94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 17 January 2023

Sec. Nuclear Energy

Volume 10 - 2022 | https://doi.org/10.3389/fenrg.2022.1067892

This article is part of the Research Topic Dynamics and Control for Nuclear Energy View all 8 articles

Thanks to its unique characteristics of high power-to-mass ratio, shallow reactivity poisoning, and quick response to reactivity control, power supply system based on lithium-cooled space nuclear reactor is preferred for various exploration missions into outer and deep space. However, due to its nature of few-people or even unmanned on-duty, an intelligent autonomous control of the reactor system, especially an accurate control of the reactor core power following the demanding power output, is of vital importance for such a space nuclear reactor. In this study, a core-power controller for a megawatt ultra-small lithium-cooled space nuclear reactor was designed based on the concept of fuzzy model predictive control (FMPC) combining model predictive control and T-S fuzzy theory. Performance of the FMPC controller was simulated and assessed with the Simulink platform for five typical operation transients including ramp, step and disturbance transient. The results show that the intelligent FMPC controller possesses an excellent load-following ability and anti-interference ability, both of which are of vital importance for space exploration missions. When compared with the classical PID controller, the FMPC controller designed in this study shows also a much better performance with smaller overshoot, lesser adjusting time and lower integral time-squared error.

Over the past century, human beings have actively carried out various space explorations. Remarkable accomplishments have been achieved, which continuously expanded the boundaries of human knowledge. Many of these accomplishments going to the unknown outer and deep space are largely benefited from the successful development and application of solar cell battery or space radio-isotopic battery, which exploits the energy either from the solar irradiation (Baraskar et al., 2022) or the energy released during decay process of certain radioactive isotopes (Bennett et al., 1996) to provide the necessary power supply. In addition to continuing the deep-space exploration, the next important step will be surface explorations of planetary satellites and other-than-earth planets, among which lunar exploration projects have already been carried out by many countries or international organizations, see for instance in the reviews by Zheng et al. (2008), Ehrenfreund et al. (2012) and Marov and Slyuta (2021). Manned surface exploration of the Mars is also undergoing the process of intense discussions (McNutt et al., 2015). For surface exploration of other-than-earth planets or planetary satellites, traditional solutions of power supply based on solar cell battery or radio-isotopic battery will not be able to meet the needs due to the impact of weak solar light, extreme high or low temperature, dust storms, as well as the demand of a power supply in hundreds of kilowatts or even megawatts and a mission task cycle that can easily last more than 10 years or even decades (Akimov et al., 2012).

Thanks to its unique advantages of high power-to-mass ratio, shallow reactivity poisoning and quick response to reactivity control (IAEA, 2002), a liquid metal-cooled space nuclear reactor, which adopts a fast neutron spectrum reactor core cooled by liquid metal or liquid metal alloys, is the preferred solution to provide the necessary high-power supply also in the environment of lacking or no solar irradiation. As recently reviewed in (Song et al., 2021), worldwide 80% of the prototype designs and 100% of the actual tested space power supply systems are based on various designs of liquid metal-cooled space nuclear reactors. Thanks to its high boiling point and low density, liquid lithium has attracted more and more attentions as the coolant for space nuclear reactor from both industrial and scientific community, see for instance in (Harty and Mason, 1993; Demuth, 2003; Jin, et al., 2022) etc. However, to meet the requirements of safety, reliability, viability, and the long-life expectancy of a space exploration mission, autonomous intelligent control of the reactor are of vital importance when designing the control system of a space nuclear reactor (Zhao at al., 2012). In terrestrial nuclear power plants (NPPs), human operators can manually perform the necessary control functions required for normal and abnormal operating conditions. On the contrary, for space missions into outer and deep space characterized by uncertain environments, rare events, and communication delays, all control functions of the reactor must be performed through a robust control system with very limited or even no human intervention from the Earth (Zhao at al., 2012). The basic requirement is to achieve a fast and accurate control of the reactor core power following the desired power output in different operation modes, including not only steady-state operation at different power levels, but more importantly, also transients between these power levels, and transient modes during startup and emergency shutdown of the reactor.

Thanks to its advantages of stability and maturity, the classical proportional-integral-derivative (PID) control scheme is still widely installed as the standard core-power control scheme in current PWR power plants. However, PID control scheme is not able to well handle the load-following operation modes of a nuclear reactor (Liu et al., 2009). In the past decades, various techniques to enhance the control performance of nuclear reactor have been extensively studied. Advanced control schemes including fuzzy control (Mamdani, 1974), neural network control (Mamdani, 1974), fuzzy PID control (Liu et al., 2009; Zeng et al., 2021) etc. have been proposed. But it is very difficult to design an optimized controller for a nuclear reactor due to its high system complexity and nonlinearity, continuous variations of the reactor parameters with operation time and burn up levels, as well as the inevitable modeling uncertainties of real plant behaviors. In this regard, the methodology of model predictive control (MPC), which has received increased attention as a powerful tool for the control of industrial processing systems (Richalet et al., 1978; Garcia et al., 1989), was also proposed as a suitable strategy for the control of nonlinear, time-varying systems such as nuclear reactors thanks to its unique characteristic of online rolling optimization (Na, 2001; Na et al., 2003; Na et al., 2005; Liu and Wang, 2014). The basic concept of MPC is the utilization of a predictive model describing input, output, and state constraints of the objective system, to solve, at each sampling timestep, an online optimization problem to determine the optimal control actions for a finite future counting from the current time instant (Liu and Wang, 2014). However, once a future trajectory of control moves has been obtained, only the first element of that trajectory is employed as input of the controller. The same optimization calculation will be then conducted at each subsequent time instants. This method has many advantages over the conventional infinite horizon optimal control because it is a suitable control strategy for nonlinear, time-varying systems (Na et al., 2006; Eliasi et al., 2012).

It should be noted, for nonlinear, time-varying systems such as a nuclear reactor core, model predictive controller can be readily defined based on state-space model linearized at locally defined steady-state working points. However, a non-distortive description of the system dynamics can be guaranteed only in the vicinity of these points. Hence, the local predictive controller is only meaningful to system dynamic process near these specific points. Consequently, severe mismatch between the model and the actual plant will significantly worsen the control effect when the control range expands beyond these specific steady-state working points. Fortunately, the nonlinear model of a nuclear reactor core can be divided into multiple linear models according to different core power levels. The reactor power control is a typical so-called multi-model control problem, for which a fuzzy “integration” based on the T-S fuzzy theory (Takagi and Sugeno, 1985) could be employed. Nonlinear feature of the global system can be approximated by a fuzzy “integration” using multiple linear features carefully designed at specific local steady-state working points according to the so-called parallel distributed compensation (PDC) scheme. This methodology of combining model predictive control and fuzzy integration is termed in this study as the so-called fuzzy model predictive control (FMPC). The basic idea is that for each locally linearized state-space model, a MPC controller is designed. Afterwards, the overall controller, which is by its nature still nonlinear, is then obtained via a fuzzy “blending” of all the linear controllers individually designed at local steady-state working points (Ma and Sun, 2000).

In this study, the concept of FMPC was adopted to design the core-power controller of a megawatt ultra-small lithium-cooled space nuclear reactor (Song et al., 2021), which is a prototype design for the space exploration program developed in the framework of the National Key R&D Program of China. Full rated power (FP) of the liquid lithium cooled reactor core is

Fuzzy model predictive control (FMPC) is a modern intelligent control methodology combining model predictive control (MPC) (Garcia et al., 1989) and T-S fuzzy theory (Takagi and Sugeno, 1985). In this section, a brief description of model predictive control and T-S fuzzy theory will be provided.

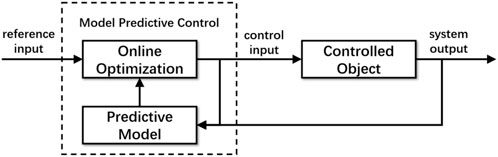

In this study, MPC algorithm with linearized state-space equations as the predictive model was adopted. According to the basic principle depicted in Figure 1, a MPC controller consists of a predictive model and an online optimization. The basic idea to calculate a sequence of optimal control moves over a certain number of future timesteps, known as the control horizon

FIGURE 1. Schematic diagram of model predictive control based on linearized state-space equations as predictive model.

Predictive model is used to predict the future output of the controlled object through its historical information, as well as the assumed future control input. In the following, derivation of the predictive model from a linear state-space model will be given. Considering a linear discrete system described by a state-space equation:

where

To predict the system output in future

The above equations are written in the vector form to finally yield:

where the definition of

Eq. 4 in vector form meets the functional requirements of a predictive model. The system state at the current moment

The basic principle of the receding horizon optimal control is depicted in Figure 2. A brief description is given in the following.

At the present time moment

(1). To determine

(2). Meanwhile, to predict future

Accordingly, the following quadratic objective function

where

If

With Eq. 7 an analytical expression of the optimal control moves

Although future

with

Reactor core power control is a typical so-called multi-model control problem. In this regard, fuzzy control is an effective method to solve multi-model control problems. The T-S fuzzy model is the most common multi-model solution used in the study of fuzzy systems describing large-scale range of linear input-output relations through the IF-THEN rule (Takagi and Sugeno, 1985).

The IF-THEN rule is used to describe the input and output relationship of the nonlinear system near specific local steady-state working point. Let the relative power

in which

For each fuzzy rule of the nuclear reactor power given in Eq. 10, the corresponding local predictive controller is designed by using the MPC method to obtain the

Where

According to the parallel distributed compensation (PDC) scheme, the global control move of the nonlinear system can be obtained by performing a fuzzy integration of

where:

The control move given in Eq. 12 is then finally the control move implemented to the nonlinear controlled object.

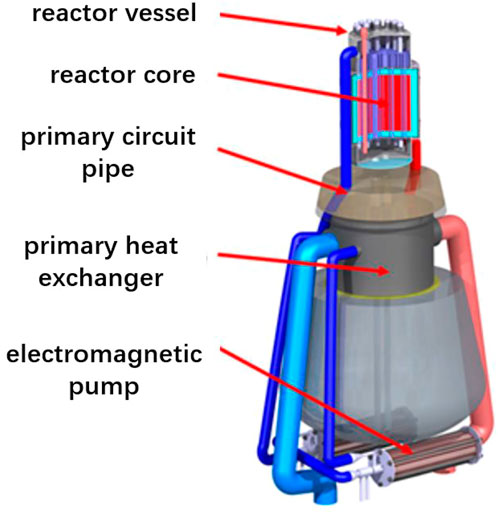

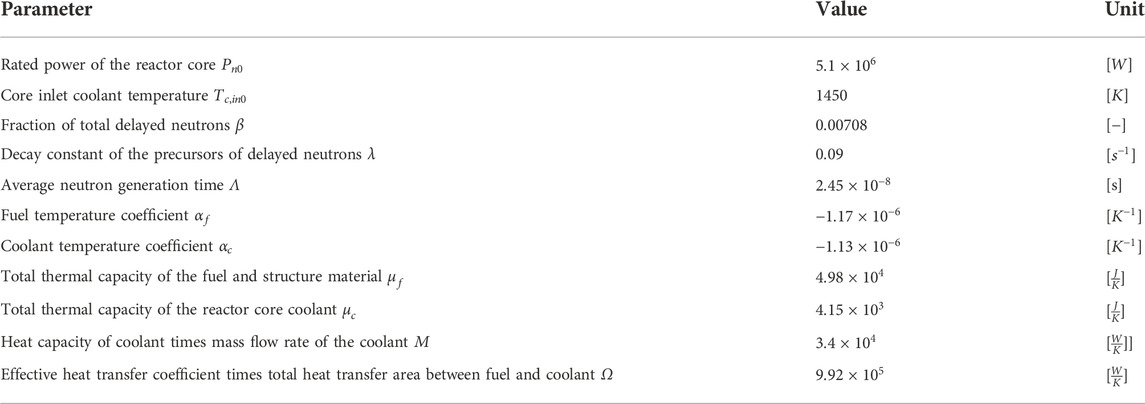

In the framework of the National Key R&D Program of China, a prototype design of a megawatt ultra-small lithium-cooled space nuclear reactor to meet the requirements of inherent safety, light weight and long lifetime for typical outer and deep space exploration missions was presented (Song et al., 2021). Principle design of the reactor core is depicted in Figure 3, which adopts liquid lithium circulated by an electromagnetic primary pump as the coolant to transfer the heat released in the reactor core to the secondary Brayton cycle via the primary heat exchanger. In this study, the basic neutronic and thermohydraulic characteristics of the liquid lithium-cooled reactor core were adopted as the object of investigation, for which the most important neutronic and thermohydraulic parameters of the reactor core model are summarized in Table 1. A brief description is also given in the following:

(1) According to the design concept, full rated power (FP) of the reactor core

(2) For simplification, all the delayed neutrons are averaged into a single group with a total fraction

(3) All the thermohydraulic characteristics of the reactor core are also considered with lumped parameters. Thermal capacity of the fuel and core coolant are simply taken as constant value. The total thermal capacity of the fuel

FIGURE 3. Schematic diagram of the ultra-small lithium-cooled space nuclear reactor (Song et al., 2021).

TABLE 1. Neutronic and thermohydraulic parameters of the core model for the lithium-cooled space nuclear reactor.

Based on the above lumped neutronic and thermohydraulic parameters, the following mathematical model describing the most essential neutronic and thermohydraulic behavior of the liquid lithium-cooled reactor core was able to be established, which yields:

In the above equation system,

(1)

(2)

(3)

(4) Temperature of the fuel and coolant are described with lumped parameters, including the average fuel temperature

(5) The total reactivity of the reactor core

in which

Due to the feedback reactivity by fuel and coolant temperature as given in Eq. 15, the reactor core model established in Eq. 14 describing the most essential neutronic and thermohydraulic behavior of the liquid lithium-cooled reactor core is, by its nature, a nonlinear equation system. Before designing a core-power controller according to the concept of model predictive control, the reactor core model needs to be first linearized, for which the following consideration were taken:

(1) At a given moment

(2) For a steady state, reactivity of the reactor core is zero, it will yield:

(3) When the reactor core is subjected to an external disturbance, assuming that the core inlet coolant temperature is unchanged, it will yield:

With the above assumptions, the reactor core model given in Eq. 14 is linearized at the steady-state working point

Furthermore, the state-space variables

Finally, the linearized model is given as:

where the coefficients

Eq. 18 with the coefficients given in Eq. 19 is the form of the linearized reactor-core model at the steady-state working point characterized by

The coefficients

in which

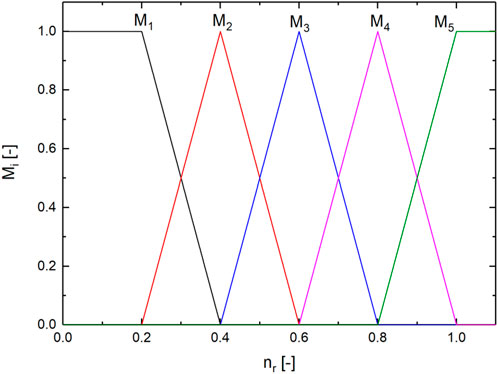

According to the concept of FMPC introduced in Section 2, a “fuzzy” integration of several locally defined MPC controllers at different steady-state working points characterized by different power levels

FIGURE 4. Definition of the five membership functions

To assess the performance of the designed FMPC core-power controller, simulations were performed in this study within the Simulink platform embedded in MATLAB software. Simulink block diagram including the five local MPC controllers and the fuzzy integration for the global FMPC controller is then depicted in Figure 5. A brief description of the block diagram is given in the following:

(1) First, it should be noted, since neither an actual lithium-cooled space reactor, nor a full-scope simulator of the reactor are available for the present study, the nonlinear reactor core model derived in Section 3 (Eq. 14 with the corresponding parameters summarized in Table 1) was used in the Simulink simulations as the controlled object, i.e., the module “NuclearReactor” in Figure 5.

(2) The desired relative core power is displayed in the module “Reference” as depicted in Figure 5, while the actual relative core power

(3) The corresponding local MPC controllers designed for the five selected local state points are designated in Figure 5 with the modules “mpc20,” “mpc40,” “mpc60,” “mpc80,” and “mpc100”, respectively. Construction of the five MPC controllers share the same principle with two inputs “ref” and “mo,” and one output “mv.” “ref” is the desired reference core power, while “mo” is the feedback deviation between the reference core power and the actual core power. For each of the five local MPC controller, its output signal “mv” will then be multiplied with its individual weighting factor, followed by a summation of all the five weighted signals to finally obtain the global control signal for the nonlinear “NuclearReactor”, i.e., “Reactivity” in Figure 5.

(4) The module “Disturbance” depicted in Figure 5 will be used only for the simulation of the disturbance transient, in which a finite reactivity will be added to the reactor core to simulate the case of the reactor core affected by an external disturbance reactivity. For the ramp and step transients, the disturbance reactivity is by default zero.

To verify and assess the performance of the FMPC controller, the following five transient operation conditions representative to a space nuclear reactor were defined and investigated in this study. In all the transients, the reactor core was initially assumed at the steady state of

(1) Local ramp transient: 1

(2) Global ramp transient:

(3) There are various unforeseen uncertainties in the space nuclear reactor in the space environment. In the most extreme emergency cases, the reactor core power needs to be reduced to a certain low level as soon as possible to only maintain the necessary power supply needed by the nuclear reactor itself. Therefore, an emergency transient of

(4) Besides the above three transients of ramp change, a step transient was also defined with

(5) Last but not the least, a disturbance transient was also defined, in which an external

In all the above five transient operation conditions, the desired objective of the FMPC controller is to enable the reactor core to follow the desired reference power as close as possible during the respective ramp, step or disturbance transient. Figures 6–15 show then the response of the FMPC controller. The adjustment time of the FMPC controller is defined in this study as the total time required for the absolute overshoot of larger than

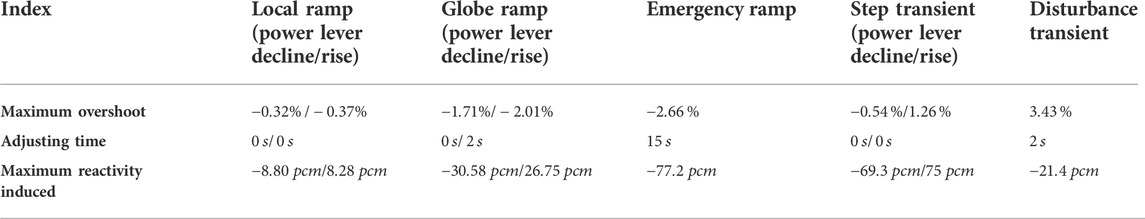

(1) Figure 6 shows the FMPC control effect for the local ramp transient, during which an excellent load-following performance of the reactor core power was established with the FMPC controller. On contrary, the control effect of PID shows a much higher overshoot. An obvious oscillation of the controlled power was also observed, which is not present with the FMPC controller. As depicted in the enlarged views of Figures 7A,B, with the FMPC controller, the maximal overshoot for the power declining and power rising local ramp change are

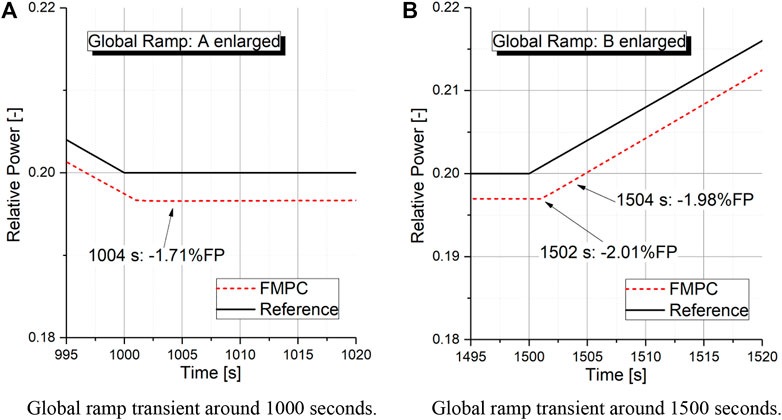

(2) Figure 8 shows then the FMPC control effect for the global ramp transient. Like the local ramp transient, the FMPC controller also shows an excellent load-following ability better than PID controller. With the FMPC controller, the maximal overshoot for the power declining global ramp change, as shown in Figure 9A, is

(3) Figure 10 shows the FMPC control effect for the emergency fast ramp transient. Overall, the actual power level follows well that of the desired reference level. Again, the control effect of the FMPC controller is better than PID controller with smaller overshoot and less adjusting time. The maximum reactivity introduced by the FMPC controller occurs around 300 s, where the reactor power reaches the desired level of

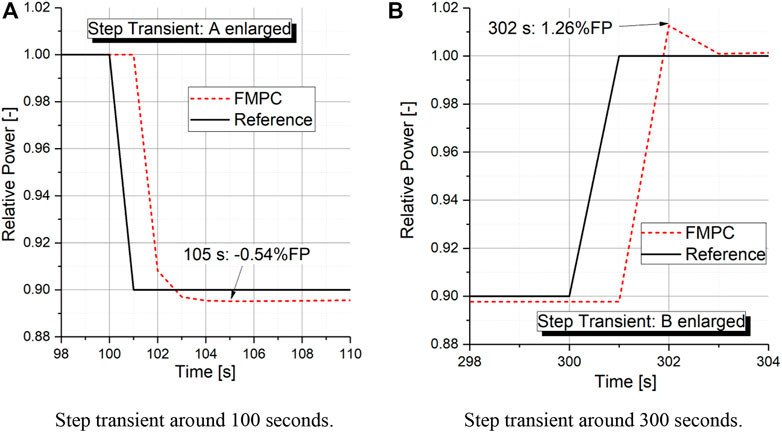

(4) Figure 12 shows the FMPC control effect for the step transient. Like the ramp transients, the FMPC controller also shows an excellent load-following ability. With the PID controller, on the other hand, the core power experienced an obvious oscillation and much larger overshoot than with the FMPC controller. As observed in the two enlarged views of the area A and B in Figures 13A,B, with the FMPC controller, the maximal overshoot for the power declining and power rising step change are

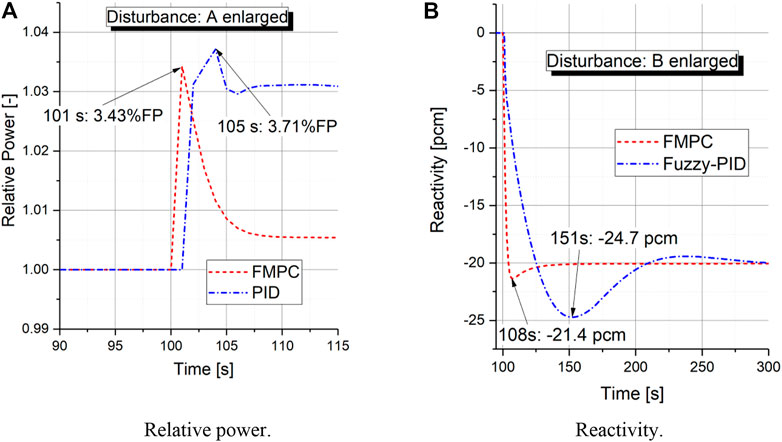

(5) Figure 14 shows the control effect for the disturbance transient, in which a

FIGURE 7. Enlarged view of the area A and B for the local ramp transient. (A) Local ramp transient around 100 s. (B) Local ramp transient around 250 s.

FIGURE 9. Enlarged view of the area A and B for the global ramp transient. (A) Global ramp transient around 1,000 s. (B) Global ramp transient around 1,500 s.

FIGURE 13. Enlarged view of the area A and B for the step transient. (A) Step transient around 100 s. (B) Step transient around 300 s.

FIGURE 15. Enlarged view of the area A and B for the disturbance transient. (A) Relative power. (B) Reactivity.

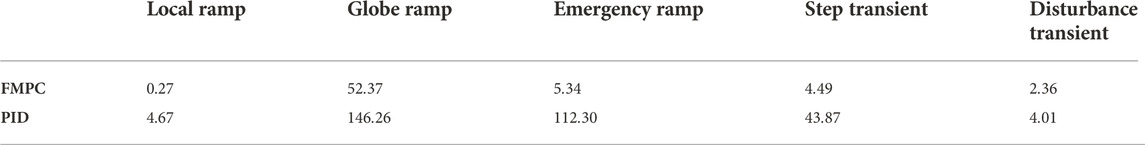

Furthermore, the integral time-squared error (ITSE) was applied to evaluate the performance of the FMPC controller and PID controller in each of the above five simulations according to:

where

TABLE 2. ITSE values of the FMPC controller and PID controller for the five simulated transient operation conditions.

Finally, to better demonstrate the control effect of the FMPC controller, Table 3 summarizes the most important performance indices of the FMPC controller, including maximal overshoot, adjusting time and maximal reactivity induced for the five investigated transient operation conditions. In conclusion, the core-power controller designed based on fuzzy model predictive control can fulfill various load-following control tasks under typical transient working conditions of the lithium-cooled space nuclear reactor. Furthermore, the fuzzy model predictive control shows also a certain anti-interference capability.

TABLE 3. Performance indices of the FMPC controller for the five simulated transient operation conditions.

In this study, a fuzzy model predictive control based on model predictive control and T-S fuzzy theory was designed for the core-power control of a megawatt ultra-small lithium-cooled space nuclear reactor. Firstly, neutronic and thermohydraulic behaviors of the lithium-cooled reactor core described by nonlinear state-space equations were linearized at five steady-state working points characterized by relative core power of

Although investigations in this study were conducted for a simplified neutronic and thermohydraulic model of a lithium-cooled space nuclear reactor, it successfully demonstrates the feasibility of fuzzy model predictive control to design sophisticate and effective core-power controller also for typical nonlinear and time-varying nuclear reactors with a fast neutron spectrum. The design method adopted in this study for the core-power controller can be readily extended to other designs of space nuclear reactors, provided more in-depth detailed specifications of specified designs are become available in the future. Nevertheless, it should be pointed out, physical constraints regarding driving mechanism of the control rods are not available for the prototype design of the lithium-cooled space nuclear reactor. Therefore, control constraint is not considered in the FMPC controller designed in this study, which, however, should be included in further investigations if the driving mechanism of the control rods become available. Furthermore, applicability of the fuzzy model predictive control is still worthy further investigations for a wide range of realistic working scenarios of space nuclear reactors, especially for those scenarios of large and abrupt disturbances to the reactor, provided they are become available in the future.

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

YY—Conceptualization; Methodology; Project administration; Writing—original draft preparation; Funding acquisition; ZY—Software; Investigation; Data Curation; Visualization; Writing—original draft preparation; BP—Methodology; Writing—original draft preparation; Writing—review and editing; Funding acquisition; YX—Software; Data Curation; Visualization; YD—Software; Writing—review and editing; Project administration.

This work was financially supported by the University Stability Support Program of Shenzhen (Grant No. 20200803132736020) and the National Key R&D Program of China (Grant No. 2018YFB19006).

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Akimov, V. N., Koroteev, A. A., and Koroteev, A. S. (2012). Space nuclear power systems: Yesterday, today, and tomorrow. Therm. Eng. 59 (13), 953–959. doi:10.1134/s0040601512130022

Baraskar, A., Yoshimura, Y., Nagasaki, S., and Hanada, T. (2022). Space solar power satellite for the Moon and Mars mission. J. Space Saf. Eng. 9 (1), 96–105. doi:10.1016/j.jsse.2021.10.008

Bennett, G. L., Hemler, R. J., and Schock, A. (1996). Status report on the U.S. Space nuclear program. Acta Astronaut. 38 (4–8), 551–560. doi:10.1016/0094-5765(96)00038-0

Demuth, S. F. (2003). SP100 space reactor design. Prog. Nucl. Energy 42 (3), 323–359. doi:10.1016/s0149-1970(03)90003-5

Ehrenfreund, P., McKay, C., Rummel, J. D., Foing, B. H., Neal, C. R., Masson-Zwaan, T., et al. (2012). Toward a global space exploration program: A stepping stone approach. Adv. Space Res. 49 (1), 2–48. doi:10.1016/j.asr.2011.09.014

Eliasi, H., Menhaj, M. B., and Davilu, H. (2012). Robust nonlinear model predictive control for a PWR nuclear power plant, Prog. Nucl. Energy, 54, 177–185.

Garcia, C. E., Prett, D. M., and Morari, M. (1989). Model predictive control: Theory and practice - a survey. Automatica 25 (3), 335–348. doi:10.1016/0005-1098(89)90002-2

Harty, R. B., and Mason, L. S. (1993). 100-kWe Lunar/Mars surface power utilizing the SP-100 reactor with dynamic conversion. AIP Conf. Proc. 271 (2), 1065–1071. doi:10.1063/1.43087

IAEA (2002). The role of nuclear power and nuclear propulsion in the peaceful exploration of space. Vienna, Austria: International Atomic Energy Agency.

Jin, Z., Wang, C., Liu, X., Dai, Z., Tian, W., Su, G., et al. (2022). Operation and safety analysis of space lithium-cooled fast nuclear reactor. Ann. Nucl. Energy 166, 108729. doi:10.1016/j.anucene.2021.108729

Liu, C., Peng, J. F., Zhao, F. Y., and Li, C. (2009). Design and optimization of fuzzy-PID controller for the nuclear reactor power control. Nucl. Eng. Des. 239 (11), 2311–2316. doi:10.1016/j.nucengdes.2009.07.001

Liu, X., and Wang, M. (2014). Nonlinear fuzzy model predictive control for a PWR nuclear power plant. Math. Problems Eng. 2014, 1–10. doi:10.1155/2014/908526

Ma, X. J., and Sun, Z. Q. (2000). Output tracking and regulation of nonlinear system based on takagi– Sugeno fuzzy model. IEEE Trans. Syst. Man. Cybern. B 30 (1), 47–59. doi:10.1109/3477.826946

Mamdani, E. H. (1974). Application of fuzzy algorithms for control of simple dynamic plant. Proc. Inst. Electr. Eng. UK. 121 (12), 1585–1588. doi:10.1049/piee.1974.0328

Marov, M. Y., and Slyuta, E. N. (2021). Early steps toward the lunar base deployment: Some prospects. Acta Astronaut. 181, 28–39. doi:10.1016/j.actaastro.2021.01.002

McNutt, R. L., and Ostdiek, P. H. (2015). Nuclear power assessment study final report. Laurel, MD: The Johns Hopkins University Applied Physics Laboratory.

Na, M. G. (2001). Design of a receding horizon control system for nuclear reactor power distribution. Nucl. Sci. Eng. 138, 305–314. doi:10.13182/nse01-a2216

Na, M. G., Shin, S. H., and Kim, W. (2003). A model predictive controller for nuclear reactor power. Nucl. Eng. Technol. 35 (5), 399–411.

Na, M. G., Jung, D. W., Shin, S. H., Wook Jang, J., Lee, K. B., and Lee, Y. J (2005). A model predictive controller for load-following operation of PWR reactors. IEEE Trans. Nucl. Sci. 52 (4), 1009–1020. doi:10.1109/tns.2005.852651

Na, M. G., Hwang, I. J., and Lee, Y. J. (2006). Inferential sensing and monitoring for feedwater flowrate in pressurized water reactors. IEEE Trans. Nucl. Sci. 53 (3), 2335–2342. doi:10.1109/tns.2006.878159

Richalet, J., Rault, A., Testud, J. L., and Papon, J. (1978). Model predictive heuristic control: Applications to industrial processes. Automatica 14, 413–428. doi:10.1016/0005-1098(78)90001-8

Song, Y., Zhou, T., Jiang, J., Liu, C., Wang, L., Tan, P., et al. (2021). Progress and prospects on lithium cooled space nuclear reactor power. China Basic Sci. 21 (3), 21–50.

Takagi, T., and Sugeno, M. (1985). Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man. Cybern. 15 (1), 116–132. doi:10.1109/tsmc.1985.6313399

Zeng, E., Jiang, Q., Liu, Y., Yan, S., Zhang, G., Yu, T., et al. (2021). Core power control of a space nuclear reactor based on a nonlinear model and fuzzy-PID controller. Prog. Nucl. Energy 132, 103564. doi:10.1016/j.pnucene.2020.103564

Zhao, Z., Jiang, X., Wang, L., and Chen, L. (2012). Neutronics characteristic of conceptual space lithium cooled fast neutron reactor. Atomic Energy Sci. Technol. 46, 374–378.

Keywords: model predictive control, T-S fuzzy theory, fuzzy model predictive control, lithium-cooled space nuclear reactor, core-power control

Citation: Yin Y, Yuan Z, Pang B, Xiao Y and Deng Y (2023) Design and assessment of a core-power controller for lithium-cooled space nuclear reactor based on the concept of fuzzy model predictive control. Front. Energy Res. 10:1067892. doi: 10.3389/fenrg.2022.1067892

Received: 12 October 2022; Accepted: 07 November 2022;

Published: 17 January 2023.

Edited by:

Peiwei Sun, Xi’an Jiaotong University, ChinaReviewed by:

Zhou Shiliang, North China Electric Power University, ChinaCopyright © 2023 Yin, Yuan, Pang, Xiao and Deng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yangbin Deng, ZGVuZ3lhbmdiaW5Ac3p1LmVkdS5jbg==

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.