- 1State Grid Shandong Electric Power Research Institute, Jinan, China

- 2School of Electrical and Information Engineering, Changsha University of Science & Technology, Changsha, China

Nanoparticles are found to have the capacity to improve the specific properties of polypropylene (PP) for recyclable cable insulation material. However, previous studies have focused on the modification effect at room temperature, and few studies, on the nano-modification effect under high temperature environments. This article aims to study the effects of nanoparticles on the electrical and dielectric properties of PP at different high temperatures. Both TiO2 nanoparticles and PP/TiO2 nanocomposite samples are prepared in the laboratory by the wet chemical method and surface modification. Then, the AC and DC breakdown strength, conductivity, permittivity, and dielectric loss of the PP/TiO2 nanocomposite are measured at different temperatures. The results show that TiO2 nanoparticles introduce a small amount of charge traps into PP to restrain the conductivity and improve the breakdown strength of PP. But due to the additional interfacial polarization between TiO2 nanoparticles and the PP matrix, the permittivity and dielectric loss of the PP/TiO2 nanocomposite are enhanced, especially at low frequency.

1 Introduction

By 2025, about 900,000 km of ultra-high-voltage overhead transmission lines will be built in China. The dense overhead lines seriously affect the natural landscape, and their electromagnetic problems also compress the living space of human beings. More importantly, failures of large-capacity voltage overhead transmission lines caused by natural disasters such as icing, air pollution, and lightning strikes seriously threaten the safe operation of the power grid. High-voltage cables have become the preferred solution for replacing overhead transmission lines in special environments due to their advantages of large capacity, low loss, and small electromagnetic environmental effects (Chen et al., 2015; Ghorbani et al., 2017).

The extruded plastic-insulated cable is the most widely used cable type in the field of high-voltage transmission (Maekawa et al., 1994; Khalil, 1997; Chen et al., 2015; Du et al., 2017). It generally uses cross-linked polyethylene (XLPE) as the insulation material (Montanari et al., 2005; Teyssedre et al., 2005). However, the cross-linking process makes the original thermoplastic polyethylene (PE) into the thermosetting XLPE, which makes recycling a new problem for cable insulation materials. Compared to XLPE, polypropylene (PP) is a kind of thermoplastic material, with a high suitable working temperature and comparable insulating strength. More importantly, the recyclability of PP makes it an alternative to XPLE as the next-generation electrical insulation material (Green et al., 2011; Li et al., 2016; Zhang et al., 2015). Considering the thermal, mechanical, aging, and other properties of the matrix material in practical industrial applications, it is generally necessary to modify polypropylene to get the higher performance.

Adding nanoscale fillers was found to improve the mechanical, electrical, and flame retardant properties of dielectric materials (Azmi et al., 2022; Li et al., 2021; Xiaozhen et al., 2021). Zhou et al. (Yao et al., 2015) found that MgO nanoparticles would introduce deep traps to suppress the injection of homopolarity charges from the electrode. By adding 3phr of MgO nanoparticles, the breakdown field strength is 29% higher than that of pure PP. With the high electron affinity of fullerene, Dang et al. effectively suppressed space charge accumulation and increased the volume resistivity of PP by nearly 10 times (Bin et al., 2017). Yang et al. (2018) loaded polyethyleneimine (PEI) onto nanoscale mesoporous SiO2 molecular sieves through structural design, thereby increasing the DC breakdown strength of PP by 16%. Jiang (Xingyi et al., 2009) found that polydimethylsiloxane surface-treated SiO2 nanoparticles can minimize space charge accumulation in PP due to their better interfacial compatibility. L. S. Schadler (Zhang et al., 2017) studied the dispersibility of SiO2 nanoparticles in PP and the electrical properties of nanocomposite dielectrics. Compared to anthracene, polymethacrylate-modified SiO2 nanoparticles have better dispersibility, and the corresponding DC breakdown field strength is increased by 33%. Cheng et al. (2019) found that MgO nanoparticles with abundant surface defects can provide more deep traps into the PP/SEBS composite to significantly improve the DC breakdown voltage and permittivity in room temperature. Hu et al. (2020) studied the effect of silane coupling agents on the MgO nanoparticle-modified PP. The octyl-modified MgO nanoparticles show the best modification on the electrical properties of PP due to the large quantity of deep traps. However, there is a temperature rise due to the load current and dielectric loss during the operation of the cable. In some specific overload or fault conditions, the operating temperature can even reach above 70°C. But most of the previous research was carried out at room temperature. The effect of temperature rise on the electrical and dielectric properties of nanomodified PP has rarely been studied.

This article focuses on the electrical and dielectric performance of TiO2-modified PP at high temperatures. The spheric TiO2 nanoparticles with surface modification were prepared in the laboratory to improve the interaction between nanoparticles and matrix materials. Then, after modification by using TiO2 nanoparticles, the AC and DC breakdown voltages of the nanocomposite were measured first. The conduction current and dielectric spectrum of the PP/TiO2 nanocomposite were then studied under different temperatures. With the results of thermally stimulated current (TSC) measurement, the mechanism was discussed for the modification of the electrical and dielectric performance of the PP/TiO2 nanocomposite.

2 Experiment

2.1 Material preparation

According to the regularity of its methyl space arrangement, the type of PP can be divided into isotactic PP, syndiotactic PP, and atactic PP (Wypych, 2013). Among them, the isotactic PP molecular chain structure is relatively regular, so it is easy to crystallize and has a high melting point, which is generally above 160°C, and the long-term use temperature is above 100°C. Atactic PP is an elastic material, but its preparation technology is difficult. Syndiotactic PP has better transparency, toughness, and flexibility and can be used to prepare high-performance elastomers. However, its rigidity and hardness are not as good as those of isometric PP, and its current application is limited due to the high price. The PP used in this article is the F401 Isotactic PP produced by Sinopec Yangzi Petrochemical Co., Ltd. Its isotacticity is about 96%, with a density of 0.9 g/cm3, and the solution flow rate is about 2.3 g/10 min.

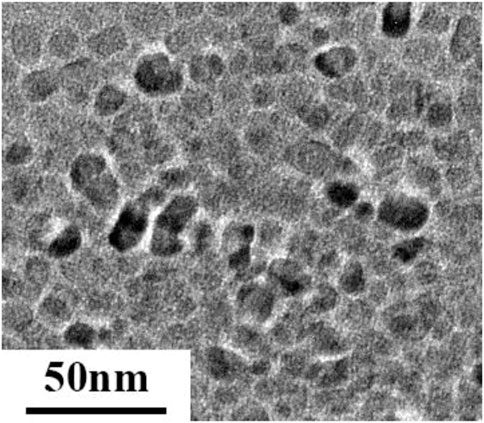

The preparation of TiO2 nanoparticles by the wet chemical method in the laboratory is as follows. Using a non-aqueous solvent as the reaction medium, the reaction system is heated to a critical temperature by high temperature. The precursor material reacts, crystallizes, nucleates, grows, and finally forms crystal grains with a certain particle size and crystal shape in the hydrothermal medium. The desired nanoparticles are then obtained through the separation, washing, and drying process. As shown in Figure 1, the shape of TiO2 nanoparticles is spherical with a diameter of 20 nm approximately.

Anhydrous ethanol and deionized water were mixed uniformly with a volume ratio of 95:5. Then, 50 g of TiO2 nanoparticles were added to the solution, and the mixed solution was fully dispersed by high-speed shearing with a rotation speed of 1 × 104 r/min. After the pH value was adjusted to 8.0, the mixed solution was ultrasonically vibrated for 20 min. Then, 7.5 g of the silane coupling agent KH-570 (analytical grade, Sinopharm Chemical Reagent Chemical Co., Ltd.) was slowly added dropwise to the dispersion, and the reaction was stirred and refluxed for 2 h under the condition of 70°C in an oil bath. The reactants were centrifuged and washed with absolute ethanol several times to remove the unreacted KH-570. Finally, it was then dried in a vacuum oven at 160°C for 24 h to obtain KH-570-modified TiO2 nanoparticles.

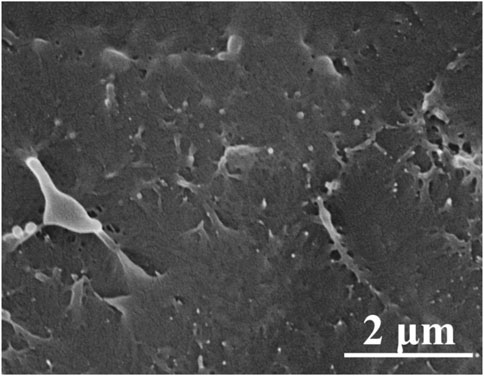

To prepare the TiO2 nanocomposite, the temperature of the twin-roll mixer is kept at 190°C. The amount of PP is added and mixed for 3 min to make the materials stick to the rollers evenly. Then, the desired amount of prepared TiO2 nanoparticles is added and mixed for 15 min to obtain TiO2 nanoparticle-modified PP. The film samples are prepared by compression molding. The micromorphology of the prepared PP/TiO2 nanocomposite film is analyzed using a scanning electron microscope (SEM), as shown in Figure 2. The KH-570-modified TiO2 nanoparticles are uniformly distributed in the PP matrix.

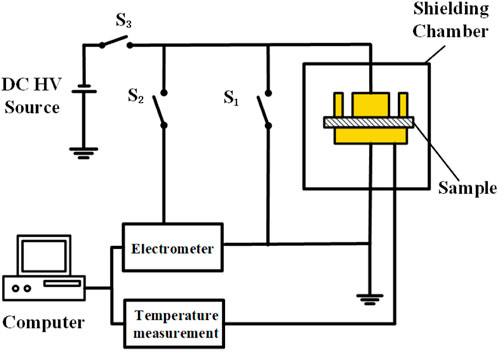

2.2 AC and DC breakdown strength

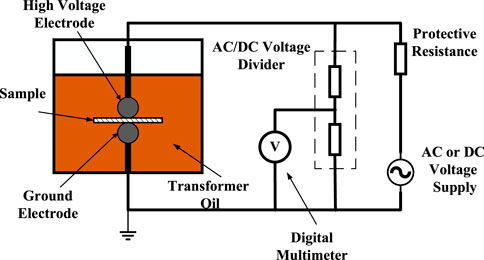

The sphere–sphere electrodes with a diameter of 20 mm are used to measure the breakdown strength of PP and PP/TiO2 nanocomposites. The experimental setup is shown in Figure 3. The thickness of the specimen is 0.05 mm. In order to avoid a flashover along the edge of the film sample, the electrodes and the sample were placed in transformer oil during the experimental process. By heating the oil, different test temperatures can be obtained.

Before each test, the sample was wiped with alcohol to remove impurities on the surface. It was then placed in a temperature-controlled oven at 60°C for 24 h to eliminate the moisture. The breakdown strength was measured by the continuous boost method with a boost rate of 0.5 kV/s. For each kind of samples, total 18 breakdown tests were carried. The Weibull tools are used to analyze the breakdown results.

2.3 Conduction current and dielectric spectrum

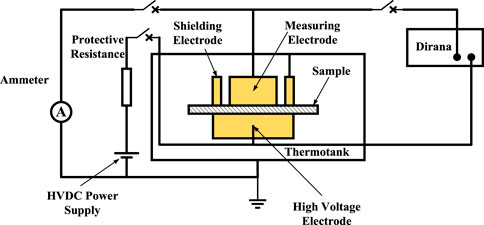

The electrometer Keithley 6517B and the dielectric response tester Dirana are used to measure the conduction current of PP samples. The experimental setup is shown in Figure 4. The electrode system is composed of three electrodes, namely, the measuring electrode, the high-voltage electrode, and the shielding electrode, with diameters of 50 mm, 80 mm, and 54 mm, respectively. The shielding electrode is used to eliminate the surface leakage current that flows through the surface of the sample. The electrode system and sample were placed in a temperature-controlled oven. The temperature control system of the oven adjusts the temperature in real time through high-precision thermocouples. The temperature adjustment panel can set the internal temperature of the oven and keep it stable for a long time so as to realize the conduction current and dielectric spectrum characteristic tests at different temperatures. The thickness of the sample used for the measurement is around 100 μm, and the applied DC electric field was 30 kV/mm for conductivity measurement.

2.4 Thermally stimulated current

The experimental setup of thermally stimulated current (TSC) is shown in Figure 5. The temperature adjustment during the measurement is carried by a KP-31E digital programmable temperature controller, and the picoamp current is measured using a Keithley 6517A system. K1 and K2 are the pressure and the measuring switches, respectively. The voltage range for the DC power supply is 0–10 kV. The film samples have a thickness of 100 μm.

At the beginning, the film sample is short-circuited at 40°C for 10 min to remove the inside residual space charge. Then, it is charge injected and polarized under an electric field of 40 kV/mm for 30 min. To keep the polarization voltage, the sample is cooled to −100°C with liquid nitrogen. The polarization voltage is removed, and the sample is then short-circuited for 1 min at −100°C. After that, the temperature is increased from −100°C to 120°C with a heating rate of 2°C/min. The TSC of the sample is measured during the heating process.

3 Results and discussion

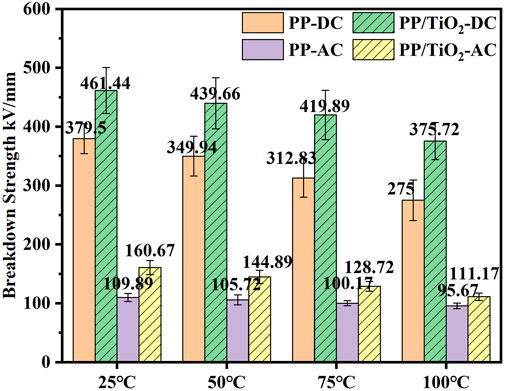

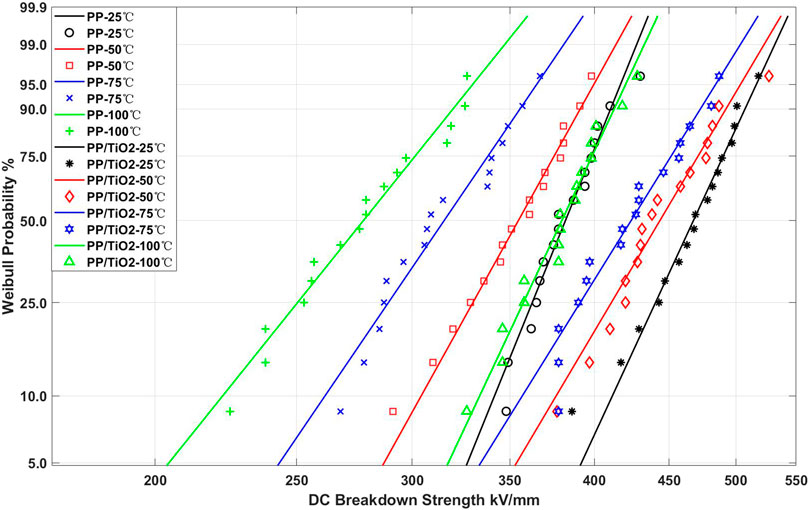

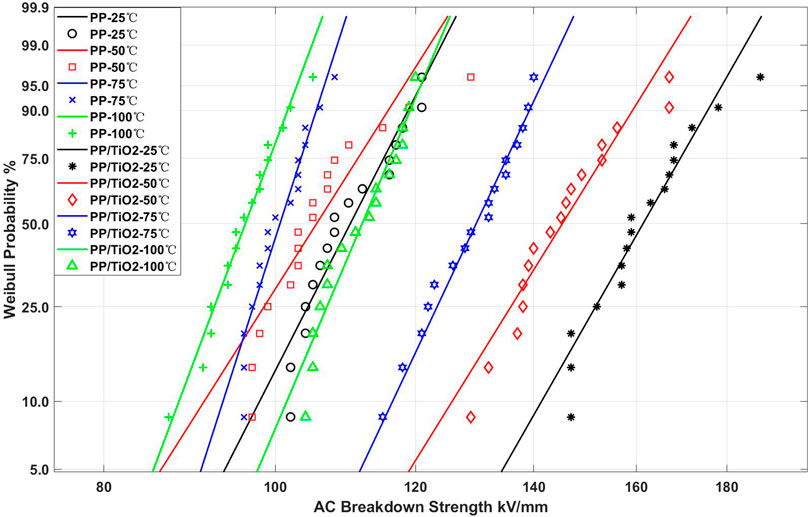

3.1Breakdown strength

The DC and AC breakdown electric fields of PP and PP/TiO2 nanocomposite samples are shown in Figure 6. With the increase in temperature, the breakdown strength of PP decreases. For pure PP samples, the DC and AC average breakdown electric fields of pure PP are 379.50 and 109.89 kV at room temperature, whereas they decrease to 275.21 and 95.67 kV when the test temperature reaches 100°C. Compared to pure PP, the breakdown strengths of PP/TiO2 nanocomposite samples are much higher. The DC and AC average breakdown electric fields of PP/TiO2 nanocomposite samples at room temperature are 461.44 and 160.67 kV, respectively, which is 1.22 and 1.46 times that of pure PP.

To further demonstrate the difference in insulating properties between PP and PP/TiO2 nanocomposite samples, the breakdown electric field is analyzed by using Weibull tools, as shown in Figures 7, 8. The fitted parameters are listed in Table 1. The breakdown strength of PP/TiO2 nanocomposites is much higher than that of pure PP. It should be noted that the breakdown strength of PP/TiO2 nanocomposites at 100°C is even comparable to that of pure PP at 25°C, indicating adding TiO2 nanoparticles can significantly improve the breakdown strength of PP.

3.2 Conduction current

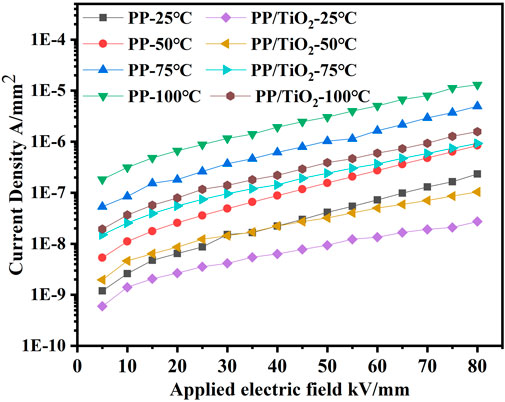

The conduction current of pure PP and PP/TiO2 nanocomposite samples is studied at different applied electric fields and temperatures, as plotted in Figure 9. It is shown that the current density of PP increases exponentially with electric field and temperature approximately. Compared to the pure PP film, the current density of the PP/TiO2 nanocomposite is much smaller at different temperatures and electric fields. For example, for the applied electric field of 40 kV/mm, the current density of pure PP is 87.87 nA/mm2 whereas that of the PP/TiO2 nanocomposite is 22.21 nA/mm2 at 50°C, indicating that adding TiO2 nanoparticles would restrain the conduction of charge carriers in PP.

3.3 Dielectric spectrum

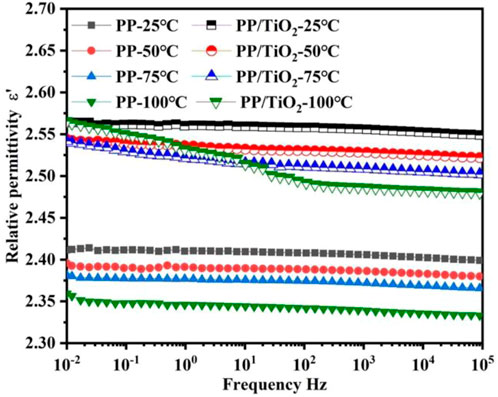

Figures 10, 11 show the dielectric spectrum results of pure PP and PP/TiO2 nanocomposites at the frequency from 102 to 105 Hz with different temperatures. It can be seen from Figure 10 that the relative permittivity of PP slightly increases with the decrease in frequency and decreases with the increase in temperature. This may be because PP is a kind of dielectric with weak polarity. The polarization of PP is mainly due to electronic polarization and a small amount of interfacial polarization, as well as space charge polarization (Takala et al., 2010). With the decrease in frequency, the interfacial polarization and space charge polarization processes gradually keep up with the frequency change, which leads to the increase in permittivity, which is consistent with the Debye relaxation theory (Yanbin et al., 2016). The increase in temperature causes the volume of the dielectric to expand. The number of molecules then decreases in unit volume, which causes the decrease in electron polarization and the relative permittivity. Compared to pure PP, the permittivity of the PP/TiO2 nanocomposite is higher. More interestingly, there is a remarkable increased permittivity of the PP/TiO2 nanocomposite at a low frequency range when the measurement temperature is higher than 75°C, indicating that adding TiO2 nanoparticles introduces more polarization into the PP matrix, especially at high temperatures.

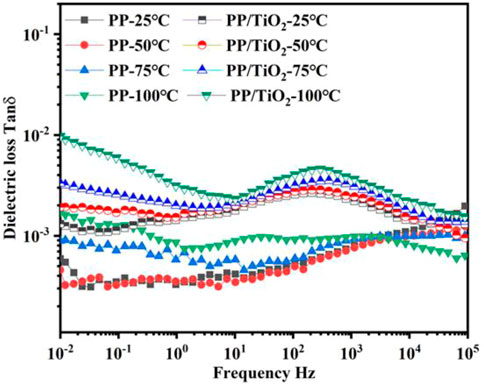

Tanδ can be used to qualitatively represent the dielectric loss of the sample during the polarization process, as shown in Figure 11. It can be seen that there is an increase in dielectric loss with the increased temperature of PP which is attributed to the increased conductivity at high temperatures. After adding nanoparticles, the dielectric loss is increased, and a peak appears in the middle-frequency region (between 102 and 103 Hz), which means additional dielectric relaxation polarization is introduced by adding TiO2 nanoparticles. In addition, the dielectric loss of the PP/TiO2 composite is also increased with temperature, especially at a frequency lower than 10 Hz.

3.4 Thermally stimulated current

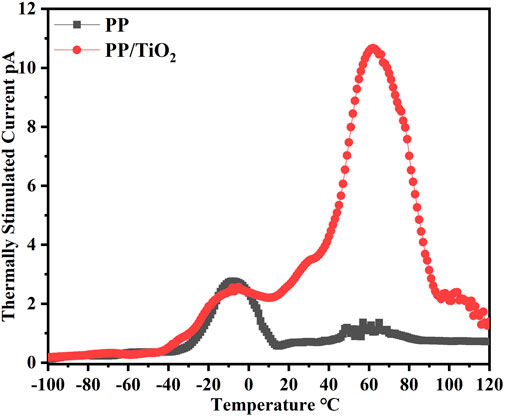

Figure 12 shows the TSCs from −100°C to 120°C relevant to both pure PP and PP/TiO2 nanocomposite films. For pure PP, there is an evident peak located at about −8°C which is attributed to the glass transition (Zhou et al., 2019). In addition, a less obvious peak can also be observed between 40°C and 80°C. This peak may be caused by the dissociation of impurities and the detrapping of space charges at high temperatures. By adding TiO2 nanoparticles, the high-temperature peak of the PP/TiO2 nanocomposite is enhanced remarkably, whereas the glass transition peak is almost identical to that of pure PP. Specifically, the value of the high-temperature peak of the PP/TiO2 nanocomposite is 10.67 pA at 62°C, whereas that of pure PP is only 1.05 pA.

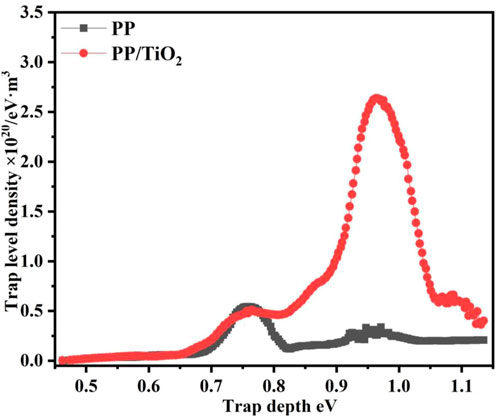

Trap characteristics in PP and PP/TiO2 nanocomposite samples are analyzed by a modified TSC theory (Tian et al., 2011a), as shown in Figure 13. It should be noted that the peak of 0.7–0.8 eV is attributed to the glass transition of PP, not true charge traps. This is because the simplified model considers that all TSCs are caused by electron detrapping, ignoring currents due to other factors such as polarization. For the peak at 0.97 eV, the trap level density increased to 2.63 × 1,020/eVm3, which indicates that adding TiO2 nanoparticles can introduce charge traps into PP.

4 Discussion

The aforementioned experimental results show that adding TiO2 nanoparticles has significant effects on the electrical and dielectric properties of PP. The conductivity is reduced, and both AC and DC breakdown strengths are improved. Even though the resistance and breakdown strength are degraded with an increase in temperature, the insulation of the PP/TiO2 composite is still higher than that of pure PP.

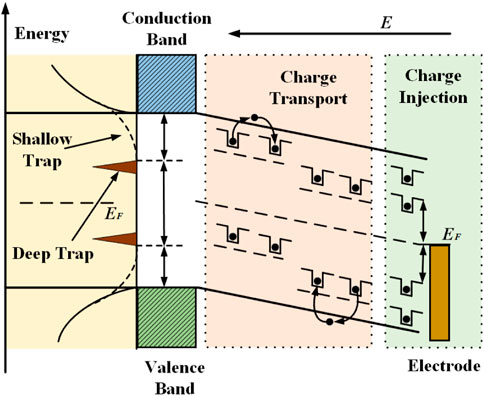

The improved insulating properties may be related to more charge traps in the PP/TiO2 composite. Figure 14 shows the basic mechanism of charge injection and charge transport in nanodielectrics. Under the electric field, the charges migrate between the traps due to the electric field force and thermal excitation by jumping over potential barriers. Considering the effect of traps in nanocomposites, the hopping conductive current can be expressed as follows (Bässler, 1994):

where n is the charge density, e is the charge of an electron, λ represents the hopping distance, ν is the thermal vibration frequency, u is the trap depth, k is the Boltzmann constant, T is the temperature, and E is the local electric field. The expression can be simplified to be

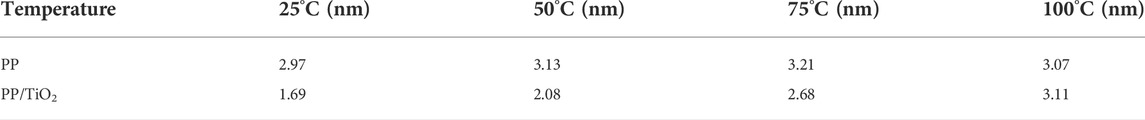

By using Eq. 2, the hopping distance λ of pure PP and PP/TiO2 nanocomposites was fitted, as listed in Table 2. The hopping distances of different temperatures are in the range between 1.69 and 3.11 nm, which is similar to that of Cao et al. (2004). But compared to pure PP, the hopping distance of the PP/TiO2 nanocomposite is smaller at low temperatures. But the hopping distance of the PP/TiO2 nanocomposite increases with the temperature. When the temperature reaches 100°C, the hopping distance of the PP/TiO2 nanocomposite is almost identical to that of PP.

As mentioned earlier, the conduction of PP is attributed to the hopping process between traps. Therefore, there is a direct correlation between the electrical conductivity and the trap characteristics (Tian et al., 2011b). The deeper the trap energy level is, the carriers captured by the trap are harder to be thermally excited to participate in electrical conduction, which results in the lower concentration of transferable carriers. The greater the trap density, the greater is the probability of carriers being captured by the traps, hindering the migration and reducing the mobility of charge carriers.

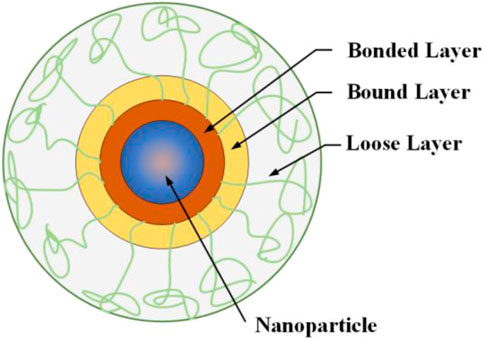

Due to the huge specific surface area of nanoparticles, a huge interaction zone is then formed when nanoparticles are introduced into a polymer matrix (Li et al., 2011). The interaction region is the bridge connecting the nanoparticles and the polymer matrix, whose physicochemical properties are different from those of both the nanoparticles and the base matrix. A multicore model has been proposed to explain the structure of the interaction region (Tanaka et al., 2005; Tanaka, 2005), as shown in Figure 15. The interaction region between the nanoparticles and polymer matrix is divided into a three-layered structure of a bonded layer, a bound layer, and a loose layer from inside to outside. The covalent bonds and hydrogen bonds in the bonded layer have a greater effect on the charge. The bound layer interacts with the surface of nanoparticles through the bonded layer. Its properties affect the free volume and trap characteristics of the nanocomposite, thereby affecting the dielectric and electric properties. The loose layer is a region with different chain conformation, chain mobility, and free volume or crystallinity. The thickness of the bound layer is in the range of 2–9 nm, which may be smaller than the average free path of charge carriers (Li et al., 2011). The energy obtained from the external electric field may not be enough for the charge carriers to jump over the deep trap barrier. Then, the charges are trapped in these regions, leading to the decrease in the carrier mobility. After adding TiO2 nanoparticles, the interaction region increases, introducing more deep traps in the PP/TiO2 nanocomposite, which can be observed at the additional peak of about 0.97 eV in the TSC results. On the other hand, the migration of charge carriers is also related to the aggregated structure of the polymer matrix. The charges are more likely to migrate in the amorphous region or at the interface between the amorphous region and the crystalline region. It has been reported that the nanoparticles would play as nucleating agents during the crystallization process of PP (Zhe et al., 2016). The crystallinity is then increased, and the charge transport becomes difficult, which is also the reason for the decrease in conductivity of the PP/TiO2 nanocomposite.

As the temperature increases, the dissociated impurities in PP increase, resulting in an increase in the number of charge carriers. On the other hand, the charge carriers in the traps gain more energy due to thermal vibrations and thus are more easily de-trapped from the traps, resulting in increased mobility of charge carriers. As a result, the conductive current increases with temperature. For the conduction of the PP/TiO2 nanocomposite, the hopping distance is found to be increased with temperature. This may be attributed to the introduced trap depth distribution of TiO2 nanoparticles. It can be seen from Figure 13 that the depth of traps of PP/TiO2 nanocomposites is in the range between 0.80 and 1.05 eV. At low temperatures, the charge carriers are repeatedly trapped and de-trapped in these traps, resulting in a smaller hopping distance of the PP/TiO2 nanocomposite than pure PP. When the temperature increases, the energy of the charges also increases. Relatively shallow traps are then difficult to trap charges for a long time. The charge carriers are only localized to those deeper traps, resulting in an increase in the apparent hopping distance of charge carriers, as shown in Figure 16.

Both the improved AC and DC breakdown strength of the PP/TiO2 nanocomposite may also be attributed to the increased trap density (Chi et al., 2019). The ionized charges are easily captured in these traps and then released by the thermal vibration. With the repeated trapping and de-trapping process, the charges gradually lose their energy, causing a reduced probability of further ionization. On the other hand, the charges captured by the deep traps at the electrode-dielectric interface form homopolarity space charges. The homopolarity space charges would reduce the electric field near the electrode and suppress the charge injection process (Wang et al., 2016). As a result, the increase in deep traps in the PP/TiO2 nanocomposite is beneficial to the improvement of breakdown performance, even at high temperatures.

Although the improved insulation of the PP/TiO2 nanocomposite, it is found that the permittivity and dielectric loss are increased by TiO2 nanoparticles. Permittivity is related to the polarization phenomena in and between dielectrics. On the one hand, the interaction between nanoparticles and the PP matrix would restrict the movement of the molecular chains, therefore restraining the polarization and reducing the permittivity. On the other hand, the polarization of nanoparticles and the interfacial polarization between the TiO2 nanoparticles and the PP matrix would increase the permittivity (Singha and Thomas, 2009; Ling et al., 2014). These two opposite phenomena together determine the permittivity of nanodielectrics depending on which one is dominant. In this study, the relative permittivity of TiO2 nanoparticles was much higher than that of PP. Thus, they introduce a large amount of dipole moment to increase the permittivity of the PP/TiO2 nanocomposite. As the temperature increases, the conduction of the PP/TiO2 nanocomposite increases, making it easier for charges to accumulate on the surface of nanoparticles to generate interfacial polarization. Therefore, the low-frequency permittivity of nanodielectrics increases significantly in high-temperature environments. Even though the traps introduced by TiO2 nanoparticles limit the conduction loss, the interfacial polarization loss of nanoparticles leads to a much larger Tanδ of the PP/TiO2 nanocomposite, which could also be confirmed by the Tanδ peak appearing in the middle-frequency region.

5 Conclusion

This article investigates the effect of TiO2 nanoparticles on the electrical and dielectric properties of PP at different temperatures. The main conclusions are summarized as follows:

Adding TiO2 nanoparticles could improve the breakdown strength of PP. The DC and AC breakdown electric fields of the PP/TiO2 nanocomposite are 1.22 and 1.46 times as those of pure PP at room temperature. Even though the high temperature reduces the breakdown strength, the breakdown strength of PP/TiO2 nanocomposites at 100°C is comparable to that of pure PP at 25°C.

The conduction of PP is retrained by TiO2 nanoparticles. The reduced conductive current of the PP/TiO2 nanocomposite would be attributed to the charge traps formed at the interaction region between TiO2 nanoparticles and the PP matrix. With the increase in temperature, the charge carriers with high energy are not easier to be localized in the traps, resulting in an increase in the hopping distance in the PP/TiO2 nanocomposite.

The interfacial polarization caused by TiO2 nanoparticles enhances the relative permittivity and dielectric loss of PP. The increased temperature expands the volume, leading to the slight decrease in permittivity of PP. But the increased conduction accelerates the accumulation of charges on the surface, resulting in the increase in permittivity and dielectric loss of PP/TiO2 nanocomposites at low frequencies.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

HZ contributed to the conception of the study; YD, MX and GM performed the experiment; HZ and MX contributed significantly to analysis and manuscript preparation; YD, GM and PL performed the data analyses and wrote the manuscript; HZ and JQ helped perform the analysis with constructive discussions.

Funding

This research is supported by the State Grid Corporation of China Headquarters Management Science and Technology Project (52060022002H).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Azmi, A., Lau, K. Y., Ahmad, N. A., Abdul-Malek, Z., Tan, C. W., Ching, K. Y., et al. (2022). Dielectric properties of thermally aged polypropylene nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 29, 1–550. doi:10.1109/TDEI.2022.3163796

Bässler, H. (1994). Hopping conduction in polymers. Int. J. Mod. Phys. B 8, 847–854. doi:10.1142/s0217979294000385

Bin, D., Jun, H., Yao, Z., and Jinliang, H. (2017). Remarkably improved electrical insulating performances of lightweight polypropylene nanocomposites with fullerene. J. Phys. D. Appl. Phys. 50, 455303. doi:10.1088/1361-6463/aa89d9

Cao, Y., Irwin, P. C., and Younsi, K. (2004). The future of nanodielectrics in the electrical power industry. IEEE Trans. Dielectr. Electr. Insul. 11, 797–807. doi:10.1109/TDEI.2004.1349785

Chen, G., Hao, M., Xu, Z., Vaughan, A., Cao, J., and Wang, H. (2015). Review of high voltage direct current cables. CSEE Power Energy Syst. 1, 9–21. doi:10.17775/CSEEJPES.2015.00015

Cheng, Q., Zha, J. W., Zhai, J. T., Zhang, D. L., Dang, Z. M., Chen, G., et al. (2019). Improved space charge suppression in PP/SEBS nanocomposites by controlling MgO nanoparticles with abundant surface defects. Appl. Phys. Lett. 115, 102904. doi:10.1063/1.5123208

Chi, X. H., Cheng, L., Liu, W. F., Zhang, X. H., and Li, S. T. (2019). Dynamic mechanism of breakdown in polypropylene-based nano-dielectric. AIP Adv. 9, 015135. doi:10.1063/1.5062583

Du, B. X., Li, Z., Yang, Z., and Jin, L. (2017). Application and research progress of HVDC XLPE cables. High. Volt. Eng. 43, 344–354. doi:10.13336/j.1003-6520.hve.20170123002

Ghorbani, H., Abbasi, A., Jeroense, M., Gustafsson, A., and Saltzer, M. (2017). Electrical characterization of extruded DC cable insulation — the challenge of scaling. IEEE Trans. Dielectr. Electr. Insul. 24, 1465–1475. doi:10.1109/TDEI.2017.006124

Green, C. D., Vaughan, A. S., Stevens, G. C., Sutton, S. J., and Fairhurst, M. J. (2011). “Electrical and mechanical properties of new recyclable power cable insulation materials based upon polyethylene blends,” in Proceedings of the 17th International Symposium on High Voltage Engineering, Hannover,Germany, 22-26 Aug. 2011.

Hu, S., Zhou, Y., Yuan, C., Wang, W., Hu, J., Li, Q., et al. (2020). Surface-modification effect of MgO nanoparticles on the electrical properties of polypropylene nanocomposite. High. Volt. 5, 249–255. doi:10.1049/hve.2019.0159

Khalil, M. S. (1997). International research and development trends and problems of HVDC cables with polymeric insulation. IEEE Electr. Insul. Mag. 13, 35–47. doi:10.1109/57.637152

Li, J., Xing, Y., Xiao, M., Zhang, J. W., and Du, B. (2016). Discharge breakdown characteristics with fluorinated polyimide films in high-temperature superconducting cable insulation. IEEE Trans. Appl. Supercond. 26, 1–5. doi:10.1109/TASC.2016.2594873

Li, S., Yin, G., Bai, S., and Li, J. (2011). A new potential barrier model in epoxy resin nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 18, 1535–1543. doi:10.1109/TDEI.2011.6032822

Li, Z. L., Fan, M. S., Zhou, S. F., and Du, B. X. (2021). BNNS encapsulated TiO2 nanofillers endow polypropylene cable insulation with enhanced dielectric performance. IEEE Trans. Dielectr. Electr. Insul. 28, 1238–1246. doi:10.1109/TDEI.2021.009574

Ling, Z., Yuanxiang, Z., Meng, H., Yanchao, S., Jihuan, T., and Qing, Y. (2014). Effect of nanoparticle surface modification on charge transport characteristics in XLPE/SiO2 nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 21, 424–433. doi:10.1109/tdei.2013.004145

Maekawa, Y., Yamaguchi, A., Hara, M., and Sekii, Y. (1994). Development of XLPE insulated DC cable. Elect. Eng. Jpn. 114, 1–12. doi:10.1002/eej.4391140801

Montanari, G. C., Laurent, C., Teyssedre, G., Campus, A., and Nilsson, U. H. (2005). From LDPE to XLPE: Investigating the change of electrical properties. Part I. Space charge, conduction and lifetime. IEEE Trans. Dielectr. Electr. Insul. 12, 438–446. doi:10.1109/TDEI.2005.1453448

Singha, S., and Thomas, M. J. (2009). Influence of filler loading on dielectric properties of epoxy-ZnO nanocomposites. IEEE Trans. Dielectr. Electr. Insul. 16, 531–542. doi:10.1109/TDEI.2009.4815189

Takala, M., Ranta, H., Nevalainen, P., Pakonen, P., Pelto, J., Karttunen, M., et al. (2010). Dielectric properties and partial discharge endurance of polypropylene-silica nanocomposite. IEEE Trans. Dielectr. Electr. Insul. 17, 1259–1267. doi:10.1109/TDEI.2010.5539698

Tanaka, T. (2005). Dielectric nanocomposites with insulating properties. IEEE Trans. Dielectr. Electr. Insul. 12, 914–928. doi:10.1109/tdei.2005.1522186

Tanaka, T., Kozako, M., Fuse, N., and Ohki, Y. (2005). Proposal of a multi-core model for polymer nanocomposite dielectrics. IEEE Trans. Dielectr. Electr. Insul. 12, 669–681. doi:10.1109/TDEI.2005.1511092

Teyssedre, G., Laurent, C., Montanari, G. C., Campus, A., and Nilsson, U. H. (2005). From LDPE to XLPE: Investigating the change of electrical properties. Part II. luminescence. IEEE Trans. Dielectr. Electr. Insul. 12, 447–454. doi:10.1109/TDEI.2005.1453449

Tian, F., Bu, W., Shi, L., Yang, C., and Lei, Q. J. (2011a). Theory of modified thermally stimulated current and direct determination of trap level distribution. J. Electrost. 69, 7–10. doi:10.1016/j.elstat.2010.10.001

Tian, F., Yang, C., He, L., Han, B., and Lei, Q. (2011b). Recent research advancement in dielectric properties and the corresponding mechanism of polymer/inorganic nanocomposite. Diangong Jishu Xuebao/Transactions China Electrotech. Soc. 26, 1–12. doi:10.3724/SP.J.1011.2011.00211

Wang, W., Min, D., and Li, S. (2016). Understanding the conduction and breakdown properties of polyethylene nanodielectrics: Effect of deep traps. IEEE Trans. Dielectr. Electr. Insul. 23, 564–572. doi:10.1109/TDEI.2015.004823

Xiaozhen, H., Ilkka, R., Rafal, A., Amirhossein, M., Minna, N., Eetta, S., et al. (2021). Combining good dispersion with tailored charge trapping in nanodielectrics by hybrid functionalization of silica. E-POLYMERS 21, 897–909. doi:10.1515/epoly-2021-0054

Xingyi, H., Pingkai, J., and Yi, Y. (2009). Nanoparticle surface modification induced space charge suppression in linear low density polyethylene. Appl. Phys. Lett. 95, 242905. doi:10.1063/1.3275732

Yanbin, S., Suibin, L., Shuhui, Y., Rong, S., and Ching-Ping, W. (2016). Surface-modified barium titanate by MEEAA for high-energy storage application of polymer composites. High. Volt. 1, 175–180. doi:10.1049/hve.2016.0066

Yang, Y., Li, Q., and He, J. (2018). “The dielectric properties of PP nanocomposites doped with mesoporous silica nanoparticles,” in Proceedings of the 2018 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Cancun, Mexico, 21-24 Oct. 2018. doi:10.1109/CEIDP.2018.8544907

Yao, Z., Jinliang, H., Jun, H., and Bin, D. (2015). Surface-modified MgO nanoparticle enhances the mechanical and direct-current electrical characteristics of polypropylene/polyolefin elastomer nanodielectrics. J. Appl. Polym. Sci. 133, 42863. doi:10.1002/app.42863

Zhang, L., Khani, M. M., Krentz, T. M., Huang, Y., Zhou, Y., Benicewicz, B. C., et al. (2017). Suppression of space charge in crosslinked polyethylene filled with poly(stearyl methacrylate)-grafted SiO2 nanoparticles. Appl. Phys. Lett. 110, 132903. doi:10.1063/1.4979107

Zhang, Z., Zheng, X., Jin, Y., Wu, J., Wu, W., and Lei, W. (2015). Surface flashover characteristics in polyimide/ZnO nanocomposite under DC voltage in vacuum. IEEE Trans. Dielectr. Electr. Insul. 22, 5951–5957. doi:10.1109/TDEI.2015.004318

Zhe, L., Weikang, C., Gehao, S., Xiuchen, J., and Danikas, G. M. (2016). Experimental study on space charge and electrical strength of MgO nano-particles/polypropylene composite. IEEE Trans. Dielectr. Electr. Insul. 23, 1812–1819. doi:10.1109/tdei.2016.005181

Keywords: nanocomposite, polypropylene, breakdown strength, conductivity, permittivity, trap

Citation: Zhang H, Duan Y, Xie M, Ma G, Li P and Qin J (2022) The effects of TiO2 nanoparticles on the temperature-dependent electrical and dielectric properties of polypropylene. Front. Energy Res. 10:999438. doi: 10.3389/fenrg.2022.999438

Received: 21 July 2022; Accepted: 08 August 2022;

Published: 06 September 2022.

Edited by:

Yiyi Zhang, Guangxi University, ChinaCopyright © 2022 Zhang, Duan, Xie, Ma, Li and Qin. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hao Zhang, c2RxenpoQDE2My5jb20=

Hao Zhang

Hao Zhang Yubing Duan

Yubing Duan Maojie Xie

Maojie Xie Guoqing Ma

Guoqing Ma Pengfei Li

Pengfei Li Jiafeng Qin

Jiafeng Qin