effectively avoiding near-wellbore formation damage, protecting the oil and gas reservoir, improving reservoir permeability, and facilitating easy flowback, compared with the traditional water-based fracturing fluids. Moreover, supercritical CO2 fracturing fluid can dehydrate tight clay formations, open up sandstone pore channels, and reduce the skin factor of the wellbore.

FIGURE 1. CO2 phase transitions (from the supercritical state to CO2 liquid) observed through a pressure-resistent window during a depressurization and cooling process, from 8.10 MPa to 42.5°C (I) to 5.80 MPa and 12.6°C (IV).

In this study, we adopt a specific definition of CO2 fracturing, specifically referring to supercritical CO2 (SC-CO2) fracturing, which is distinct from other forms of CO2 fracturing such as CO2 foam. For one reason, the focus on supercritical CO2 fracturing is justified by its similarity to the process of CO2 storage, as it eliminates the use of water and demonstrates higher efficiency in CO2 storage (Hou et al., 2020; Hou and Elsworth, 2021). The flowback rate of fracturing injected CO2 is lower than other forms of CO2 storage, for instance, CO2-EOR (Hou et al., 2024b). This indicates a higher efficiency of permanent CO2 storage. This approach presents a more environmentally friendly solution for CCUS in the oil and gas field. For the other reason, CO2 fracturing represents one of the most promising approaches to large-scale carbon sinks. If water-based fracturing operations could be replaced by CO2 fracturing, one single horizontal well may store more than ten thousand tons of CO2. Considering that thousands of wells may be fractured in a single oil or gas field, the CO2 storage capacity by CO2 fracturing shows enormous potential. Therefore, the promotion of CO2 fracturing for CCUS represents a critical approach to carbon sinks and carbon neutrality.

3 Results

3.1 Fracture creation by CO2

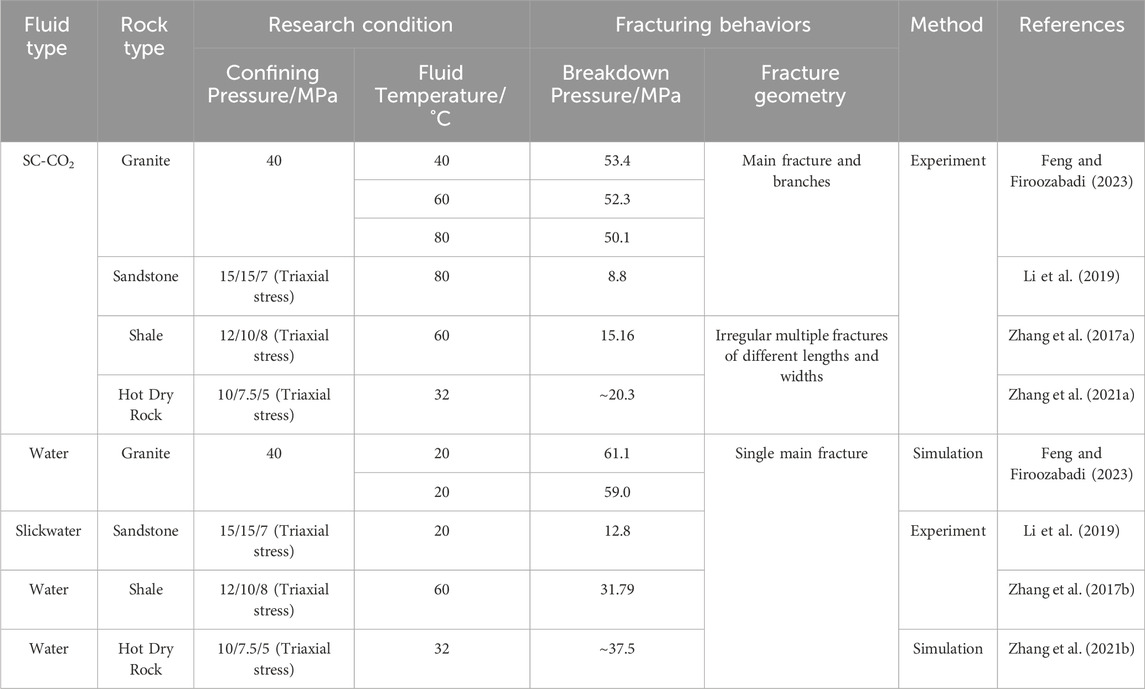

Fractures formed through supercritical CO2 fracturing exhibit distinct characteristics that are influenced by the properties of supercritical CO2. One notable effect is the reduction in the breakdown pressure of the formation, allowing for easier penetration into the rock matrix due to its low viscosity, high diffusivity, and absence of surface tension. Supercritical CO2 exhibits a lower viscosity (three magnitudes or even smaller) compared to alternative fracturing fluids like water-based fluids (Kuang et al., 2023). This attribute allows for smoother flow through minuscule pores and fractures within the reservoir rock, enabling deeper penetration into the rock matrix and generating fractures with enhanced tortuosity. This characteristic allows the injected fluid to effectively access the pre-existing fracture, and as the induced fracture propagates along its path, there is a significant reduction (∼50%) in breakdown pressure (Zhang et al., 2017a; Li et al., 2019; Zhang et al., 2021; Feng and Firoozabadi, 2023), as summarized in Table 2.

TABLE 2. Comparisons between the fractures created by SC-CO2 and water-based fluids (Zhang et al., 2017a; Li et al., 2019; Zhang et al., 2021; Feng and Firoozabadi, 2023).

Laboratory tests have indicated that fractures created by CO2 have higher tortuosity, as illustrated in Figure 2 (Song et al., 2019). Tortuosity pertains to the extent of deviation from a linear trajectory observed in fractures. The higher degree of fracture tortuosity indicates that CO2 follow intricate routes within the reservoir rock, thereby augmenting their interaction surface. Additionally, CO2 fracturing holds the potential to generate a more intricate network of interconnected fractures within the reservoir, surpassing the complexity of fractures induced by water-based fluids (Wang and Sharma, 2023). This characteristic enhances the fracture surface area and the volume of the reservoir that is stimulated. The increased fracture surface area provides more flowing pathways for in situ hydrocarbons during production operations, thus improving well productivity and enhanced recovery rates from unconventional formations.

FIGURE 2. The fracture morphology created by CO2 and fracturing fluids. Reproduced with permission from Ref. Song et al. (2019), copyright (2019) Elsevier.

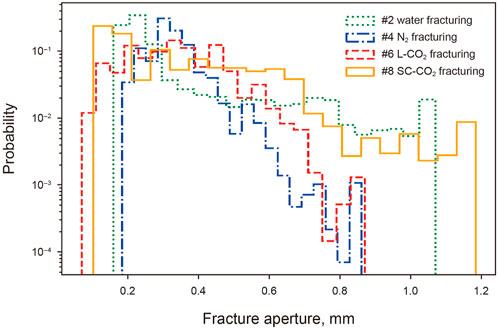

However, a significant challenge associated with CO2-created fractures is their underdeveloped width, primarily due to the high rate of CO2 leak-off and the net stress loss within the fracture. This loss of driving force leads to narrower and shorter fractures (Zhou and Burbey, 2014; Wang et al., 2017; Ranjith et al., 2019). The average fracture aperture of water, N2, L-CO2 and SC-CO2 shows relatively small variances falling in the range between 0.304 mm and 0.317 mm, as presented in Figure 3. However, the largest standard deviation (0.201) of the aperture formed by SC-CO2 fracturing is obtained, followed by water fracturing (0.171), L-CO2 fracturing (0.123), and N2 fracturing (0.091). This suggests the maximum roughness of the fractures created by SC-CO2 (Yang et al., 2021). Furthermore, given the higher complexity and tortuosity of CO2-created fractures, the injection of proppants afterward becomes more challenging, resulting in elevated operation wellhead pressures. More careful planning and innovative solutions tailored specifically for CO2 fracturing techniques are essential to overcome these challenges posed by narrow and short CO2-created fractures with complex geometries.

FIGURE 3. The distribution of fracture apertures induced by CO2 and fracturing fluids. Reproduced with permission from Ref. Yang et al. (2021), copyright (2022) Elsevier.

3.2 Proppant transport by CO2

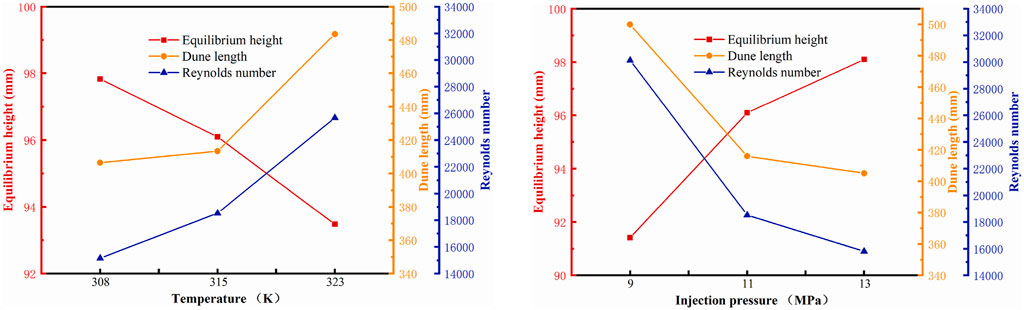

In addition to the more challenging conditions for proppant transport, a significant hurdle in CO2 fracturing is the low viscosity of supercritical CO2, which is similar to gaseous CO2. As a result, proppant particles settle rapidly, leading to the formation of accumulations known as dunes (Hou et al., 2015). These dunes vary in shape and size as continuous injections progress. Within fractures, the proppant is then transported in the form of these dunes, creating a dynamic and complex process, unlike water-based high-viscosity fluids that evenly suspend the proppant (Hou et al., 2022a; Hou et al., 2022b). When the mass flow remains constant, altering the injection temperature to a higher value or reducing the injection pressure will lead to a decrease in both viscosity and density of supercritical CO2, resulting in evolutions of equilibrium height and distance for dune transport, as presented in Figure 4 (Zheng et al., 2022b).

FIGURE 4. Effects of injection temperature and pressure on dune equilibrium height and length based on experiments. Reproduced with permission from Ref. Zheng et al. (2022b), copyright (2022) Elsevier.

Furthermore, the high leak-off of CO2 and the distribution of the injected fluid in complex fracture networks exacerbate proppant accumulation and can even cause sand screen-out due to the loss of the carrying fluid. Previous studies have demonstrated the influence of supercritical CO2 on the settling, restarting, and flowing behaviors of proppants (Hou et al., 2017a; Chen and Sun, 2023). It has been observed that the high density of CO2, which is similar to liquid CO2, contributes to an enhanced capacity for proppant transport in supercritical CO2, as depicted in Figure 5. Each black point (P1, P2, P3, P4 and P5) represents a proppant particle captured by the high-speed camera. The dashed lines derived from the black points represent the moving trajectory of the proppant particles, which are plotted automatically by the image analysis software. The terminal settling velocity of proppants in CO2 is slightly higher, within the same magnitude, compared to settling velocities in water (Hou et al., 2015). Additionally, the slippage between the particles and the carrying CO2 can be eliminated by increasing the flow rate of the slurry (Hou et al., 2017b). Restarting the movement of particles in CO2 is even easier than in water due to the absence of interfacial tension and the generation of additional Magnus force through high-speed spinning, facilitating the restarting process (Hou et al., 2019).

FIGURE 5. Proppant particle movements (trajectories in colorized dashes), from the right side to the left side, in supercritical CO2 captured by the high-speed camera.

3.3 Improving the research work on CO2 fracturing

The primary objectives of a fracturing fluid are to create fractures and transport proppants. However, CO2 fracturing faces significant challenges in both areas, as outlined in Figure 6. In terms of fracture creation, there are several approaches that can be employed to improve performance. These include reducing the leakage of CO2 into the rock matrix and natural fractures, establishing net stress within the fractures, and then enhancing the propagation of fracture networks. On the other hand, the capacity of CO2 to carry proppants can be enhanced by addressing issues such as particle settling, eliminating slippage between the particles and CO2, and improving proppant transport within complex fracture networks.

FIGURE 6. Synthetical analyses of fracture creation and proppant transport regarding CO2 fracturing.

In order to address these challenges, various solutions have been analyzed and summarized in Figure 6. One common approach is the use of CO2 thickeners, which increase the viscosity of the fluid. This serves to reduce both proppant settling and CO2 leak-off (Enick et al., 2012; Al Hinai et al., 2018). Additionally, it has been observed through numerical and experimental simulations that fracture width and particle slippage are influenced by the CO2 pump rate. Higher pump rates facilitate fracture growth and help eliminate slippage (Lei et al., 2016). CO2 leak-off is another prevalent issue that hampers fracture propagation and proppant transport. Therefore, promising research directions for improving CO2 as a fracturing fluid include the development of friction reducers, investigating the effects of flow loss (caused by leak-off) and distribution (within fracture networks), as well as studying the shear viscosity of thickened CO2 (the performance of the thickener under high pump-rate condition).

4 Discussion

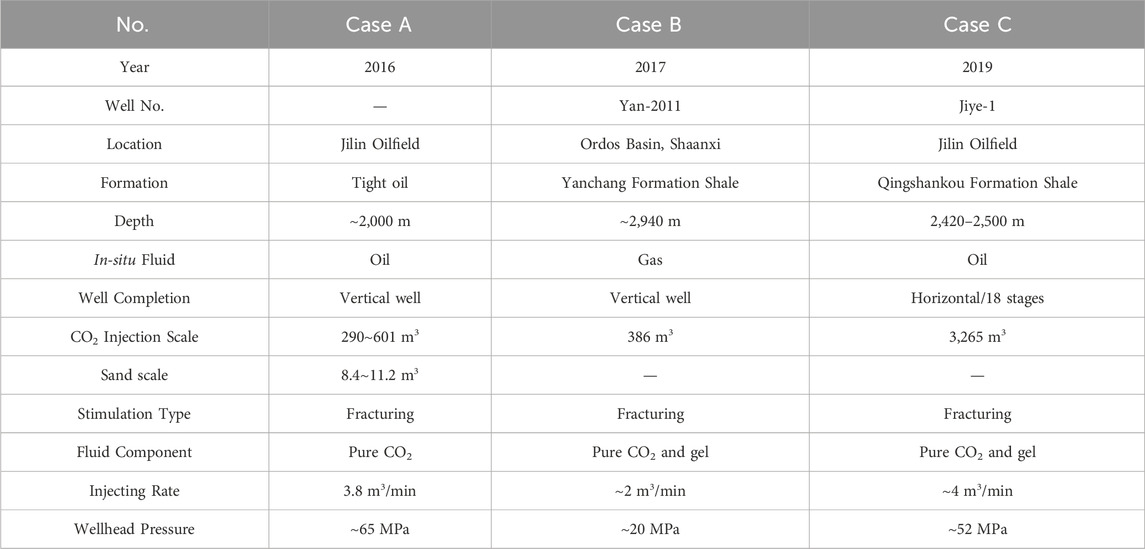

4.1 Case study of CO2 fracturing

The CO2 fracturing technique is mainly applied in unconventional formations that have extremely tight rock matrix and nano-Darcy permeability (decreasing the leak-off of CO2). Three representative cases of CO2 fracturing in tight oil, shale gas, and shale oil formations are summarized in Table 3 (Meng et al., 2016; Yiyu et al., 2021; Jing et al., 2022). Case A uses pure CO2 for cracking fractures and carrying proppant. Two types of additives are tested to increase the viscosity of CO2 and its proppant-carrying capacity. Cases B and C only use CO2 to crack the formation and create complex fracture networks. The high-viscosity gel is applied afterward to further develop the networks and carry the proppant. Generally, both the fracturing scale and pump rate are relatively small for CO2 fracturing compared with those for water-based fracturing.

Approximately ∼300 m3 of CO2 is injected in each well or stage, with approximately ∼180 m3 of CO2 injected in each stage of the horizontal well in Case C. The pump rate may be restricted by the high friction encountered along the wellbore when using CO2, resulting in a high wellhead pressure of approximately ∼65 MPa, as indicated in Table 3. The sand ratio in Case A is around 5.6%, which is less than half of the sand ratio typically used in water-based fracturing. The efficiency of CO2 fracturing in field trials is relatively low due to the limited scale of fracturing (both proppant and CO2 volumes), low sand ratio, restricted pump rate, and comparatively high injection pressure. This could be one of the main reasons, as well as the high cost of CO2 additives, why recent tests have opted for a hybrid approach that combines CO2 injection with water-based fracturing, as illustrated in Cases B and C.

4.2 Potential of CO2 fracturing for CCUS

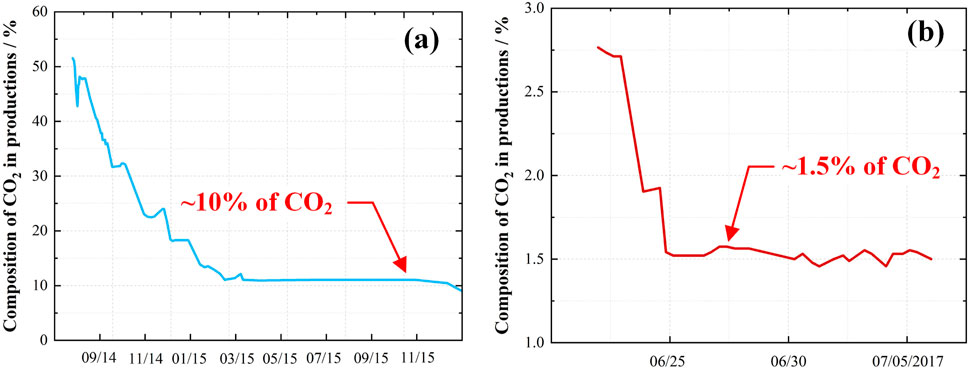

Most of the current CO2 fracturing field cases are reported along with the development of shale oil in China (Hou et al., 2024a). The field engineers injected CO2 as a pre-fracturing process, aiming to create more complex fracture networks. The following injected conventional water-based fluids continuously develop the fracture dimensions and transport the proppant into fractures (Yang et al., 2022). Therefore, the usage of CO2 (several hundred scales for each fracturing stage) is significantly smaller than the water-based fluids for the main fracturing operation, as listed in Table 3. However, the flowback rate of fracturing injected CO2 is approximately one order of magnitude lower than other forms of CO2 storage (as shown in Figure 7), indicating a higher efficiency of permanent CO2 storage (Louk et al., 2017; Hou et al., 2024a). The usage of CO2 may be improved by increasing its proportion in the total fracturing fluids. A possible approach is using CO2 to share the proppant injection task, for instance, carrying the fine proppant (100 mesh) (Hou et al., 2017a; Hou et al., 2017b). Meanwhile, the developments of the carbon market and carbon capture techniques may reduce the cost of CO2 sources. The policy incentives are also essential to encourage the operators to promote the usage of CO2, for instance, the tax preference applied in the United States (Ren et al., 2022). The increasing proportion and decreasing cost may significantly promote the potential and contribution of CO2 fracturing to CCUS, considering the huge consumption of fracturing fluids.

FIGURE 7. Recovery of CO2 after injections in (A) CO2 huff-and-puff case and (B) CO2 fracturing case. Reproduced with permission from Ref. Hou et al. (2024a), copyright (2024) Elsevier.

The other challenge of CO2 fracturing for CCUS is the mismatch between CO2 sources and fracturing sites (Munkejord et al., 2016), for instance, transporting the captured CO2 from power plants to oil and gas fields. Pipelines may be necessary for the continuous transport of CO2 for huff-and-puff, EOR or direct storage in relatively fixed sites (Onyebuchi et al., 2018). Trucks may be essential for fracturing operations to transport CO2 from one site to another (Gao et al., 2011). Both pipelines and trucks will increase the investments in construction and equipment, as well as the potential for extra CO2 emissions. Therefore, CO2 transport has become a common issue for all kinds of CO2 storage because of the geographical distance between CO2 sources and storage sites. For CO2 fracturing, a hybrid transport system may be a solution to improve the flexibility of CO2 transport from site to site.

4.3 Gap between theory and practice

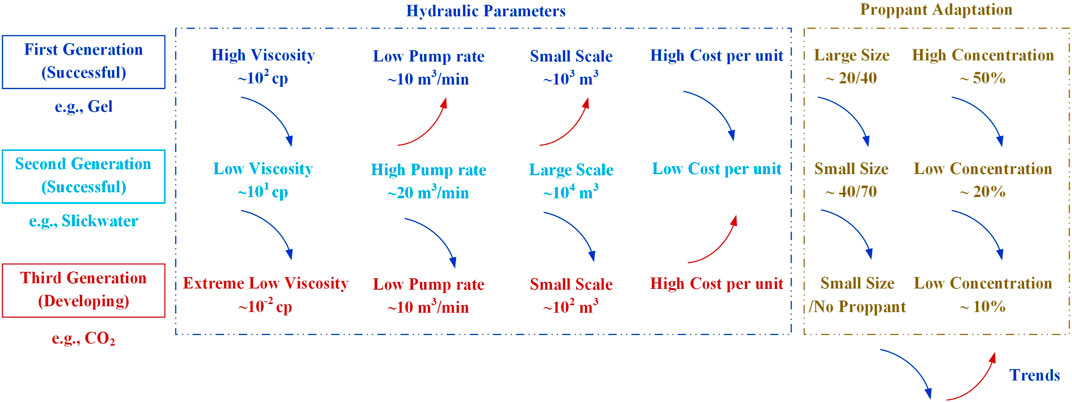

Although fundamental research has highlighted the advantages and feasibility of CO2 fracturing, field trials have encountered significant challenges, as summarized in Table 3. To reveal the disparity between the theory and practice of CO2 fracturing, we compared key injection parameters recorded during field operations using different fracturing fluids, as presented in Figure 8. Initially, in conventional reservoirs, guar gel (referred to as the first generation of fracturing fluid) was used to create large bi-wing fractures with a high concentration of large proppants. Subsequently, slickwater (with lower viscosity) was employed at a much higher pump rate to carry smaller proppants at lower concentrations, achieving a balance between fracturing efficiency and investment-production ratio (Barati and Liang, 2014; Zhang et al., 2017b). CO2 fracturing, known as the third generation of fracturing fluid, is considered environmentally friendly. Pump rates and injection scales are both reduced for CO2 fracturing, reflecting its status as a developing technique.

FIGURE 8. Comparison of hydraulic parameters for field operations among the three generations of fracturing fluid.

Compared to conventional fluids, the disparity between fundamental research and field application primarily lies in pump rate and operation scale, as depicted in Figure 8. Current efforts to thicken CO2 may draw inspiration from the success of first-generation fluids, characterized by high viscosity gel. However, the second-generation fluid (represented by low-viscosity slickwater) compensates for the low-viscosity drawback with a high pump rate, which offers valuable insights. Therefore, the utilization of friction reducers becomes another crucial technique for CO2 fracturing. Correspondingly, the performance of CO2 thickener (enhanced CO2 viscosity after the high-pump-rate shear) becomes an essential criterion for the relevant research, which currently is barely reported. Other valuable insights include enhancing fracturing scales through the development of low-cost additives, increasing the proportion of fine proppant, and adopting hybrid approaches that incorporate water-based fluids (inspired by Cases B and C).

The relatively low pump rate may represent one of the most significant gaps between the theory and practice of CO2 fracturing. Firstly, the proppant usually settles down rapidly in low-viscosity fluids (CO2 and slickwater). The horizontal transport distance of the proppant before its settlement reduces under a low pump rate condition due to the lower horizontal dragging force (Hou et al., 2017b; Hou et al., 2019). This significantly constrains the proppant transport capability of supercritical CO2, and then the scale of proppant injection in fields (Table 3). Secondly, the high diffusion feature of supercritical CO2 induces a high leak-off of fluid from fractures into the formation. The low pump rate may weaken the supplementary fluid in fractures, thus constraining the propagation of fracture networks. Meanwhile, the relatively low fracturing scale further deteriorates the development of underground fractures. Correspondingly, the stimulated reservoir volume is restricted for enhancing oil/gas production. Regarding the CO2 storage concern, the low fracturing scale reduces the usage of CO2 during fracturing operations. The limited artificial fracture volume will further decrease the inventory capacity of CO2 storage in unconventional reservoirs, because the artificial fracture may contribute most to the capacity of CO2 storage (Hou et al., 2024a; Hou et al., 2024b). Therefore, the relatively low fracturing scale may represent the other critical gap between the theory and practice of CO2 fracturing in accordance with the aforementioned rationale.

5 Conclusion

(1) The primary disparity between theory and practice in CO2 fracturing lies in pump rate and operation scale.

(2) New research directions for improving both fracture propagation and proppant transport in CO2 fracturing include the use of friction reducers, addressing flow loss caused by leak-off and distribution in fracture networks, and enhancing the shear viscosity of thickened CO2.

(3) Field operations of CO2 fracturing can be optimized by enhancing scales through the incorporation of low-cost additives, increasing the proportion of fine proppant, and utilizing a hybrid approach that integrates conventional fluids.

Author contributions

LH: Conceptualization, Funding acquisition, Methodology, Writing–original draft, Writing–review and editing. JL: Writing–review and editing. PG: Data curation, Methodology, Writing–review and editing. YJ: Conceptualization, Investigation, Writing–review and editing. LZ: Data curation, Investigation, Writing–review and editing.

Funding

The authors declare that financial support was received for the research, authorship, and/or publication of this article. This research is funded by the National Natural Science Foundation of China under the grant 42377138.

Conflict of interest

Author PG was employed by Shengli Oilfield Service Corporation.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Al Hinai, N. M., Saeedi, A., Wood, C. D., Myers, M., Valdez, R., Sooud, A. K., et al. (2018). Experimental evaluations of polymeric solubility and thickeners for supercritical CO2at high temperatures for enhanced oil recovery. Energy and Fuels 32 (2), 1600–1611. doi:10.1021/acs.energyfuels.7b03733

Barati, R., and Liang, J.-T. (2014). A review of fracturing fluid systems used for hydraulic fracturing of oil and gas wells. J. Appl. Polym. Sci. 131 (16), n/a. doi:10.1002/app.40735

Busch, A., Alles, S., Gensterblum, Y., Prinz, D., Dewhurst, D. N., Raven, M. D., et al. (2008). Carbon dioxide storage potential of shales. Int. J. Greenh. Gas Control 2 (3), 297–308. doi:10.1016/j.ijggc.2008.03.003

Chen, D., and Sun, Z. (2023). Numerical simulation of the proppant settlement in SC-CO2 sand-carrying fluid in fracturing fractures. Energies 16 (1), 11. doi:10.3390/en16010011

Crawford, H. R., Neill, G., Bucy, B., and Crawford, P. (1963). Carbon dioxide - a multipurpose additive for effective well stimulation. J. Petroleum Technol. 15 (03), 237–242. doi:10.2118/571-pa

Enick, R. M., et al. (2012). “Mobility and conformance control for CO2 EOR via thickeners, foams, and gels--A literature review of 40 Years of research and pilot tests,” in SPE improved oil recovery symposium (Society of Petroleum Engineers).

Feng, Y., and Firoozabadi, A. (2023). Phase-field simulation of hydraulic fracturing by CO2 and water with consideration of thermoporoelasticity. Rock Mech. Rock Eng. 56 (10), 7333–7355. doi:10.1007/s00603-023-03355-7

Gao, L., Fang, M., Li, H., and Hetland, J. (2011). Cost analysis of CO2 transportation: case study in China. Energy Procedia 4, 5974–5981. doi:10.1016/j.egypro.2011.02.600

Gilfillan, S. M., Lollar, B. S., Holland, G., Blagburn, D., Stevens, S., Schoell, M., et al. (2009). Solubility trapping in formation water as dominant CO 2 sink in natural gas fields. Nature 458 (7238), 614–618. doi:10.1038/nature07852

Godec, M., Koperna, G., Petrusak, R., and Oudinot, A. (2014). Enhanced gas recovery and CO2 storage in gas shales: a summary review of its status and potential. Energy Procedia 63, 5849–5857. doi:10.1016/j.egypro.2014.11.618

Goodman, A., et al. (2020). Shale pore alteration: potential implications for hydrocarbon extraction and CO2 storage. Fuel (Lond), 265. doi:10.1016/j.fuel.2019.116930

Honglei, L., et al. (2022). Research and practice of SRV fracturing technology for inter-salt shale oil. Special Oil Gas Reservoirs 29 (2). (In Chinese).

Hou, L., Bian, X., Geng, X., Sun, B., Liu, H., and Jia, W. (2019). Incipient motion behavior of the settled particles in supercritical CO2. J. Nat. Gas Sci. Eng. 68, 102900. doi:10.1016/j.jngse.2019.102900

Hou, L., and Elsworth, D. (2021). Mechanisms of tripartite permeability evolution for supercritical CO2 in propped shale fractures. Fuel, 292. doi:10.1016/j.fuel.2021.120188

Hou, L., Elsworth, D., and Geng, X. (2020). Swelling and embedment induced by sub- and super-critical-CO2 on the permeability of propped fractures in shale. Int. J. Coal Geol. 225, 103496. doi:10.1016/j.coal.2020.103496

Hou, L., Elsworth, D., Wang, J., Zhou, J., and Zhang, F. (2024a). Feasibility and prospects of symbiotic storage of CO2 and H2 in shale reservoirs. Renew. Sustain. Energy Rev. 189, 113878. doi:10.1016/j.rser.2023.113878

Hou, L., Elsworth, D., Zhang, L., Gong, P., and Liu, H. (2024b). Recalibration of CO2 storage in shale: prospective and contingent storage resources, and capacity. Energy 290, 130067. doi:10.1016/j.energy.2023.130067

Hou, L., et al. (2021). Review of fundamental studies of CO2 fracturing: fracture propagation, propping and permeating. J. Petroleum Sci. Eng., 205. doi:10.1016/j.petrol.2021.108823

Hou, L., et al. (2022a). Effect of slickwater-alternate-slurry injection on proppant transport at field scales: a hybrid approach combining experiments and deep learning. Energy, 242. doi:10.1016/j.energy.2021.122987

Hou, L., Jiang, T., Liu, H., Geng, X., Sun, B., Li, G., et al. (2017a). An evaluation method of supercritical CO2 thickening result for particle transporting. J. CO2 Util. 21, 247–252. doi:10.1016/j.jcou.2017.07.023

Hou, L., Sun, B., Geng, X., Jiang, T., and Wang, Z. (2017b). Study of the slippage of particle/supercritical CO2 two-phase flow. J. Supercrit. Fluids 120, 173–180. doi:10.1016/j.supflu.2016.09.016

Hou, L., Sun, B., Wang, Z., and Li, Q. (2015). Experimental study of particle settling in supercritical carbon dioxide. J. Supercrit. Fluids 100, 121–128. doi:10.1016/j.supflu.2015.02.020

Hou, L., Wang, X., Bian, X., Liu, H., and Gong, P. (2022b). Evaluating essential features of proppant transport at engineering scales combining field measurements with machine learning algorithms. J. Nat. Gas Sci. Eng. 107, 104768. doi:10.1016/j.jngse.2022.104768

Jia, B., Tsau, J.-S., and Barati, R. (2019). A review of the current progress of CO2 injection EOR and carbon storage in shale oil reservoirs. Fuel 236, 404–427. doi:10.1016/j.fuel.2018.08.103

Jing, B., et al. (2022). The stimulation mechanism and performance analysis of supercritical CO2 and hydraulic sand-carrying composite volume fracturing technology on continental shale reservoirs. Acta Pet. Sin. 43 (3), 399–409. (In Chinese).

Kuang, N.-j., Zhou, J. p., Xian, X. f., Zhang, C. p., Yang, K., and Dong, Z. q. (2023). Geomechanical risk and mechanism analysis of CO2 sequestration in unconventional coal seams and shale gas reservoirs. Rock Mech. Bull. 2 (4), 100079. doi:10.1016/j.rockmb.2023.100079

Lab, G. C. D. (2022). World annual CO2 emissions from fossil fuels and industry. Available at https://ourworldindata.org/co2-dataset-sources.

Lei, H., et al. (2016). Calculation on the following performance of proppant in supercritical carbon dioxide. Acta Pet. Sin. 37 (8), 1061–1068. (In Chinese).

Levine, J. S., Fukai, I., Soeder, D. J., Bromhal, G., Dilmore, R. M., Guthrie, G. D., et al. (2016). U.S. DOE NETL methodology for estimating the prospective CO2 storage resource of shales at the national and regional scale. Int. J. Greenh. Gas Control 51, 81–94. doi:10.1016/j.ijggc.2016.04.028

Li, S., Zhang, S., Ma, X., Zou, Y., Chen, M., et al. (2019). Hydraulic fractures induced by water-/carbon dioxide-based fluids in tight sandstones. Rock Mech. Rock Eng. 52 (9), 3323–3340. doi:10.1007/s00603-019-01777-w

Lillies, A. T., and King, S. R. (1982). “Sand fracturing with liquid carbon dioxide,” in SPE production Technology symposium (New Mexico: Hobbs).

Louk, K., Ripepi, N., Luxbacher, K., Gilliland, E., Tang, X., Keles, C., et al. (2017). Monitoring CO2 storage and enhanced gas recovery in unconventional shale reservoirs: results from the Morgan County, Tennessee injection test. J. Nat. Gas Sci. Eng. 45, 11–25. doi:10.1016/j.jngse.2017.03.025

Lv, Q., Li, Z., Li, B., Zhang, C., Shi, D., Zheng, C., et al. (2017). Experimental study on the dynamic filtration control performance of N2/liquid CO2 foam in porous media. Fuel 202, 435–445. doi:10.1016/j.fuel.2017.04.034

Martin, D. F., and Taber, J. J. (1992). Carbon dioxide flooding. J. Petroleum Technol. 44 (04), 396–400. doi:10.2118/23564-pa

Meng, S., et al. (2016). “Optimisation and performance evaluation of liquid CO2 fracturing fluid formulation system,” in SPE asia pacific oil and gas conference and exhibition (OnePetro).

Middleton, R. S., Carey, J. W., Currier, R. P., Hyman, J. D., Kang, Q., Karra, S., et al. (2015). Shale gas and non-aqueous fracturing fluids: opportunities and challenges for supercritical CO2. Appl. Energy 147, 500–509. doi:10.1016/j.apenergy.2015.03.023

Munkejord, S. T., Hammer, M., and Løvseth, S. W. (2016). CO2 transport: data and models – a review. Appl. Energy 169, 499–523. doi:10.1016/j.apenergy.2016.01.100

Onyebuchi, V. E., Kolios, A., Hanak, D., Biliyok, C., and Manovic, V. (2018). A systematic review of key challenges of CO2 transport via pipelines. Renew. Sustain. Energy Rev. 81, 2563–2583. doi:10.1016/j.rser.2017.06.064

Ranjith, P. G., Zhang, C. P., and Zhang, Z. Y. (2019). Experimental study of fracturing behaviour in ultralow permeability formations: a comparison between CO2 and water fracturing. Eng. Fract. Mech., 217. doi:10.1016/j.engfracmech.2019.106541

Ren, B., Male, F., and Duncan, I. J. (2022). Economic analysis of CCUS: accelerated development for CO2 EOR and storage in residual oil zones under the context of 45Q tax credit. Appl. Energy 321, 119393. doi:10.1016/j.apenergy.2022.119393

Rutqvist, J., Birkholzer, J., and Tsang, C.-F. (2008). Coupled reservoir–geomechanical analysis of the potential for tensile and shear failure associated with CO2 injection in multilayered reservoir–caprock systems. Int. J. Rock Mech. Min. Sci. 45 (2), 132–143. doi:10.1016/j.ijrmms.2007.04.006

Sanguinito, S., Goodman, A., Tkach, M., Kutchko, B., Culp, J., Natesakhawat, S., et al. (2018). Quantifying dry supercritical CO2-induced changes of the Utica Shale. Fuel 226, 54–64. doi:10.1016/j.fuel.2018.03.156

Sharifzadeh, M., Triulzi, G., and Magee, C. L. (2019). Quantification of technological progress in greenhouse gas (GHG) capture and mitigation using patent data. Energy and Environ. Sci. 12 (9), 2789–2805. doi:10.1039/c9ee01526d

Shen, M., Kong, F., Tong, L., Luo, Y., Yin, S., Liu, C., et al. (2022). Carbon capture and storage (CCS): development path based on carbon neutrality and economic policy. Carbon Neutrality 1 (1), 37. doi:10.1007/s43979-022-00039-z

Song, X., Guo, Y., Zhang, J., Sun, N., Shen, G., Chang, X., et al. (2019). Fracturing with carbon dioxide: from microscopic mechanism to reservoir application. Joule 3 (8), 1913–1926. doi:10.1016/j.joule.2019.05.004

Tao, Z., and Clarens, A. (2013). Estimating the carbon sequestration capacity of shale formations using methane production rates. Environ. Sci. Technol. 47 (19), 11318–11325. doi:10.1021/es401221j

Tayari, F., Blumsack, S., Dilmore, R., and Mohaghegh, S. D. (2015). Techno-economic assessment of industrial CO2 storage in depleted shale gas reservoirs. J. Unconv. Oil Gas Resour. 11, 82–94. doi:10.1016/j.juogr.2015.05.001

Wang, H., Li, G., Zhu, B., Sepehrnoori, K., Shi, L., Zheng, Y., et al. (2019a). Key problems and solutions in supercritical CO2 fracturing technology. Front. Energy 13 (4), 667–672. doi:10.1007/s11708-019-0626-y

Wang, H., and Sharma, M. M. (2023). Uniquely determine fracture dimension and formation permeability from diagnostic fracture injection test. Rock Mech. Bull. 2 (2), 100040. doi:10.1016/j.rockmb.2023.100040

Wang, J., Elsworth, D., Wu, Y., Liu, J., Zhu, W., and Liu, Y. (2017). The influence of fracturing fluids on fracturing processes: a comparison between water, oil and SC-CO2. Rock Mech. Rock Eng. 51 (1), 299–313. doi:10.1007/s00603-017-1326-8

Wang, J., Wang, Z., Sun, B., Gao, Y., Wang, X., and Fu, W. (2019b). Optimization design of hydraulic parameters for supercritical CO2 fracturing in unconventional gas reservoir. Fuel 235, 795–809. doi:10.1016/j.fuel.2018.08.078

Xiangzeng, W., Jinqiao, W., and Juntao, Z. (2014). Application of CO2 fracturing technology for terrestrial shale gas reservoirs. Nat. Gas. Ind. 34 (1), 64–67. (In Chinese).

Yang, B., Wang, H., Wang, B., Shen, Z., Zheng, Y., Jia, Z., et al. (2021). Digital quantification of fracture in full-scale rock using micro-CT images: a fracturing experiment with N2 and CO2. J. Petroleum Sci. Eng. 196, 107682. doi:10.1016/j.petrol.2020.107682

Yang, B., Wang, H. Z., Li, G. S., Wang, B., Chang, L., Tian, G. H., et al. (2022). Fundamental study and utilization on supercritical CO2 fracturing developing unconventional resources: current status, challenge and future perspectives. Petroleum Sci. 19 (6), 2757–2780. doi:10.1016/j.petsci.2022.08.029

Yiyu, L., et al. (2021). Research progress and prospect of the integrated supercritical CO2 enhanced shale gas recovery and geological sequestration. Nat. Gas. Ind. 41 (6). (In Chinese).

Yost, A., Mazza, R., and Gehr, J. (1993). “CO2/Sand fracturing in devonian shales,” in SPE eastern regional meeting (Society of Petroleum Engineers).

Zhang, R.-H., et al. (2021a). Numerical simulation of the feasibility of supercritical CO2 storage and enhanced shale gas recovery considering complex fracture networks. J. Petroleum Sci. Eng., 204. doi:10.1016/j.petrol.2021.108671

Zhang, W., Wang, C., Guo, T., He, J., Zhang, L., Chen, S., et al. (2021b). Study on the cracking mechanism of hydraulic and supercritical CO2 fracturing in hot dry rock under thermal stress. Energy 221, 119886. doi:10.1016/j.energy.2021.119886

Zhang, X., Lu, Y., Tang, J., Zhou, Z., and Liao, Y. (2017a). Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 190, 370–378. doi:10.1016/j.fuel.2016.10.120

Zhang, X., Wang, J., Gao, F., and Ju, Y. (2017b). Impact of water, nitrogen and CO2 fracturing fluids on fracturing initiation pressure and flow pattern in anisotropic shale reservoirs. J. Nat. Gas Sci. Eng. 45, 291–306. doi:10.1016/j.jngse.2017.06.002

Zhang, Z., Pan, S. Y., Li, H., Cai, J., Olabi, A. G., Anthony, E. J., et al. (2020). Recent advances in carbon dioxide utilization. Renew. Sustain. Energy Rev. 125, 109799. doi:10.1016/j.rser.2020.109799

Zhao, C., Ju, S., Xue, Y., Ren, T., Ji, Y., and Chen, X. (2022). China’s energy transitions for carbon neutrality: challenges and opportunities. Carbon Neutrality 1 (1), 7. doi:10.1007/s43979-022-00010-y

Zheng, Y., Gao, L., Dong, R., and He, S. (2022a). Role of CCUS in carbon neutral power system. Carbon Neutrality 1 (1), 19. doi:10.1007/s43979-022-00015-7

Zheng, Y., Wang, H., Tian, G., Liu, M., Li, G., and Kuru, E. (2022b). Experimental investigation of proppant transport in hydraulically fractured wells using supercritical CO2. J. Petroleum Sci. Eng. 217, 110907. doi:10.1016/j.petrol.2022.110907

Zhou, X., and Burbey, T. J. (2014). Fluid effect on hydraulic fracture propagation behavior: a comparison between water and supercritical CO2-like fluid. Geofluids 14 (2), 174–188. doi:10.1111/gfl.12061

Keywords: CCUS, CO2 fracturing, case study, fracture propagation, proppant transport

Citation: Hou L, Luo J, Gong P, Ji Y and Zhang L (2024) Promotion of CO2 fracturing for CCUS—the technical gap between theory and practice. Front. Energy Res. 12:1348375. doi: 10.3389/fenrg.2024.1348375

Received: 02 December 2023; Accepted: 01 March 2024;

Published: 14 March 2024.

Edited by:

Xindi Sun, Slippery Rock University of Pennsylvania, United StatesReviewed by:

Gang Lei, China University of Geosciences Wuhan, ChinaTimothy A. Barckholtz, ExxonMobil Technology and Engineering, United States

Daigang Wang, China University of Petroleum, Beijing, China

Copyright © 2024 Hou, Luo, Gong, Ji and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Peibin Gong, cGVpYmluZ29uZ0AxNjMuY29t; Ya Ji, aml5YUBzanR1LmVkdS5jbg==

Lei Hou

Lei Hou Jiangfeng Luo1

Jiangfeng Luo1