- Yunfu Power Supply Bureau of Guangdong Power Grid Co., Ltd., Guangdong, China

The intelligentization, informationization, and internalization of power system infrastructure equipment are the key technologies to achieve the low-carbon transformation of the power system. To tackle the low degree of intelligence and the internet in the monitoring and early warning of mechanical faults of the disconnecting switch, this paper designs an intelligent monitoring system for the disconnecting switch operation status based on sensing technology. Torque sensors, angle encoders, micro-switches, attitude sensors, and temperature and humidity sensor technology are used to monitor the operation status of the disconnecting switch, and an advanced RISC machine (ARM) embedded terminal system is used as the disconnecting switch status monitoring center. The intelligent monitoring system aims to accurately monitor the temperature and humidity environment in the disconnector operating mechanism box, the opening and closing position state of the disconnector, and the torque angle variation characteristics of the disconnector according to the operating parameters collected by the sensor, while achieving remote real-time state monitoring of the disconnecting switch. The function tests and field tests show that the system performance is stable, and the state information collection, intelligent analysis, and remote monitoring meet the actual needs, which can improve the efficiency of disconnecting switch operation, maintenance, and overhaul, thereby reducing the risk of power grid outages.

1 Introduction

Under the background of “double carbon,” improving the intelligentization, informationization, and internalization of the power system infrastructure equipment are the key technologies to actively promote the low-carbon transformation of the power system (Zeng et al., 2021). As important primary electrical equipment in the construction of smart substations, the disconnecting switch is an important component to isolate voltage and ensure the safety of other primary equipment during substation maintenance (Song et al., 2018). With the transformation and upgrading of the power system, the maintenance mechanism transits from regular maintenance to condition-based maintenance, which puts forward higher requirements for the life cycle of the disconnecting switch (Chen et al., 2019). Simultaneously, because the high-voltage disconnecting switch is greatly influenced by environmental and climatic conditions, it is easy for equipment improperly closed or damaged. Remote status monitoring of disconnecting switches can solve the above problems.

With the continuous application of artificial intelligence technology (Ahmed and Tahir, 2017; Wang et al., 2019a; Wang et al., 2019b; Wei et al., 2021; Zhai et al., 2021), ubiquitous power sensing technology, sensor technology, and wireless information transmission technology in the field of primary equipment of power systems, improving the automation and intelligent level of high-voltage disconnecting switches has become an urgent demand for the construction and development of future substation. At present, the theoretical research on the status monitoring and early warning of disconnecting switches has been relatively mature. Cheng et al. combined the weighted grey target theory and the analytic hierarchy process to analyze the health value of each part of the disconnecting switch and classified the health status of the disconnecting switch (Cheng et al., 2016). Liu et al. introduced the support vector machine algorithm into the fault diagnosis of the mechanical state of a high voltage switch (Cheng et al., 2014; Liu C. et al., 2020). By taking the current characteristic quantity or the starting point of vibration events in mechanical vibration signal as the input of the support vector machine, the corresponding fault diagnosis model of the switch was established, so as to improve the accuracy of fault diagnosis of the mechanical state of high voltage switch gear. Liu et al. studied and analyzed the curvilinear relationship between the operating torque and the rotation angle of the disconnecting switch operating mechanism in the normal state and the typical mechanical fault state, indicating that there is a correlation between the stator current and the operating torque of the motor (Huang et al., 2015; Liu C. et al., 2020). They proposed the detection technology of the operating torque and the rotation angle of the disconnecting switch and the fault diagnosis scheme of the disconnecting switch jam based on motor current detection. Qiu et al. studied the fault type and location diagnosis method of a high voltage disconnecting switch based on characteristic quantity optimization and back-propagation (BP) neural network (Qiu et al., 2015). Aiming at the problem of data explosion brought by massive heterogeneous multi-source monitoring data to the state perception and diagnosis of intelligent switch equipment, Yuan et al. proposed a method of real-time state perception of disconnecting switches based on dempster-shafer (DS) evidence theory and generative adversarial network to accurately perceive the real-time state of equipment and raise alarms for abnormal information (Yuan et al., 2021). Du et al. established an attitude sensor system detection platform based on the motor control technology for double confirmation of the switching position of the disconnecting switch, which met the requirements of measurement accuracy and performance testing of the attitude sensor system (Du et al., 2019). Lei et al. designed the mechanical state monitoring and diagnosis system of the disconnecting switch and judged whether the mechanical state of the isolation switch was abnormal by accurately measuring the state variables of disconnecting switch torque and rotation angle (Lei et al., 2018). The above studies mainly put forward many feasible technical schemes in the fault classification, fault diagnosis, and state perception of the disconnecting switch. However, with the deepening of the practice of sensing technology, realizing the refinement, intelligence, and visualization of the monitoring technology of the operating state of the disconnecting switch and integrating the sensing technology with the primary equipment of the traditional power grid is the basic support to realizing the one-button control technology of the intelligent substation.

According to the above research, this paper designs an intelligent monitoring system for the operation state of a disconnecting switch based on sensing technology. The contributions of this paper are summarized as follows: 1) An intelligent monitoring system for the isolating switch based on sensing technology is designed, which uses torque sensors, angle encoders, micro-switches, attitude sensors, and temperature and humidity sensor technology to monitor the operation status of the disconnecting switch. 2) The ARM embedded terminal system is proposed as the disconnecting switch status monitoring center, which can accurately monitor the temperature and humidity environment in the disconnector operating mechanism box, the opening and closing position state of the disconnecting switch, and the torque angle variation characteristics of the disconnecting switch according to the operating parameters collected by the sensor. 3) Based on the intelligent analysis of the possible problems of the disconnecting switch, the system can realize data record traceability, remote diagnosis, and early warning, which can provide reliable guidance for the operation, maintenance, and repair of the disconnecting switch, improve the efficiency of the operation, maintenance and repair of the disconnecting switch, and reduce the power failure risk.

2 Basic Theory of the Disconnecting Switch Status Monitoring Technology Based on the Internet of Things

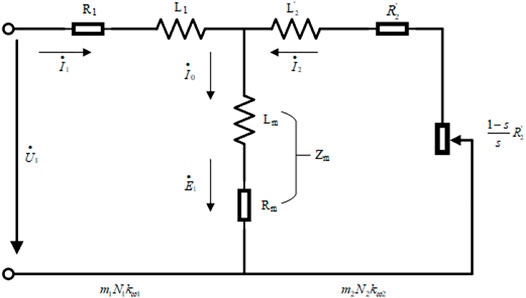

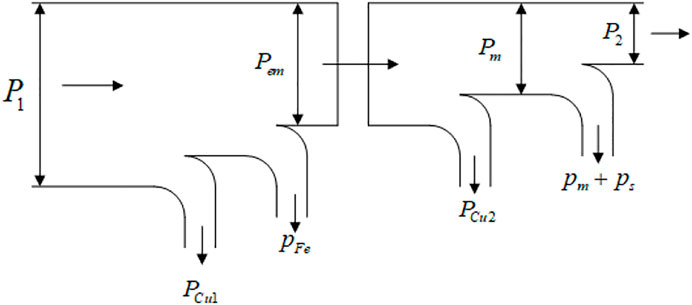

The current disconnecting switch generally uses an alternating current motor as the power source, and drives the disconnecting switch through the turbine worm reducer to realize the opening and closing movement. Therefore, the mechanical fault of the previous paper can judge the characteristics and mechanical state of the disconnecting switch by monitoring the performance state of the motor. Combined with the existing research results, we chose torque and angle as the main monitoring objects. According to the principle of the three-phase asynchronous motor, the converted T-type equivalent circuit can be made, as shown in Figure 1.

Based on the T-type equivalent circuit and the power balance equation,

where

The torque balance equation is derived according to Eq. 1.

T is calculated by

Here

Based on the circuit relationship in Figure 2, Eq. 4 can be transformed into

where

The rated torque at rated voltage,

Hence, the output torque after the reducer is as follows:

where

Torque monitoring adopts mature, stable, and reliable strain electrical measurement technology. The small deformation of the torque axis causes the change of the bridge resistance value, and the change of the strain bridge resistance is transformed into the change of the electrical signal to realize the torque measurement.

The resistance strain gauge is pasted at the specified position on the surface of the elastomer of the measured object. When the elastomer is subjected to strain, the resistance of the resistance strain gauge changes. Through the Wheatstone bridge and the measurement circuit, the stress is converted into an electrical signal (voltage, current, frequency, etc.), so as to realize non-electricity measurement.

The resistance value of a section of metal is derived by

where

Accordingly, considering the cylindrical material, Eq. 9 can be expressed as,

where

According to the mechanics principle, when the material is subjected to torsional deformation, it will produce normal stress and shear stress

where

where

The electric potential is

Due to the four patch resistors having the same resistance value, Eq. 13 is transformed into

Based on Eqs. 11 and 14, torque is proportional to resistance change value, and resistance change value is proportional to potential. Therefore, the relationship between potential and torque can be known by combining Eqs. 11 and 14.

3 Design of Intelligent Disconnector Monitoring System Architecture

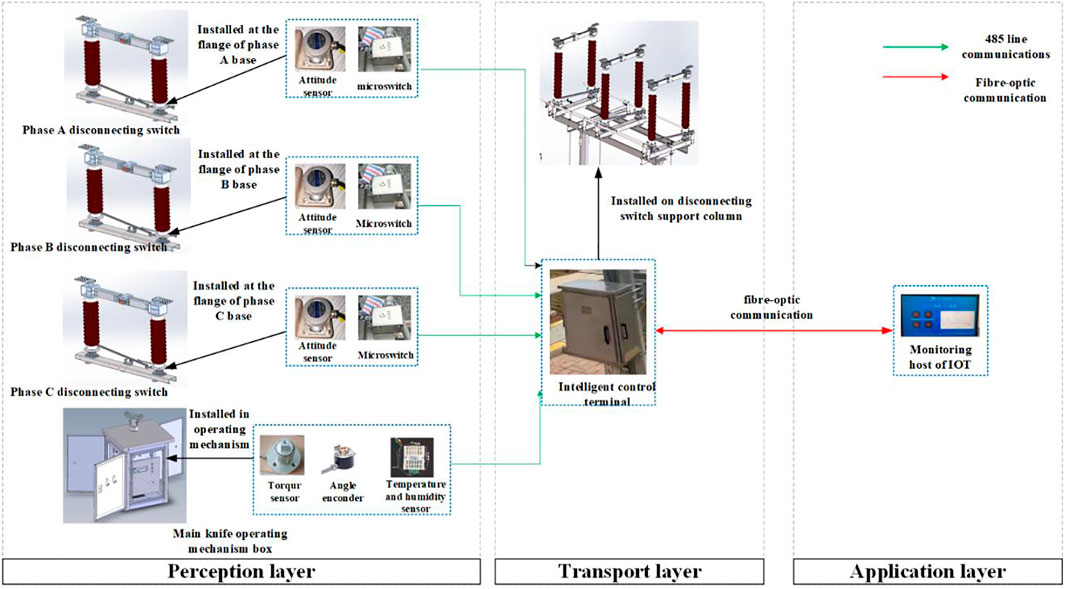

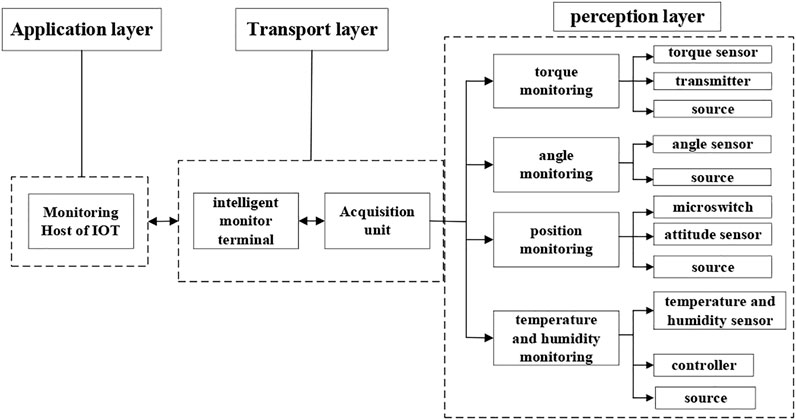

The architecture of the intelligent disconnector monitoring system is shown in Figure 3. This system is based on the ESP32Mesh network design architecture, which includes the perception layer, the transport layer, and the application layer. The perception layer is the basis of the system, which arranges the attitude, torque, angle, temperature, and humidity sensors to collect data, and then the information is collected through the network to the intelligent monitoring terminal of the transmission layer. The transmission layer adopts ESP32-Mesh wireless networking technology to transmit the data collected by the sensing layer to the application layer to realize the transmission and synchronization of data and control instructions. The application layer uses the collected data and control model to control the operation state of the disconnecting switch and achieve the purpose of data management and application. The specific design of each architectural layer is described as follows.

3.1 Perception Layer

The perception layer adopts a modular design, which mainly includes a temperature and humidity monitoring module, a torque monitoring module, an angle monitoring module, and a position monitoring module. The temperature monitoring module is installed in the disconnecting switch operating mechanism to monitor the temperature and humidity changes in real-time. The torque monitoring module is installed in the middle of the spindle of the disconnecting switch operating mechanism box, and the angle monitoring module is installed in the position of the output shaft of the disconnecting switch operating mechanism box. The two sensors rotate with the spindle of the electric mechanism, collect the torque variation value of the spindle and the rotation angle signal, and transmit them to the intelligent processing center for processing. The position monitoring module mainly refers to the micro-switch, that is, two micro-switches are installed at the bearing position of each phase disconnecting switch (low potential) to monitor the opening and closing of the switch, respectively, through the steel bracket. When the switch moves to the correct place of opening and closing, the two micro-switches operation heads are touched so that the normal opening point is closed. The position signal of the disconnecting switch is sent out. Together with the auxiliary switch signal in the disconnecting switch operation mechanism, it can be used as the criterion to meet the position “double confirmation” of the disconnecting switch.

3.2 Transport Layer

The transport layer is an intelligent unit and gateway designed with an intelligent control terminal as the core and composed of various sensors and communication units. It can complete the perception of the operational state of the disconnecting switch and enable the comprehensive application of intelligent monitoring and remote control of the disconnecting switch. It mainly includes communication between the acquisition unit and intelligent control terminal and communication between the intelligent control terminal and the monitoring system management center. The communication mode between the acquisition unit and the intelligent processing center adopts the user datagram protocol (UDP) communication protocol for transmission, that is, the Ethernet interface is designed, and the communication mode can be switched by the monitoring center. The intelligent control terminal realizes ESP-Mesh wireless networking through the ESP32 chip. The mesh network layer has adaptive and automatic repair functions. When a path in the transmission link is blocked or disconnected, it can automatically select other paths for transmission to avoid the bandwidth congestion problem in the transmission process of a wireless sensor network and effectively solve the delay effect of a wireless sensor network.

3.3 Application Layer

The application layer includes a disconnecting switch monitoring system, which can realize the storage, analysis, and management of various sensor information, provide threshold setting, alarm information prompt, intelligent exhaust heating lighting, and other functions. It can also record alarm information and actions so that users can view them at any time. The disconnecting switch monitoring system in the application layer has four main functions: data display, information management, intelligent control, and data communication. The data display function is the management center of the data. Information management functions refer to the analysis and management of database information. The data source includes the operation state information of the disconnecting switch collected by various sensors, and the collected data is stored in a specific format after sorting. The intelligent control function is mainly to process the collected monitoring data and output the control commands. The data communication function realizes communication with each module unit.

4 Design of System Hardware

The intelligent control terminal needs to have the functions of collecting sensor parameters, communication, and data transmission. At the same time, it also needs to ensure the low cost, reliable and stable operation of the system. It mainly includes two parts: the acquisition unit and the control unit, which are composed of the main control chip, sensor data acquisition module, power module, and communication module. The hardware structure is shown in Figure 4.

4.1 Acquisition Unit

The monitoring unit is composed of the main control module and a sensor module. The core processor of the main control module selects the arm microcontroller, which is responsible for reading the data collected by the sensor module, packaging and fusing the data, and connecting the module through the serial port and UDP communication. Temperature and humidity monitoring uses temperature and humidity sensors and mature and stable semiconductor refrigeration dehumidification technology to achieve intelligent monitoring of temperature and humidity. Torque monitoring adopts mature, stable, and reliable strain electrical measurement technology. The small deformation of the torque shaft causes the change of bridge resistance, and the change of strain bridge resistance changes the electrical signal to realize torque measurement. It has the advantages of high precision, fast frequency response, high reliability, long cycle life, and strong anti-interference ability. The angle monitoring adopts a simple and compact mechanical design, which has the advantages of high measurement accuracy, high robustness, strong anti-interference ability of signal output, and good compatibility. A high-performance three-dimensional motion attitude measurement system based on micro-electro-mechanical system (MEMS) technology to achieve attitude sensing. The three-dimensional attitude and azimuth data output without blind area in full-scale is realized when combined with the three-dimensional algorithm based on quaternion and special data fusion technology. The micro-switch adopts a modular combination, which can change the head and the orientation of cable accessories at any time. Its body is made of zinc alloy with high corrosion resistance and protection level, and it has flame retardant and corrosion resistance.

4.2 Control Unit

The control unit is composed of the main control chip, a power conversion circuit, and a relay module circuit. The main control chip has communication functions with low energy consumption. The power conversion circuit isolates power supply module and generates 5 V direct current, which is then converted to 3.3 V direct current through the three-terminal regulator. The solid-state relay without contact is selected to avoid the electromagnetic interference of the relay with constant contact on the master chip.

4.3 Communication Module

The communication module is mainly composed of the communication circuit of the ESP32 chip. The EPS32 is a micro-controller chip with extremely low power consumption, dual-mode communication, and high integration. Therefore, each intelligent terminal is a network node, multiple intelligent control terminals and a monitoring host constitute a wireless MESH network, so when the network signal cannot be fully covered, it can be automatically re-networked to achieve self-healing of the network. This networking method can ensure that the network maintains self-stability in the case of unmanned monitoring, which greatly ensures network security.

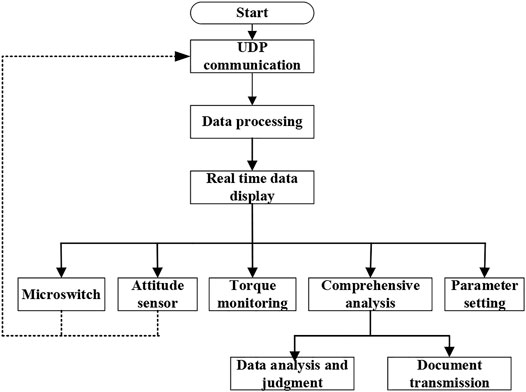

4.4 Software Design

The system software design mainly includes the software design of the acquisition unit and the control unit, as well as the application and design of the monitoring host. The overall process is shown in Figure 5. The application design of the monitoring host mainly includes visual monitoring interface design and alarm push management. According to the development tools provided by the monitoring host, the intelligent monitoring system of the disconnecting switch is designed to provide historical data query, threshold setting, alarm, disconnecting switch torque-angle characteristic curve view, and other functions. The acquisition unit software mainly completes the data acquisition. After the system terminal equipment is powered, the sensor module is driven to work, and all the collected information is packaged and uploaded to the monitoring host. The monitoring host provides a communication interface to realize the reporting, storage, and analysis of the data collected by the sensing layer and monitors the operation state of the disconnecting switch and the intelligent control terminal. Through the developed visual interface, the dynamic display of the data is realized, so that the parameters of the disconnecting switch and its intelligent analysis results can be remotely viewed.

5 Test and Field Operation

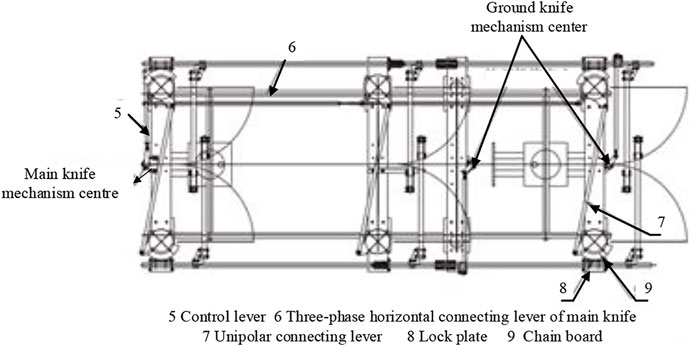

The disconnecting switch operation state intelligent monitoring system based on sensing technology described in this paper has been tested in the disconnecting switch factory. Taking the widely used GW4C-126 disconnecting switch as the test object, the monitoring effect of the developed intelligent monitoring system on the operation state of the disconnecting switch is observed. Figure 6 shows the model diagram of the GW4C-126 disconnecting switch.

5.1 Functional Test

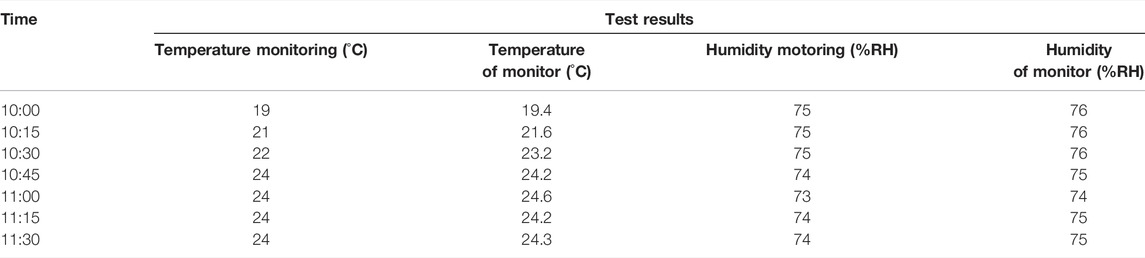

5.1.1 Function Test of Temperature and Humidity Monitoring

The temperature and humidity monitoring was taken as the test object, accurately monitoring the temperature and humidity in the operating mechanism box from 10:00 to 11:30, and recording results every 15 min. The test results are shown in Table 1. It can be seen from the table that the test value is basically the same as the standard value, and is within the tolerance error range of ±5°C allowed by the monitoring system. The temperature and humidity sensors can accurately reflect the temperature condition during the operation of the high voltage disconnecting switch. Through the visual interface, the temperature and humidity of the operating mechanism box are preset to 5–40°C and 80% RH, respectively. The program is set to open the heater when the average temperature is lower than 5°C, and to close the heater when the average temperature is higher than 40°C. Similarly, the dehumidifier is turned on when the average humidity is greater than 80% RH, and the dehumidifier is closed when the average humidity is less than 80% RH.

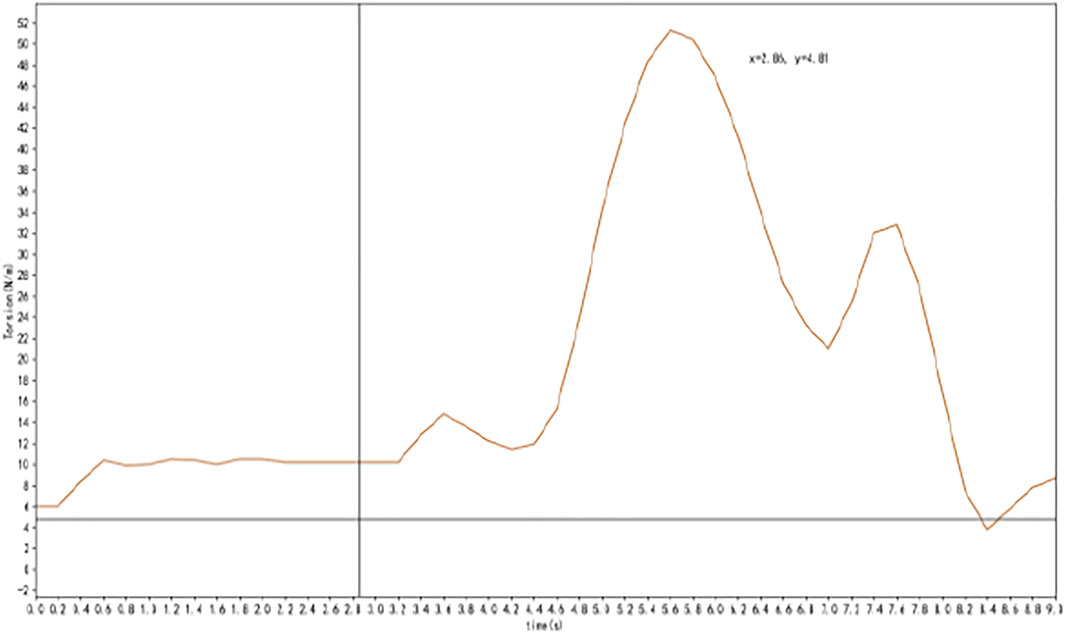

5.1.2 Function Test of Torque and Angle Monitoring

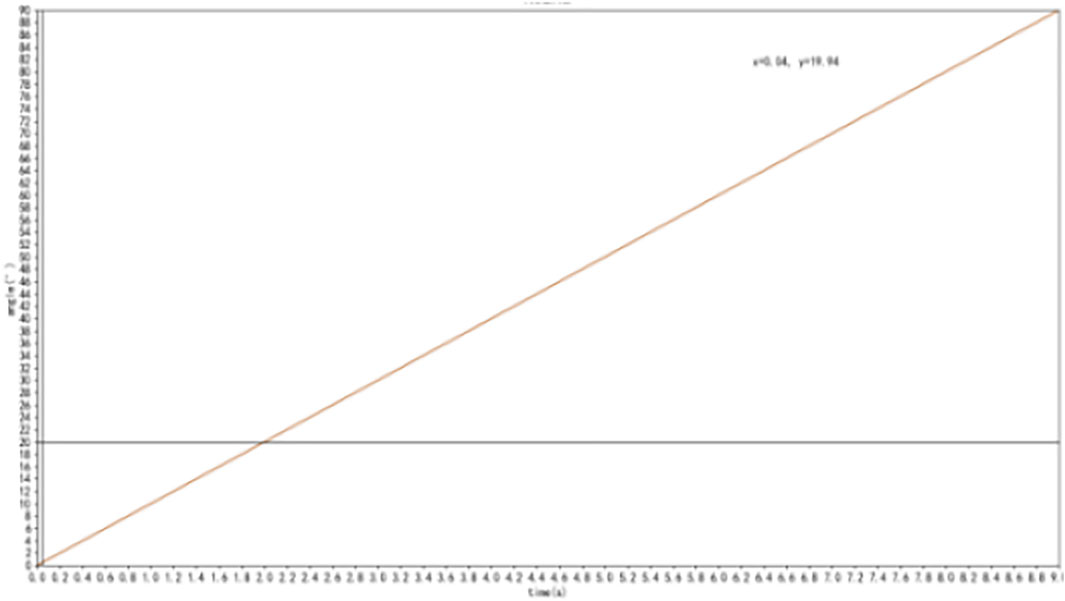

The movement process of the GW4C-126 disconnecting switch is as follows. The changing characteristics of torque with time during the closing process are shown in Figure 7. It can be seen from the figure that the torque waveform clearly reflects the contact process between the contact and the finger in the closing movement, and the whole waveform conforms to the stress state of the transmission mechanism during the movement of the GW4D-126 disconnecting switch. Figure 8 shows the changing characteristics of turn angle with time during the closing process. The angle sensor is installed in the motor shaft and rotates synchronously with the spindle. In theory, the change in the rotation angle signal of the spindle can be measured by the angle sensor.

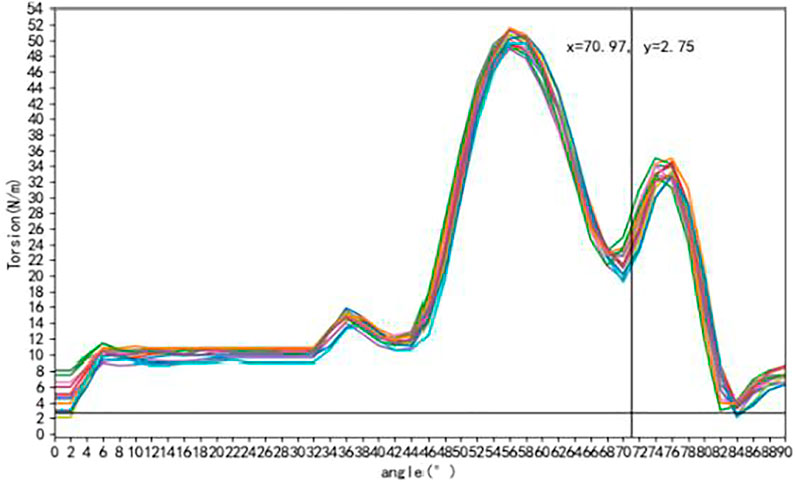

According to the 100 closing experiments of the disconnecting switch in the normal state, the torque-angle motion curve is drawn, as shown in Figure 9. From the pictures, the changing trends of 100 monitoring curves are consistent, indicating that the data has high repeatability. It can be seen from the figure that the overall change of operating torque gradually increases in the closing process. This is because, with the contact between the contact finger and the contact in the closing process, the contact finger and the spring of the contact seat gradually store the elastic potential energy.

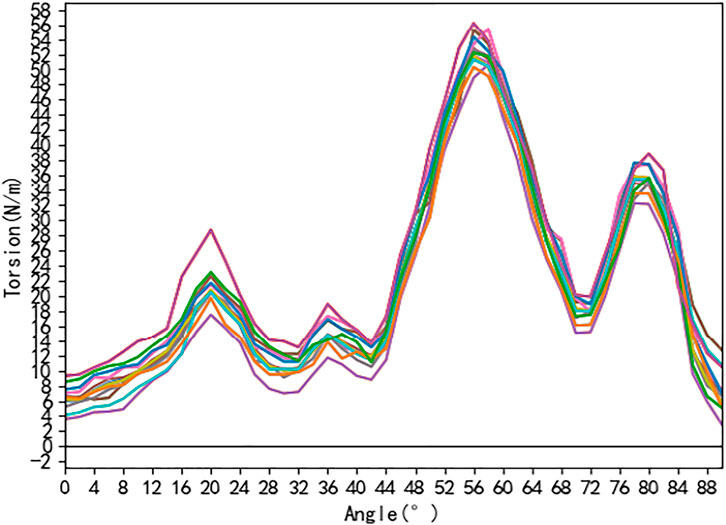

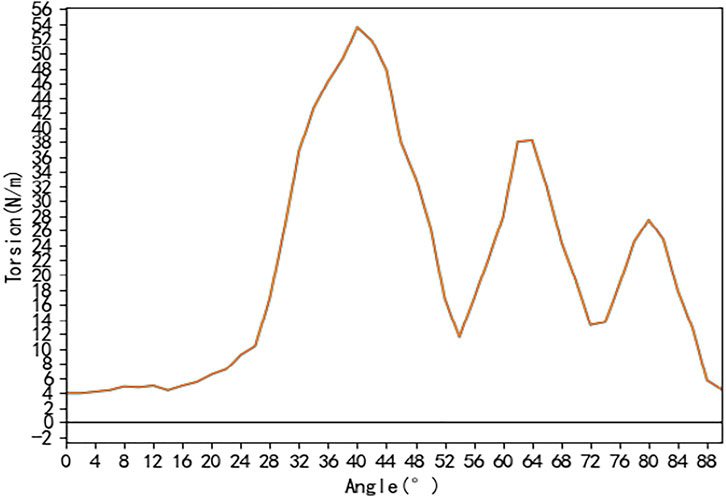

Figure 10 shows the state curves of the mechanical locking jam when the disconnecting switch is in the state of closing. Compared with Figure 9, it can be seen that the curve position has an obvious deviation compared with the normal conditions when the mechanical locking of the disconnecting switch is jammed. Taking the locking of the disconnecting switch as an example, the maximum torque value of the normal value is 52 N/m, while the maximum torque value increases to 56 N/m during the locking jam, the angle position is advanced. The simulation results are consistent with the current situation. Figure 11 shows the diagram of the abnormal contact position of the contact and the contact finger when the disconnecting switch is switched off. It can be seen from the picture that when the contact position of the contact and the contact finger of the disconnecting switch are abnormal, the curve position is obviously shifted compared with the normal condition. During the closing process of the disconnecting switch, the torque at the abnormal location is larger than the normal curve because of the serious wear of the contact and the contact finger. The separation time of the contact and the contact figure increases, and the separation torque also increases.

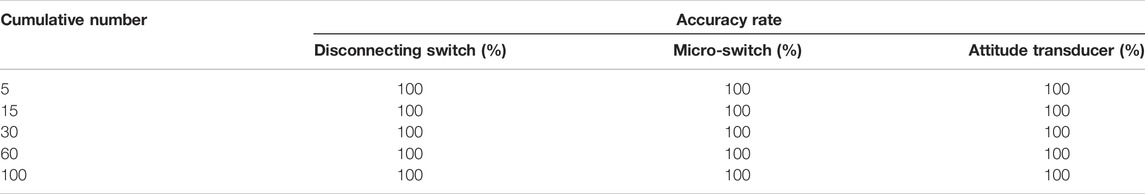

5.1.3 Function Test of Position Monitoring

The closing position monitoring of the disconnecting switch is taken as the test object, and the closing position of the disconnecting switch is accurately monitored. A total of 100 closing tests are carried out throughout the test process, and the test results are shown in Table 2. According to the results in Table 2, both sensors can accurately reflect the closing position of the high-voltage disconnecting switch in the operation process, which is completely consistent with the actual situation of the disconnecting switch. The opening tests are the same.

5.2 Analysis and Summary of Test

From the test results, it can be seen that the sensing layer acquisition sensor of the disconnecting switch state monitoring system based on sensing technology can normally obtain the state data of the disconnecting switch, and according to the data, the torque-angle characteristic curve is plotted to distinguish the status of the opening and closing position and the temperature and humidity of the operating mechanism box. In particular, the possible problems of the high-voltage disconnecting switch are analyzed by comparing the curve of the normal and abnormal torque-angle characteristic, the status of the opening and closing position, the temperature and humidity value, and the threshold of the operating mechanism box, to achieve the intelligent monitoring, analysis, and prediction of the disconnecting switch, which helps to prolong the service life of the disconnecting switch and reduce the number of power outages.

5.3 On-Site Trial Running

The intelligent monitoring system for the motion state of the disconnecting switch based on sensor technology developed in December 2021 has been successfully piloted in Yunfu’s 110 kV Fenghuang Phase II Substation in Guangdong Province. The measurement data of the entire system are correct in field operation, the repeatability and consistency of the monitoring data such as torque angle are good, and the accuracy rate of distinguishing the switching state is 100%. The actual operation is shown in Figure 12. The successful operation of this on-site trial run shows that the intelligent monitoring system for the motion state of the disconnecting switch based on the sensing technology developed in this project has good performance and can realize the intelligent monitoring of the motion state of the disconnecting switch.

6 Conclusion

This paper designs an intelligent monitoring system for the disconnecting switch operation status based on sensing technology. The research and application show that the system extends the monitoring contact angle to the disconnecting switch through a special sensor and realizes the collection and remote monitoring of the temperature and humidity of the disconnecting switch operating mechanism box, the opening and clocking position of the disconnecting switch, and the torque-angle characteristics of the disconnecting switch in the motion state, providing data support for the evaluation of the operation state of the disconnecting switch. The practical application effect is verified by in-plant test and field pilot operation, which can objectively and accurately reflect the operation state of the disconnecting switch and achieve the goal of accurate monitoring, analysis, and prediction.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author Contributions

JC: Project design, methodology, and writing—original draft preparation. GW: Software, simulation. XJ: Experiment. LC: Software, experiments. SC: Experiment, visualization. RC: Investigation, ideas, supervision.

Funding

This study received funding from the Science and Technology Project Funding of Guangdong Power Grid Co., Ltd. (51467003).

Conflict of Interest

Authors JC, GW, XJ, LC, SC, and RC are employed by Guangdong Power Grid Co., Ltd.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ahmed, H., and Tahir, M. (2017). Accurate Attitude Estimation of a Moving Land Vehicle Using Low-Cost MEMS IMU Sensors. IEEE Trans. Intell. Transport. Syst. 18 (7), 1723–1739. doi:10.1109/TITS.2016.2627536

Chen, W., Zhao, J., Bian, K., Wang, D., Wang, B., Zhou, Z., et al. (2019). Research Progress on Transient Electromagnetic Disturbance Due to Switching Operations in GIS Substation. Proc. CSEE 39 (16), 4935–4948. doi:10.13334/j.0258-8013.pcsee.181400

Cheng, W., Yu, T., and Yin, H. (2016). Health State Evaluation of Disconnector Based on Weighted Grey Target Theory. Electr. Meas. instrumentation 53 (14), 84–89. doi:10.3969/j.issn.1001-1390.2016.14.016

Cheng, X., Guan, Y., Zhang, W., and Tang, C. (2014). Mechanical Fault Diagnosis Method of High Voltage Circuit Breaker Based on Factor Analysis and Support Vector Machine Algorithm. J. electrotechnics 29 (7), 209–215. doi:10.19595/j.cnki.1000-6753.tces.2014.07.027

Du, F., Wang, G., Zhang, H., Gong, Y., and Ge, D. (2019). A Detection Platform of Attitude Sensor System Used for Double Reconfirmation Technology of Disconnecting Switch's Opening and Closing Position. Electric Power 52 (11), 153–158. doi:10.11930/j.issn.1004-9649.201905002

Huang, Y., Ruan, J., Qiu, Z., Wu, J., and Zhang, E. (2015). Study on the Relationship between Motor Output Shaft Torque and Current of Disconnector Operating Mechanism. High voltage apparatus 51 (6), 139–144. doi:10.13296/j.1001-1609.hva.2015.06.025

Lei, X., Xu, N., Li, Y., He, M., and Wang, S. (2018). Development of Mechanical Condition Monitoring and Diagnosis System for Disconnector. Power and energy 39 (6), 834–836. doi:10.11973/dlyny201806023

Liu, C., Zhou, T., Ma, H., Zhang, H., and Qiu, Z. (2020). Typical Mechanical Fault Diagnosis of GW4-126 Disconnector Based on Torque and Angle Detection. High voltage apparatus 56 (02), 232–239. doi:10.13296/j.1001-1609.hva.2020.02.035

Liu, C., Song, l., Guo, W., and Liu, W. (2020). Fault Diagnosis of High Voltage Disconnector Mechanism Based on Stator Current Characteristics and SVM. High voltage apparatus 56 (6), 289–295. CNKI:SUN:GYDQ.0.2020-06-043.

Ni, Y., Lu, D., Yu, Q., Xu, Y., and Xie, N. (2021). Internet of Things Information Gathering of Substation Based on ESP-Mesh Network. J. Shanghai Jiao Tong Univ. 55 (S2), 60–63. doi:10.16183/j.cnki.jsjtu.2021.S2.009

Qiu, Z., Ruan, J., Huang, d., Zhang, Y., and Zhang, E. (2015). Summary of Mechanical Fault Analysis and Diagnosis Technology of High Voltage Disconnector. High voltage apparatus 51 (08), 171–179. doi:10.13296/j.1001-1609.hva.2015.08.029

Song, J., Zhou, J., Bao, W., Huang, W., and Gao, X. (2018). Expansible Modeling and Applied Strategies Based on Semantic Web for Expert System of AC-DC Intelligent Substation. J. Shanghai Jiao Tong Univ. 52 (09), 1072–1080. doi:10.16183/j.cnki.jsjtu.2018.09.010

Wang, B., Jiang, Y., Wen, C., Duan, H., Yi, J., Xiong, X., et al. (2019b). Research and Application on Method for Breaking-Closing Position Discrimination of Isolation Switches Based on Generative Adversarial Network. Smart Grid 47 (10), 77–84. doi:10.3969/j.issn.1673-7598.2019.10.012

Wang, B., Mao, W., Jiang, Y., Huang, M., Yi, J., and Zhou, H. (2019a). “Review on Breaking-Closing Position Monitoring Method for Intelligent Disconnecting Switch,” in Paper presented at the Proceedings of 2018 International Conference on Advanced Technologies in Energy, Qingdao, China, 26–28 October 2018. doi:10.1088/1755-1315/223/1/012026

Wei, J., Cao, Y., Wu, Q., Li, C., Huang, S., Zhou, B., et al. (2021). Coordinated Droop Control and Adaptive Model Predictive Control for Enhancing HVRT and post-event Recovery of Large-Scale Wind Farm. IEEE Trans. Sustain. Energ. 12 (3), 1549–1560. doi:10.1109/TSTE.2021.3053955

Yuan, P., Wang, B., Mao, W., Jiang, Y., and Li, P. (2021). Research on State Perception and Diagnosis of Intelligent Switches Based on Triple Generative Adversarial Networks. Power Syst. Prot. Control. 49 (06), 67–75. doi:10.19783/j.cnki.pspc.200733

Zeng, L., Li, C., Li, Z., Shahidehpour, M., Zhou, B., and Zhou, Q. (2021). Hierarchical Bipartite Graph Matching Method for Transactive V2V Power Exchange in Distribution Power System. IEEE Trans. Smart Grid 12 (1), 301–311. doi:10.1109/TSG.2020.3016597

Keywords: intelligent substation, disconnecting switch, condition monitoring, sensor, smart device

Citation: Chen J, Wu G, Jian X, Cai L, Chen S and Chen R (2022) Research on State Monitoring System of Intelligent Disconnecting Switch Based on Sensing Technology. Front. Energy Res. 10:895301. doi: 10.3389/fenrg.2022.895301

Received: 13 March 2022; Accepted: 08 April 2022;

Published: 26 May 2022.

Edited by:

Chuan-Ke Zhang, China University of Geosciences Wuhan, ChinaReviewed by:

Juan Wei, Hunan University, ChinaLong Zeng, Guangdong University of Technology, China

Qi Zhu, Xi’an Shiyou University, China

Copyright © 2022 Chen, Wu, Jian, Cai, Chen and Chen. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Rixin Chen, eHV6aTIwMTFAMTI2LmNvbQ==

Jinhong Chen

Jinhong Chen Guibin Wu

Guibin Wu