- 1State Key Laboratory of Shale Oil and Gas Enrichment Mechanisms and Effective Development, Beijing, China

- 2State Energy Center for Shale Oil Research and Development, Beijing, China

- 3School of Petroleum Engineering, Yangtze University, Wuhan, China

- 4Sinopec Petroleum Exploration and Production Research Institute, Beijing, China

Introduction

With the growth of the world economy, the demand for oil and gas is also rising, and conventional oil and gas resources have been unable to meet the huge energy demand (Tong et al., 2018; Akadiri et al., 2019; Feng et al., 2020; Li et al., 2020; Lin and Agyeman, 2021). Shale oil and gas resources are widely distributed and abundant, which will become an important area for strategic replacement and development. Since the successful development of shale gas reservoirs in North America, hydraulic fracturing has become a key technology for the development of unconventional oil and gas reservoirs (Cipolla et al., 2008; Yao et al., 2012; Xu et al., 2013). The reservoir stimulated technology represented by volume fracturing, to produce a complex fracture network and clarifying the morphology of the complex fracture network, is an important prerequisite for the evaluation of the fracturing effect (Sheng et al., 2019; Zhao et al., 2021). However, shale reservoirs have complex mineral composition, natural fractures, and bedding structures. The existing fracture diagnosis technology is not mature enough, and there are problems of low efficiency and poor simulation accuracy, which cannot accurately match the actual fracture network morphology (Huang et al., 2021). Fracture diagnostic technology is the main approach to determine fracture network morphology. The purpose of conventional hydraulic fracturing is not to form complex hydraulic fractures or fracture networks. These methods are mainly suitable for conventional bi-wing fracture types and have great limitations for the diagnosis of complex fracture networks (Yao, 2018). Therefore, this article discussed the current research progress of the fracture diagnosis technology, analysis shortcomings of different methods, and provides suggestions for further research.

Fracture Diagnosis Technology

The induced fractures produced by hydraulic fracturing are complex, and the morphology of the fracture network plays a key role in productivity. There are four main kinds of the fracture diagnosis technology, namely, the fracturing data analysis method, production data analysis method, near-wellbore measurement method, and far-wellbore measurement method (Nolte, 1979; Romero et al., 2000; Qu et al., 2013).

Fracturing Data Analysis Method

Fracturing data analysis is the most economical method. However, the accuracy of this method is also not high. This method mainly includes the double logarithmic curve diagnosis method, net pressure fitting method, pressure fluctuation evaluation method, and G function method (Nolte, 1979; Molenaar et al., 2012).

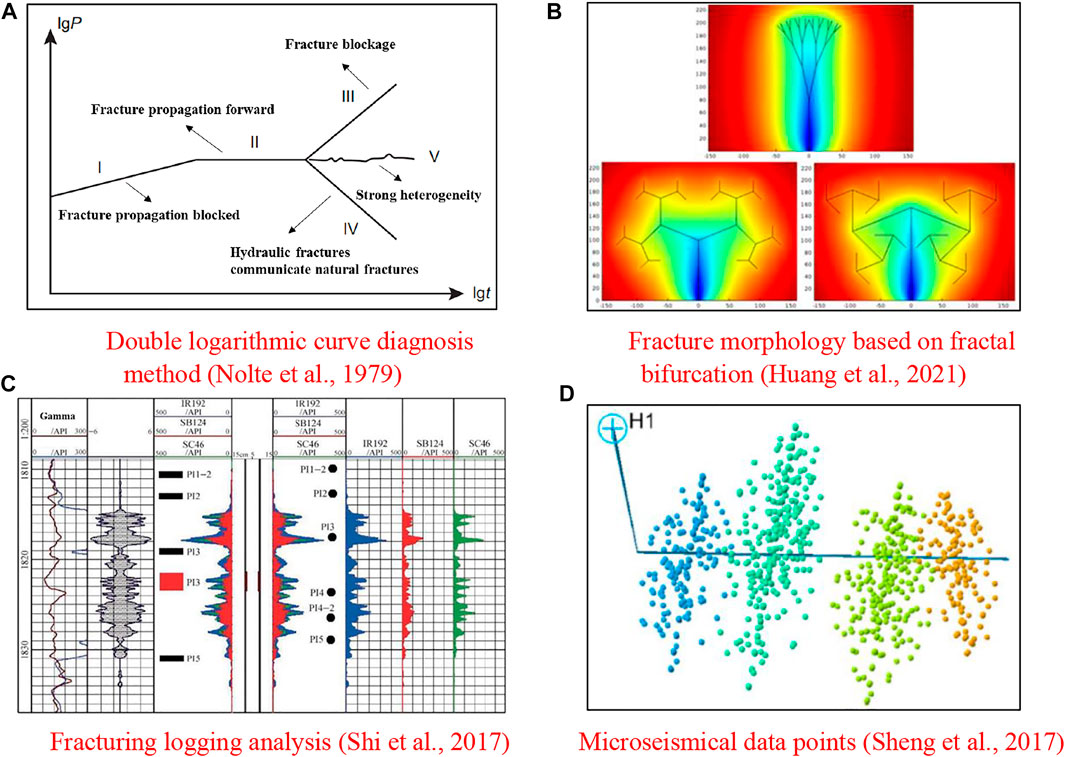

• Double logarithmic curve diagnosis method: the variation of bottom pressure with time during hydraulic fracturing reflects the propagation of fractures (Nolte, 1979; Meyer and Bazan, 2011; Molenaar et al., 2012). Nolte (1979) first proposed the double logarithmic curve diagnosis technology for fracture diagnosis, as shown in Figure 1A. By analyzing the curve of logarithmic bottom hole pressure (lgP) with logarithmic time (lgt), the fracture propagation morphology is judged. Minner et al. (1996) improved the accuracy of the method and provided the basis for fracturing and evaluation.

• Net pressure fitting method: Since the 1990s, scholars began to study how to analyze the fracture parameters by fitting the actual net pressure and the net pressure calculated by the mathematical model so as to improve the success rate of hydraulic fracturing (Minner et al., 1996; Romero et al., 2000). Yang (2021) proposed the net pressure fitting method, changing the fracture parameters to fit the net pressure. In the process of net pressure fitting, the net pressure calculated from the wellhead is considered as actual net pressure. The error between the calculated net pressure and the actual net pressure is reduced by adjusting the fracture parameters. The fracture morphology calculated by the net pressure fitting method has a high fitting rate with the actual fracturing data.

• Pressure fluctuation evaluation method: Bian et al., 2016) proposed a pressure fluctuation evaluation method based on fracturing data. This method divides the fracturing operation curve into the ahead fluid injection stage and fracture propagation stage. The brittleness and plasticity of the reservoir can be qualitatively judged by counting the number of reservoir ruptures, the average pressure drop, and the average pressure drop rate during the ahead fluid injection stage (Eshkalak et al., 2014). The study showed that the frequency and amplitude of pressure fluctuation in the fracturing stage reflect the complexity of the fracture network, and the fracture morphology of the far well can be comprehensively diagnosed combined with the brittleness and plasticity of the reservoir.

• G function method: the pressure drop equation is established by establishing the relationship between the pressure drop after the pump stop and the G function. Subsequently, the closure of hydraulic fractures is identified, and the fracture parameters are calculated (Nolte, 1979). The G function method based on the pressure drop curve needs the pressure test data after a long time of pump shutdown. If the time of reservoir monitoring pressure is short, it cannot be used to describe hydraulic fractures (Soliman et al., 2010; Wu et al., 2011; Yao, 2018).

Production Data Analysis Method

The production data analysis method mainly includes an analytical/semi-analytical model and a numerical simulation model (Stalgorova and Mattar, 2012; Huang et al., 2021).

• Analytical/semi-analytical model: The analytical/semi-analytical model of hydraulic fracturing is a necessary means for dynamic analysis (Chen et al., 2019). Combined with the actual unstable pressure response, the fracture parameters such as the fracture length, fracture flow capacity, and fracture width are inverted (Tian et al., 2017). Chen et al. (2019) proposed a dynamic inversion method for comprehensive analysis of microseismical data, production data, and well test data, which further reduced the multiplicity of inversion results of fracture parameters.

• Numerical simulation model: Based on microseismic data and production data, Mayerhofer et al. (2010) evaluated fracture network morphology, fracture spacing, and fracture total length by the historical fitting method. Based on the fracture propagation model and production data, Cipolla et al. (2011) established a fracture parameter inversion method considering microseismic data and production data. However, most of the aforementioned work is based on the assumption of single fractures or orthogonal fractures, without considering the actual fracture network morphology, as shown in Figure 1B.

Near-Wellbore Measurement Method

Near-wellbore measurement methods often use radiotracers to monitor wellbore data (Guo et al., 2019; Liu et al., 2018; Jin et al., 2021; Liu et al., 2020a). Different radioactive materials were put into the fracturing fluids, gamma spectrum was measured by using a logging instrument, the distribution of the proppant was obtained, and then the fracture height and width were calculated (Gulrajani and Romero, 1996; Shi et al., 2017; Liu et al., 2020b), as shown in Figure 1C. Near-wellbore measurement technology is limited by a small monitoring range, resulting in low accuracy of evaluation results. This method is suitable for small fracture ranges or for rough analysis.

Far-Wellbore Measurement Method

The far-wellbore measurement methods mainly include the microseismical monitoring technology, inclinometer fracture monitoring technology, and potentiometric fracture monitoring technology (Albright and Pearson, 1982).

• Microseismical monitoring technology: microseismical monitoring technology is based on acoustic emission and seismology. It draws spatial images of fractures by observing tiny seismic points generated during hydraulic fracturing and monitors the propagation of hydraulic fractures (McMechan et al., 1985; Warpinski et al., 2009; Sheng et al., 2017), as shown in Figure 1D. By analyzing the microseismical monitoring results, we can not only analyze the fracture propagation along various directions but also analyze the fracture trend of each section and judge the maximum horizontal stress direction of the reservoir.

•Inclinometer fracture monitoring technology: two sets of inclinometers are arranged at the wellhead and downhole in adjacent wells to monitor the reservoir inclination data caused by fracture propagation during hydraulic fracturing. Combined with the inclinometer data, the fracturing parameters are determined by geophysical inversion calculation (Shi and Lin, 2021).

• Potentiometric fracture monitoring technology: potentiometric fracture monitoring technology is also an effective method widely used to monitor hydraulic fractures (Shi and Lin, 2021). The technology is based on the theory of electrical exploration, by monitoring the changes in the ground electric field caused by the fracturing fluid injected into the reservoir with high ionization energy, to explain the parameters of fracture morphology, length, and orientation.

Comparison and Analysis

Compared with different fracture diagnosis methods, the traditional fracturing data analysis methods and production data analysis methods are more economical. However, most of these methods are based on single or orthogonal fracture assumption, without considering the actual complex fracture network morphology. The near-wellbore measurement method and far-wellbore measurement method are mostly based on field experiments, which are difficult in technology and high in cost, and are not conducive to popularization and application.

In the aforementioned method, the net pressure fitting method can be combined with the fracture propagation model, and the fracture morphology is constrained by the pump pressure and injection rate. This method is closely related to the reservoirs. However, the net pressure fitting method still has some problems to be solved. 1) A fast and efficient fracture propagation simulation method with certain randomness is needed. 2) A fast and efficient calculation method and a fitting method of net pressure for complex fractures are needed. The time of hydraulic fracturing is short, and there are many influencing factors. It is important to determine the practicability of this method to realize net pressure fitting by appropriate methods.

Conclusion and Suggestion

1) The fracturing data analysis method and production data analysis method cannot describe the fracture morphology. Near-wellbore measurement method and far-wellbore measurement method are difficult to be popularized. The net pressure fitting method can make good use of fracturing data, combined with the fracture propagation model, and can significantly improve the accuracy.

2) At present, there are still some urgent problems to be solved in the net pressure fitting method, that is, it needs a fast and efficient fracture propagation simulation technology with certain randomness, a fast and efficient calculation method, and the net pressure fitting method of complex fractures.

Author Contributions

YC was responsible for the overall research and writing work, TZ was responsible for the main idea of the article, and other authors were responsible for writing and layout.

Funding

This study was supported by the project from the Sinopec Key Laboratory of Shale Oil/Gas Exploration and Production Technology (33550000-21-ZC0613-0311).

Conflict of Interest

Authors HW and TZ were employed by Sinopec.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Akadiri, A. C., Akadiri, S. S., and Gungor, H. (2019). The Role of Natural Gas Consumption in Saudi Arabia's Output and its Implication for Trade and Environmental Quality. Energy policy 129, 230–238. doi:10.1016/j.enpol.2019.02.001

Albright, J. N., and Pearson, C. F. (1982). Acoustic Emissions as a Tool for Hydraulic Fracture Location: Experience at the Fenton Hill Hot Dry Rock Site. Soc. Petroleum Eng. J. 22 (04), 523–530. doi:10.2118/9509-pa

Bian, X., Jiang, X., Jia, C., and Wang, H. (2016). A New Post-fracturing Evaluation Method for Shale Gas Wells Based on Fracturing Curves [J]. Nat. Gas. Ind. 36 (02), 60–65. doi:10.1016/j.ngib.2016.03.010

Chen, Z., Liao, X., Zhao, X., Yu, W., and Sepehrnoori, K. (2019). A Workflow Based on a Semianalytical Model to Estimate the Properties of Stimulated Reservoir Volume of Tight-Oil Wells. J. Petroleum Sci. Eng. 178, 892–903. doi:10.1016/j.petrol.2019.04.002

Cipolla, C. L., Fitzpatrick, T., Williams, M. J., and Ganguly, U. K. (2011). “Seismic-to-simulation for Unconventional Reservoir Development,” in Paper presented at the SPE Reservoir Characterisation and Simulation Conference and Exhibition, Abu Dhabi, UAE, October 9–11, 2011 (OnePetro). doi:10.2118/146876-MS

Cipolla, C. L., Warpinski, N. R., Mayerhofer, M. J., and Lolon, E. P. (2008). The Relationship between Fracture Complexity, Reservoir Properties, and Fracture Treatment Design. SPE Annu. Tech. Conf. Exhib. OnePetro 25, 438–452. doi:10.2118/115769-PA

Eshkalak, M., Aybar, U., and Sepehrnoori, K. (2014). “An Economic Evaluation on the Re-fracturing Treatment of the US Shale Gas Resources,” in Paper presented at the SPE Eastern Regional Meeting, Charleston, WV, USA, 21-23 October (OnePetro). doi:10.2118/171009-MS

Feng, Q., Xu, S., Xing, X., Zhang, W., and Wang, S. (2020). Advances and Challenges in Shale Oil Development: A Critical Review. Adv. Geo-Energy Res. 4 (4), 406–418. doi:10.46690/ager.2020.04.06

Gulrajani, S. N., and Romero, J. (1996). “Evaluation and Modification of Fracture Treatments Showing Near-Wellbore Effects,” in Paper presented at the European Petroleum Conference, Milan, Italy, October 1996 (OnePetro). doi:10.2118/36901-MS

Guo, H., Pan, Q., and Zhang, L. (2019). The Artificial Fracture Longitudinal Profile Testing Technology in the Application of Hydraulic Fracturing in Daqing Oil Field[J]. J. Isotopes 32 (2), 115.

Huang, L., Sheng, G., Li, S., and Tong, G. (2021). A Review of Flow Mechanism and Inversion Methods of Fracture Network in Shale Gas Reservoirs[J]. Geofluids 2021. doi:10.1155/2021/6689698

Jin, G., Ugueto, G., Wojtaszek, M., and Guzik, A. (2021). Novel Near-Wellbore Fracture Diagnosis for Unconventional Wells Using High-Resolution Distributed Strain Sensing during Production[J]. SPE J. 26, 3255–3264. doi:10.2118/205394-PA

Li, M., Magsipoc, E., Abdelaziz, A., Ha, J., Guo, J., Peterson, K., et al. (2020). “Mapping Fracture Complexity in Hydraulically Fractured Montney Shale by Serial Section Reconstruction,” in Paper presented at the 54th US Rock Mechanics/Geomechanics Symposium, June 28–July 1, 2020 (OnePetro).

Lin, B., and Agyeman, S. (2021). Impact of Natural Gas Consumption on Sub-saharan Africa's CO2 Emissions: Evidence and Policy Perspective. Sci. Total Environ. 760, 143321. doi:10.1016/j.scitotenv.2020.143321

Liu, Q., Liu, J., Pei, G., and Zhu, Z. (2020a). A New Method for Artificial Core Reconstruction of a Fracture-Control Matrix Unit. Adv. Civ. Eng. 2020, 7469584. doi:10.1155/2020/7469584

Liu, Q., Song, R., Liu, J., Pei, G., and Lei, Y. (2020b). Mass Transfer Model of Fracture-Controlled Matrix Unit: Model Derivation and Experimental Verification Based on Fractal Theory and Micro-CT Scanning Technology. Energy Rep. 6, 3067–3079. doi:10.1016/j.egyr.2020.11.016

Liu, R., Jiang, Y., Huang, N., and Sugimoto, S. (2018). Hydraulic Properties of 3D Crossed Rock Fractures by Considering Anisotropic Aperture Distributions. Adv. Geo-Energy Res. 2 (2), 113–121. doi:10.26804/ager.2018.02.01

Mayerhofer, M. J. J., Lolon, E. P. P., Warpinski, N. R. R., Cipolla, C. L. L., Walser, D., and Rightmire, C. M. M. (2010). What Is Stimulated Reservoir Volume? SPE Prod. Operations 25 (01), 89–98. doi:10.2118/119890-pa

McMechan, G. A., Luetgert, J. H., and Mooney, W. D. (1985). Imaging of Earthquake Sources in Long Valley Caldera, California, 1983[J]. Bull. Seismol. Soc. Am. 75 (4), 1005–1020.

Meyer, B. R., and Bazan, L. W. (2011). “A Discrete Fracture Network Model for Hydraulically Induced Fractures-Theory, Parametric and Case Studies,” in SPE hydraulic fracturing technology conference, The Woodlands, Texas, USA, January 24–26, 2011 (Woodlands, TX: OnePetro). doi:10.2118/140514-MS

Minner, W. A., Wright, C. A., and Dobie, C. A. (1996). “Treatment Diagnostics and Net Pressure Analysis Assist with Fracture Strategy Evaluation in the Belridge Diatomite,” in SPE Western Regional Meeting, Anchorage, Alaska, May 22–24, 1996 (Anchorage, Alaska: OnePetro). doi:10.2118/35696-MS

Molenaar, M. M., Fidan, E., and Hill, D. J. (2012). “Real-time Downhole Monitoring of Hydraulic Fracturing Treatments Using Fibre Optic Distributed Temperature and Acoustic Sensing,” in SPE/EAGE European Unconventional Resources Conference and Exhibition, Vienna, Austria, March 20–22, 2012 (Vienna, Austria: OnePetro). doi:10.2118/152981-ms

Nolte, K. G. (1979). “Determination of Fracture Parameters from Fracturing Pressure Decline,” in [SPE Annual Technical Conference and Exhibition, Las Vegas, Nevada, September 23–26, 1979 (Las Vegas, Nevada: OnePetro). doi:10.2118/8341-MS

Qu, G., Qu, Z., and Yue, Y. (2013). The Diagnosis Method of Fracturing Curve[J]. Sci. Technol. Eng. 13 (05), 1281–1284+1288.

Romero, J., Mack, M. G., and Elbel, J. L. (2000). Theoretical Model and Numerical Investigation of Near-Wellbore Effects in Hydraulic Fracturing. SPE Prod. Facil. 15 (02), 76–82. doi:10.2118/63009-pa

Sheng, G., Su, Y., and Wang, W. (2019). A New Fractal Approach for Describing Induced-Fracture Porosity/permeability/Compressibility in Stimulated Unconventional Reservoirs. J. Petroleum Sci. Eng. 179, 855–866. doi:10.1016/j.petrol.2019.04.104

Sheng, G., Su, Y., Wang, W., Javadpour, F., and Tang, M. (2017). Application of Fractal Geometry in Evaluation of Effective Stimulated Reservoir Volume in Shale Gas Reservoirs. Fractals 25 (04), 1740007. doi:10.1142/s0218348x17400072

Shi, C., and Lin, B. (2021). Principles and Influencing Factors for Shale Formations[J]. Petroleum Sci. Bull. 6 (01), 92–113.

Shi, X., Yang, L., Li, M., and Cheng, Y. (2017). “Induced Stress Interaction during Multi-Stage Hydraulic Fracturing from Horizontal Wells Using Boundary Element Method,” in 4th ISRM Young Scholars Symposium on Rock Mechanics, Jeju, Korea, May 10–13, 2017 (Jeju, Korea: OnePetro).

Soliman, M. Y., East, L., and Augustine, J. (2010). “Fracturing Design Aimed at Enhancing Fracture Complexity,” in SPE EUROPEC/EAGE Annual Conference and Exhibition, Barcelona, Spain, June 14–17, 2010 (Barcelona, Spain: OnePetro). doi:10.2523/130043-MS

Stalgorova, E., and Mattar, L. (2012). “Practical Analytical Model to Simulate Production of Horizontal Wells with Branch Fractures,” in SPE Canadian unconventional resources conference, Calgary, Alberta, Canada, October 30–November 1, 2012 (Calgary, Alberta: OnePetro). doi:10.2118/162515-MS

Tian, B., Lei, G., Yang, L., and Rao, P. (2017). A Novel Method to Interpret Fracture Parameters of Multistage Fractured Horizontal Well in Reservoirs with micro-Fractures[J]. Oil Gas Geol. 38 (02), 400–406. doi:10.11743/ogg20170221

Tong, X., Zhang, G., Wang, Z., Wen, Z., Tian, Z., Wang, H., et al. (2018). Distribution and Potential of Global Oil and Gas Resources. Petroleum Explor. Dev. 45 (4), 779–789. doi:10.1016/s1876-3804(18)30081-8

Warpinski, N. R., Mayerhofer, M. J., Vincent, M. C., Cipolla, C. L., and Lolon, E. P. (2009). Stimulating Unconventional Reservoirs: Maximizing Network Growth while Optimizing Fracture Conductivity. J. Can. Petroleum Technol. 48 (10), 39–51. doi:10.2118/114173-pa

Wu, Q., Xu, Y., Wang, T., and Wang, X. (2011). The Revolution of Reservoir Stimulation: An Introduction of Volume Fracturing[J]. Nat. Gas. Ind. 31 (4), 7–12. doi:10.3787/j.issn.1000-0976.2011.04.002

Xu, B., Li, X., Haghighi, M., and Zhang, R. (2013). A New Model for Production Analysis in Naturally Fractured Shale Gas Reservoirs[J]. Zhongguo Shiyou Daxue Xuebao 37 (4), 99–105. doi:10.3969/j.issn.1673-5005.2013.06.015

Yang, C. (2021). A Fully Coupled and Full 3D Numerical Simulation of Hydraulic Fracturing Based on the Finite Element method[D]. Xi'an, China: Xi'an Shiyou University. doi:10.27400/d.cnki.gxasc.2021.000451

Yao, Y., Wu, Y.-S., and Zhang, R. (2012). The Transient Flow Analysis of Fluid in a Fractal, Double-Porosity Reservoir. Transp. Porous Med. 94 (1), 175–187. doi:10.1007/s11242-012-9995-y

Yao, Z. (2018). The Evaluation of Hydraulic Fracturing Fractures Complexity by Using Fracturing Pressure Curve[D]. Beijing): University of Petroleum. doi:10.27643/d.cnki.gsybu.2018.000532

Zhao, H., Sheng, G., Huang, L., Xun, Z., Jingang, F. U., Jialing, M., et al. (2021). “Application of Lightning Breakdown Simulation in Inversion of Induced Fracture Network Morphology in Stimulated Reservoirs,” in Paper presented at the International Petroleum Technology Conference, March 23–April 1, 2021 (OnePetro). doi:10.2523/IPTC-21157-MS

Keywords: shale reservoirs, fracture diagnosis technology, hydraulic fractures, fracture description, net pressure fitting

Citation: Chen Y, Wang H, Li F and Zhou T (2022) Research Advance on the Diagnosis Technology of Hydraulic Fractures in Shale Reservoirs. Front. Energy Res. 10:919917. doi: 10.3389/fenrg.2022.919917

Received: 14 April 2022; Accepted: 13 May 2022;

Published: 29 June 2022.

Edited by:

Qi Zhang, China University of Geosciences Wuhan, ChinaReviewed by:

Mianmo Meng, China University of Geosciences Wuhan, ChinaQiang Liu, Liaoning Technical University, China

Copyright © 2022 Chen, Wang, Li and Zhou. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Tong Zhou, dG9uZ196aG91MTk4NkAxNjMuY29t

Yanan Chen1,2,3

Yanan Chen1,2,3 Tong Zhou

Tong Zhou