- 1School of Civil Engineering, Guilin University of Technology, Guilin, China

- 2Guangxi Key Laboratory of Green Building Materials and Construction Industrialization, Guilin University of Technology, Guilin, China

- 3China Water Resources Pearl River Planning, Surveying and Designing Co., Ltd., Guangzhou, Guangdong, China

- 4School of Mechanics and Civil Engineering, China University of Mining and Technology, Beijing, China

- 5Guilin Guolida Construction and Installation Engineering Co., Ltd., Guilin, China

Intelligent construction is a necessary way to improve the traditional construction method, and digital twin can be a crucial technology to promote intelligent construction. However, the construction field currently needs a unified method to build a standardized and universally applicable digital twin model, which is incredibly challenging in construction. Therefore, this paper proposes a general method to construct a digital twin construction process model based on the Industry Foundation Classes (IFC) standard, aiming to realize real-time monitoring, control, and visualization management of the construction site. The method constructs a digital twin fusion model from three levels: geometric model, resource model, and behavioral model by establishing an IFC semantic model of the construction process, storing the fusion model data and the construction site data into a database, and completing the dynamic interaction of the twin data in the database. At the same time, the digital twin platform is developed to realize the visualization and control of the construction site. Combined with practical cases and analysis, the implementation effect of the method is shown and verified. The results show that the method can adapt itself to different scenarios on the construction site, which is conducive to promoting application of the digital twin in the field of construction and provides a reference to the research of practicing digital twin theory and practice.

1 Introduction

In recent years, the convergence and development of a new generation of information technology and communication technology, such as the Internet of Things, big data, cloud computing, artificial intelligence, and so on, has pushed digital twin technology forward in a big way. It has become a powerful driving force for digital transformation and intelligent upgrading by providing functions to support new business models and decision support systems. Therefore, it is subject to more and more attention and exploration from all walks of life (VanDerHorn and Mahadevan, 2021).

Dr. Michael Grieves originally defined the digital twin concept as a three-dimensional digital twin model consisting of three parts: the physical product, the virtual product, and the connection between the two (Grieves and Vickers, 2017). In 2012, digital twin technology was first applied in aerospace and aviation (Glaessgen and Stargel, 2012) and has since been extended to various fields such as industry (Tao et al., 2018; Ogunsakin et al., 2023), manufacturing (Soori et al., 2023), construction (Opoku et al., 2021), etc., Academia and industry have become increasingly interested in digital twin technology and have gradually conducted in-depth research on its fundamental theories and key technologies. The construction of the digital twins’ framework and technology development are the keys to the research on the basic theory and technology of digital twin creation. The construction of the framework defines the concept and overall idea of digital twins from a macro perspective, and the development of the technology is to dig deeper into how to create digital twins with the value of grounded applications. Fundamental theories such as the five-dimension digital twin model, digital twin modeling methods (Zhang et al., 2022; Liu et al., 2022), digital twin framework research (Ascone and Vanderhaegen, 2022; Chiachío et al., 2022; Wang et al., 2024), digital twin applications, and future direction (Boje et al., 2020; Pregnolato et al., 2022) are dug deeper. At the same time, the critical technology of the digital twin has begun to realize the actual application on the ground. For example, the manufacturing industry builds digital twin for dealing with production anomalies or fault diagnosis (Lu et al., 2020; Xiao et al., 2023), logistics process planning (Glatt et al., 2021), complex task scheduling optimization (Wang et al., 2014; Jiang et al., 2022), and so on. There are already more mature digital twin technologies and corresponding products. However, compared to the manufacturing industry, the construction industry faces tremendous challenges in building digital twins due to its inherent architectural characteristics, resulting in most of the related research remaining in building the overall framework, for example, exploration of the complete life cycle digital twin framework and establishment methodology (Yoon, 2023), creating a digital twin platform reference architecture (Fei et al., 2024), information management for complex infrastructure systems (Jiang et al., 2023), future research directions for digital twin in construction (Boje et al., 2023) and so on. Therefore, methods to truly implement digital twins in the architectural domain must be studied deeply.

Several scholars have addressed the ground-up application of digital twins in the field of architecture. Feng Jiang et al. (Jiang et al., 2021) reviewed 134 papers in the field of digital twins and civil engineering and 27 papers related to digital twins, Building Information Modeling (BIM) and Cyber Physical Systems (CPS), analyzed the similarities and differences among the three, and proposed that constructing digital twins based on BIM and CPS can help to promote the digitization of civil engineering and enhance the level of intelligent construction; Calin Boje et al. (Boje et al., 2023) demonstrated the potential and necessity of combining BIM with digital twins by studying the use of BIM in architecture and analyzing the current need for building information to move from static, closed environments to Web-based environments; In addition, Calin Boje et al. (Boje et al., 2023) combine digital twins and BIM to create a framework for complete Life Cycle Sustainable Assessment (LCSA) of buildings; Jinghai Xu et al. (Xu et al., 2023) designed a digital twin conceptual model by combining Building Information Modeling (BIM) and real-scene 3D modeling for monitoring the structural health status of a building during the operation and maintenance phase. It can be seen that BIM can be used as an entry point for building digital twins in the construction field. With the massive application of 3D, 4D, 5D, and even nD BIM (Hu et al., 2008; Pan and Zhang, 2021) in the construction phase, the fragmented construction data is increasing exponentially, and there is an urgent need for a unified standard to integrate these distributed data and information to form an orderly closed-loop management process. BuildingSMART proposed IFC as a data standard for BIM information exchange, a widely recognized international standard for model data exchange and sharing, aiming to achieve interoperability between building information modeling software applications in the AEC/FM industry. By leveraging the potential of its semantic modeling at the intersection of IoT and AI, it provides strong support for building digital twin (Boje et al., 2020; Marmo et al., 2020; Zhu et al., 2023).

For example, Xiongwei Huang et al. (Huang et al., 2023) proposed a BIM and IoT data fusion framework to address the issues of massive data, technology diversity, data heterogeneity from multiple sources, and hierarchical abstraction. They studied four significant aspects: data extraction from BIM models based on the IFC standard, joint representation and analysis of the data, and application, respectively. Yue Pan et al. (Pan and Zhang, 2021) utilized the IFC schema for the integration of BIM, Internet of Things (IoT), and Data Mining (DM), developed a digital twin model framework containing physical models, virtual models, and connected data, and used a time-column prediction model to predict the trend of construction productivity. Haidar Hosamo et al. (Hosamo et al., 2023) used a BIM platform as the basis for integrating BIM, IoT, and Machine Learning (ML) technologies to build a digital twin framework for automated fault detection and prediction. Mehrzad Shahinmoghadam et al. (Shahinmoghadam et al., 2021) proposed a digital twin system consisting of a three-tier architecture of data acquisition, middleware, and application for real-time thermal comfort assessment of building envelopes by leveraging the synergistic strengths of BIM, IoT, and Virtual Reality (VR) in the development of immersive VR. Micheal Sakr et al. (Sakr and Sadhu, 2023) explored the integration of BIM and IoT in conjunction with the IFC model for structural health inspection of civil infrastructures to develop a digital twin at an early stage to present static and real-time dynamic data in a rich BIM database.

In summary, the creation of digital twins in the construction field is often inseparable from BIM technology, and at the same time, the IFC standard plays a vital role in it. However, as a whole, the construction methods for digital twin models have not been unified, and there is a lack of standard and common digital twin construction and application system, which makes it impossible to establish digital twin models that are adaptive to different construction scenarios. In order to bridge this gap, this paper proposes a digital twin model construction method for building construction process based on the IFC standard, which takes the BIM model as the entry point and utilizes the IFC standard’s unique interoperability among multiple BIM tools to build a semantic model of the construction process, including geometric model, resource model, and behavior model. JS language is used to parse the IFC files efficiently and store them in the database. At the same time, combined with database technology, twin data such as semantic model data and construction site data are unified into structured data and fused in the database. In addition, the web framework is used for back-end data processing, and the digital twin platform is used for model generation, data processing, and visualization analysis to assist decision-makers in making intelligent judgments. Through the development of IFC model data to database mapping, “model-data” fusion, and online visualization and analysis of information implementation methods, to improve the adaptability and versatility of building digital twin models, aiming to provide valuable reference solutions for the application of digital twin in the construction phase.

The rest of the paper is organized as follows. Section 2 analyzes the function of the digital twin model for the construction phase, lays down the goal of constructing digital twin model with service as the center, and gives the reason for choosing the IFC standard in this study by comparing the differences of model data standards. Section 3 describes the process of constructing digital twin model based on the IFC system and the interaction mechanism of twin data, based on which the digital twin platform is established. Section 4 applies the method to the actual building construction and verifies the feasibility of the method. Section 5 summarizes the work of this paper and discusses the future research direction.

2 Conceptual model of the digital twin

2.1 Analysis of model requirements

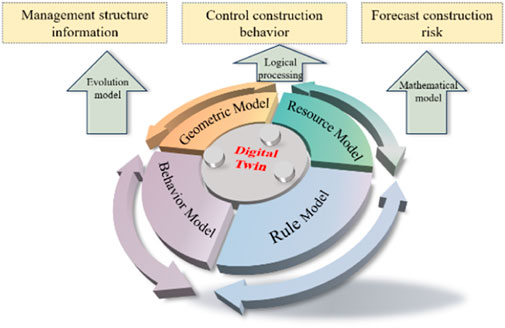

The building construction process is a high-incidence stage of information generation, integration, exchange, and updating activities (Gangolells et al., 2009; ELZomor and Parrish, 2016). As shown in Figure 1, in order to monitor and control the building construction process in real-time, its digital twin model needs to meet the following three requirements:

(1) The ability to manage structural information. Includes geometric parameters and physical properties of construction project building elements for the integrated management of component information such as beams, slabs, and columns, as well as dynamic and static mechanical analysis of structures under environmental influence.

(2) The ability to control construction behavior. The spatiotemporal evolution of construction behavior is analyzed based on the changes in the building site and environment as well as the effects of the internal operating mechanisms of construction: disturbances such as site layout, weather changes, or lack of resources at the construction site lead to different responses in construction behavior.

(3) The ability to predict construction status. Based on the knowledge base and rule base information, such as construction schedule, building information modeling construction application standards, etc., along with monitoring information from IoT devices such as laser scanners, sensors, drones, etc., it analyzes and predicts the work status of the construction site by responding to changes in the physical entities in real-time, and further provides optimized scheduling solutions.

In construction, information and data are the key elements for constructing a digital twin model. BIM provides a digital representation of the physical and functional characteristics of a building’s physical entity model and is able to describe and integrate the management of the building construction process and organization (Volkov et al., 2016; Wen et al., 2021; Xie et al., 2022), so the first requirement can be achieved by using BIM as an entry point for constructing a digital twin model of the building construction process. However, in the process of engineering construction, due to different construction stages, different participants, and different design specialties, the BIM model needs to be established by different types of software, which often leads to cumbersome data interaction operations within the BIM model, missing information, etc. (Zhang et al., 2022; Gartoumi et al., 2023; Zhang et al., 2023); in addition, the construction site data obtained by adopting IoT devices needs to interact with the BIM model data, which in turn can describe and portray construction site behavioral state. Therefore, the selection of model data exchange standards and the study of a common method of interaction between BIM model data and construction site data are the focus of realizing the second and third requirements and are also the keys to establishing the digital twin model in this study.

2.2 Selection of model data interaction standard

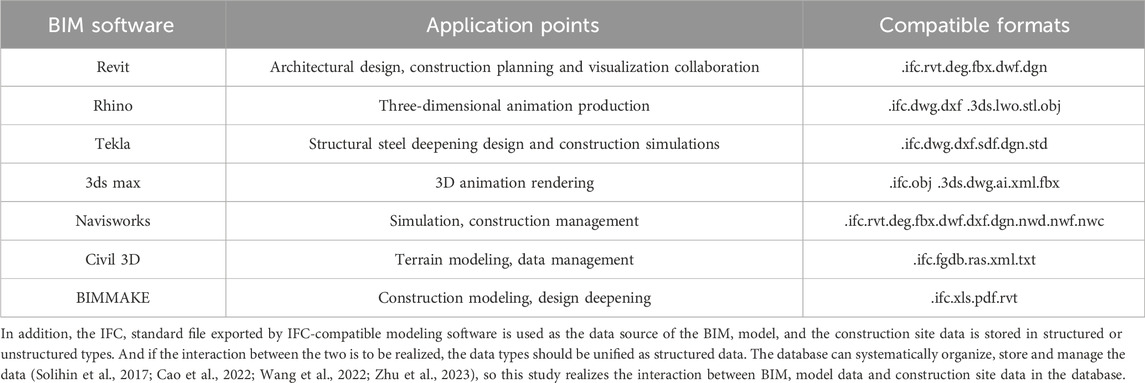

In recent years, the market for different applications of professional development of many BIM software, respectively, corresponding to the compatibility of different model data standards (Vysotskiy et al., 2015; Bouška, 2016), mainstream software, including Autodesk’s Revit, Navisworks products, the United States of America Robert McNeel & Assoc development of Rhino products, etc., such as Table 1 summarizes the application of the main-stream software and its support for the file format, it can be seen that the IFC standard is one of the most widely used BIM standards. The IFC standard is developed and managed by BuildingSMART as an international common standard for model data exchange and sharing, which is characterized by stability, openness, and integrity on the one hand, and the use of object-oriented and normalized EXPRESS language to define building product data on the other (Terkaj and Šojić, 2015). EXPRESS is a standardized data modeling language for expressing product data that provides a detailed description of building information models and building engineering data, as well as a description of the information and constraints associated with those product data. This indicates that the IFC data model can express factual information about physical objects, such as component attributes, construction resources, etc., through information description, the organizational relationship between entities, and the way information flows, such as the state of construction behavior (Kim et al., 2018; Justo et al., 2021; Ruiz-Zafra et al., 2022).

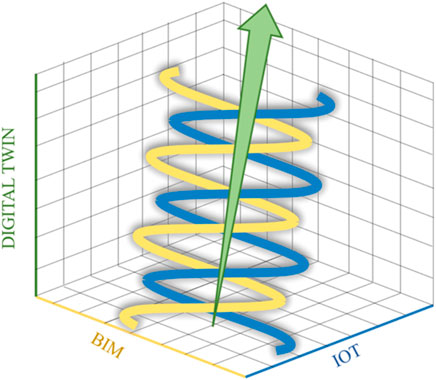

In summary, this study selects the IFC standard for data fusion of digital twin models and exploits the potential of semantic models at the intersection of IoT and AI. As illustrated in Figure 2, by combining BIM technology and IoT technology, we gradually promote the application of digital twin technology in the construction industry; at the same time, along with the development of BIM technology and IoT technology, the digital twin technology is prompted to develop in a spiraling manner.

3 Methods for establishing digital twin

3.1 Model building process

Based on the IFC system, a digital twin model establishment framework is proposed to describe and portray the building construction process in terms of mul-ti-dimensional multi-temporal and spatial scales, which mainly includes the geometric structure of the target building, the resources and behavioral state of the construction site. As shown in Figure 3, it is developed from the following four aspects: (1) building construction process fusion modeling based on the IFC system, (2) twin data interaction, (3) rule/scheduling modeling, and (4) digital twin platform development.

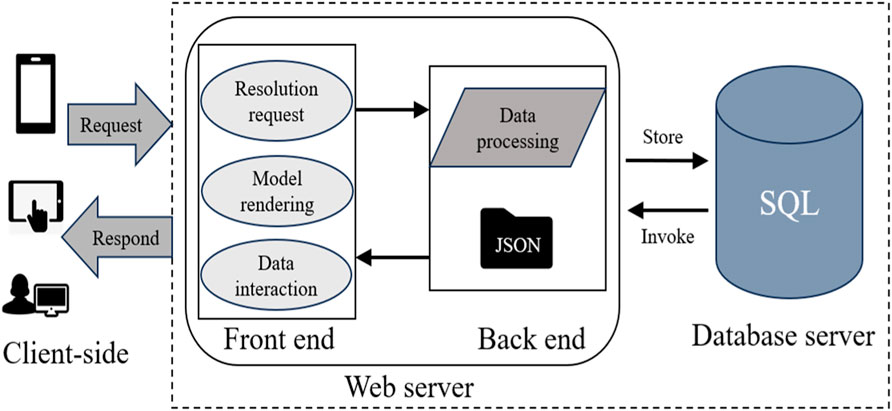

The IFC model is the entry point for establishing the digital twin model. To map the IFC model data to the database, firstly, the JavaScript language is used to extract the data in the IFC standard file, and the geometric and non-geometric information (i.e., the IFC model data) of the model is obtained through parsing, which is converted into Object objects. Secondly, the Object object is encapsulated as a JSON file and transferred to the background. The index between the IFC standard and JSON data files is established to ensure the bidirectional association between the 3D model and the attribute information. Then, the IFC model data is stored in the relational database by constructing the mapping rules from the JSON format file to the relational database. At the same time, IoT devices, drones, sensors, and 2D construction log forms are used to obtain construction site data and store them in the database, which is used to generate the 2D relational model and to systematically organize the interaction of virtual and accurate data, and the fusion of information-physical data. Combined with the Web framework, the rule/scheduling model is established according to the construction field’s relevant standards, specifications, and knowledge base. Finally, based on the above, the digital twin platform is developed to integrate model simulation, data processing, algorithm selection, scheduling optimization, etc. Based on the Web framework, in the back-end, according to the business requirements, the IFC model data in the relational database, the information generated by the actual construction process, and other business data are called and indexed, sliced, and further logical processing is carried out, to display the construction site data in real-time on the lightweight model and form the twin model, and show the data statistical analysis results in the form of charts. Analyzing the current construction status gives feedback and regulation to the construction site.

3.2 IFC modeling methodology

IFC, or Industrial Foundation Class, is a standardized digital description of the built environment, including buildings and civil infrastructure. It is an open international standard (ISO 1639-1:2018) intended to be vendor-neutral or agnostic and can interface with various hardware devices, software platforms, and many different use cases. Specifically, the IFC schema is a standardized data model that logically encodes identifiers and semantics, characteristics and attributes, relationships, objects, processes, etc.

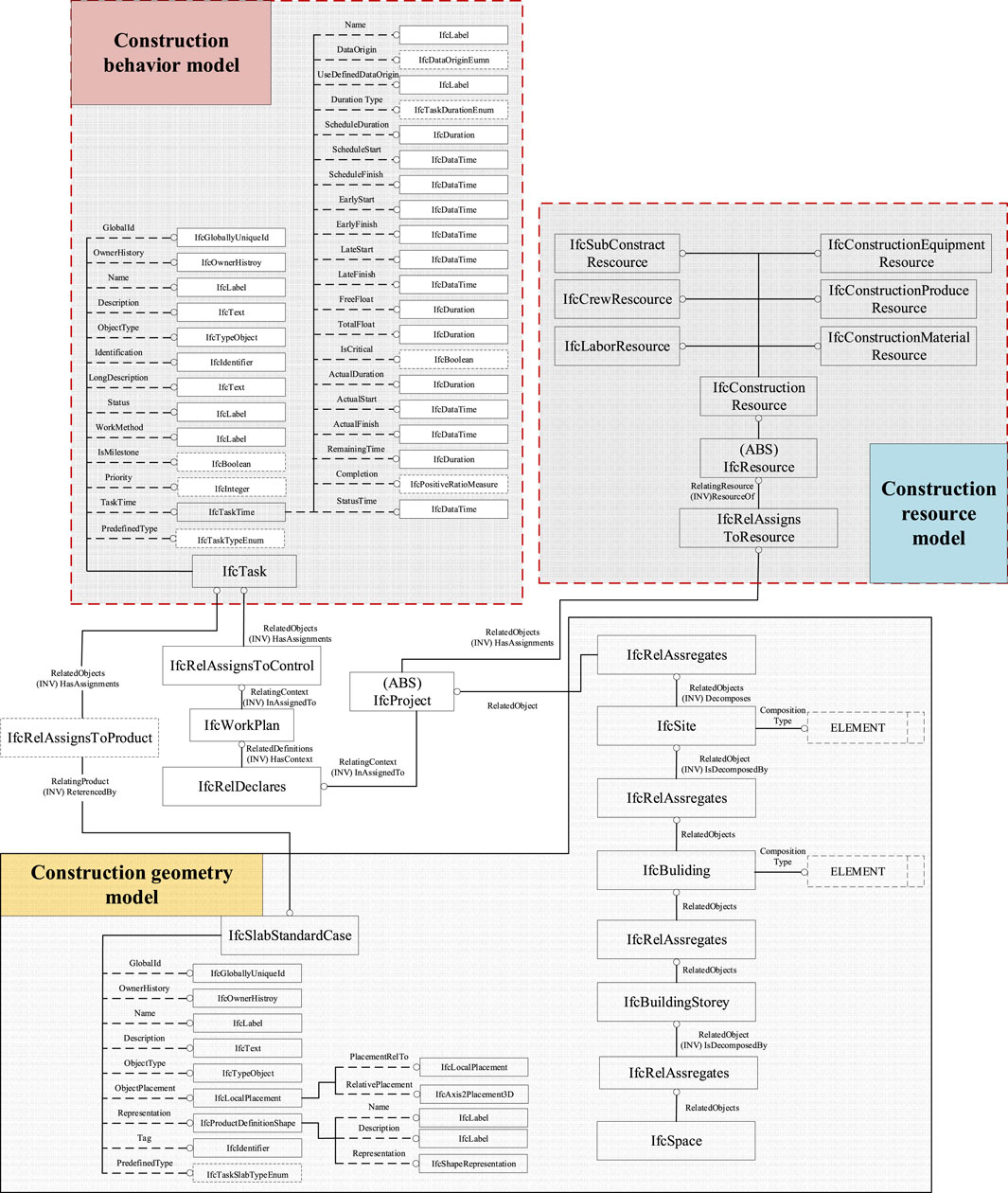

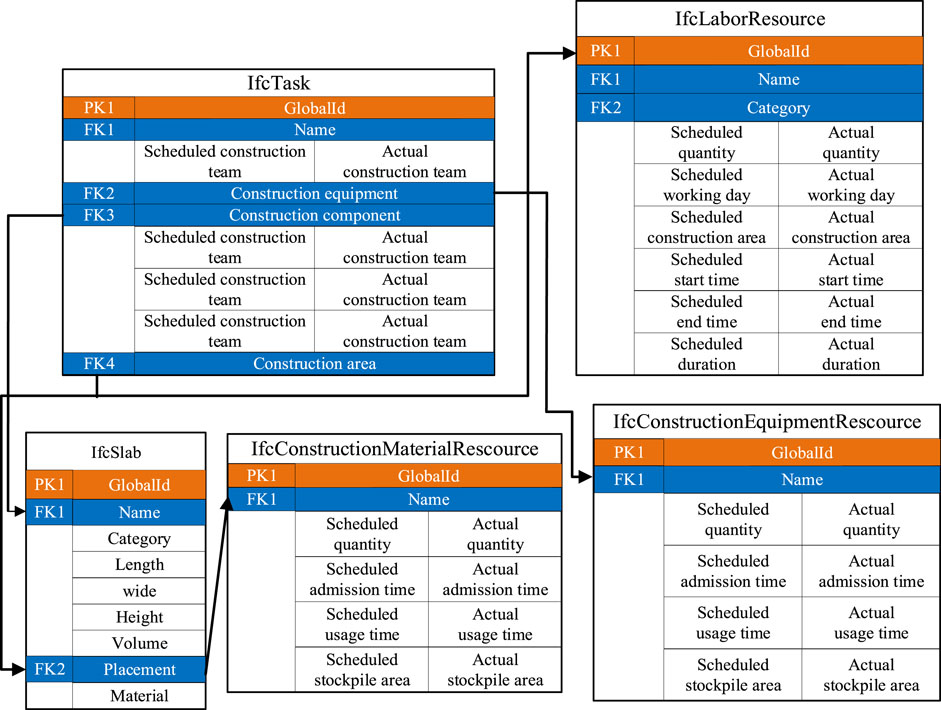

The IFC model provides a generic data model for representing processes; the IFC semantic model established in this paper mainly involves the target building geometry, construction resources, construction time, and construction tasks and realizes the simulation of construction behavioral states by assigning time parameters to construction tasks. As shown in Figure 4 illustrates how to use IfcProject as the background of the work plan or work schedule to establish the IFC semantic model of the building construction process and use IfcTask, IfcWorkPlan, etc., to group and manage the tasks to be executed.

The construction geometric model is depicted as an example of IfcSlabStandardCase building blocks, including GlobalId, OwnerHistory, Name, ObjectPlacement, etc., GlobalId is the assignment of a globally unique identifier within the entire software world; OwnerHistory is the assignment of the information about the current ownership of that object, including owning actor, application, local identification, and information captured about the recent changes of the object; Name is that Optional name for use by the participating software systems or users; The spatial location of the artifact is defined through the ObjectPlacement attribute, which references the geometric resources of the resource layer and describes the relative spatial location of the artifact through the IfcLocalPlacement entity. ObjectPlacement is the Placement of the product in space; the Placement can either be absolute (relative to the world coordinate system), relative (relative to the object placement of another product), or constraint (e.g., relative to grid axes). It is determined by the various subtypes of IfcObjectPlacement, which includes the axis placement information to determine the transformation for the object coordinate system.

The construction resource model is built through the entity IfcResource and its derived entity IfcConstructionResource. Establish the relationship between IfcProduct and IfcResource using the specified resource relationship entity IfcRelAssignsToResource(Being assigned to a resource: assigned using IfcRelAssignsToResource linking the IfcProduct to an IfcResource), the description of engineering resource information is realized by connecting IfcLabor, IfcCrew, IfcSubConstract, IfcConstruc-tionProduct, IfcConstructionMaterial, IfcConstructionEquipment resource information through its derived entity IfcConstructionResource.

The construction behavior model is described through the IfcTask content in the IFC standard, where an IfcTask represents each construction task, and the construction task can be identified as a milestone task or not, as well as the construction time, work method, status, or priority involved can be described. The IFC standard defines construction sequences as the relationship between IfcProcess instances using the IfcRelSequence to establish interrelationships. It defines construction intervals and construction sequences(Being assigned to a process: assigned using IfcRelAssignsToProcess linking the IfcProduct to an IfcProcess). On this basis, by expanding the IFC model data, such as cost information and safety information, the digital twin is utilized to assist in various management activities, such as resource management, cost management, safety management, etc., to provide a more comprehensive digital twin service for the construction site.

3.3 Storage and interaction of twin data

3.3.1 Mapping of IFC model data to relational databases

On the Web site, the use of Three.js (a JavaScript package encapsulated based on WebGL) can reconstruct and render the IFC model and realize the functions such as panoramic roaming and zooming, but this only represents a lightweight display of the building information model. According to the functional analysis of the model in the previous section, the digital twin model should be able to analyze the monitoring data of the construction process and realize the evolution of the construction process. Therefore, further storing the IFC data in the database, and at the same time storing the construction site data in the database, utilizing the function of the database to establish the association of twin data, realizing the interaction of twin data, and laying the data foundation for the calling of twin data in the digital twin management platform.

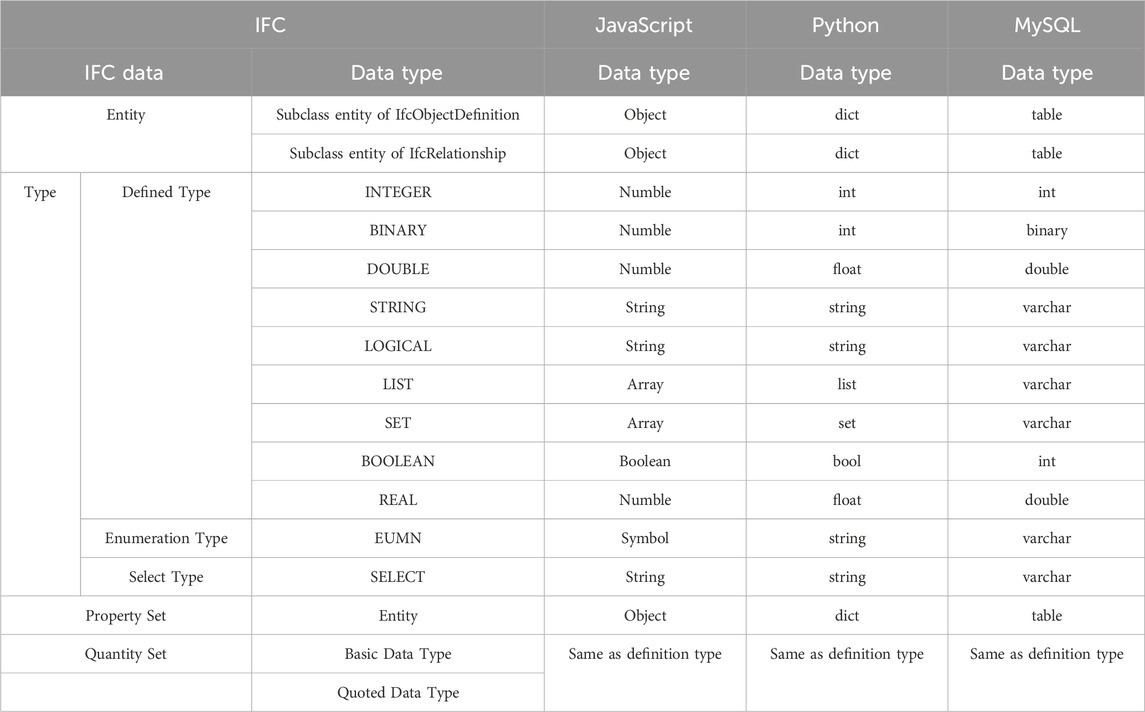

Using JavaScript to parse the IFC standard files into JSON files and establish the mapping rules from JSON files to relational databases in the back-end, Python and the open-source Object Relational Mapping (ORM) framework are used to store the IFC data to relational databases, and the mapping rules are shown in Table 2, which corresponds to the IFC data architecture, and are established from the entities, types, functions, rules, attribute sets, and quantity sets, respectively, to the MySQL database.

To map entities, entities in IFC data refer to objects with specific properties and behaviors. Python classes can be used to define the structure and behavior of entity objects, and inheritance and polymorphism can be implemented; MySQL database tables can be used to represent the attributes and organizational relationships of entity objects, i.e., entities in IFC data are parsed into Object objects using the JavaScript language and then mapped to Python classes and MySQL database tables. The defined types in the IFC data are converted to basic or reference data types in JavaScript and then mapped to the corresponding data types in the Python classes and MySQL database tables. The enumeration type is a particular data type that can be used to limit the range of values of a variable, corresponding to the Symbol type in JavaScript and the string type in Python classes, and stored as the varchar type in the MySQL database. Selection types represent entities with multiple possible forms and allow for checking the values of variables, also corresponding to the string type in Python classes and the varchar type in MySQL databases. In IFC data, functions are used to compute the values of entity attributes and check the correctness of the model, corresponding to the function names in Python classes; rules are specifications, conditions, or conventions used to constrain the data model, corresponding to the logical procedures in Python classes, and are usually of string type. However, functions and rules are not stored in the MySQL database. The attribute and quantity sets represent multiple sets of attribute and quantity information for an entity, mapped to the string type in the Python class and therefore stored as a varchar type in the MySQL database.

3.3.2 Interaction of construction site data with IFC model data

As a carrier for storing data tables, a relational database can be used to store IFC model data on the one hand and effective data generated during the whole life cycle of engineering construction on the other hand. For example, IFC model data in a relational database can be divided into IfcColumn table, IfcBeam table, IfcSlab table, and other component category information tables; the data generated by the actual construction can be divided into component design table, construction schedule table, material table, construction team table and other stages of information tables. As shown in Figure 5, the two-dimensional relationship model between tables is established by setting foreign keys or adding new columns to improve the efficiency of data retrieval in relational databases and to realize one-to-one, one-to-many, or many-to-many connections between tables, to integrate the IFC model data with the actual construction process data, and to prepare for the next step of data processing.

FIGURE 5. Two-dimensional relational modeling of twin data interactions (MySQL). (Source: Author Original).

As the carrier of information interaction, the database stores all the business data, and the back-end accesses the data in the database according to specific business requirements and calls the rule model/scheduling model to form the scenarios through the logical processing of screening, slicing, and converting the business data, and after data cleaning and data processing. At the same time, on the Web site, the IFC standard file can be used as a format file to support WebGL to visualize the 3D model directly without converting it to other formats. The use of Three.js (a JavaScript package encapsulated based on WebGL) can reconstruct the rendering of the IFC model and realize the functions of panoramic roaming and scaling to achieve the interactive correlation of the IFC model and the data in the relational database, as shown in Figure 6. The interaction between the IFC model and the data in the relational database is realized, as shown in Figure 6.

3.4 Digital twin platform construction

To meet the needs of enterprise users for intelligent management of construction application scenarios, functions, and modes, it is necessary to develop a universally adaptable digital twin platform to support digital twin model construction, data processing, algorithm design, configuration, and so on. The real value of the digital twin platform lies in its ability to integrate multi-source data, including sensor data, equipment status data, construction progress data, and other related data sources, as well as information data generated during the construction process. Integrating these data provides the digital twin platform with comprehensive building information, including real-time status and performance data, providing a solid foundation for intelligent management.

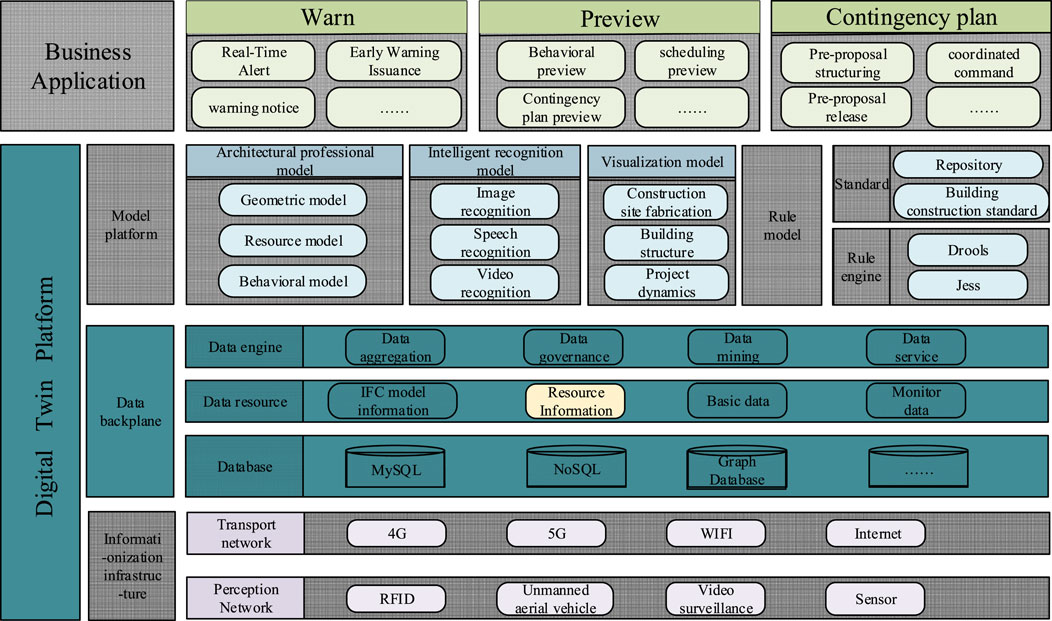

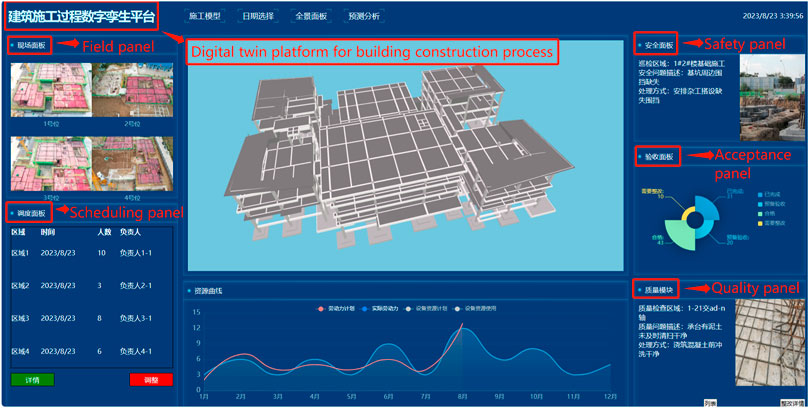

The construction of digital twin platform in this study takes the realization of construction process preview and prediction as the core objective. It adopts Browser/Server architecture mode, under JavaScript development environment, WebGL framework, and database technology, combined with relevant standards and specification system and expert experience base to realize the standardized, safe, and efficient operation of the platform. The digital twin platform develops different functions according to the business applications, mainly including three significant parts: model platform, data baseboard, and information technology infrastructure, each of which is interactively connected by different API interfaces, enabling users to view and analyze the status of buildings and construction sites in real-time, and to provide decision support functions to help users formulate more effective construction plans, resource allocation and risk management strategies. The architecture of the platform is shown in Figure 7.

4 Digital twin implementation case study

In order to validate the effectiveness of the paper’s proposal to establish a digital twin for the construction process based on the IFC system, the method is applied to a project example. For the requirements/functions of the digital twin model proposed in Section 2.1, the validation is carried out in the case study.

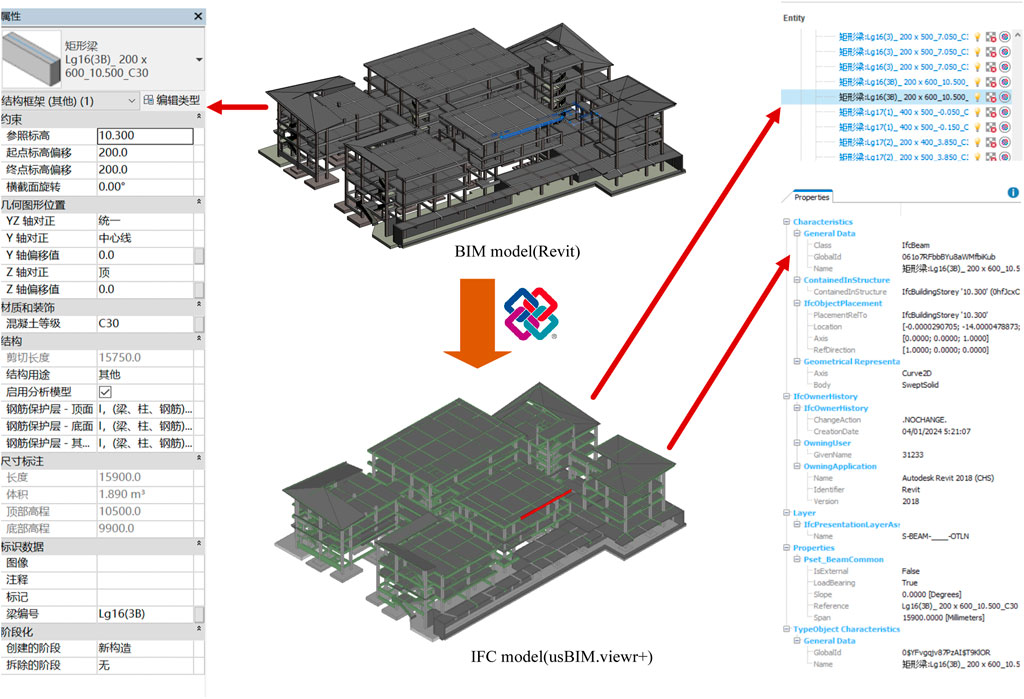

The project is an assembled monolithic frame structure, and the building is a public office building. According to the engineering drawings, Autodesk Revit version 2020 software is used to establish a BIM model containing components such as raft foundation, independent foundation, precast columns, precast beams, and precast slabs, which is exported to an IFC file, which can be opened by using the usBIM.viewr + software to view the information of the components expressed in IFC semantics, as shown in Figure 8.

Revit exported IFC files as the information source, using the standard system of IFC files to store the model geometry, resources, and behavioral information in the form of structural trees. Adopting the Browser/Server architecture mode, the IFC file is deeply parsed by JavaScript under the JavaScript development environment. The nodes in the IFC structure tree are accessed recursively to obtain all entity attribute information. Based on the mapping rules from IFC model data to MySQL database in Section 3.3.1, Python and the open source Object Relational Mapping (ORM) framework are used to store the component information of the project in the database so that the digital twin can manage structural details.

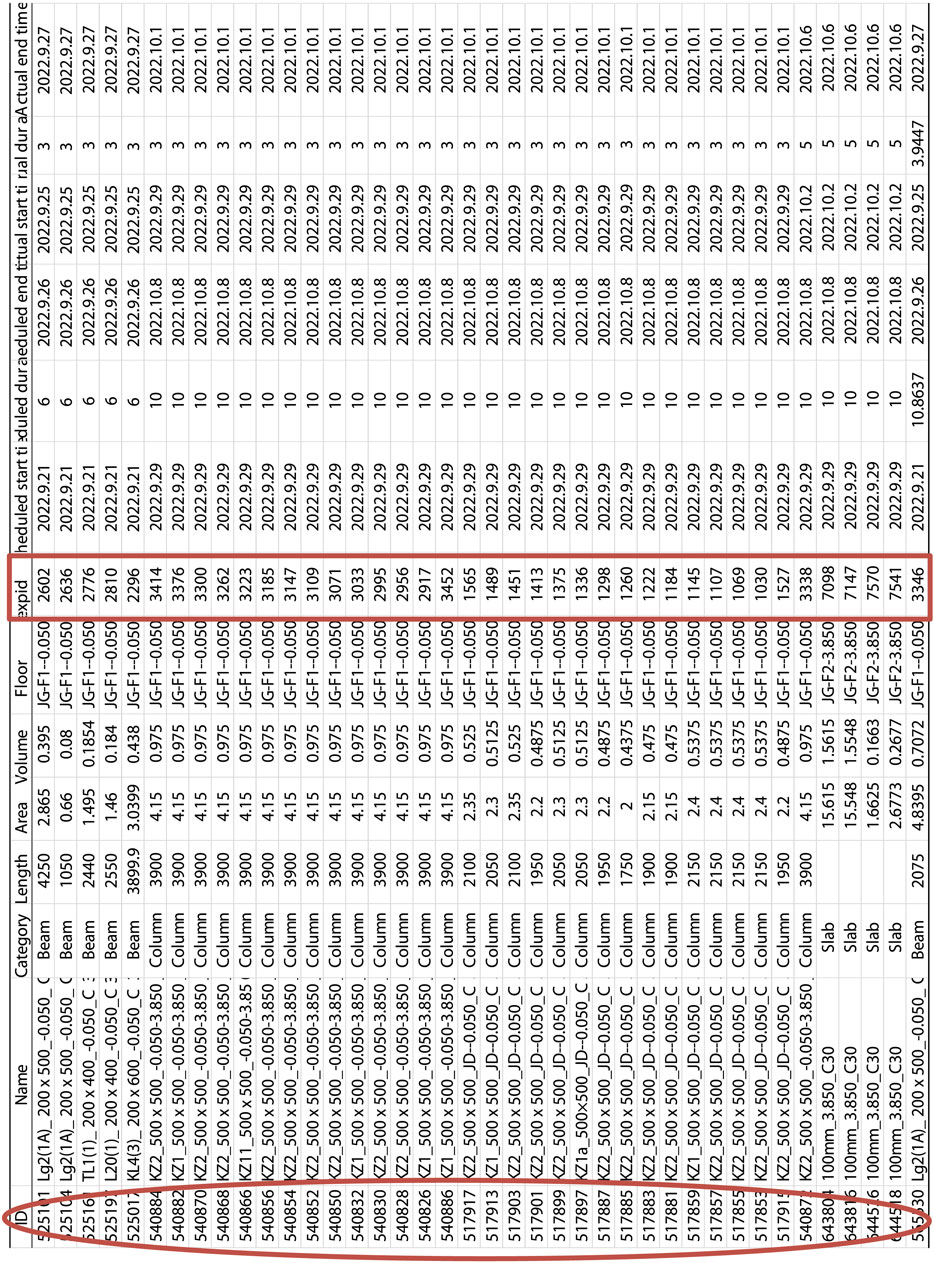

Taking progress information management as an example, the twin data of construction process can be divided into construction activities, construction components, construction team, machinery and equipment, materials and other information in progress service, which are represented by IFC model data in MySQL database as construction task schedule table, component information table, construction resource al-location schedule table, etc.; the construction site data are represented by construction actual progress table, construction actual resource allocation information table, etc., in MySQL database. Information table, construction real resource allocation information table, etc.; construction site data is represented in the MySQL database as construction real progress information table, construction actual resource allocation information table, etc., The construction process data are collected through construction logs and drones, as shown in Figures 9A, B, and the two are associated using a two-dimensional table model, where the Primary Key is used to uniquely identify a field group or attribute group of a table, and the Foreign Key is used to establish a connection with other tables, describing one-to-one, one-to-many, or many-to-many connections between tables, so as to realize the IFC model data. Links between tables, thus learning the interaction between IFC model data and construction site data to achieve the goal of controlling construction behavior. As shown in Figure 10, in this case, the unique ID of the component is used to associate the component design information with the actual information of the construction, and the expid is used to bind the relevant components that are actually collected, and Three.js is used to perform more visualization operations on them.

FIGURE 9. (A) Forms to collect construction data; (B) Drone construction data. (Source: Author Original).

The construction process digital twin management platform is designed and developed based on JS language, WebGL technology, and database technology, which is versatile and convenient without the need to build various environments and utilize different commercial software. Applying the digital twin management platform to this project example mainly includes a human-computer interaction interface, construction site simulation, and visualization monitoring. As shown in Figure 11, the human-computer interaction interface primarily consists of scene selection (physical model, virtual model), work scheduling, and quality checking. When the virtual model scene is selected, clicking on any component will display its geometric structure information and construction site information on the platform page. The construction site simulation uses JS language to lighten the display of the geometric model to portray the shape, size, and assembly relationship of the building. At the same time, by collecting site data and storing it in the database, it establishes a connection between the site data and the geometric model, adopts color changes to reflect the construction status of the site, realizes intelligent early warning, and provides decision-makers with optimized scheduling solutions to assist decision making.

5 Conclusion and future works

Aiming at the lack of a generalized construction method for digital twins in the construction phase of the construction field and the difficulty of actual application on the ground, this study proposes a method for constructing a digital twin model of the construction process based on the IFC standard, which promotes the digitization and intelligence of the construction process of a building through the integration of BIM, Internet of Things, and database technologies. More specifically, BIM technology generally plays a more significant role in the design phase but often deviates from the site in the construction phase. By combining the Internet of Things with construction site data as the basis for physical synchronization of information and fusing it with the IFC model, thus forming a synchronously updated digital twin model, it is more conducive to intelligent construction and provides data and model support for the whole life cycle management of buildings. The contributions of this research can be summarized as follows:

(1) Based on the IFC system, the geometric, resource, and behavioral models of the construction process have been established, which cover more comprehensive information about the construction process through a standardized language. In the JavaScript development environment, there is no need to convert file formats, install commercial software, or build various environments to parse the IFC standard files and map the IFC model data to the database. For different construction projects, the use of IFC-compliant BIM tools to build building models can directly access the BIM data source through this method.

(2) Combined with the Internet of Things technology, the construction site data is obtained through drones and QR code construction logs, which are synchronized and stored in the database, and the database is used to fuse the site data with the IFC model data to realize the practical storage of twin data. In addition, it can provide adequate data and an exemplary model for the construction operation and maintenance phase management, as well as provide rules and experience summarization of historical correlation data for similar projects.

(3) Based on the Three.js engine to build a digital twin model lightweight interaction platform, associating the model entity with database information, and realizing data integration display and analysis on the Web site through data analysis and intelligent reasoning.

However, the proposed method also has some limitations and should be further improved in the future in the following areas:

(1) The architecture and functionality must be further iterated and improved to ensure adaptability and stability for various building construction application scenarios. Due to project constraints, this study only validated the method in a five-story office building in the practical application validation, and it should be certified for larger projects in the future.

(2) The fusion between the multi-source heterogeneous data and the IFC model needs further research. In this study, only the construction site’s progress and quality inspection information were acquired through the drone and QR code. However, the information on safety, environment, and other aspects is still not acquired and applied, and the data types in the construction site are complex and diverse. Unifying and standardizing them is one of the critical points in the construction of the digital twin model.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding authors.

Ethics statement

The studies involving humans were approved by the College of Civil Engineering and Architectural, Guilin University of Technology, Guilin 541004, China. The studies were conducted in accordance with the local legislation and institutional requirements. The participants provided their written informed consent to participate in this study.

Author contributions

CD: Writing–review and editing. KC: Writing–original draft. BL: Writing–review and editing. XZ: Writing–review and editing. QL: Writing–review and editing. ZK: Writing–review and editing.

Funding

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. This research has been supported by the National Natural Science Foundation of China (Grant No. 52068013), the Guangxi Natural Science Foundation Program (Grant No. 2022GXNSFAA035581), Guangxi Key Laboratory of Green Building Materials and Construction Industrialization (22-J-21-28).

Conflict of interest

Author BL was employed by Surveying and Designing Co., Ltd. Author ZK was employed by Guilin Guolida Construction and Installation Engineering Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ascone, C., and Vanderhaegen, F. (2022). Towards a holistic framework for digital twins of human-machine systems. IFAC-PapersOnLine 55 (29), 67–72. doi:10.1016/j.ifacol.2022.10.233

Boje, C., Guerriero, A., Kubicki, S., and Rezgui, Y. (2020). Towards a semantic construction digital twin: directions for future research. Automation Constr. 114, 103179. doi:10.1016/j.autcon.2020.103179

Boje, C., Menacho, Á. J. H., Marvuglia, A., Benetto, E., Kubicki, S., Schaubroeck, T., et al. (2023). A framework using BIM and digital twins in facilitating LCSA for buildings. J. Build. Eng. 76, 107232. doi:10.1016/j.jobe.2023.107232

Bouška, R. (2016). Evaluation of maturity of BIM tools across different software platforms. Procedia Eng. 164, 481–486. doi:10.1016/j.proeng.2016.11.648

Cao, J., Bucher, D. F., Hall, D. M., and Eggers, M. (2022). A graph-based approach for module library development in industrialized construction. Comput. Industry 139, 103659. doi:10.1016/j.compind.2022.103659

Chiachío, M., Megía, M., Chiachío, J., Fernandez, J., and Jalón, M. L. (2022). Structural digital twin framework: formulation and technology integration. Automation Constr. 140, 104333. doi:10.1016/j.autcon.2022.104333

Elzomor, M., and Parrish, K. (2016). Investigating building construction process and developing a performance index. Procedia Eng. 145, 211–218. doi:10.1016/j.proeng.2016.04.063

Fei, T., Xuemin, S., Cheng, J., Yonghuai, Z., Weiran, L., Yong, W., et al. (2024). makeTwin: a reference architecture for digital twin software platform. Chin. J. Aeronautics 37 (1), 1–18. doi:10.1016/j.cja.2023.05.002

Gangolells, M., Casals, M., Gasso, S., Forcada, N., Roca, X., and Fuertes, A. (2009). A methodology for predicting the severity of environmental impacts related to the construction process of residential buildings. Build. Environ. 44 (3), 558–571. doi:10.1016/j.buildenv.2008.05.001

Gartoumi, K. I., Zaki, S., and Aboussaleh, M. (2023). Building information modelling (BIM) interoperability for architecture and engineering (AE) of the structural project: a case study. Mater. Today Proc. doi:10.1016/j.matpr.2023.05.408

Glaessgen, E., and Stargel, D. (2012). “The digital twin paradigm for future NASA and US Air Force vehicles,” in 53rd AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference 20th AIAA/ASME/AHS adaptive structures conference 14th AIAA.

Glatt, M., Sinnwell, C., Yi, L., Donohoe, S., Ravani, B., and Aurich, J. C. (2021). Modeling and implementation of a digital twin of material flows based on physics simulation. J. Manuf. Syst. 58, 231–245. doi:10.1016/j.jmsy.2020.04.015

Grieves, M., and Vickers, J. (2017). Digital twin: mitigating unpredictable, undesirable emergent behavior in complex systems. Transdisciplinary perspectives on complex systems: new findings and approaches, 85–113.

Hosamo, H. H., Nielsen, H. K., Kraniotis, D., Svennevig, P. R., and Svidt, K. (2023). Digital Twin framework for automated fault source detection and prediction for comfort performance evaluation of existing non-residential Norwegian buildings. Energy Build. 281, 112732. doi:10.1016/j.enbuild.2022.112732

Hu, Z., Zhang, J., and Deng, Z. (2008). Construction process simulation and safety analysis based on building information model and 4D technology. Tsinghua Sci. Technol. 13 (S1), 266–272. doi:10.1016/s1007-0214(08)70160-3

Huang, X., Liu, Y., Huang, L., Onstein, E., and Merschbrock, C. (2023). BIM and IoT data fusion: the data process model perspective. Automation Constr. 149, 104792. doi:10.1016/j.autcon.2023.104792

Jiang, F., Ma, L., Broyd, T., and Chen, K. (2021). Digital twin and its implementations in the civil engineering sector. Automation Constr. 130, 103838. doi:10.1016/j.autcon.2021.103838

Jiang, Y., Li, M., Li, M., Liu, X., Zhong, R. Y., Pan, W., et al. (2022). Digital twin-enabled real-time synchronization for planning, scheduling, and execution in precast on-site assembly. Automation Constr. 141, 104397. doi:10.1016/j.autcon.2022.104397

Jiang, Y., Li, M., Wu, W., Wu, X., Zhang, X., Huang, X., et al. (2023). Multi-domain ubiquitous digital twin model for information management of complex infrastructure systems. Adv. Eng. Inf. 56, 101951. doi:10.1016/j.aei.2023.101951

Justo, A., Soilán, M., Sánchez-Rodríguez, A., and Riveiro, B. (2021). Scan-to-BIM for the infrastructure domain: generation of IFC-compliant models of road infrastructure assets and semantics using 3D point cloud data. Automation Constr. 127, 103703. doi:10.1016/j.autcon.2021.103703

Kim, K., Kim, H., Kim, W., Kim, C., Kim, J., and Yu, J. (2018). Integration of ifc objects and facility management work information using Semantic Web. Automation Constr. 87, 173–187. doi:10.1016/j.autcon.2017.12.019

Liu, J., Wen, X., Zhou, H., Sheng, S., Zhao, P., Liu, X., et al. (2022). Digital twin-enabled machining process modeling. Adv. Eng. Inf. 54, 101737. doi:10.1016/j.aei.2022.101737

Lu, Q., Xie, X., Parlikad, A. K., and Schooling, J. M. (2020). Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Automation Constr. 118, 103277. doi:10.1016/j.autcon.2020.103277

Marmo, R., Polverino, F., Nicolella, M., and Tibaut, A. (2020). Building performance and maintenance information model based on IFC schema. Automation Constr. 118, 103275. doi:10.1016/j.autcon.2020.103275

Ogunsakin, R., Mehandjiev, N., and Marin, C. A. (2023). Towards adaptive digital twins architecture. Comput. Industry 149, 103920. doi:10.1016/j.compind.2023.103920

Opoku, D.-G. J., Perera, S., Osei-Kyei, R., and Rashidi, M. (2021). Digital twin application in the construction industry: a literature review. J. Build. Eng. 40, 102726. doi:10.1016/j.jobe.2021.102726

Pan, Y., and Zhang, L. (2021). A BIM-data mining integrated digital twin framework for advanced project management. Automation Constr. 124, 103564. doi:10.1016/j.autcon.2021.103564

Pregnolato, M., Gunner, S., Voyagaki, E., De Risi, R., Carhart, N., Gavriel, G., et al. (2022). Towards civil engineering 4.0: concept, workflow and application of digital twins for existing infrastructure. Automation Constr. 141, 104421. doi:10.1016/j.autcon.2022.104421

Ruiz-Zafra, A., Benghazi, K., and Noguera, M. (2022). IFC+: towards the integration of IoT into early stages of building design. Automation Constr. 136, 104129. doi:10.1016/j.autcon.2022.104129

Sakr, M., and Sadhu, A. (2023). Visualization of structural health monitoring information using Internet-of-Things integrated with building information modeling. J. Infrastructure Intell. Resil. 2 (3), 100053. doi:10.1016/j.iintel.2023.100053

Shahinmoghadam, M., Natephra, W., and Motamedi, A. (2021). BIM-and IoT-based virtual reality tool for real-time thermal comfort assessment in building enclosures. Build. Environ. 199, 107905. doi:10.1016/j.buildenv.2021.107905

Solihin, W., Eastman, C., and Lee, Y.-C. (2017). Multiple representation approach to achieve high-performance spatial queries of 3D BIM data using a relational database. Automation Constr. 81, 369–388. doi:10.1016/j.autcon.2017.03.014

Soori, M., Arezoo, B., and Dastres, R. (2023). Digital twin for smart manufacturing A review. Sustain. Manuf. Serv. Econ., 100017. doi:10.1016/j.smse.2023.100017

Tao, F., Zhang, H., Liu, A., and Nee, A. Y. (2018). Digital twin in industry: state-of-the-art. IEEE Trans. industrial Inf. 15 (4), 2405–2415. doi:10.1109/tii.2018.2873186

Terkaj, W., and Šojić, A. (2015). Ontology-based representation of IFC EXPRESS rules: an enhancement of the ifcOWL ontology. Automation Constr. 57, 188–201. doi:10.1016/j.autcon.2015.04.010

VanDerHorn, E., and Mahadevan, S. (2021). Digital twin: generalization, characterization and implementation. Decis. Support Syst. 145, 113524. doi:10.1016/j.dss.2021.113524

Volkov, A., Chelyshkov, P., and Lysenko, D. (2016). Information management in the application of BIM in construction. The roles and functions of the participants of the construction process. Procedia Eng. 153, 828–832. doi:10.1016/j.proeng.2016.08.250

Vysotskiy, A., Makarov, S., Zolotova, J., and Tuchkevich, E. (2015). Features of BIM implementation using autodesk software. Procedia Eng. 117, 1143–1152. doi:10.1016/j.proeng.2015.08.248

Wang, S., Zhang, J., Wang, P., Law, J., Calinescu, R., and Mihaylova, L. (2024). A deep learning-enhanced Digital Twin framework for improving safety and reliability in human–robot collaborative manufacturing. Robotics computer-integrated Manuf. 85, 102608. doi:10.1016/j.rcim.2023.102608

Wang, W.-C., Weng, S.-W., Wang, S.-H., and Chen, C.-Y. (2014). Integrating building information models with construction process simulations for project scheduling support. Automation Constr. 37, 68–80. doi:10.1016/j.autcon.2013.10.009

Wang, Y., Zhang, L., Yu, H., and Tiong, R. L. (2022). Detecting logical relationships in mechanical, electrical, and plumbing (MEP) systems with BIM using graph matching. Adv. Eng. Inf. 54, 101770. doi:10.1016/j.aei.2022.101770

Wen, Q.-J., Ren, Z.-J., Lu, H., and Wu, J.-F. (2021). The progress and trend of BIM research: a bibliometrics-based visualization analysis. Automation Constr. 124, 103558. doi:10.1016/j.autcon.2021.103558

Xiao, B., Qi, Q., and Tao, F. (2023). Multi-dimensional modeling and abnormality handling of digital twin shop floor. J. Industrial Inf. Integration 35, 100492. doi:10.1016/j.jii.2023.100492

Xie, M., Qiu, Y., Liang, Y., Zhou, Y., Liu, Z., and Zhang, G. (2022). Policies, applications, barriers and future trends of building information modeling technology for building sustainability and informatization in China. Energy Rep. 8, 7107–7126. doi:10.1016/j.egyr.2022.05.008

Xu, J., Shu, X., Qiao, P., Li, S., and Xu, J. (2023). Developing a digital twin model for monitoring building structural health by combining a building information model and a real-scene 3D model. Measurement 217, 112955. doi:10.1016/j.measurement.2023.112955

Yoon, S. (2023). Building digital twinning: data, information, and models. J. Build. Eng. 76, 107021. doi:10.1016/j.jobe.2023.107021

Zhang, F., Chan, A. P., Darko, A., Chen, Z., and Li, D. (2022a). Integrated applications of building information modeling and artificial intelligence techniques in the AEC/FM industry. Automation Constr. 139, 104289. doi:10.1016/j.autcon.2022.104289

Zhang, H., Qi, Q., and Tao, F. (2022b). A multi-scale modeling method for digital twin shop-floor. J. Manuf. Syst. 62, 417–428. doi:10.1016/j.jmsy.2021.12.011

Zhang, J., Li, J., Liu, B., Li, H., and Yang, W. (2023). The design and application of BIM+ refined management and control platform for the Jingxiong railway bridge. High-speed Railw. 1 (3), 211–218. doi:10.1016/j.hspr.2023.07.001

Zhu, A., Pauwels, P., and De Vries, B. (2023a). Component-based robot prefabricated construction simulation using IFC-based building information models. Automation Constr. 152, 104899. doi:10.1016/j.autcon.2023.104899

Keywords: digital twin, building information model (BIM), industry foundation classes (IFC), construction process, database

Citation: Dai C, Cheng K, Liang B, Zhang X, Liu Q and Kuang Z (2024) Digital twin modeling method based on IFC standards for building construction processes. Front. Energy Res. 12:1334192. doi: 10.3389/fenrg.2024.1334192

Received: 06 November 2023; Accepted: 09 January 2024;

Published: 23 January 2024.

Edited by:

Libor Pekař, Tomas Bata University in Zlín, CzechiaReviewed by:

Koorosh Gharehbaghi, RMIT University, AustraliaAleš Mizera, Tomas Bata University in Zlín, Czechia

Alice Paola Pomè, Polytechnic University of Milan, Italy

Copyright © 2024 Dai, Cheng, Liang, Zhang, Liu and Kuang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Chengyuan Dai, MjAxNjAxNUBnbHV0LmVkdS5jbg==; Qizhou Liu, bGl1cXpAZ2x1dC5lZHUuY24=

Chengyuan Dai1,2*

Chengyuan Dai1,2* Ke Cheng

Ke Cheng