95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

OPINION article

Front. Energy Res. , 16 June 2022

Sec. Advanced Clean Fuel Technologies

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.921552

This article is part of the Research Topic Recent Advances in High-efficiency Development of Conventional/Unconventional Gas Reservoirs and CCUS Technologies View all 51 articles

The recoverable reserve of continental shale oil is about 5.5 billion tons in China, and the shale oil reservoirs are mainly distributed in 22 provinces and 47 basins. Shale oil is considered to be the most promising and strategic oil replacement resource in China (Zhao et al., 2020). Different from marine shale oil reservoirs, continental shale oil reservoirs are usually characterized by unstable deposition, low density, and a small distribution area. In addition, marine shale oil reservoirs commonly have a higher brittleness index than continental shale oil reservoirs, which results in the difficulties of creating complex fracture networks by large-scale hydraulic fracturing (Li and Zhu, 2020). The development experiences in North America have proved that the stereo well pattern deployment is an efficient technology for the development of tight and shale reservoirs, and it has been introduced into the development of continental shale oil reservoirs in different oilfields in China recently, such as Daqing oilfield, Xinjiang oilfield, and Shengli oilfield. However, because of the short development time and different characteristics of the tight reservoirs, the productivity evaluation methods for the stereo well pattern in shale oil reservoirs, including analytical models and numerical models, are still not completely established. This article summarizes current methods and challenges of the productivity evaluation using the stereo well pattern in shale oil reservoirs and puts forward some potential methods which are helpful for petroleum engineers.

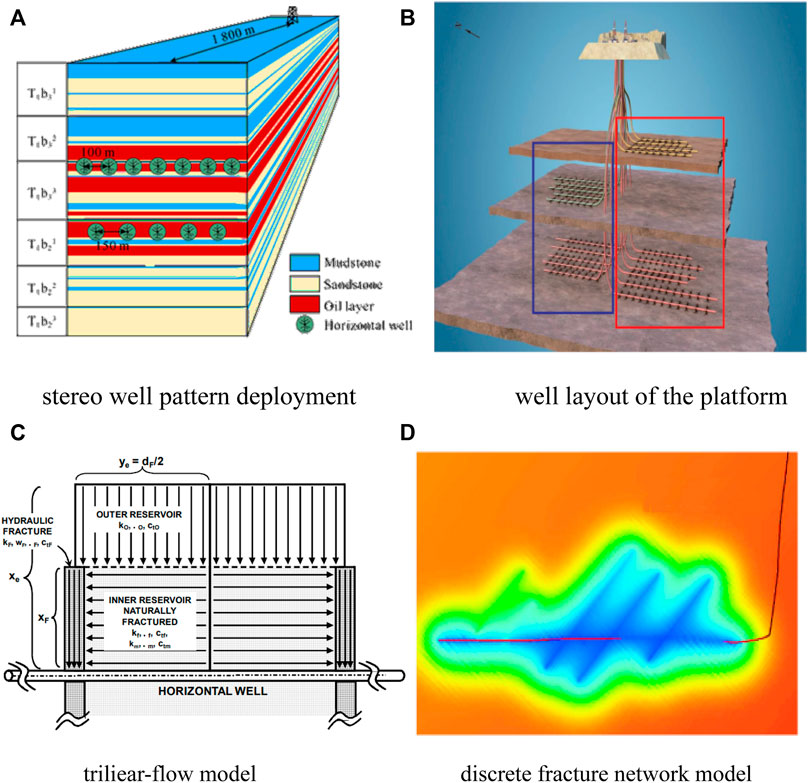

Stereo well pattern deployment is the key technology of “the second unconventional reservoir revolution” in North America, and the schematic diagram of the stereo well pattern deployment technology is shown in Figure 1A (Li et al., 2020). The advantages of the stereo well pattern deployment in tight or shale reservoirs can be summarized as the following points:

1) Reducing the cost per barrel of crude oil and improving development benefit;

2) High integration, efficiency of well factory operations, and integrated management carrier;

3) In-depth understanding of geological reservoirs and promoting the progress and comprehensive application of drilling, fracturing, and other engineering technologies;

4) Strengthening the system and global optimization and establishing a new development mode carrier to realize the “exploit every hydrocarbon molecule” concept;

5) Scaling the EOR carrier for unconventional reservoirs.

FIGURE 1. Stereo well pattern deployment technology ((A)Li et al., 2020; (B) Li et al., 2021 (C) Brown et al., 2009 and (D) Zhang et al., 2011).

If we want to take full advantage of the stereo well pattern in continental shale oil reservoirs, some requirements need to be followed:

1) Research on high-precision geological reservoirs to meet the high-density stereo well pattern deployment;

2) High-efficiency drilling and short construction cycle to service quick construction and production of the super-platform;

3) Customized fracturing technology to achieve the distribution of stereo wells and the collaborative optimization of hydraulic fracturing;

4) Intensive and highly detailed planning, organization, and implementation.

However, the stereo well pattern deployment technology has some obvious disadvantages, such as the large investment intensity and density, long first-oil time, and large decision-making pressure. The well spacing of stereo well pattern deployment in North America ranged from 304 to 367 m in the early stage, which ranges from about 100 to 152 m now. The children and mother wells are encrypted to increase the available reserves per unit area. With the development of long horizontal well technology, the drilling cost decreases significantly, which increases the net present value of shale oil well.

In China, the development of continental shale oil is still in its infancy. The main exploration and development areas include Lucaogou Formation in Jimusar Sag, Kongdian Formation in Bohai Bay Basin, Qingshankou Formation in Songliao Basin, and Yanchang Formation in Ordos Basin (Fu et al., 2015).

A few studies of the stereo well pattern deployment have proved that the “stress vortex,” that is, a complex stress field distribution, is caused by uneven pressure drop near the wellbore, which may cause hydraulic fractures to burst along the edge of the vortex in the hydraulic fracturing process and result in inadequate reservoir reconstruction (Li et al., 2021). In order to avoid serious interwell interference (Pankaj et al., 2018), during the implementation of the stereo well pattern deployment, the principle of “once layout of well pattern” is adopted to make full use of the original stress field and improve the overall development effect. Finally, a multilayer system can be developed by the stereo well pattern mode, as shown in Figure 1B.

The application of stereo well pattern deployment technology in shale oil reservoirs in China has developed rapidly in recent years. In the implemented platform in Changqing oilfield, the length of the horizontal well reaches more than 2000m, and the well spacing in the same layer ranges from 300 to 400 m. The typical platform H60 consists of 22 wells in longitudinal three layers, and the controlled geological reserves reach about 600 × 104 tons, achieving one-time development of several layers. The daily oil production of the single well in the platform H60 is about 16.0–20.0 tons/day, which is increased by more than 30%. In the implemented platform in Xinjiang oilfield, the length of the horizontal well is about 1800m, and the well spacing in the same layer is just 200 m. The typical platform 58 consists of 8 wells in longitudinal two layers with a thickness of 10m, and the daily oil production of the single well can reach 42.5 tons/day. The Gulong shale oil reservoirs in Songliao Basin are developed using the compartment pattern. The designed length of the horizontal well is more than 2500 m, and the designed well spacing in the same layer ranges from 300 to 400 m. The typical platform consists of 12 wells, and the predicted daily production of a single well can reach 20 tons/day (Wang et al., 2021).

In conclusion, the geological properties and production of continental shale oil vary greatly in different regions. At present, the productivity evaluation methods for shale oil reservoirs are mainly introduced from the experiences of tight oil reservoirs, including analytical methods and numerical methods. Analytical or semi-analytical methods are mainly based on some simple assumptions to characterize the production performance of a single horizontal fractured well. The analytical methods mainly include the empirical methods and the linear flow models. The empirical methods are commonly derived from the original model of Arps decline (Ambrose et al., 2011; Hao et al., 2012). The linear flow models are usually improved from the trilinear-flow model developed by Brown et al. (2009), as shown in Figure 1C. The numerical models for the horizontal well in unconventional reservoirs include three categories: wire-mesh model based on the main fractures and orthogonal fracture system assumption (Meyer and Bazan et al., 2011), discrete fracture network model (DFN), which can characterize the complex fracture networks (Fisher et al., 2002), shown in Figure 1D, and multiple media models proposed by some scholars (Zhang et al., 2011), based on the classical Warren and Root model. However, at present, there are few methods applicable to the productivity evaluation of the shale oil well.

Analytical models can be used to analyze the production performance of the single shale oil well, but the complex fractures network is simplified, and the flow characteristics of shale oil are not considered, especially the production performance of the shale oil horizontal well is complex and difficult to be predicted in the whole life cycle by conventional methods. Chen et al. (2021) took the shale oil horizontal well of Lucaogou Formation in Jimsar as an example and divided the production performance of the single shale oil well into four stages, including soaking stage, up production stage, production decline stage, and low and stable production stage. They developed a quantitative characterization model of a shale oil horizontal well to realize the prediction and parameter interpretation inversion.

However, for stereo well pattern deployment, the production performance of one shale oil horizontal well is affected by other wells in the platform. Numerical models can be used to simulate the production performance of multiple shale oil wells in a platform at the same time. The complex fracture networks and well spacing are the main effects on the production performance of the stereo well pattern. Considering the real extension of the hydraulic fractures and geological characteristics, the geology engineering integration software of Schlumberger has been used to design the development policies of the stereo well pattern deployment in shale oil reservoirs and achieved good results.

1) The stereo well pattern deployment is an efficient development technology for unconventional reservoirs, especially for continental shale oil reservoirs in China.

2) Influenced by geological parameters and fracturing parameters of the well platform in shale oil reservoirs, the productivity of the shale oil horizontal well varies widely in different oilfields in China, which makes the productivity evaluation of shale oil well more difficult.

3) At present, the analytical models proposed by Chen et al. can be used for predicting the production performance of a single shale oil well, but the complex fracture networks and fluid flow characteristics are ignored. The numerical methods developed by Schlumberger can be applied to simulate the production performance for the well platform.

ML contributed to writing the draft. ZW contributed to the methodology. AL contributed to validation. LZ contributed to resources.

Authors ML, ZW, AL, LZ were employed by the company Sinopec.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ambrose, R., Clarkson, C., Youngblood, J., Adams, R., and Biseda, B. (2011). Life-cycle Decline Curve Estimation for Tight/shale Gas Reserovirs. Texas The Woodlands, TX: SPE-140519-MS.

Brown, M., Ozkan, E., Raghavan, R., and Kazemi, H. (2009). Practical Solutions for Pressure Transient Response of Fractured Horizontal Wells in Uncoventional Reservoirs. New Orleans, LA: SPE 125043.

Chen, Y., Zhou, Y., Liang, C., Xu, T., and He, Y. (2021). Quantitative Characterization Model of Shale Oil Horizontal Well Production Change. J. Southwest Petroleum Univesity Sci. &Technology Ed. 43 (5), 97–103.

Fisher, M., Wright, C., and Davidson, B. (2002). Integrating Fracture Mapping Technologies to Optimize Stimulation in the Barnett Shale. San Antonio, TX: SPE 77441.

Fu, J., Yu, J., Xu, L., Niu, X., Feng, S., Wang, X., et al. (2015). New Progress in Exploration and Development of Tight Oil in Ordos Basin and Main Controlling Factors Fo Large-Scale Enrichment and Exploitable Capacity. China Pet. Explor. 20 (5), 9–19.

Hao, M., Hu, Y., and Li, F. (2012). Production Decline Laws of Fractured Horizontal Wells in Ultra-low Permeability Reservoirs. Acta Pet. Sin. 33 (2), 5.

Li, G., Wu, Z., Li, Z., Chen, Q., Xian, C., and Liu, H. (2021). Optimal Selection of Unconventional Petroleum Sweet Spots inside Continental Source Kitches and Actual Application of Three-Dimensional Development Technology in Horizontal Wells: a Case Study of the Member 7 of Yanchang Formation in Ordos Basin. Acta Pet. Sin. 42 (6), 736–750.

Li, G., and Zhu, R. (2020). Progress, Challenges and Key Issues of Unconventional Oil and Gas Development of CNPC. China Pet. Explor. 25 (2), 1–13.

Li, G., Qin, J., Xian, C., Fan, X., Zhang, J., and Ding, Y. (2020). Theoretical Understandings, Key Technologies and Practices of Tight Conglomerate Oilfield Efficient Development: A Case Study of the Mahu Oilfield, Junggar Basin, NW China. Petroleum Explor. Dev. 47 (6), 1275–1290. doi:10.1016/s1876-3804(20)60135-0

Meyer, B. R., and Bazan, L. W. (2011). A Discrete Fracture Network Model for Hydraulically Induced Fractures: Theory, Parametric and Case Studies. Texas The Woodlands, TX: SPE 140514.

Pankaj, P., Shukla, P., Kavousi, P., and Carr, T. (2018). Determing Optimal Well Spacing in the Marcellus Shale: A Case Study Using an Integrated Workflow. Neuquen, Argentina: SPE191862.

Wang, Y., Wang, R., Dai, X., Chen, M., and Si, L. (2021). Compartment Development Design Method of Horizontal Well for Gulong Shale Oil in Songliao Basin. Petroleum Geol. Oilfield Dev. Daqing 40 (5), 157–169.

Zhang, S., Mou, S., and Cui, Y. (2011). Numerical Model Analysis of Shale Gas Fracturing. Nat. Gas. Ind. 31 (12), 81–84.

Keywords: shale oil, stereo well pattern, productivity analysis, hydraulic fracturing, numerical models

Citation: Lu M, Wang Z, Li A and Zhang L (2022) Productivity Evaluation Methods for Stereo Well Pattern Deployment in Continental Shale Oil Reservoirs: Methods and Challenges. Front. Energy Res. 10:921552. doi: 10.3389/fenrg.2022.921552

Received: 16 April 2022; Accepted: 16 May 2022;

Published: 16 June 2022.

Edited by:

Xun Zhong, Yangtze University, ChinaReviewed by:

Lei Zhang, China University of Geosciences Wuhan, ChinaCopyright © 2022 Lu, Wang, Li and Zhang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Mingjing Lu, bHVtaW5namluZzAwMUAxMjYuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.