95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 23 November 2022

Sec. Bioenergy and Biofuels

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.979502

Parts of this article's content have been modified or rectified in:

Erratum: Enhancing biomass utilization by combined pulp and fuel production

A shift from fossil fuels to renewable energy sources is essential to reduce global greenhouse gas emissions and climate change effects. Biofuels represent a promising low-carbon alternative for sectors that are hard to electrify, such as freight transport or aviation. This work investigates possible pathways for increasing the value of biomass at a Kraft pulp mill, focusing on black liquor and bark streams. Mathematical programming is coupled with superstructure optimization and systematic solution exploration to identify meaningful process configurations. The analysis of solutions under market variations allows for the identification of robust and competitive configurations for the co-production of pulp and fossil fuel alternatives. The results show that the integration of biorefineries in pulp mills results in better resource use and higher energy efficiency - diversifying the product portfolio and providing bio-based fuel products to the market while being economically viable. By incorporating fuel production in the conventional Kraft process, the carbon conversion efficiency of the mill can be increased from 48% to up to 67%. Extending the analysis, up to 2% of the European road freight transportation fuel could be provided with combined pulp and fuel production, and 5% of the worldwide fuel demand for passenger aviation.

In the context of climate change, the reduction of energy use and greenhouse gas (GHG) emissions is a major challenge for society. In 2015, 196 nations committed to limiting global temperature rise to below 2°C, with a target of 1.5°C in the Paris Agreement. Achieving this goal requires a transition away from fossil fuels in all sectors. The industrial sector was responsible for 32% of the total fuel consumption and 13% of the energy-related CO2 emissions in the European Union (EU) in 2017 (International Energy Agency, 2020). In the new Energy strategy presented in 2020 in the frame of the European Green Deal, key measures for each branch are presented to make Europe the first climate-neutral continent by 2050. Even though no set emission goals are required from the industrial sector, the overall strategy is to make it greener, more circular and more digital. Particular recommendations for decreasing GHG emissions–apart from policy measures such as carbon pricing and energy efficiency audits–include decarbonization strategies in the form of direct usage of renewable energy from biomass and waste heat; carbon capture and utilization; and the deployment of hydrogen solutions (International Energy Agency, 2020). The transportation sector accounts for 28% of the fuel consumption and 29% of the energy-related CO2 emissions. Over 64% of the energy consumption in the transport sector is in the form of diesel, 24% gasoline, 5% biofuels and 2% electricity. The European Green Deal aims at a 90% reduction of greenhouse gas emissions from transport by 2050, while the EU Renewable Energy Directives (RED) requires the EU to meet a 10% target of renewable energy by 2020 and 14% by 2030 (International Energy Agency, 2020). Besides shifting large shares of freight transport to rail and improving energy efficiency in vehicles, switching to renewable energy and sustainable biofuels is one of the main measures addressed. According to the International Energy Agency (IEA), biofuels, defined as liquid and gaseous fuels derived from organic matter, could provide up to 27% of the total transport fuel by 2050, replacing diesel, kerosene and jet fuels (International Energy Agency, 2020). As biomass is a limited resource, biomass-based industries are increasingly motivated to improve the conversion efficiency of biofuel production processes and enhance waste streams. Over 19% of the European roundwood is currently consumed in the pulp and paper industry (European Commission, 2019). This industrial sector represents 10% of the fuel consumption of the EU’s industry when considering non-energetic usage of fuel, and features the lowest emission intensity of all sectors, accounting for 0.7 tons of CO2 per ton of energy due to the use of mostly bioenergy and electricity in Nordic countries (International Energy Agency, 2020). Currently, this industrial branch is not only one of the biggest consumers of fuel in the EU, it is the only sector that - apart from producing pulp - is a net-exporter of energy in the form of electricity. Thus, the pulp and paper industry represents one of the biggest suppliers and consumers of renewable energy, while holding great potential to contribute to the objectives of reducing GHG emissions in the industrial sector by means of efficient resource valorization and biofuel production (Larson et al., 2003).

Owing to the complexity of systems such as the one described herein, mathematical programming and optimization are not only required as decision support tools for the design, but also to identify the potential of combined pulp and fuel production. Moreover, effects of an uncertain surrounding market economy can be analyzed.

Mathematical programming and optimization methods have been applied intensively to similar superstructure optimization problems (Gassner and Maréchal, 2009; Tock et al., 2010; Santibañez-Aguilar et al., 2011; Viana Ensinas et al., 2013; Celebi et al., 2017; Castro-Amoedo et al., 2021). As noted by Liu et al. (2012), when generating results by means of optimization, deriving a set of feasible alternatives may be preferred to the generation of a single system design - one that is only potentially optimal under certain external conditions. In that context, multi-objective optimization solved with heuristic or deterministic approaches is one widely applied method for generating a set of alternative solutions (Branke et al., 2008). When generating solutions based on market assumptions, the question of uncertainty comes to mind. Given the current political, societal and environmental situations, it is noticeable that – apart from fluctuations originating from regular demand and supply shifts and mismatches – extreme events like natural disasters, wars or global pandemics can change the playing field within hours, rendering outcomes solely on a market configuration unusable. Moreover, investment cost assumptions are often proven to be incorrectly estimated retrospectively. Such uncertainty can be considered by decoupling the objective function from the uncertainty parameters and choosing an objective that is independent, as done by Tock and Maréchal (2015), who used CO2 capture and energy efficiency as objectives. Alternatively, uncertainty can be included directly in the solution generation procedure, either by generating solutions with different economic scenarios while keeping a deterministic approach, or by embedding uncertain penalizing weights in the objective function. The review by Soroudi and Amraee (2013) presents the state-of-the-art in decision-making under uncertainty applied to energy systems; a classification of different uncertainty handling methods is given, together with prospective advantages and disadvantages.

The main objective of this study is to identify alternative pathways for biomass utilisation in pulp mills, increasing the value of key residue streams and decreasing the release of greenhouse gas emissions at a system level. Identified solutions need to be robust towards market fluctuations, providing resilience and reliable supply of products. Resilience in this regard should be interpreted as the plant’s ability to react to external disruptions by being self-sufficient, particularly regarding electricity supply.

The following Section 2 introduces a review of current research in the field of biomass conversion in pulp mills, with a special focus on biofuel production. Subsequently, the methodology for process modeling and solutions generation is presented (Section 3). Section 4 shows the results of applying the suggested methods, and discussion of the matter is provided in Section 5.

The ongoing shift to a renewable-based society is driving a focus on improving energy efficiency and on finding new ways of processing forest material into profitable products. Their well-established biomass supply chains, experience with wood handling and processing, and diversity of available biomass streams make Kraft pulp mills promising candidates for transformation into integrated product biorefineries. According to the International Energy Agency, biorefining can be defined as the “the sustainable processing of biomass into a spectrum of bio-based products (food, feed, chemicals, and materials) and bioenergy (biofuels, power and/or heat)” (IEA Bioenergy, 2014). In addition to pulp, integrated Kraft pulp mill biorefineries could produce value-added products such as polymers, composites, textile fibres and/or transportation fuels as well as energy products such as district heat and low-carbon electricity, profiting from improved resource and energy efficiency and benefiting from a broader, more robust product portfolio (Isaksson et al., 2016). Additionally, implementing non-conventional alternative biorefinery concepts in pulp mills is not an entirely new idea, with attempts made to produce pure lignin from pulp mills dating back to the 1940s (Pettersson et al., 2012). Apart from the production from fermentation products such as succinic acid, lactic acid and ethanol, carbon capture and storage and the thermo-chemical treatment of residuals are promising pathways to increase resource efficiency in a pulp mill. A detailed overview of possible options to be integrated is available in Mongkhonsiri et al. (2018) and Hamaguchi et al. (2012).

While not strictly classified as waste according to the European Waste Catalogue since it forms part of the production process, black liquor has received considerable attention due to its high energy content (Monte et al., 2009). In a conventional Kraft mill, the spent black liquor, also known as weak black liquor, is concentrated before being burned in a recovery boiler to produce heat and electricity for the pulping process. It holds about half the energy of the wood input to a Kraft pulp mill, and approximately six times the energy contained in other biomass by-products generated by a typical mill (Larson et al., 2003). This highly alkaline weak black liquor contains large amounts of water, between 80 and 85 weight percent (wt%), as well as organic residues from the pulping process, inorganic cooking chemicals and small amounts of inorganics dissolved from wood. Black liquor has a high volatile content, with fixed carbon representing only 20% of the organic solids. However, due to a high-moisture content, its heating value is extremely low, requiring a concentration step prior to energy recovery (Gullichsen et al., 1999). The spent liquor contains a large amount of inorganics, owing the presence of used cooking chemicals, as well as significantly more sulphur than woody biomass, which is present in the form of organic and inorganic compounds (Ek et al., 2016).

Another key waste stream in the Kraft pulp mill is the bark which is removed from the logs during the debarking process. It represents approximately 10% of the total pulpwood input stream (Consonni et al., 2009). The amount of residue depends on the process, wood type, and local conditions. For example, eucalyptus is usually debarked in the forest, decreasing the amount of woody residue at the mill (Kuparinen and Vakkilainen, 2017). Chemical pulps, such as those produced in the Kraft process, use a mixture of hard and softwoods Bajpai (2015). Generally, bark contains more ash, less cellulose, and more lignin than wood (Nosek et al., 2015). Bark has also significantly lower amounts of volatile matter and thus more fixed carbon, which influences the gasification behaviour (Wilk et al., 2011).

Numerous studies explore the opportunity to valorise black liquor and woody residue streams in the context of an energy integration and optimization framework.

The pathways currently being investigated to increase the value of the woody residue stream at pulp and paper mills can be grouped into three main categories: bio-chemical, thermo-chemical and physical (Hamaguchi et al. , 2012). Likewise, the outputs of these processes can be grouped roughly into three types: fuel, heat and electricity.

The particularly high ash and alkali content of bark limits the maximum allowable temperature in combustion boilers. As such, bark is mainly used as a boiler fuel for producing low pressure process steam or hot water (Ahlström et al., 2019). Excess bark from pulp mills in Scandinavia, for example, is commonly sold to local combined heat and power (CHP) plants, or used as fuel for lime kilns. In the 1980s, during the second oil crisis, commercial wood-residue gasifiers for use with lime kilns were built at mills in Sweden, Finland and Portugal to replace oil with biomass (Kuparinen and Vakkilainen, 2017; Breitholtz, 2009). Scandinavian countries also began to fire powdered wood residues directly into their lime kilns as a simpler alternative to biomass gasification (Francey et al., 2009). However, this fuel option requires low feed moisture content and the use of additional purchased lime to control non-process elements. Bark powder-fired kilns also show lower availability than the traditional oil fired lime kiln which is typically between 80 and 90% (Berglin (2010)), and the bark firing system suffers from low reburned lime availability, high power consumption, and mechanical wear. Nevertheless, there has been renewed interest in bark use in the lime kiln. In a modern pulp mill the lime kiln is the only unit operation which uses fossil fuels during normal operation and, consequently, the only source of fossil fuel-based emissions (Kuparinen and Vakkilainen, 2017). Therefore, by using biomass, the normal Kraft mill operations can become CO2 neutral.

A range of different applications has been investigated for syngas production via gasification of the wood residue stream. In its broadest sense, the term gasification describes the conversion of any carbonaceous fuel to a gaseous product with a useable heating value (Higman and Burgt, 2008). A typical gasification system consists of several process units including a feedstock preparation area, gasifier, gas cleaning section, sulphur recovery unit, as well as downstream processes (Speight, 2014). Andersson and Harvey (2007) used syngas from bark and wood gasification for hydrogen production. Andersson et al. (2014) examined using syngas to generate methanol while Ljungstedt et al. (2013) used syngas to produce Fischer-Tropsch fuels. Wetterlund et al. (2011) compared syngas co-generation via a biomass integrated gasification combined cycle with a fuel synthesis unit to produce dimethyl ether (DME). Consonni et al. (2009) and Isaksson et al. (2016) compared exploiting biomass for co-generation or fuel synthesis. Consonni et al. (2009) focused on three different synthetic fuel options: Fischer-Tropsch liquids, DME and mixed-alcohols whereas Isaksson et al. (2016) investigated methanol, Fischer-Tropsch fuels and synthetic natural gas (SNG) production.

The Kraft chemical recovery process is a mature, effective technology that allows recycling of inorganic pulping chemicals, efficient generation of steam and electricity from black liquor, as well as effective disposal of wood residues (Tran and Vakkilainen, 2016). Without the recovery cycle, the Kraft pulping process would be both economically and environmentally intolerable (IEA Bioenergy, 2007). Black liquor is a key part of this recovery cycle, so it is crucial that alternative valorisation does not penalize the recovery of the cooking chemicals. Black liquor gasification is currently being developed for recovery of cooking chemicals and energy in pulp mills as a replacement for the conventional Tomlinson recovery boiler, which has several disadvantages in terms of electricity generation efficiency owing to limits on operating temperature due to high alkali content, smelt-water explosion and reduced-sulphur gas emissions (Naqvi et al., 2010). In the gasification process, the organic content of the black liquor is converted to a synthesis gas. The cooking chemicals are recovered and can be returned to the pulping process. Many of the studies on black liquor gasification focus on dry black liquor gasification technologies. This process still requires the use of energy-intensive evaporation and concentration stages, prior to the recovery boiler stage. Nonetheless, a number of studies have examined the integration of black liquor supercritical water gasification (SCWG) at Kraft pulp mills. Naqvi et al. (2009), Cao et al. (2017a) and Granacher et al. (2019) examined replacing the recovery boiler with a supercritical gasification unit, while Magdeldin and Järvinen (2020) Özdenkçi et al. (2019) focused on integration of SCWG in parallel with the recovery boiler. Consonni et al. (2009), Andersson et al. (2014) and Andersson and Harvey (2007) examined the combination of biomass and black liquor gasification technologies. In a preliminary study, Granacher et al. (2019) found that using black liquor in a catalytic hydrothermal gasification unit instead of a recovery boiler would allow the reference Kraft pulp mill to export electricity and SNG while being self-sufficient with respect to the heat demand of the pulp production process. Naqvi et al. (2009) compared two different bio-refinery pathways for valorisation of black liquor: dry oxygen blown pressurised gasification followed by DME synthesis and catalytic hydrothermal gasification with methane synthesis. The biofuel production potential and the fuel-to-product efficiency were higher for methane than for DME production owing to a better integration with the pulping process and elimination of the evaporation unit in the pulp mill. Cao et al. (2017a) performed a system analysis of the pulping process coupled with SCWG of black liquor for combined hydrogen, heat and power production. Magdeldin and Järvinen (2020) studied the integration of a supercritical water reactor system in a market Kraft pulp mill. By re-directing 30–50% of the weak black liquor stream to the SCWG unit, the pulp production could be increased by 75% with mill steam and power requirements still satisfied and minimal disruptions to mill chemistry. Özdenkçi et al. (2019) investigated the thermo-economic feasibility of supercritical water gasification of the black liquor stream at a Kraft pulp mill, comparing different reactor materials and target products. The analysis was based on performance data from laboratory scale experiments, and further validation for scale up is required due to the uncertainty in the catalytic effect of the reactor material (Özdenkçi et al., 2019).

Numerous studies focus on the gasification of either black liquor or bark residues, but limited work including both is available. Even though the co-production of pulp and fuel is frequently addressed, there is only limited work available on the full integration between pulp and fuel production and how the energy balance of the overall system can be closed. Moreover, looking into methods on how solutions are generated and analyzed, most studies rely on a simulation-based approach rather than rigorous optimization tools. When optimization is used, it is mostly based on single-objective approaches. Furthermore, parameter uncertainty and solution robustness is frequently overlooked. This work develops a superstructure-based approach in which biomass conversion to fuel and products in a pulp mill and its benefits is investigated. Furthermore, potential synergies of storing electricity from renewable resources in form of value-added products such as liquid fuel and hydrogen while producing pulp are explored. Solutions for different economic scenarios are generated and analyzed, taking into account decision makers’ preferences as well as solution robustness regarding economic uncertainty. Robustness in this context is defined as being stable in performance independently of variations in the parameter space. In that regard, typical configurations are identified; their economic and environmental performance and potential benefits for the transportation sector in different regions are discussed. Furthermore, the role of the market concerning selected performance criteria is investigated.

Kraft pulp mills, currently representing the dominant technology to produce pulp, have been identified as the biomass-based sector having the largest potential for the implementation of new technologies; the co-production of high-value energy products motivates the research on the topic (IEA ETSAP, 2015). In a modern Kraft mill, wood is debarked, chipped and then screened to remove non-wood materials. Wood chips are sent to the cooking process (digester) where they are boiled under high pressure and high temperature in the presence of sodium sulphide (Na2S) and sodium hydroxide (NaOH), separating the cellulosic fibres (pulp). Following the cooking process, the pulp is washed to remove the spent liquor, and then screened, bleached and dried ready for market. The spent liquor, also called weak black liquor, is concentrated in multi-stage evaporators to increase the solids content to approximately 65–85%, allowing efficient combustion in the recovery boiler (Clay, 2020). Reducing conditions at the bottom of the furnace permits recovery of sodium and sulphur as molten Na2S and sodium carbonate (Na2CO3), known as smelt. In the upper section of the furnace the organic material is completely oxidised to provide heat for high-pressure steam generation. When the concentrated liquor is sprayed into the boiler, a substantial part of the organic carbon is converted to carbon (C) and carbon monoxide (CO). At high temperatures, C and CO reduce all the oxidised sulphur chemicals to Na2S. The molten smelt (containing Na2CO3 and Na2S) is tapped from the bottom of the boiler and subsequently dissolved in a water solution forming green liquor, which is then sent to the cauticising stage, where Na2CO3 is converted to caustic soda via addition of calcium oxide (CaO). Calcium carbonate (CaCO3) formed during causticising is precipitated and removed from the liquor, originating a then called white liquor. CaCO3 is burned in the lime kiln to reform CaO, releasing CO2 (Lachenal, 2016; Quina and Pinheiro, 2020).

CO2 is primarily produced via combustion processes. The largest sources of CO2 are the recovery boiler, the biomass (bark) boiler and the lime kiln. Given that the majority of fuel used at the pulp mill is biomass-based, the CO2 produced is largely biogenic (Kuparinen et al., 2019). Generally, the lime kiln is the only source of fossil fuel-based CO2 emissions during normal operation. Modern pulp mills are often self-sufficient and can supply power to the grid, steam to local heating plants, or heat to a district heating grid (IEA ETSAP, 2015; Tran and Vakkilainen, 2016).

The pulp mill model developed for this study is based on the work of Kermani et al. (2019), while the model for the lime kiln is based on Adams (2007) and the recausticizing on Sanchez (2000). The key modeling assumptions are summarized in the Supplementary Information (SI).

The main identified biogenic residue streams, i.e., black liquor and bark, can be valorised in alternative process routes to cogenerate fuel, heat and electricity and thus improve the overall resource efficiency of the Kraft mill. Gasification technology is selected as the main focus of this work for valorising the bark stream, as it enables low-quality solid fuels like biomass to be converted to a synthetic fuel (Higman and Burgt, 2008).

For the gasification and fuel synthesis from bark, different process routes of gasification and fuel synthesis types are considered, yielding Fischer-Trospsch fuels (FT), DME and methanol (MeOH). The general setup of all routes consists of pretreatment, gasification, gas cleaning, gas conditioning and fuel synthesis. All chosen fuels are generated in exothermic fuel synthesis reactions and comprise promising application opportunities as transportation fuels. As an alternative to liquid fuel production, producer gas can be upgraded via methanation to SNG. The process models for SNG and alternative fuel production are adapted from Peduzzi (2015) and Tock et al. (2010), further details can be found in the Supplementary Material.

Since the conventional operation of the recovery boiler fueled by concentrated black liquor is energy intensive due to evaporation and concentration, hydrothermal gasification has been considered a promising alternative to treat the weak black liquor. This process is a type of gasification characterised by operating above the critical point of water, where water has the advantage of behaving like a non-polar solvent with a low dielectric constant, high diffusivity and a low dissociation constant (Huet et al., 2015). As water is needed in the processes as both a reactant and a reaction medium, no evaporation and concentration steps prior to gasification are necessary (Kruse, 2016). Firstly, organic matter is solubilized and rapidly decomposed by hydrolysis into smaller molecules, generating a gas mixture. These reactions in solution are much faster due to little to none heat and mass transfer limitations (Blasio et al., 2016). Inorganic compounds of the black liquor are precipitated because of the low dielectric constant in a salt separation step prior to gasification (Huet et al., 2015). Depending on the reaction temperature, the producer gas is rich in methane or hydrogen. Low reaction temperatures require the application of a catalyst, proven to be challenging in combination with black liquor (Cao et al., 2017b). Therefore, in this study the focus lies on the production of hydrogen from black liquor at high reaction temperatures. The models on gasification, salt separation, hydrolysis and gas separation of black liquor are based on the work of Gassner et al. (2011); Mian (2016) and adapted to non-catalytic operation with information available from Magdeldin et al. (2016), more details can be found in the Supplementary Material.

Gasifying weak black liquor instead of sending it to the conventional recovery cycle affects the operation of the mill. During gasification, a natural partitioning of sulphur and sodium results in a fraction of the sulphur leaving the gasifier in the gas phase, and the remainder in the liquid phase. The sulphur-sodium split during gasification leads to a higher causticiser and lime kiln load compared to processing the black liquor in a conventional recovery boiler. Less sulphur is available in the condensed phase to form Na2S, resulting in a larger amount of sodium carbonate (Na2CO3) being formed. The additional carbonate must be converted to NaOH in the causticising unit, resulting in a higher lime consumption, a higher load on the lime kiln and an associated increase in lime kiln fuel consumption or lime purchase (Larson et al., 2007).

Apart from the gasification of black liquor, different types of electrolysis are considered to benefit from the net positive electricity balance of the conventional Kraft process. Next to alkaline water electrolysis, brine electrolysis facilitates the recovery of NaOH and Na2CO3 using membranes. Co-electrolyis profits from high-temperature solid oxide electrolysis cells (SOECs) used to convert CO2/H2O into valuable chemicals (starting from CO/H2).

Aside from generating fuels, SNG and hydrogen by means of gasification and electrolysis, the extraction of lignin from black liquor prior to burning it in the recovery boiler is analyzed as an option to improve the mill’s resource efficiency.

In our approach, all process units are connected via a utility system, comprising a steam network. The steam generation level is set at high pressure and distribution takes place at multiple pressure levels, chosen according to temperature-enthalpy profiles of the system. It should be noted that due to the extremely high alkali content of black liquor, advanced recovery boilers in Kraft paper mills are limited to operating at steam temperatures approaching 500 °C, being well below other advanced boilers (Naqvi et al., 2010). Similarly, steam parameters must be chosen conservatively. The described superstructure is summarized in Figure 1; further details regarding individual processes are provided in the Supplementary Material.

FIGURE 1. Overall process superstructure of the proposed integrated biorefinery concept. Black arrows represent mass flows. A detailed model description is provided in the Supplementary Material.

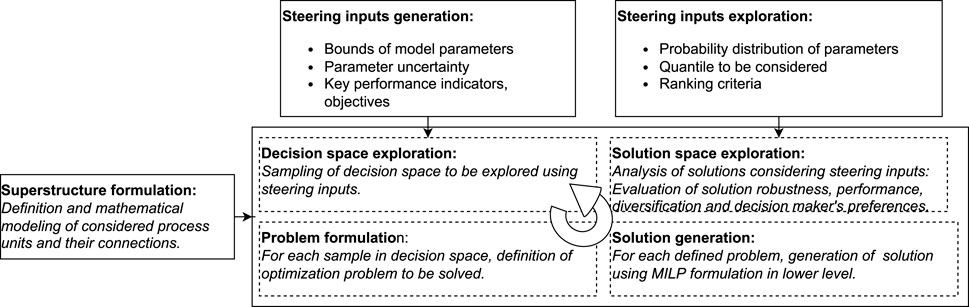

The methodology for generating and exploring solutions is adapted from Granacher et al. (2022), where an Interactive Digital Twin assists the generation and exploration of meaningful solutions for a given process superstructure in a bi-level approach. Decision makers can influence the decision-making process at different stages of the process by translating their needs into computer language and steering the solution synthesis in the desired direction (Figure 2).

FIGURE 2. Simplified flowchart of proposed methodology InDiT for the synthesis and exploration of solutions for superstructure optimization (Granacher et al., 2022).

In the first step, the units included in superstructure are formulated in the lower level by means of mathematical programming considering heat integration, following the MILP formulation in Section 3.3. The unit’s behavior thereby is described through resource and energy demands, specified at the respective temperature levels. Units are related to specific costs for investment, operation and maintenance, as well as environmental impact. They share layers of in- and outgoing streams, enabling them to be connected for synthesizing feasible designs when generating solutions. As further specified in Kantor et al. (2020); Maronese et al. (2015), units are subjected to sizing constraints based on physical and technical feasibility. After the superstructure has been formulated in the lower level, the upper level framework explores the decision space and defines a set of problems to be solved based on steering inputs specified by the decision maker (Figure 2). In this case, steering inputs include economic parameters subjected to uncertainty pun and binary variables for adding or neglecting parts of the superstructure.

Quasi-random Sobol sampling (Sobol, 1967) is used to generate the decision space, allowing for fast and efficient decision space exploration compared to classic pseudo-random methods (Hou et al., 2019). For each sample in the decision space, a Pareto-front of optimal results is generated applying an adapted version of the augmented ɛ-constraint method (Mavrotas, 2009), to the MILP formulation inherent in the lower level. This results in the generation of a diverse solutions space, containing Pareto-optimal fronts for different economic scenarios. A Pareto front of ten points is created for each of the 50 decision space samples that are generated, with total annual expenditure (TOTEX) and environmental impact (EI) as objectives. The generated solutions are reported to the upper level, where strategic solution exploration is applied to identify promising configurations for the decision maker.

The methodology for the mathematical formulation of the superstructure and optimization in the lower level is adapted from Gassner and Maréchal (2009) and Kantor et al. (2020). For each unit u in the system, energy and mass flow models describe in the unit regarding conversion processes, physical properties, mass and energy balances, and are used to obtain the characteristics of the interfaces offered for integration with other units. Presuming a set of possible units U and a set of possible system states, binary decision variables

All units are connected to a utility system, allowing for the exchange between the process and utilities to satisfy the mass and energy demand and supply profile of each unit. Chemical reactions, when relevant, are included for the respective units by either calling simulation software to provide reaction characteristics or blackbox models. For the economic analysis, operating and investment costs are calculated as a function of equipment size, using cost functions available in Turton et al. (2008); Ulrich and Vasudevan (2003). For environmental assessment, the LCI (Life Cycle Inventory) Ecoinvent database (Wernet et al., 2016) is used to estimate the environmental impacts associated with waste streams and material use for the unit’s construction (Gerber et al., 2013). Pinch analysis (Marechal and Kalitventzeff, 1998) and heat recovery for optimal utility selection is used to model heat recovery and the utility system integration by introducing the heat cascade constraints.

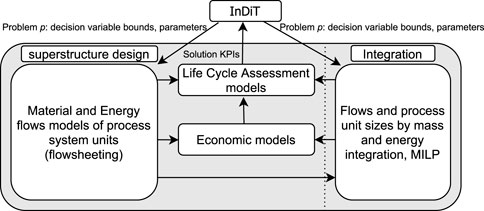

The decision variables in the lower level framework for a solution are fixed solving a mixed-integer linear programming (MILP) problem formulated in AMPL optimization language (Fourer et al., 2002), using the CPLEX branch-and-bound algorithm (IBM, 2017). Figure 3 shows the simplified structure of the lower-level framework, including the superstructure description and the solution evaluation for each problem formulated by the upper-level framework.

FIGURE 3. Simplified flowchart of lower level framework integrated in upper level Interactive Digital Twin (InDiT), adapted from Granacher et al. (2022).

Steering inputs have the purpose to guide the generation of meaningful solutions, taking parameter uncertainty and desired key performance indicators into account. Acknowledging parameter variations is of great importance as relying on current market conditions to steer the solution generation might - if chosen poorly - lead to system configurations that do not apply in real-world applications (Tock and Maréchal, 2015). Therefore, uncertainty is involved directly in the solution generation procedure, considering different economic scenarios for solution generation. This allows us to include solutions that are favourable under certain market conditions, and identify robust ones (e.g., showing good performance) for a large variety of market conditions. Similar approaches were followed by Gassner and Maréchal (2012), who decoupled thermodynamic performance from economic metrics and in that way generated system configurations that are independent of market conditions. For choosing the distribution, caution needs to be taken as the proper definition of sharp distributions is challenging. Regardless of the approach followed, when applying uncertainty or sensitivity analyses, the use of parameter distribution constitutes a major challenge. Bertsimas and Sim (2004) demonstrated that the usage of ranges is a viable opportunity, the hypothesis being validated in Moret (2017) on energy system design. Following this reasoning, variations of ±20% in the parameters are considered when exploring the decision space for solution generation. The assumptions on economic and environmental parameters are summarized in the Supplementary Material.

Apart from considering different market scenarios, different process units can be considered, generating a diverse solution space. As illustrated in Section 3.3, each unit is associated with a binary decision variable, defining whether it is used or not. Defining an upper bound Yu for this decision variable and varying it when generating the decision space creates different problems that can be solved by the MILP. While some units are always considered, Yu is varied in the steering input for others, in order to make the solution space more diverse. This approach resembles an integer-cut constraint approach applied to the upper level formulation. The Supplementary Material provides additional detail on decision variables inherent to each unit.

To evaluate generated system configurations, economic, thermodynamic and environmental criteria are chosen. They are intended to serve decision makers in evaluating solutions by using commonly used macro-indicators.

Operating expenditure OPEX consist of two main components:

The environmental impact (EI) of the energy system is calculated based on direct and indirect fossil

The currently included impact category is the Global Warming Potential GWP 100a from IPCC 2013 (

As a measure of resilience, the plant’s self sufficiency in regard to electricity (E)

The energetic efficiency ηen takes into account the conversion efficiency of biomass into energetic products such as biofuels, SNG, hydrogen and electricity. It is calculated using the lower heating values (LHV) of each component. The carbon conversion efficiency ηcarbon is defined as the ratio of carbon (C) leaving the mill in products over the carbon entering the system. The exergy efficiency relates the exergetic value

In order to identify and analyze alternatives to treat residuals in a systematic way, the previously described superstructure of pulp production integrated with various biomass conversion processes is synthesized and used for solution generation. The pulp production is set constant, and the import of biomass remains unchanged. Thus, the main aspects of the superstructure include the alternative process routes for converting the residue streams, and the resulting products. The superstructure is formulated using mathematical programming and multi-objective optimization is applied to generate results, as specified in the methods. Obtained solutions are fully integrated in terms of mass and energy concerns, profiting from heat recovery between the individual processes.

Solution exploration is realized as an interactive visualization and filtering procedure, in which the decision maker can specify needs and retrieve the most suitable designs. Aside from filtering solutions based on objective functions and other performance criteria, parameter uncertainty as well as the diversity of the solution space are considered (Granacher et al., 2022). For quantifying uncertainty, key performance indicators of solutions featuring unique configurations are recalculated for parameter distributions. This generates insights on the resilience of a given configuration to variations in market conditions, and provides means of informed decision-making. The economic KPIs are recalculated with a sample set of 10,000 parameters that represent a uniform variation of the nominal market conditions (see SI) by 20%. With the obtained distributions, a desired percentile of economic KPIs can be derived for each configuration and included in the decision making process. In the presented case study, all solutions in which the 95th percentile of the total cost (TOTEX 95%) is negative are selected for further considerations, meaning that the configuration is profitable in 95% of the parameter sets in the distribution. From 500 generated configurations, 441 feature unique configurations, of which all are profitable under the given definition.

Profitable solutions are further clustered based on configurations to derive typical solutions. The number of clusters is decided based on Shiluette Rousseeuw (1987) and Elbow Davies and Bouldin (1979) criteria, after data normalization and dimensionality reduction. The t-distributed stochastic neighbor embedding formulation is employed to convert a high-dimensional space to a 2D object using principal component analysis and retaining a high-degree (0.99) of explained variance. The K-medoids algorithm is used for clustering; for each cluster, the solution performing preferably with respect to a user-defined key performance indicator is selected. In the presented case, cluster representatives are selected as being the centroids, ensuring maximum presentability of the identified configurations.

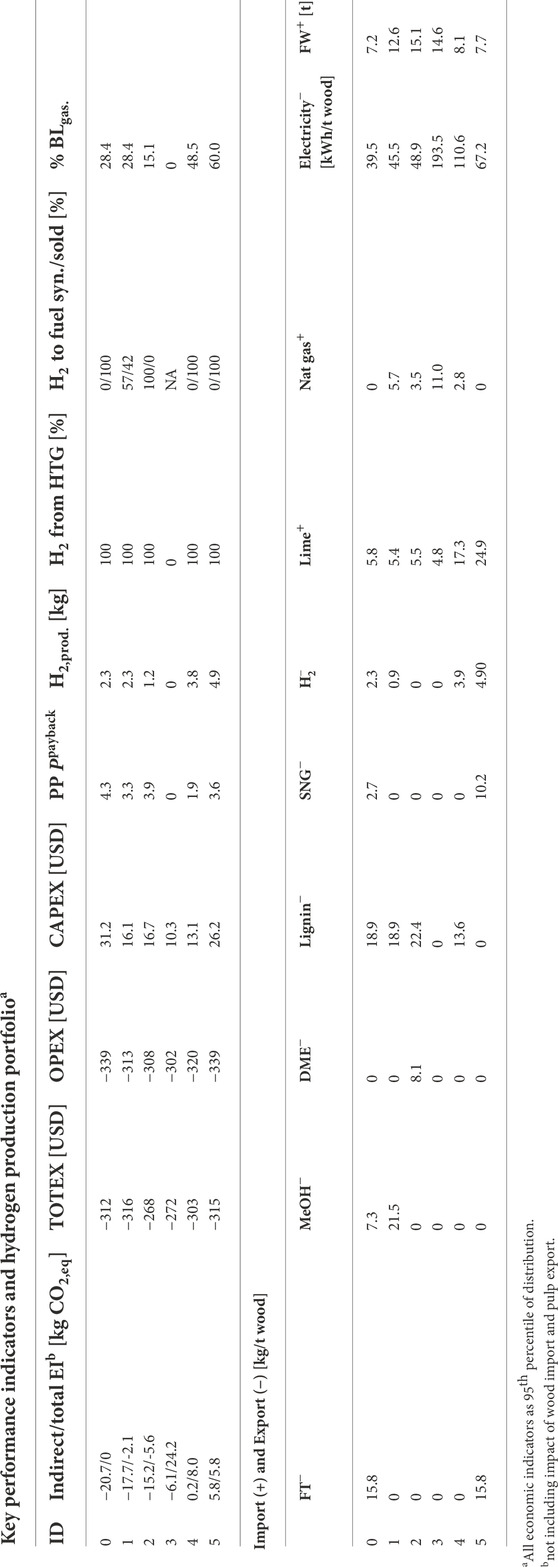

Clustering based on configurations yields six typical solutions, all but one featuring additional equipment compared to conventional mill operation (Table 1). In the following, they are displayed and labeled by increasing EI, considering only indirect emissions. ID0, the configuration with the lowest EI is defined by simultaneous production of liquid fuels (MeOH, FT), lignin extraction, electricity export and hydrogen generation from gasification. In this configuration, all available bark and 28% of the available black liquor are gasified (Table 1). ID1 features a similar configuration, although more MeOH is produced at the tradeoff of no FT fuel production. Natural gas consumption is triggered due to less offgas avalability for fueling the lime kiln; 57% of the produced hydrogen is used for fuel synthesis. In ID2, liquid fuel production (DME) is coupled with hydrogen production for usage in fuel synthesis by gasifying 24% of the available black liquor. ID3 includes no additional units compared to the conventional operation of the mill and represents the cluster of typical mill operation. ID4 combines the export of lignin and hydrogen from gasification of 48% of the black liquor. ID5 includes FT fuel and SNG production, coupled with hydrogen export from gasification of 61% of the available black liquor. The high share of black liquor gasification increases the lime demand, but natural gas can be replaced completely with offgases of the hydrogen and fuel production. It needs to be noted that the solutions were generated with no restriction on the amount of black liquor gasified. In future work, this assumption needs to be validated regarding feasible operation of the recovery boiler at reduced load; and potentially the option to increase pulp production could be explored.

TABLE 1. Key performance indicators and production characteristics of typical configurations per ton of wood.

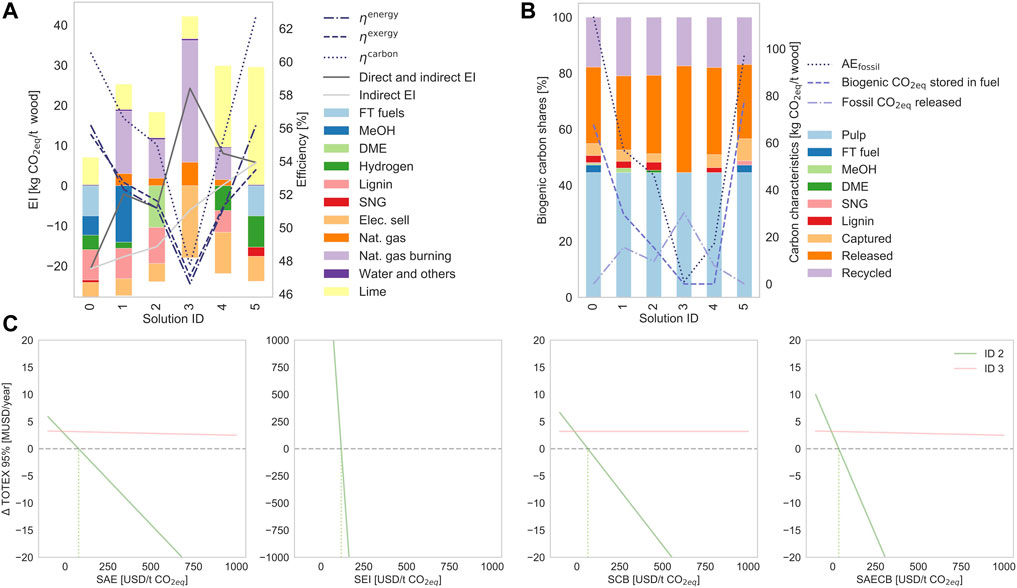

While the indirect fossil emissions increase continuously throughout the selected solutions, the direct fossil emissions on site are only dependent on the burning of natural gas (Figure 4A). As more natural gas is needed in ID1 compared to ID0 without an increase in negative impact from product sales, an increase in EI between ID0 and ID1 is notable. Carbon, energy and exergy efficiencies are decreasing, due to less carbon and energy being stored/available in the form of fuel (Figures 4A,B). Indirect fossil emissions increase further when only DME and lignin are produced in ID2, while direct fossil emissions decrease. Both, the biogenic carbon stored in fuel and fossil carbon emissions due to natural gas consumption decrease compared to the previous configuration. However, the overall effect is still a decrease in avoided fossil emissions (AE). ID3 mirrors the conventional operation of the mill, where no additional products apart from pulp and electricity are produced, leading to positive EI from natural gas and lime consumption, the highest share of released biogenic and fossil carbon throughout the configuration portfolio and the lowest carbon, energy and exergy efficiencies. When the product portfolio in ID4 becomes more diverse again, the indirect EI increases further, since a high share of black liquor gasification causes a high demand for lime, which can not be offset by the negative impact factor of the products. The same effect can be observed in ID5, where over 60% of the black liquor is gasified, yielding - on the one hand - a rich product portfolio, and high energetic efficiencies, but on the other hand, increases lime purchase needs due to exploited capacity limitations of the existing lime kiln. However, direct EI are completely avoided, due to the usage of offgases in the lime kiln. All five typical solutions are self-sufficient regarding electricity consumption and allow for export of electricity. Overall, there is a relation between avoided fossil emissions, carbon in fuel and natural gas consumption, as they influence each other directly. The more carbon captured in fuel, the more emissions from burning fossil alternatives can be avoided, while natural gas consumption has a counter-acting role on this relation. From the energetic and environmental perspective, there is no strong relation between biogenic carbon allocation and natural gas consumption, as different market values were assumed, so the monetary incentives of buying natural gas/selling electricity played a role in generating the solutions. Storing or converting biogenic carbon instead of releasing it does not lead inevitably to less fossil carbon emissions, as some of the effects described above lead to higher fossil fuel consumption, for example for lime kiln operation. Furthermore, increasing lime purchase demands due to capacity limitations of the lime kiln can lead to a significant increase in EI when large shares of black liquor are gasified.

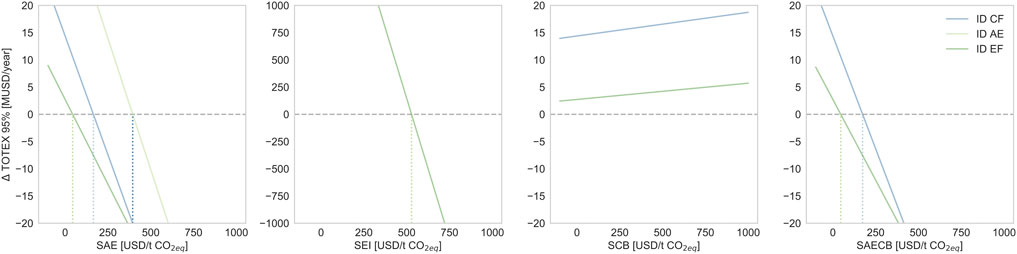

FIGURE 4. Energetic and environmental aspects of identified configurations. (A): Environmental impact split and efficiencies, (B): relative biogenic carbon shares and carbon characteristics, (C): Profit sensitivity analysis of ID2,3 for different benefit structures

From the six typical configurations obtained from the solution exploration, four perform better economically compared to the conventional operation of the mill, based on TOTEX 95%. For the remaining two (ID2,3), subsidies compensating the ΔTOTEX 95% between the respective configuration and the conventional mill are calculated for selected emission characteristics. The first emission property analyzed is avoided fossil emissions AEfossil, accounting for avoided direct and indirect emissions and avoided emissions from burning fossil products substituted by biogenic fuels, further referred to as SAE. Furthermore, avoided direct and indirect emissions as calculated in EI between a configuration and the conventional mill (SEI); captured biogenic CO2 (SCB) and the sum of avoided fossil emissions and captured biogenic CO2 (SAECB) are considered. Figure 4C shows that for ID2, ΔTOTEX 95% can reach zero by providing benefits of 78 USD/t CO2,equ to SAE. As ID3 does not only feature higher total cost but also only slightly less SAE emissions, no compensation scheme that lies in a reasonable monetary range is possible for avoided fossil emissions. When SEI is considered for providing offset, ID2 reaches ΔTOTEX 95% of zero for 118 USD/t CO2,equ. However, when captured biogenic carbon is rewarded (SCB), compensating subsidies are at 64 USD/t CO2,eq for ID2. Since no biogenic carbon is captured in ID3, the TOTEX stays indifferent to the rewarding assumptions. For SAECB, the break-even compensation can be reduced to 35 USD/t CO2,equ for ID2.

Thus, for the configurations analyzed, rewarding captured biogenic CO2 and avoided fossil emissions is the most effective way to make configurations profitable for the mill compared to conventional configuration of the Kraft process. Solely basing the benefit analysis on avoided fossil emissions is less efficient than providing benefits for captured CO2.

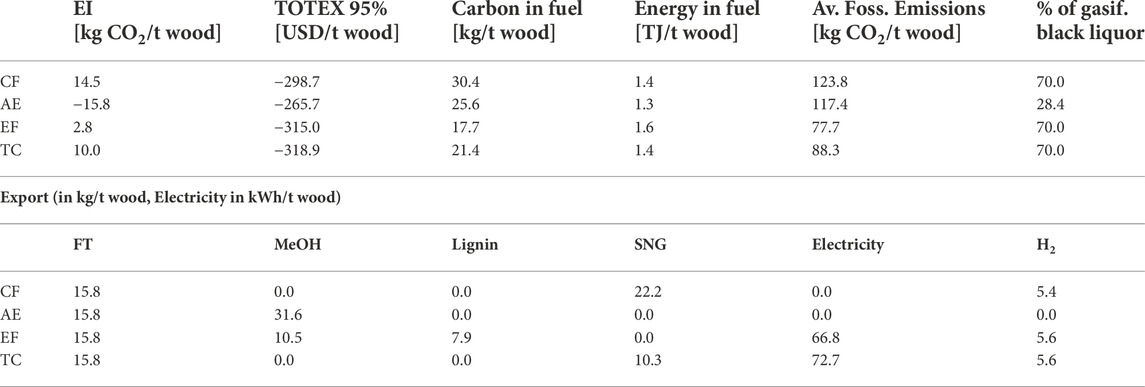

To extend the analysis, three additional configurations are selected from the set of unique configurations; one with the largest share of carbon in fuel (CF) observed though all unique configurations, one with largest amount of energy in fuel (EF) and one with highest avoided fossil emissions (AE). Revenues for avoided CO2 for which the respective solution becomes as profitable as the solution performing best economically (TC) are calculated, providing insights on the sensitivity of the system’s profitability towards compensation subsidies in extreme cases (Figure 5). Minimum TOTEX 95% is achieved by simultaneous production of FT fuels, SNG, electricity and hydrogen from black liquor gasification, the latter being completely exported and not used in fuel synthesis (Table 2). TOTEX 95% reaches the minimum of -320 MUSD/t wood. The maximum share of carbon stored in fuels is achieved by the joint production of FT, SNG and hydrogen. 69% of the black liquor is gasified, leading to over double the lime import compared to conventional operation. TOTEX 95% is 7% above the minimum and can be offset by benefits on CO2 between 165 (SAE) and 174 USD/t CO2 (SAECB) (Figure 5).

FIGURE 5. Sensitivity analysis of three configurations regarding compensation benefits for avoided fossil emissions (SAE), EI (SEI), captured biogenic CO2 (SCB) and the combination of SAE and SCB (SAECB).

TABLE 2. Production characteristics of identified configurations of highest carbon in fuel (CF), highest avoided fossil emissions (AE), highest energy in fuel (EF) and lowest total cost (TC).

Highest avoided emissions are achieved by a combination of FT and MeOH production. Only 28% of the black liquor is gasified, yielding less impact caused by importing additional lime. Overall, TOTEX 95% is 17% above the minimum in the economically best-performing scenario TC, and can be offset by benefits of 395 USD/t CO2 for SAE. When the highest energy content in fuel is elected, the optimal configuration features FT, MeOH, lignin, electricity and hydrogen production, with 70% of the black liquor being gasified. Compensation for the 2% higher TOTEX 95% compared to the best economic scenario can be achieved by benefits between 43 (SAECB) and 528 USD/t CO2 (SEI, Figure 5). It is worth noting that scenarios CF and EF perform better economically than the reference operation of the mill, with a TOTEX 95% improvement between 1 and 6%. For AE, the same economic performance as in the reference operation can be achieved for carbon benefits between 202 (SAECB) and 239 USD/t CO2 (SEI).

Thus, if the impact factor is to stay below the conventional operation of the mill, fuel production is limited by the emissions of increased lime demand, while natural gas consumption can be avoided by burning offgases of gasification in the lime kiln. In addition, the observed variations of the TOTEX 95% in all extreme solutions remain relatively small, allowing for offsetting emissions with realistic compensation schemes, thus making environmentally profitable solutions economically viable.

In order to identify the benefit from combined consideration of pulp and fuel production from both, bark and black liquor gasification simultaneously, the solution space of all unique configurations is filtered for solutions only applying bark gasification and solutions only considering black liquor gasification. These solutions were generated due to the approach of varying unit considerations in the steering inputs of the solution generation (Section 3.4). For the configurations only considering bark or black liquor gasification, average economic and environmental key performance indicators are compared to the results obtained for all unique configurations. When only bark gasification is considered and all black liquor is treated in the conventional recovery boiler, energetic efficiency is on average 3% lower than the obtained average from all considered configurations, while the carbon efficiency is decreased by 6%. Configurations considering only black liquor gasification have decreased energetic efficiency of 2% and decreased carbon efficiency of 6%. On average, 53% less fossil emissions are avoided when only bark gasification is included; for the cases with only black liquor gasification, it is 26% less than the average over all configurations. Average environmental impact is increasing by 15% in the bark-related configurations; for the black liquor configurations, the average stays within 1% of the one obtained from all configurations. Self-sufficiency is not influenced, as all obtained unique configurations are fully self-sufficient in electricity demand. When looking at the economic performance indicators, average TOTEX 95% of both solution subsets is within 2% of the respective indicator for the whole set of configurations. In summary, it is found that environmental and energetic indicators generally profit from the integration of combined bark and black liquor gasification, whereas self-sufficiency and economic considerations are not influenced significantly.

Looking more carefully at the energy system of tomorrow, the question to answer regarding transportation fuel will eventually be, how the fossil energy carriers - especially those used for freight transport - can be replaced with sustainable alternatives. While electricity is a promising option for personal transport, trucks and lorries are often dependent on the high energy density of fossil options. The configuration with maximum energy in fuel (EF) is selected to provide a perspective of combined production on the energy system. As Table 3 displays, a total of 1,634 MJ of fuel equivalent is produced per ton of wood, split into FT, MeOH and hydrogen. Scaling this production to France and the European Union using the roundwood consumption of the pulp industry leads to a perspective in production of 7216 TJ of fuels from the pulp mills in France and 89,545 TJ in all of Europe. When the generated fuels are used to replace fossil energy carriers in road freight transport, about 2% can be replaced for France and the EU. Assuming a worldwide demand of 8.8 Terra revenue passenger kilometers (RPK) in 2019 (International Civil Aviation Organization, 2019), approximately 5% of passenger aviation energy demand could be replaced with the worldwide fuel potentially available from combined pulp and fuel production.

Comparing the TOTEX 95% of the configuration EF to that of the conventional mill operation, a competitive selling price of 0.011 USD per MJ of fuel is sufficient for the mill to break-even with the conventional TOTEX 95%. This corresponds to a diesel price of 0.57 USD/l, a gasoline price of 0.67 USD/l and a hydrogen price of 1.39 USD/kg. When following a more conservative approach and limiting the maximum amount of black liquor to be treated alternatively to 30%, the competitive selling prices are 2.2 USD/l for diesel, 5.6 USD/kg for hydrogen and 2.7 USD/l for gasoline. Considering the current market prices of the energy carriers, the prospective increasing demand, as well as policies and political instability, the co-production of pulp and fuels seems to be economically interesting and environmentally sound.

To select one solution From the pool of typical configurations identified, the relationship between economic KPIs and parameter uncertainty is taken into account. To calculate the correlations, the same Sobol sequence sampling algorithm previously used to calculate the KPI distribution for economic uncertainty is applied to the set of economic parameters, with a sampling size of 10,000. Correlations between a KPI of interest and the parameter set of the optimization are derived using the Spearman correlation (Dodge, 2008), and displayed in a polar plot sequenced by decreasing significance (Figure 6). For TOTEX, the most significant parameter in the Pareto-optimal solution set is the quicklime price, followed by freshwater price, interest rate and lifetime. OPEX is most dependent on freshwater price, electricity price, FT and quicklime price (Figure 6). For CAPEX, the interest rate, lifetime and the equipment cost of the FT and MeOH units are most relevant. Although the selected solution set considers the variation in economic parameters, one must keep in mind that variations in the identified parameters of interest certainly influence the economic performance previously evaluated.

Taking the analysis one step further, the correlations between KPIs and parameters are derived for each individual solution in the Pareto-optimal set to help make an informed decision. Table 4 shows the parameters with the highest correlation towards a KPI for each Pareto-optimal solution. Not surprisingly, CAPEX is always dependent on the interest rate and lifetime of equipment, as well as the investment cost of the most significant units in the configuration. For OPEX and TOTEX, more diversity is observed; depending on the activated units of a given solution, different parameters are more relevant than others. This could serve as an indication for preferring certain solutions over others for different market assumptions.

The future development of the energy system comprises the replacement of fossil fuels, the integration of renewable energy resources and the need for negative emission processes. Biomass as a sustainable energy carrier offers promising opportunities to provide thermal energy at high temperature and, at the same time, energy storage opportunities. In this work, the realization of the design of a Kraft pulp mill integrated with biomass conversion technologies to improve energy efficiency while enabling the production of storable energy in the form of liquid fuels is presented. The two main residual streams, bark and black liquor, are treated via gasification processes, and different types of fuel synthesis options from producer gas are included in the analysis. The black liquor is gasified in hydrothermal conditions, making the energy-intensive evaporation and concentration in the mill redundant. Moreover, the usage of electrolysis units is enabled, which can benefit from excess electricity in the grid for the production of hydrogen and syngas. The main implication thereby is to generate solutions that profit from full energy integration when co-producing pulp and fuel, without penalizing the anticipated pulp production. Furthermore, our superstructure is profiting from energetic benefits arising from combined consideration of bark and black liquor gasification. Rigorous mathematical programming is coupled with multi-objective optimization for the generation of a variety of solutions. A filtering mechanism is suggested for selecting solutions based on competing objectives and performance under economic uncertainty. From six typical configurations identified, four are economically preferable compared to the conventional Kraft mill configuration, while also providing energetic benefits featuring higher carbon and energy efficiencies. For configurations achieving the highest energetic and environmental performance, subsidies for avoided fossil emissions or captured biogenic carbon could realistically offset financial deficiencies. Looking closely at the European energy system, 2% of the required energy for road freight transport could be provided by the suggested superstructure configurations, while worldwide, approximately 5% of passenger aviation fuel could be replaced. From the mill perspective, the co-production of fuel and pulp is viable above a certain fuel selling price which is currently identified as being well below market prices. Even though the current approach includes a variety of process units in the superstructure optimization for combined pulp and fuel production, the holistic analysis is constrained by the limited number of units included. For a complete analysis, production of other fuels as well as bio-based products could be included in the analysis, to enhance the consideration of a fully integrated biorefinery. Additionally, further investigation on the feasibility of operating the recovery boiler at low capacities, or potentially decoupling the recovery cycle from the pulp production to increase the production capacity is required. Furthermore, the investigation of power-to-X technologies such as electrolysis is hindered by the lack of multi-time considerations, that would be able to capture the benefit of such technologies in the light of varying electricity availability. Future work includes the careful assessment of superstructure completeness and potential consideration of additional processes, such as hydrothermal liquefaction. Furthermore, consideration of time-dependent mill operation, taking into account seasonal resource price variations, and its potential to serve as an energy hub for reliably storing and providing energy when required will be included, yielding promising findings for assisting the energy transition.

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

JG performed literature review, developed process models and the solution synthesis methodology, defined scenarios and synthesized solutions. EM developed process models and conducted literature review. R-CA contributed to the methodology development and the result analysis. T-VN supported the process modeling and methodology development. FM supervised the work. The original manuscript was prepared by JG and reviewed by all authors.

This research has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement 818011 and under the Marie Skłokodowska-Curie grant agreement N°754462 and 754354. Open access funding was provided by the École Polytechnique Fédérale de Lausanne.

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/fenrg.2022.979502/full#supplementary-material

European Environment Agency (2020). Energy efficiency. Available at: https://www.eea.europa.eu/publications/ENVISSUENo12/page027.html.

International Energy Agency (2021). Energy intensity of passenger aviation in the sustainable development scenario, 2000-2030 – charts – data & statistics. Available at: https://www.iea.org/data-and-statistics/charts/energy-intensity-of-passenger-aviation-in-the-sustainable-development-scenario-2000-2030.

International Energy Agency (2020). “European union 2020-energy policy review,” in Tech. rep. (Paris, France: International Energy Agency). Available at: https://iea.blob.core.windows.net/assets/ec7cc7e5-f638-431b-ab6e-86f62aa5752b/European_Union_2020_Energy_Policy_Review.pdf.

Ahlström, J. M., Alamia, A., Larsson, A., Breitholtz, C., Harvey, S., and Thunman, H. (2019). Bark as feedstock for dual fluidized bed gasifiers-Operability, efficiency, and economics. Int. J. Energy Res. 43, 1171–1190. doi:10.1002/er.4349

Andersson, E., and Harvey, S. (2007). Comparison of pulp-mill-integrated hydrogen production from gasified black liquor with stand-alone production from gasified biomass. Energy 32, 399–405. doi:10.1016/j.energy.2006.06.021

Andersson, J., Lundgren, J., and Marklund, M. (2014). Methanol production via pressurized entrained flow biomass gasification – techno-economic comparison of integrated vs. stand-alone production. Biomass Bioenergy 64, 256–268. doi:10.1016/j.biombioe.2014.03.063

Bajpai, P. (2015). “Basic overview of pulp and paper manufacturing process,” in Green chemistry and sustainability in pulp and paper industry (Cham: Springer International Publishing), 11–39. Book Authors: _:n3. doi:10.1007/978-3-319-18744-0_2

Bertsimas, D., and Sim, M. (2004). The price of robustness. Operations Res. 52, 35–53. doi:10.1287/opre.1030.0065

Blasio, C. D., Lucca, G., Özdenkci, K., Mulas, M., Lundqvist, K., Koskinen, J., et al. (2016). A study on supercritical water gasification of black liquor conducted in stainless steel and nickel-chromium-molybdenum reactors. J. Chem. Technol. Biotechnol. 91. doi:10.1002/jctb.4871

Branke, J., Branke, J., Deb, K., Miettinen, K., and Slowiński, R. (2008). Multiobjective optimization: Interactive and evolutionary approaches. Berlin, Germany: Springer Science & Business Media.

Castro-Amoedo, R., Morisod, N., Granacher, J., and Maréchal, F. (2021). The role of biowaste: A multi-objective optimization platform for combined heat, power and fuel. Front. Energy Res. 9, 417. doi:10.3389/fenrg.2021.718310

Cao, C., Guo, L., Jin, H., Cao, W., Jia, Y., and Yao, X. (2017a). System analysis of pulping process coupled with supercritical water gasification of black liquor for combined hydrogen, heat and power production. Energy 132, 238–247. doi:10.1016/j.energy.2017.05.104

Cao, C., Xu, L., He, Y., Guo, L., Jin, H., and Huo, Z. (2017b). High-efficiency gasification of wheat straw black liquor in supercritical water at high temperatures for hydrogen production. Energy Fuels 31, 3970–3978. doi:10.1021/acs.energyfuels.6b03002

Celebi, A. D., Ensinas, A. V., Sharma, S., and Maréchal, F. (2017). Early-stage decision making approach for the selection of optimally integrated biorefinery processes. Energy 137, 908–916. doi:10.1016/j.energy.2017.03.080

Consonni, S., Katofsky, R. E., and Larson, E. D. (2009). A gasification-based biorefinery for the pulp and paper industry. Chem. Eng. Res. Des. 87, 1293–1317. doi:10.1016/j.cherd.2009.07.017

Davies, D. L., and Bouldin, D. W. (1979). “A cluster separation measure,” in IEEE Transactions on Pattern Analysis and Machine Intelligence PAMI-1, 224–227. doi:10.1109/TPAMI.1979.4766909

M. Ek, G. Gellerstedt, and G. Henriksson (Editors) (2016). Pulping chemistry and technology. Bd. 2 in Pulp and paper chemistry and technology (Berlin: de Gruyter). OCLC: 945130405.

Fourer, R., Gay, D., and Kernighan, B. (2002). Ampl: A modeling language for mathematical programming. Manag. Sci., 519. doi:10.1287/mnsc.36.5.51936

Francey, S., Tran, H., and Jones, A. (2009). Current status of alternative fuel use in lime kilns. Tappi J. 8, 33–39.

Gassner, M., and Maréchal, F. (2009). Methodology for the optimal thermo-economic, multi-objective design of thermochemical fuel production from biomass. Comput. Chem. Eng. 33, 769–781. doi:10.1016/j.compchemeng.2008.09.017

Gassner, M., and Maréchal, F. (2012). Thermo-economic optimisation of the polygeneration of synthetic natural gas (SNG), power and heat from lignocellulosic biomass by gasification and methanation. Energy Environ. Sci. 5, 5768. doi:10.1039/c1ee02867g

Gassner, M., Vogel, F., Heyen, G., and Maréchal, F. (2011). Optimal process design for the polygeneration of SNG, power and heat by hydrothermal gasification of waste biomass: Process optimisation for selected substrates. Energy & Environ. Sci. 4, 1742–1758. doi:10.1039/C0EE00634C

Gerber, L., Fazlollahi, S., and Maréchal, F. (2013). A systematic methodology for the environomic design and synthesis of energy systems combining process integration, Life Cycle Assessment and industrial ecology. Comput. Chem. Eng. 59, 2–16. doi:10.1016/j.compchemeng.2013.05.025

Granacher, J., Maréchal, F., Celebi, A. D., and Kermani, M. (2019). Potential of hydrothermal black liquor gasification integrated in pulp production plant. Proc. ECOS 2019, 2299–2309.

Granacher, J., Nguyen, T.-V., Castro-Amoedo, R., and Maréchal, F. (2022). Overcoming decision paralysis—a digital twin for decision making in energy system design. Appl. Energy 306, 117954. doi:10.1016/j.apenergy.2021.117954

Gullichsen, J., and Paulapuro, H. Suomen Paperi-Insinöörien Yhdistys and Technical Association of the Pulp and Paper Industry (Editors) (1999). Papermaking science and technology: A series of 19 books covering the latest technology and future trends. Book 6 B: chemical pulping […] (Helsinki: Fapet Oy). OCLC: 833680723.

Hamaguchi, M., Cardoso, M., and Vakkilainen, E. (2012). Alternative technologies for biofuels production in kraft pulp mills—potential and prospects, 22.

Higman, C., and Burgt, M. v. d. (2008). Gasification. 2nd ed edn. Amsterdam; Boston: Gulf Professional Pub./Elsevier Science. OCLC: ocn182621531.

Hou, T., Nuyens, D., Roels, S., and Janssen, H. (2019). Quasi-Monte Carlo based uncertainty analysis: Sampling efficiency and error estimation in engineering applications. Reliab. Eng. Syst. Saf. 191, 106549. doi:10.1016/j.ress.2019.106549

Huet, M., Roubaud, A., and Lachenal, D. (2015). Conversion of sulfur-free black liquor into fuel gas by supercritical water gasification. Holzforschung 69, 751–760. doi:10.1515/hf-2014-0254

IEA Bioenergy (2007). “Black liquor gasification summary and conclusions from the IEA bioenergy ExCo54 workshop,” in Tech. Rep. (Wageningen, Netherlands: IEA BIOENERGY: ExCo:2007:03).

IEA Bioenergy (2014). “Iea bioenergy task42 biorefining,” in Tech. rep. (Wageningen, Netherlands: IEA Bioenergy).

IBM (2017). IBM ILOG CPLEX optimization studio CPLEX user’s manual. Village, NV. Available at: https://or.stackexchange.com/questions/2662/citing-cplex-12-9.

Isaksson, J., Jansson, M., Åsblad, A., and Berntsson, T. (2016). Transportation fuel production from gasified biomass integrated with a pulp and paper mill - Part B: Analysis of economic performance and greenhouse gas emissions. Energy 103, 522–532. doi:10.1016/j.energy.2016.02.092

Kantor, I., Robineau, J.-L., Bütün, H., and Maréchal, F. (2020). A mixed-integer linear programming formulation for optimizing multi-scale material and energy integration. Front. Energy Res. 8, 49. doi:10.3389/fenrg.2020.00049

Kermani, M., Kantor, I. D., Wallerand, A. S., Granacher, J., Ensinas, A. V., and Maréchal, F. (2019). A holistic methodology for optimizing industrial resource efficiency. Energies 12, 1315. doi:10.3390/en12071315

Kruse, A. (2016). “Supercritical water gasification for biomass-based hydrogen production,” in Hydrogen science and engineering : Materials, processes, systems and technology. Editors P. D. D. Stolten, and D. B. Emonts (Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA), 109–130. doi:10.1002/9783527674268.ch06

Kuparinen, K., and Vakkilainen, E. (2017). Green pulp mill: Renewable alternatives to fossil fuels in lime kiln operations. BioResources 12, 4031–4048. doi:10.15376/biores.12.2.4031-4048

Kuparinen, K., Vakkilainen, E., and Tynjälä, T. (2019). Biomass-based carbon capture and utilization in kraft pulp mills. Mitig. Adapt. Strategies Glob. Change 24, 1213. doi:10.1007/s11027-018-9833-9

Lachenal, D. (2016). “Kraft pulping,” in Lignocellulosic fibers and wood handbook. Editors N. Belgacem, and A. Pizzi (Hoboken, NJ, USA: John Wiley & Sons), 207–223. doi:10.1002/9781118773727.ch7

Larson, E. D., Consonni, S., Katofsky, R. E., Iisa, K., and Frederick, W. J. (2007). “A cost-benefit assessment of gasification-based biorefining in the kraft pulp and paper industry,” in Tech. rep. (Princeton, NJ: The Trustees Of Princeton University). doi:10.2172/912520

Larson, E. D., Katofsky, R. E., and Consonni, S. (2003). A cost-benefit assessment of biomass gasification power generation in the pulp and paper industry. Tech. Rep.

Liu, P., Nguyen, T.-D., Cai, X., and Jiang, X. (2012). Finding multiple optimal solutions to optimal load distribution problem in hydropower plant. Energies 5, 1413–1432. doi:10.3390/en5051413

Ljungstedt, H., Pettersson, K., and Harvey, S. (2013). Evaluation of opportunities for heat integration of biomass-based Fischer–Tropsch crude production at Scandinavian kraft pulp and paper mill sites. Energy 62, 349–361. doi:10.1016/j.energy.2013.09.048

Magdeldin, M., and Järvinen, M. (2020). Supercritical water gasification of Kraft black liquor: Process design, analysis, pulp mill integration and economic evaluation. Appl. Energy 262, 114558. doi:10.1016/j.apenergy.2020.114558

Magdeldin, M., Kohl, T., De Blasio, C., Järvinen, M., Won Park, S., and Giudici, R. (2016). The BioSCWG project: Understanding the trade-offs in the process and thermal design of hydrogen and synthetic natural gas production. Energies 9, 838. doi:10.3390/en9100838

Marechal, F., and Kalitventzeff, B. (1998). Process integration: Selection of the optimal utility system. Comput. Chem. Eng. 22, S149–S156. doi:10.1016/S0098-1354(98)00049-0

Maronese, S., Ensinas, A. V., Mian, A., Lazzaretto, A., and Maréchal, F. (2015). Optimum biorefinery pathways selection using the integer-cuts constraint method applied to a MILP problem. Ind. Eng. Chem. Res. 54, 7038–7046. doi:10.1021/acs.iecr.5b01439

Mavrotas, G. (2009). Effective implementation of the ε-constraint method in multi-objective mathematical programming problems. Appl. Math. Comput. 213, 455–465. doi:10.1016/j.amc.2009.03.037

Mian, A. (2016). Optimal design methods applied to solar-assisted hydrothermal gasification plants. Ph.D. thesis (Vaud, Switzerland: EPFL).

Mongkhonsiri, G., Gani, R., Malakul, P., and Assabumrungrat, S. (2018). Integration of the biorefinery concept for the development of sustainable processes for pulp and paper industry. Comput. Chem. Eng. 119, 70–84. doi:10.1016/j.compchemeng.2018.07.019

Monte, M., Fuente, E., Blanco, A., and Negro, C. (2009). Waste management from pulp and paper production in the European Union. Waste Manag. 29, 293–308. doi:10.1016/j.wasman.2008.02.002

Moret, S. (2017). Strategic energy planning under uncertainty. Ph.D. thesis (Vaud, Switzerland: EPFL). doi:10.5075/epfl-thesis-7961

Naqvi, M., Yan, J., and Dahlquist, E. (2010). Black liquor gasification integrated in pulp and paper mills: A critical review. Bioresour. Technol. 101, 8001–8015. doi:10.1016/j.biortech.2010.05.013

Naqvi, M., Yan, J., and Fröling, M. (2009). Bio-refinery system of DME or CH4 production from black liquor gasification in pulp mills. Bioresour. Technol. 101, 937–944. doi:10.1016/j.biortech.2009.08.086

Nations, F. F. A. A. O. O. T. U. (2020). Yearbook of forest products 2018. Rome, Italy: FAO. doi:10.4060/cb0513m

Nosek, R., Holubcik, M., and Jandacka, J. (2015). The impact of bark content of wood biomass on biofuel properties. BioResources 11, 44–53. doi:10.15376/biores.11.1.44-53

Özdenkçi, K., De Blasio, C., Sarwar, G., Melin, K., Koskinen, J., and Alopaeus, V. (2019). Techno-economic feasibility of supercritical water gasification of black liquor. Energy 189, 116284. doi:10.1016/j.energy.2019.116284

Pettersson, K., Mahmoudkhani, M., and Schenk, A. (2012). Opportunities for biorefineries in the pulping industry. Syst. Perspect. Biorefineries 2012, 48–58.

Quina, M. J., and Pinheiro, C. T. (2020). Inorganic waste generated in Kraft pulp mills: The transition from landfill to industrial applications. Applied Sciences 10, 2317. doi:10.3390/app10072317

Rousseeuw, P. J. (1987). Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 20, 53–65. doi:10.1016/0377-0427(87)90125-7

Sanchez, D. R. (2000). “Recausticizing - principles and practice,” in Kraft recovery short course (Orlando, FL: TAPPI Press), 30.

Santibañez-Aguilar, J. E., González-Campos, J. B., Ponce-Ortega, J. M., Serna-González, M., and El-Halwagi, M. M. (2011). Optimal planning of a biomass conversion system considering economic and environmental aspects. Ind. Eng. Chem. Res. 50, 8558–8570. doi:10.1021/ie102195g

Sobol, I. (1967). The distribution of points in a cube and the approximate evaluation of integrals. Zh. Vychisl. Mat. i Mat. Fiz. 7, 784–802.

Soroudi, A., and Amraee, T. (2013). Decision making under uncertainty in energy systems: State of the art. Renew. Sustain. Energy Rev. 28, 376–384. doi:10.1016/j.rser.2013.08.039

Dodge, Y. (2008). “Spearman Rank correlation coefficient,” in The concise encyclopedia of statistics (New York, NY: Springer), 502–505. doi:10.1007/978-0-387-32833-1_379

Speight, J. G. (2014). Gasification of unconventional feedstocks. Waltham, MA: Gulf Professional Publishing. OCLC: ocn861211359.

Tock, L., Gassner, M., and Maréchal, F. (2010). Thermochemical production of liquid fuels from biomass: Thermo-economic modeling, process design and process integration analysis. Biomass Bioenergy 34, 1838–1854. doi:10.1016/j.biombioe.2010.07.018

Tock, L., and Maréchal, F. (2015). Decision support for ranking Pareto optimal process designs under uncertain market conditions. Comput. Chem. Eng. 83, 165. doi:10.1016/j.compchemeng.2015.06.009

Tran, H., and Vakkilainen, E. (2016). “The kraft chemcial recovery process,” in Tech. rep. (Torronto Canada: Pulp and paper centre, University of Torronto).

Turton, R., Bailie, R. C., Whiting, W. B., and Shaeiwitz, J. A. (2008). Analysis, synthesis and design of chemical processes (pearson education). Google-Books-ID: kWXyhVXztZ8C.

Turton, R., Shaeiwitz, J. A., Bhattacharyya, D., and Whiting, W. B. (2018). Analysis, synthesis, and design of chemical processes. 2 edn. Boston: Prentice-Hall. OCLC: 1041858461

Ulrich, G. D., and Vasudevan, P. T. (2003). Chemical engineering process design and economics: A practical guide. 2 edn. Boca Raton, FL: CRC Press.

Viana Ensinas, A., Codina Gironès, V., Queiroz Albarelli, J., Maréchal, F., and Silva, M. A. (2013). Thermo-economic optimization of integrated first and second generation sugarcane ethanol plant. Chem. Eng. Trans. 35, 523. doi:10.3303/CET1335087

Wernet, G., Bauer, C., Steubing, B., Reinhard, J., Moreno-Ruiz, E., and Weidema, B. (2016). The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 21, 1218–1230. doi:10.1007/s11367-016-1087-8

Wetterlund, E., Pettersson, K., and Harvey, S. (2011). Systems analysis of integrating biomass gasification with pulp and paper production – effects on economic performance, CO2 emissions and energy use. Energy 36, 932–941. doi:10.1016/j.energy.2010.12.017

Keywords: pulp and paper industry, superstructure optimization, resource valorization, biofuels, process integration

Citation: Granacher J, Nguyen T-V, Castro-Amoedo R, McDonald EC and Maréchal F (2022) Enhancing biomass utilization by combined pulp and fuel production. Front. Energy Res. 10:979502. doi: 10.3389/fenrg.2022.979502

Received: 27 June 2022; Accepted: 18 July 2022;

Published: 23 November 2022.

Edited by:

Jalel Labidi, University of the Basque Country, SpainReviewed by:

Martin Atkins, University of Waikato, New ZealandCopyright © 2022 Granacher, Nguyen, Castro-Amoedo, McDonald and Maréchal. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Julia Granacher, anVsaWEuZ3JhbmFjaGVyQGVwZmwuY2g=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.