- 1School of Digital Arts and Design, Dalian Neusoft University of Information, Dalian, Liaoning, China

- 2Department of Art Convergence, Daejin University, Pocheon-si, Gyeonggi-do, Republic of Korea

- 3Industrial Design, Daejin University, Pocheon-si, Gyeonggi-do, Republic of Korea

Conservation and efficient use of water resources are key to combating global climate change. The development of low-carbon industries plays an important role in promoting the protection of water resources. Based on this, this paper combines the measures of green production and consumption, and uses the concept of low-carbon packaging design to study the impact of water resource protection. First of all, this paper studies the impact of the packaging industry on the ecological environment, and combines the concept of global low-carbon development to implement a low-carbon packaging industry structure. Secondly, adhering to the concept of sustainable development, from green packaging design to green packaging consumption, this paper uses the water resources protection analysis impact model to empirically analyze the impact of the low-carbon packaging industry on water resources protection. The experimental results showed that after the implementation of the low-carbon packaging industry structure model in Zhejiang Province, China, the impact efficiency of the region on water resources was as high as 90%, and the sewage discharge showed a decreasing and stable trend, sewage discharge in the light industrial zone was reduced from 120,000 to 80,000 cubic meters, and two water pollutants, chemical oxygen demand (COD) and biochemical oxygen demand (BOD), were reduced by 4,600 and 2,200 tons respectively. Studies have shown that low-carbon packaging design can reduce carbon emissions from packaging production to a certain extent and reduce pollutant emissions, thereby improving the efficiency of water resource protection and management.

1 Introduction

The acceleration of urbanization has led to increasingly serious problems of water resource pollution and shortage. The packaging industry has always been prone to resource waste and environmental pollution, and the large amount of packaging waste generated by the packaging industry has a serious impact on water resources and the environment. The packaging of traditional plastic products, regardless of the treatment method, would cause serious pollution to the Earth’s environment, with water pollution being the most severe. According to statistics, the amount of packaging waste exceeds one-third of the total amount of household waste. Water resources are the primary condition for maintaining the sustainable development of the Earth’s ecological environment. Water resource protection is a huge project, and the protection of water resources is not just a surface project, but needs to be approached from a fundamental perspective. The transformation of the packaging industry is an inevitable measure to protect water resources. In the context of carbon neutrality, green packaging design has become one of the effective solutions to reduce the pollution caused by the packaging industry. Low carbon production and manufacturing have become consumer demands in the new era, and packaging and manufacturing enterprises are gradually transitioning towards low carbon production.

In the face of the demand for sustainable economic and ecological development in the new era, reducing water resource pollution and promoting sustainable development of water resources require joint efforts from various fields and industries. Water resource protection has always been a focus of attention in the field of ecological environment. Li A conducted an empirical analysis on the energy industry prospect of Xinjiang’s water resources by expanding the energy economic model. He also analyzed the interaction between economic growth, energy development, energy consumption, water demand, and carbon dioxide emissions in Xinjiang, and proposed suggestions for coal development and utilization technology of limited water resources in Xinjiang (Li et al., 2019). Wen Y believed that by setting scenarios for returning farmland to forests and ecological protection, the value of ecosystem services would increase on the basis of ecological compensation standards. This method directly reflected the increasing value of ecosystem services since the implementation of measures to protect the ecological environment. This method was more convincing and feasible than using ecological compensation standards based on regional ecosystem service values determined by land use/cover types, providing a new approach for ecological compensation assessment in the Guanting Reservoir Basin and other areas (Wen et al., 2018). Risha Uaa provided practical solutions to protect the studied aquifers, such as rainwater collection, artificial groundwater recharge, and safe pumping of groundwater, and identified suitable locations for implementing these measures using geographic information systems (Risha and Sturchio, 2018). These literature have certain research significance, but most of them are explored from a theoretical perspective.

Under the continuous impact of the global low carbon economy, the packaging industry is facing the challenge of transformation. The development of green and low carbon packaging materials is in line with the current trend of sustainable development concepts, and green packaging design has attracted more and more attention. Tan J’s study compared the effects of two carbon quota models on corporate profits and total carbon emissions under three scenarios: non-technical emission reduction, technological emission reduction investment, and consumer low carbon preferences. The conclusion indicated that in the case of technology emission reduction investment, the profit of the unit quota model was higher than that of the total quota model; in the context of low carbon consumption preferences, the carbon quota model had no impact on the profits of enterprises (Tan et al., 2019). C Das highlighted some of the practical results of previous research on low carbon inventory control, transportation planning, facility allocation, location selection, and supply chain coordination. These studies would help supply chain practitioners make decisions in the decision-making process, and a comprehensive review of literature on supply chain management scheduling issues was conducted (Das and Jharkharia, 2019). Vilarinho Fernanda reviewed the potential applications of cellulose based nanocomposites in food packaging materials, and highlighted several types of biopolymers and nanocellulose fillers. These materials were used to form biological nanomaterials, and the trend of nanocellulose packaging applications was discussed (Vilarinho et al., 2018). These studies have certain research significance for water resource protection, but most of them have not been analyzed based on actual situations.

Low-carbon packaging design can save various resources such as materials, energy, and water resources, and reduce waste of resources. Therefore, it helps to improve the resource utilization efficiency and economic benefits of enterprises, thereby promoting the development of low-carbon packaging design. The main scientific issues studied in this article are: 1). How to evaluate and quantify the water resource conservation benefits of low-carbon packaging design, and how to evaluate and control the impact of new materials used in low-carbon packaging design on the water environment? 2) How to coordinate and improve the interrelationship between low-carbon packaging design and packaging waste recycling? 3) How to realize and promote the innovation of low-carbon packaging design and manufacturing technology? Combined with the development status of the packaging industry, this paper studies the impact of the traditional packaging industry, and also expounds the relationship between the low-carbon industry and the protection of water resources. Combined with the development model of the low-carbon packaging industry, the impact model of water resource protection is used to analyze the data of the low-carbon packaging industry in Zhejiang Province, China, and its beneficial effects on water resource protection have been confirmed in experiments.

2 Water resource protection measures and impacts

2.1 Packaging industry and water resource protection

2.1.1 Impact of the packaging industry

With the rapid development of the social economy, the acceleration of urbanization, and the development of the logistics and packaging industry, a large amount of packaging waste has caused serious environmental pollution. Currently, packaging materials have the characteristics of short service life, high usage, and difficulty in degradation. These types of packaging materials have caused serious harm to the water resource environment and human body. According to statistics, the fashion packaging industry is the world’s second largest polluter, second only to the petrochemical industry. People’s consumption of the packaging industry is increasing day by day. Currently, the use of packaging materials is the main cause of pollution in the packaging industry, mainly manifested in its impact on air, water resources, soil resources, global climate, and other aspects.

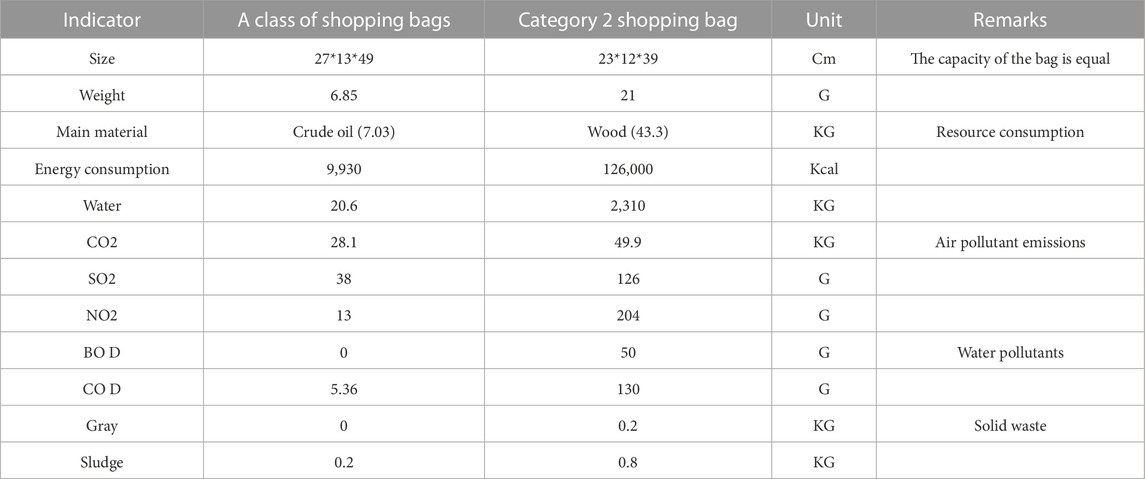

1) The impact on the atmosphere, water resources, and soil: The production of packaging materials also needs to go through several stages such as raw material extraction, production processing, use, recycling, and recycling. Each link may have an impact on the environment. Some packaging materials may release harmful substances into water and soil during the production process, which would remain on Earth for years. Another situation is that when producing a packaging material, although the product does not have an impact on the environment, the resources consumed in the production process, including harmful substances separated from it, and emissions generated from the production of the product, would have a serious impact on the atmosphere, water, and soil. For example, when producing paper products, although paper products are made from trees as raw materials and do not pollute the Earth’s environment, the materials consumed in the production process also have a significant impact on the natural environment. Therefore, the manufacturing process of packaging materials is very important. The impact of packaging materials on the natural environment can be evaluated through their lifecycle. The life cycle assessment of materials refers to the assessment of the entire life cycle of materials, including the acquisition of raw materials, product manufacturing, product use, etc., and their impact on the natural environment. Table 1 shows the life cycle assessment of shopping bag packaging materials with different materials.

Table 1 listed the life cycle assessment tables for two types of shopping bags, with one type referring to high-density polyethylene shopping bags and the second type referring to unbleached kraft paper shopping bags. The table also listed the resources consumed by the two types of shopping bags, including raw material consumption, energy consumption, water, etc. Among them, the use of shopping bags generated atmospheric pollutants such as carbon dioxide (CO2), sulfur dioxide (SO2), nitrogen dioxide (NO2), as well as water quality pollutants such as COD and BOD. Solid waste included ash and sludge. The data in the table showed that the emissions of Class II shopping bags were higher than those of Class I shopping bags in all three pollutants. It can be seen that a type of shopping bag causes less pollution to the natural environment. However, according to the data in the above table, both types of shopping bags do not meet hygiene standards.

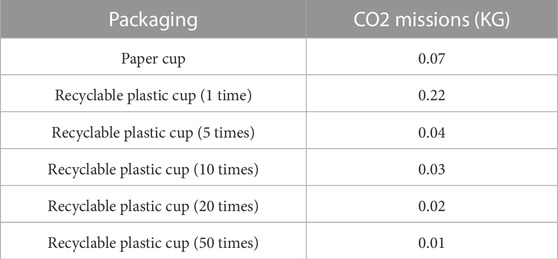

2) The impact of global climate change: Due to the combustion of harmful substances in the production process of packaging, coupled with the deforestation of a large number of forests, this leads to an increase in the carbon dioxide content of the Earth’s atmosphere, a sharp increase in the greenhouse effect, and global warming, resulting in rising sea levels. The chain reaction caused by the unreasonable production of packaging poses immeasurable harm to the Earth. The packaging industry directly or indirectly generates carbon dioxide in processes such as manufacturing, storage, production, use, sales, and disposal. Different packaging materials would have varying degrees of carbon emissions, and the selection of packaging materials can control the carbon emissions of the packaging materials, as shown in Table 2.

From the data in Table 2, it can be seen that different packaging materials affect carbon emissions, and there is a significant difference in carbon emissions between paper cups and recyclable plastic cups. However, as the number of recyclable plastic cups increases, the carbon emissions gradually decrease and are less than those of paper cups. It can be seen that the higher the recycling rate of packaging materials, the greater the positive impact on carbon emissions. This can effectively reduce carbon emissions. The significant consumption of natural resources by manufacturing and the resulting pollution make it necessary to study the potential of environmentally friendly materials, such as recycled aggregates and recycled fibers (Gillani et al., 2023).

2.1.2 Packaging industry is facing transformation

The needs of human production and social progress consume the resources of the Earth. With the development of productivity, the resource and environmental carrying capacity of some countries around the world has exceeded the upper limit, and the ecological and environmental problems brought about by production have become increasingly severe, including climate change, environmental pollution, and scarcity. The pollution impact of packaging on water resources is enormous, with marine pollution being particularly prominent. The plastic waste generated by the packaging industry causes serious pollution to marine water resources. Due to the non degradability of plastic products, both incineration and landfill can cause serious pollution. The plastic foam in the express industry, the plastic lunch boxes and plastic bags in the takeaway industry would produce a huge amount of plastic waste. Plastic products also consume a large amount of petrochemical products during the production and manufacturing process, resulting in a large amount of pollutant emissions. As the awareness of environmental protection gradually deepens in people’s hearts, consumers’ consumption needs are gradually oriented towards green and environmentally friendly products. By vigorously developing the proportion of industries with high levels of clean production and reducing the proportion of industries with “high energy consumption and high pollution,” sustainable economic and ecological development can be achieved (Au Yong and Chin, 2019). How to reduce environmental pollution caused by packaging materials and establish a low carbon production system is an important research direction to solve this problem.

2.2 Low carbon production

2.2.1 Relationship between low carbon production and water resource protection

The problem of waste and pollution of water resources is particularly serious, and the water cycle plays an important role in global climate change. Realizing the safe and efficient use and protection of water resources is an inevitable requirement under the current new situation. Water is an essential but scarce resource. It is estimated that 663 million people worldwide are unable to access sufficient and safe living water, and demand is also increasing. By 2030, the world would have to cope with a 40% water shortage, which would inevitably affect the supply of drinking water, sanitation facilities, and food production (Viljoen and Walt, 2018). At present, the phenomenon of large-scale consumption, waste disposal, and emissions by people around the world to meet their production and living needs is quite prominent. In China, the per capita carbon dioxide emissions have reached the world average level, with a per capita emission of approximately 5 tons. In people’s production and daily life, it is inseparable from the consumption of water resources. When producing cans of packaging materials, 40 L of water need to be consumed. Production and consumption not only consume a large amount of water resources, but also generate a large amount of carbon dioxide. The two have a common effect, which means that low carbon and water resource conservation and protection are interdependent. The impact of climate change on water resources is also uncertain, which increases the difficulty of water resource protection and management. The rational and utilization of water resources can not only promote resource conservation, but also reduce carbon emissions. The low carbon production model can play an important role in promoting water resource planning and utilization, and improving the ecological benefits of water resource system operation. In order to better protect water resources, it is necessary to comprehensively analyze the impact of climate change on water resources, upgrade the industrial structure of industries with high carbon emissions, and carry out low-carbon concept implementation work. Low-carbon production refers to minimizing greenhouse gas emissions and energy consumption in the production process, and adopting energy-saving, efficient and clean production methods to reduce environmental pollution and the impact of climate change. Low-carbon production can be achieved through technological innovation, optimization of production processes, and energy conservation. It can include measures such as reducing the use of fossil energy, adopting renewable energy, and optimizing product design. Low-carbon production is an important strategy for sustainable development, aiming to achieve coordinated economic, social and environmental development. In recent years, China has upgraded its industrial structure, implemented measures such as carbon neutrality and carbon emission reduction, and formulated a green and low carbon industrial development model. The industrial structure has an increasing demand for low carbon resources and scenario energy. The main role of green finance is to promote low carbon development and environmental protection, but it is not the best tool to promote the growth of manufacturing industry and improve the level of industrial structure. Due to the spillover effect of green finance in the process of promoting the development of the manufacturing industry, it is necessary to continuously increase green finance investment for a long time and gradually promote the low carbon and sustainable development of the manufacturing industry (Xu et al., 2023).

Different regions are facing different water resource problems. In China, the distribution of water resources is uneven, the supply-demand contradiction is prominent, and the utilization rate of water resources is not high, which leads to serious water resource waste. The traditional packaging industry has brought serious pollution to people’s living environment. Plastic and other packaging materials with polluting properties have caused a large amount of sewage discharge during the production process. In addition, due to the low recycling rate of packaging materials, the garbage generated by packaging materials has brought serious pollution to groundwater resources. The carbon dioxide greenhouse gases generated during the production process also pose serious obstacles to the protection and management of water resources. Reducing carbon emissions in the packaging industry is an inevitable measure to reduce pollution in the packaging industry. The packaging industry is facing transformation challenges in the context of sustainable development requirements in the new era. Low carbon production refers to a new production method that integrates the core concept of reducing carbon development into the entire process of products, with the main goal of reducing carbon emissions and improving the production process. Building an environmentally friendly society, clean and renewable energy plays a crucial role (Yang et al., 2023). Low carbon production is in line with the concept of sustainable development, and the use of clean energy has a huge promoting effect on promoting low carbon emissions and reducing energy consumption.

2.2.2 System boundary classification of the packaging industry

The packaging industry is a huge industry, covering many different types of packaging and applications. In this industry, different packaging types are designed and produced to meet a variety of different needs and markets. Therefore, the system boundary classification of the packaging industry is also very extensive.

First of all, the system boundaries of the packaging industry can be classified according to the materials used. These materials include paper, plastic, metal, etc.,. For example, paper products include all kinds of cardboard, corrugated cardboard, wrapping paper, etc.,; Plastic products include PET, PE, PP, PS, etc.,; metal products include aluminum, iron, tin, etc.

Secondly, the system boundaries of the packaging industry can be classified according to the purpose of packaging. Food packaging, pharmaceutical packaging, cosmetic packaging, industrial supplies packaging, etc., all belong to different categories. Each application requires specific materials and processes to meet its special needs.

In addition, the system boundaries of the packaging industry can also be classified according to the production process. For example, printing and packaging require printing technology, injection molding packaging requires injection molding technology, and blow molding packaging requires blow molding technology. Different processes will affect the quality, characteristics and sustainability of products. The system boundaries of the packaging industry can also be classified according to product types. There are bagged products, bottled products, boxed products, canned products, etc.,. Each product type requires a specific packaging design and production process.

Finally, the system boundaries of the packaging industry can be classified according to the market area. Daily necessities packaging, industrial supplies packaging, medical supplies packaging, etc., all belong to different categories. These areas cover a variety of different types of applications, each of which requires a specific packaging solution.

In short, the system boundary classification of the packaging industry is very extensive. In product design and production, understanding the characteristics and requirements of each classification can help companies better meet market needs and provide better products and solutions.

2.2.3 Production mode of low carbon packaging materials

Under the background of carbon neutrality and the common goal of carbon emission reduction in modern society, water resources protection and utilization would be oriented to green, intelligent, integrated, coordinated, innovative and other innovative directions. The packaging industry should integrate the concept of green and low carbon into the whole process of packaging production, improve the production mode of manufacturing, and promote carbon emission reduction and carbon cycle, so as to play an effective role in the utilization and protection of water resources. In the dual context of energy economy and environmental protection, the optimal decision to expand the low carbon supply chain is of great significance for the energy manufacturing industry (Wu and Xia, 2023). Reforming the production methods of the packaging industry requires starting from various aspects of the industry. Firstly, it is necessary to choose high-efficiency packaging production equipment and green supporting facilities. Low carbon packaging raw materials need to be selected and advanced production technologies that improve resource utilization are adopted, so as to achieve the goal of reducing the generation of packaging waste and repair products. In the design process of packaging, it is necessary to adhere to the concept of green production and consumption, and design packaging products that meet the requirements of hygiene standards. The safety and stability of the packaging production process should be ensured to prevent the discharge and overflow of harmful pollutants during the production process. The waste of packaging materials should be recycled, and the production process should be adapted to clean energy as much as possible. For the packaging industry, paper and plastic products account for more than half of the raw material usage of packaging materials. The packaging industry needs to improve its production process and reduce the use of packaging materials from the source in order to reduce pollution to the water and atmospheric environment. It is necessary to consider the carbon emission intensity coefficient and economic cost of packaging materials, analyze their data, and make scientific decisions. In terms of packaging design functions, it is necessary to optimize and design low carbon, green, and environmentally friendly packaging products. The design of the production model of low-carbon packaging materials needs to consider the following aspects.

1) Choice of green materials: choose recyclable and biodegradable materials, such as paper, bio-based plastics, etc., to replace traditional plastics, and try to use local or short-distance transportation of raw materials.

2) Optimize the production process: By optimizing the production process, minimize waste, energy consumption and greenhouse gas emissions, such as the use of high-efficiency production equipment, production technology and production management.

3) Reduce the amount of packaging: Under the premise of ensuring product quality, minimize the material and volume of packaging and reduce the impact of packaging waste on the environment.

4) Adopt renewable energy: use renewable energy to drive production equipment, such as solar energy, wind energy, etc., to reduce carbon emissions in the production process.

5) Establish a recycling system: establish a recycling system to recycle and recycle waste packaging materials, extend the life of materials, and reduce waste of resources and environmental pollution.

Through the above measures, the design of a production model of low-carbon packaging materials can achieve energy conservation and emission reduction, reduce carbon emissions, and achieve the goal of sustainable development.

2.3 Investigation on low carbon packaging design for water resource protection

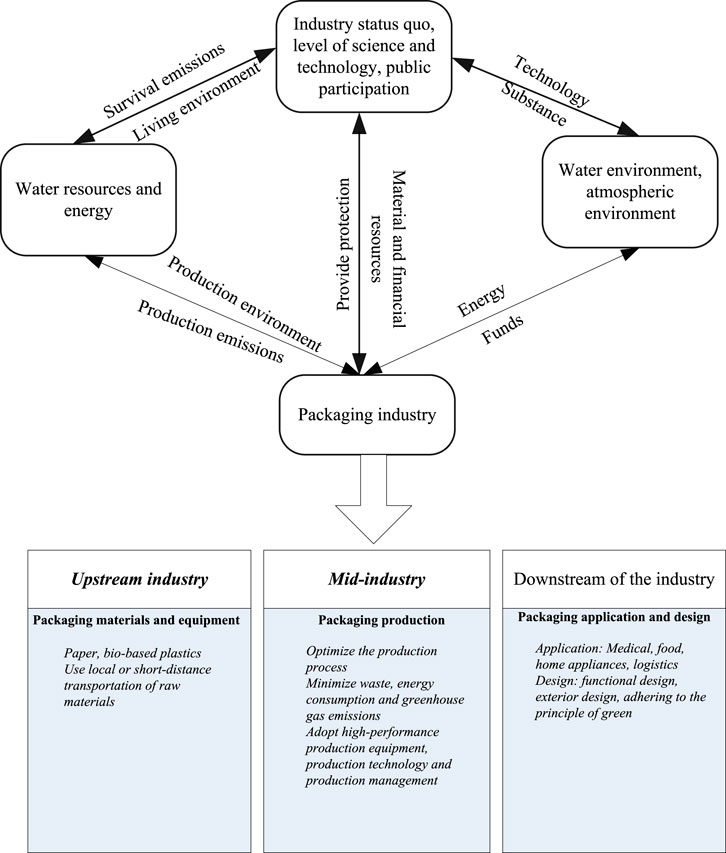

Since the primitive era, the protection and management of water resources have also been considered a very important issue (Gopakumar, 2019). From the mid to late 20th century to the present, people have taken a large number of protective measures, and many water-saving methods and technologies have also emerged, including industrial water conservation, living water conservation, water supply system water conservation, and other water conservation technologies. The utilization, protection, and management of water resources have developed together, which has to some extent improved the utilization rate of water resources. However, with the increasing demand for water resources, the carbon emissions generated by human production and life are also increasing year by year, and the impact on global climate is particularly serious. The problem of water resource shortage is still significant. The shortage of water resources in major cities is severe and long-term. With the intensification of urbanization, water pollution continues to deteriorate (Ondigo et al., 2018). The low carbon production structure has a huge promoting effect on the field of environmental protection. In the process of model research and analysis on the impact of low carbon packaging design and industrial upgrading on water resource environmental protection, it is necessary to link various elements in the model, and combine the common influencing factors of the packaging industry and water resource management departments for research. The impact of low carbon packaging design and industrial structure upgrading on water resource protection can be studied from social, economic, environmental and other indicators. With the positive correlation between environmental performance and environmental protection, the higher the level of environmental performance achieved, the better the environmental quality. The environmental performance of the manufacturing sector can be further improved by promoting environmental management plans (Wang et al., 2022; Xiao et al., 2022), as shown in Figure 1.

FIGURE 1. Research model on the impact of low carbon packaging industry on water resource protection.

Figure 1 shows the relationship between the packaging industry and water resources, water environment, and society. This model indicates that upgrading the industrial structure of the packaging industry needs to be carried out within the allowable range of water resources and environment (Simons, 2020).

Data evaluation refers to the verification, inspection, analysis and evaluation of the collected data to ensure the accuracy, completeness, consistency and reliability of the data. The main methods of data evaluation are as follows.

1) Descriptive statistical analysis: Perform descriptive statistical analysis of the frequency distribution, mean, standard deviation, skewness, kurtosis, etc., of the data in order to understand the distribution of the data and the quality of the data.

2) Logic verification: Verify the correctness and consistency of the data by checking the logical relationship, numerical range, normative, etc., in the data.

3) Sampling and testing: Through sampling and testing of the data, the accuracy and reliability of the data are checked.

4) Data comparison: Check the consistency and accuracy of the data by comparing with other data.

5) Data model inspection: Through the use of data to establish a model, and the model is inspected and verified to check the reliability and validity of the data.

6) Data integrity check: Verify the integrity and validity of the data by checking whether there are missing values, duplicate values, outlier values, etc., in the data.

In summary, the main methods of data evaluation include descriptive statistical analysis, logical verification, sampling detection, data comparison, data model inspection, and data integrity inspection. Depending on the data type and evaluation purpose, different methods can be selected for data evaluation. In the above-mentioned research model on the impact of the low-carbon packaging industry on the protection of water resources, the relationship between economy, environment, resources, etc., is included. You can use mathematical formulas to represent the logical relationship between them, such as the following formula:

In Formula (1),

When

In Formula (2), if

In Formula (3),

From the analysis of Formulas 3, 4, and combined with Formulas 1–3, it can be seen that

3 Data evaluation on the impact of low carbon packaging on water resources

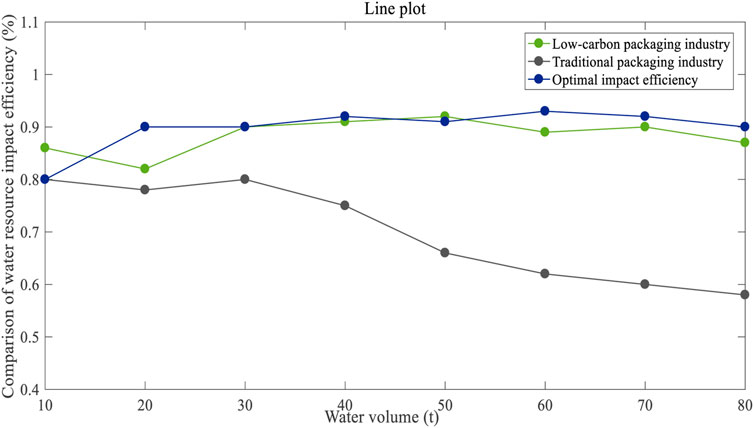

The experimental data sample for this article was selected from a water resource utilization sample in a certain region of China. China has abundant water resources, but its utilization rate is low (Huang et al., 2022). Water resource allocation is unreasonable, and China is a country with developed packaging manufacturing industry, which brings huge economic benefits to the people. The packaging industry has caused serious pollution to water and natural resources due to the discharge of various wastewater and sewage during the production process, as well as the huge carbon emissions generated during the manufacturing process (PKWPP063 and Kim, 2023). To verify the effectiveness of the above model, a water resource environment in a similar region of Zhejiang Province, China was selected as the experimental object. As a major manufacturing province in China, Zhejiang Province has seen rapid development in its packaging industry. In recent years, the packaging industry has successfully transformed under the requirements of sustainable development concepts. The experiments conducted data statistics on the efficiency of the impact of low carbon packaging industry and traditional packaging industry on water resources in the region, as shown in Figure 2.

Figure 2 showed the comparison of low carbon packaging industry and traditional packaging industry, as well as the best impact efficiency indicators. From the results in the figure, it could be seen that the efficiency of the low carbon packaging industry’s impact on water resources was relatively close to the optimal efficiency indicator (Yin et al., 2017). As the amount of water resources increases, the efficiency of the traditional packaging industry’s impact on water resources gradually decreased. The efficiency of the low carbon packaging industry’s impact on water resources was as high as about 90%, which was close to the data of the optimal impact probability efficiency indicator. With the increase of water consumption, when the water consumption reached 80 tons, the efficiency of the impact on water resource protection was still as high as 87%. The efficiency of the traditional packaging industry decreased to 58% at this time. It could be seen that the transformation of the packaging industry towards a low carbon structure had a higher impact efficiency on water resources. The transformation of packaging enterprises could greatly improve the efficiency of their impact on water resources and the environment (Deng et al., 2019).

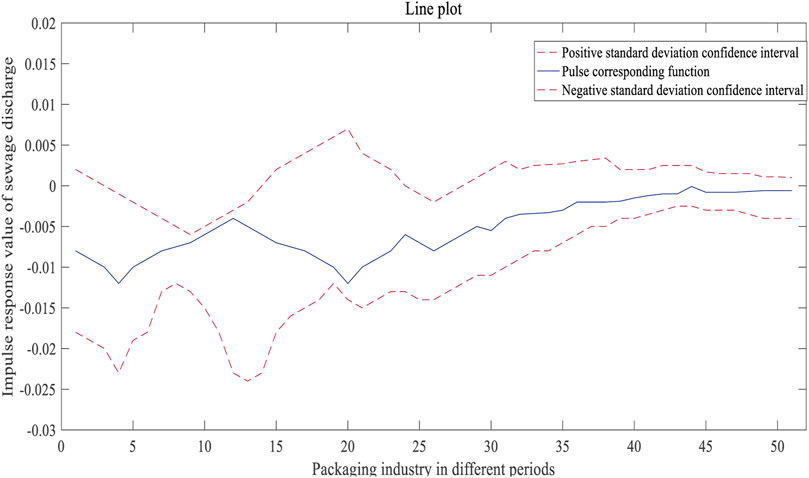

The packaging industry belongs to the tertiary industry, and the implementation of low carbon packaging design in the region also has a certain impact on the sewage discharge in the region (Jabeer, 2020). The packaging industry in the province developed during the transition from the secondary industry to the tertiary industry. At present, industrial upgrading is oriented towards the development of green production and consumption structure (Cao and Qian, 2023). The pulse impact curve of the packaging industry on sewage discharge in the region during a certain period of time also varied, as shown in Figure 3.

Figure 3 showed the pulse curve of the packaging industry’s sewage discharge in different periods in the region of Zhejiang Province. During the 0–10 period, it referred to the packaging industry during the first industrial structure period. During the period of 10–35, it referred to the second industry structure period. 35–50 referred to the current period of the tertiary industry structure. From the impact of packaging production on sewage discharge during different periods in the figure, it could be seen that during the first industry period, due to the incomplete development of the packaging industry and the budding period, sewage discharge showed a downward trend. During the packaging industry period of the secondary industry, the packaging industry was a traditional form of industrial structure and developed rapidly. The pulse curve of sewage discharge accelerated in the early stage, indicating that the sewage discharge generated during the traditional packaging industry period was relatively large. In the mid-term stage, the pulse curve decreased, indicating that the local government took corresponding sewage treatment measures. In the later stage, the amount of sewage discharge increased again. In the period of the tertiary industry structure, the packaging industry already transformed and implemented the concept of green and low carbon (Jeon, 2022). From the positive pulse standard deviation curve in the figure, it could be seen that the sewage discharge during the low carbon package installation industry during the tertiary industry period decreased, and the curve was relatively stable, indicating that the sewage discharge during this period was controlled. It could be concluded that packaging design in a low carbon environment could to some extent reduce sewage emissions.

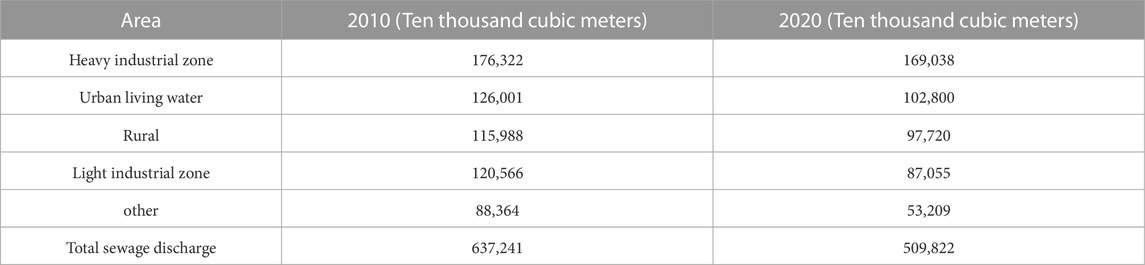

The following was a statistical analysis of the sewage discharge volume and contribution rate of different regions in the province. A comparison was made between the sewage discharge volume before and after the implementation of low carbon industries in the region, as shown in Tables 3, 4.

From the data in Tables 3, 4, it could be seen that the sewage discharge decreased in 2010 and 2020, and the sewage discharge in different regions of the province underwent varying degrees of change since the implementation of low carbon industries. The data in Table 3 showed that the sewage discharge in the light industrial zone decreased from over 120,000 m³ of sewage discharge to over 80,000 m³ of discharge. Compared with heavy industry, urban living water and rural areas, light industry sewage discharge had the largest proportion of decline, while sewage discharge in other areas declined to varying degrees. For example, urban living water consumption decreased from 120,000 m³ to 100,000 m³. The results of Table 4 also showed that the contribution rate of wastewater from light industrial zones decreased by 10%. It could be seen that since the implementation of low carbon industries in the province, the amount of sewage discharge was alleviated to a certain extent, especially in the light industry. This could reflect that the implementation of low carbon packaging industry had a certain promoting effect on reducing sewage discharge and protecting water resources.

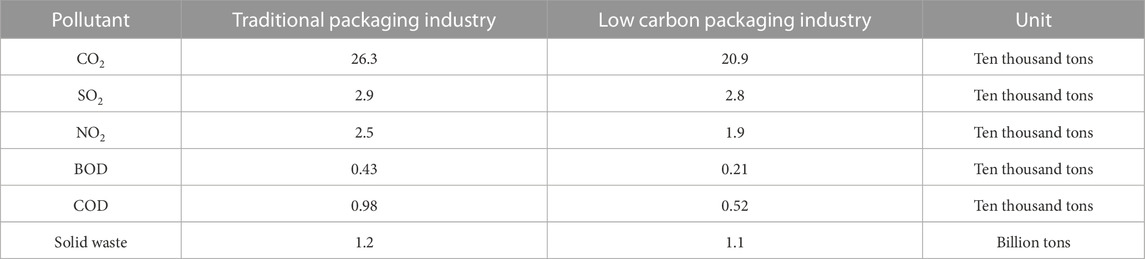

From the data in Table 5, it could be seen that after implementing the low carbon packaging industry in the province, the average value of pollutants brought by packaging materials decreased. The emissions of atmospheric pollutants such as carbon dioxide, sulfur dioxide, and nitrogen dioxide all decreased. Especially, the emission of carbon dioxide decreased by over 60,000 tons, and the water quality pollutants generated by the low carbon packaging industry also decreased. The data showed that the BOD and COD water pollutants decreased by 2,200 tons and 4,600 tons, respectively. The solid waste generated decreased by 0.1 tons. From this data, it could be seen that the low carbon packaging industry had significant effects in water resource protection, thus reducing the emissions of water pollutants and carbon emissions, which could to some extent improve the efficiency of water resource protection and management.

4 Conclusion

The packaging industry is increasingly developing and plays an important role in environmental protection. The environmental problems brought by the traditional packaging industry are becoming increasingly severe. This article studied the impact of the packaging industry on the ecological environment, including its impact on water resources. Reducing carbon emissions was of great significance for water resource protection. Combining the concept of low carbon development, utilizing the low carbon packaging industry model, green production and consumption, and reducing water pollution caused by the packaging industry were of great significance for water environment protection. To analyze the impact of low carbon industries on water resource protection, a model was proposed, which summarized various factors that affected water resource protection. Finally, in the experimental section, taking the current situation of water resource protection and packaging industry in Zhejiang Province, China as an example, the impact of low carbon packaging industry on the water resource protection efficiency and sewage discharge in the region was analyzed. The experimental data showed that compared to the traditional packaging industry, the low carbon packaging industry to some extent reduced sewage emissions, reduced the average total carbon emissions generated by the packaging industry, and improved the efficiency of water resource protection. However, the article also had its shortcomings. In studying the impact model of low-carbon packaging industry on water resource protection, the proposed model would consume a lot of calculation time when calculating water resource data. In the future, the model would continue to be improved to play a better role in the benefits of water resource protection.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding authors.

Author contributions

HY and KH: writing—original draft preparation. RY: editing data curation, supervision. All authors contributed to the article and approved the submitted version.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Au Yong, H. N., and Chin, Y. H. (2019). Cleaner production and sustainability: Stakeholder pressure and the adoption of pollution prevention measures of industrial hazardous waste in Malaysia. IOP Conf. Ser. Earth Environ. Sci. 268 (1), 12027. doi:10.1088/1755-1315/268/1/012027

Cao, Z., and Qian, L. (2023). Crowding effect of institutional openness based on the big data algorithm on the efficiency of new energy technology innovation. Front. Bioeng. Biotechnol. 11, 1178737. doi:10.3389/fbioe.2023.1178737

Das, C., and Jharkharia, S. (2019). Low carbon supply chain: A state-of-the-art literature review. J. Manuf. Technol. Manag. 29 (2), 398–428. doi:10.1108/jmtm-09-2017-0188

Deng, J., Lam, C. S., Wong, M. C., Sin, S. W., and Martins, R. P. (2019). Instantaneous power quality indices detection under frequency deviated environment. IET Sci. Meas. Technol. 13 (8), 1111–1121. doi:10.1049/iet-smt.2018.5123

Gillani, S. T. A., Hu, K., Ali, B., and Elhadi, K. M. (2023). Life cycle impact of concrete incorporating nylon waste and demolition waste. Environ. Sci. Pollut. Res. 30 (17), 50269–50279. doi:10.1007/s11356-023-25905-w

Gopakumar, L. (2019). Temple ponds as a traditional water management option in Kerala, India. Indian J. Environ. Prot. 39 (5), 445–448.

Huang, X., Rudolph, D. L., and Glass, B. (2022). A coupled thermal-hydraulic-mechanical approach to modeling the impact of roadbed frost loading on water main failure. Water Resour. Res. 58 (3), e2021WR030933. doi:10.1029/2021wr030933

Jabeer, N. (2020). BIOFOR biological aerated filter in environmental biology. Acad. J. Environ. Biol. 1 (1), 1–9.

Jeon, M. (2022). Construction of sewage treatment system integrating boosting and bagging algorithms and artificial intelligence. Water Pollut. Prev. Control Proj. 3 (2), 41–49. doi:10.38007/WPPCP.2022.030205

Li, A., Liu, .Y., Chen, G., and Hu, M. (2019). Scenario analysis of low-carbon development of energy industry with restriction of water resource in Xinjiang. J. water Clim. change 10 (2), 263–275. doi:10.2166/wcc.2018.178

Ondigo, D. A., Kavoo, A. M., and Kebwaro, J. (2018). Water resources and management under increasing urban demography: A Kenyan perspective-A review. J. water Resour. Prot. 10 (9), 919–938. doi:10.4236/jwarp.2018.109054

PKWPP063 Kim, J. (2023). Anomaly detection of water pollution prevention ecosystem based on artificial intelligence. Water Pollut. Prev. Control Proj. 4 (2), 1–9. doi:10.38007/WPPCP.2023.040201

Risha, U., and Sturchio, N. (2018). The impact of hydrogeological setting on the protection of coastal groundwater aquifers, El Dabaa, Northwestern Coast, Egypt. Res. J. Environ. Sci. 5 (3), 174–186.

Simons, M. (2020). Marine engineering water environment based on numerical simulation analysis. Front. Ocean Eng. 1 (3), 1–9.

Singh, A. (2020). Influence characteristics of offshore engineering OaGD under environmental impact assessment. Front. Ocean Eng. 1 (3), 36–43. doi:10.38007/FOE.2020.010305

Tan, J., Meng, L. I., and Yan, L. N. (2019). Comparative study on optimum production decision of enterprise under the carbon quota mechanism based on historical emissions (an environmental perspective). J. Environ. Prot. Ecol. 20 (3), 1544–1553.

Vilarinho, F., Sanches Silva, A., Vaz, M. F., and Farinha, J. P. (2018). Nanocellulose in green food packaging. Crit. Rev. food Sci. Nutr. 58 (9), 1526–1537. doi:10.1080/10408398.2016.1270254

Viljoen, G., and Walt, K. (2018). Suid-Afrika se waterkrisis - 'n Interdissiplinêre benadering. Tydskrift Vir. Geesteswet. 58 (3), 483–500. doi:10.17159/2224-7912/2018/v58n3a3

Wang, Y., Wang, Y., and Yang, J. (2022). Forest ecological security rating and its spatio-temporal evolution analysis in the Yellow River Basin. Acta Ecol. Sin. 42 (6), 2112–2121. doi:10.5846/stxb202103180728

Wen, Y., Liu, G., and Rui, W. (2018). Eco-compensati on in guanting Reservoir watershed based on spatiotemporal variations of water yield and purification services. J. Resour. Ecol. 9 (4), 416–425. doi:10.5814/j.issn.1674-764x.2018.04.009

Wu, Q., and Xia, J. (2023). Differential decision of low-carbon supply chain based on market preferences with fairness concerns. J. Industrial Manag. Optim. 19 (6), 4064–4094. doi:10.3934/jimo.2022122

Xiao, G., Wang, T., Chen, X., and Zhou, L. (2022). Evaluation of ship pollutant emissions in the ports of los angeles and long beach. J. Mar. Sci. Eng. 10 (9), 1206. doi:10.3390/jmse10091206

Xu, L., Liu, Y., Zhang, B., and Xiang, B. (2023). Study on the impact of green finance on low carbon development of manufacturing industry from the perspective of multidimensional space: Evidence from China. Environ. Sci. Pollut. Res. 30 (17), 50772–50782. doi:10.1007/s11356-023-25690-6

Yang, X., Xie, Z., Lu, X., Wei, M., Tan, X., Ling, H., et al. (2023). Research on the utilization of ultra-long carbon nanotubes in lithium-ion batteries based on an environment-friendly society. Environ. Sci. Pollut. Res. 30 (19), 56003–56015. doi:10.1007/s11356-023-26309-6

Keywords: water resource protection, packaging design, low carbon industry, carbon emissions, sustainable development

Citation: Yang H, Hong K and Yu R (2023) Investigation on the impact of low carbon packaging design on water resource protection. Front. Energy Res. 11:1224724. doi: 10.3389/fenrg.2023.1224724

Received: 18 May 2023; Accepted: 06 July 2023;

Published: 26 July 2023.

Edited by:

Amrit Mukherjee, University of South Bohemia in České Budějovice, CzechiaReviewed by:

Pei Yin, University of Shanghai for Science and Technology, ChinaJun Zheng, Baotou Teachers’ College, China

Copyright © 2023 Yang, Hong and Yu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Haojie Yang, eWFuZ2hhb2ppZUBuZXVzb2Z0LmVkdS5jbg==; Kyungmin Hong, bWluaW1pbkBkYWVqaW4uYWMua3I=

Haojie Yang

Haojie Yang Kyungmin Hong3*

Kyungmin Hong3*