Abstract

Microbial fuel cells (MFCs) have undergone great technological development in the last 20 years, but very little has been done to commercialize them. The simultaneous power production and wastewater treatment are features those greatly increase the interest in the use of MFCs. This kind of distributed power generation is renewable and friendly and can be easily integrated into a smart grid. However, there are some key issues with their commercialization: high construction costs, difficulty in developing high power structures, MFC lifespan, and maintaining a high level of efficiency. The objective of this article is to explore the possibilities of using MFCs in urban wastewater not only regarding the technical criteria of their application, but also mainly from an economic point of view, to determine the conditions through which the viability of the investment is ensured and the possibilities of their integration in a smart grid are identified. Initially, this article explores the implementation/configuration of a power plant with MFCs within an urban wastewater treatment plant on a theoretical basis. In addition, based on the corresponding physical quantities for urban wastewater treatment, the construction and operational costs are determined and the viability of the investment is examined based on classic economic criteria such as net present value, benefit–cost ratio, internal rate of return, and discounted payback period. Furthermore, sensitivity analysis is carried out, concerning both technical parameters, such as the percentage of organic matter removal, power density, sewage residence time, MFC efficiency, etc., and economical parameters, such as the reduction of construction costs due to change of materials, change of interest rate, and lifetime. The advantages and disadvantages of their use in smart grids is also analyzed. The results show that the use of MFCs for power generation cannot be utopian as long as they are integrated into the structure of a central wastewater treatment plant on the condition that the scale-up technical issues of MFCs are successfully addressed.

1 Introduction

Microbial fuel cells (MFCs) are chemical reactor systems that generate electricity from the biodegradation of organic materials with the help of suitable microbial substrate. The first substrates used in the laboratory were mainly glucose, acetate, or other simple substrates to determine the behavior of electrode materials, membranes, and such others, as well as the reactor architecture or microbial activity. The study using real wastewater as a substrate began in 2004. The main advantage was the energy savings from the wastewater aeration and sludge treatment (Wang and Ren, 2013). In addition, less production of sludge is achieved by MFCs than the processes of aerobic activated sludge (AS) treatment systems and of anaerobic digesters. These are less sensitive to temperature changes, sludge treatment plants and the associated electrical installations are limited and no energy is consumed for aeration (He et al., 2017). In a series of articles, there has been an extensive description of MFCs (Santoro et al., 2017a), their operation principle (Kumar et al., 2015; Lee et al., 2017; Mohamed et al., 2021), their electric performance (Capodalgio et al., 2015; Vilajeliu-Pons et al., 2016), the electron and ion transport mechanisms (Hubenova and Mitov, 2015; Kumar et al., 2016; Oliot et al., 2016; Sure et al., 2016; Abbas et al., 2017; Saratale et al., 2017), the biofilms (Cristiani et al., 2013; Saratale et al., 2017), the anodes (Santoro et al., 2015a; Yu et al., 2016; Hindatu et al., 2017; Sonawane et al., 2017; Cai et al., 2020; Huang et al., 2021), the cathodes (Ewusi-Mensah et al., 2021; Huang et al., 2021; Mutuma et al., 2021; Santoro et al., 2014; Santoro et al., 2015c; Sawant et al., 2017; Yu et al., 2016), the additional electrodes (Ieropoulos et al., 2018; Soavi and Santoro, 2020), the separators/membranes (Daud et al., 2015; Oliot et al., 2016; Ghassemi and Slaughter, 2017), the mediating solutions (Yong et al., 2014; Cristiani et al., 2020; Mutuma et al., 2021), the catalysts (Santoro et al., 2015b; Santoro et al., 2016a; Santoro et al., 2017b; Santoro et al., 2017c; Santoro et al., 2017d; Santoro et al., 2017e; Santoro et al., 2018a; Santoro et al., 2018b; Santoro et al., 2020; Rojas-Carbonell et al., 2017; Kodali et al., 2017; Erable et al., 2018; Salar Garcia et al., 2019; Ficca et al., 2020; Babanova et al., 2021), the influence of operational variables (Molognoni et al., 2016), and their mathematical modeling (Kato Marcus et al., 2007; Picioreanu et al., 2007; Zeng et al., 2010; Ortiz-Martínez et al., 2015; Capodaglio et al., 2017; Jadhav et al., 2021a). Moreover, various MFCs are constructed, i.e., ceramic brick (You et al., 2019), photo (Greenman et al., 2019), benthic (Reimer et al., 2006; Kagan et al., 2014; Karra et al., 2014; Abbas et al., 2017; Tommasi and Lombardelli, 2017), sediment (Donovan et al., 2008; Ewing et al., 2017; Mohamed et al., 2017), desalination (Borjas et al., 2017; Ewusi-Mensah et al., 2021; Moruno et al., 2018; Ramírez-Moreno et al., 2019; Ramírez-Moreno et al., 2021; Santoro et al., 2017e), supercapacitive (Santoro et al., 2016b; Walter et al., 2020b; Poli et al., 2020; Soavi and Santoro, 2020), and floating (Martinucci et al., 2015; Cristiani et al., 2019). Special MFCs are also designed, such as those from constructed wetland (Aguirre-Siera et al., 2016; Ramírez-Vargas et al., 2019; Ebrahimi et al., 2021; Kataki et al., 2021), combined microalgal photobioreactor/MFC system (Bolognesi et al., 2021b), and hybrid nature-based systems, i.e., constructed wetlands and microalgae–integrated phytoremediation plants integrated with MFCs (Capodaglio et al., 2021), which, however, are under research. In any case, MFCs can offer power generation (Santoro et al., 2013a; Trapero et al., 2017), cogeneration of hydrogen and power (Santoro et al., 2016b), feedstock treatment (Habermann and Pommer, 1991), wastewater treatment (Martinucci et al., 2015; Trapero et al., 2017; Gajda et al., 2018a), metal recovery (Wang and Ren, 2014; Gajda et al., 2017), nutrient recovery (Kelly and He, 2014), sensing for monitoring wastewater and energy harvesting (Cristiani et al., 2019), and salt reduction (Moruno et al., 2018). For practical use, MFCs can use various household wastewater [e.g., kitchen sink, bathroom, dishwasher, etc. (You et al., 2021)], domestic wastewater (Tommasi and Lombardelli, 2017; Linares et al., 2019; Rossi et al., 2019; Tan et al., 2021), municipal wastewater (Sonawane et al., 2014; Ali et al., 2015; Martinucci et al., 2015; Park et al., 2017; Estrada-Arriaga et al., 2018; Liag et al., 2018; Hiegemann et al., 2019; Blatter et al., 2021; Tan et al., 2021), and industrial wastewater [e.g., high organic load wastewater from a juice processing plant (Trapero et al., 2017), swine (Ding et al., 2017), lemon peel (Miran et al., 2016), wine lees (Sciarria et al., 2015), brewery (Lu et al., 2017), distillery (Sonawane et al., 2014)], microalgae (Greenman et al., 2019), urine (Gajda et al., 2018b; Ieropoulos et al., 2013; Ieropoulos et al., 2016; Salar Garcia et al., 2019; Santoro et al., 2013b; Walter et al., 2018; You et al., 2019), and unrefined organic matter, such as flies, crustacean organisms, and fruits (Ieropoulos et al., 2005)]. MFCs have in practice been deployed as power sources for monitoring systems (Ewing et al., 2017; Cristiani et al., 2019), portable power sources (Ren et al., 2012), a mobile phone (Ieropoulos et al., 2013), wireless sensors (Shantaran et al., 2005), sensor networks (Mohamed et al., 2017), oceanographic instruments (Kagan et al., 2014), a microcomputer (Walter et al., 2020c), a meteorological buoy (Tender et al., 2008), autonomous thermo-sensors in robotics (Greenman et al., 2021), lighting (Walter et al., 2018), a self-powered floating biosensor for online water quality monitoring (Pasternak et al., 2017), a robot (Ecobot II) (Ieropoulos et al., 2005), a swimming robot (Row-bot) combining an energy source (MFC) and a mechanical actuation to meet refueling needs (Philamore et al., 2015), and “pee-power urinal” (Ieropoulos et al., 2016; Walter et al., 2018). More general descriptions of applications can be found in the following sources: Wang and Ren (2013), Evelyn et al. (2014), Abrevaya et al. (2015a), Abrevaya et al. (2015b), Pandey et al. (2016)Gajda et al. (2018), Kumar et al. (2018), and Jatoi et al. (2021).

Essentially, wastewater is the most popular substrate for an MFC operation due to its high percentage in organic load and zero cost, especially the agro-food wastewater is very suitable due to its high biodegradability (Trapero et al., 2017; Molognoni et al., 2018; Bolognesi et al., 2021a). The various electro-active and complementary non–electro-active microorganisms transform the chemical energy stored in the chemical compounds of biomass or wastewater into electrical energy. This direct conversion of chemical to electrical energy avoids the application of the Carnot thermodynamic cycle at an ideal thermal machine with its limited thermal efficiency. Theoretically, MFCs can achieve higher efficiency (>70%), similar to conventional fuel cells. Moreover, due to the use of wastewater, it is a renewable energy source (Seelam et al., 2015), whose “fuel” supply can be controlled relatively more easily than wind turbines where the wind is completely uncontrolled and photovoltaics where the sunlight is uncontrollable, although predictable. This is an advantage in the case of its application as a distributed power unit or being a part of a smart grid. Of course, its performance is not fully controlled due to the involvement of bacteria in electricity production. Energy production is time-varying and proportional to the growth of bacteria, in contrast to biomass thermal units, as long as they are supplied by organic materials of approximately constant calorific value. However, cross-laboratory studies on MFCs have been carried out using domestic wastewater in identical single-chamber MFCs around the world, where maximum power densities and chemical oxygen demand efficiencies have been quite similar, while the startup time and acclimation stage have been different because of the diversity of the microbial communities (Santoro et al., 2021). It should be noted that there is a plethora of articles dealing with the installation and operation of renewable energy sources in smart grids, with an emphasis on photovoltaics and wind turbines, taking into account their stochasticity (Ullah et al., 2021), demand-side management programs (Osório et al., 2019; Ullah et al., 2020), reliability indices (Pathan et al., 2020), and the use of electric vehicles (Wei et al., 2021). However, the use of MFCs has not been proposed according to the relevant literature.

Although MFCs have not yet been developed with economically viable prices per kW of installed power and with a high nominal power (equivalent to renewable power plants of the order of MW), research on MFCs has however been progressing rapidly and continuously. This is due to the fact that the output power density per unit area of anode now ranges from 10 to 50 mW/m2 for wastewater and from 250 to 500 mW/m2 for glucose (Tharali et al., 2016), while the power density per unit volume of urban wastewater ranges from 40 mW/m3 to 54 W/m3 with a typical value of about 10 W/m3 depending on the substrate and the inoculum source (Zhao et al., 2017). However, the chemical energy content of usual urban wastewater with 600 mg/L chemical oxygen demand (COD) is about 1.67–2.33 kWh/m3 (Rossi et al., 2019; Capodaglio and Olsson, 2020; Tan et al., 2021), which can give a theoretical power density from 8.7 to 129.4 W/m3 for hydraulic retention time from 18 to 192 h (Estrada-Arriaga et al., 2018; Hiegemann et al., 2019; Linares et al., 2019; Rossi et al., 2019; Tan et al., 2021), which is extremely higher than the respective experimental values. Over the past 3 years, efforts to develop cheaper and larger MFCs have intensified, trying to keep COD removal, power density, and columbic efficiency at high levels and hydraulic retention time low (Liang et al., 2018; Abdallah et al., 2019; Flimban et al., 2019; Hiegemann et al., 2019; AlSayed et al., 2020; Leicester et al., 2020; Jadhav et al., 2021b; Tan et al., 2021).

In addition to electricity generation, MFCs are mainly used for wastewater treatment and more rarely for the production of hydrogen (Sharma and Li, 2010; Escapa et al., 2016; Kitching et al., 2017; Kumar et al., 2017), methane (Tharali et al., 2016), or some special forms of biomass (Adelaja et al., 2015; Logroño et al., 2015; Moqsud et al., 2015; Sciarria et al., 2015; Miran et al., 2016; Ding et al., 2017), for the removal of metals (Wang and Ren, 2014; Nancharaiah et al., 2015; Jadhav et al., 2017) and nitrates from water (Kelly and He, 2014), etc. The use of glucose (and similar others) as a “fuel” is not of direct practical interest because it is usually a component of biomass and not a pure substance, making its initial production too expensive for use in a power plant (Tharali et al., 2016; Leicester et al., 2020). The sediment at the sea bottom can also be used in benthic cells (Abbas et al., 2017). This only concerns specific research applications which use sensors of usually small load and are situated at great distances from conventional power sources. On the contrary, the use of wastewater and its degradation/consumption has two main advantages: wastewater is unwanted and thus practically has zero purchase cost; on the other hand, its degradation is desirable, since in modern societies, wastewater cannot be discharged into the aquifer or surface water bodies (i.e., sea, rivers, lakes, etc.), unless it goes through quite expensive treatment satisfying quality parameters.

As far as the study of economic characteristics is concerned, the relevant research is limited. In 2005, the installation cost of a classic MFC for sludge treatment as a power unit was estimated between 1,300 $/kW for a power density of 400 W/m

3and 5,200 $/kW for a power density of 100 W/m

3(

Logan, 2008). While the installation cost of an anaerobic sludge digester as a power unit was 1,800 $/kW versus the indicative price of 1,000 $/kW for a conventional thermal unit. Of course, its use is required for the treatment of sewage sludge. To keep the MFC installation cost in line with the cost of the anaerobic digestion unit, the cost must amount to about 720 $/m

3, while to reach the biological filter levels must fall to 530 $/m

3. In 2010, the cost reduction could succeed with technology development (

Pant et al., 2011). Specifically, the indicative price for the electrode chamber is as follows:

• 4,000 €/m3 in 2006, with a capital cost ten times that of its corresponding part of anaerobic digestion,

• 2,025 €/m3 in 2008, including the cost of graphite felt anode electrodes, platinum descent electrodes with catalyst, membrane, current collector, and reactor,

• 2,816 €/m3 in 2010 for a complete industrial scale MFC system for wastewater treatment 100,000 m3/day consisting of 1,667 individual cells,

• 1,137 €/m3 in 2010, including the cost of anode electrodes from activated carbon, platinum-free cathode, membrane, current collector, and reactor.

It is noted that the catalyst cost per Watt increases significantly as the catalyst loading increases in a linear trend (Santoro et al., 2018b).

In Fornero et al. (2010), the economic comparison between an AS wastewater treatment plant (AS-WT) and an MFC one had been carried out theoretically fοr 100,000 L/day with a biochemical oxygen demand (BOD) at 2,000 mg/L, where the former was slightly superior to the latter (32,760 $/year and 35,731 $/year, respectively, in 2008). It has been clarified that the respective MFC systems have been proposed to be implemented by utilizing 1,667 MFC modules with anode volumes of 20 L for a hydraulic retention time of 8 h. In Wang et al. (2013), the energy production of different sewage sludge was examined using MFC technology, taking into consideration the energy losses in pumps, reactors, membrane cleaning, etc. The recovered energy could reach 0.689 kWh/kg in case of a dynamic membrane separation bioreactor with MFC, 0.223 kWh/kg in case of a low organic loading membrane reactor with MFC, 0.435 kWh/kg in case of a conventional membrane bioreactor with MFC, however, no economic comparison was performed. In Li et al. (2014), the normalized energy recovery had been estimated at 0.004 kWh/kg COD with a profit of 0.0005 $/kg COD using MFC instead of normalized energy consumption at 0.6 kWh/kg COD for AS-WT with a cost of 0.12 $/kg COD in 2014. However, the MFC capital cost was 30 times the AS-WT capital cost, with a typical lifespan of 10 years, rendering the MFC approach nonviable financially (equivalent total cost 3.0 $/kg in 2014). In Stoll et al. (2016), classical MFC systems, with different anode materials, for domestic wastewater treatment, had been evaluated thoroughly, applying electrochemical impedance spectroscopy, cyclic voltammetry, and rRNA sequencing, with no mention of the technical lifespan. More specifically, one 20-ml chamber has been used, with three different titanium core anodes: graphite brush, hard carbon felt, and carbon foam. The normalized cost, based on power output had been estimated at 8.42, 4.55, and 48 $/mW, respectively, in 2016. It is noted that in all cases, the cathode electrode was from stainless steel mesh, coated with a specialized activated carbon powder mixed with de-ionized water and polytetrafluorothylene. In 2017, a continuous flow rate tubular MFC, with a cost of 60 $/m3 treated wastewater, was presented, with an analytical description of capital and operation costs for a 10-year operation life (Lu et al., 2017). Furthermore, the microbial electrolysis fuel cells (MECs), for hydrogen production using urban wastewater, have been proposed, presenting some financial data and claiming that MECs could be applied in the future (Khan et al., 2017).

In Ding et al. (2017), a swine wastewater treatment plant was proposed, based on single-chamber air–cathode MFCs with a solution volume of 340 ml in laboratory scale, with an additional low-cost flocculation process, achieving an energy recovery of 0.664 kWh/m3 wastewater mixture (consisting of 40% raw swine wastewater and 60% denitrified effluent wastewater), a net economic profit of 0.024 $/m3 (in 2017), a COD removal efficiency of 96.6%, an ammonia removal efficiency of 60%, power density of 37.5 W/m3, a Coulombic efficiency of 21.6%, and without noting the capital cost. In Trapero et al. (2017), an extensive research for the theoretical scale-up, industrial commercialization of MFC technology, was presented based on the net present value (NPV) and internal rate of return (IRR), implementing a sensitivity analysis for the installation cost, COD removal, and Coulombic efficiency, using high organic load wastewater from a juice processing plant. The respective results were quite satisfactory and financially viable against an AS-WT. Specifically, the proposed wastewater treatment plant consisted of 10 MFCs in a series electrical connection and parallel hydraulic connection. Each MFC had a 2.25-m3 anolyte chamber, a 1.125-m3 catholyte chamber with a 20-mm methacrylate wall, carbon cloth electrodes, a catalyst cathode with platinum or without platinum, a proton exchange membrane (PEM), and its own electromechanical machinery (DC to AC converter, pump, air blower, etc.). The hydraulic retention time was determined at 10 h, and the effluent flow rate at 54 m3/day. The capital cost for the MFC installation reached 43,010 € (for a non-platinum catalyst) and 44,850 € (for a platinum catalyst), while that for an AS-WT reached 36,000€ in 2017. The detailed cost of the equipment has been presented in Table 1 of Trapero et al. (2017). So, the equivalent capital cost with respect to the effluent flow rate was 796.5 €/(m3/day) for a non-platinum catalyst, 830.6 €/(m3/day) for a platinum catalyst, and 666.7 €/(m3/day) for the AS-WT. Furthermore, at every 5 years of MFC operation, the electrodes and the PEM should be replaced with a total extended maintenance cost of 5,900 € for a non-platinum catalyst and 7,500 € for a platinum catalyst, raising the equivalent extended maintenance cost (with respect to effluent flow rate) to 109.3 and 138.9 €/(m3/day), respectively. In all the examined cases of electric energy production in combination with high organic load wastewater treatment, the NPV was positive, for an investment life period of 15 years, taking into consideration the maintenance cost per 5 years, even when the pessimistic scenarios of COD removal and of Coulombic efficiency were tested. In Logan (2015), the cost of an MFC for a wastewater treatment plant reached to 1,870 €/m2 membrane area in the case of the typical MFC configuration based on a graphite brush anode, air cathode with carbon cloth platinum electrode, PEM Nafion membrane, and polytetrafluoroethylene diffusion layer. This cost was crucial, as a reactor chamber of 1 m3 could incorporate 10 m2 of membrane, using 10 modules in a parallel design (a single anode–cathode module of 1 m2 is 10-cm thick). If new inexpensive materials for catalysts, membranes, and electrodes were used, the cost could drop at 36.55 €/m2 membrane area, making the investment financially viable. In addition, in Tommasi and Lombardelli (2017), the energy payback period was examined and found equal to 546 years for a typical MFC and equal to 2.7 years for a benthic MFC, which means that only the latter is of practical use. In 2018, the normalized recovery energy based on COD was estimated at 0.216 ± 0.048 kWh/kg-COD, for a flat panel air cathode MFC, using domestic wastewater, with anode spacing of 5 mm and hydraulic retention time (HRT) of 30 min (which is quite satisfactory), while the total electrical energy recovery was equal to 0.63 kWh/kg-COD (Park et al., 2018). That increase was due to methane emission at a subsequent treatment stage. The proposed MFC solution was inferior only to the anaerobic system (0.99 kWh/kg-COD). In some cases, no electrical production is achieved, but the electrical consumption is limited, i.e., ammonium nitrogen recovery from wastewater as fertilizer needs 1.6 kWh/kgN using a bioelectrochemical system (Losantos et al., 2021) or 6.1 to 8.2 kWh/kgN using a three-chamber bioelectroconcentration cell instead of 25 kWh/kgN in AS process and fertilizer production (Koskue et al., 2021). In bioelectrochemical systems, CO2 is converted to CH4 through electromethanogenesis having a specific energy consumption of 16–18 kWh/m3 CH4 (Rodríguez-Alegre et al., 2019). Similarly, no electrical consumption has been referred to in nutrient recovery systems from human urine (Freguiea et al., 2019).

In conclusion, various criteria have been applied for the economic evaluation of the MFCs, and the respective results have been ambiguous. In 2006, the MFC was not financially viable as a single power generator (Logan, 2008). The same conclusion was reached, taking into consideration the typical values of the power level, the efficiency (from power input to electrical output), the technical lifespan, the capital cost per installed nominal active power, and the capacity factor for classical power plants (e.g., coal steam plant, gas turbine, combined gas turbine, etc.), common renewable energy sources (e.g., solar photovoltaic panels, wind turbines, geothermal steam plant, hydroelectric plant, etc.), and the usual fuel cells (e.g., phosphoric acid fuel cell, molten carbonate fuel cell, etc.) (see Table 3 in Sharaf and Orhan, 2014). However, the application of the MFC in a wastewater treatment plant will lead to economic viability of the investment if the wastewater treatment cost is significantly curtailed (Logan, 2008) and if the scale-up technical issues of the MFCs are solved, because full-scale wastewater treatment plants do not exist until today and only few scaling-up trials have been examined in actual plant conditions (Martinucci et al., 2015; Cristiani et al., 2019). Similarly, the electric power production, through bioelectrochemical processes, is quite promising on the condition that pilot studies and targeted future research are carried out, giving favorable results (Leicester et al., 2020).

In this article, the essential conditions for the economic viability of the MFC are investigated and the MFC application in a smart grid is examined, since the connection between MFCs and smart grids has not been presented according to the relevant bibliography. Specifically, the MFC wastewater treatment plant is being utilized as a power plant on a theoretical basis similar to that mentioned in Trapero et al. (2017), with the sole difference being the use of domestic wastewater (instead of high organic load wastewater from a juice processing plant), which is ample in cities, towns, and villages. Initially, the reasons for an MFC installation, the issues of MFC scaling-up, and the respective advantages and disadvantages are presented here. Then, the MFC sizing (for an urban wastewater treatment plant) is carried out (instead of an AS system), the capital and operation costs are estimated, and the financial viability is studied based on the classical economic criteria, such as NPV, benefit–cost ratio (BCR), IRR, and discounted payback period (TDPB). However, either of the technical (e.g., the ratio of organic load removal over influent, MFC Coulombic efficiency, etc.) or financial (e.g., capital cost, extended maintenance cost, deflated interest rate, investment life period, etc.) parameters have not been univocally specified, therefore an extended sensitivity analysis is performed. Additionally, the advantages and disadvantages of the MFC installation in smart grids are analyzed thoroughly. Τhe respective results show that the MFC application, as a power generator, is no utopia, on the condition that the MFCs are integrated into a wastewater treatment plant and the scale-up technical issues of MFCs are solved.

2 Materials for Wastewater Treatment System Configuration With MFC

2.1 Biological Treatment General Structure

In essence, the MFC is examined within the context of its incorporation in a waste treatment unit in order to acquire a low-cost fuel in large quantities. The kind and level of such wastewater treatment (liquid sewage or waste of specific industrial units) depend on the characteristics of the recipient or the scope of its reuse. The minimum required treatment involves mainly the removal of suspended solids and organic materials to a smaller or larger degree (Von Sperling, 2007; Spellman, 2014). The main stages of such an installation are described in Figure 1. With a suitable combination of its main components, it is possible to achieve the required degree of treatment each time.

FIGURE 1

Flow chart of a biological treatment installation: the dashed “black” line represents the sludge flow; the continuous “gray” line represents the treated waste flow; and the dashed “gray” line in grey represents the alternative flow of treated waste.

In particular, the following stages are included:

1. Preliminary stage: the removal of inorganic materials (i.e., coarse solids and grit) is mainly accomplished with physical procedures (i.e., screens and grit chamber).

2. Primary treatment stage: it includes settlers where a partial removal of the organic materials (mainly settleable, suspended, and floating solids) is achieved with physical/physicochemical procedures.

3. Secondary treatment stage: this consists mainly of biological procedures. With the use of some sort of biological reactor and a final settler, the almost complete removal of suspended materials is attained and the removal of a larger part of the soluble organic substances. Moreover, in certain cases, the removal of phosphorous/nitrogen can also take place.

4. Tertiary treatment stage: it is the synthesis of individual units, which varies with respect to the waste being treated. Such units are a refinery or a membrane installation. The removal of nutrient components (nitrogen and phosphorous) takes place at this stage, if not already concluded at earlier stages, with the aid of additional biological procedures.

5. Disinfection stage: this stage aims at the elimination of all pathogens and is applied when there is risk of contamination to the final disposal (irrigation and swimming facilities).

6. Sludge treatment stage: this is the stage in which sludge, retrieved from the previous four stages, is properly treated so as to acquire a form appropriate for the easy and safe disposal of the by-products. It usually consists of thickeners, digesters, and dewatering systems.

2.2 Microbial Fuel Cell Installation in a Biological Treatment System

Taking into consideration the functional chain of a wastewater treatment system, an MFC can easily be used to replace/modify elements of the secondary waste and sludge treatment, whereas it should be more difficult to replace components for the removal of nutrients and heavy metals. To this end, the following alternatives have been suggested (

Logan, 2008;

AlSayed et al., 2020;

Leicester et al., 2020):

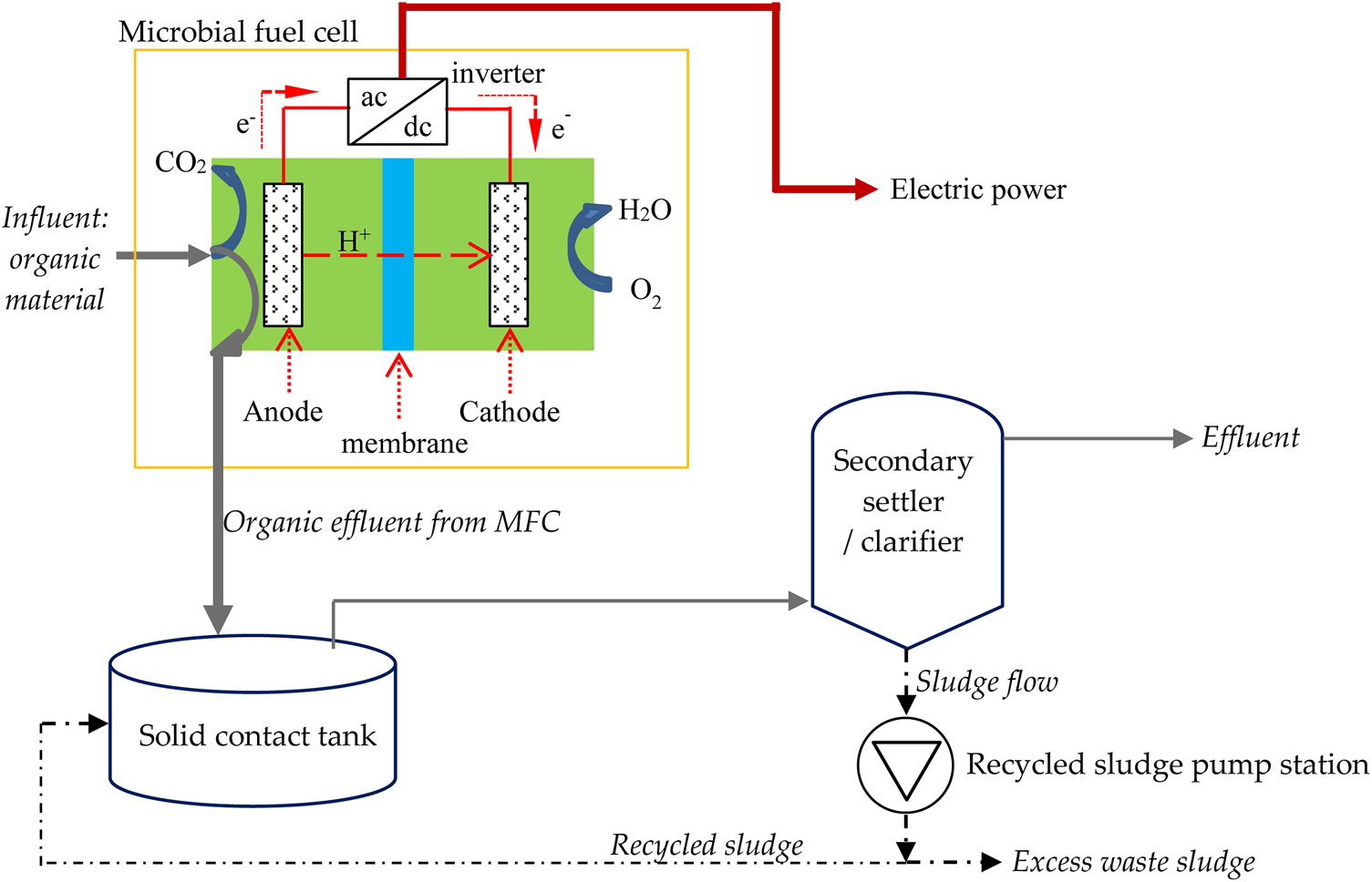

• Replacing the AS system or the biological filter: in this case, the MFC will be used similarly to the a biological filter having a conventional role, as shown in Figure 2. The MFC, due to the formation of a biofilm, is more effective in the removal of the organic load diluted within the waste and less in organic solids. Hence, it is necessary to include a procedure for solids retention, in order to obtain the required solids treatment with regard to domestic sewage. The treated waste recirculation is not required at the MFC inflow, since it operates in the anaerobic state, contrary to the biological filter which is open to atmospheric air. The operational design of the solid contact tank and that of the settler is dependent on the MFC solid effluence, operating similarly to the solid effluence of the microbial biomass of the biological filter.

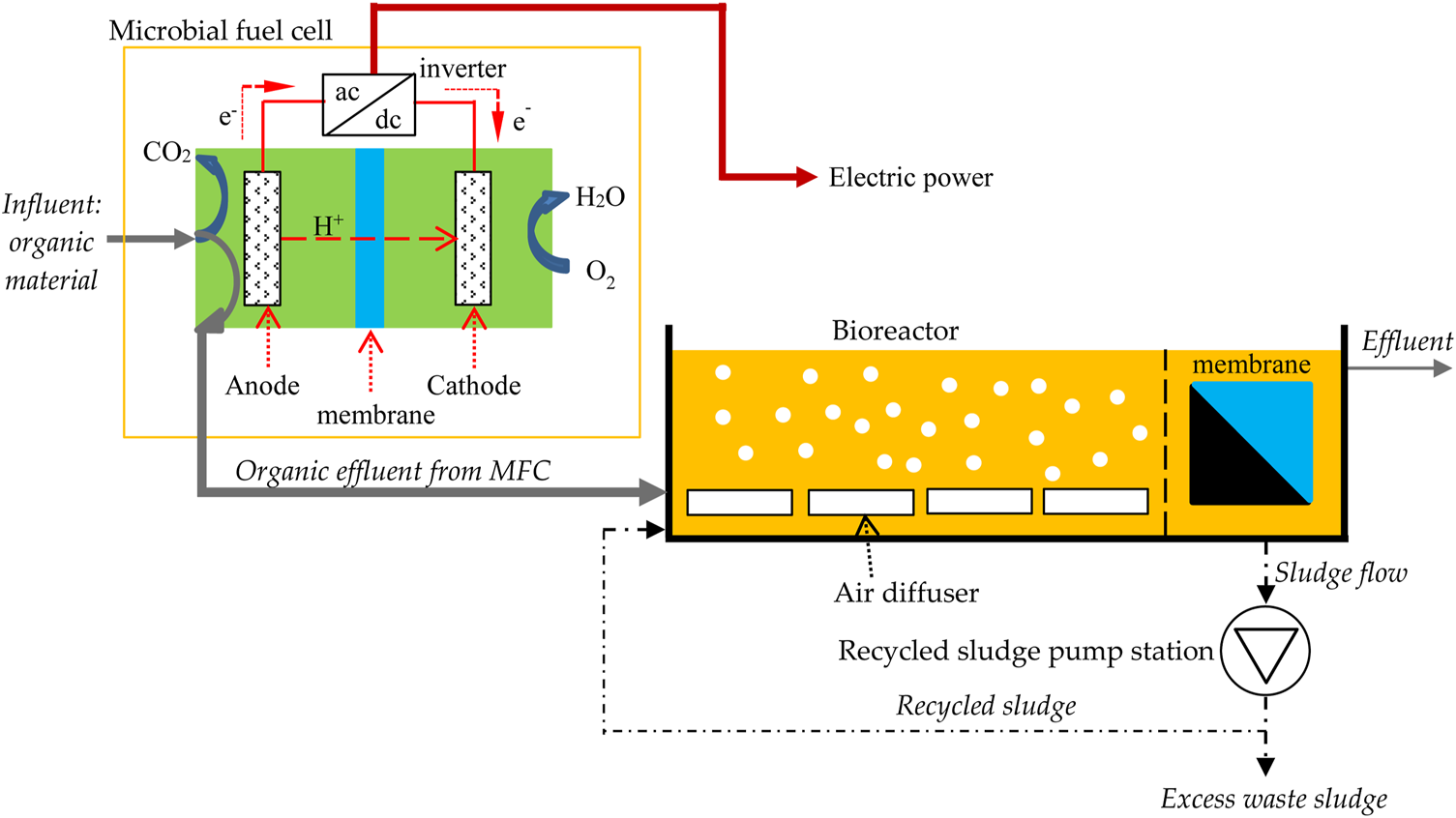

• Using a membrane bioreactor: in this case, the MFC is combined with a membrane bioreactor, as shown in Figure 3. The reactor consists of a series of membranes through which wastes are channeled, solids are filtered, and the biomass is retained on the filter, functioning simultaneously as a treatment and settling element. This method is quite expensive due to the energy consumed for the aeration and filtering. The MFCs can be used to reduce energy consumption, because they are electric power producers (not consumers), the organic solids production and the oxygen demand are reduced.

• Developing the MFC as a membrane bioreactor: this is based on the construction of cathodes that are capable of functioning both as cathodes and filter tubes. The advantages of this solution are the smaller size of the reaction chamber and the reduced power consumption in comparison to the standard membrane reactors, while the risk of an emphraxis is also high. Furthermore, the standard bioreactors function under the presence of atmospheric air throughout their tube, so as to reduce the accumulation of solids due to bacterial growth, while the MFCs function anaerobically. The use of a ventilated MFC bioreactor is under examination as most electrogenic bacteria can function both aerobically and anaerobically. Certainly, the solution of the intermediate aeration requires further examination (Logan, 2008; AlSayed et al., 2020).

• A sediment MFC can be used, in which the sludge is diffused appropriately in sediment form, inside the anode chamber, which it fills (Abbas et al., 2017). Alternatively, the combination of the MFC with the appropriate hybrid systems can be constructed. For instance, two MFCs can be used, the first one with an upflow dynamic membrane separation reactor and the second one with a low organic loading membrane bioreactor, so as to improve the effluent quality. Another solution is a hybrid system combined with a conventional membrane bioreactor (Wang et al., 2013).

• Developing the MFC for the removal of nutrients (nitrogen and phosphorous compounds): In this case, hybrid bioreactor systems with parallel nitrification ‐ denitrification in cathode (Park et al., 2017), or two sets of MFCs (aerobic and anaerobic cathode), or tubular MFC etc. (Kelly and He, 2014) can be employed. The nitrates removal percentage for domestic sewage varies from 70 to 97% with a retention time of 1–144 h and removal rates from 0.001 up to 0.62 kg-N/m3/day in the laboratory scale (Park et al., 2017).

• Developing the MFC for the removal of heavy metals: Specialized MFCs are used at the secondary treatment stage in similar forms with the respective ones in Figures 2, 3, as long as the respective metals are suspended within the waste. In case of solid particles formation and their removal in sludge form, the corresponding MFC needs to be placed in the sludge treatment stage. In each case, depending on the type of wastewater metal, more MFCs may have to be installed in series, as each may remove specific metals (but not all) due to the use of additional chemicals or specialized bacteria with different retention times (Nancharaiah et al., 2015).

FIGURE 2

Flow chart of the conventional installation of a microbial fuel cell at the secondary treatment stage, placing downstream a solid contact tank, a secondary settler, tube, and recycled sludge pump station (Logan, 2008).

FIGURE 3

Flow chart of a microbial fuel cell installation at the secondary treatment stage with the use of a membrane bioreactor receiving the required power from the cell (Logan, 2008; AlSayed et al., 2020).

2.3 Reasons for a Microbial Fuel Cell Installation in a Biological Treatment System

The main advantages of using MFCs over conventional bioreactors are as follows (

Logan, 2008;

AlSayed et al., 2020;

Leicester et al., 2020):

• Power generation: the produced electric current intensity depends mainly on the amount of wastewater, the organic load of the wastewater, and the Coulombic efficiency (CE). Alternatively, MECs are used to produce hydrogen.

• Reduction of waste aeration: in an MFC of one chamber with an air cathode, the transfer of the necessary oxygen is achieved passively. In any case, the air supply is considerably reduced compared to a secondary AS treatment system that requires about 50% of the electric power consumed by the waste treatment plant.

• Reduction of solids production: the MFC functions anaerobically, therefore the bacterial biomass production will be more limited than in the aerobic operation of an AS system or a biological filter. This has the effect of reducing the cost of expensive sewage sludge treatment installations.

• Potential for odor control: due to the anaerobic operation of the MFCs, it is possible to avoid the extensive—open to the air—areas of the biological filters, and the large quantities of air flow in the aeration basins of the AS systems, hence considerably reducing the release of disturbing odor to the surroundings.

2.4 Issues of Scaling-Up Microbial Fuel Cell Installation in a Biological Treatment System

So far, the experience around MFCs is mainly limited to laboratory sizes, while the cost per installed kW is quite high and its lifespan is undetermined under actual operating conditions. With regard to the configuration of secondary waste treatment plants, it would be ideal if the wastewater treatment efficiency and the power density remained unchanged when the MFC chamber size would vary in scale from a few cubic millimeters or a few liters up to cubic meters or even thousands of cubic meters. However, this does not happen because a number of issues should be solved (Liu and Cheng, 2014).

2.4.1 Increasing the Size of the “Electric Power” Plant

There are two main ways to develop MFC for industrial-sized waste treatment plants of hundreds or thousands of cubic meters:

i. Increasing the size of each chamber of the MFC: when increasing the volume of the respective MFC chambers from a few tens of milliliters to a few liters or more, a reduction in volumetric power density by 100 to 10,000 times has been observed. The main reasons that lead to the increased power loss are the following:

➢ Increase of the internal resistance of the MFC, which happens as the MFC chamber size is enlarged. In order to reduce the resistance, two solutions have been proposed:

⁃ Reduction of spacing between the electrodes: it reduces the solution resistance and pH variations, with the disadvantage of increasing the risk of short circuits or increasing the oxygen diffusion to the anode, which can eventually lead to a reduction in output power. Disadvantages are limited by the use of a low cost, thin, high power density separator/membrane between the electrodes, which prevents the growth of cell microorganisms on them so as to not degrade their behavior, but this can cause an increase in the internal resistance again.

⁃ Increase of solution conductivity and ability to absorb pH variations, which increase the power density by increasing the MFC chamber size. The cathode behavior is improved by lowering the pH using pure oxygen instead of air in the catholyte and increasing the flow rate. Electrolyte recirculation between anode and cathode chambers or the addition of acidifiers to the catholyte achieve pH balance. The use of acidifiers cannot be easily applicable to industrial-sized facilities.

It is generally recommended to increase the solution flow rate or the mixing intensity so as to decrease the accumulation of H+/OH− ions around the anodes/cathodes to tackle the reduced ability to absorb pH variations. A device with a small distance between the electrodes, with increased surface area, and the selection of high reactivity materials can limit the electrode potential and face with the low conductivity domestic sewage (Liu and Cheng, 2014). It is also possible to place more than one pair in series (initially the anodes and separately the cathodes) or not (e.g., anodes around a tubular cathode), or alternatively place elementary anode–cathode pairs in the same tank (Logan, 2008). However, the scaled-up height in self-stratifying membraneless MFCs (treating urine) is limited to some centimeters (Walter et al., 2020a).

➢ Non-homogenization of the chamber solution: it is mainly due to the different substrate concentrations and the hydraulic pressures in different parts of the chamber. The first problem has a negative effect on the mass transfer rate, electrochemical reaction rate, and power generation and is solved by increasing the mixing intensity by changing the hydraulic retention time (HRT) and by increasing the internal recycling flow rate and/or the air flow rate, provided that the biofilm does not detach from the anode electrode and a sufficient organic load is not removed. The second problem is due to the fact that the pressure increase causes a power density decrease in a nonlinear way. This may not affect the growth of the anode microbial community but presents a negative impact on the metabolism and electrochemical activity of exocellular electron transfer bacteria, which is solved only by finding pressure-resistant bacteria. The reduced cathode efficiency, due to high hydraulic pressures, results from the filling-up of the catalyst with water, followed by an increase in charge transfer resistance and diffusion resistance and is limited by the development of suitable geometric electrode forms (Liu and Cheng, 2014). Additionally, different MFC performances have been observed even in similar cathode chambers due to the reactor’s hydrodynamics, which is mainly related to the amount of dead volume and to the absence of granular graphite electrodes (Cecconet et al., 2018).

ii. Use of individual similar MFCs in stacks: Alternatively, a stack of individual medium-size MFCs can be constructed and connected either in series (to increase the voltage) or in parallel (to increase the intensity of the electric current). Existing experience shows that voltage reversal and short circuits (due to the presence of ions) lead to a significant reduction in the efficiency of in-series stack devices by reducing the theoretical expected values by up to 60%. Voltage reversal can be avoided by using high-efficiency air cathodes, maintaining similar catalytic activity in anode biofilms, and increasing homogeneity in substrate distribution between different fuel cells. The ionic short circuit occurrences are observed when the same anolyte or catholyte is being shared between different in-series fuel cells. Therefore, if the anolyte is separated into individual cells, ionic short circuits are practically prevented, but the manufacture and maintenance cost of the MFC stack increases. An alternative construction is a stack of MFCs connected in series as well as in parallel. In this way, the voltage of each cell and the respective electric current intensity are amplified, while the substrate is decomposed satisfactorily. Nevertheless, further research is needed on the interaction between the individual MFC and their interconnectivity to maximize power density and maintain the stable operation of the entire MFC stack (Liu and Cheng, 2014). Especially in terms of interconnectivity, experimental research is intense, sometimes leading to opposing results. For example, it is mentioned in Estrada-Arriaga et al. (2018) that when the hydraulic MFCs connection is in series and the electrical connection is in series or parallel, for domestic sewage treatment, the electrical in-series connection is advantageous. However, Asensio et al. (2017) reaches to an opposing conclusion. In particular, three experiments have been performed, the first with two identical MFCs with the same components but different behaviors, the second with five units hydraulically in series and then either in series or in parallel, and the third with 10 units hydraulically in series and then again either in series or in parallel. They suggest the in-parallel electrical connection of MFCs to improve electrochemical behavior and COD removal. The in-series connection only achieves an output voltage increase and not proportionally in the case of using a hydraulic connection. Repeatability is also a problem even for similar MFCs. The electrical in-series MFCs connection does not always ensure better power generation performance due to the higher resistance and reduced organic fuel toward the last cells. COD consumption and power generation are directly related to the membrane surface area of an MFC.

2.4.2 Reduction of Capital Cost

The MFC development on an industrial scale requires high capital costs due to the expensive materials. To reduce costs, it is necessary to use—for anodes, cathodes, and membranes—scalable materials with high efficiency and low cost. As for the anode electrodes, they need to have a brush-type current collector, made of either graphite—embedded carbon fiber around a corrosion-resistant metal core (such as stainless steel or titanium)—or activated carbon granules with tungsten or stainless steel. As for the cathode electrodes, the cost of which in a typical MFC reaches between 47 and 75%, the air cathode is recommended based on the development of inexpensive, metal mesh current collectors, such as stainless steel or nickel foam, which have low cost and high conductivity (Liu and Cheng, 2014). Alternatively, the abiotic cathodes can be substituted by biocathodes giving a simple, cost-effective way for developing MFCs (Cristiani et al., 2020; Santoro et al., 2021). Diffusion layers and binders such as polytetrafluoroethylene and polydimethylsiloxane are preferred over the expensive Nafion, and catalysts from non-precious metals or activated carbon instead of platinum. An additional difficulty in curtailing costs is the requirement of a complex three-state interface (solid-liquid-gas) for oxygen reduction, which makes the selection of the cathode material more difficult and the design of the cathode structure more demanding. In addition, the separator is another expensive component, necessary in large MFCs to place the electrodes at close range so as to reduce internal resistance and prevent oxygen diffusion to the anode. It requires the development of a low-cost membrane, capable of proton transfer and long-term stable behavior. A low-cost membrane could consist of a material such as fabric, made of noncontinuous fibers (short) and long fibers (continuous long), interconnected through chemical, mechanical, thermal, or solvent treatment. Still, the mechanical strength and long-term stable behavior of such a membrane needs improvement (Liu and Cheng, 2014).

2.4.3 Power Output Management

An MFC is difficult to connect directly to an actual electric load, even when operating at the point of maximum power generation, due to low voltage and current levels. This is why it is necessary for the MFC to operate with a power management system (PMS) in order to appropriately modify the electric current characteristics for powering electrical appliances. This system can harvest and use power by utilizing a DC to DC voltage boost converter or a DC to AC inverter, with the aid of modern high-frequency switching metal-oxide field-effect transistors, achieving a required stable DC voltage (e.g., 1.5 V or 3.3 V) or AC voltage, and high power exploitation levels of up to 75%. Furthermore, it is equipped with a suitable automatic control system that executes the maximum power point tracking algorithm minimizing the energy losses of the MFCs (Molognoni et al., 2014). In addition, it is common to use capacitors at the outlet of the MFC, where the desired amount of energy is expected to be stored and delivered at the appropriate time period by discharging the capacitor into the electrical circuit. In this way, low power sensors (of a few Watts) can be supplied. For large MFCs, it is also critical to limit the high power losses due to the large ohmic resistance of the big electrodes. This is because the distance between the areas where the electrons are generated/consumed and the leading-out/leading-in terminals (where currents flow in/out of the electrodes) increases as the size of the electrodes increases. The leading-out terminals arrangement plays an important role in the design of large chambers (Liu and Cheng, 2014). In any case, the appropriate automatic control system is required, since each MFC modifies its behavior in terms of power production over time (Premier et al., 2011).

2.4.4. Achieving Long-Term Stable Operation

It is desirable that the MFC operation remains unaltered in long-term time scale in order to maintain energy balance and to check the economic viability of the MFC investment with reliable data (

Liu and Cheng, 2014). But in reality, its efficiency decreases over time because of the following:

➢ Variations in the electrochemical activity of the anode biofilm: the wastewater substrate is influenced by many factors, i.e., the wastewater composition, substrate concentration, solution electric conductivity, solution temperature, etc., through various mechanisms which are not, as yet, fully predictable. In order to keep the electrochemical activity of the anode biofilm stable over time, one needs to focus on the following:

⁃ understanding the electron transfer between exocellular electron transfer bacteria and the electrodes,

⁃ increasing the biofilm conductivity in order to reduce its internal resistance,

⁃ understanding the correlation among the properties of the biofilm, the biomass diffusion, and the electron transfer,

⁃ understanding the complex interactions between exocellular electron transfer bacteria and other bacteria (of which some operate collaboratively and others competitively).

➢ Cathode behavior deterioration: over time, cathode behavior has been observed to deteriorate due to the following factors:

⁃ Deactivation of oxygen reduction catalysts: especially for catalysts based on metals, such as iron, cobalt, and platinum, the respective oxygen reduction reaction is hypersensitive to the MFC environmental conditions, which can change negatively due to chemical reactions, biological activity, and variations in catholyte composition. Also, the level of catalysts concentration in the catholyte significantly affects the efficiency, while the increase in pH and catalyst poisoning caused by polymeric substances of exocellular electron transfer of adherent microorganisms or of other ions within the waste adversely affect the oxygen reduction rate.

⁃ Contamination of the biofilm cathode: the development of a biofilm on the air cathode electrode side, in contact with the solution, may lead to a decrease in cathode efficiency in the long run, especially in single-chamber MFCs. A thick aerobic biofilm at the cathode can act as a diffusion barrier to H+ ions carried to the catalyst or can block the transport of OH− ions out of the electrode causing a significant accumulation of OH− ions in the cathode microenvironment leading to a lower cathode efficiency. Furthermore, aerobic bacteria can consume some of the available oxygen on the catalyst side, thus reducing the oxygen reduction rate. Catalyst poisoning may also occur due to exocellular electron transfer polymeric compounds of attached microorganisms. The result of utilizing a biofilm is an increase in internal resistance and a reduction in power generation. The problem can be solved by the reconfiguration of the catalyst using metal nanoparticles, the reduction of oxygen transfer to the electrodes in contact with the anolyte, the proper cooperation of bactericidal substances at the level of the cathode catalyst, the change of physicochemical properties of cathodes (Liu and Cheng, 2014). Santini et al. (2015, 2017) note that in all electrochemical systems operating in natural water, the formation of calcium carbonate on the cathodes impedes the electrochemical process and not the functioning of the biofilm, whose main function is the conversion of abiotic cathodes to bio-cathodes. Edvardsen et al. (2020) have investigated scale deposition on graphite electrode surfaces thoroughly. The use of biocathodes also allows Pt material to work, despite the poisoning caused by the presence of organics and other elements inhibiting the Pt catalysis in the wastewater environment (Cristiani et al., 2013). Additionally, the behavior of bio-cathodes is very promising and cost-effective, even though the scaling-up issues need further research (Ramanaiah et al., 2021).

⁃ Salt concentration and power collector corrosion: during the long-term MFC operation, concentration of salts on the surface of the cathode electrodes have been observed, which reduces the catalyst activity and the cathode efficiency. However, the relevant mechanisms of such concentration and its effect are not yet known. Using anticorrosive materials, such as stainless steel or carbon, can solve the problem, but attention must be paid to the ohmic resistance and the effective surface area when selecting the appropriate cathode power collectors.

➢ Fouling with undesirable materials: the mechanism is quite complex, as biological, chemical, and physical interactions between contaminators and separators occur simultaneously at the fouling process, reducing ion transfer capacity, conductivity, and ion diffusion coefficients, resulting in an increase of internal resistance and a pH change between the two electrodes. Consequently, the separator material needs to be designed in such a way as to avoid biofilm growth, salt retention, and reaction with other ions.

➢ Separator deformation: it is caused by gas and water being trapped between the separator and the electrode leading, in the long run, to a reduction in the MFC efficiency. The solution hides in the electrode construction using high hardness porous materials, such as stainless-steel mesh, which by compression provide suitable protection to the separator from deformation over time. Obviously, this aggravates the cost and construction complexity.

➢ MFC clogging due to biomass and solid pollutants: in case of flow of large amounts of biomass and solid pollutants through the urban/rural/industrial waste, clogging of the electrodes may occur (mainly the anode). Therefore, the organic load flow to the cell, through the waste, should be properly controlled (Liu and Cheng, 2014; Bolognesi et al., 2021a).

➢ Ambient temperature variations: in real constructions, the MFC is externally placed, consequently subjected to significant temperature changes during the year (e.g., from 0°C to 40°C, in the area of Athens, Greece), in contrast to the laboratory, where the range is more limited (e.g., from 18°C to 30°C). This affects the microorganisms’ activity in power production and waste decomposition significantly. So, it is very difficult to maintain a stable MFC efficiency at all temperatures. Of course, the operation of the classic secondary waste treatment plants is more sensitive to temperature variations.

Based on the above, it can be seen that constantly maintaining the MFC performance, in the long run, is quite difficult and complex, although there are now some pilot real waste treatment projects that have been operating at constant levels for some years (Liu and Cheng, 2014). In any case, and for their successful operation as waste treatment units, the HRT and power density (in relation to the flow and substrate composition) must also be taken into account, in addition to the appropriate configuration of the electrodes (Logan, 2008).

Generally, the performance of each wastewater treatment system is determined by discharge standards (effluent quality and volumetric treatment rate) according to the directives/legislation of the respective national or international regulatory authorities. However, the MFC performance, as well as of each biological treatment system, is affected by a number of operational factors which include (

Leicester et al., 2020):

• Waste and sludge composition, with the most characteristic elements being BOD, COD, total suspended solids, total nitrogen, total phosphate, and pathogenic microorganisms. This composition must be known at both the influent and effluent of the biological treatment system.

• The kind/composition and conductivity of the substrate, as the first one is affected by wastewater composition, while the conductivity is influenced not only by wastewater but also by the MFC electrical behavior.

• Organic loading rate, which is determined by the influent COD supply and the size of the reactor or the HRT.

• Reactor depth and volume.

• Volumetric treatment rate COD, which is defined by the reduction of COD in the respective HRT.

• Energy balance, calculated by comparing energy demands and energy recovery per mass unit of COD, where, in the case of a biological treatment with aerobic stage of secondary treatment, significant amounts of energy are required, while, with the use of MFC, clean power production can be achieved.

• Ambient temperature, which should ideally be between 10 and 25°C, otherwise bacterial growth and life span are strongly affected.

So, when comparing different systems, one should refer to the same benchmarks, which is not easily achieved.

2.5 Integration of Biological Treatment Plant With Microbial Fuel Cells in Smart Grid

Provided that MFC scaling-up issues are solved and full scale-up projects are realized, the use of biological treatment units, with MFCs (either in the secondary stage of biological waste treatment or in the tertiary stage during the removal of heavy metals, nitrates, phosphates, etc., or even in the sludge treatment), presents significant advantages when integrated into a smart grid, the most important of which are the following:

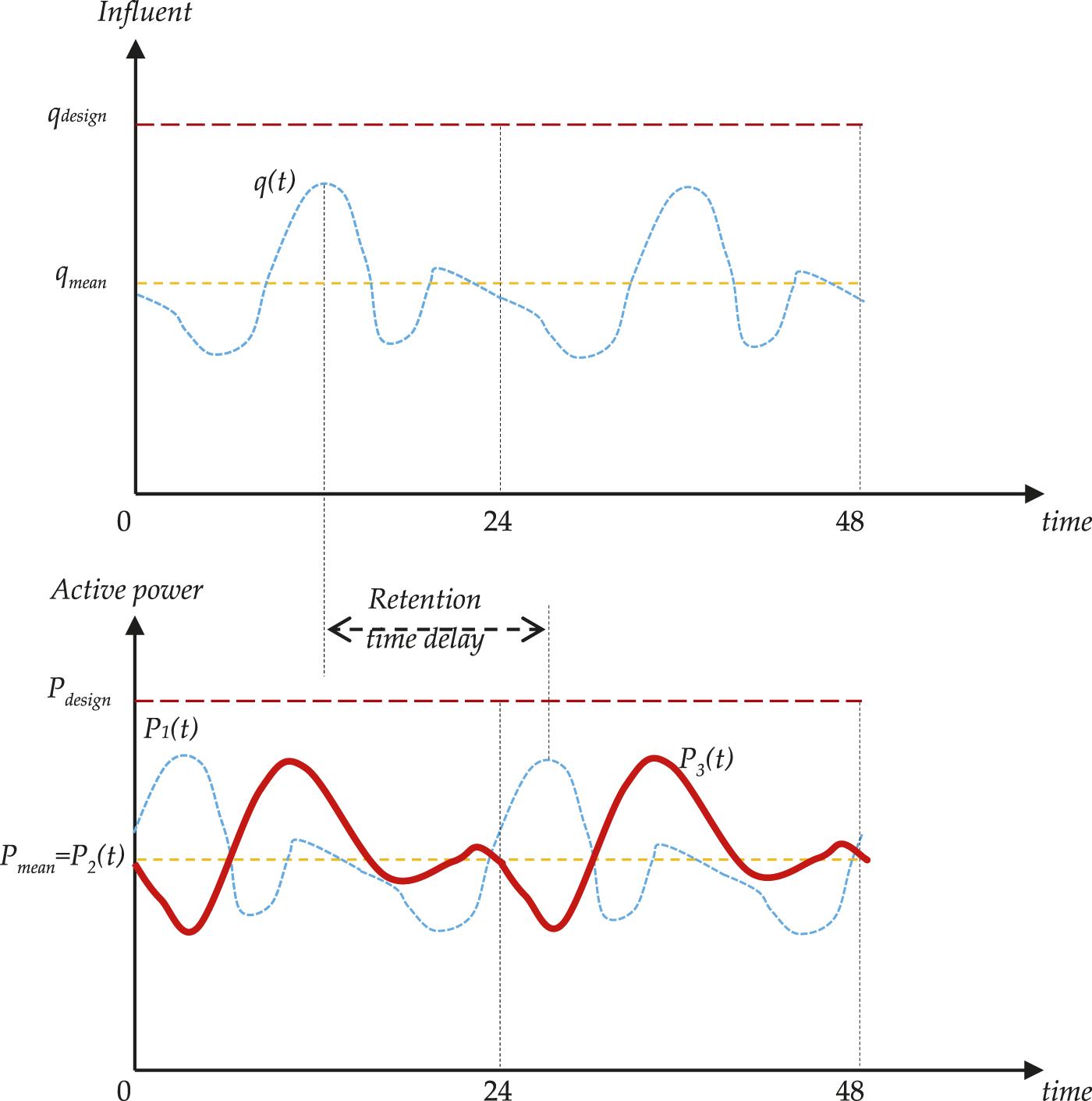

1. Conversion of a power consumption device into a partially controlled power producer: in a settlement or a city, the biological treatment plant is a significant consumer of electricity; for as shown in Logan (2008), an AS secondary treatment plant requires 1,020 ÷ 2,550 kW/(m3/s) of influent or with a membrane bioreactor requires 8,520 kW/(m3/s). By contrast, the respective MFC devices could produce a few hundred kW/(m3/s) theoretically. Since the primary waste treatment tank precedes, the waste flow can be significantly controlled, thus making possible the reduction of produced electric power variations over the 24-h period or by even adjusting it in the desired way (if this is allowed by the maximum possible influent, the biological treatment plant can process). Specifically, Figure 4 shows the correlation between influent/active power of the biological treatment plant with MFC. The produced active power curve P1(t) slides by a time delay with respect to the influent curve q(t), due to wastewater remaining at the primary treatment tanks and also because of the time required by the electrogenic bacteria to decompose the organic material. Alternatively, if through the primary treatment tanks the wastewater inflow into the secondary treatment is constant and corresponding to qmean, then the produced active power P2(t) is expected to approach the value of the mean produced active power Pmean, ignoring any environmental effects (temperature, etc.). In addition, with the help of PMS, primary treatment tanks, and perhaps small energy storage devices, the produced active power curve P3(t) can be adjusted to either the demand load (in combination with a suitable demand side management program) or to the electricity sale price, if the tariff is variable. At this point, it presents an advantage over wind turbines, photovoltaic units, and small hydroelectric plants due to the lower stochasticity of its “fuel”, but lags behind thermal units which use biomass or biogas. That is why it is suitable for installation in a smart grid. Alternatively, instead of direct power production from MFCs, one could turn to biofuel synthesis, through MECs [e.g., bioelectrochemical systems for electromethanogenesis could be used as power to biogas technology with gas storage capability (Ceballos-Escalera et al., 2020) or bioelectrochemical systems combined with heterotrophic microalgae batch reactors can convert CO2 into oil compatible biodiesel (Bolognesi et al., 2022)]. Consequently, these biofuels can be utilized in thermal power plants in a smart grid or elsewhere (Molino et al., 2015; Braco and Delfino, 2017).

2. Availability of metering devices: the operation of a system with MFCs requires an integrated system of automatic control of both wastewater and electrical quantities (of the cells themselves as well as of the AC converters), rendering them easily integratable on a smart grid, which requires complex metering devices to control and protect them.

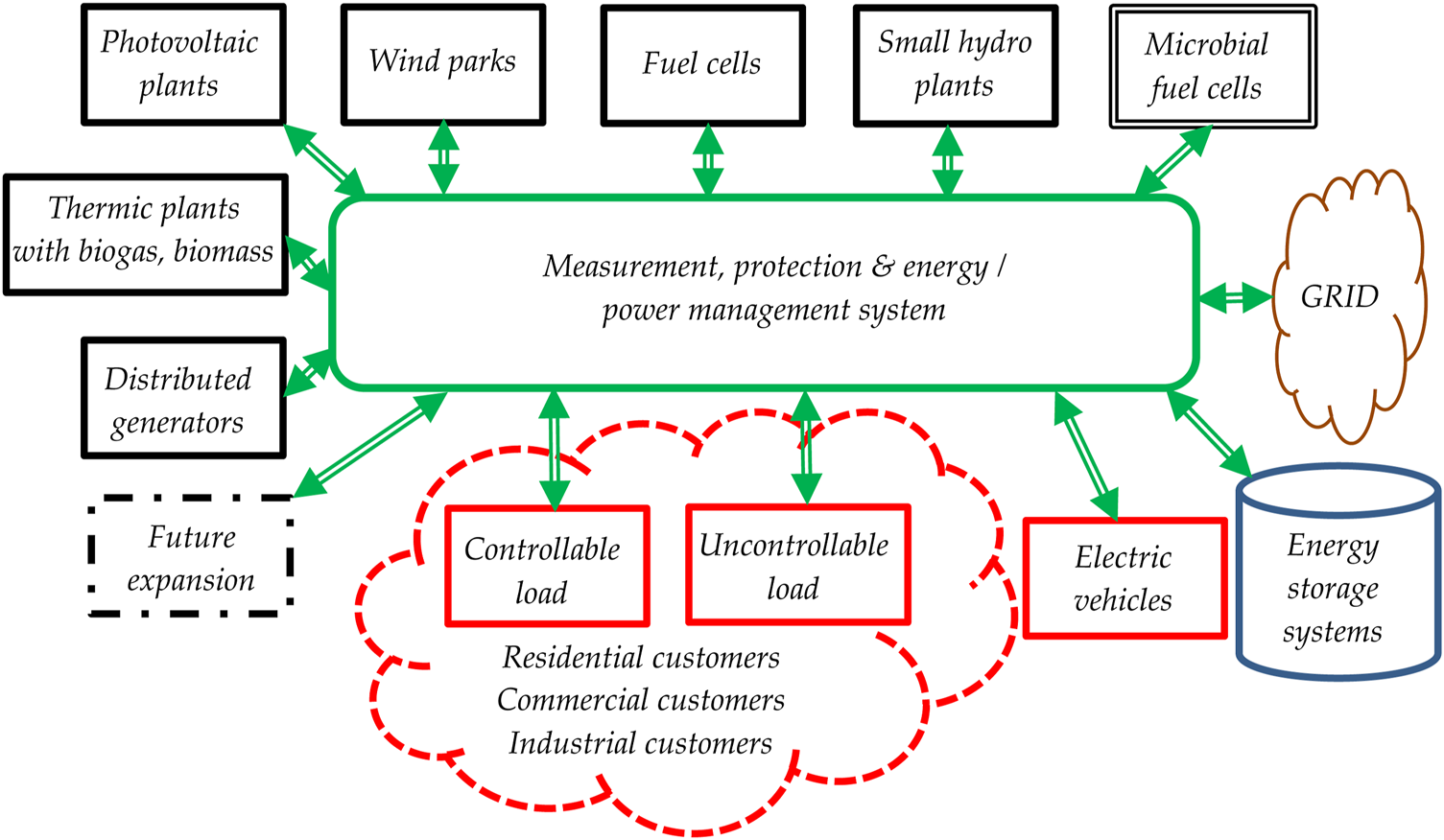

3. Kind of distributed power generation: it has all the basic characteristics of a distributed energy resources with small stochastic behavior regarding the power produced, with the possibility of easy implementation of a demand-side management program, through the available PMS and the converters it already has. It can essentially be integrated with the other renewable energy sources (RES) into a smart grid, as shown in Figure 5, extending the respective power network schemes, as those shown in Figure 4 of Ullah et al. (2021) and Figure 1 of Narkhede et al. (2013) and Ullah et al. (2020).

4. Reduction of losses in power transmission and distribution networks: converting a biological treatment plant from a large power consumer to a small power production unit reduces the corresponding power losses on the transmission and distribution lines, thereby reducing the environmental impact of the power system and enhancing sustainability.

5. No spatial expansion of the facilities: the biological wastewater treatment plant with MFC in the secondary stage does not require a larger area than the conventional installations do (such as AS clarifiers and oxidation basins). Furthermore, the process is done in closed structures, without the use of oxygen, thereby reducing odor issues (Logan, 2008). However, reducing the gross volume of the installation remains an outstanding challenge. For instance, in Blatter et al. (2021), an MFC system treating 1 m3 of wastewater, in industrial scale, occupies a gross volume of 16.3 m3.

6. Limitation of visual nuisance vis-a-vis other RES: since the biological treatment plant must be constructed for environmental treatment purposes, it does not impose further visual burden on the environment, since it would anyway exist, unlike other RES (mainly wind turbines and photovoltaic panels) which occupy additional land.

7. Improving power systems behavior in terms of power quality and reliability: due to lower stochasticity in the supply of “fuel” (i.e., waste and the corresponding organic load) and its much more limited fluctuations, the MFC integration improves power reliability and quality of distributed generation in a smart grid, in relation to the corresponding behavior of the dominant RES (wind turbines and photovoltaics).

8. Intensified research on the MFC development: it is the most promising technology, constantly evolving and improving over the last decade, while already yielding economically viable results for high organic load wastewater on a theoretical basis (Trapero et al., 2017), which leads to larger power densities freeing the environment from the effects of aquifer pollution from the most polluting wastes.

FIGURE 4

Correlated influent and active power curves, over time, of a wastewater treatment plant with MFC.

FIGURE 5

Virtual power block diagram for smart grid.

Nevertheless, and in spite of their advantages, MFCs have not yet found commercial application, since there are a number of disadvantages at present, the most important of which are the following:

1. High installation and maintenance costs per kW: the installation cost per kW as an individual electric power plant has not been investigated because emphasis has been given in wastewater treatment financial characteristics. From indicative reports and further processing, it is of the order of 100 k€/kW for wastes plentiful in organic load (e.g., wastewater from fruit juice factory with 15 gr/l with a COD reduction by 60% and Coulombic efficiency by 10%) (Trapero et al., 2017), while for domestic/urban wastewater becoming even greater (proving to be multiple, compared to the already existing units—e.g., coal plants, 1.1 ÷ 1.7 k€/kW; wind parks, 0.85 ÷ 2.55 k€/kW; and photovoltaic plant, 1.2÷3.5 k€/kW). However, as a cogeneration power plant (i.e., taking into account its role as a wastewater treatment plant), it results in the proposed technical solution being economically viable over a 15-year period for different types of MFCs (with platinum catalyst—high power density and without platinum—low power density) for various COD removal and Coulombic efficiency scenarios (Trapero et al., 2017), provided that the scale-up technical issues of the MFCs are successfully addressed. The latter is supported theoretically by Logan (2008), Fornero et al. (2010), Wang et al. (2013), Sharaf and Orhan (2014), Logan (2015), Khan et al. (2017), and Park et al. (2018), whilst the opposite is supported by others (Tommasi and Lombardelli, 2017). In any case, its technological improvement is very promising, in terms of reducing the cost of membranes and electrodes according to Sharaf and Orhan (2014), provided that it is considered as a combination of wastewater treatment plant and power plant and not as a power plant alone.

2. Technological maturation lag: the relevant technology around MFCs has not yet achieved the required levels of maturation, but is still constantly evolving. Therefore, the basic technical solutions for various issues have not yet emerged, e.g., what is the appropriate retention time inside the MFC chamber in order to achieve the appropriate COD removal; depending on the electrogenic microbes used, what are the most suitable materials for making membranes and electrodes; and what are the most suitable dimensions of the tanks? In addition, the long-term operation of the respective devices has not been tested thus far. At present, there are speculations for a lifespan of 15 years, while they have been experimentally measured/tested for up to 1 year (Liu et al., 2017; Blatter et al., 2021).

3. Issues regarding the up-scaling of MFCs: according to Section 2.4, the necessary technological development has not yet been achieved to up-scale the MFCs to industrial size, although in the last 5 years, MFCs systems of up to 1 m3 have been developed with satisfactory efficiency (Blatter et al., 2021).

4. Use of microbes for power generation: the MFC operation is based on electrogenic and non-electrogenic microbes/bacteria, which act in synergy on the MFC electrodes (Santoro et al., 2021). However bacterial behavior is affected by a variety of parameters, such as the nature and size of the organic load (in COD and BOD), possible microbe poisoning, ambient temperature, and wastewater pH (Logan, 2008; Liu and Cheng, 2014). Hence, their behavior is uncertain. However, their stochastic behavior is more limited than that of wind turbines and photovoltaic panels.

5. Reconfiguration of the power distribution network: the conversion of a wastewater treatment plant from a power consumer to a power producer, through the use of MFC, results in the alternation of power flow behavior of the respective distribution power network (from mono-directional to bidirectional), resulting in changes in the electric power protection devices and in the dimensioning of the conductors and other components with respect to short circuit studies. Of course, this problem exists with all distributed energy recourses and with the development of smart grids.

6. Limitations to produced power and energy: depending on the amount of influent, the nature of the organic load, the nutrients and metals contained, and their treatment method, as well as the desired levels of purity of the effluent (in terms of BOD, COD, pathogens, etc.) to the final recipient (sea, rivers, and lakes), which largely determine the produced electric power and the annual energy delivered to the grid.

7. Limited location options for utilization by wastewater treatment plants: the location sites of wastewater treatment plants (regardless of whether they are with MFC or AS) are limited, since the sewerage network is mainly gravitational and of radial operation, that gathers, in a final pipeline, the total of the wastewater and transfers it to the respective plants, which is at a lower or equal altitude as that of the settlement/city being served. It also requires specialized staff at present and with current technology, which creates additional difficulties in terms of its operation.

8. Uncertainty concerning economic viability: due to the high installation cost (as pointed out in the first disadvantage), along with the high maintenance costs, the issue of financial viability is always raised, which is examined in each case separately (Trapero et al., 2017).

Despite their disadvantages, the advantages of MFCs are enough to warrant further examination.

3 Method of Economic Comparison Between MFC and Activated Sludge Urban Wastewater Treatment Systems

3.1 Introduction

Essentially, the way of studying wastewater systems with MFC, presented in Trapero et al. (2017), is extended here for the case of urban wastewater using the layout of Figure 1 in Trapero et al. (2017), modifying more econometric parameters. The preliminary theoretical design of the wastewater treatment system takes place and the relevant methodology is based on three stages: 1) determination of the wastewater supply characteristics, 2) preliminary study of technical/economic characteristics of the MFC wastewater treatment system against the AS system, and 3) economic evaluation—comparison, as analyzed below.

3.2 Stage of Typical Wastewater Supply Determination

By convention, based on Koutsogiannis (1999), the design period Tdesign is 40 years (which exceeds the technical life Ttech of the wastewater treatment plant, and is considered indicatively to reach 15 years due to technological aging). The population Ppop and the area Αtown of the under study region can either be considered constant over time or they can change up to the maximum value, during the technical lifespan Ttech. Initially, the average daily domestic water consumption per inhabitant qhab, the equivalent daily consumption of small/large industries qind, and the equivalent daily community/municipal consumption qmun are determined through relative statistical analysis, so the total average daily water consumption per inhabitant q/tot is equal to:

If the ratio of water consumption entering the sewerage network is ρ, then the total average sewage supply per inhabitant qtot is equal to:

Therefore, the total average daily supply of sewage by inhabitants is equal to:

In addition, the subterranean aquifer is at a relatively large depth, and the sewerage network is completely modern. So, based on Equation 2.12 of Koutsogiannis (1999) concerning infiltration in the sewerage network due to the area, for new networks (with watertight wells and elastic sealing rings of the joints), it results from a statistical/empirical study that the additional inflow per hectare qi is equal to:

So, the additional inflow to the network Qi, due to infiltration, etc., is equal to:

Therefore, the total average daily supply of untreated wastewater Qwaste, or nominal supply, is equal to:

Since the primary wastewater treatment system is common and mandatory, it is not taken into account in the techno-economic study. Simply, if the urban wastewater initially had a content in chemical oxygen demand CODin1 and biochemical oxygen demand BOD5-in1 (after dark storage for 5 days in 20°C) after the primary treatment, the resulting quantities of primary treatment outflow and secondary wastewater treatment inflow CODin2 and BOD5-in2 (through the respective removal ratios rCOD-1 and rΒOD-1) are:

Three main variables can already be noted that affect the financial viability of the investment which are: 1) the total average daily supply of untreated wastewater Qwaste, 2) the chemical oxygen demand CODin2, and 3) the biochemical oxygen demand BOD5-in2 at the secondary treatment inflow.

3.3 Preliminary Study Stage of Techno-Economic Characteristics of Urban Wastewater Treatment Plant With MFC Against the Activated Sludge System

The steps of the preliminary study stage are the following:

• Basic MFC size calculations for secondary treatment: based on the standard MFC in Trapero et al. (2017) of a specific anode chamber volume Vanode and with a hydraulic retention time tHRT, the required number of MFCs nMFC is determined using the nominal wastewater supply Qwaste:

where

tMFCis the annual operating hours of the MFC. The nominal operating inflow per MFC

qwaste, with parallel hydraulic connection of

nMFCMFCs, is then calculated as follows:

where

rcis a nominal operation correction factor, with typical value

rc= 1, which is taken into account in case of deviation when dimensioning the sewerage system (namely, a kind of sensitivity parameter of the wastewater system treatment design with respect to the nominal wastewater supply).

• Power density calculation: taking into account that the expected ratio of organic load removal over influent (in the form of chemical oxygen demand) is nΔCOD, the expected Coulombic efficiency CE, the current per MFC IMFC, the nominal active power per MFC PMFC, the nominal active power of the MFC stack Ptot-MFC, and the respective power density PDMFC are calculated taking into account the Faraday constant F (equal to 96485.3383 C/mol), the influent supply per MFC qwaste by Eq. 10, the molecular weight of the reducing chemical agent ΜΒred (equal to 31.998 g/mol for oxygen), the number of electrons released from one molecule of the above chemical compound ne (equal to 4 for O2), the initial organic load of secondary wastewater treatment influent in the form of CODin2, the output voltage per MFC Vout (assuming that the output voltage remains constant over time despite small variations of wastewater inflow, the wastewater composition, and other functional parameters), the volume of the anode chamber per MFC Vanode, and the energy conversion factor nconv which includes both the efficiency of the DC to AC power converter and the efficiency due to losses owing to the non-uniformity of power generated between the different MFC chambers are calculated as follows:

• Calculation of fixed and variable operating costs of MFC and AS systems: the total capital costs of the AS system TCAS and that of the MFC system TCMFC are calculated by:

where

CASis the AS capital cost per wastewater supply,

tASis the annual operating hours of the AS system, and

CMFCis the capital cost per MFC.

Consequently, the following values are calculated taking into consideration the assumptions made in Trapero et al. (2017):

➢ The annual operating costs for the AS secondary treatment stage FTCAS without the operating costs of AS air blower/diffuser are calculated by:

➢ The annual operating costs of AS system VCAS (due to air blower/diffuser) are calculated by:

➢ The annual operating costs for the MFC secondary treatment stage FTCMFC without the operating costs of MFCs auxiliary devices are calculated by:

➢ The annual operating costs of MFCs auxiliary devices VCMFC (due to air blower/diffuser mainly) are calculated by:

➢ The total annual operating costs for the AS secondary treatment ToCAS are calculated by:

➢ The total annual operating costs for the MFC secondary treatment ToCMFC are calculated by:

➢ The annual operating costs for the sludge treatment, produced by the AS system STAS are calculated by:

➢ The annual operating costs for the sludge treatment, produced by the MFC STMFC are calculated by:where qAS is the operational wastewater inflow of the AS system, qMFC(=nMFC∙qwaste) is the operational inflow of the MFC system, FC is the constant energy consumption at the secondary treatment stage beyond the AS and MFC systems, tAS is the annual operating hours of the AS system, tMFC is the annual operating hours of the MFC system, Cblower is the energy consumption per cubic meter of sludge on behalf of the air diffuser/blower, pair-AS and pair-MFC are the energy factors of the necessary air quantity (artificially provided through air diffuser/blower) to the AS system (aerobic digestion) and MFC, respectively, ckWh is the electricity sale cost on behalf of the power grid, csludge_AS is the additional annual operating cost factor due to sludge treatment for the AS system, and csludge_MFC_AS is the reduction factor of sludge produced from the MFCs over that from the AS system.

To ensure equivalent results, in terms of operation of the two wastewater treatment subsystems, the following must apply:

The annual profit from electric power generation EMFC is determined by the product of power density PDMFC by the MFC volume of wastewater treatment (nMFC∙Vanode), which lasts a hydraulic retention time tHRT, multiplied by the number of loading repetitions (tMFC/tHRT) and the electricity market cost from the power grid skWh:

In the case that the operational supply (nMFC∙qwaste) does not match the corresponding design supply (nMFC∙Vanode/tMFC), then the latter one is replaced by the operational supply:

The difference in operating costs ΔOC, by replacing the AS system by MFCs, reaches an annual total of:

3.4 Financial Evaluation Stage

The financial viability of this investment can be estimated using the following criteria:

• The NPV at the commencement of the commercial operation, which is defined by the following:

where

C0is the investment cost,

NCin-tis the net cash inflow of the year

texpressed in prices of that specific time period (i.e., disregarding inflation),

kis the deflated discount rate, and

nis the investment life period. The project investment will be recommended if

NPVis greater than zero. Between two investment projects with the same life period, the one with the highest

NPVis preferred. It is reminded that the net cash inflow is given by the following:

where

Cainis the cash income,

Copis the operation cost,

Crecis the investment recoup,

Cintis the interest cost for the loans, and

ftaxis the constant tax factor.

• The IRR, which is defined as the discount rate that makes the NPV equal to zero, is given by:

The project investment will be recommended if

IRRis greater than the minimum required discount rate, with the assumption of positive net cash inflow. Between two investment projects with the same lifespan, the one with the highest

IRRis preferred.

• The TDPB, which is defined as the investment life period that makes the NPV equal to zero, is given by:

The project investment will be recommended if

TDPBis smaller than the investment life period

n. Between two investment projects with the same investment life period, the one with the lowest

TDPBis preferred.

• The BCR is defined by dividing the proposed total net cash inflow of the project by the proposed investment cost and is given by:

The project investment will be recommended if BCR is greater than one. Between two investment projects with the same life period, the one with the highest BCR is preferred.

It is pointed out that in all the above cases, the capital is placed only at the beginning of the operating period. Any extended maintenance will be considered as negative cash flow.

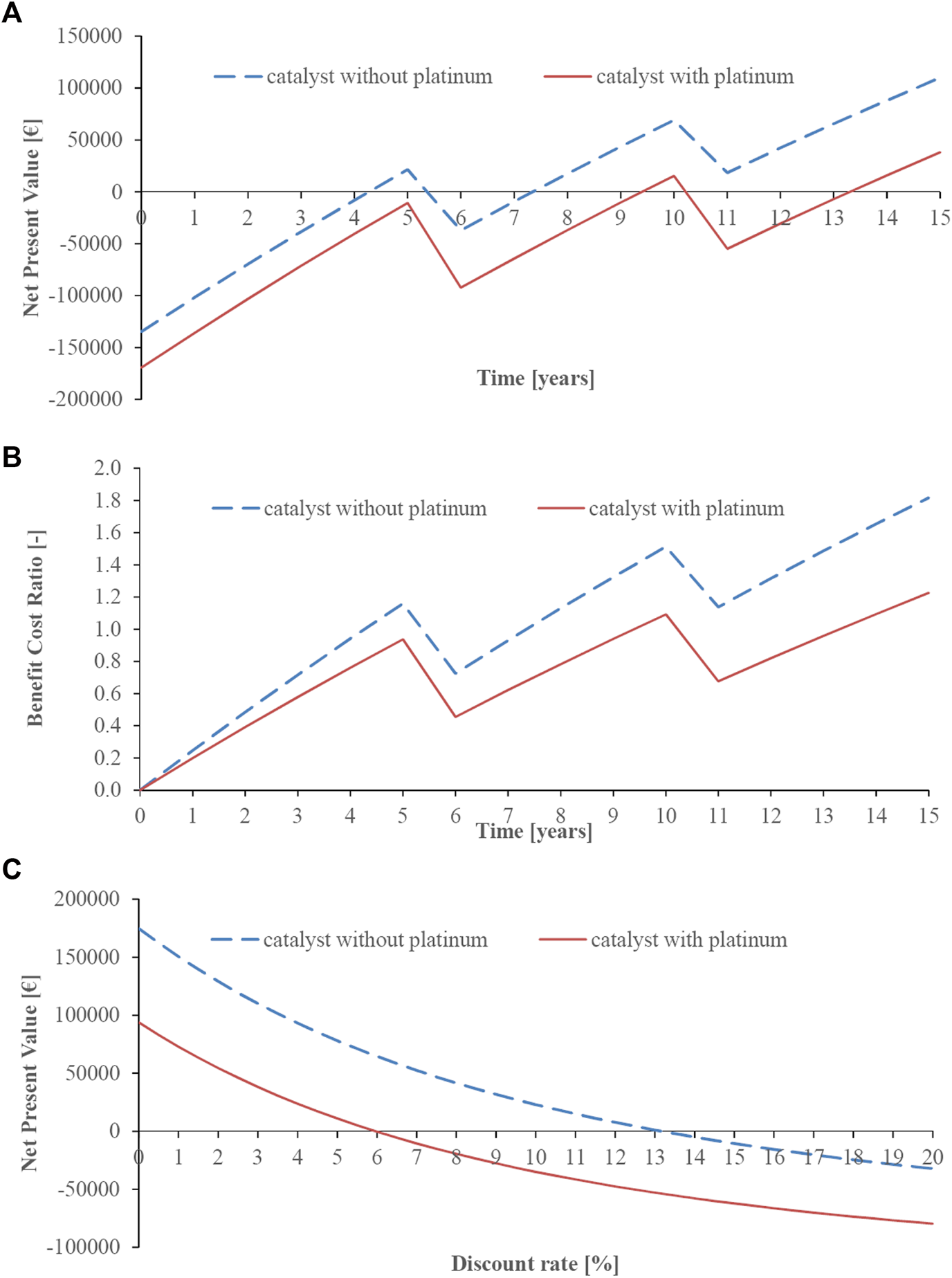

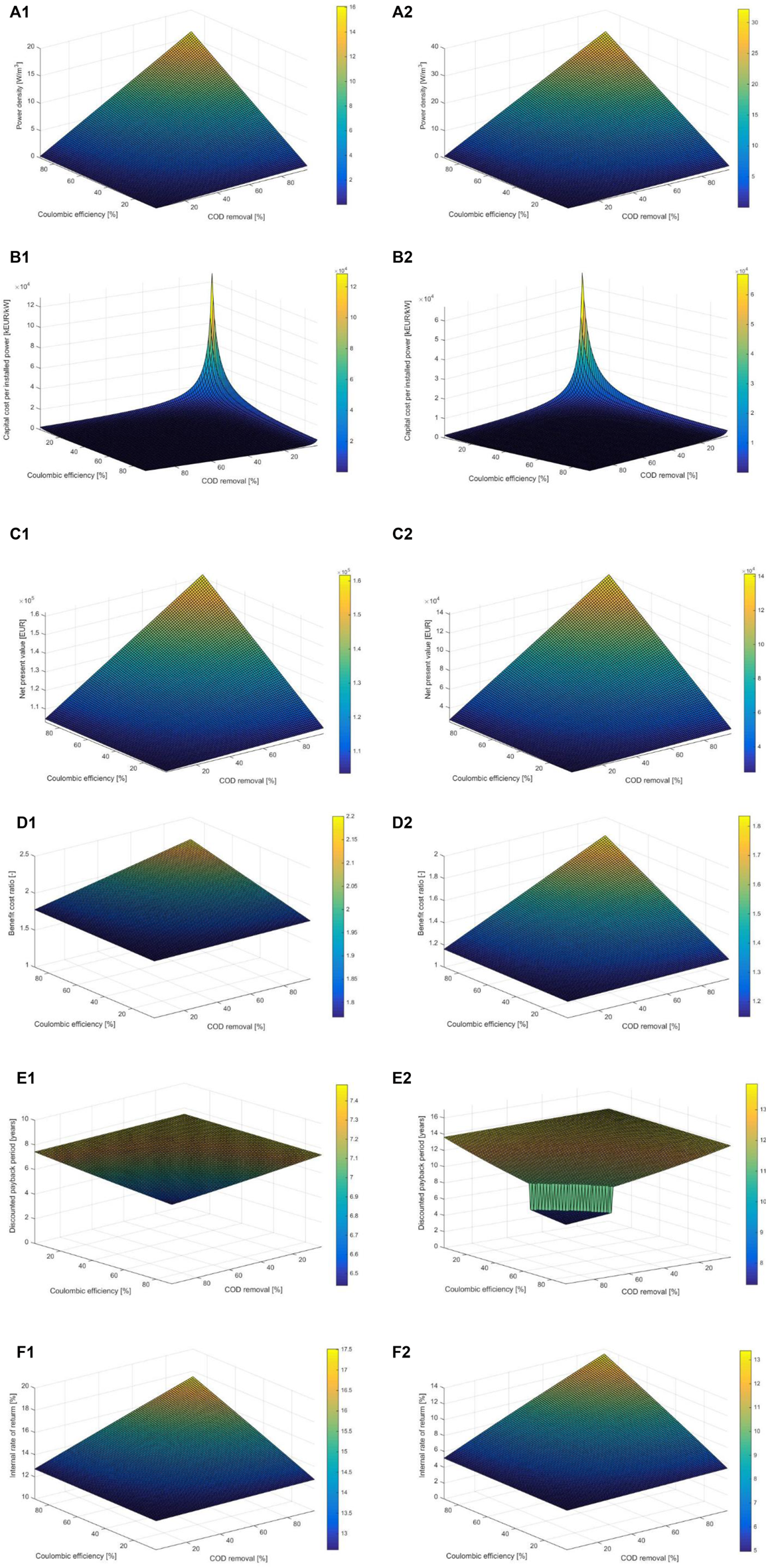

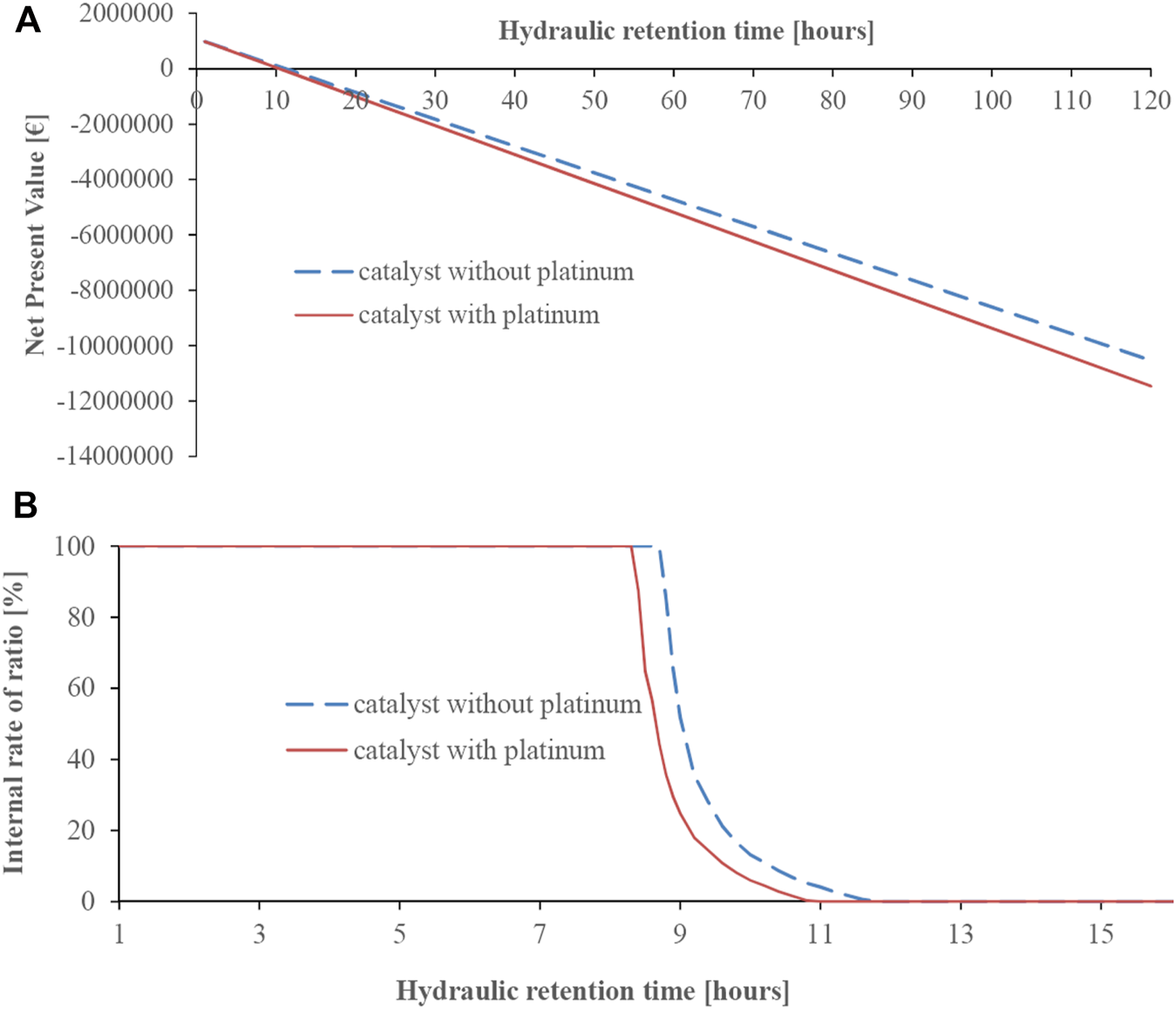

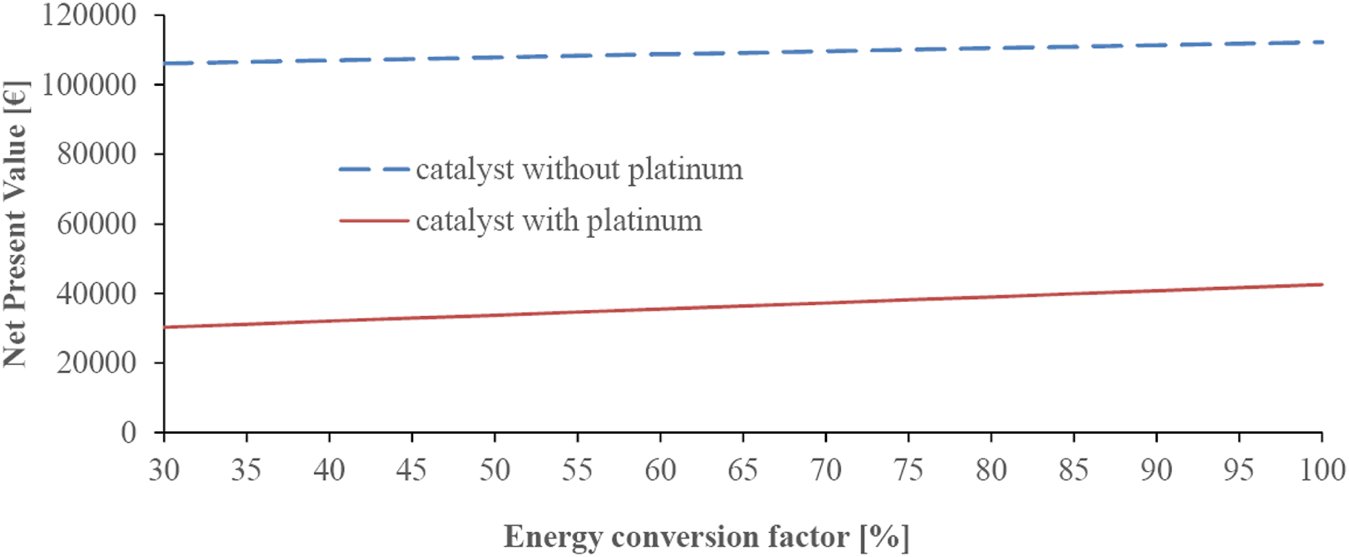

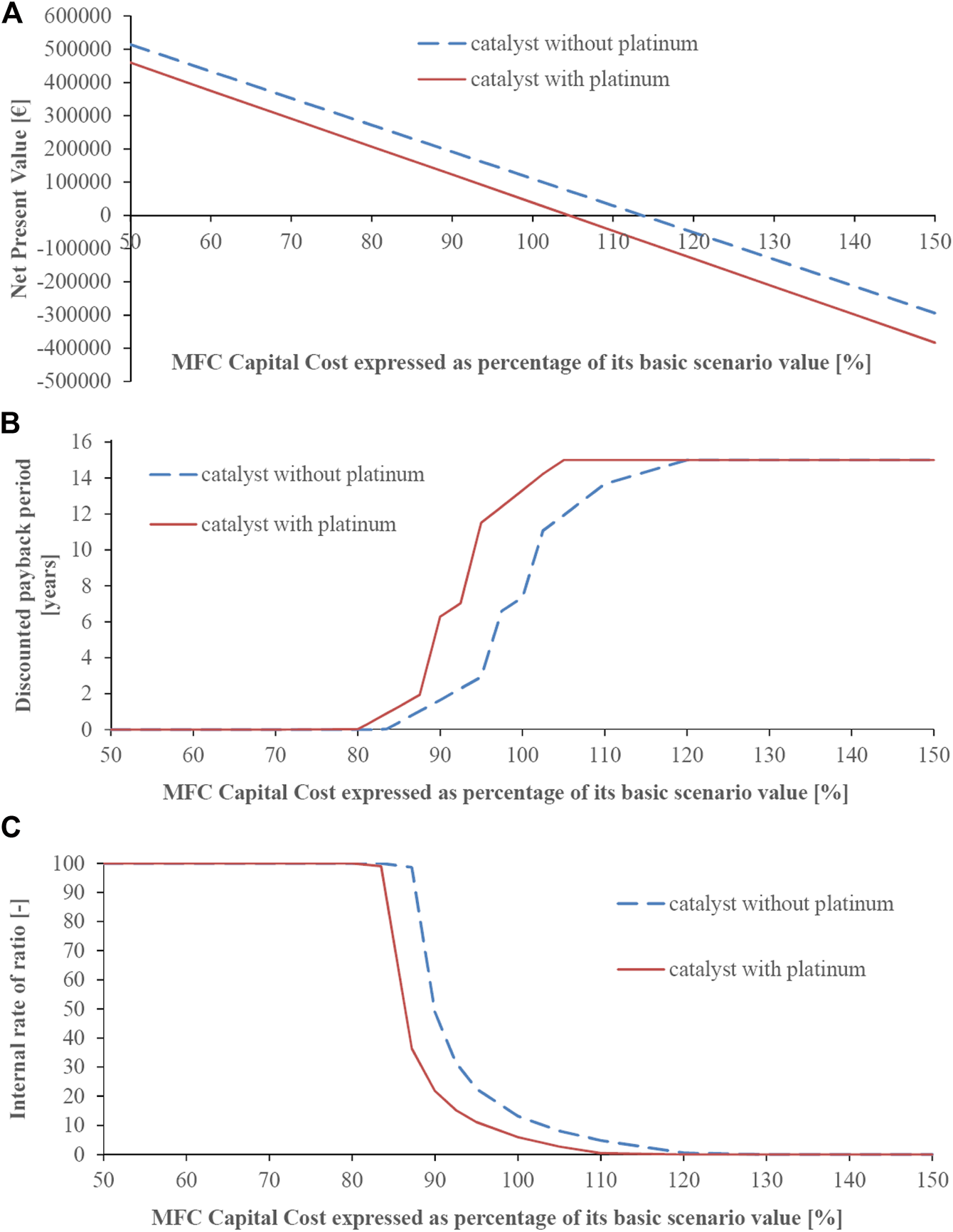

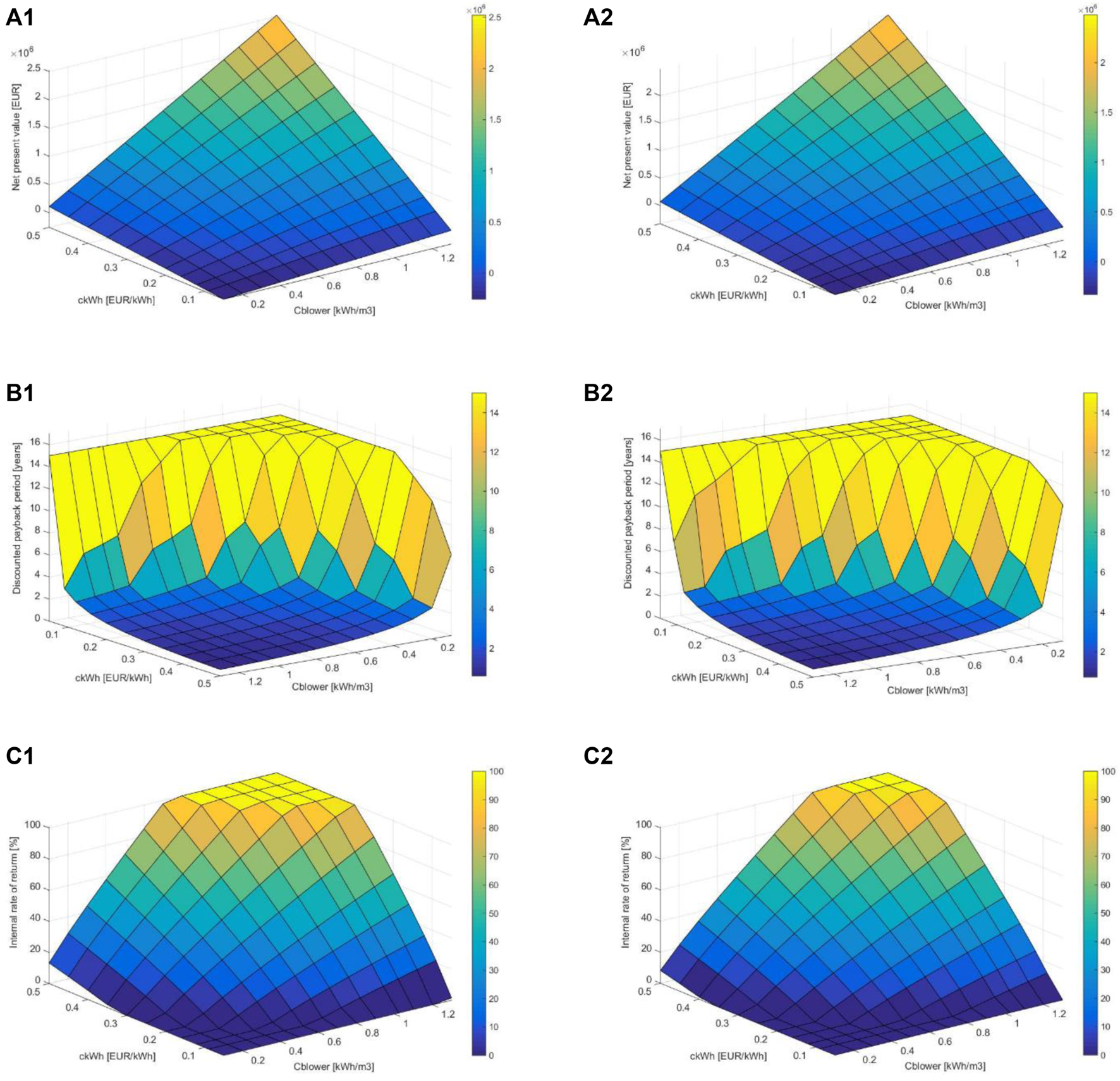

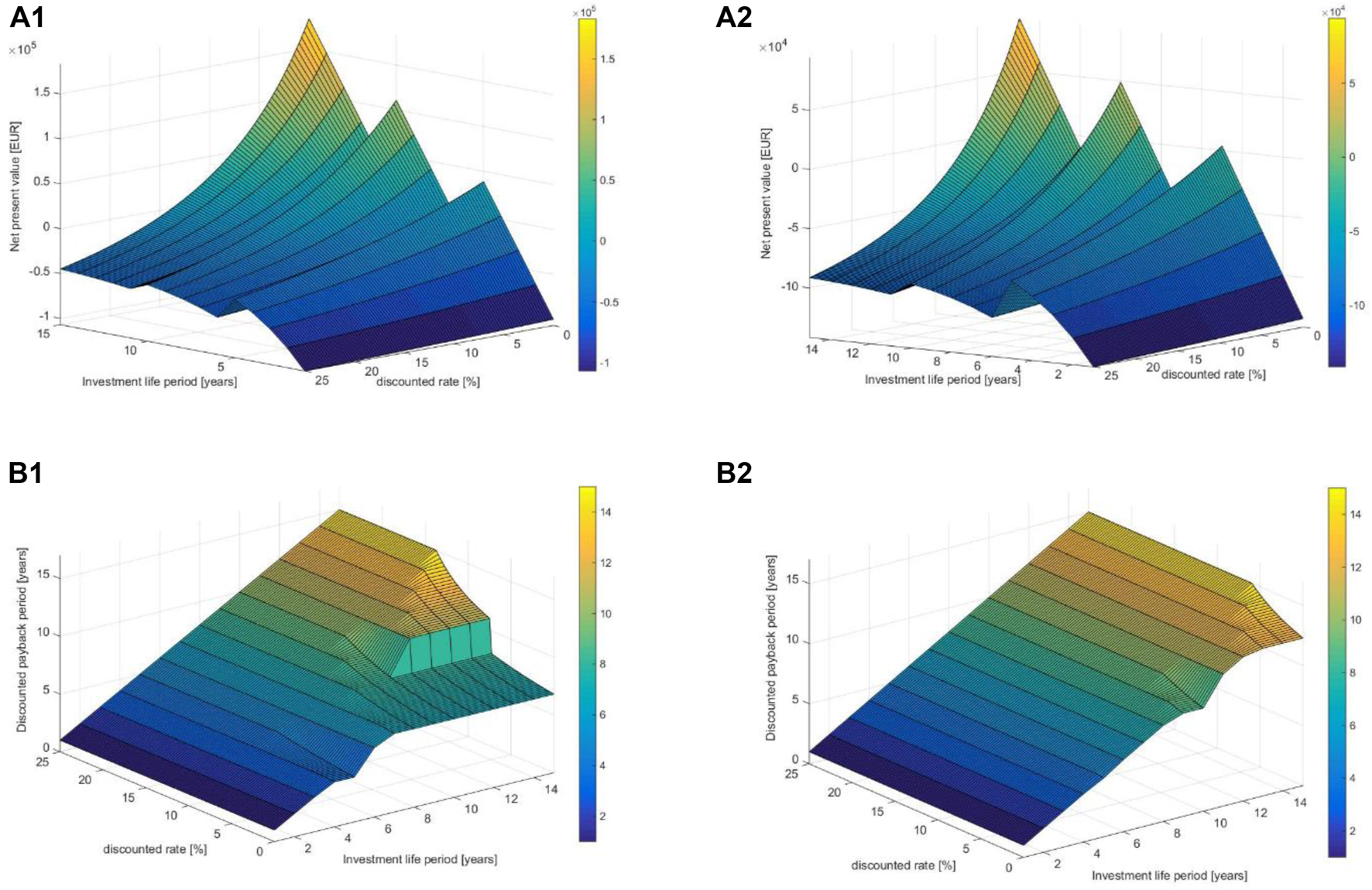

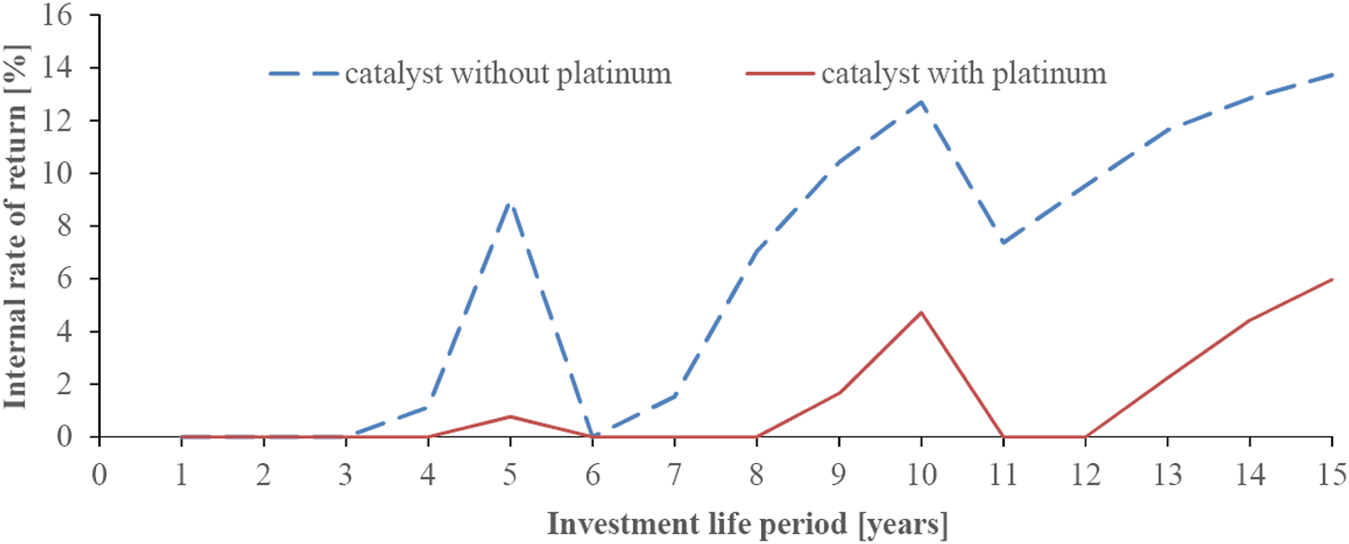

In the present study, the NPV difference between the use of an MFC and AS system determines the respective financial evaluation. So, the corresponding criteria are as follows:where Tperiod is the study time period of the two projects (which, in this case, coincides with the technical lifespan Ttech and the investment life period n), t is the current year, TMCMFC-t is the total cost of extended maintenance of the MFCs per period Τmaintance_MFC (which, in turn, is calculated from the product of the nominal wastewater supply Qwaste by the corresponding cost of MFC extended maintenance per inflow supply ΜCMFC):