- 1Heavy Oil Company, Xinjiang Oilfield Company of CNPC, Karamay, China

- 2Ministry of Education Key Laboratory of Oil & Gas Resources and Exploration Technology, Wuhan, China

Introduction

Xinjiang conglomerate reservoir is the main reservoir type in Xinjiang oilfield development and also the typical representative of conglomerate reservoir in the world (Zou et al., 2007; Jia et al., 2016; Zheng and Fan 2019). Most of these reservoirs belong to conglomerate reservoirs dominated by alluvial fan-braided river deposits at the edge of the Piedmont continental basin (Chen et al., 2016). The reservoirs include Permian, Triassic, and Jurassic systems, with an average porosity of 11–18.8% and permeability of 0.01–817 mD, and the reservoir properties are poor (Qu et al., 2013; Lu et al., 2015; Zhang et al., 2016). The main reservoir space types are intergranular dissolution pores, intergranular dissolution pores, and microfractures. The development practice of conglomerate reservoirs shows that the waterflooding development effect is poor (Wu et al., 2014). The JL2 reservoir is a typical conglomerate reservoir in Xinjiang oilfield. The 23 vertical wells in the JL2 reservoir had an average initial production of 4.2 t/d, resulting in low production and poor development. So far, CCUS and its application have been carried out worldwide and achieved remarkable results for low-permeability reservoirs (Park et al., 2017; Khather et al., 2019). The numerical simulation of this reservoir proves that CO2 flooding is an effective EOR method for low-permeability conglomerate reservoir (Huang et al., 2016; Ding et al., 2017). Through further research on well type, it is concluded that the development effect of CO2 injection in vertical well and horizontal well is better than that of vertical well (Wang et al., 2017). Therefore, based on the understanding of the development of low-permeability sandstone reservoirs, the current production wells are mainly horizontal wells. As we know, horizontal well has the advantages of large contact area with reservoirs. Horizontal wells have high initial productivity and slow production decline and also can effectively control gas channeling (Yin et al., 2021).

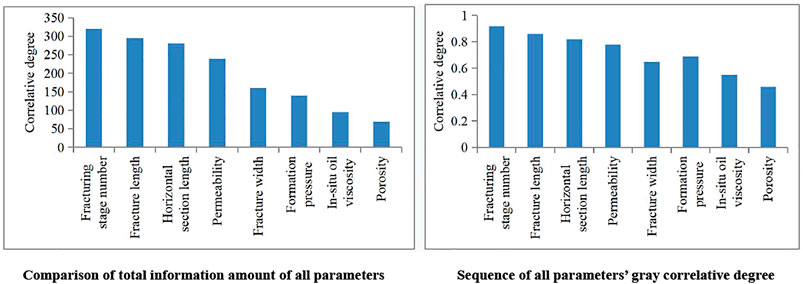

Eight horizontal wells have been put into production in the JL2 reservoir, with an average initial productivity of 32.9 t/d. The practice of CO2 injection in conglomerate reservoir further shows that horizontal well development is a reasonable development mode for low-permeability conglomerate reservoir and can effectively reduce the risk of gas channeling (Liu et al., 2019). At the same time, due to the low permeability, conglomerate reservoir must be developed by fracturing. Although the average productivity of horizontal well is high, there are also differences between the productivity of each horizontal well. Because of the special geological conditions of conglomerate reservoir, the productivity of horizontal well is complicated (Zhao et al., 2020). Therefore, the initial productivity of horizontal wells is affected by many factors. Based on in-depth analysis of geological conditions and fracturing parameters of a single horizontal well, most scholars adopted single-factor or multi-factor analysis methods to find out the main controlling factors affecting horizontal well productivity (Figure 1).

FIGURE 1. Grey correlation analysis method for horizontal well productivity. Sources: Liang et al. (2013) and Luo et al. (2021).

Single-Factor Analysis

A total of eight horizontal wells were put into production in JL2 oilfield in 2021. Also, eight horizontal wells were deployed in two small zones, P3w11 and P3w12, with a well spacing of 100 m. The two sets of wells were longitudinally staggered and separated to form a three-dimensional well pattern. Because of the poor permeability of conglomerate reservoir, horizontal wells are put into production by volume fracturing. By analyzing the relationship between the length of the horizontal section and the initial productivity of the eight horizontal wells, it can be found out that the productivity of the eight horizontal wells is weakly correlated with the length of the horizontal wells, and the productivity of horizontal wells does not increase with the increase of the length of the horizontal section, which is inconsistent with the understanding of theoretical research. Through the analysis of all reservoirs drilled in the horizontal section of a single well, it can be seen that there are certain differences in the properties of reservoirs drilled in different horizontal wells. With oil saturation as the main evaluation index and permeability and porosity as the auxiliary evaluation index, the horizontal reservoir is classified and evaluated, and the reservoir is divided into three types. Therefore, the thickness of the first- and second-type reservoirs drilled by each horizontal well can be calculated. On the basis of reservoir classification and evaluation, the relationship between the initial productivity of the eight horizontal wells and the thickness of the first-class oil layer and the total thickness of the first-, second-, and third-class oil layer can be obtained. It can be seen from the figure that there is a strong correlation between the productivity of horizontal wells and the length of class I reservoir. The initial productivity of horizontal wells increases with the thickness of class I reservoir drilled, and the initial productivity increases, while the correlation with the total thickness of class I and class II reservoir is weak.

Due to the poor physical properties of the conglomerate reservoir, the oil production of the horizontal wells is very low without fracturing, so all the eight horizontal wells were put into production by fracturing. Different fracturing parameters will inevitably lead to different initial productivities of horizontal wells. This study analyzed the relationship between the total number of stages, total number of clusters, average stage spacing, average cluster spacing, total amount of fracturing fluid and sand addition, and initial productivity. The statistical analysis of the productivity of the eight horizontal wells and the number of fracturing stages and total clusters shows that there is little correlation between the productivity of horizontal wells and the number of fracturing stages and total clusters, but there is such a rule that the horizontal wells with fewer fracturing stages and total clusters have a lower initial productivity, so the number of fracturing stages and total clusters has a greater impact on the initial productivity of the horizontal well. The statistical analysis of the productivity of the eight horizontal wells and the average fracturing stage spacing and cluster spacing shows that the average fracturing stage spacing and cluster spacing have no regular influence on the productivity of each horizontal well, which can be judged to be a weak correlation between the productivity of the horizontal well and the average fracturing stage spacing and cluster spacing. The relationship between average fracturing stage spacing and average cluster spacing and horizontal well productivity is shown in the figure. The statistical analysis of the productivity of the eight horizontal wells and total fracturing fluid and sand addition shows that there is a certain correlation between the productivity of the horizontal well and total fracturing fluid and sand addition. With the increase of total fracturing fluid and sand addition, the initial productivity of the horizontal well will increase relatively.

With the large-scale development of low-permeability and tight shale oil and gas reservoirs in recent years, many scholars have found that the relationship between fracturing fluid flowback rate and well productivity is different from the previous understanding. Therefore, this study made statistics on the relationship between the productivity of the eight horizontal wells and fracturing fluid flowback rate and concluded that there was a good correlation between the productivity of the horizontal well and flowback rate. The lower the flowback rate, the higher the initial productivity of the corresponding horizontal well.

Grey Correlation Analysis

The abovementioned single factor was used to analyze the factors affecting the productivity of the horizontal well; the influence degree of each factor was not clear, so the grey correlation method was used for analysis (Liang et al., 2013; Zhang et al., 2016). The degree of correlation is a measure of the degree of correlation between the factors of two systems, which varies from time to time or object to object. In the process of system development, if the change trend of the two factors is consistent, that is, the degree of synchronous change is high, it can be said that the degree of correlation between the two is high; on the contrary, it is lower. Therefore, the grey correlation analysis method is a method to measure the degree of correlation among factors according to the degree of similarity or dissimilarity between the development trends of factors, that is, “grey correlation degree.”

The specific calculation steps are as follows:

(1) First, the analysis index system is determined according to the analysis purpose.

(2) The reference data column is determined.

(3) Dimensionless index data.

(4) The absolute difference between the object indicator sequence and reference sequence is calculated one by one:

(5) It is made sure

(6) The correlation coefficient

(7) The association order is calculated:

The absolute difference between the index sequence of the object and the reference sequence and the absolute difference between the index sequence (comparison sequence) of each evaluated object and the corresponding element of the reference sequence are calculated one by one, and the maximum and minimum values are found out.

Through the correlation degree analysis of the abovementioned factors, the correlation order between the initial productivity of the horizontal well and all factors can be obtained: type I reservoir thickness > total fracturing fluid > sand volume > flowback rate > total thickness of the first- and second-class oil layer > total number of stages > length of the horizontal well > length of the transformed section > total number of clusters. Therefore, it can be concluded that the initial productivity of the horizontal well in conglomerate reservoirs is closely related to the thickness of the first class oil layer drilled, the total amount of fracturing fluid, sand addition, and flowback rate, which is basically consistent with the understanding obtained from single-factor analysis.

Conclusion

CO2 flooding is an effective EOR method for low-permeability conglomerate reservoirs. Based on the in-depth analysis of geological conditions and fracturing parameters of the eight horizontal wells in the JL2 well area, this paper conducted single-factor and multi-factor analysis on the productivity of a CO2-injected horizontal well in a conglomerate reservoir and found out the main controlling factors of productivity of the horizontal well, such as the thickness of the high-quality reservoir drilled by the horizontal well, total amount of fracturing fluid, sand addition amount, and flowback rate. The understanding obtained from single-factor analysis and grey correlation analysis is basically consistent. The abovementioned research provides technical support for the next horizontal well deployment in conglomerate reservoir.

Author Contributions

JS, LQ, CH, NL, AZ, XD, and YQ contributed equally to this work.

Funding

This work was supported by the Natural Science Foundation of China (NSFC) (Grant No. 52104019).

Conflict of Interest

Author SJ, QL, HC, NL, AZ, and XD were employed by Heavy Oil Company, Xinjiang Oilfield Company of CNPC. Author YQ was employed by the Ministry of Education Key Laboratory of Oil Gas Resources and Exploration Technology.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chen, Z., Cao, Y., Wang, X., Qiu, L., Tang, Y., and Yuan, G. (2016). Oil Origin and Accumulation in the Paleozoic Chepaizi-Xinguang Field, Junggar Basin, China. J. Asian Earth Sci. 115, 1–15. doi:10.1016/j.jseaes.2015.09.019

Ding, M., Yuan, F., Wang, Y., Xia, X., Chen, W., and Liu, D. (2017). Oil Recovery from a CO 2 Injection in Heterogeneous Reservoirs: The Influence of Permeability Heterogeneity, CO 2 -oil Miscibility and Injection Pattern. J. Nat. Gas Sci. Eng. 44, 140–149. doi:10.1016/j.jngse.2017.04.015

Huang, F., Huang, H., and Wang, T. (2016). Assessment of Miscibility Effect for CO2 Flooding EOR in a Low Permeability Reservoir. J. Pet. Sci. Eng. 145, 328–335.

Jia, C., Pang, X., and Jiang, F. (2016). Research Status and Development Directions of Hydrocarbon Resources in China. Pet. Sci. Bull. 1, 2–23.

Khather, M., Saeedi, A., Myers, M. B., and Verrall, M. (2019). An Experimental Study for Carbonate Reservoirs on the Impact of CO2-EOR on Petrophysics and Oil Recovery. Fuel 235, 1019–1038. doi:10.1016/j.fuel.2018.08.094

Liang, T., Chang, Y., Guo, X., Liu, B., and Wu, J. (2013). Influence Factors of Single Well's Productivity in the Bakken Tight Oil Reservoir, Williston Basin. Pet. Exploration Dev. 40, 383–388. doi:10.1016/s1876-3804(13)60047-6

Liu, W., Zhang, Q., and Zhu, W. (2019). Numerical Simulation of Multi-Stage Fractured Horizontal Well in Low-Permeable Oil Reservoir with Threshold Pressure Gradient with Moving Boundary. J. Pet. Sci. Eng. 178, 1112–1127. doi:10.1016/j.petrol.2019.04.033

Lu, X., Shi, J. A., Zhang, S., Zou, N., Sun, G., and Zhang, S. (2015). The Origin and Formation Model of Permian Dolostones on the Northwestern Margin of Junggar Basin, China. J. Asian Earth Sci. 105, 456–467. doi:10.1016/j.jseaes.2015.02.024

Luo, A., Li, Y., Wu, L., Peng, Y., and Tang, W. (2021). Fractured Horizontal Well Productivity Model for Shale Gas Considering Stress Sensitivity, Hydraulic Fracture Azimuth, and Interference between Fractures. Nat. Gas Industry B 8, 278–286. doi:10.1016/j.ngib.2021.04.008

Park, H., Jiang, L., Kiyama, T., Zhang, Y., Ueda, R., Nakano, M., et al. (2017). Influence of Sedimentation Heterogeneity on CO2 Flooding. Energ. Proced. 114, 2933–2941. doi:10.1016/j.egypro.2017.03.1422

Qu, J., Zhang, S., and Li, H. (2013). Control Factors of the Triassic Baikouquan Reservoirs in Mabei Area of Junggar Basin. Spec. Oil Gas Reservoirs 20, 51–56.

Wang, S., Kadhum, M. J., Chen, C., Shiau, B., and Harwell, J. H. (2017). Development of In Situ CO2 Generation Formulations for Enhanced Oil Recovery. Energy Fuels 31 (12), 13475–13486. doi:10.1021/acs.energyfuels.7b02810

Yin, F. L., Gao, Y. H., and Zhang, H. (2021). Comprehensive Evaluation of Gas Production Efficiency and Reservoir Stability of Horizontal Well with Different Depressurization Methods in Low Permeability Hydrate Reservoir. Energy 239, 122422.

Zhang, C., Wang, X., and Zhu, R. (2016). Litho-Facies Classification of Baikouquan Formation in Mahu Sag, Junggar Basin. Xinjiang Pet. Geology. 37, 606–614.

Zhao, F., Wang, P., Huang, S., Hao, H., Zhang, M., and Lu, G. (2020). Performance and Applicable Limits of Multi-Stage Gas Channeling Control System for CO2 Flooding in Ultra-low Permeability Reservoirs. J. Pet. Sci. Eng. 192, 107336. doi:10.1016/j.petrol.2020.107336

Zheng, M., and Fan, X. (2019). Superposition of Deep Geological Structural Evolution and Hydrocarbon Accumulation in the Junggar Basin. Earth Sci. Front. 26, 22–32.

Keywords: CO2 driven, horizontal well, conglomerate reservoir, grey correlation analysis, productivity

Citation: Ju S, Lv Q, Chen H, Li N, Zheng A, Du X and Qu Y (2022) Study on the Influencing Factors of Productivity of a CO2-Driven Horizontal Well in a Conglomerate Reservoir. Front. Energy Res. 10:857119. doi: 10.3389/fenrg.2022.857119

Received: 18 January 2022; Accepted: 14 February 2022;

Published: 07 March 2022.

Edited by:

Hui Zhao, Yangtze University, ChinaReviewed by:

Shaohua Gu, SINOPEC Petroleum Exploration and Production Research Institute, ChinaZupeng Ding, China National Offshore Oil Corporation (China), China

Copyright © 2022 Ju, Lv, Chen, Li, Zheng, Du and Qu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yaguang Qu, cXlnNTIxMjJAMTI2LmNvbQ==

Shichang Ju1

Shichang Ju1 Yaguang Qu

Yaguang Qu