- The No. 2 Cementing Branch of PetroChina Bohai Drilling Engineering Company, Tianjin, China

The damage of cement slurry to the reservoir is directly related to the production of oil and gas wells, and is a problem that must be solved for the efficient and economic development of oil and gas reservoirs. According to the characteristics and field conditions of reservoir damage caused by cement slurry, this paper analyzes the main factors affecting the degree of reservoir damage, puts forward the technical index requirements of the evaluation device, and establishes the evaluation method of reservoir damage caused by cement slurry in case of loss of injection. The results show that the influence of temperature on the damage of the cement slurry layer is small, and the influence of pressure difference on the damage to the cement slurry layer is large; When the pressure difference is 22 Mpa, the penetration damage rate caused by cement slurry to the pore center without mud cake attachment is about 43%. After a day of core maintenance, the permeability damage rate will reach 61.2%; The damage of cement slurry to the pore micro-fractured core is very serious. After 1 day of maintenance, the damage to the core permeability after cement slurry solidification is as high as 83%, with an average of 76.5%; When the risk of leakage is low, the cement slurry system with low density and low water loss can be used for cementing operation. The filtrate of cement slurry should be better matched with the formation clay minerals, formation water, and drilling fluid filtrate. When the risk of leakage is high, high-density cement slurry, balanced pressure cementing, pressure control cementing, and other technologies to avoid leakage can be used for cementing operations. When the cementing conditions are more difficult, the cementing slurry system can be used to dissolve the cementing slurry system at a later stage. The research results provide theoretical data support for the study of reducing the damage of cement slurry to the reservoir.

Introduction

Reservoir damage refers to the situation that the output of reservoir oil and gas and the injection capacity of displacement fluid decrease due to various factors in the process of drilling, worker, stimulation, later transformation and development, and production of oil and gas (Yuan et al., 2014; Guo et al., 2020; Li et al., 2021). With the development of drilling and its supporting technologies in China, the drilling depth is also increasing, and the number of deep wells and ultra-deep wells in China is developing rapidly. In 2018, there were 160 wells drilled by China National Petroleum Corporation with a drilling depth of more than 6000 m. Different from conventional wells, deep wells have higher temperatures, pressure, and pressure difference, and there may be a regional formation pressure deficit (Sabins, 1990; Xi et al., 2021; Yang et al., 2022). With the continuous decrease of the original formation pressure, the pressure difference between the wellbore and the reservoir will reach 30 Mpa when newly cementing, and a large amount of cement slurry filtrate may invade the reservoir, resulting in reservoir permeability damage. The difference between bottom hole pressure and formation pressure is called differential pressure. According to this method, wellbore pressure can be divided into overbalanced, underbalanced, and balanced. Overbalance (also called positive differential pressure) refers to the bottom hole pressure being greater than the formation pressure; Underbalanced (also called negative pressure difference) refers to the bottom hole pressure being less than the formation pressure; Balance refers to the condition that the bottom hole pressure is equal to the formation pressure. Near-balanced pressure drilling refers to overbalanced pressure drilling with the pressure difference within the specified range. In order to find out the severity of reservoir damage, to choose appropriate protection measures, at present, among the devices and methods for evaluating reservoir damage caused by cementing slurry, there is no device that can simulate the high-temperature and high-pressure downhole environment, no evaluation method for reservoir damage caused by lost cementing slurry, and no effective indoor research device and matching calculation method for invasion depth of slurry filtrate (Al-Jubori et al., 2009; Han et al., 2016; Du et al., 2021). Therefore, it is necessary to carry out the evaluation method of cementing slurry reservoir damage by simulating cementing conditions when conducting research.

At present, the research results on the evaluation device and experimental method of reservoir damage caused by cementing cement slurry have been relatively rich, and the evaluation methods of reservoir damage mainly include the evaluation method of static displacement damage evaluation and the evaluation method of dynamic damage evaluation device (Cellini et al., 2019; Lashof and Ahuja, 2019; Sha et al., 2019). When some researchers carry out the damage of cement slurry filtrate to the formation, they mainly focus on experimental research, using a water loss meter to make cement slurry filtrate, pass the filtrate through the damaged core of the static damage evaluation device, and using the core permeability as the main index to evaluate the damage law of cement slurry to the reservoir. Some researchers have used static cement slurry to evaluate the device for reservoir damage to conduct experiments on the dynamic damage of cement slurry filtrates of different components to the core and concluded that the chemical reactions of cement slurry filtrate and formation groundwater, clay minerals, and drilling fluid filtrates such as flocculation, expansion, and scaling are the most important factors causing reservoir damage, and external additives will also affect the chemical properties of cement slurry filtrate, reducing or aggravating harmful ion content to varying degrees (Bai et al., 2015; Shadravan et al., 2017; Wang et al., 2022). Some researchers use SW-II type core dynamic damage meter to evaluate the damage of cement slurry to the reservoir, the instrument mainly realizes the evacuation of the core, prepares saturated formation water, and measures the original permeability of the core, by soaking the drilling fluid filtrate for 24h, and comparing the dynamic reservoir damage of the drilling fluid under a pressure difference of 4.5Mpa and the dynamic damage of the drilling fluid to the core to form mud cake, by measuring the thickness of the mud cake, Core permeability and cement slurry dynamic damage core as well as the final permeability and total filter cake thickness, so as to calculate the damage rate of the permeability, while manually scraping off the outer mud cake and cleaning with clean water, cement slurry dynamic damage core measures the final permeability and filter cake thickness to calculate the permeability damage rate. Some researchers have proposed a set of damage evaluation methods for different reservoir types in view of the protection of dense clastic rock reservoirs in western Sichuan, and mainly carried out different indoor simulation evaluations: 1) the degree of blockage of filtrate containing polymer treatment agents on the width of the core joints by experimental simulation of the damage of the cores, and characterize the core permeability, and evaluate the cement slurry filtrate damage by static evaluation devices (Prohaska et al., 1995; Rongchao et al., 2007; Cui et al., 2021; Sahu et al., 2021); 2) The core is pretreated, and the gas permeability is measured after water and nitrogen displacement and saturation formation stabilization. The core is loaded into the core holder, and the core is damaged with room temperature and 3.5 MPa working fluid. The filter cake at both ends of the core is scraped to measure the gas permeability. The damage characteristics of water mud on the core are studied (Abimbola et al., 2016; Lian et al., 2020; Yin et al., 2021); 3) Through a series of experiments, the results show that the depth and degree of damage of cement slurry to the core are mainly positively related to the intrusion depth of its filtrate, and the evaluation of the double damage degree of drilling fluid and cement slurry to the reservoir is evaluated by calculating the filtrate depth (Barclay et al., 2001; Yue et al., 2018; Ahad et al., 2020). Some researchers have studied the evaluation method of cement slurry reservoir damage based on the proposed indoor evaluation method of drilling fluid and completion fluid damage. In order to make up for the shortcoming that this method can only evaluate the solid working fluid, the FDS-800-1000 formation damage evaluation system is used in the main experiment. In the experiment, vacuum and saturated formation water are pretreated by the core to measure its permeability, the mud cake of drilling fluid is formed through dynamic damage, and the external mud cake is scraped off. The permeability of the core is measured by scraping off the dynamic damage of the cement slurry and the filter cake. For cores with good cementation quality, the multi-point permeability measuring device is used to determine the damage depth. For the core with poor cementite quality, the damage depth is determined by the permeability of the fracture. Based on this, the degree of dual damage of drilling fluid and cement slurry to the reservoir is evaluated (Elkatatny, 2018; Cheng et al., 2022). Some scholars have analyzed the variation of coal seam permeability and the effect of enhanced recovery of coalbed methane, and calculated the degree of permeability damage caused by different factors. Studies have shown that burial depth, bottom hole pressure and dehydration rate have an effect on the effective stress acting on the coal reservoir, which in turn causes changes in permeability, productivity and other indicators. The elastic modulus of coal reflects the compressive capacity of coal: the higher the elastic modulus, the smaller the decline in permeability (Tao et al., 2012a). Some researchers have carried out FVS analysis on coal cores under different initial permeability, injection rate and injection intensity, and discussed the production response of coalbed methane wells to FVS at different drainage stages (Tao et al., 2017). Some scholars have studied the permeability damage of coalbed methane caused by increasing the pressure difference of displacement during the development of coalbed methane. The results show that in the development process, it is better to control the production pressure difference below the critical value of pressure drop (Tao et al., 2012b).

Oil and gas reservoir protection is subject to exploration, drilling, development, and downhole operations, and reducing the damage of cemented cement slurry to reservoirs during the cementing process is an important research topic (Ali et al., 2020; Bu et al., 2020). In this paper, taking the typical clastic rock reservoir of an oilfield in western China as the research object, according to the characteristics and site conditions of cementing cement slurry on reservoir damage, the main factors affecting reservoir damage are analyzed, the technical index requirements of the evaluation device are proposed, and the core damage and evaluation experiments are carried out to calculate the intrusion depth of cement slurry filtrate, so as to establish the damage evaluation method of the cement slurry to the reservoir when cementing leakage is lost, and provide theoretical data support for the study of reducing the damage of cemented cement slurry to the reservoir (McLeod, 1984).

Reservoir characteristics and cementing overview of the study area

Reservoir characteristics

In this paper, a typical clastic rock block of an oil field in western China is taken as the research object. The oil-bearing clastic rock reservoirs in the research area are mainly distributed in the Paleogene Kumglemu Formation, Cretaceous Bashi Kichik Formation, and Brazil Restructuring, among which the reservoir lithology of Paleogene Kumglemu Formation is mainly fine sandstone, silty mudstone, glutenite and argillaceous siltstone. The reservoir lithology of the Bashi Kichik Formation in the Cretaceous is mainly fine sandstone, mudstone, siltstone, argillaceous siltstone, and silty mudstone. The lithology of the reformed reservoirs in Cretaceous Brazil is mainly mudstone, fine sandstone, silty mudstone, and argillaceous siltstone, and there are obvious characteristics of upper mud and lower sand.

The temperature distribution of the stratum in study area A is as follows: the stratum temperature gradient is 1.98∼2.21°C/100 m; The clastic rock reservoir section is generally buried within 4000∼5000 m, and the temperature of the clastic rock reservoir section is about 100∼120°C. After the oil and gas exploitation of the study area, there was a significant pressure deficit in the clastic rock reservoir section, and with the development of the mining progress, the pressure coefficient has dropped to below 1. The pressure coefficient is defined as the ratio of the measured formation pressure to the hydrostatic pressure at the same depth, which is a dimensionless quantity to measure the abnormal degree of the formation pressure (Singh and Roy, 2021). If the pressure coefficient is higher than 1.2, it is abnormally high pressure; If it is lower than 0.8, it is abnormally low pressure; Normal pressure is between 0.8 and 1.2. Table 1 gives the pressure measurement coefficient of the reservoir section of the study area in different time periods, which can be seen from the table: Due to the obvious pressure deficit, the pressure difference during cementing is as high as 15 Mpa above.

Through the investigation of the drilling core of the reservoir, it was found that the upper part of the clastic rock reservoir in the study area was subjected to less pressure on the overlying formation, resulting in a loose rock cementation structure, mainly forming a pore-type formation, the lower reservoir was subjected to a large pressure on the overlying formation, the cementation between the rocks was dense, and it was very easy to crack under the action of structural deformation and structural stress, forming a shrinkage joint or structural joint. Therefore, the permeability of the reservoir is better. This paper studies well A-16 in this block. Table 2 shows the statistics of core fractures. 8 of the 50 cores selected for the reservoir section of the well have structural fractures or shrinkage fractures, accounting for 16% of the fractures, and the maximum width of the structural fractures is 0.4 mm, penetration distance of 3 mm. The width of the shrinkage joint reaches 0.3 mm, and the crack width is still large, penetration distance of 1 mm. Therefore, when the cementing pressure difference is operated, the cement slurry can easily enter the reservoir directly through the fracture.

Overview of cementing

The cementing in the study area was mainly a 5-layer casing structure of 20"×13 3/8"× 7"× 5". The tailpipe cementing process is adopted, and the cement injection method is carried out at one time. Reduce the heat release, shrinkage and temperature change of concrete by adding fly ash and slag powder, and improve the crack resistance and durability of concrete. Through water reducers, coagulants and accelerators, it reduces the amount of cement used in concrete, improves fluidity and plasticity, reduces the viscosity of cement paste, delays the setting time of cement paste, and accelerates the setting and strength development of cement paste. The toughness, crack resistance and impact resistance of concrete can be increased by fiber materials, improving the durability and load bearing capacity of concrete. Table 3 shows the tailpipe cementing slurry formulation of a randomly selected well.

In this paper, the preparation of drilling fluid in the research area was investigated, and the reservoir section mainly adopted polysulfonite anti-collapse drilling fluid system, mainly using (wt%): bentonite (4%), caustic soda (0.4%), anti-high temperature filtration loss agent (3%), sealing lubricant (2%), oil-soluble resin (3%), shielding temporary plugging agent type 1 (1%–2%), shielding temporary plugging agent type 2 (1∼). 2%) and aggravators. The isolation liquid system used in cementing is a micro-fierce isolation liquid system, and the main materials are water, suspension agent (1%), retardant (3%) Dispersant (3%), aggravating agent (50%), defoamer (0.5%).

Reservoir rocks with higher porosity, permeability and toughness are more sensitive to the intrusion of fracturing fluid, which can easily cause reservoir damage, while the greater the depth of fracturing fluid intrusion, the more serious the degree of reservoir damage may be, and post-treatment measures such as cleaning, acidizing and sealing of fracturing fluid are conducive to mitigating and repairing the damage to the reservoir.In order to determine the depth of reservoir damage, the cement slurry filtrate was mixed with formation water at a certain volume ratio and placed in a wide-mouthed bottle, and then water bath maintenance was carried out after all the scaling phenomenon, which included granular crystals and flocculated precipitation.

Cementing slurry reservoir damage evaluation method

Influencing factors of reservoir damage

The causes of the damage to the cementing reservoir are often multifaceted, and the severity of the damage is also closely related to the physical properties of the reservoir, the performance of the cement slurry, the downhole environment, etc. The appearance is complex, but in the final analysis, the root cause of the damage is that the solid particles and liquid invading the formation are incompatible with the formation, resulting in damage to the reservoir. At the same time, there is no mud cake attached to the rock wall around the fractures, so the invasion of solid particles of the cement slurry will be larger and deeper than that attached to the mud cake on the well wall. Therefore, the damage depth of the cement slurry reservoir is mainly related to the extension and development of fractures, the damage degree, and the width of fractures, which can’t be studied by indoor core experiments.

In this paper, in order to study the influencing factors of reservoir damage, the cement slurry contact core damage experiment is carried out, and the influencing factors of cementing leakage cement slurry on reservoir damage are analyzed. In the process of cementing leakage, the damage of cement slurry to the reservoir is mainly affected by temperature and pressure differences. In this paper, an experimental study of the damage of cement to the reservoir under temperature and pressure differences will be carried out.

The experimental equipment in this paper adopts a new cement slurry reservoir damage evaluation instrument, and the core selects a natural sandstone core with a diameter of 2.5 cm and a length of 5 cm, and the water of the saturated formation is treated by vacuum, and the formation water is treated with standard brine. The drilling fluid is formulated with KCI polymer drilling fluid, which has a wide range of uses, and the solid phase content and water loss of the drilling fluid are high. The isolation solution is made of water, GYW-201, GYW-301, and barite, the isolation liquid density is 1.75 g/cm3, and the isolation fluid, drilling fluid, and cement slurry are mixed in a ratio of 50:25:25 for rheological experiments, and no chemical reactions such as flocculation and flash condensation occur. Cement paste is prepared from G grade cement, water loss reducing agent, dispersant, retarder and water. Water loss reducing agent improves the fluidity and plasticity of concrete, which contributes to the early hardening and curing of cement, dispersant improves the dispersibility of cement paste, which contributes to the uniform dispersion and early hardening of cement, and retarder slows down the setting time of cement paste. The density is 1.89 g/cm3, the flow rate is 27 cm, and the API water loss is75 ml, the free liquid is less than 0.3%, the sedimentation stability is less than 0.02 g, the viscosity of cement slurry is 44 s and the thickening time is more than 200 min.

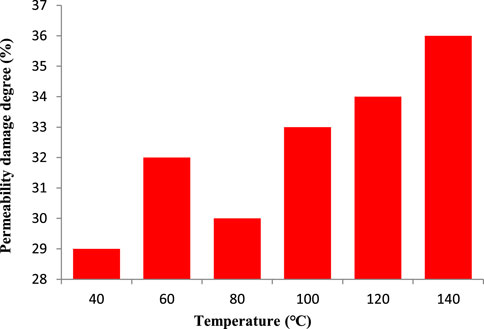

Test process: the surrounding pressure in the experiment is set to 15 Mpa, the core adopts the liquid permeability test method, and the cement slurry with different temperatures, 10 Mpa, 150rpm stirring speed, and fluid speed of about 0.5 m/s damage to the core is 1h, and the temperature is selected 40°C, 60°C, 80°C, 100°C, 120°C, Perform a comparative experiment at 140°C. Figure 1 shows the degree of core permeability damage at different temperatures, as can be seen from the figure: under the condition of maintaining the pressure difference and the shape of the mud cake, with the increase of temperature, the degree of core permeability damage does not change much, but the overall situation is still slowly increasing, the relationship between temperature and the degree of core penetration damage is 0.07%/°C.

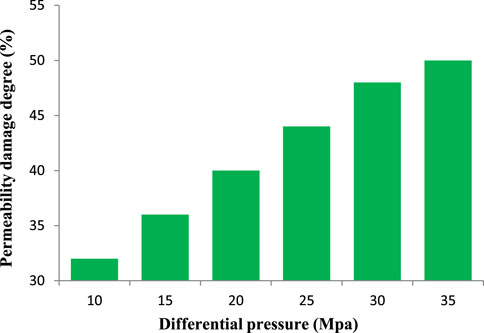

The core temperature was selected for the test to be 100°C, the confining pressure was set to 15Mpa, and the core was measured by liquid permeability test method, and cement slurry with different temperatures, 10 Mpa, 150 rpm stirring speed and fluid speed of about 0.5 m/s was used to damage the core 1 h. Figure 2 shows the damage degree of different pressure differences on core permeability. It can be seen from the figure that the pressure difference increases from 10 Mpa to 35 Mpa and the damage rate of core permeability increases by about 18% while maintaining the same temperature and mud cake shape, the relationship between differential pressure and the degree of core infiltration damage is 0.72%/MPa. The pressure difference has a great impact on the damage to the cement slurry reservoir.

By analyzing the influence of temperature and pressure difference on the damage to the cement slurry reservoir, the temperature effect is small, and the pressure difference is large. Therefore, when establishing the damage evaluation method of the cement slurry reservoir, the influence of pressure difference needs to be considered according to the actual working conditions.

Cementing leakage grout reservoir damage evaluation method

(1) Preparation before the damage experiment: check that all instruments and utensils work properly and close the valves; Put a core containing saturated formation water into a core holder; The upper kettle cover and the lower kettle cover are connected in a sealed way through kettle body threads and connected to a magnetic stirrer; The nitrogen bottle is used to drive the formation water into the kettle body, and the emptying valve is opened until the whole kettle body is filled and the core is soaked in the formation water, and a uniform load is applied to make the core holder clamp the core.

(2) Cement slurry damage experiment process: loading the prepared cement slurry into a container; Open the drain valve to drain the formation water; Nitrogen drives cement slurry to completely replace the residual formation water and fill the upper kettle; Set the temperature and pressure of the upper and lower kettle bodies, manually set the pressure limiting value of the pressure limiting valve of the lower kettle body, and synchronously set the rotating speed of the stirrer; After the experiment started, the cement slurry began to damage the core, and the preset experimental temperature and pressure could be reached in about 15 min. At the same time, the time was started and the filtrate volume was measured. When the damage test reaches 60 min, stop heating and pressing, open the upper-pressure relief valve and discharge the high-pressure cement slurry; Close the pressure-limiting valve of the kettle body, measure the core permeability at constant pressure, finally close the experimental equipment and clean the kettle body and pipelines, and measure the core permeability again after curing the damaged core for 1 day.

Through the study of cementing leakage, the maximum depth of cement slurry damage to the reservoir is the depth of fracture and the depth of filtrate invasion into the porous reservoir. Because of the great difference in fracture development, the reservoir invasion depth under the condition of cementing loss is generally not considered in the evaluation method of reservoir damage.

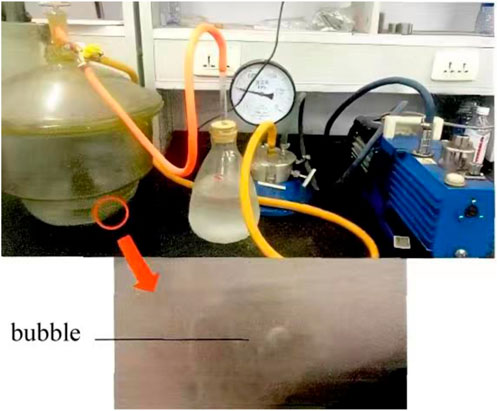

Engineering applications

In this paper, the cores retrieved from a typical clastic reservoir in an oil field in western China are selected, and it is found that the permeability values of the cores are quite different through measurement. In order to ensure the effectiveness of the experiment and the stability of the results, cores with similar permeability were grouped to reduce the variability between core samples, improve the reliability of the experiment and the comparability of the results, and more accurately study the interaction between formation water and rock (Figure 3). Core vacuum saturation with formation water was performed after grouping. In the experimental process of core vacuum saturated formation water, the core samples are put into the vacuum chamber and the air is extracted by the vacuum pump to form a vacuum environment, and the formation water is gradually injected into the core samples by means of injecting water or other liquids until the cores are completely saturated, and the saturation process of the water is more thorough in a vacuum environment, which can more accurately study the interactions between the formation water and the rocks, as shown in Figure 4.

Through the drilling fluid retrieved on-site, re-agitation is carried out before the experiment, heated to the experimental set temperature, and the performance of the drilling fluid is measured by a twelve-speed rotary viscometer to ensure that the drilling fluid is still within the validity period. If it fails, part of the drilling fluid material needs to be supplemented to meet the design requirements. Load the drilling fluid and the isolating fluid material retrieved on-site into an intermediate container for later use.

In the experiment, a well with cementing injection slurry leakage was selected to carry out the experiment, and the well number was A-45, the structure of the well was a three-open straight well, and the last opening was a drill bit with a diameter of 216 mm, and the depth of the well was 5230 m. The well uses a casing suspension cementing with a diameter of 178 mm, and the sealing section is up to 5134 m. The reservoir type of the well is clastic rock, the construction displacement of the cement slurry operation is 20 L/s, and the cement slurry density is 1.9 g/cm3, drilling fluid density of 1.2 g/cm3, isolation fluid density of 1.7 g/cm3, maximum annular pressure of 75 Mpa. The liquid column pressure is 70 Mpa, the annular air pressure consumption is 3.5 Mpa, the formation pore pressure is 52KN, and the maximum pressure difference is 22 Mpa. In the cementing process, due to the excessive pressure difference, the pressure leakage formation appears, the cement slurry is lost by 3 m3, and the core is taken by the proximity well. The development of microcracks in the core was found, and it can be determined that the microcracks were pressed open during cementing and caused leakage.

When evaluating reservoir damage experiments, it is mainly divided into damage experiments of ordinary pore-type core cement slurry and pore-micro-fracture core cement slurry. When ordinary cores are used to simulate larger fractures, the cement slurry causes damage to the porous reservoirs around the fracture due to the inflow into the fractures; When the pore-microcrack core is a man-made microcrack core in the room, the core is used to simulate the damage to the reservoir when the formation microcrack development causes small cement leakage analyses.

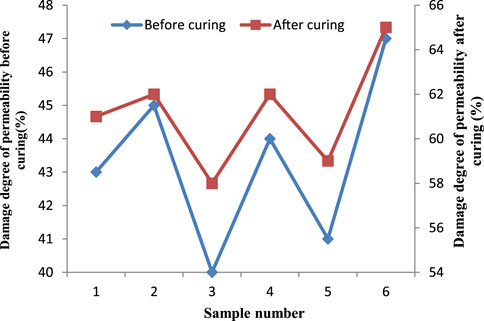

The test of reservoir damage caused by porous core cement slurry during cementing leakage is divided into two stages, that is, permeability damage caused by dynamic solid particles and filtrate invasion of cement injection operation, and permeability damage caused by hydration and consolidation of cement slurry solid particles in reservoir pores. After simulating the dynamic damage evaluation experiment of cement slurry, the core permeability is measured once, and after 1 day of maintenance in the high-temperature curing kettle, the permeability is measured again. During the experiment, the density of cement slurry was measured at 1.7 g/cm3, the temperature was 110°C, and the differential pressure was taken 22 Mpa, the mixing speed of the leaf loading is set to 200 rpm, the dynamic damage time is set to 1 h, and the curing time for 1 day Figure 5 shows the experimental results of the leakage damage of the pore core cement slurry, which can be seen from the figure: when the pressure difference is at 22 Mpa, the permeability damage rate caused by the cement slurry to the core without mud cake attachment is about 43%, and when the damaged core is maintained for 1 day, the damage will be further aggravated, and the penetration damage rate will be reached 61.2%. Therefore, after damaging the core maintenance, the cross-sectional cement slurry filter cake and the solid phase particles that intrude into the core undergo hydration and consolidation, which will lead to the blockage of the pore throat, resulting in its penetration rate decreasing.

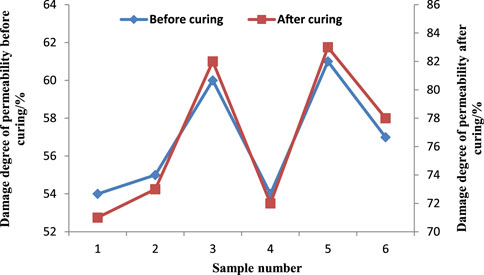

In the experiment on reservoir damage caused by porosity-microcrack cement slurry at the time of cementing leakage, the basic conditions set by the test are consistent with the pore core cement slurry. Figure 6 shows the experimental results of leakage damage of cement slurry with micro-cracks. It can be seen from the figure that the damage of cement slurry to the pore micro-fractured core is very serious, and after 1 day, the core permeability damage caused by cement slurry solidification can be as high as 83%, with an average of 76.5%. Therefore, when choosing a fractured core, you should choose a core with lower penetration, the crack must be the main seepage channel of the low permeability core, and the cement slurry enters the blocked fracture to cause the permeability sharp drop, even above 90%.

Through the evaluation test of cement slurry reservoir damage caused by cementing leakage, it can be concluded that the risk of lost circulation is higher and the formation pressure window is narrow. When low density cement slurry system is used for cementing operation, balanced pressure cementing or controlled pressure cementing technical measures shall be taken to avoid leakage and loss under the condition of limited cementing well conditions and high possibility of leakage, and the cement slurry that needs to be acid-soluble sealed in the later stage.

Conclusion

Oil and gas reservoir protection is affected by exploration, drilling, development, and downhole operations, and is a complex system engineering. In the cementing process, the high-pressure difference between the annular space and the formation, as well as the high filtration loss and high solid phase content of cementing cement slurry, how to reduce the damage of cemented cement slurry to the reservoir is the main research topic. At present, the evaluation of the damage of cement slurry to the reservoir includes the following problems: the evaluation device does not meet the application conditions of deep wells, and there is no evaluation method for the damage of cement slurry to the reservoir when the cement slurry is lost. In this paper, taking the typical clastic rock reservoir of an oilfield in western China as the research object, according to the characteristics of cementing cement slurry on reservoir damage, the main factors affecting reservoir damage are analyzed, and the damage evaluation method of the cement slurry to the reservoir when cementing is lost is established, to provide theoretical data support for the study of reducing the damage of cemented cement slurry to the reservoir. The main research results are.

(1) At present, the drilling depth is deepened, the pressure of the cementing fluid column is increased, the formation pore pressure is deficient in some blocks due to long-term exploitation, and the differential pressure between the well profile and the formation is even up to 30 MPa, but the existing evaluation device cannot achieve such high experimental conditions. In this paper, a cement slurry reservoir damage simulation and evaluation instrument are processed, and a cement slurry reservoir damage simulation device with a real simulation temperature of 200°C, pressure of 60 Mpa, and differential pressure of 35 Mpa is developed after several improvements. By analyzing the influence law of temperature and differential pressure on cement slurry reservoir damage, the temperature has less influence, while the differential pressure has greater influence.

(2) The permeability damage rate caused by the porosity core damaged by cementing leakage cement slurry reservoir is about 43%, and the permeability damage rate will reach 61.2% after 1 day of damage core maintenance; The damage of cement slurry to pore-micro-fissure cores is very serious, and after 1 day of maintenance, the damage to the core permeability caused by cement slurry curing can be as high as 83%, with an average of 76.5%; When the risk of leakage is small, cementing construction operations can use low-density, low-water loss cement slurry system and cement slurry filtrate should be better proportioned with formation clay minerals, formation water and drilling fluid filtrate, etc. When the risk of leakage is large, cementing construction operations use low-density cement slurry, balanced pressure cementing and pressure-controlled cementing, and other technologies to avoid leakage, when cementing conditions are more difficult, the cementing cement slurry system can be used to dissolve the cementing cement slurry system in the later stage.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Acknowledgments

The authors would like to show sincere thanks to those techniques who have contributed to this research.

Conflict of interest

Authors JL, DW, RZ, CL, and QZ were employed by The No 2 Cementing Branch of PetroChina Bohai Drilling Engineering Company.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Abimbola, M., Khan, F., and Khakzad, N. (2016). Risk-based safety analysis of well integrity operations. Saf. Sci. 84, 149–160. doi:10.1016/j.ssci.2015.12.009

Ahad, N. A., Jami, M., and Tyson, S. (2020). A review of experimental studies on sand screen selection for unconsolidated sandstone reservoirs. J. Petroleum Explor. Prod. Technol. 10 (4), 1675–1688. doi:10.1007/s13202-019-00826-y

Al-Jubori, A., Johnston, S., Boyer, C., Lambert, S. W., Bustos, O. A., Pashin, J. C., et al. (2009). Coalbed methane: Clean energy for the world. Oilfield Rev. 21 (2), 4–13.

Ali, J. A., Kalhury, A. M., Sabir, A. N., Ahmed, R. N., Ali, N. H., and Abdullah, A. D. (2020). A state-of-the-art review of the application of nanotechnology in the oil and gas industry with a focus on drilling engineering. J. Petroleum Sci. Eng. 191, 107118. doi:10.1016/j.petrol.2020.107118

Bai, M., Sun, J., Song, K., Li, L., and Qiao, Z. (2015). Well completion and integrity evaluation for CO2 injection wells. Renew. Sustain. Energy Rev. 45, 556–564. doi:10.1016/j.rser.2015.02.022

Barclay, I., Pellenbarg, J., Tettero, F., Pfeiffer, J., Slater, H., Staal, T., et al. (2001). The beginning of the end: A review of abandonment and decommissioning practices. Oilfield Rev. 13 (4), 28–41.

Bu, Y., Du, J., Guo, S., Liu, H., Liang, Y., Su, Z., et al. (2020). Effects of formation water influx on the bonding strength between oil well cement and the formation. Constr. Build. Mater. 251, 118989. doi:10.1016/j.conbuildmat.2020.118989

Cellini, S. R. N., Turner, N., and Ahuja, D. R. (2019). Gainfully employed? Assessing the employment and earnings of for-profit college students using administrative data. J. Hum. Resour. 54 (2), 342–370. doi:10.3368/jhr.54.2.1016.8302r1

Cheng, H., Yang, D., Lu, C., Qin, Q., and Cadasse, D. (2022). Intelligent oil production stratified water injection technology. Wirel. Commun. Mob. Comput. 2022, 1–7. doi:10.1155/2022/3954446

Cui, K. X., Jiang, G. C., Yang, L. L., Deng, Z. Q., and Zhou, L. (2021). Preparation and properties of magnesium oxysulfate cement and its application as lost circulation materials. Petroleum Sci. 18 (5), 1492–1506. doi:10.1016/j.petsci.2021.08.002

Du, X., Fang, H., Wang, S., Xue, B., and Wang, F. (2021). Experimental and practical investigation of the sealing efficiency of cement grouting in tortuous fractures with flowing water. Tunn. Undergr. Space Technol. 108, 103693. doi:10.1016/j.tust.2020.103693

Elkatatny, S. (2018). Application of artificial intelligence techniques to estimate the static Poisson's ratio based on wireline log data. J. Energy Resour. Technol. 140 (7). doi:10.1115/1.4039613

Guo, J., Zheng, Y., Li, W., Li, B., Yuan, B., and Xu, B. (2020). Design and application of well cementing technology based on the precise managed pressure balancing method in narrow pressure window hole sections. Nat. Gas. Ind. B 7 (3), 285–291. doi:10.1016/j.ngib.2019.11.004

Han, J., Cheng, H., Shi, Y., Wang, L., Song, Y., and Zhnag, W. (2016). Connectivity analysis and application of fracture cave carbonate reservoir in Tazhong. Sci. Technol. Eng. 16 (5), 147–152.

Lashof, D. A., and Ahuja, D. R. (2019). Relative contributions of greenhouse gas emissions to global warming. Nature 344 (6266), 529–531. doi:10.1038/344529a0

Li, J., Su, D., Tang, S., Li, Z., Wu, H., Huang, S., et al. (2021). Deformation and damage of cement sheath in gas storage wells under cyclic loading. Energy Sci. Eng. 9 (4), 483–501. doi:10.1002/ese3.869

Lian, W., Li, J., Tao, Q., Liu, G., Wang, W., and Ren, K. (2020). Sealing failure mechanism and control method for cement sheath during hydraulic fracturing. Acs Omega 5 (32), 19978–19994. doi:10.1021/acsomega.0c01326

McLeod, H. O. (1984). Matrix acidizing. J. Petroleum Technol. 36 (12), 2055–2069. doi:10.2118/13752-pa

Prohaska, M., Fruhwirth, R., and Economides, M. J. (1995). Modeling early-time gas migration through cement slurries. SPE Drill. Complet. 10 (03), 178–185. doi:10.2118/27878-pa

Rongchao, C., Ruihe, W., Huilian, C., Yuhuan, B., and Yuanfang, C. (2007). Development and evaluation of a new nanometer-based spacer NMS-I. Petroleum Sci. 4 (1), 49–54. doi:10.1007/bf03186573

Sabins, F. L. (1990). Problems in cementing horizontal wells. J. petroleum Technol. 42 (04), 398–400. doi:10.2118/20005-pa

Sahu, C., Kumar, R., and Sangwai, J. S. (2021). A comprehensive review on well completion operations and artificial lift techniques for methane gas production from natural gas hydrate reservoirs. Energy Fuels 35 (15), 11740–11760. doi:10.1021/acs.energyfuels.1c01437

Sha, F., Lin, C., Li, Z., and Liu, R. (2019). Reinforcement simulation of water-rich and broken rock with Portland cement-based grout. Constr. Build. Mater. 221, 292–300. doi:10.1016/j.conbuildmat.2019.06.094

Shadravan, A., Tarrahi, M., and Amani, M. (2017). Intelligent tool to design drilling, spacer, cement slurry, and fracturing fluids by use of machine-learning algorithms. SPE Drill. Complet. 32 (02), 131–140. doi:10.2118/175238-pa

Singh, J., and Roy, A. K. (2021). Numerical simulation of a conical roofed low-rise building to estimate the wind pressure coefficients. Electron. J. Struct. Eng. 21, 34–45. doi:10.56748/ejse.21289

Tao, S., Tang, D., Xu, H., Li, S., Geng, Y., Zhao, J., et al. (2017). Fluid velocity sensitivity of coal reservoir and its effect on coalbed methane well productivity: A case of baode block, northeastern ordos basin, China. J. Petroleum Sci. Eng. 152, 229–237. doi:10.1016/j.petrol.2017.02.021

Tao, S., Wang, Y. B., Tang, D. Z., Xu, H., and Lv, Y. M. (2012b). Coal permeability damage caused by production pressure difference. Energy Sources, Part A Recovery, Util. Environ. Eff. 34 (19), 1801–1807. doi:10.1080/15567036.2012.692756

Tao, S., Wang, Y., Tang, D., Xu, H., Lv, Y., He, W., et al. (2012a). Dynamic variation effects of coal permeability during the coalbed methane development process in the Qinshui Basin, China. Int. J. Coal Geol. 93, 16–22. doi:10.1016/j.coal.2012.01.006

Wang, M., Cheng, H., Wei, J., Zhang, K., Cadasse, D., and Qin, Q. (2022). High-temperature-resistant, clean, and environmental-friendly fracturing fluid system and performance evaluation of tight sandstone. J. Environ. Public Health 2022, 1–7. doi:10.1155/2022/5833491

Xi, Y., Li, J., Fan, L., Wang, W., and Zha, C. (2021). Mechanism and numerical simulation of a new device of bypass cementing device for controlling casing shear deformation induced by fault slipping. J. Petroleum Sci. Eng. 196, 107820. doi:10.1016/j.petrol.2020.107820

Yang, G., Liu, T., Zhu, H., Zhang, Z., Feng, Y., Leusheva, E., et al. (2022). Heat control effect of phase change microcapsules upon cement slurry applied to hydrate-bearing sediment. Energies 15 (12), 4197. doi:10.3390/en15124197

Yin, B., Li, B., Liu, G., Wang, Z., and Sun, B. (2021). Quantitative risk analysis of offshore well blowout using bayesian network. Saf. Sci. 135, 105080. doi:10.1016/j.ssci.2020.105080

Yuan, C. D., Pu, W. F., Jin, F. Y., Zhang, Y. C., Jia, H., and Zhao, T. H. (2014). Performance of oil-based cement slurry as a selective water-plugging agent in high-temperature and high-salinity cave-fractured carbonate reservoirs. Industrial Eng. Chem. Res. 53 (14), 6137–6149. doi:10.1021/ie4000129

Keywords: reservoir damage, evaluation method, simulation device, cementing, cement slurry

Citation: Li J, Wu D, Zhang R, Li C and Zou Q (2023) Evaluation method for reservoir damage of cementing slurry. Front. Energy Res. 11:1227981. doi: 10.3389/fenrg.2023.1227981

Received: 24 May 2023; Accepted: 28 July 2023;

Published: 08 August 2023.

Edited by:

Xiaojin Zheng, Princeton University, United StatesCopyright © 2023 Li, Wu, Zhang, Li and Zou. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Ji Li, dGFuY2FpNzM5OTE5QDE2My5jb20=

Ji Li

Ji Li Dapeng Wu

Dapeng Wu