95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 29 December 2023

Sec. Sustainable Energy Systems

Volume 11 - 2023 | https://doi.org/10.3389/fenrg.2023.1337846

This article is part of the Research Topic Sustainable Road Infrastructure: Technologies and Assessments View all 14 articles

In this study, three typical oil source asphalt binders, Karamay asphalt A, CNOOC 36-1 asphalt B, Qinhuangdao CNPC asphalt C, were selected to prepare asphalt binders together with the warm mix agent Evotherm M1. The effects of warm mix agents on asphalt from different oil sources were experimentally studied via dynamic shear rheological (DSR), thermogravimetric analysis (TG), and Raman spectroscopy tests. The asphalt binders with different oil sources exhibit different properties. The rheological test results indicate that the addition of warm mix agent can slow down the decrease of asphalt viscosity during the aging process and the aging of asphalt. The results of the thermogravimetric test showed that the residual mass of asphalt with the addition of a warm mix agent significantly decreased after aging. Warm mixing agents can slow down the conversion of lightweight components to heavy components during the aging process of asphalt. By calculating the reflectivity of asphalt in Raman spectroscopy, it can be concluded that the reflectivity of asphalt decreases after adding a warm mix agent. The warm mixing agent reduces the degree of thermal evolution of asphalt. Warm mixing agents can make the chemical components in asphalt relatively stable and less prone to further pyrolysis or cracking reactions.

Building a low-carbon society has become a strategic focus worldwide. The construction temperature of hot mix asphalt mixture is generally 160°C∼180°C (Qiu et al., 2012; Zhang et al., 2023). The mixing temperature of rubber asphalt and special modified asphalt can even reach over 190°C. This not only requires a large amount of heating fuel, but also generates a large amount of harmful and toxic substances such as greenhouse gases and asphalt smoke. The working temperature of Warm Mix Asphalt (WMA) is usually between 90°C and 130°C. It can be divided into chemical process, foam process and organic additive process (Guo et al., 2017; Hou et al., 2017).

Chemical additives such as warm mix asphalt can reduce the working temperature by up to 35°C∼55°C. Additives can reduce the surface tension of the aggregate asphalt interface, improve low-temperature coating and construction workability (Xu and Huang, 2010; Sun et al., 2011; Bowers et al., 2014). At present, there are various types of asphalt on the market, and the performance of asphalt after adding warm mix agents shows diversity. This results in varying quality and implementation effects of warm mix asphalt, making it difficult to estimate the impact on the final pavement performance (Dong et al., 2017).

By studying the warm mixing characteristics of asphalt from different oil sources, it is beneficial to choose the compatibility between asphalt and warm mixing agents. Further explore the impact mechanism of additives on the chemical components of asphalt, and ultimately improve the application effect of warm mix asphalt in road engineering.

This article selects three representative oil sources of road petroleum asphalt and uses dynamic shear rheological test (DSR), thermogravimetric analysis test (TG), and Raman spectroscopy test to study the characteristics of warm mixed asphalt from different oil sources. The article explores the influence of warm mixing agents on the performance and chemical composition of asphalt. It can guide the selection and analysis of warm mixed asphalt.

According to the type of asphalt oil source, we selected three representative 70 # road asphalt as samples, which are labeled as: Karamay asphalt (A), CNOOC 36-1 asphalt (B), and Qinhuangdao CNPC asphalt (C).

Karamay asphalt is made from high quality naphthenic base heavy oil in Block 9. The process of blending vacuum residue with deoiled asphalt is used to produce road petroleum asphalt (Badre et al., 2006; Menapace et al., 2016). Karamay asphalt belongs to naphthenic base crude oil, which has the characteristics of low solidifying point, low wax content, low sulfur content and high resin content. It is currently the only road petroleum asphalt with a density less than 1 g/cm3, which has the characteristics of high dynamic viscosity and high ductility after aging. Mainly used in areas with large temperature differences between day and night, long exposure to sunlight, and strong ultraviolet radiation.

CNOOC 36-1 asphalt is made from rare crude oil from the Suizhong 36-1 oilfield. Suizhong crude oil is a low sulfur cycloalkyl, high acid heavy oil with high density, low wax content, and high gum content. It has the characteristics of high low-temperature ductility, good low-temperature crack resistance, and good water stability.

Qinhuangdao China Petroleum Asphalt is mainly composed of Venezuelan Persian Cane crude oil. This crude oil has high acid value, heavy metal content, and residual carbon, while it has low saturated hydrocarbon content, high gum and asphaltene content, and low wax content.

In this study, three different original asphalt recorded as AO, BO, CO. Three types of asphalt added with warm mix agents are respectively recorded as AP, BP, CP.

The performance index test results of three types of asphalt are shown in Table 1. The test method refer to the “Test Specification for Asphalt and Asphalt Mixtures in Highway Engineering” (JTG E20).

The warm mixing agent Evotherm M1 is a surface active dosage form developed by Meadwestvaco in the United States. The warm mixing agent is a dark brown liquid at room temperature.

The preparation method of warm mixed asphalt binder: Heat the asphalt to 135°C. Calculate the amount of warm mix additives added (based on 0.6% of asphalt mass). Slowly pour the weighed warm mixing agent into the asphalt in a mixed state, with a speed of 200-300 r/min and a mixing time of 20–30 min.

In this study, the rheological properties, thermal stability, and molecular structure information of three representative oil sources of asphalt before and after warm mixing were studied. Dynamic shear rheological test, thermogravimetric analysis test, and Raman spectroscopy test were used.

This study used the dynamic mechanical analysis method ASTM D7175 to test and analyze the rheological properties of asphalt. Test the high-temperature rheological properties of warm mixed asphalt as a function of temperature. Using a frequency of 10 rad/s. Scan with a temperature range of 58°C∼82°C, and test at 6°C intervals (Qian et al., 2001). The constant temperature curing time at each temperature point is 10 min. Through rheological analysis, the viscoelastic indicators of asphalt before and after warm mixing, such as high temperature domain modulus of elasticity (G′) and phase angle, are obtained through testing(δ), Viscous modulus (G″), rutting factor (G*/sin δ) Etc.

Thermogravimetric analysis is an analytical technique that measures the mass changes of samples at different temperatures under program-controlled temperature conditions. Warm mixed asphalt undergoes corresponding chemical changes, decomposition, and composition changes at a certain temperature, accompanied by changes in quality (Abo-Qudais and Al-Shweily, 2007; Hsu et al., 2011; Wang et al., 2022). This study uses thermogravimetric analysis to evaluate the thermal stability of warm mixed asphalt binder. In thermogravimetric analysis, test conditions are set based on the physical and chemical properties of warm mix asphalt, and appropriate sample quality and heating rate are selected. Excessive heating speed can lead to significant errors or reaction delays in obtaining real-time quality and other information of the sample. If the heating rate is too slow, it may not reflect the true state of thermal decomposition of warm mixed asphalt. In this study, METTLER TOLEDO’s TGA/DSC 2 1600HT was used to test the thermal gravimetric analysis of asphalt before and after the addition of a warm mix agent and the aging effect. The test temperature was selected from 0°C to 800°C, and the heating rate was 10°C/min.

Raman spectroscopy, as a scattering spectrum, can obtain information on molecular vibration and rotation (Wang et al., 2015). In this study, Horiba LabRAM HR Evolution was used to measure the changes in molecular structure of asphalt before and after warm mixing. Identify the size, intensity, and shape of Raman shifts in warm mix asphalt.

Asphalt samples can exhibit typical D and G peaks (Curtis et al., 1993). There may be interference from background signals in the original spectrogram, and it is necessary to perform background removal and peak splitting processing on the spectrogram to obtain effective spectral information.

The parameters of the Raman spectrum are shown in the Figure 1: H is the peak height, W is the half peak width, S is the lowest point between the D and G peaks, and H '/S is defined as the saddle index (Tan and Guo, 2014).

Temperature scanning experiments were conducted on three typical asphalt samples before and after adding warm mix agents under three conditions: original asphalt, RTFOT, and PAV after RTFOT. An available DSR was used for rheological testing to obtain the changes in rutting factor and phase angle under different aging conditions.

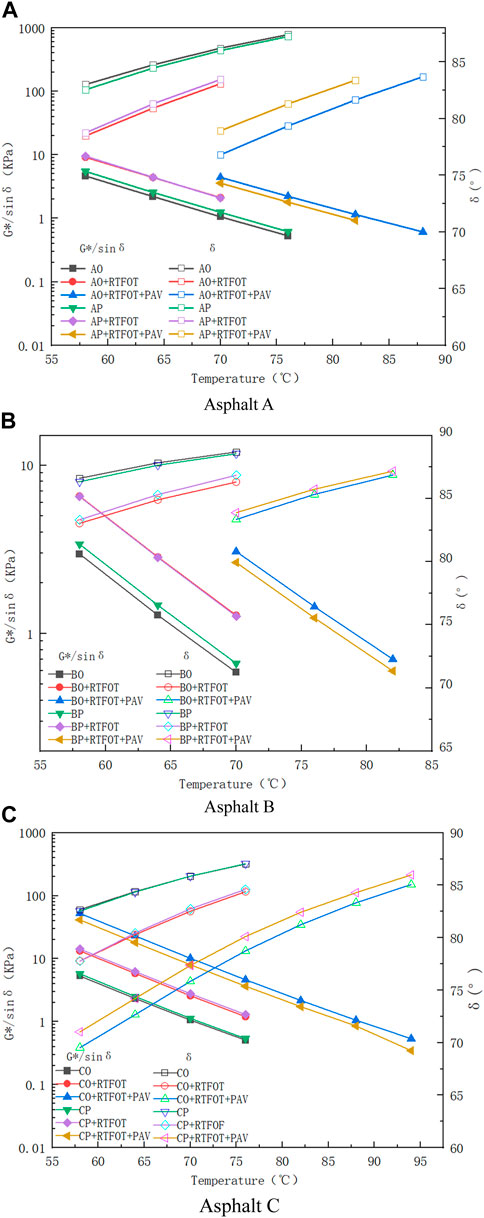

The elastic modulus of warm mixed asphaltvaries with different oil sources, mainly determined by the interaction forces between its components and asphalt molecules. The rutting factor and phase angle of different asphalt before and after warm mixing under different aging conditions are shown in Figure 2.

FIGURE 2. Rheological properties of warm mixed asphalt with different oil sources. (A) Asphalt A, (B) Asphalt B, (C) Asphalt C.

From the scanning results, it can be seen that as the temperature increases, the rutting factor of asphalt decreases and the phase angle increases. This means that the viscosity of asphalt decreases and the resistance to rutting decreases. The rutting factors are as follows: AO+RFTOT+PAV>AO+RFTOT>AO. After experiencing short-term and long-term aging, the modulus of asphalt continues to increase. The rutting factor of warm mixed asphalt is: AP + RFTOT + PAV>AP + RFTOT>AP. The rutting factor of warm mixed asphalt gradually increases with the deepening of aging degree. Comparing the rutting factors of asphalt and warm mix asphalt under the same aging state, it can be seen that the rutting factor of warm mix asphalt is slightly greater than the rutting factor of the original asphalt. The addition of warm mix agents makes asphalt have stronger resistance to deformation. After RTFOT, the rutting factor of warm mix asphalt is the same as that of the original asphalt. After experiencing both short and long-term aging, the rutting factor of asphalt in its original state is greater than that of warm mix asphalt. From this, it can be seen that the addition of warm mix agents can slow down the aging and hardening degree of the base asphalt.

Phase angle δ As the aging state changes, there is a continuous increasing trend within the scanning temperature range. The phase angle of the original asphalt sample is in descending order: AO>AO+RTFOT>AO+RTFOT+PAV.

As the aging degree deepens, the phase angle gradually decreases and the viscosity of asphalt gradually decreases. The phase angle of warm mixed asphalt is in the order of AP>AP+RTFOT>AP+RTFOT+PAV, which is consistent with the phase angle variation of the original asphalt sample.

Comparing the phase angles of asphalt and warm mix asphalt under the same aging effect, it can be seen that the phase angle of warm mix asphalt is slightly smaller than the phase angle of the original asphalt. The addition of warm mix agent slightly reduces the viscosity of asphalt, further explaining the principle that warm mix agent can mix at low temperature. After RTFOT, the phase angle of warm mixed asphalt is slightly greater than that of the original asphalt. After short and long-term aging, the phase angle of warm mix asphalt is much greater than that of the original asphalt. The phase angle characterizes the viscosity of asphalt, and the smaller the phase angle, the smaller the viscosity of asphalt. The addition of warm mix agents can delay the decrease in viscosity of asphalt under aging and alleviate its aging.

In the lower temperature scanning stage, the deeper the aging degree of asphalt, the better the content of high molecular weight components in asphalt. Asphalt binders exhibit better elastic properties, resulting in lower phase angles compared to other aging stages. As the temperature increases, the asphalt material gradually softens and tends towards viscous flow dynamics. The asphalt samples with deeper aging degree show a faster increase in viscosity composition and a significant increase in phase angle with the increase of temperature.

B asphalt and C asphalt exhibit similar rheological properties as A asphalt. The delaying effect of warm mix agent on B asphalt is not as good as A asphalt. The performance is better when mixed with asphalt A.

This study controls the temperature rise and fall rate of the sample, and then measures the mass change of the sample at different temperatures. Determine the thermal decomposition of asphalt at different temperatures. Test the mass loss rate of the sample before and after warm mixing at different temperatures. Analyze the influence of warm mixing agents on the thermal stability of asphalt.

The quality of asphalt remains basically unchanged between 0°C and 214.46°C, and its performance remains stable. The quality of asphalt will not be lost during the heating and mixing process of asphalt and aggregates at 214°C. Asphalt begins to experience mass loss from 296°C. The thermal decomposition process is basically completed at around 500°C. Asphalt materials are basically completely carbonized.

The thermal decomposition process of asphalt after PAV basically ends at around 543°C, and the thermogravimetric curve remains stable. After adding a warm mixing agent to asphalt, there is basically no effect on the inflection point temperature and residual quality of the original asphalt sample. After long-term aging, the residual mass of the original sample increases, while the residual mass of the warm mixing agent decreases.

As the temperature increases, each component in asphalt begins to decompose. The original small molecules and decomposed small molecules in asphalt gradually break free from intermolecular forces and escape from the asphalt material (Hou et al., 2015; Hou et al., 2016). Therefore, the thermal stability of asphalt before and after warm mixing is evaluated by analyzing the inflection point temperature and residual mass ratio of the thermogravimetric curve of asphalt materials.

The inflection point temperature and residual mass data of three types of asphalt are shown in the Table 2.

Analyze the residual quality changes of three types of asphalt samples, long-term aging PAV, and warm mix asphalt after long-term aging PAV, as shown in Figure 3.

The residual mass of asphalt from different oil sources gradually increases with long-term aging. Aging can cause the association and aggregation of asphalt molecules. The addition of warm mix agents will have a certain impact on the composition and microstructure of asphalt components. After the aging of warm mix asphalt binder, the residual quality significantly decreases, indicating that the warm mix agent will slow down the conversion of light components to heavy components in the aging process of asphalt. Warm mix agents can reduce the molecular association of asphalt during aging and slow down the aging of asphalt.

By comparing the residual quality of different types of asphalt, A asphalt has the smallest residual quality after thermogravimetric analysis, followed by B asphalt. C asphalt has more carbonized components that have not been decomposed. The residual mass of asphalt with more asphaltene content after thermogravimetric analysis is greater. Asphalt has a high content of asphaltene and is prone to carbonization. The higher the content of non decomposable components at high temperatures, the higher the residual mass ratio of thermogravimetry. Generally, components that cannot be decomposed above 460°C have larger molecular weights, more condensed aromatic rings, and are prone to carbonization. Therefore, there will be significant differences in the residual quality of asphalt from different oil sources.

This study used Raman spectroscopy to test the changes in molecular structure and chemical bond information of warm mixed asphalt from different oil sources. Raman spectroscopy is a non-destructive spectroscopy technique that uses laser irradiation of asphalt samples to measure the changes in photon energy scattered by asphalt, thereby obtaining molecular structure and composition information before and after warm mixing of asphalt (Shan et al., 2010).

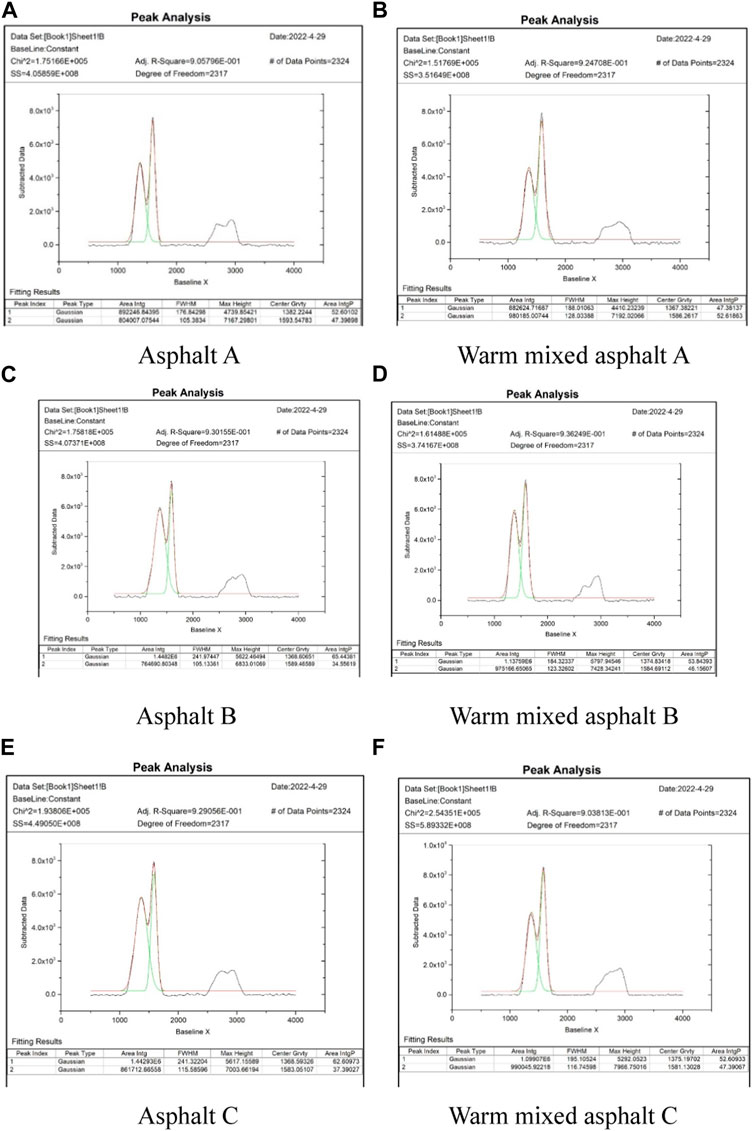

This study used HORIBA Scientific LabRAM HR Evolution for Raman spectroscopy testing. Raman spectroscopy is a surface test with a detection depth of about 10 nm and a spot size of 1um.The Raman spectra of three different types of warm mixed asphalt were shown in Figure 4.

FIGURE 4. Raman spectra of three different types of warm mixed asphalt. (A) Asphalt A, (B) Warm mixed asphalt A, (C) Asphalt B, (D) Warm mixed asphalt B, (E) Asphalt C, and (F) Warm mixed asphalt C.

Based on the Raman spectra of each asphalt, determine the positions of the D and G peaks and perform peak fitting. Obtain quantitative characterization parameters for the D and G peaks, mainly including: (Zhang et al., 2023) Peak position: WD and WG represent the positions of D and G peaks, respectively; (Qiu et al., 2012) Half height width: FWHMD and FWHMG; (Guo et al., 2017) Peak height: H; (Hou et al., 2017) Half peak width: W; (Sun et al., 2011) S is the lowest point between the D and G peaks; (Bowers et al., 2014) Saddle index: H '/S.

Wilkins et al. [*] proposed a method for peak separation of asphalt Raman spectra through extensive experimental data analysis, and provided a formula for calculating asphalt reflectance using Raman spectral parameters. The formula for calculating the reflectance of asphalt Raman spectroscopy parameters is:

In the formula, vD and vG are the peak positions of D and G peaks, with peak spacing of (vG-vD). The half width at half height of D and G peaks is FWHM-D and FWHM-G and the saddle index. Calculate the Raman spectral parameters of different types of asphalt in the Table 3.

Raman spectroscopy parameters can better characterize the maturity of asphalt. By using the Lorentz peak fitting method to process the original test results, effective characteristic parameters of Raman peaks can be obtained. The saddle index and reflectance changes of asphalt before and after warm mixing can be analyzed as shown in the Figure 5.

As the degree of thermal evolution gradually increases, the alkane structure in asphalt gradually decreases. Due to the association effect, the spacing between aromatic ring structures decreases, resulting in an increase in reflectivity. The warm mix agent reduces the degree of thermal evolution of asphalt. The reflectivity of different types of asphalt decreases after adding warm mix agents. The decrease in thermal evolution indicates that the components in asphalt are relatively stable and less prone to further thermal decomposition.

Through dynamic shear rheological test, thermal weight loss test, and Raman spectroscopy test, the rheological properties, thermal decomposition stability, and the influence of temperature mixing agents on the microstructure of three typical oil source asphalt were studied. The results indicate that asphalt binders with different oil sources exhibit different warm mix properties.

(1) The addition of warm mix agents can delay the decrease in viscosity of asphalt under aging and alleviate the aging of asphalt.

(2) Asphalt with high asphaltene content has a large residual mass after thermal decomposition. Warm mix agents can slow down the molecular association of asphalt during the aging process. The residual mass of warm mixed asphalt after thermal decomposition has decreased.

(3) The reflectivity of different types of asphalt decreases after adding warm mix agents, indicating that warm mix agents reduce the degree of thermal evolution of asphalt. Warm mixing agents can make the components in asphalt relatively stable and less prone to further pyrolysis or cracking reactions.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding authors.

RC: Writing–original draft. AS: Writing–review and editing. JW: Writing–review and editing.

The author(s) declare financial support was received for the research, authorship, and/or publication of this article. Supported by the Program Fund of Non-Metallic Excellence and Innovation Center for Building Materials, 2022TDA2-4.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Abo-Qudais, S., and Al-Shweily, H. (2007). Effect of aggregate properties on asphalt mixtures stripping and creep behavior. Constr. Build. Mater. 21 (9), 1886–1898. doi:10.1016/j.conbuildmat.2005.07.014

Badre, S., Goncalves, C. C., Norinaga, K., Gustavson, G., and Mullins, O. C. (2006). Molecular size and weight of asphaltene and asphaltene solubility fractions from coals, crude oils and bitumen. Fuel 85 (1), 1–11. doi:10.1016/j.fuel.2005.05.021

Bowers, B. F., Huang, B., Shu, X., and Miller, B. C. (2014). Investigation of reclaimed asphalt pavement blending efficiency through GPC and FTIR. Constr. Build. Mater. 50, 517–523. doi:10.1016/j.conbuildmat.2013.10.003

Curtis, C. W., Ensley, K., and Epps, J. (1993). Fundamental properties of asphalt-aggregate interactions including adhesion and absorption[R]. No. SHRP-A-341. Washington, DC: National Research Council.

Dong, Z., Liu, Z., Wang, P., and Gong, X. (2017). Nanostructure characterization of asphalt-aggregate interface through molecular dynamics simulation and atomic force microscopy. Fuel 189, 155–163. doi:10.1016/j.fuel.2016.10.077

Guo, M., Tan, Y., Wang, L., and Hou, Y. (2017). Diffusion of asphaltene, resin, aromatic and saturate components of asphalt on mineral aggregates surface: molecular dynamics simulation. Road Mater. Pavement Des. 18 (3), 149–158. doi:10.1080/14680629.2017.1329870

Hou, Y., Sun, W., Das, P., Song, X., Wang, L., Ge, Z., et al. (2016). Coupled Navier–Stokes phase-field model to evaluate the microscopic phase separation in asphalt binder under thermal loading. J. Mater. Civ. Eng. 28 (10), 04016100. doi:10.1061/(asce)mt.1943-5533.0001581

Hou, Y., Wang, L., Pauli, T., and Sun, W. (2015). Investigation of the asphalt self-healing mechanism using a phase-field model. J. Mater. Civ. Eng. 27 (3), 04014118. doi:10.1061/(asce)mt.1943-5533.0001047

Hou, Y., Wang, L., Wang, D., Guo, M., Liu, P., and Yu, J. (2017). Characterization of bitumen micro-mechanical behaviors using AFM, phase dynamics theory and MD simulation. Materials 10 (2), 208. doi:10.3390/ma10020208

Hsu, C. S., Hendrickson, C. L., Rodgers, R. P., McKenna, A. M., and Marshall, A. G. (2011). Petroleomics: advanced molecular probe for petroleum heavy ends. J. mass Spectrom. 46 (4), 337–343. doi:10.1002/jms.1893

Menapace, I., Masad, E., Papavassiliou, G., and Kassem, E. (2016). Evaluation of ageing in asphalt cores using low-field nuclear magnetic resonance. Int. J. Pavement Eng. 17 (10), 847–860. doi:10.1080/10298436.2015.1019503

Qian, K., Robbins, W. K., Hughey, C. A., Cooper, H. J., Rodgers, R. P., and Marshall, A. G. (2001). Resolution and identification of elemental compositions for more than 3000 crude acids in heavy petroleum by negative-ion microelectrospray high-field Fourier transform ion cyclotron resonance mass spectrometry. Energy and Fuels 15 (6), 1505–1511. doi:10.1021/ef010111z

Qiu, J., Van de Ven, M., Wu, S., Yu, J., and Molenaar, A. (2012). Evaluating self healing capability of bituminous mastics. Exp. Mech. 52 (8), 1163–1171. doi:10.1007/s11340-011-9573-1

Shan, L., Tan, Y., Underwood, S., and Kim, Y. R. (2010). Application of thixotropy to analyze fatigue and healing characteristics of asphalt binder. Transp. Res. Rec. 2179 (1), 85–92. doi:10.3141/2179-10

Sun, D. Q., Zhang, L. W., and Zhang, X. L. (2011). Quantification of SBS content in SBS polymer modified asphalt by FTIR. Trans. Tech. Publ. 287, 953–960. doi:10.4028/www.scientific.net/amr.287-290.953

Tan, Y., and Guo, M. (2014). Micro-and nano-characteration of interaction between asphalt and filler. J. Test. Eval. 42 (5), 20130253–20131097. doi:10.1520/jte20130253

Wang, D., Baliello, A., Poulikakos, L., Vasconcelos, K., Kakar, M. R., Giancontieri, G., et al. (2022). Rheological properties of asphalt binder modified with waste polyethylene: an interlaboratory research from the RILEM TC WMR. Resour. Conservation Recycl. 186, 106564. doi:10.1016/j.resconrec.2022.106564

Wang, P., Dong, Z., Tan, Y., and Liu, Z. y. (2015). Investigating the interactions of the saturate, aromatic, resin, and asphaltene four fractions in asphalt binders by molecular simulations. Energy and Fuels 29 (1), 112–121. doi:10.1021/ef502172n

Xu, T., and Huang, X. (2010). Study on combustion mechanism of asphalt binder by using TG–FTIR technique. Fuel 89 (9), 2185–2190. doi:10.1016/j.fuel.2010.01.012

Zhang, F., Sha, A., Cao, Y., Wang, W., Song, R., and Jiao, W. (2023). Characterization of self-healing properties of asphalt pavement materials containing carbon nanotubes: from the binder and mix level based on grey relational analysis. Constr. Build. Mater. 404, 133323. doi:10.1016/j.conbuildmat.2023.133323

Keywords: warm mixed asphalt, chemical additives, oil source, rheological properties, peak temperature, saddle index, asphalt reflectance

Citation: Chang R, Sha A and Wang J (2023) Effect of warm mix agent on the chemo-mechanical performance of binder with different oil sources. Front. Energy Res. 11:1337846. doi: 10.3389/fenrg.2023.1337846

Received: 13 November 2023; Accepted: 30 November 2023;

Published: 29 December 2023.

Edited by:

Di Wang, University of Ottawa, CanadaReviewed by:

Peng Lin, Delft University of Technology, NetherlandsCopyright © 2023 Chang, Sha and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Aimin Sha, YW1zQGNoZC5lZHUuY24=; Jie Wang, ai53YW5nQHJpb2guY24=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.