- 1Department of Mechanical Engineering, Iowa State University, Ames, IA, United States

- 2Bioeconomy Institute, Iowa State University, Ames, IA, United States

- 3Department of Chemical and Biological Engineering, Iowa State University, Ames, IA, United States

Sugars are precursors to the majority of the world’s biofuels. Most of these come from sugar and starch crops, such as sugarcane and corn grain. Lignocellulosic sugars, although more challenging to extract from biomass, represent a large, untapped, opportunity. In response to the increasing attention to renewable energy, fuels, and chemicals, we review and compare two strategies for extracting sugars from lignocellulosic biomass: biochemical and thermochemical processing. Biochemical processing based on enzymatic hydrolysis has high sugar yield but is relatively slow. Thermochemical processing, which includes fast pyrolysis and solvent liquefaction, offers increased throughput and operability at the expense of low sugar yields.

1 The need for sugars

Transferring society’s dependence from petroleum to biomass resources for the production of liquid transportation fuels and commodity chemicals can improve the sustainability of energy and chemical industries by reducing pollution and managing greenhouse gas (GHG) emissions. Biofuels can play a key role in meeting the growing demands for renewable energy and help alleviate global climate change (Smith, 2016; IPCC, 2018). In addition to fuels, biomass can be converted into chemical building blocks, replacing some of the most commonly used petroleum-based chemicals (Werpy et al., 2004). The constituents of biomass include carbohydrates, lipids, protein, and lignin, all of which, in principle, can be converted into renewable fuels and chemicals. However, most of the current supply and much of the projected supply of these bio-based products are anticipated to come from carbohydrates, which is the focus of this review.

2 Fuels and chemicals

2.1 Fuels

Transportation constitutes approximately 27% of the total GHG emissions in the world, thus representing one of the largest opportunities to displace fossil fuels (Sources of Greenhouse Gas Emissions, 2020). The current transportation sector is based on spark-ignition engines, which require high-octane fuels like gasoline, and compression-ignition engines, which require high-cetane fuels like diesel. Ethanol, with an octane number of 113, is attractive for replacing gasoline, while methyl esters, with a cetane number approximately 55, can replace diesel fuel. Ethanol is readily produced by fermenting carbohydrates, while methyl esters (familiarly known as biodiesel) are the product of transesterification of plant lipids and animal fats (Brown and Brown, 2014). The potential energy supply from carbohydrates is far in excess of the energy that could be produced from plant lipids and animal fats. Accordingly, much of the future supply of biofuels is premised on fermenting sugars from various kinds of carbohydrates into either ethanol for use in spark-ignition engines or lipids and terpenes for compression-ignition engines and jet engines.

Sugar and starch crops such as sugarcane and corn are the source of carbohydrates to produce so-called first-generation (1G) ethanol, which accounts for most of the growth in the biofuels industry to date. Today, essentially all gasoline in the United States of America (USA) is blended with 10% ethanol (EIA, 2016). Other countries of the world have also established policies to encourage production of biofuels. In 2008, the worldwide ethanol production was 66.77 billion liters (Gupta and Verma, 2015), which subsequently increased to 106.6 billion liters in 2022 with Brazil and USA contributing to over 80% of the total ethanol production (Renewable Fuels Association, 2023).

Ethanol has several advantages as transportation fuel. From an environmental perspective, ethanol is biodegradable and less toxic than gasoline. An analysis by the Renewable Fuels Association showed that ethanol blended with gasoline resulted in a cumulative CO2 savings of 1.212 billion metric tons to date (Unnasch et al., 2023). From a performance perspective, blends of ethanol and gasoline have octane ratings higher than gasoline (Anderson et al., 2012). Ethanol has disadvantages as a fuel that periodically raises concerns in the press. Consumers notice lower fuel economy (distance driven per volume of fuel) for ethanol–gasoline blends, especially as the blend ratio increases, arising from the lower volumetric energy density of ethanol than of gasoline. Although this is not an energy efficiency issue, it is an inconvenience, requiring more frequent refueling. Gasoline–ethanol blends can phase-separate when contaminated with water, which prevents their distribution in exiting gasoline pipelines (Furey and Perry, 1991; Whims, 2002; Wallner et al., 2009). However, these problems are relatively modest when compared to the challenges of transforming the large and diverse global resource of carbohydrates into fermentable sugars.

Sugarcane contains sucrose, a disaccharide, which both microorganisms and animals (such as humans) can metabolize. Starch is the carbohydrate in corn and other grains, a storage polysaccharide, which is readily hydrolyzed to monosaccharide glucose through the action of acids, enzymes, and microorganisms found in the digestive system of many animals. As many critics to biofuels point out, first-generation ethanol is produced from feedstocks that are an important part of the human food chain.

In response to concerns about worldwide food insecurity and indirect land use change, as well as on the potential for increased rural economic growth, biofuel policies around the world incentivize the use of non-food crops for the production of biofuels. Of special interest are plants classified as lignocellulosic biomass, such as wood, grasses, and crop residues. Lignocellulosic biomass, which are rich sources of the structural carbohydrates, cellulose and hemicellulose, include a wide range of waste and dedicated energy crops that are high yielding, abundant, and of relatively low cost. Like storage carbohydrates, structural carbohydrates can be hydrolyzed to fermentable sugars and metabolized, although only a relatively few organisms have evolved to directly utilize them as sources of energy and carbon. Further challenges include releasing polysaccharides from the lignocellulosic structure, hydrolyzing the polysaccharides to simple sugars, removing fermentation inhibitors from the substrate, and efficiently fermenting both hexoses (six-carbon sugars) and pentoses (five-carbon sugars) produced from the polysaccharides. Overcoming these technical challenges is not enough; the resulting process for the production of cellulosic ethanol must be carbon-efficient, cost-effective, and environmentally sustainable.

Structural carbohydrates can be converted into liquid fuels other than ethanol such as hydrocarbons for diesel and jet fuels or completely new fuel molecules such as 2,5-dimethylfuran (Chidambaram and Bell, 2010; Climent et al., 2014; Braun and Antonietti, 2017; Eagan et al., 2017). Microbial fermentation can transform biomass-derived sugars into a variety of biofuels such as ethanol, butanol, isobutanol, and acetone (Tao and Aden, 2009). Conventionally, butanol is produced commercially through ABE (acetone, butanol, and ethanol) fermentation of molasses using anaerobic bacteria. Clostridium acetobutylicum, genetically modified Saccharomyces cerevisiae, and Escherichia coli strains are the basis for producing butanol from sugars (Mohagheghi et al., 2002; Zhang et al., 2008). Genetically engineered E. coli can also convert sugars into structurally tailored fatty acids suitable for biodiesel production (Steen et al., 2010). Various recent reports show that engineered oleaginous yeasts with cost-efficient bioconversion processes and lipid extraction mechanisms can effectively convert simple sugars into drop-in transportation fuels (Kruger et al., 2018; Xu, P. et al., 2016).

Hydrocarbons can be produced from sugars (Davis et al., 2013; Climent et al., 2014). This area has deservedly received much attention, but their biological production often involves complex metabolic pathways. Instead of trying to adapt microorganisms to the production of conventional fuel molecules, many researchers advocate adapting fuel infrastructure to molecules that are more readily produced biologically (Shanks and Keeling, 2017).

2.2 Chemicals

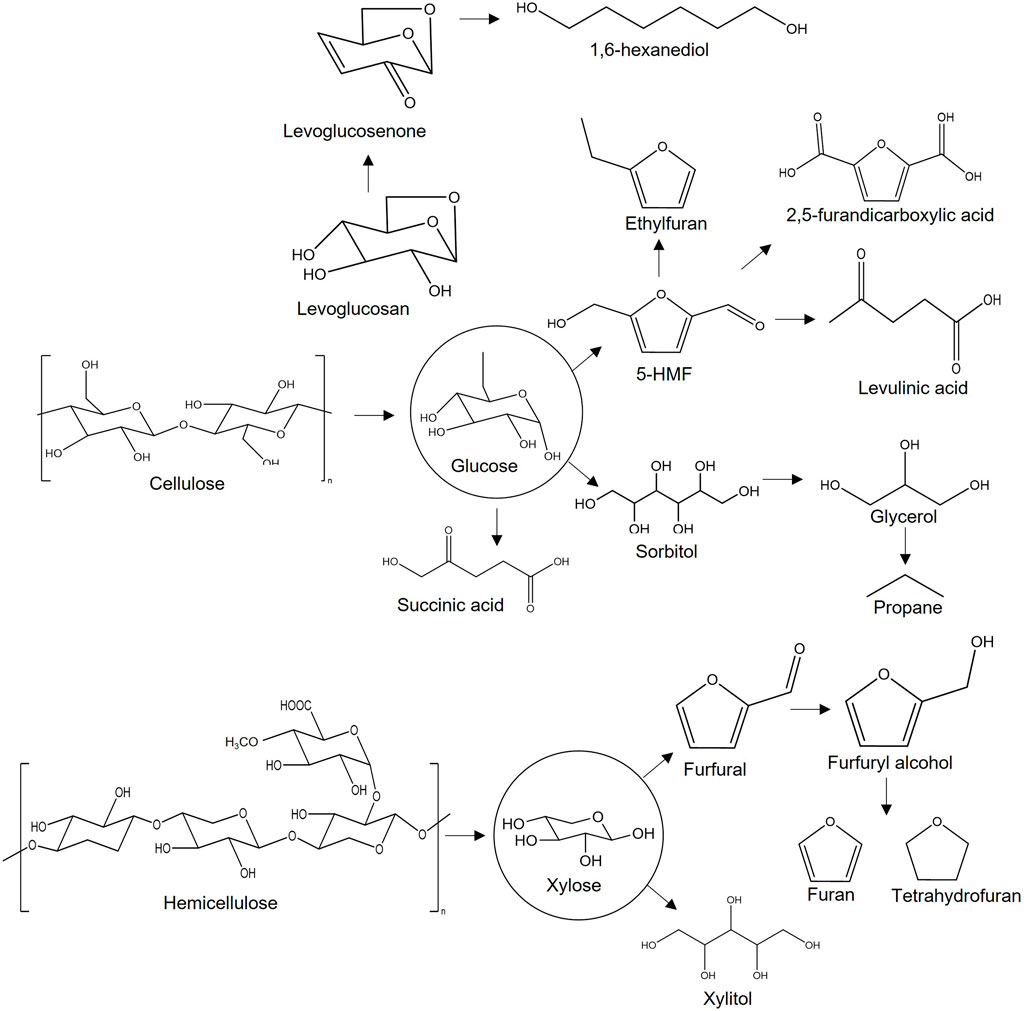

Sugars can be converted into bio-based products other than biofuels. Chemicals typically have higher price points than fuels, which allows small, specialized companies to compete with much larger producers. Lignocellulosic sugars can be used to manufacture commodity chemical suitable for the production of polymers, pharmaceuticals, reagents, and solvents (Mika et al., 2018). Researchers have demonstrated that sugars can be transformed into high-value chemical precursors that are not easily produced from petroleum. For instance, the chiral structure of levoglucosan, an anhydrosugar from thermal deconstruction of cellulose, is useful in creating unique molecules for the pharmaceutical and plastic industries (Itabaiana Junior et al., 2020). Production of levoglucosan and other carbohydrates from petroleum is very inefficient, involving many low-yielding synthesis steps. Recently, researchers have established highly selective levoglucosan production methods at a purity of up to 95% from completely renewable biomass sources in a small number of steps (Chen et al., 2016; Rover et al., 2019). Levoglucosenone, which is doubly dehydrated glucose, also has chiral characteristics that make it an attractive building block for pharmaceutical products (Comba et al., 2018). Levoglucosenone can be converted into 1,6-hexanediol, a nylon precursor, and dihydrolevoglucosenone (cyrene), a bio-based solvent that can replace many toxic polar aprotic solvents (Cao et al., 2015; Kudo et al., 2017).

Sugar-based furanic dehydration products also have the potential as chemical building blocks. One of the most interesting molecules is 5-hydroxymethylfurfural (5-HMF), typically produced by a triple dehydration of fructose or isomerization of glucose to fructose and subsequent dehydration. It can be used to produce a range of useful molecules such as furandicarboxylic acid, levulinic acid, and dimethylfuran via catalytic routes (van Putten et al., 2013). These products, among others, can be used as platform chemicals for making solvents, polymers, fuel additives, and plastics (Werpy et al., 2004; Dutta et al., 2012; Delidovich et al., 2016; Galbis et al., 2016). Similarly, furfural, a dehydrated furanic compound derived from xylose, can be transformed into commodity chemicals such as furan, tetrahydrofuran (THF), furfuryl alcohol, tetrahydrofurfuryl alcohol, maleic acid, and methyl furan, among others, all of which are highly useful as polymer precursors, industrial solvents, and fuels (Mariscal et al., 2016). Polyols such as glycerol, and propylene and ethylene glycol are precursor chemicals for manufacturing fuel alkanes or aromatic hydrocarbons. These polyols can be generated from sorbitol, the result of glucose hydrogenation (Kunkes et al., 2008). Simple sugars can also be readily fermented into carboxylic acids such as lactic acid and succinic acid, which have applications in the food, pharmaceutical, and adhesive industries (Luterbacher et al., 2014).

Carbohydrate-derived chemicals are attractive precursors for the manufacture of new kinds of fine and commodity chemicals due to their unique properties and, in some cases, reduced environmental impact. Figure 1 illustrates a selection of the many pathways from sugars to bio-based fuels and chemicals.

3 Sugars from lignocellulosic biomass

The two most abundant biopolymers in the world are cellulose (Heinze et al., 2018) and hemicellulose (Rao et al., 2023), usually occurring together as lignocellulose, a biocomposite of these two polysaccharides along with lignin. Lignocellulose evolved as recalcitrant structural material found in the roots, stems, leaves, and seed casings of terrestrial plants. Lignocellulose is water-insoluble and resists microbial and insect-based attacks. Although this recalcitrance is a key to plant survival, it becomes a significant hurdle in efforts to release fermentable sugars from the polysaccharides in lignocellulose (Himmel et al., 2007; Zhao et al., 2012; Lindstrom et al., 2019b).

This recalcitrance is chiefly responsible for the continued dominance of 1G ethanol production from grains, sugarcane, and sugar beets despite government policies around the world being intended to promote second-generation (2G) refineries (Bertrand et al., 2012). By contrast, converting starch to fermentable sugars using enzymes or heat does not pose a significant technical or economic challenge (Kelsall et al., 2003; Bertrand et al., 2012; Brown and Brown, 2014).

Monosaccharides and disaccharides from sugar and starch crops are edible carbohydrate, which has led to the so-called “food vs. fuel” debate (Wallington et al., 2012). The basic premise is simple: using crops to produce fuels reduces the world food supply causing scarcity, increase in prices, and even deforestation in the tropics (Wallington et al., 2012). This debate gained credibility in 2008 when the price of food spiked, at a time when biofuel production increased in the USA and the European Union (EU). The World Bank and others linked these two events, appearing to validate this concern. The World Bank’s report blamed biofuel production for increasing food prices, leading to riots and financial hardship in developing nations (Mitchell, 2008). As more data become available and the initial trends failed to hold, the World Bank reviewed the 2008 event 2 years later and changed their opinion on the cause of the spike in food prices. With more time and data, they determined that the commodity price boom was mostly the result of energy prices and financial investors—not due to biofuel production (Baffes and Haniotis, 2010). The nonpartisan Congressional Budget Office agreed (Congressional Budget Office, 2009). Hoping to end the debate, the Renewable Fuels Association commissioned an analysis in 2016 when crop prices were falling and biofuel production was at record levels. Despite finding no link between food prices and biofuels (Informa Economics, 2016), the reputation of 1G biofuels was damaged in the eyes of many environmental groups and parts of the public. In principle, cellulosic biofuels circumvent this concern although one might argue that depolymerizing cellulose into glucose has transformed a structural polysaccharide into food. At the heart of this debate is deciding what level of human intervention in the environment is acceptable to provide society with basic needs beyond food.

Beyond policy or society pressures, utilizing lignocellulosic biomass instead of food crops has the potential for higher efficiency. On a land area basis, corn produces less carbohydrate than many lignocellulosic crops. Crop yields matter to both farmers and biorefineries. Transporting crops over large distances is often very expensive due to their low volumetric density, so crop yields in the surrounding areas can influence the size of a planned biorefinery (Jacobson et al., 2014). The 2016 Billion-Ton Report details the untapped potential of lignocellulosic biomass (U.S. Department of Energy, 2016). Note that sugar comprises the majority of lignocellulosic biomass (Williams et al., 2016). The amount of sugar that can actually be extracted from structural carbohydrate depends upon the biochemical or thermochemical process employed, which is explored in detail in this review.

4 Policies

Over 60 countries have put in place policies to encourage adoption of biofuels (Lane, 2019). International associations of nations have also set out goals to reduce carbon emissions that impact biofuels adoption. This section summarizes some of the most impactful policies around the world.

4.1 The United States

Two major pieces of legislation influencing biofuels' adoption emerged in the USA at the turn of the 21st century. The US Energy Policy Act of 2005 established the Renewable Fuel Standard (RFS). The standard was subsequently replaced and expanded upon by the Energy Independence and Security Act of 2007. Soon afterward, California established the Low-Carbon Fuel Standard (LCFS). Although it only applies to fuel use in California, by virtue of its large economic impact on the United States, California’s LCFS has influenced other states to adopt similar fuel policies.

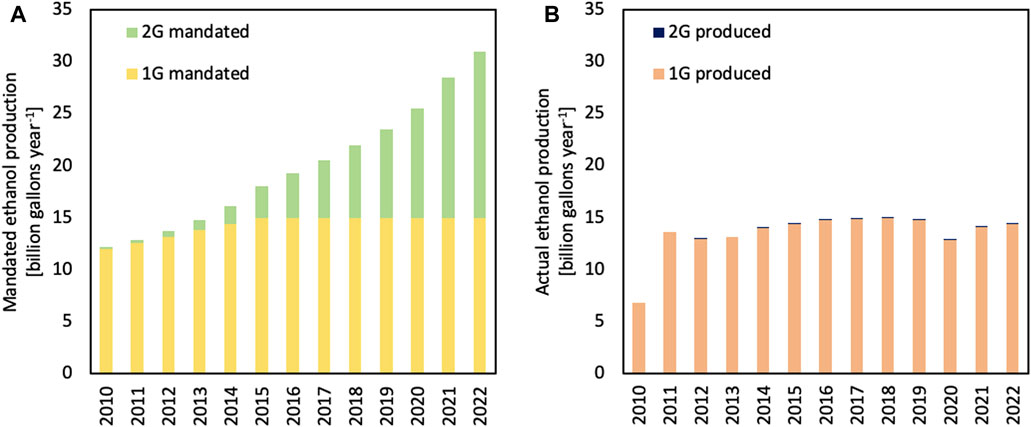

The updated RFS (RFS2) created a target of 36 billion gallons (136 billion liters) of renewable fuels in the USA by 2022 (Figure 2A) (Renewable Identification Number, 2023). Of this amount, approximately 15 gallons (57 billion liters) could be 1G ethanol, whereas the remaining 21 billion gallons (79 billion liters) was mandated to be other kinds of biofuels, such as 2G ethanol, also commonly known as cellulosic ethanol (Perlack et al., 2005). The RFS is enforced through the use of renewable volume obligations (RVOs), which requires fuel producers to blend renewable fuels or purchase renewable identification numbers (RINs) from a producer who has blended more than the obligated volume (McPhail et al., 2011). The original plan called for an aggressive expansion of cellulosic biofuel production, beginning in 2010 (Energy Independence and Security Act of 2007, 2007; Regulation of Fuels and Fuel Additives, 2011).

FIGURE 2. Biofuel mandates in the USA (A) have been met only for first-generation (1G) biofuels, while volumes of second-generation (2G) biofuels are less than 5% of the volumes envisioned by 2022. Actual ethanol production in the USA is shown in (B). Figures are based on Renewable Identification Number data, which excludes exported 1G ethanol, from the USA EPA.

As illustrated in Figure 2B, while 1G biofuels targets were met much faster than mandated, production of 2G biofuels is still less than 5% of mandated volumes. This failure would be even more glaring if the US Environmental Protection Agency (EPA) had not ruled that methane from the anaerobic digestion of organic wastes such as manure and wastewater solids, known as renewable natural gas (RNG), could be counted as 2G biofuels. The actual volumes of cellulosic ethanol are currently less than 15 million gallons (57 million liters) per year.

While some commercial-scale cellulosic ethanol plants were built in the USA, none remain operating today. This failure of the cellulosic fuel industry has several causes (Kramer, 2022). In part, the difficulties of deconstructing lignocellulosic biomass were not fully acknowledged, especially when scaling up technology identified in the laboratory. However, there were also market forces and policy failures at work. When the price of petroleum surged in 2008 to $146 per barrel, a 140% increase in 2 years, the future of advanced biofuels looked bright. However, the next year, the price dropped to $35 per barrel, destroying the market price of fuel ethanol along with the business model of the cellulosic ethanol industry. Finally, the volatility of RIN prices, often politically influenced, added to the risk of making long-term investments in new technology (Brown, 2019, 2018).

The (Clean Air Act of 1970) allows California to ask the EPA for a waiver to regulate transportation emissions more strictly than federal standards. This exemption was included because California established an air quality agency known as the California Air Resource Board (CARB) prior to the federal government’s standards. The unique climate and geography of California encouraged stricter emission standards than the Clean Air Act to reach air quality improvement. This waiver ultimately allowed California to explore innovations such as the LCFS to improve air quality in the state. The California LCFS works by assigning carbon intensity scores to every fuel based upon the life cycle analysis of GHGs using the California (CA) Greenhouse gases, Regulated Emissions, and Energy use in Transportation (GREET) model (California Air Resources Board, 2023). The total California fuel pool carbon intensity is set, and credits are earned for having lower scores and must be purchased for fuels that exceed the limit.

More recent policy developments include the Inflation Reduction Act of 2022, touted as the most significant of government commitments to low-carbon biofuels since the establishment of the Renewable Fuel Standard. This act includes the Higher Blend Infrastructure Incentive Program, which sets aside $500 million in government funding to expand infrastructure for biofuels production and distribution (Inflation Reduction Act of 2022, 2022). The act also extends the $1/gallon biomass-based diesel blender’s tax credit until 31 December 2024 and the $0.50/gallon alternative fuels tax credit through 2025 (Inflation Reduction Act of 2022, 2022). While expired at the end of 2021, the second-generation biofuel income tax credit was extended through 2024 (Inflation Reduction Act of 2022, 2022). Additionally, a new sustainable aviation fuel (SAF) credit was established (Inflation Reduction Act of 2022, 2022). A new Clean Fuel Production Credit will take effect in 2025 to incentivize fuels with low life-cycle greenhouse gas emissions (Inflation Reduction Act of 2022, 2022).

4.2 Brazil

Until 2006, Brazil was the largest ethanol producer worldwide (International Energy Statistics, 2017). Unlike the USA, which started its major biofuels program in 2005, Brazil launched the National Alcohol Program in 1975 in response to the 1973 oil crisis (Sewalk, 2014). This program was highly successful, leading to a rapid expansion of the Brazilian ethanol industry. Ethanol blending reached the target level of 20% in only a few years (Hira and de Oliveira, 2009). Today, standard gasoline blend in Brazil contains 27% ethanol with the option of using hydrous ethanol in specifically designed vehicles (Barros, 2018). With the passage of the Paris Agreement, Brazil introduced a new biofuels program called RenovaBio that took effect in 2020 (Barros, 2021). The new program was introduced to accelerate the transition to renewable fuels to meet the Brazilian carbon reduction commitment (Barros, 2018). Unlike the National Alcohol Program, the government does not guarantee a selling price for ethanol. RenovaBio will use tradable decarbonization credits to reach mandated carbon intensity reduction targets. Second-generation ethanol plants would utilize the vast quantities of bagasse from production of sugarcane ethanol, further reducing the carbon intensity of ethanol production in Brazil.

4.3 The European Union

The Renewable Energy Directive (RED) establishes the overall policies for renewable energy production and promotion within the EU. According to this directive, the EU had to supply at least 42.5% of its total energy requirements from renewable sources by 2030 (Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on energy efficiency and amending Regulation (EU) 2023/955 (recast), 2023). In this directive, biofuels have been identified as instrumental in meeting the goals for renewable transportation fuel production in Europe. Furthermore, the RED also set sustainability criteria for biofuel production and consumption. The major criteria require biofuel production to achieve at least a 50% reduction in GHG emissions for biofuel operations that started production before 5 October 2015 and a 60% reduction for those that started after the same date. The RED ensures that high biodiversity areas (e.g., wetlands and forests) are not used for biofuel feedstock production. This directive encourages the biofuels industry to use dedicated energy crops and agricultural residues as feedstock (Directive (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on energy efficiency and amending Regulation (EU) 2023/955 (recast), 2023).

4.4 China and India

The world’s two most populous nations are aggressively developing wind and solar energy but have less ambitious goals for biofuels. For this reason, their renewable transportation fuels policies are only briefly outlined.

In 2017, China established a goal of 10% ethanol in their gasoline transportation fuel supply by 2020. At that time, domestic biorefineries were producing approximately 1 billion gallons (3.8 billion liters) of ethanol annually (Li et al., 2017), a fifth of the amount required to blend with all gasoline (UPDATE 1-China’s Tianjin to use gasoline with ethanol in most vehicles, 2018). Few biorefineries have been proposed and even fewer approved to meet this demand through domestic production alone. Faced with these constraints, China has decided to suspend the program rather than purchase ethanol from the USA or Brazil to achieve its goal (Gu et al., 2020).

Under the National Policy on Biofuels established in 2008, India set an ambitious goal of blending 20% biofuels in gasoline and diesel by 2017 (Aradhey, 2017). India missed this target, managing to blend only 3.3% in 2016 (Aradhey, 2017). This low blend rate resulted from limited supply because domestic biofuels' production was restricted to non-food feedstocks (Aradhey, 2017). Currently, the main ethanol feedstock is waste sugarcane molasses; however, the policy intended for the production goals to be met with 2G ethanol (Aradhey, 2017). India has amended its National Biofuels Policy to target 20% blend by 2025 and to permit additional feedstocks for fuel production, which include food sources (Das and Rosmann, 2023). In 2022, the average national blend rate in India was 11.5%; however, it is still expected that India will struggle to meet its 20% blend target by 2025 (Das and Rosmann, 2023).

4.5 Association of Southeast Asian Nations

While currently heavily dependent on fossil fuel, the 10 developing countries in the Pacific known as the Association of Southeast Asian nations (ASEAN) are strategically capable to produce advanced biofuels from their abundant lignocellulosic feedstocks, particularly palm biomass residues. The first ASEAN country to sign the government policy to promote the biofuels industry was Thailand in 2000, targeting 1.9% biofuel contribution to the total energy consumption by 2011 (Bloyd, 2017). The current Alternative Energy Development Plan (AEDP) in Thailand set a guideline of 20%–25% renewables target from ethanol and biodiesel by the year 2036 (Bloyd, 2017). Indonesia’s National Energy Policy in 2006 targeted energy diversification that led to a subsequent Biofuel Program with blending mandates of B35 as of 2023 (Rahmanulloh, 2022). Indonesia is a significant producer of biofuels at 9.3 billion liters in the year 2022 (Biofuel production by country/region and fuel type, 2016–2022, 2022). The other member states with blending mandates of bioethanol and biodiesel are Malaysia, Thailand, Vietnam, and the Philippines (Chanthawong and Dhakal, 2016).

4.6 The Paris Agreement

In December 2015, the United Nations Framework Convention on Climate Change (UNFCCC) met in Paris where it reached a landmark consensus on fighting climate change, establishing accelerated actions and investments to encourage a low-carbon future (Savaresi, 2016). The central aim of the Paris Agreement was to strengthen efforts to keep the rise in global temperature below 2°C from pre-industrial levels with ambitions to further reduce this rise to only 1.5°C. As of 2023, every country recognized by the United Nations has signed the agreement, although not all countries have ratified it (United Nations Treaty Collection, 2023).

Furthermore, this agreement has set a goal of strengthening the ability of countries to deal with the impacts of climate change. To achieve these ambitious goals, it is becoming increasingly important to develop 2G ethanol.

5 Deconstruction methods

In this review, we discuss three major pathways for biomass deconstruction to produce precursor sugars for advanced biofuels production. Biochemical deconstruction employs enzymatic hydrolysis to break down plant polysaccharides into fermentable sugars. Thermal deconstruction, which uses thermal energy to convert lignocellulosic biomass into monosaccharides, includes fast pyrolysis and solvent liquefaction. Challenges to sugar production via the three described routes are separately described.

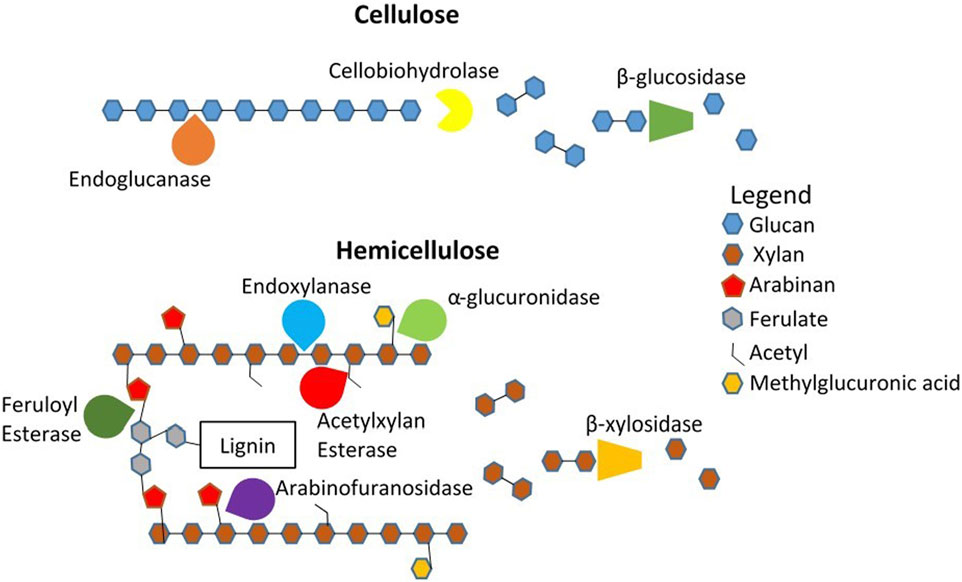

Enzymatic hydrolysis utilizes a system of enzymes known as cellulases to facilitate the multistep depolymerization of cellulose in the presence of water to produce monosaccharides (Brown and Brown, 2014). In this process, insoluble cellulose is first broken down at the interface of solid and liquid by the action of endoglucanase and cellobiohydrolase to produce cellodextrins and cellobiose (Yang et al., 2011). Cellodextrins are further hydrolyzed to cellobiose by these two enzymes, while cellobiose is subsequently hydrolyzed to glucose by β-glucosidase (Dien and Bothast, 2003). The enzyme system can also include hemicellulases to hydrolyze hemicellulose although this polysaccharide is often partially or fully solubilized during pretreatments intended to improve the accessibility of enzymes to the interior of the lignocellulosic structure (Dien and Bothast, 2003).

Fast pyrolysis is the rapid thermal deconstruction of biomass in the absence or near absence of oxygen and at temperatures in the range of 400°C–600°C to produce liquid, gas, and char (Polin et al., 2019; Polin et al., 2019; Venderbosch, 2019). The predominant carbohydrate products in bio-oil are anhydrosugars that include anhydrohexoses, anhydropentoses, and di-anhydrosugars, which are formed from thermal cracking rather the hydrolysis of glycosidic bonds (Patwardhan et al., 2011a; 2009). However, the presence of xylose among the products of pyrolysis suggests that sufficient moisture is present to support partial hydrolysis of hemicellulose. Importantly, these anhydrosugars and monosaccharides have vapor pressures high enough at pyrolysis temperatures to allow them to vaporize and escape the pyrolyzer along with other volatile products. Microorganisms have evolved in burnt environments that can metabolize anhydrosugars (Layton et al., 2011; Linger et al., 2016). Furthermore, anhydrosugars such as levoglucosan and cellobiosan can be acid hydrolyzed into glucose and cellobiose, respectively, which are readily fermented by S. cerevisiae. On the other hand, S. cerevisiae is unable to convert xylose (Jansen et al., 2017) although other kinds of wild-type yeast and genetically modified microorganisms can be employed for this purpose (Seike et al., 2019).

Solvent liquefaction uses a solvent to aid in thermal deconstruction of biomass, converting cellulose and hemicellulose into carbohydrates dissolved in the solvent. This process occurs at moderate temperatures and high pressures (105°C–350°C, up to 20 MPa), depending upon the solvent system and kind of biomass (Ghosh and Haverly, 2019). Solvent liquefaction is sometimes facilitated with a homogeneous catalyst. The carbohydrate products include anhydrosugars, mono- and oligosaccharides, or alkylated sugars, depending on the type of solvent system implemented.

6 Lignocellulosic feedstock logistics

6.1 Milling and comminution

The first step in producing sugars from lignocellulosic biomass is comminution (particle size reduction). Comminution increases the surface-area-to-volume ratio of the feedstock, reducing heat and mass transfer barriers to deconstruction. For example, the rates of conversion and yields of liquid products from pyrolysis and solvent liquefaction often require very small particles to overcome heat and mass transport limitations (Gaston et al., 2011). On the other hand, enzymatic hydrolysis is typically kinetically limited by slow enzyme reaction rates and can therefore accept larger particles as long as the structure has been opened up to make the biomass more accessible to the enzymes (Cullis et al., 2004).

The cost of comminution, which typically involves one or more milling operations, can be significant. Modest size reduction may only require energy input of 90 kWh ton−1, while reducing biomass to fine powder can consume 600 kWh ton−1 (Schell and Harwood, 1994; Oyedeji et al., 2020). The desired particle size dictates the kind of milling equipment employed and affects power demand for comminution. Himmel et al. (1985) found that energy requirement increases exponentially as the milled particle size decreases, with electricity costs increasing accordingly (Mayer-Laigle et al., 2018). Finer milling increases equipment wear, which is exacerbated if the feedstock contains abrasive ash (Tolan, 2002). Additionally, predicting the costs of milling is difficult because of the great variability in biomass composition and process requirements (Kenney et al., 2013; Man, 2022).

6.2 Solid handling

Solid biomass poses significant handling issues compared to liquid and gaseous feedstocks. Whereas pumps and compressors can efficiently and reliably move liquids and gases around a biorefinery, biomass has relatively poor and unpredictable flow properties resulting in handling and conveyance equipment that is sometimes unreliable and difficult to fully automate. The 1G ethanol industry could adopt technologies developed over several decades by the food industry to handle grains and seeds, which have flow properties vastly superior to fibrous biomass. The 2G ethanol industry is still developing feedstock logistics for chipped and baled biomass.

Many industries successfully handle friable solid materials like coal and minerals, which are readily crushed to desired sizes of roughly spherical particles with manageable flow properties. Lignocellulose, on the other hand, consists of flexible plant fibers that cannot be readily crushed into small particles. Instead, these fibers must be subjected to repeated cutting operations to achieve the desired size comminution. This milling process is energy intensive and produces elongated particles of roughly cylindrical shape (Ciesielski et al., 2015). These cylindrical particles readily cling together and cause the well-known phenomenon of bridging in vertical containers or packing in bends and even vertical runs of pipes (Mattsson, 1990; Stasiak et al., 2019). Material handling becomes much easier post-deconstruction once the majority of the biomass has been solubilized or converted to liquid.

7 Biochemical deconstruction

7.1 Enzymatic hydrolysis

Enzymatic hydrolysis requires several kinds of enzymes to break glycosidic bonds in cellulose and hemicellulose. These enzymes work by diffusing into the biomass, binding to the polysaccharides, and breaking glycosidic bonds at specific locations. Given the different enzyme mechanisms, this process ultimately requires a cocktail of enzymes to liberate monosaccharides from the polysaccharides.

Enzymatic depolymerization of cellulose requires a consortium of three classes of cellulases: endoglucanase, exoglucanase (specifically cellobiohydrolase), and β-glucosidase (Figure 3) (Selinger et al., 1996). Endoglucanase targets amorphous regions of cellulose fibrils, attacking mid-chain bonds to break the cellulose into shorter cellodextrin chains (Lambertz et al., 2014). This step creates new reducing and nonreducing ends upon which cellobiohydrolase liberates some glucose units but primarily breaks cellulose down into cellobiose or longer oligosaccharides (Lambertz et al., 2014). Finally, β-glucosidase catalyzes end-chain hydrolysis of glycosidic bonds, extracting glucose from cellobiose and cellodextrin (Lambertz et al., 2014).

FIGURE 3. Typical enzymatic activity in saccharification of cellulose and hemicellulose entails many enzymes acting on specific locations. Figure based on Selinger et al. (1996).

The mechanism by which enzymes break glycosidic bonds is complex and highly selective. This complexity results in the enzymes being extremely sensitive to environmental conditions and structural perturbations in the enzymes. Even minor changes in geometry (less than 2 Å) to the active sites of these enzymes can result in a major reduction in hydrolysis performance (Yan et al., 2011). The mechanism of breaking glycosidic bonds varies among different kinds of enzymes. The endoglucanase protein is formed with its active site located in a large cleft that allows it to bind to cellulose at midchain positions (Brás et al., 2011). Once bound to an exposed cellulose chain, amino acids at the active site bend the cellulose chain to change the conformation of the glucan unit, thereby priming the glycosidic bond for hydrolysis (Petersen et al., 2009). Hydrolysis is carried out by opposing acid and base moieties. In the case of endoglucanase isolated from Clostridium thermocellum, these moieties are composed of glutamic acid and aspartate (Petersen et al., 2009). The glutamic acid initiates hydrolysis by protonating the oxygen on one side of the bond (Petersen et al., 2009). The aspartate then coordinates a nucleophilic attack by water on the carbon at the other end of the bond deprotonating the water molecule in the process (Petersen et al., 2009). By utilizing many small steps, endoglucanase reduces the activation energy of hydrolysis to 36 kcal mol−1 (Petersen et al., 2009). Once the glycosidic bond is severed, the endoglucanase protein unbinds from the surface, and the process repeats. Endoglucanase alone is not useful in producing monomeric sugar. Brás et al. (2011) found endoglucanase had reduced activity on cellopentaose, producing only cellotriose and cellobiose with no activity on shorter chains, indicating endoglucanase is incapable of producing glucose (Brás et al., 2011). The production of monomers and dimers from cellulose therefore requires a different enzymatic mechanism.

The active site of cellobiohydrolase, for example, isolated from Trichoderma reesei, contains one aspartic acid and two glutamic acid moieties. Through a series of hydrogen bonding interactions between enzyme and polymer, the reducing end of the cellulose chain is extracted from the cellulose fiber bundle and drawn into the enzyme (Knott et al., 2014a). The geometry of the enzyme causes the cellulose chain to twist, straining the glycosidic bond in the proximity of the enzyme’s active site (Knott et al., 2014a). With the glycosidic bond primed, a concerted acid and base attack on opposing sides of the glycosidic bond is carried out by glutamic acid and its conjugate base glutamate breaking the glycosidic bond, liberating a cellobiose molecule from the end of the polymer chain (Knott et al., 2014b). This coordinated action reduces the activation energy for glycosidic bond fragmentation from 54.4 kcal mol−1 to only 15.5 kcal mol−1, allowing the reaction to proceed at appreciable rates at modest temperatures (Mayes and Broadbelt, 2012; Knott et al., 2014b). The cellobiohydrolase enzyme moves along the cellulose chain at 3.5 nm s−1, releasing additional cellobiose molecules as it proceeds (Igarashi et al., 2009). Cellobiohydrolase, like many enzymes, have high turnover number, defined as the maximum number of chemical conversions of substrate molecules per second that a single enzyme will execute for a given enzyme concentration. However, because cellobiohydrolase can only bond with the end of a long polymer chain (Cozier, 2015), the overall rate at which it can depolymerize cellulose decreases with the increasing degree of polymerization. Consider that cellulose polymers in corn stover, for example, contain on average 2,500 glucan monomer units (Hallac and Ragauskas, 2011), then enzymatic hydrolysis by cellobiohydrolase alone would be unacceptably slow for a commercial process.

While the combination of endoglucanase and cellobiohydrolase can consume cellulose, the resulting solution of cellobiose requires a final hydrolysis step to yield glucose. Unlike the other enzymes, which bind to solid cellulose, β-glucosidase’s activity occurs in solution, which changes its kinetic behavior (Andric et al., 2010). Most β-glucosidases utilize the same active site mechanism as cellobiohydrolase with a concerted acid and base attack (Cairns and Esen, 2010). The active site is similar to that of cellobiohydrolase, but the binding domain can be quite varied. Some enzymes mimic the tunnel structure of cellobiohydrolase or cleft of endoglucanase, while others simply contain a surface depression or crater referred to as a catalytic pocket (Sørensen et al., 2013). As with most catalysts, the stabilization of the transition state speeds up the reaction rates in both directions. Endoglucanase and cellobiohydrolase prevent the reverse reaction by only binding to the cellulose chains longer than four units or by processing down the cellulose chain, respectively. In the case of β-glucosidase, the products and reactants compete to bind at the active site. This competition greatly inhibits the rate and final concentration of glucose achieved by enzymatic hydrolysis. The inhibition can be very strong with β-glucosidase from Daldinia eschscholzii being inhibited at only 0.79 mM glucose (Karnchanatat et al., 2007), while β-glucosidase isolated from Aspergillus terreus is inhibited at 13.6 mM (Kitamura et al., 1991). Due to the abundance of β-glucosidases in nature, the search for enzymes that stay productive at high glucose concentrations is ongoing (Cairns and Esen, 2010).

7.2 Pretreatment

The structure of plant cell walls and the presence of hemicellulose and lignin impede the diffusion of cellulases to cellulose fibers. As a result, enzymatic hydrolysis of unmodified lignocellulosic biomass liberates little sugar even after days or weeks of treatment (Hatakka, 1983; Rohrbach and Luterbacher, 2021). The rate and yield of enzymatic hydrolysis can be greatly increased by removing lignin and hemicellulose, which is the goal of biomass pretreatments that are frequently employed prior to enzymatic hydrolysis. Cellulases can bind to cellulose at greater rates when the normal crystalline cellulose structure is broken up into amorphous regions where cellulose is more susceptible to attack (Ciesielski et al., 2019). Success in enzymatic hydrolysis of lignocellulosic biomass requires pretreatments that both increase accessibility of enzymes to polysaccharides and transform crystalline cellulose into amorphous cellulose.

Effective pretreatments can be characterized as physiochemical, altering both the physical structure and chemical composition of the biomass. A wide range of pretreatments have been developed, ranging from soaking biomass in hot compressed water (Ko et al., 2015) to irradiation with electron beams (Bak, 2014). One way to classify pretreatments is whether they primarily target lignin or hemicellulose for removal to improve the accessibility of cellulases to cellulose.

Lignin can be modified or removed from the lignocellulosic matrix by a variety of pretreatments (Talebnia et al., 2010). Because lignin forms a protective sheath around cellulose, its removal or displacement allows cellulase to diffuse more easily to cellulose fibers. Furthermore, removal of lignin prevents the non-productive binding of enzymes to the lignin surface, increasing the effectiveness of enzymes (Kim et al., 2016).

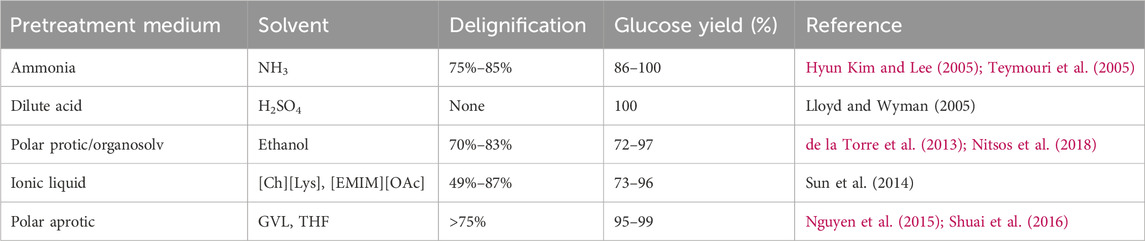

Other pretreatments target hemicellulose in biomass, often with the goal of hydrolyzing this polysaccharide to monosaccharides, mainly xylose, along with smaller amounts of other monosaccharides. Pretreatments that are focused on hydrolyzing hemicellulose employ dilute acid or processes that generate an acidic environment via deacetylation of hemicellulose (Talebnia et al., 2010). These treatments are effective in opening the cellulose fibers as hemicellulose crosslinks cellulose and lignin. During these pretreatments, lignin detaches and migrates to the biomass surface forming distinct droplets (Donohoe et al., 2008). This reduced the surface-area-to-volume ratio of these lignin droplets compared to unmodified lignin strands mitigates, although does not eliminate, non-productive binding to enzymes. This effect can be further mitigated through the addition of nonionic surfactants (Qi et al., 2010). Examples of common pretreatment methods and their efficacy in delignifying biomass and increasing polysaccharide digestibility are summarized in Table 1.

TABLE 1. Delignification and sugar recovery from enzymatic hydrolysis of lignocellulosic biomass for various pretreatment processes.

7.2.1 Ammonia

Ammonia infusion into biomass is a relatively low-cost pretreatment that is effective in removing lignin. The two most common ammonia-based pretreatments are ammonia recycle percolation (ARP) and ammonia fiber explosion (AFEX).

In ARP, ammonia interacts directly with lignin and solubilizes it. Hyun Kim and Lee (2005) reported 75%–85% removal of lignin along with 50%–60% removal of hemicellulose while retaining 92% of cellulose (Hyun Kim and Lee, 2005). This significant delignification not only opened up the structure of the biomass but also allowed the use of relatively low enzyme loadings since enzyme deactivation by lignin was substantially reduced (Hyun Kim and Lee, 2005).

AFEX exploits the fact that ammonia can be easily liquefied at moderate pressure, allowing it to readily diffuse into the biomass. When system pressure is subsequently reduced, the infused liquid ammonia instantly boils. The rapid expansion of the volatilized ammonia causes the biomass to explode, breaking the biomass into fibers. Furthermore, lignin tends to condense into droplets on the surface of the fibers and cellulose crystallinity is reduced (Mosier et al., 2005). The pretreated biomass is susceptible to enzymatic hydrolysis at modest enzyme loadings. Teymouri et al. (2005) demonstrated that ammonia pretreatment of corn stover for 5 minutes at 90°C yields almost 100% glucose and 80% xylose upon enzymatic hydrolysis. The advantage of using ammonia over other chemicals is that it is easily recovered and recycled (Kim et al., 2016). However, amide-containing by-products such as acetamide, phenolic amides, pyrazines, and imidazole are formed (Zhao et al., 2020).

7.2.2 Solvent-based pretreatments

Organic solvents are a well-known media for effective pretreatment of biomass. Solvent-based pretreatment typically implements either of the two types of solvents: polar protic or polar aprotic solvents. Each of these solvent-based pretreatment technologies is discussed below.

Biomass pretreatment using primarily polar protic solvents such as primary alcohols and formic acid is a well-established technology known as the organosolv process. Originally developed for the paper pulping industry to generate clean cellulose (Johansson et al., 1987), it was adopted as a pretreatment technique for enzymatic hydrolysis (Nitsos et al., 2018). In the organosolv process, ethanol is commonly used to solubilize the lignin and remove it from the biomass at moderate temperatures (Zhao et al., 2009). The use of ethanol as a solvent can make the pretreatment process more sustainable and more cost-effective (Silveira et al., 2015). Although not a protic solvent, acetone is also used widely for the organosolv process (Huijgen et al., 2010). An acid catalyst is often added to break apart the hemicellulose and liberate the lignin (Zhao et al., 2009). The organic solvent can be diluted with water causing the relatively unmodified lignin to precipitate from the solution, thereby facilitating its recovery (Nitsos et al., 2018). Because ethanol, methanol, and acetone can be obtained from biomass conversion technologies, these are considered green solvents. The organosolv process has the added benefit of producing a relatively pure lignin as a by-product (Sun et al., 2016).

The high rates of lignin removal make the organosolv process an attractive pretreatment for woody biomass, which is more resistance to enzymatic hydrolysis due to its high lignin content (Zhao et al., 2009). de la Torre et al. (2013) reached 87% lignin removal from wheat straw after 30 min using ethanol as the solvent. Nitsos et al. (2018) could achieve cellulose conversion yields of 72%–97% from softwood biomass. However, due to the high temperatures used, much of the hemicellulose and some of the cellulose are converted into biological inhibitors (Nitsos et al., 2018). Similar to ammonia pretreatment, organic solvents can be recovered and recycled.

Enzymatic hydrolysis of biomass polysaccharides can be significantly enhanced through thermochemical pretreatment with polar aprotic solvents. This type of pretreatment uses mild acid-catalyzed reaction conditions and water as the co-solvent for promoting solubilization and hydrolysis of hemicellulose, recovering xylose as a water-soluble product. Lignin is highly soluble in most polar aprotic solvents (Sameni et al., 2016). As a result, biomass so pretreated is rendered into a largely delignified, cellulose-rich feedstock (Nguyen et al., 2015). These compositional changes contribute to the opening of the polymeric matrix of biomass, and thus the biomass becomes substantially more susceptible to enzymatic hydrolysis (Nguyen et al., 2015; Shuai et al., 2016).

Nguyen et al. (2015) have demonstrated enhanced production of glucose, xylose, and arabinose from enzymatic hydrolysis of corn stover after pretreatment in a mixture of THF and water at 150°C with sulfuric acid serving as a catalyst. Significantly, the overall sugar yields as a result of this pretreatment reached approximately 95% even at the lowest enzyme loading of 2 mg g−1 (glucan basis) after 14 days, whereas the yield from corn stover that had been pretreated with dilute acid, a commercial benchmark for cellulosic ethanol production, was only approximately 70% under the same enzymatic hydrolysis conditions. The high sugar recovery at such a low enzyme loading was probably the result of substantial lignin removal, a conclusion supported by compositional analysis, fractal kinetic modeling, and scanning electron microscopy images (Nguyen et al., 2015).

Shuai et al. (2016) describe a mild pretreatment using biomass-derived polar aprotic solvent, γ-valerolactone (GVL), for the production of concentrated sugar solutions from hardwood biomass. This process, using 80% GVL and 20% water as co-solvents with 75 mM sulfuric acid at 120°C, could achieve 80% delignification while retaining 96%–99% of the original cellulose in the pretreated biomass. The pretreated substrate upon enzymatic hydrolysis yielded 99% and 100% of the total glucose and xylose, respectively, which was recovered at 99.5% using a liquid carbon dioxide extraction method. This GVL pretreatment process attains a threefold higher enzyme digestibility than other organic solvents, such as THF and ethanol, and 20-fold higher than pure water as the solvent.

Alkaline pretreatment uses a base, such as sodium hydroxide, to cleave lignin–carbohydrate linkages. It also solubilizes hemicellulose by saponifying ester bonds in acetyl and uronic acid moieties (Whistler, 1993). Alkaline treatments have been used for many years by the pulp and paper industry to extract lignin from wood while leaving the cellulose fibers nearly unaltered. A strong base will partially solubilize lignin in addition to hemicellulose. Weaker bases, such as calcium hydroxide, are less effective, resulting in lower lignin removal rates (Kim et al., 2016). Using sodium hydroxide at 160°C, Karp et al. (2015) could achieve 80% cellulose and xylan conversion from switchgrass. They could remove up to 70% of the lignin while retaining most of the polysaccharides, even when low concentrations of sodium hydroxide were used (Karp et al., 2015). Since alkaline pretreatment does not break glycosidic bonds in hemicellulose, enzymatic hydrolysis must include xylanases as well as cellulases to recover pentose sugars (Chen et al., 2013).

Dilute acid pretreatments generally use mineral acids, often sulfuric acid due to its low cost. The goal is to preferentially hydrolyze hemicellulose, which is more accessible to acid molecules than the tightly bundled microfibrils of cellulose (de Oliveira Santos et al., 2018). This method has the advantage of selectively removing xylose while making the cellulose fibers more accessible to cellulase during subsequent enzymatic hydrolysis (Taherzadeh and Karimi, 2007). Hsu et al. (2010) converted 89% of the hemicellulose in rice straw to xylose after dilute acid pretreatment with sulfuric acid at 160°C and 180°C, eliminating hemicellulases from the enzyme cocktail employed for subsequent enzymatic hydrolysis. Lloyd and Wyman (2005) reported cellulose conversion of near 100% after enzymatic hydrolysis of dilute acid–pretreated corn stover with a 5-minute pretreatment at 180°C and pH of 1.25.

Dilute acid pretreatments can have the unintended consequence of converting some of the released sugars into fermentation inhibitors, such as furfural and hydroxymethylfurfural (Rasmussen et al., 2014). Additionally, enzymes can bind to residual lignin, increasing enzyme loadings for effective hydrolysis of cellulose. While non-productive binding of enzymes to lignin can occur with all kinds of treatments, it can be particularly problematic with dilute acid pretreatments, with the extent depending upon the severity of the dilute acid pretreatment (Kellock et al., 2019). Despite this prominent disadvantage, the relatively low cost of dilute acid pretreatment has made it the standard pretreatment for enhancing enzymatic hydrolysis (Humbird et al., 2011).

Using only hot water, it is possible to liberate acetyl groups from hemicellulose, which further react with water to form acetic acid. This produced acid can hydrolyze hemicellulose in a manner similar to dilute acid pretreatment, which is described as autohydrolysis. Because autohydrolysis depends upon the presence of acetyl groups in biomass, this simple and inexpensive pretreatment is restricted to biomass with high acetyl content such as hardwoods (Singh et al., 2015).

By pretreating hardwoods with hot compressed water, Ko et al. (2015) could achieve cellulose conversion yields of 70%, although this required high enzyme loadings. Unfortunately, lignin in the pretreated biomass bound and deactivated the enzymes, with the result that low enzyme loadings were ineffective in converting cellulose to sugars (Ko et al., 2015).

If the hot, liquid water in the biomass is rapidly depressurized, the resulting steam explosion will, like AFEX, shatter the biomass into fibers (Taherzadeh and Karimi, 2007). However, steam explosion, unlike AFEX, promotes conversion of acetyl groups into acetic acid. As in autohydrolysis, the acid hydrolyzes hemicellulose, further opening the structure of the biomass to enzymatic hydrolysis. Unfortunately, the elevated temperature promotes degradation of the sugars into enzyme inhibitors.

Ionic liquids (ILs) have drawn increasing attention as a pretreatment for enzymatic saccharification due to their high polysaccharide solubilization capability (van Osch et al., 2017) and tunable physiochemical properties (Hayes et al., 2015; van Osch et al., 2017). Ionic liquids consist of an organic cation and an inorganic or organic anion that promote disruption of cellulose crystallinity and, therefore, significantly increase sugar yields during enzymatic hydrolysis, even at temperatures below 100°C (Zhao et al., 2010; Tadesse and Luque, 2011).

In a typical pretreatment, cellulose is substantially dissolved in IL followed by the addition of an anti-solvent such as water to precipitate the cellulose, which can be enzymatically hydrolyzed in the absence of hemicellulose and lignin (Zhao et al., 2010). During IL pretreatment, a part of the hemicellulose and lignin are depolymerized and dissolved, which can end up in the regenerated biomass (Arora et al., 2010). Most ILs are inhibitory toward enzymatic activity, so their thorough removal is required prior to enzymatic hydrolysis.

Ionic liquid pretreatment can significantly delignify biomass (greater than 80% removal) (Sun et al., 2014; Verdía et al., 2014), which increases accessibility of enzymes to cellulose in pretreated biomass. Additionally, this ability is tunable. For example, imidazolium acetate-based ILs have greater delignification efficiency (86%) and can produce up to 96% of glucose yields by enzymatic hydrolysis post-treatment (Sun et al., 2014).

7.3 Systems for converting lignocellulosic biomass into fermentation products

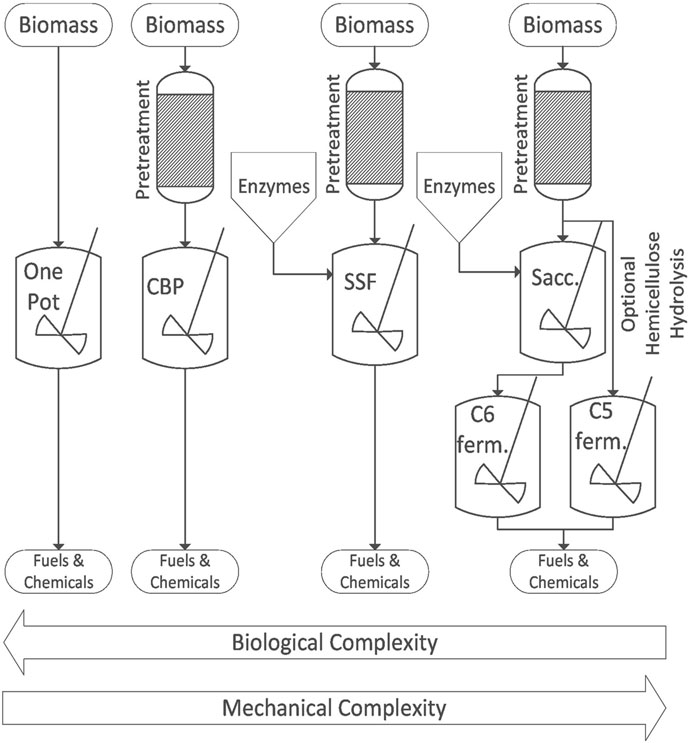

Like most biochemical processes, enzymatic hydrolysis and fermentation exhibit product inhibition, which complicates the design of biochemical systems to produce bio-based products. For example, cellobiose inhibits the activity of endoglucanase and cellobiohydrolase and glucose inhibits β-glucosidase (Dien and Bothast, 2003; Grata, 2020). The desire for both high reaction rates and high product yields has resulted in several distinct approaches to designing bioprocesses that incorporate enzymatic hydrolysis: separate hydrolysis and fermentation (SHF), simultaneous saccharification and fermentation (SSF), consolidated bioprocessing (CBP), and one-pot bioprocessing. These designs grapple with the trade-off between systems of complex mechanical design and those involving complex bioconversions (Figure 4). Those involving complex mechanical design consist of many unit operations that come at high capital costs and require sophisticated control systems. Conversely, systems involving complex bioconversions are potentially less expensive to build and easier to operate but require long and costly investment in research and development ahead of commercialization.

FIGURE 4. The biological and mechanical complexity of biochemical deconstruction processes are inversely correlated.

7.3.1 Separate hydrolysis and fermentation

This approach separates pretreatment, enzyme production, hydrolysis, and fermentation into separate unit operations. Biomass is pretreated to solubilize hemicellulose and improve subsequent cellulose hydrolysis. The solubilized hemicellulose can be separated from the cellulose/lignin pulp for separate saccharification and fermentation or processed together. Sufficient water is added to the cellulose–lignin pulp to form a pumpable slurry, which is transferred into a saccharification tank along with enzymes that are either purchased or produced in a separate enzyme production facility (Humbird et al., 2011). After hydrolysis is complete, the resulting sugar solution(s) are pumped into fermentation tank(s) where appropriate yeasts or bacteria are introduced to metabolize the sugars to desired products. If the sugars from cellulose and hemicellulose are separately fermented, the processes can be optimized but at the cost of mechanical complexity (Brethauer and Studer, 2015).

7.3.2 Simultaneous saccharification and fermentation

Mechanical complexity can be significantly decreased by combining saccharification and fermentation in the same reactor. Pretreated biomass is combined with both enzymes and fermentation microorganisms to simultaneously produce and consume sugars (Brethauer and Studer, 2015). Not only does SSF simplify the process but the suppression of sugar concentration in the reactor also mitigates enzyme inhibition (Wright et al., 1988).

In typical SSF processes, the biomass, enzymes, and yeast are mixed together at the beginning of the process. Adding these components incrementally allows for a more consistent sugar level, the process that is known as fed-batch SSF. Fed-batch SSF improves yeast activity and product yields by overcoming substrate inhibition and increasing solids loading, which exacerbates mass transfer limitations (Hemansi and Saini, 2023). Nguyen et al. (2017) achieved an ethanol yield of 90.5% from pretreated corn stover using fed-batch SSF at a solids loading of 20 wt%. Cellulosic emulsions have also been applied to SSF to increase mass transfer between enzymes and cellulose fibers (Hoffman et al., 2021).

Another challenge is the incompatibility of temperature and pH for hydrolysis and fermentation steps (Afedzi and Parakulsuksatid, 2023). Attempting to optimize temperature for saccharification and fermentation processes has proven to show lower fermentation yields (Sarkar et al., 2012). Thermotolerant bacteria and yeasts are being explored for their ability to withstand the optimal temperatures of both fermentation and hydrolysis (Choudhary et al., 2016; de Barros et al., 2017; Wu et al., 2021; Ndubuisi et al., 2023; Panda and Maiti, 2024). A co-culture of high temperature-resistant Saccharomyces cerevisiae and xylose-utilizing S. cerevisiae could convert corn stover to 59.8 g L−1 ethanol at 42°C (Zhu et al., 2020). A new approach shows cyclic temperature shifting with a thermotolerant yeast species to improve ethanol production from rice straw by up to 5.1-fold (Panda and Maiti, 2024).

Although mechanically simpler than SHF, SSF still requires purchase or separate manufacturing of enzymes. The capital and operating costs of SSF can be reduced if enzymes are produced on-site while also reducing the overall environmental impact (Nogueira et al., 2022).

7.3.3 Consolidated bioprocessing

The goal of CBP is to accomplish enzyme production, enzymatic hydrolysis, and fermentation using a single microorganism. The fact that this microorganism must produce a variety of enzymes and metabolize both pentose and hexose sugars into the desired product makes it the most complex bioconversion proposed for processing lignocellulosic biomass (Brethauer and Studer, 2015). The consolidation of these operations into a single reactor greatly reduces the capital and operating costs of a biorefinery (Dempfle et al., 2021). The difficulty of CBP lies in developing a microorganism with the desired metabolic pathways that is sufficiently robust to survive and produce high titers of the desired products under potentially harsh operating conditions (Lynd et al., 2016). Thus, thermophilic microorganisms have historically been the preferred microorganisms for CBP (Govil et al., 2022). The thermophile C. thermocellum converts pretreated empty fruit bunch from oil palm into glucose, acetic acid, and ethanol without the addition of external enzymes (Triwahyuni et al., 2022). Other naturally cellulolytic microorganisms have been explored, but they lack the ability to produce target compounds in desired quantities (Singh et al., 2018; Dutta and Suresh Kumar, 2023). Thus, research has pivoted toward either using a microbial consortium (Shahab et al., 2018) or genetic engineering non-cellulolytic microorganisms known to produce commercially relevant compounds (Yan and Fong, 2017; Banner et al., 2021). The non-conventional yeast Yarrowia lipolytica was genetically engineered to enhance cellulolytic function and achieved a 50% conversion rate of pretreated corn stover (Xu et al., 2018). Many studies emphasize the potential of yeast S. cerevisiae as a CBP candidate due to its heightened fermentation properties and ability to undergo genetic manipulation (Banner et al., 2021; Minnaar et al., 2024). Adding an enzyme cocktail of laccase, cellulase, and xylase to aid in lignin depolymerization enhanced ethanol production of S. cerevisiae (Rajak and Banerjee, 2020). Industrial scale implementation of CBP requires advanced research to identify robust microorganisms and widen the product range. Currently, no single microorganism has been identified nor engineered to enzymatically deconstruct lignocellulose, hydrolyze to sugars, and ferment to desired products (Minnaar et al., 2024).

7.3.4 One-pot integrated processing

A simple example of one-pot processing is the anaerobic digestion of mixed streams of lignocellulosic biomass and manure (Neshat et al., 2017). Raw feedstock without pretreatment is added into a reactor where enzymes released from a consortium of bacteria and fungi hydrolyze polysaccharides, fats, and proteins into simple sugars, fatty acids, and amino acids, respectively. Acetogens convert these intermediate products into carboxylic acids, which are subsequently converted by methanogens into methane, all within the same reactor. Even the separation of gaseous products from the reactants and solid products occurs in the same reactor. It might be argued that nature perfected this one-pot integrated process, but it is a useful model for envisioning engineered systems developed along the same principle of all reactions occurring in a single vessel.

Attempting to mimic the natural bioreactor process used by bovine animals has led to the development of co-treatment. This process, developed by the BioEnergy Science Center at the Oak Ridge National Laboratory, does not employ chemical pretreatment. Instead, biomass is deconstructed by continual or periodic milling, during or after partial enzymatic digestion (Paye et al., 2016; Balch et al., 2017). The combination of enzymes and milling creates a synergistic effect that achieves sugar yields from switchgrass up to 88% (Balch et al., 2017). As co-treatment is a relatively new technology, further development is required to improve microorganism survivability and optimize the in situ milling process. Eliminating toxic chemicals and harsh processing conditions makes co-treatment with CBP a very promising approach to liberate sugars from biomass (Lynd et al., 2017).

The Joint BioEnergy Institute at the Sandia National Laboratories has recently developed another approach to a single-pot process, made possible through the discovery of biocompatible ionic liquids such as cholinium lysinate ([Ch][Lys]) that readily solubilize cellulose (Liszka et al., 2016; Xu, F. et al., 2016). Because these so-called “bionic liquids” are non-toxic to enzymes and microorganisms, the solubilized carbohydrate does not have to be recovered from the solvent to perform enzymatic hydrolysis and fermentation. Its current manifestation still requires separate addition of enzymes although the microorganisms developed for CBP, in principle, could be used in this one-pot integrated process to truly combine all the steps required to convert lignocellulosic biomass in a single reactor.

7.4 Industrial considerations

7.4.1 Enzyme cocktail

To assure fast and efficient conversion of polysaccharides in biomass to fermentable sugars, enzyme cocktails must be tailored to the specific biomass feedstock. In addition to cellulases, hemicellulases can be added if the substrate includes significant hemicellulose (Dien and Bothast, 2003). Due to the variety and quantity of enzymes that must be produced, enzyme cocktails are expensive and represent a large operating cost for sugar production.

7.4.2 Enzyme production and recycling

To reduce enzyme costs, on-site manufacture and recycling have been contemplated for commercial operations. Onsite enzyme production eliminates transportation costs and offers cost savings through integration with other processes in the plant (Humbird et al., 2011). Recycling has proven difficult to accomplish as processes used to concentrate the enzymes can also destroy them. One of the most promising methods recycles the solid residue from saccharification, which contains significant amounts of enzymes adsorbed onto the solid residue (Humbird et al., 2011).

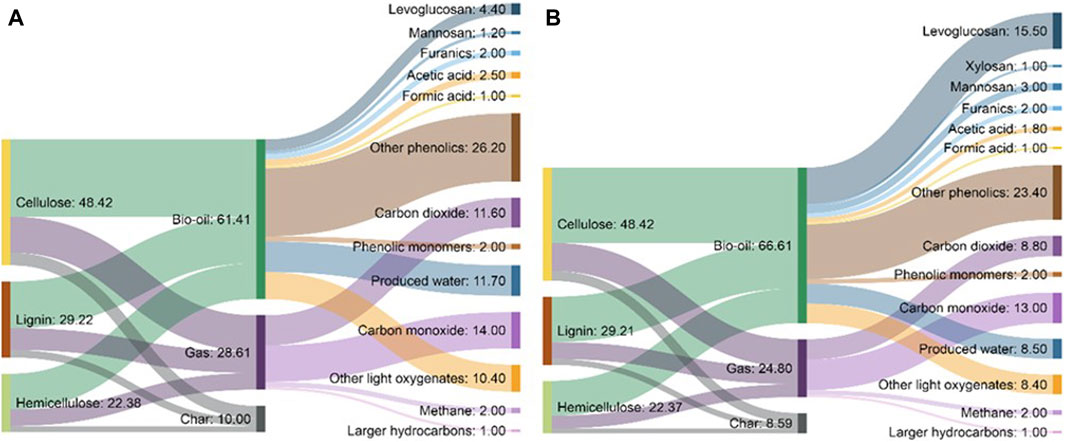

7.5 Process flow

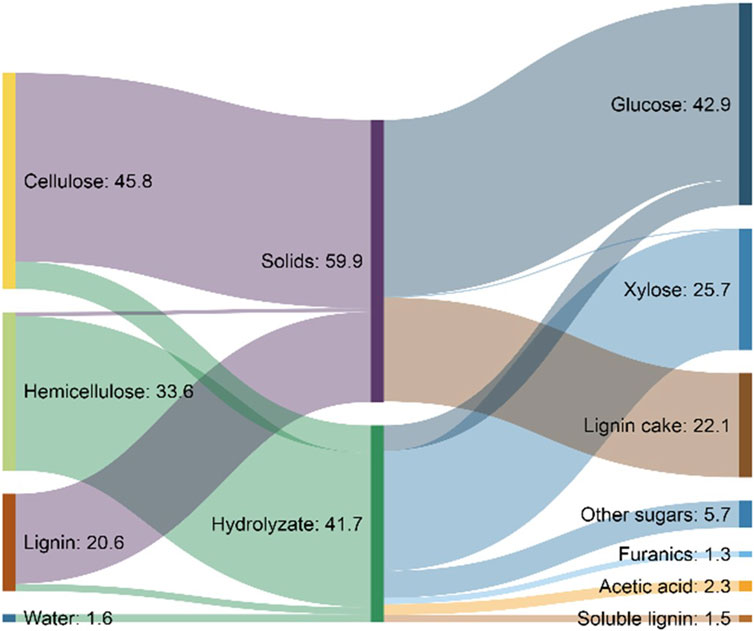

The flow of materials through a biorefinery based on dilute acid pretreatment and enzymatic hydrolysis is illustrated in Figure 5. The high selectivity of enzymes results in most of the carbohydrate being converted to monosaccharides, while lignin is essentially unconverted and removed as lignin cake. In practice, this lignin stream often contains substantial carbohydrates not effectively separated or saccharified in the process.

FIGURE 5. Theoretical mass flows in a 2,000-ton-per-day ethanol biorefinery using dilute acid pretreatment of corn stover as modeled by the National Renewable Energy Laboratory (NREL) (Humbird et al., 2011).

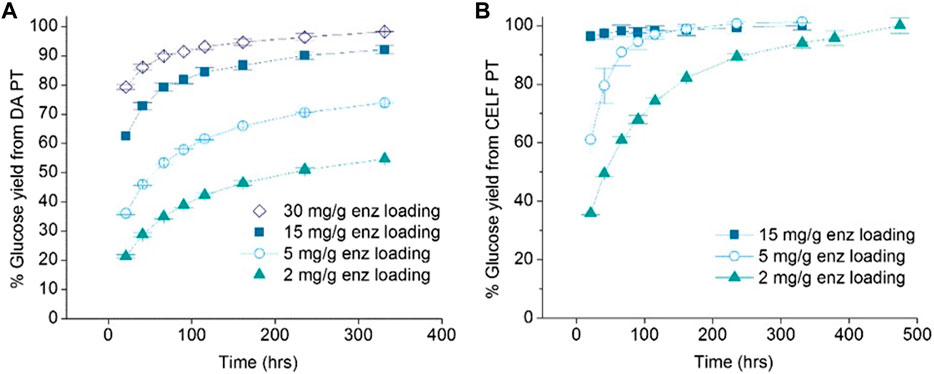

7.6 Challenges to sugars via enzymatic hydrolysis

Enzymatic hydrolysis is a highly selective process for deconstructing polysaccharides, achieving over 90% yields of glucose and xylose at low temperatures. Nevertheless, it is yet to become an economically viable technology. As evident from Figure 6, the mass loading of enzymes with respect to the carbohydrate substrate correlates positively with the increased rate of enzymatic hydrolysis. This trend holds for well-established dilute acid pretreatment (Figure 6A) as well as more recently developed organic solvent-based pretreatments (Figure 6B). Regardless of the pretreatment, enzymatic hydrolysis takes several hours to a few days to achieve sugar yields surpassing 70% (Nguyen et al., 2015).

FIGURE 6. Glucose release with reaction time for (A) dilute acid-pretreated corn stover using enzyme and (B) THF/water/acid-pretreated corn stover using enzyme. Reprinted with permission from Nguyen et al. (2015). DAPT, dilute acid pretreatment; CELF PT, so-called solvent-enhanced lignocellulosic fractionation pretreatment.

The catalytic activity of cellulases can suffer from product inhibition, a common phenomenon in bioconversion processes. The xylo-oligomers, furans, and phenolic compounds generated during pretreatment also negatively impact enzyme activity (Qing et al., 2010; Kim et al., 2011). Furthermore, biochemical processing requires substrate-specific enzymes, sterilization of reaction vessels and piping, and complicated separations to recover enzymes (Brown and Brown, 2014).

8 Thermochemical deconstruction

Thermochemical deconstruction of biomass includes fast pyrolysis and solvent liquefaction (Brown and Zhang, 2019). These processes were developed to deconstruct biomass into liquids known as bio-oil or biocrude. As traditionally produced, these liquids contain furans and other light oxygenates derived from polysaccharides but very little sugar. In recent years, biomass pretreatments and processing conditions have been identified that generate significant quantities of mono- and disaccharides (Ghosh and Haverly, 2019; Venderbosch, 2019). Although the yields are typically lower than that achieved through enzymatic hydrolysis, the processes are fast and simple and have the potential to produce inexpensive sugars from lignocellulosic biomass.

8.1 Fast pyrolysis

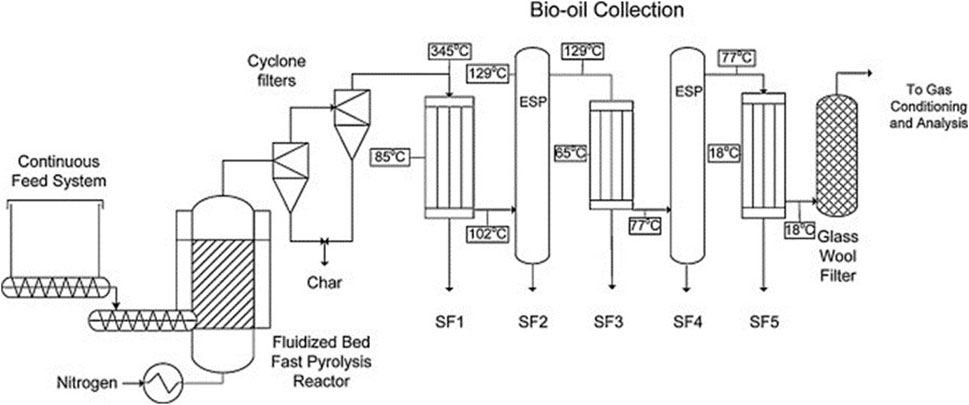

Fast pyrolysis is the thermal decomposition of organic matter in the absence of significant oxidation at moderate temperatures (400°C–600°C) producing primarily liquid products (bio-oil) as well as solid (biochar) and non-condensable gases (NCG) (Radlein and Quignard, 2013; Pecha et al., 2019; Venderbosch, 2019). As the name implies, the feedstock must be rapidly heated. Under ideal circumstances, fast pyrolysis of biomass can yield up to 75 wt% bio-oil, where 60 wt% is organic compounds with the balance comprising water (Bridgwater, 2012). Biochar and NCG can be combusted for process heat although there is increasing interest in using biochar for other applications such as for use as a soil amendment and carbon sequestration (Brewer et al., 2009; Woolf et al., 2010; Brown et al., 2015; Smith, 2016).

8.1.1 Bio-oil

Bio-oil is the liquid product from pyrolysis of biomass. Most of this liquid is condensed from vapors released during pyrolysis (Lindstrom et al., 2019b; Tiarks et al., 2019). Organic vapors must be rapidly removed from the pyrolyzer and cooled to prevent secondary decomposition reactions, reducing the yield of bio-oil such as in the decomposition of volatilized sugars (Shin et al., 2001; Evans and Nimlos, 2002; Zhang et al., 2012; Haverly et al., 2015). The liquid from pyrolysis of lignocellulosic biomass includes hundreds of compounds (Chaala et al., 2004; Patwardhan et al., 2011b; 2011a; 2009), which complicates its analysis and the separation of products (Carpenter et al., 2014). It is well known that phenolic compounds derived from lignin are chiefly responsible for the high viscosity (Bridgwater, 2003) of bio-oil, while phenolic compounds and carboxylic acids both contribute to its high corrosivity (Bridgwater, 2003; Keiser et al., 2014; Haverly et al., 2015). Less well known, bio-oil can also contain significant quantities of sugar, depending on how the biomass is prepared and processed.

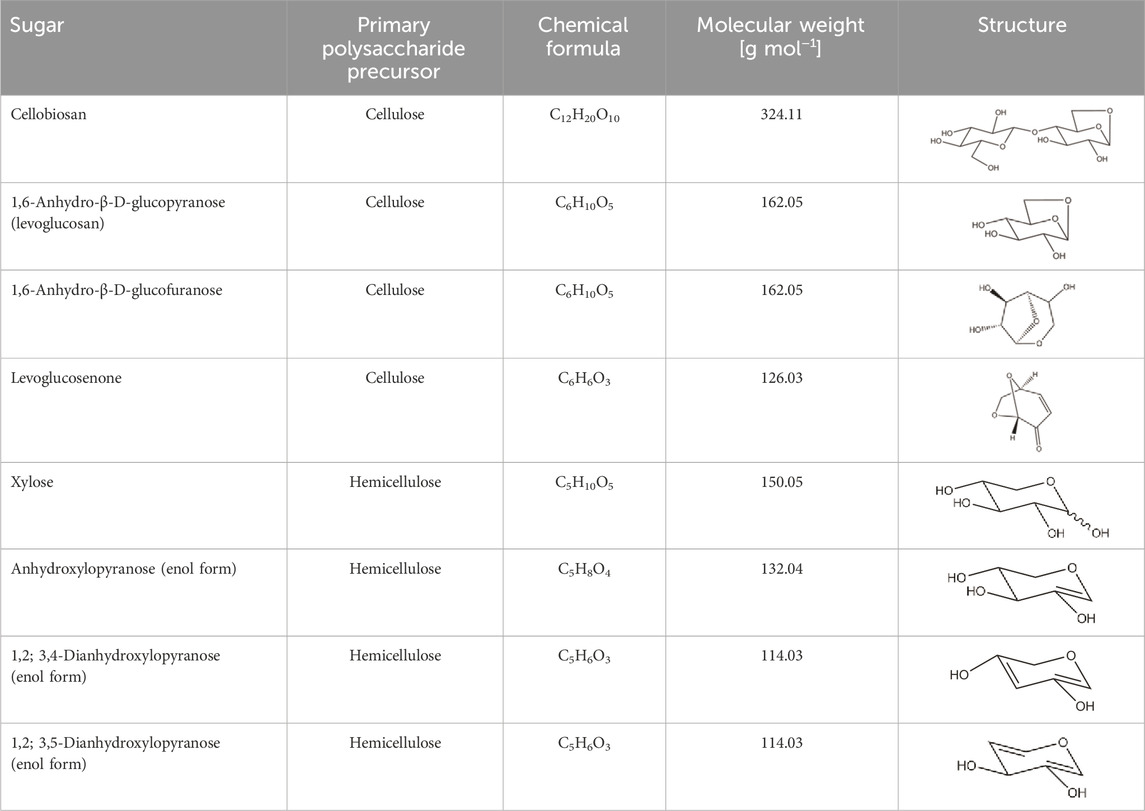

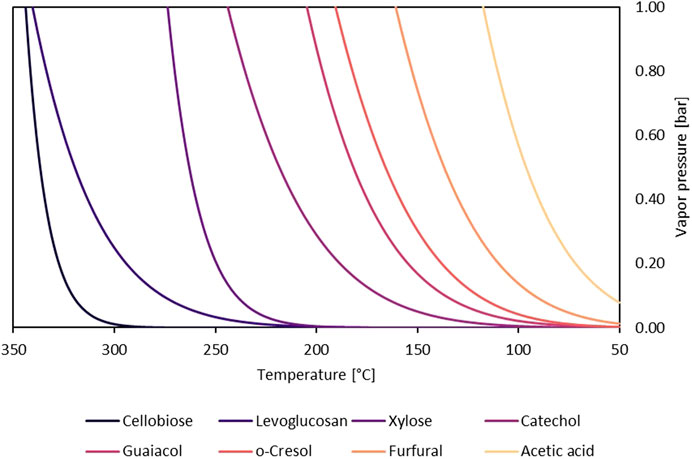

Most sugars have vanishingly small vapor pressures (Oja and Suuberg, 1999; Westerhof et al., 2011), and their discovery in bio-oil was somewhat surprising, encouraging the idea that thermal ejection was responsible for their presence. However, studies on sugars and anhydrosugars, a class of carbohydrates that lack one or more water molecules when compared to standard carbohydrates, which are found in bio-oil, revealed that they had significant vapor pressures at pyrolysis temperatures (Oja and Suuberg, 1999). Heating these carbohydrates as pure compounds revealed that they can be readily volatilized (Bai et al., 2013). Table 2 depicts the most common sugar products from biomass fast pyrolysis. Sugar yield depends upon the type of polysaccharide, reaction conditions, and whether secondary reactions that degrade sugars proceed to a significant extent.

TABLE 2. Major sugars products from biomass fast pyrolysis organized by descending molecular weight and the most likely polysaccharide precursor: cellulose (Patwardhan et al., 2009) or hemicellulose (Patwardhan et al., 2011a).

The yields of these sugars are also highly dependent on the presence of naturally occurring alkali and alkaline earth metals (AAEMs) in the biomass, which catalyze pyranose and furanose ring fragmentation in polysaccharides (Patwardhan et al., 2010; Kuzhiyil et al., 2012; Zhou et al., 2016). Secondary interactions with biochar, which contains AAEM, catalyze secondary reactions of levoglucosan decomposition and degrade pyrolytic vapors, leading to decreased sugar yields during pyrolysis (Plouffe et al., 2022). Biomass pretreatment to remove or passivate AAEM is therefore required to obtain high sugar yields from biomass.

8.1.2 Biomass pretreatment to enhance pyrolytic sugar production

During biomass pyrolysis, AAEM cations interact with polar moieties and functional groups in carbohydrates, leading to greatly reduced sugar yields compared to pure polysaccharides (Mayes et al., 2015). Sugar yields comparable to pure polysaccharides can be achieved for lignocellulose by either liquid extraction of soluble AAEMs or passivating the catalytic activity of AAEMs in situ prior to pyrolysis (Golova and Krylova, 1960; Kilzer and Broido, 1965; Broido, 1966; Patwardhan et al., 2010; Kuzhiyil et al., 2012; Bai et al., 2014; Dalluge et al., 2014; Wang et al., 2014; Oudenhoven et al., 2016a; 2016b). Regardless of the pretreatment method, AAEMs must be dealt with thoroughly as each metal atom is estimated to catalyze up to 1,000 fragmentations of pyranose or furanose rings (Zhou et al., 2016).

Both AAEM extraction and passivation improve sugar yields from fast pyrolysis of lignocellulosic biomass, but the application of these pretreatments differs substantially. Extraction involves using water to wash the AAEMs from the biomass. Inclusion of acids, such as carboxylic acid produced during pyrolysis, improves the extraction (Oudenhoven et al., 2016b). This technique increases sugar yields compared to no pretreatment (Oudenhoven et al., 2016b) but has significant drawbacks. Washing requires substantial water usage, which in turn is expensive to dry prior to pyrolysis and to treat prior to discharge (Oudenhoven et al., 2016b). For these economic reasons, this review focuses primarily on passivation.

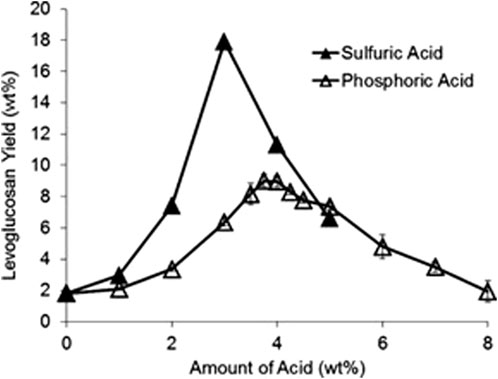

Passivation predominantly uses mineral acids to convert AAEM cations in biomass into thermally stable salts (Kuzhiyil et al., 2012). When using acids, AAEMs likely bind to the conjugate base, forming inorganic salts. For example, if sulfuric acid is used, the conjugate base would be sulfate or hydrogen sulfate (bisulfate), which bonds with AAEMs forming salts such as calcium sulfate and sodium hydrogen sulfate (Kuzhiyil et al., 2012). AAEMs are less catalytically active when bonded as thermally stable salts. Although the protons released into the biomass in this manner do not appear to catalyze pyranose and furanose ring fragmentation, excessive acid can diminish sugar yields. Accordingly, there appears to be an optimal acid pretreatment level to passivate AAEMs (Figure 7) (Kuzhiyil et al., 2012).

FIGURE 7. Levoglucosan yield from corn stover pyrolysis can be improved by judicious acid pretreatment reproduced from Kuzhiyil et al. (2012) with permission from Wiley Online Library.

Optimal infusion of mineral acid into lignocellulosic biomass can effectively passivate all catalytic activity of AAEMs, achieving sugar yields in (batch) micro-pyrolyzers equal to those from pyrolysis of pure polysaccharides, up to approximately 60 wt% (Patwardhan et al., 2010; Kuzhiyil et al., 2012; Wang et al., 2014). Enhancements from pretreating biomass are typically the greatest for biomass containing high AAEM content (Kuzhiyil et al., 2012; Dalluge et al., 2014). Continuous pyrolysis of pretreated biomass has also demonstrated enhanced sugar yields although to date they have only reached approximately 30 wt% monosaccharides on a polysaccharide basis (Kuzhiyil et al., 2012; Dalluge et al., 2014; Kim et al., 2014; David et al., 2018; 2017). Possible explanations for this discrepancy are subsequently discussed.

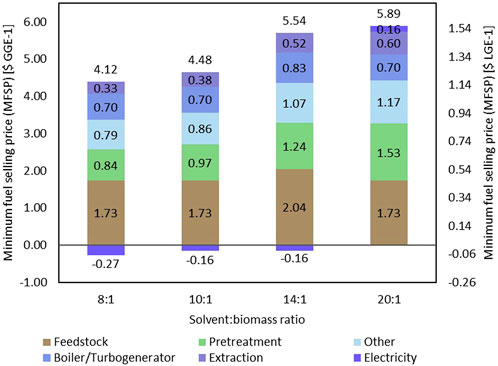

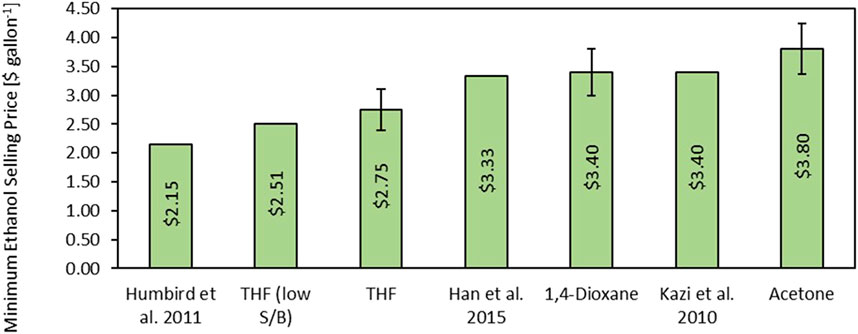

Kuzhiyil et al. (2012) developed a stoichiometric relationship between the AAEM content of biomass and amount of acid required for AAEM passivation. Polyprotic acids, such as sulfuric acid, can donate multiple protons, thereby generating more negative electric charges in the form of polyanionic conjugate bases, enhancing the AAEM passivation potential. Conversely, monoprotic acids, such as hydrochloric acid, can produce only monoanionic conjugate bases and are therefore less efficient on a molar basis. In addition to the number of protons available to donate, low acid dissociation constants (pKa) are very important. The conjugate base—not the proton—inhibits the AAEMs, so a stronger acid leads to more available conjugate base anions for a given amount of acid. In moderation, the proton itself appears unimportant and does not catalyze sugar destruction but is not wholly desirable because excessive acid addition produces lower sugar yields (Kuzhiyil et al., 2012). Theoretically, other chemicals could be used as long as they release appropriate anions and the corresponding cation does not catalytically degrade carbohydrates during pyrolysis. Additionally, these salts must be thermally stable. Kuzhiyil et al. (2012) claim that the greater thermal stability of potassium hydrogen sulfate compared to potassium dihydrogen phosphate explains the superior performance of sulfuric over phosphoric acid. This same explanation applies to carboxylic acids as they are not thermally stable and have higher dissociation constants and therefore yield less sugar (Kuzhiyil et al., 2012).