- 1Sino-French Institute of Nuclear Engineering and Technology, Sun Yat-Sen University, Zhuhai, China

- 2College of Engineering, University of Wisconsin-Madison, Madison, WI, United States

Micro and Small Modular Reactor (MSMR) is an emerging energy technology that meets the requirements of market demand, safety, efficiency, and sustainability. This paper summarizes the advantages, application scenarios, and advanced technologies to support MSMR. Now that the energy market is more flexible and the requirements are more complex, while MSMR can meet the market demand and has a lower cost compared with other clean energies such as wind and solar photovoltaic. The United States is vigorously developing MSMRs into residential energy markets. The MSMR developed around the world has more than three generations of safety characteristics that have adopted passive safety features. MSMR can be manufactured in the factory which reduces construction schedule, cost, and waste. The nuclear fuel supply chain for MSMR is complete and perfect, including the front end and back end. An increasing number of advanced technologies support the development of MSMR, including advanced materials (TRISO fuel and accident-tolerance fuel), advanced control knowledges (DI&C, cybersecurity, and AI), and an advanced computational platform (MOOSE framework).

1 Why micro/small modular reactors are good?

1.1 Meet the flexible market demand

Clean energy is a crucial global sustainability challenge (Li et al., 2023). There have been rapid innovations and cost reductions in clean energy sources in recent decades. It has been rapid technological and economic progress in solar photovoltaics, wind power, hydropower, dispatchable geothermal energy (deep and shallow), and biomass. Nuclear energy is one of the clean energy, which can provide individual energy and combine with other energy sources. Using nuclear energy can create a cleaner world and a stronger global economy (Tauseef Hassan et al., 2023). During the IAEA’s International Conference on Climate Change and Nuclear Power in October 2019, participants expressed the opinion that SMRs (Small Modular Reactors), which can generate up to 300 MWe of electricity (IAEA, 2018), would be the most efficient option to replace aging fossil fuel-powered plants. Globally, SMRs are being developed for recent deployment shortly (Markets, 2022). The SMRs include light water reactors, liquid metal reactors, and molten salt reactors (Yinrong, 2012; Rowinski et al., 2015).

Renewable energies such as wind and solar photovoltaic play a crucial role in the decarburization of the electricity sector while meeting the growing demand for energy. This can be achieved by expanding the deployment of renewable energy systems. However, the increase in the share of renewable energy tends to affect the operation of the grid. Photovoltaic solar panels produce energy that fluctuates with time, latitude, and season. Seasonal and daily weather conditions also influence wind energy. Because of their low capacity and low capital intensity, SMR is an excellent alternative to the replacement of fossil fuels and the retirement of large Nuclear Power Plants (NPP). Together with renewable energy, these reactors play an integral role in mitigating the negative impacts of conventional energy sources. In addition, the SMR design has a load-tracking function that allows the output power to be adjusted according to fluctuations in electricity demand. The SMR can operate flexibly in electrical systems with variable residual load, especially for the pursuit of wide penetration of variable renewable energies (wind, solar photovoltaic) in certain regions. Integrated hybrid energy systems involving applications such as SMR coupled with non-electric hydrogen power generation, synthetic fuels, and seawater desalination will also be supported for the deployment of variable renewable energies. These integrated systems can improve the reliability and resilience of overall horizontal energy systems, making them an economically attractive option (Markets, 2022).

There are several potential advantages to using SMRs, including the wider variety of users, the applications with flexible power generation, the ability to replace aging fossil fuel-fired power plants, and the potential for combining nuclear energy with alternative energy sources in synergetic hybrid energy systems. In a world where intermittent renewable energy is increasing in share across all continents, SMRs are seen as promising for supplying both baseload and flexible power. SMRs can be integrated with renewable resources into a single energy system coupled with smart grids. Hence, SMRs can run at a high capacity with the flexibility of generation rates (Markets, 2022).

As a subset of SMRs, microreactors range from 1 MWe to 20 MWe in capacity (Owusu et al., 2018; Hussein, 2020; McGinnis, 2020). The potential applications include supplies of competitive electricity and heat for remote and off-grid communities as well as industrial locations (Zhang et al., 2020; Zhang et al., 2022a), Microreactors have the potential to provide economic and social value in new markets. They can be used as a reliable energy source, do not pollute in normal operation, can operate for years without refueling, and are less dependent on energy imports. In addition, their value proposition includes the creation of new businesses and services that add economic and social value to communities (Ingersoll and Greenspan, 2021). For example, microreactors can help develop resources for economic development (such as mining, seaports, and regional centers). New applications can be developed to promote the deployment of microreactors through new community services and capabilities and improve the reliability of basic services such as electricity, heating, and clean water. At the same time, it also creates opportunities for entrepreneurship, including new small and medium-sized enterprises, and finally, ultimately forms the public’s attitude towards the use of nuclear energy (Shropshire et al., 2021).

1.2 Economic analysis

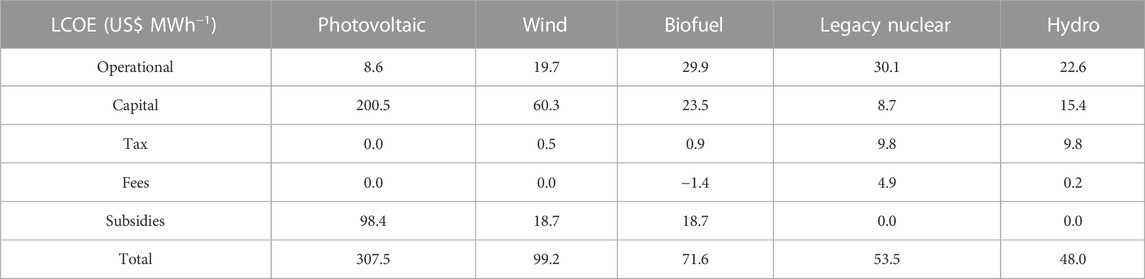

In order to demonstrate the feasibility and future markets of advanced nuclear energy systems, the economic analysis is carried out compared with other renewable energy sources, including photovoltaic, wind, biofuel and hydro.

The levelised cost of electricity (LCOE) is a traditional method to evaluate and list the dispatchable power generation facilities based on the annual production costs (Khatib and Difiglio, 2016). It includes operational, capital, tax, fees and subsidies. Table 1 shows the LCOE by photovoltaic, wind, biofuel, nuclear and hydro acquired from Energikommissionen (2016) and IEA (2015) (Hong et al., 2018). As can be seen from Table 1, the LCOE of photovoltaic, wind, biofuel is higher than that of nuclear power, while the LCOE of hydro is slightly lower than that of nuclear power. According to NuScale (Johnson, 2020) and the Energy Impact Centre (NUCLEAR, 2020), the cost of SMR is less than half the cost of energy from big new nuclear plants. Therefore, compared with other renewable energy sources, SMR is very competitive in terms of cost.

1.3 Internal safety

At present, most of the SMRs developed around the world have more than three generations of safety characteristics. The pressurized water and air-cooled reactor are the most mature, the main type of reactor developed and designed (Xijia et al., 2019). Most of SMRs designs have adopted passive safety features that minimize the risk of catastrophic accidents (Michaelson and Jiang, 2021). In this paper, the mPower and KP-FHR of the United States and the KLT-40S of Russia are examples to analyze SMR technology’s safety in terms of structure, technical objectives, etc.

The mPower SMR adopts an integrated design where the reactor core, the steam generator, the pressurizer, and the associated piping are contained in a reactor module (Prasad et al., 2015). Its design feature is a passively safe advanced light water reactor with an underground containment structure (Liang et al., 2022). The control rod drive mechanism is completely immersed in the primary circuit to avoid the control rod pop-rod accident. The core adopts an insoluble boron design. The control rod is used for reactivity control, and the passive safety system is used to realize the decay heat extraction after the accident.

The KLT-40S SMR is based on mature pressurized water reactor technology, which was developed when considering cost, safety, and regulatory issues (Hidayatullah et al., 2015; Nian and Zhong, 2020). It can achieve emergency shutdown cooling, core emergency cooling, cavity flooding, containment emergency depressurization, and other functions through the passive safety system under accident conditions (Xijia et al., 2019). The protective enclosure is added as a safety barrier, which can timely monitor and eliminate the volatile gas that may leak, and completely eliminate the emergency evacuation problem of accidents beyond the design basis.

Kairos Power is developing Kairos Power Fluorine Salt Cooled High Temperature Reactor (KP-FHR) as an economically attractive passive safety advanced reactor. KP-FHR design uses Three-structure isotropic (TRISO) Accident-Tolerant Fuel (ATF) in low pressure LiF/BeF2 cooling salt (Flibe). TRISO fuel is a high-temperature graphite-based coated particulate fuel developed for high-temperature gas reactors, which can withstand fuel temperatures of more than 1,600°C. The fluorinated molten salt mixture Flibe has stable chemical properties, low steam pressure, and boiling point of 1,430°C, which is significantly lower than the acceptable fuel temperature (Blandford et al., 2020). In order to achieve passive safety, the design of the main heat exchange system allows natural circulation after shutdown, and the heat exchange in the lower corner area provides part of the driving force. This lower corner area is an annulus surrounded by the core barrel and reactor vessel (Rubio et al., 2022).

In a word, by taking the mature SMRs technology of major international nuclear powers as examples, the paper proves that SMRs have strict safety regulations, which are higher than the technical safety objectives of the third-generation nuclear power standard, indicating that SMRs technology is safe (Budnitz et al., 2018; Xijia et al., 2019).

1.4 Manufactured in the factory (economic, quality, construction time)

In theory, SMRs should be an ideal candidate for modularity because of their small size, and they will also produce greater production volumes (Lloyd et al., 2021). Many SMRs vendors incorporate some form of modular construction into their designs regardless of reactor technology: NuScale SMRs, even if the structure is not modular, use many power modules (NuScale, 2020); Rolls-Royce SMR and land Energy Integrated molten salt reactors use modular design and construction methods (Energy, 2020; Rolls-RoyceUK Small Modular Reactor, 2020).

Many of the profits of modularity are due to higher production conditions in factories. Efficient construction is possible in plants built and equipped to simplify module manufacturing, particularly effective in reducing construction schedule, cost, and waste. The detailed benefits of produced in the factory are as follows (Lyons, 2020):

a) Shorter construction schedule: In module factories, there are better working conditions which can increase productivity. Tasks are removed from critical paths, and construction and assembly tasks can be performed simultaneously, reducing total field time. Depending on the project, build time can be reduced by 25%–50% (Mignacca et al., 2018).

b) Lower construction costs: The combined effect of higher factory productivity and lower labor productivity can reduce the construction costs of modular products. Depending on the project, construction costs can be reduced by 10%–20% (Mignacca et al., 2018).

c) Better repeatability and study: Modular design relies on the standardization of design and production processes, which aims to reuse components and achieve the reduction of learning-related cost and time in production series.

d) Improve constructability and quality: Performing construction processes improves the quality and efficiency of the construction process, including concrete placement, welding, and steel cutting in a highly controlled factory environment. Modular design can also reduce the number of components, interfaces and workers on site, and improve access and construction safety (Choi and Song, 2014).

e) Better labor availability: Modularity can solve the problem of not having skilled workers in remote areas. Because most workers remain at the plant, only skeleton workers are needed for on-site installation and assembly (Carriker and Langar, 2014).

f) Reduced environmental impact: Modularity reduces the project’s specific carbon emissions, greenhouse gas emissions, energy use, and water consumption (Lawson et al., 2012).

1.5 Supply chain

One of the problems faced by SMRs operators is ensuring the reliable supply of nuclear fuel (Rothwell, 2010). A well-functioning international nuclear fuel market is increasingly important for many member states. SMR may use traditional methods to build new reactors, but some aspects are more emphasized (SMR RF MCO Working Group, 2019).

The nuclear fuel supply chain, known as the nuclear fuel cycle, began with any other industrial enterprise extracting resources from the ground. However, with the progress of the fuel cycle, it has become more and more complex, and the risk of nuclear fuel supply cannot be ignored (Crawford and Greenspan, 2021). This cycle begins with uranium mining and ends with nuclear waste disposal. With the reprocessing of spent fuel as an option for nuclear energy, these stages form a real cycle (Zohuri and Fathi, 2015). The complete fuel cycle circuit can be divided into two steps, which are divided into the following categories:

I Front end: The front end of the nuclear fuel cycle refers to the part of the nuclear fuel cycle before the nuclear reactor generates electricity. It mainly consists of four stages: uranium mining and pretreatment, uranium conversion, uranium enrichment, and fuel manufacturing (Ruo-meng et al., 2021).

II Back end: The back end of the nuclear fuel includes spent fuel storage, reprocessing spent fuel, managing radioactive waste, and sustainability of the nuclear fuel cycle which is the process of nuclear waste disposal after it has been burned in a reactor (IAEA; Wattal, 2017).

All steps of the nuclear fuel cycle produce radioactive waste. Nuclear waste is divided into four categories based on the level of radioactivity, including very low level radioactive waste (VLLW), low level radioactive waste (LLW), intermediate level radioactive waste (ILW), and high level waste (HLW) (Wisnubroto et al., 2021). At every stage of the fuel cycle, there are mature technologies for the safe disposal of radioactive waste. For LLW and ILW, most of these technologies are being implemented. For HLW, some countries, such as French and China, need to carry out sufficient research of storage place before establishing geological storage (Wang et al., 2018; Bonnet et al., 2022); Other countries, such as the United States, have experienced political delays (Zohuri and Fathi, 2015).

Unlike other industrial wastes, the radioactivity of all nuclear wastes will decrease over time. Each radionuclide contained in waste has a half-life, and the radionuclides with a long half-life are often α and β Emitters, making them easier to handle, while those radionuclides with short half-life tend to emit more penetrating gamma rays. Finally, all radioactive waste decays into non-radioactive elements. The stronger the radioactivity of the isotope, the faster the decay (Zohuri and Fathi, 2015).

Radioactive waste management aims to treat these wastes in a way that protects human health and the environment now and in the future without causing undue burden to future generations (Natarajan et al., 2020; Gonçalves et al., 2022). To achieve this, almost all wastes have been controlled and managed, although some need to be buried deeply and permanently. Wastes from nuclear power generation are not allowed to cause harmful pollution. All toxic waste needs safe treatment, not only radioactive waste. In countries with nuclear power, radioactive waste accounts for less than 1% of the total industrial toxic waste (the remaining toxic waste is in a dangerous state indefinitely) (Zohuri and Fathi, 2015).

2 Application scenarios

The United States is vigorously developing SMRs into residential energy markets. The United States Department of Defense has long recognized that advanced SMRs can provide transformational value to the nation’s economic, energy security and environmental prospects. As a result, the Department of Defense has provided substantial support for the development of light water-cooled SMRs (Rowinski et al., 2015; Mays et al., 2021), which are under review for licensing by the Nuclear Regulatory Commission (NRC) and could be deployed in the late 2020s to early 2030s. The Department is also interested in the development of SMRs that use non-traditional coolants, such as liquid metals, salts and gases, to achieve potential safety, operational and economic benefits (Energy).

In order to accelerate the availability of United States SMR technology in domestic and international markets, building on the success of the SMR Licensing Technology Support (LTS) program (Office of Nuclear Energy, 2022), the Advanced SMR R&D Program was launched in the fiscal year 2019 to support research, development and deployment activities. Significant technical development and licensing risks are still involved in bringing advanced SMR designs to market. Achieving domestic deployment of SMRs in the late 2020s or early 2030s will require government support. Through this program, the Department of Defense partnered with NuScale Power and Utah Associated Municipal Power Systems (UAMPS) to demonstrate best-in-class reactor technology at the Idaho National Laboratory within this decade. Through these efforts, the Department will address many technical and licensing issues of SMRs and provide extensive benefits to other domestic reactor developers. It would not only promote United States energy independence, energy dominance, and grid resilience, but also ensure a clean, reliable basic load power supply in the future.

3 Advanced technologies to support the micro and small modular reactor

3.1 Advanced materials

3.1.1 TRISO fuel

TRISO fuel particles are known as the strongest nuclear fuel at present (Brown, 2020). TRISO fuel has been used in high-temperature gas-cooled reactors and has been proposed for many other nuclear applications, such as light water reactors, SMRs and molten salt reactors (Brown et al., 2013; Trellue et al., 2019). TRISO was first developed from uranium dioxide fuel in the United States and the United Kingdom in the 1960s. TRISO particles consist of spherical fuel nuclei, usually UCO or UO2, and are covered by graphite, pyrolytic carbon, and SiC layers to prevent the release of radioactive fission products (Energy, 2019; Golesorkhi et al., 2023; Griesbach et al., 2023). These particles are very small (about the size of poppy seeds) and very solid. They can be made into cylindrical particles or billiard ball-sized spheres, called “pebbles”, which are used for high-temperature gas or molten salt cooling reactors. TRISO fuel is structurally more resistant to these factors which have the greatest impact on fuel performance than traditional reactors, including fuel neutron irradiation, corrosion, oxidation and high temperature. With three layers of coating, each particle can act as its own containment system. This allows them to retain fission products under all reactor conditions (Energy, 2019).

In short, TRISO particles cannot be melted in the reactor and can withstand extreme temperatures which exceed far the current nuclear fuel threshold.

3.1.2 Accident-tolerance fuel

In 2011, since the damage to the Fukushima Daiichi NPP due to the earthquake and tsunami in Japan, the enhancement of accident tolerance for light water reactors became the subject of serious discussions (Deng et al., 2022; Wang et al., 2022). Following the guidelines of congress, the Department of Energy’s Office of Nuclear Energy has launched the development of ATF as a main component of the fuel cycle research and development campaign on advanced fuels (Bragg-Sitton, 2014). ATFs are divided into two categories, fuel pellets (Such as U3Si2, UN, UC, UO2-SiC, and Annular Fuel) and cladding materials (Such as Zirconium coated claddings, SiC/SiC sandwich cladding design and FeCrAl cladding).

The design requirements of ATF include tolerating the loss of active core cooling for a long time, higher temperatures than the current fuel system, and maintaining or improving fuel performance during normal operation (Bragg-Sitton, 2014). Because of these excellent characteristics, when it is applied to SMRs, it can greatly improve the competitiveness of SMRs. For example, as mentioned earlier, SMR is a risk-free and robust reactor concept design. Due to the safety of ATF in accident conditions, when it is used as fuel for SMRs, it can significantly enhance the safety of SMRs. The advantages of ATF that benefit to SMRs design include:

a) Backward compatibility: Compatible with existing fuel processing equipment, fuel rod or assembly geometry, and co-resident fuels in existing and future light water reactors. Maintaining or increasing the opportunities for non-invasive and intrusive examinations and inspections.

b) Operation: Maintenance or extension of the plant operation cycle, reactor power output, and reactor control; Fuel system concepts that seek regulatory approval and need to demonstrate reliability under normal operation and transients.

c) Safety: Under normal, operational transients, design baseline accident (DBA) conditions, and design extension conditions (DEC), can meet or exceed the current fuel system performance (Bischoff et al., 2018; Jiao et al., 2022).

d) Front-end of the nuclear fuel cycle: Comply with regulations and policies for fuel manufacturing facilities and operating plants with respect to technology, regulations, equipment and fuel performance.

e) The back end of the nuclear fuel cycle: No degradation of fuel transport, storage (wet and dry) or storage performance (assuming a single fuel cycle); Possible use in closed fuel cycles should be considered (NEA, 2018).

The desired ATF attributes highlight the fuel system’s performance, both fuel and cladding (but not fuel assembly structures), under normal and hypothetical accident conditions (Brachet et al., 2014; Bischoff et al., 2018). Key attributes of fuel systems that demonstrate increased accident tolerance include reducing steam reaction kinetics (reaction rate and heat of reaction), reducing the rate of hydrogen generation (or other combustible gas generation), and reducing initial and residual stored energy in the core (Shah et al., 2018; Yang et al., 2022). The desired properties should be achieved while maintaining or improving the thermal-mechanical properties of the cladding and fuel, the thermal power properties of the fuel rods, the fuel cladding interactions and the fission products properties. A set of qualitative guidelines and indicators derived from these desired properties in all fuel performance states (as opposed to specific quantified goals for each characteristic) will help optimize and prioritize candidate fuel system designs. It should also be noted that the fuel assembly’s thermal-hydraulic and mechanical properties should be maintained or improved when the ATF is introduced.

In order to be considered accident tolerance, the fuel system must also provide an improved response to expected operational events DBAs (such as reactivity induced accidents (Chun et al., 2015), coolant loss accidents (Kane et al., 2023), or plant outages and some of the conditions described by DEC, noting that the concept may not exhibit improved performance in all cases (NEA, 2018).

For applying the ATFs to the SMR, a lot of studies have been carried out using the ATFs to replace the traditional fuels in the SMRs. These studies provide reference for evaluating the feasibility and advantages of ATF application in SMR. Liang and Xiao designed a new ATF with FeCrAl cladding and particle-type burnable poisons to realize the long-term reactivity control of the KLT-40S (Tiang and Xiao, 2021). Their research proved that the proposed ATF design implemented in the KLT-40S can prevent the emergency situation of complete withdrawal of all control rods. Using TRISO fuel embedded in SiC matrix, a neutron model of natural cycle integrated pressurized water reactor (IPWR) that can deploy SMR in the near future is established by Qasim Awan et al. (2018). Yu et al. (2021) used ATFs to replace the traditional fuel rods in NuScale from the point of view of neutron and thermal power to evaluate the reliability of ATFs (U3Si5, U3Si2, FeCrAl and SiC) loaded NuScale in rod ejection accidents. The results show that ATF material can improve the safety of NuScale reactor. Liang et al. (2022) used the combination of U3Si2 and silicon carbide cladding (U3Si2-SiC) to compare it with other fuel combinations and three different types of silicon carbide cladding in a single fuel assembly and the whole core of mPower. The results show that the whole core life of U3Si2-SiC can be increased by 3.1%. From the perspective of neutronics, the whole core life of U3Si2-SiC can be used for SMR. The neutron penalty of different types of silicon carbide cladding is not significant in SMR. In general, it is feasible to use silicon carbide cladding ATF combination for mPower SMR.

3.2 Advanced control knowledges (DI&C, cybersecurity, AI)

Due to the shortcomings of analog systems such as signal drift, high maintenance costs, obsolescence and lack of industrial suppliers, the nuclear field has turned to digital instrumentation and control (DI&C), using integrated circuits and modern microcontrollers (Systems, 1997; Bao et al., 2023). Digital upgrading and NPP modernization provide the most important way to improve the performance of SMRs and reduce the cost of SMRs (Zhang et al., 2022b). As the “central nervous system” of NPP, DI&C system can make the control of SMRs more convenient compared with the analog model, such as upgrading control functions, reducing the number of components that make up the system, designing circuits capable of complex logic judgment, and realizing easy-to-understand graphical information display of process parameters, pump and valve operation status (JNES, 2007; Guo et al., 2018; Upadhyaya et al., 2021).

Although these digital DI&C systems applied in SMRs have many advantages, cybersecurity challenges follow (Zhang et al., 2021; Tian et al., 2022). Computer code and digital systems widely exist in SMRs’ design, licensing and operation. Due to the high cost of SMRs s and the radioactivity of their fuel, it is inevitable to evaluate the operation and accident conditions through simulation scenarios. The computer reactor model has been developed to simulate the behavior of SMRs s, providing insights for improving safety (Silva, 2015). In this case, the simulation environment specially designed for the systematic investigation of the behavior of cybersecurity digital systems can support the development of computer security measures, thus improving nuclear security (Busquim e Silva et al., 2021). A feasible network security risk assessment method for the power transmission and distribution system of NPP has been proposed, which is applied to the actual DI&C system. This is of great help to the power transmission and distribution system of SMRs (Tian et al., 2022).

The decision-making process in the control room of SMRs is faced with challenges such as incomplete knowledge of operators, insufficient response time for high dynamic events, and many indicators to be monitored (Boring et al., 2015; Hanna et al., 2021). In order to help operators to make timely decisions and minimize human errors so that improve the security of SMRs operation, researchers have carried out a lot of research work. They proposed to use A.I., methods to assist operators in fault detection and identification and generate control options (Cetiner and Ramuhalli, 2019; Kim et al., 2020). These A.I., methods can be roughly divided into data-driven models and knowledge representation and reasoning models.

In data-driven modeling, the source of knowledge is data obtained from SMRs history or SMRs transient simulation. Based on these data, statistical methods are employed to calculate and predict the unknown variables of interest. The more data, the more accurate the prediction (Ayodeji and Liu, 2018; Lee et al., 2018; Peng et al., 2018; Hanna et al., 2021).

In the knowledge representation and reasoning methods, the human belief basis for the real world is expressed by formulas. Knowledge representation and qualitative reasoning help to express human basic understanding of the SMRs system, the relationship between components, flow and heat paths, the experience accumulated by operators through SMRs operation history and emergency procedures, the operational constraints and the accident management guidelines (Lind and Zhang, 2014; Peng et al., 2018; Hanna et al., 2021). In order to deal with the uncertainty of reasoning, fuzzy logic is used to assist operators to take correct actions (Atkin and Altin, 1991). The event tree is also employed to generate possible corrective and control measures.

3.3 Advanced computational platform (MOOSE framework)

As a result of improved computing power, scientists are exploring computational solutions to complex problems that span multiple fields of science (Permann et al., 2020). Since SMR is a very complex system, a lot of calculation is needed in the process of design, construction and operation. MOOSE is a development and runtime high-performance computing framework which can solve linear and non-linear differential equation systems, and is widely used in simulating nuclear power, geophysics and geochemistry, multi-scale materials, advanced manufacturing technology and other physical applications (Gaston et al., 2009; Martineau, 2021). Parallel computing, space and time discretization, integration technology and the complexity of non-linear solution are all encapsulated in the MOOSE framework software package (Gaston et al., 2009; Martineau, 2021), which enables computing scientists or engineers to focus on the required physical modeling in the process of designing SMRs. MOOSE is widely used in many laboratories, universities and industries (Martineau, 2021). It is open-source and freely available at mooseframework.org.

Based on the MOOSE framework, scholars from various countries have developed nuclear power simulation tools that can be used in SMRs. Two Moose-based codes were initiated to support the risk informed margin of safety characterization approach of the LWRS program, which can help predict the life extension of current light water reactor. The first is the next-generation system analysis code called RELAP-7 (Zhang et al., 2018). The most important development objectives of RELAP-7 are to leverage advances in computer architecture, software design, numerical methods and physical modeling over the past 30 years to provide the capabilities required which can support the safety analysis of nuclear power plants. ANL has also built a Moose-based NPP analysis capability called the System Analysis Module (SAM) for the nearly incompressible single-phase liquid-cooled reactor concept (Hu, 2017). SAM is currently used to analyze sodium-cooled fast reactors and fluoride salt cooled high temperature reactors. Since they are Moose-based, both RELAP-7 and SAM can easily combine with other Moose-based codes through the MOOSE MultiApps and transfers system, such as the BISON fuel performance code to analyze nuclear fuel in an NPP setup.

MOOSE ecosystem is growing (Lindsay et al., 2022) and can satisfy the physical modules required by SMRs in the development process. MOOSE repository has added many general physical modules. In addition to the existing heat transfer and fluid flow modules, new modules for fluid-structure interaction (Dhulipala et al., 2022), ray tracing on unstructured grids (Gaston, 2020), nuclear reactor grids (Shemon et al., 2022), thermo-hydraulic system analysis and geochemistry have also been developed (Wilkins et al., 2021). MOOSE now supports scientific machine learning based on neural networks through the C++ application programming interface (API) of Pytorch (LibTorch) [102]. The modules from LibTorch can be used to generate and train various neural networks which can fast deal with a lot of information for the operators of SMRs.

Author contributions

All authors contributed to the study. The first draft of the manuscript was written by ST, HC, and JW. The manuscript was edited by SC, KW, and XL. All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Funding

This work is supported by the basic and applied basic research foundation of Guangdong province (Nos 2021A1515010343 and 2022A1515011582) and the Science and Technology Program of Guangdong Province (No. 2022A0505050029).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adam, P., Sam, G., Francisco, M., Adam, L., and James, B. (2019). Zeming lin, natalia gimelshein, luca antiga, alban desmaison, andreas kopf, edward Yang, zachary DeVito, martin raison, alykhan tejani, sasank chilamkurthy, benoit steiner, Lu fang, junjie Bai, soumith chintala, PyTorch: An imperative style, high-performance deep learning library. NIPS'19 Proc. 33rd Int. Conf. Neural Inf. Process. Syst.

Atkin, H. L., and Altin, V. (1991). Rule-based fuzzy logic controller for a PWR-type nuclear power plant. IEEE Trans. Nucl. Sci. 38 (2), 883–890. doi:10.1109/23.289405

Ayodeji, A., and Liu, Y.-k. (2018). Support vector ensemble for incipient fault diagnosis in nuclear plant components. Nucl. Eng. Technol. 50 (8), 1306–1313. doi:10.1016/j.net.2018.07.013

Bonnet, J., Mosser-Ruck, R., Sterpenich, J., Bourdelle, F., Verron, H., Michau, N., et al. (2022). Chemical and mineralogical characterizations of a low-pH cementitious material designed for the disposal cell of the high-level radioactive waste (HLW). Cem. Concr. Res. 162, 107013. doi:10.1016/j.cemconres.2022.107013

Bao, H., Zhang, H., Shorthill, T., Chen, E., and Lawrence, S. (2023). Quantitative evaluation of common cause failures in high safety-significant safety-related digital instrumentation and control systems in nuclear power plants. Reliab. Eng. Syst. Saf. 230, 108973. doi:10.1016/j.ress.2022.108973

Bischoff, J., Delafoy, C., Vauglin, C., Barberis, P., Roubeyrie, C., Perche, D., et al. (2018). AREVA NP's enhanced accident-tolerant fuel developments: Focus on Cr-coated M5 cladding. Nucl. Eng. Technol. 50 (2), 223–228. doi:10.1016/j.net.2017.12.004

Blandford, E., Brumback, K., Fick, L., Gerardi, C., Haugh, B., Hillstrom, E., et al. (2020). Kairos power thermal hydraulics research and development. Nucl. Eng. Des. 364, 110636. doi:10.1016/j.nucengdes.2020.110636

Boring, R. L., Thomas, K. D., Ulrich, T. A., and Lew, R. T. (2015). Computerized operator support systems to aid decision making in nuclear power plants. Procedia Manuf. 3, 5261–5268. doi:10.1016/j.promfg.2015.07.604

Brachet, J.-C., Lorrette, C., Michaux, A., Sauder, C., Idarraga-Trujillo, I., Le Saux, M., et al. (2014). CEA studies on advanced nuclear fuel claddings for enhanced Accident Tolerant LWRs Fuel (LOCA and beyond LOCA conditions).

Bragg-Sitton, S. (2014). Development of Advanced accident-tolerant fuels for commercial LWRs. Nucl. News 57, 83–91.

Brown, N. R. (2020). A review of in-pile fuel safety tests of TRISO fuel forms and future testing opportunities in non-HTGR applications. J. Nucl. Mater. 534, 152139. doi:10.1016/j.jnucmat.2020.152139

Brown, N. R., Ludewig, H., Aronson, A., Raitses, G., and Todosow, M. (2013). Neutronic evaluation of a PWR with fully ceramic microencapsulated fuel. Part I: Lattice benchmarking, cycle length, and reactivity coefficients. Ann. Nucl. Energy 62, 538–547. doi:10.1016/j.anucene.2013.05.025

Budnitz, R. J., Rogner, H. H., and Shihab-Eldin, A. (2018). Expansion of nuclear power technology to new countries – SMRs, safety culture issues, and the need for an improved international safety regime. Energy Policy 119, 535–544. doi:10.1016/j.enpol.2018.04.051

Busquim e Silva, R. A., Piqueira, J. R. C., Cruz, J. J., and Marques, R. P. (2021). Cybersecurity assessment framework for digital interface between safety and security at nuclear power plants. Int. J. Crit. Infrastructure Prot. 34, 100453. doi:10.1016/j.ijcip.2021.100453

Carriker, M., and Langar, S. (2014). “Factors affecting large scale modular construction projects,” in The associated school of construction international conference (Washington DC, USA.

Cetiner, S. M., and Ramuhalli, P. (2019). Transformational challenge reactor autonomous control system framework and key enabling technologies.

Choi, J., and Song, H. (2014). Evaluation of the modular method for industrial plant construction projects. Int. J. Constr. Manag. 14 (3), 171–180. doi:10.1080/15623599.2014.922728

Chun, J.-H., Lim, S.-W., Chung, B.-D., and Lee, W.-J. (2015). Safety evaluation of accident-tolerant FCM fueled core with SiC-coated zircalloy cladding for design-basis-accidents and beyond DBAs. Nucl. Eng. Des. 289, 287–295. doi:10.1016/j.nucengdes.2015.04.021

Crawford, D. C. (2021). “Introduction to fuel cycle front end: From mining through utilization,” in Encyclopedia of nuclear energy. Editor E. Greenspan (Oxford: Elsevier), 255–264.

Deng, Q., Li, S., Wang, D., Liu, Z., Xie, F., Zhao, J., et al. (2022). Neutronic design and evaluation of the solid microencapsulated fuel in LWR. Nucl. Eng. Technol. 54 (8), 3095–3105. doi:10.1016/j.net.2022.03.020

Dhulipala, S. L. N., Bolisetti, C., Munday, L. B., Hoffman, W. M., Yu, C.-C., Mir, F. U. H., et al. (2022). Development, verification, and validation of comprehensive acoustic fluid-structure interaction capabilities in an open-source computational platform. Earthq. Eng. Struct. Dyn. 51 (10), 2188–2219. doi:10.1002/eqe.3659

Energikommissionen, (2016). Memorandum on the financial conditions of the existing Swedish electricity production.

Energy, Advanced Small Modular Reactors (SMRs), These advanced reactors, envisioned to vary in size from tens of megawatts up to hundreds of megawatts, can be used for power generation, process heat. desalination, or other industrial uses aHR0cHM6Ly93d3cuZW5lcmd5Lmdvdi9uZS9hZHZhbmNlZC1zbWFsbC1tb2R1bGFyLXJlYWN0b3JzLXNtcnM=.

Energy, T. (2020). Technology: cost competitive terrestrial energy incorporated aHR0cHM6Ly93d3cudGVycmVzdHJpYWxlbmVyZ3kuY29tL3RlY2hub2xvZ3kvY29tcGV0aXRpdmUv.

Gaston, D., Newman, C., Hansen, G., and Lebrun-Grandié, D. (2009). Moose: A parallel computational framework for coupled systems of nonlinear equations. Nucl. Eng. Des. 239 (10), 1768–1778. doi:10.1016/j.nucengdes.2009.05.021

Gaston, D. (2020). Parallel, asynchronous ray-tracing for scalable, 3D, full-core method of characteristics neutron transport on unstructured mesh. Boston: Massachusetts Institute of Technology.

Golesorkhi, S., Kelly, S., and Trottier, A. (2023). Impact of the TRISO fuel homogenisation approximation in the MHTGR. Ann. Nucl. Energy 183, 109634. doi:10.1016/j.anucene.2022.109634

Gonçalves, M. F. S., Petraconi Filho, G., Couto, A. A., Silva Sobrinho, A. S. d., Miranda, F. S., and Massi, M. (2022). Evaluation of thermal plasma process for treatment disposal of solid radioactive waste. J. Environ. Manag. 311, 114895. doi:10.1016/j.jenvman.2022.114895

Griesbach, C., Gerczak, T., Zhang, Y., and Thevamaran, R. (2023). Microstructural heterogeneity of the buffer layer of TRISO nuclear fuel particles. J. Nucl. Mater. 574, 154219. doi:10.1016/j.jnucmat.2022.154219

Guo, J., Yang, M., Zou, B., Zhang, Y., Yang, J., and Dai, X. (2018). Nuclear safety-critical digital instrumentation and control system software: Reliability demonstration. Ann. Nucl. Energy 120, 516–527. doi:10.1016/j.anucene.2018.06.003

Hanna, B., Son, T. C., and Dinh, N. (2021). AI-guided reasoning-based operator support system for the nuclear power plant management. Ann. Nucl. Energy 154, 108079. doi:10.1016/j.anucene.2020.108079

Hidayatullah, H., Susyadi, S., and Subki, M. H. (2015). Design and technology development for small modular reactors – safety expectations, prospects and impediments of their deployment. Prog. Nucl. Energy 79, 127–135. doi:10.1016/j.pnucene.2014.11.010

Hong, S., Qvist, S., and Brook, B. W. (2018). Economic and environmental costs of replacing nuclear fission with solar and wind energy in Sweden. Energy Policy 112, 56–66. doi:10.1016/j.enpol.2017.10.013

Hu, R. (2017). A fully-implicit high-order system thermal-hydraulics model for advanced non-LWR safety analyses. Ann. Nucl. Energy 101, 174–181. doi:10.1016/j.anucene.2016.11.004

Hussein, E. M. A. (2020). Emerging small modular nuclear power reactors: A critical review. Phys. Open 5, 100038. doi:10.1016/j.physo.2020.100038

IAEA Getting to the core of the nuclear fuel cycle. https://www.iaea.org/sites/default/files/18/10/nuclearfuelcycle.pdf.

Iea, N. (2015). OECD, projected costs of generating electricity 2015. Paris: Organisation for Economic Co-operation and Development.

Ingersoll, D. T. (2021). “Impact of small modular reactors on the acceptance of nuclear power by the public, investors, and owners,” in Encyclopedia of nuclear energy. Editor E. Greenspan (Oxford: Elsevier), 692–705.

Jiao, Yongjun, Yu, Junchong*, Zhou, Yi, Li, Yuanming, and Chen Ping, D. (2022). Zhengang, research and development progress and application prospect of nuclear fuels for commercial pressurized water reactors. Nucl. Power Eng. 43.

JNES (2007). Digital instrumentation and control systems for safety system and main control room design in Japan nuclear power station. Tokyo: Nuclear Power Station.

Johnson, N. (2020). Nuclear power’s big new idea is really small. https://grist.org/energy/nuclear-powers-big-new-idea-is-really-small/.

Kane, K., Bell, S., Capps, N., Garrison, B., Shapovalov, K., Jacobsen, G., et al. (2023). The response of accident tolerant fuel cladding to loca burst testing: A comparative study of leading concepts. J. Nucl. Mater. 574, 154152. doi:10.1016/j.jnucmat.2022.154152

Khatib, H., and Difiglio, C. (2016). Economics of nuclear and renewables. Energy Policy 96, 740–750. doi:10.1016/j.enpol.2016.04.013

Kim, J., Lee, D., Yang, J., and Lee, S. (2020). Conceptual design of autonomous emergency operation system for nuclear power plants and its prototype. Nucl. Eng. Technol. 52 (2), 308–322. doi:10.1016/j.net.2019.09.016

Lawson, R. M., Ogden, R. G., and Bergin, R. (2012). Application of modular construction in high-rise buildings. J. Archit. Eng. 18 (2), 148–154. doi:10.1061/(asce)ae.1943-5568.0000057

Lee, D., Seong, P. H., and Kim, J. (2018). Autonomous operation algorithm for safety systems of nuclear power plants by using long-short term memory and function-based hierarchical framework. Ann. Nucl. Energy 119, 287–299. doi:10.1016/j.anucene.2018.05.020

Li, W., Yu, Y., He, Q., Xu, D., Qi, Y., and Deng, X. (2023). Impact of clean energy use on the subjective health of household members: Empirical evidence from rural China. Energy 263, 126006. doi:10.1016/j.energy.2022.126006

Liang, Y., Lan, B., Zhang, Q., Seidl, M., and Wang, X. (2022). Neutronic analysis of silicon carbide Cladding-ATF fuel combinations in small modular reactors. Ann. Nucl. Energy 173, 109120. doi:10.1016/j.anucene.2022.109120

Lind, M., and Zhang, X. (2014). Functional modelling for fault diagnosis and its application for NPP. Nucl. Eng. Technol. 46 (6), 753–772. doi:10.5516/net.04.2014.721

Lindsay, A. D., Gaston, D. R., Permann, C. J., Miller, J. M., Andrš, D., Slaughter, A. E., et al. (2022). 2.0 - MOOSE: Enabling massively parallel multiphysics simulation. SoftwareX 20, 101202. doi:10.1016/j.softx.2022.101202

Lloyd, C. A., Roulstone, T., and Lyons, R. E. (2021). Transport, constructability, and economic advantages of SMR modularization. Prog. Nucl. Energy 134, 103672. doi:10.1016/j.pnucene.2021.103672

Lyons, R. E. (2020). The effect of supply chain configuration on small modular reactor economics. Cambridge: University of Cambridge.

Martineau, R. C. (2021). The MOOSE multiphysics computational framework for nuclear power applications: A special issue of nuclear technology. Nucl. Technol. 207 (7). doi:10.1080/00295450.2021.1915487

Mays, G. (2021). “21 - small modular reactors (SMRs): The case of the United States of America,” in Handbook of small modular nuclear reactors. Editors D. T. Ingersoll, and M. D. Carelli Second Edition (Cambridge: Woodhead Publishing), 521–553.

McGinnis, E. The BIG potential for nuclear micro-reactors. https://www.energy.gov/ne/articles/big-potential-nuclear-micro-reactors (accessed January 24, 2020).

Michaelson, D., and Jiang, J. (2021). Review of integration of small modular reactors in renewable energy microgrids. Renew. Sustain. Energy Rev. 152, 111638. doi:10.1016/j.rser.2021.111638

Mignacca, B., Locatelli, G., Alaassar, M., and Invernizzi, D. C. (2018). We never built small modular reactors (SMRs), but what do we know about modularization in construction? 26th Int. Conf. Nucl. Eng.

Natarajan, V., Karunanidhi, M., and Raja, B. (2020). A critical review on radioactive waste management through biological techniques. Environ. Sci. Pollut. Res. 27 (24), 29812–29823. doi:10.1007/s11356-020-08404-0

NEA (2018). State-of-the-Art report on light water reactor accident-tolerant fuels. Paris: OECD Publishing.

Nian, V., and Zhong, S. (2020). Economic feasibility of flexible energy productions by small modular reactors from the perspective of integrated planning. Prog. Nucl. Energy 118, 103106. doi:10.1016/j.pnucene.2019.103106

Nuclear, E. O. (2020). Generation IV/economic modelling compares costs of SMR to conventional PWR. https://www.nucnet.org/news/economic-modelling-compares-costs-of-smr-to-conventional-pwr-10-4-2020.

NuScale, "Technology (2020). NuScale power LLC. https://www.nuscalepower.com/technology.

Office of Nuclear Energy (2022). SMR licensing technical support (LTS) program. aHR0cHM6Ly93d3cuZW5lcmd5Lmdvdi9uZS9zbXItbGljZW5zaW5nLXRlY2huaWNhbC1zdXBwb3J0LWx0cy1wcm9ncmFt.

Owusu, D., Holbrook, M. R., and Sabharwall, P. (2018). Regulatory and licensing strategy for microreactor technology.

Peng, M.-j., Wang, H., Chen, S.-s., Xia, G.-l., Liu, Y.-k., Yang, X., et al. (2018). An intelligent hybrid methodology of on-line system-level fault diagnosis for nuclear power plant. Nucl. Eng. Technol. 50 (3), 396–410. doi:10.1016/j.net.2017.11.014

Permann, C. J., Gaston, D. R., Andrš, D., Carlsen, R. W., Kong, F., Lindsay, A. D., et al. (2020). Moose: Enabling massively parallel multiphysics simulation. SoftwareX 11, 100430. doi:10.1016/j.softx.2020.100430

Prasad, S., Abdulla, A., Morgan, M. G., and Azevedo, I. L. (2015). Nonproliferation improvements and challenges presented by small modular reactors. Prog. Nucl. Energy 80, 102–109. doi:10.1016/j.pnucene.2014.11.023

Qasim Awan, M., Cao, L., Wu, H., Shen, W., and Li, Z. (2018). Neutronic design study of a small modular IPWR loaded with accident tolerant-fully ceramic micro-encapsulated (AT-FCM) fuel. Nucl. Eng. Des. 335, 18–29. doi:10.1016/j.nucengdes.2018.04.023

Rolls-Royce, UK Small Modular Reactor (2020). Pioneering intelligent power. Rolls-Royce Plc [Online]. Available: https://www.rolls-royce.com/products-and-services/nuclear/small-modular-reactors.aspx#/.

Rothwell, G. (2010). International light water nuclear fuel fabrication supply: Are fabrication services assured? Energy Econ. 32 (3), 538–544. doi:10.1016/j.eneco.2009.08.012

Rowinski, M. K., White, T. J., and Zhao, J. (2015). Small and medium sized reactors (SMR): A review of technology. Renew. Sustain. Energy Rev. 44, 643–656. doi:10.1016/j.rser.2015.01.006

Rubio, F., Zweibaum, N., Craig, I., Gilbreth, J., Williams, B., Heald, A., et al. (2022). Scaled validation test for high Prandtl number fluid mixed convection between parallel plates. Nucl. Eng. Des. 399, 112006. doi:10.1016/j.nucengdes.2022.112006

Ruo-meng, Q., Hui-fang, G., Rong-fang, M., and Zong-yang, L. (2021). Overview of development of the front end of nuclear fuel cycle and uranium supply in the United States.

Shah, H., Romero, J., Xu, P., Oelrich, R. L., Walters, J. L., Wright, J., et al. (2018). Westinghouse-exelon EnCore fuel lead test rod (LTR) program including coated cladding development and advanced pellets.

Shemon, E. R., Miao, Y., Kumar, S., Mo, K. Y., Jung, Y., Oaks, A., et al. (2022). MOOSE reactor module meshing enhancements to support reactor analysis.

Shropshire, D. E., Black, G., and Araujo, K. (2021). Global market analysis of microreactors. United States.

Silva, R. A. B. e. (2015). Implications of advanced computational methods for reactivity initiated accidents in nuclear reactors. Sao Paulo: University of Sao Paulo.

SMR RF MCO Working Group (2019). Report on manufacturability, supply chain management and commissioning of SMRs. Vienna: SMR RF – MCO Working Group.

Systems, T. (1997). Digital instrumentation and control systems in nuclear power plants. Washington: Safety and Reliability Issues.

Tauseef Hassan, S., Wang, P., Khan, I., and Zhu, B. (2023). The impact of economic complexity, technology advancements, and nuclear energy consumption on the ecological footprint of the USA: Towards circular economy initiatives. Gondwana Res. 113, 237–246. doi:10.1016/j.gr.2022.11.001

Tian, Y., Li, J., and Huang, X. (2022). A cybersecurity risk assessment method and its application for instrumentation and control systems in nuclear power plants. IFAC-PapersOnLine 55 (9), 238–243. doi:10.1016/j.ifacol.2022.07.042

Tiang, Z. H., and Xiao, S. (2021). Long-term reactivity control of accident tolerant fuel loaded marine small modular reactor using particle-type burnable poisons. Ann. Nucl. Energy 156, 108177. doi:10.1016/j.anucene.2021.108177

Trellue, H. R., O'Brien, J., Carpenter, J. S., Reid, R. S., Guillen, D. P., and Sabharwall, P. (2019). Microreactor demonstration and testing progress in FY19.

Upadhyaya, B. R., and Wood, R. T. (2021). “Instrumentation and control systems of nuclear power plants,” in Encyclopedia of nuclear energy. Editor E. Greenspan (Oxford: Elsevier), 373–392.

Wang, J., Chen, L., Su, R., and Zhao, X. (2018). The Beishan underground research laboratory for geological disposal of high-level radioactive waste in China: Planning, site selection, site characterization and in situ tests. J. Rock Mech. Geotechnical Eng. 10 (3), 411–435. doi:10.1016/j.jrmge.2018.03.002

Wang, M., Bu, S., Zhou, B., Li, Z., and Chen, D. (2022). Multi-scale heat conduction models with improved equivalent thermal conductivity of TRISO fuel particles for FCM fuel. Amsterdam: Nuclear Engineering and Technology.

Wattal, P. K. (2017). Back end of Indian nuclear fuel cycle-A road to sustainability. Prog. Nucl. Energy 101, 133–145. doi:10.1016/j.pnucene.2017.03.004

Wilkins, A., Green, C., Harbour, L., and Podgorney, R. (2021). The MOOSE geochemistry module. J. Open Source Softw. 6, 3314. doi:10.21105/joss.03314

Wisnubroto, D. S., Zamroni, H., Sumarbagiono, R., and Nurliati, G. (2021). Challenges of implementing the policy and strategy for management of radioactive waste and nuclear spent fuel in Indonesia. Nucl. Eng. Technol. 53 (2), 549–561. doi:10.1016/j.net.2020.07.005

Xijia, D., Tao, Z., Jialei, Z., and Liangyu, Z. (2019). Study on Technical Safety of small modular nuclear reactor. Technol. Innovation Appl. (34), 19–21.

Yang, J., Yun, D., and Junkai, L. (2022). Review on chromium coated Zirconium alloy accident tolerant fuel cladding. Mater. Rep. 36 (1), 12.

Yinrong, W. (2012). Guidelines for nuclear power preliminary work. Beijing: China Electric Power Press.

Yu, H., Cai, J., He, S., and Li, X. (2021). Analysis of neutron physics and thermal hydraulics for fuel assembly of small modular reactor loaded with ATFs. Ann. Nucl. Energy 152, 107957. doi:10.1016/j.anucene.2020.107957

Zhang, F. (2021). “Chapter 21 - nuclear power plant cybersecurity,” in Nuclear power plant design and analysis codes. Editors J. Wang, X. Li, C. Allison, and J. Hohorst (Cambridge: Woodhead Publishing), 495–513.

Zhang, H., Andrs, D., Hansel, J., Zou, L., Berry, R., and Martineau, R. (2018). RELAP-7 user's guid, Idaho national lab. (INL), Idaho falls, ID (United States). United States.

Zhang, H., Bao, H., Shorthill, T., and Quinn, E. (2022). An integrated risk assessment process of safety-related digital I&C systems in nuclear power plants. Nucl. Technol. 209, 377–389. doi:10.1080/00295450.2022.2076486

Zhang, X., Huang, G., Liu, L., Song, T., and Zhai, M. (2022). Development of an SMR-induced environmental input-output analysis model – application to Saskatchewan, Canada. Sci. Total Environ. 806, 150297. doi:10.1016/j.scitotenv.2021.150297

Zhang, X. Y., Huang, G. H., Liu, L., Chen, J. P., Luo, B., Fu, Y. P., et al. (2020). Perspective on site selection of small modular reactors. J. Environ. Inf. Lett. doi:10.3808/jeil.202000026

Keywords: passive safety, nuclear power, clean energy, accident-tolerance fuel, MOOSE, small modular reactor

Citation: Tan S, Cheng S, Wang K, Liu X, Cheng H and Wang J (2023) The development of micro and small modular reactor in the future energy market. Front. Energy Res. 11:1149127. doi: 10.3389/fenrg.2023.1149127

Received: 21 January 2023; Accepted: 27 February 2023;

Published: 10 March 2023.

Edited by:

Ellen B. Stechel, Arizona State University, United StatesReviewed by:

Jie Lian, Rensselaer Polytechnic Institute, United StatesCopyright © 2023 Tan, Cheng, Wang, Liu, Cheng and Wang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hui Cheng, Y2hlbmdoNzhAbWFpbC5zeXN1LmVkdS5jbg==; Jun Wang, anV3YW5nOTgyOTRAb3V0bG9vay5jb20=

Shaojie Tan1

Shaojie Tan1 Songbai Cheng

Songbai Cheng Kai Wang

Kai Wang Xiaoxing Liu

Xiaoxing Liu Hui Cheng

Hui Cheng Jun Wang

Jun Wang