- 1School of Food and Biological Engineering, Jiangsu University, Zhenjiang, Jiangsu, China

- 2Department of Bioproducts and Biosystems, Aalto University, Espoo, Finland

- 3Center of Excellence in Environmental Studies (CEES), King Abdulaziz University, Jeddah, Saudi Arabia

- 4Sustainable Development Study Centre (SDSC), Government College University, Lahore, Pakistan

- 5School of Chemical Engineering, Zhengzhou University, Zhengzhou, China

- 6Centre for Technology in Water and Wastewater, School of Civil and Environmental Engineering, University of Technology Sydney, Sydney, NSW, Australia

- 7Mechanical Engineering Department, Prince Mohammad Bin Fahd University, Al Khobar, Saudi Arabia

Editorial on the Research Topic

Design and application of biocatalysts for biofuel and bio-based material production

Introduction

Biological conversion of waste and biomass streams into green products (e.g., biofuels, value-added chemicals, and biobased polymers) has been a core research area over the past two decades. Microorganisms, consisting of a broad range of natural and genetically modified strains, play the central role in biocatalysis. In addition, process engineering, optimization, and technological developments play a significant role in obtaining a high-throughput biocatalysis approach. Furthermore, researchers are trying to develop high-performance biocatalysts and efficient bioprocesses with advances in the micro-environment engineering of enzymes and microorganisms. However, biobased conversion technologies are still limited by the low performance of biocatalysts, low tolerance, accumulation of toxic intermediates, instability of enzymes, and techno-economic feasibility. Therefore, multidisciplinary and multidimensional efforts are required to overcome these barriers.

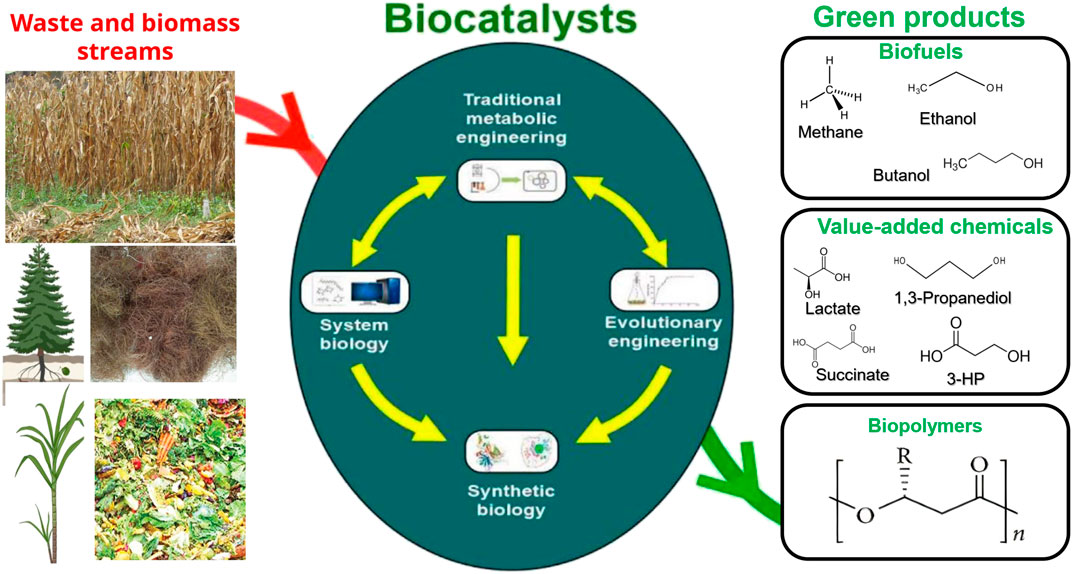

This Research Topic (RT) aims to provide insight into recent advances in biocatalysts and bioprocesses through related works according to the design shown in Figure 1. With a total of 6 compiled articles, this RT offers an up-to-date overview of the metabolic pathways, biocatalysts, conversion strategies, and optimization techniques to produce high-quality biofuels and value-added products from various biomass and waste sources. The published articles are written by researchers and academics affiliated with various prestigious institutions worldwide, including Australia, Saudi Arabia, Bangladesh, United Arab Emirates, Malaysia, Iran, China, Egypt, and Pakistan. The editorial team would like to thank all authors for their valuable contributions and for making this RT successful.

FIGURE 1. Exploitation of biocatalysts in the bioconversion of waste and biomass streams into green products.

Biomass and waste streams for biofuels and value-added products

Over the past two decades, many biomass and waste resources have been studied for producing biofuels and biobased chemicals, broadly divided into 1G to 3G, with 3G (e.g., microalgae) being more attractive in the current biorefinery research. This is because microalgae are not only promising feedstocks for biofuels and value-added compounds, but they can also capture CO2 as an essential nutrient for their growth. However, economic challenges still limit the large-scale exploitation of microalgae-based biorefineries, particularly for the cost-intensive cultivation step and low biomass yield. In this context, Rafa et al. reviewed key challenges of 3G biofuel production and highlighted the cost-effective strategies to address these challenges. According to their analysis, priority should be given to combining microalgae and aquaculture farming in wastewater to decrease biomass production costs and coproduce high-value multi-products to achieve a cost-effective 3G biorefinery. For example, the production costs of biodiesel can be reduced to $0.73 kg−1 biomass by growing microalgae in wastewater or to $0.54 L−1 by coproducing biodiesel with value-added products.

In another article, Barati et al. presented their research on CO2 sequestration by two microalgae strains of Chlamydomonas under tobacco smoke conditions. According to this novel study, tobacco smoke showed no negative effects on the growth of Chlamydomonas. At the same time, there was a decrease in the lipid content of biomass and a change in the degree of unsaturation and the amount of carbon double bonds in the biodiesel. This study is expected to attract further efforts to elucidate the effects of tobacco smoke on lipid biosynthetic pathways and associated genes, which will address the adverse effects on lipid biosynthesis and biodiesel quality. Microalgal biomass also has potential for biohydrogen production, although this bioprocess faces key technological, economic, and environmental challenges in its commercial exploitation. Ahmed et al. reviewed different biohydrogen production pathways from microalgae, where biophotolysis and electrochemical pathways showed high efficiency (80–90%) while fermentation and photo-biocatalytic routes were found more environmentally benign. Nevertheless, the production cost of biohydrogen is quite high, ranging from $1.42 to $7.24 kg−1 for biophotolysis and $7.54 to $7.61 kg−1 for fermentation. Therefore, further efforts are needed to develop cost-effective technologies for producing sustainable biohydrogen from microalgae.

Low performance and tolerance issues of biocatalysts

The performance of biocatalysts in converting particularly lignocellulosic wastes into biofuels and biochemicals is often challenged by several issues, including the inability to metabolize pentose and hexose sugars simultaneously and the toxic effects of various stressors. With advances in the tools of metabolic engineering and synthetic biology, multiple sugar-fermenting strains have now been made a reality and successfully used in the co-fermentation of hemicellulose- and cellulose-derived sugars. However, the performance of biocatalysts in lignocellulosic biorefineries is still limited by their poor tolerance to inhibitors, end products, metabolic intermediates, and physicochemical factors. The complex metabolic responses to these stressors and the poor understanding of the associated pathways or genes are the major limitations in successfully addressing these issues. In this context, omics-based studies can be promising research strategies to unveil the genetic and metabolic changes under a given stress condition. This could open a horizon for developing high-tolerant strains through directed metabolic engineering. Xu et al. published a detailed review on omics-based strategies to overcome the tolerance issues of an ethanologenic yeast. In this review, recent omics-based studies to improve tolerance to ethanol, inhibitors, oxidative stressors, and thermal tolerance have been critically analyzed and presented.

Bioprocess optimization and technoeconomic analysis

Upstream biomass processing and biocatalyst development often follow a midstream process, such as fermentation and anaerobic digestion, in which biocatalysts convert biomass-derived substrates into target products. However, it is well known that the performance of the midstream process is severely affected by various factors. As a result, it is necessary to establish optimum conditions to improve the bioprocesses’ overall conversion efficiency and production matrices (e.g., titer, productivity, and yield). In this context, a mini review on anaerobic digestion by Inayat et al. would be excellent for understanding the factors affecting this midstream process and strategies for its simulation and optimization. Besides optimization, a biorefinery process’s techno-economic analysis (TEA) is also important to evaluate the approximate costs before its large-scale exploitation. Ahmed et al. provided an overview of TEA for biohydrogen production, which might be useful for understanding the basic strategies and methods for the TEA of any biorefinery process.

Conclusion and outlook

In recent years, the development of biocatalysts and bioprocesses has received significant attention for converting various biomass and waste streams into biofuels and biochemicals. However, biocatalysts that play central roles in bioprocess technologies must be robust, stable, and high-tolerant to achieve a sustainable conversion technology. Likewise, optimizing the midstream processes is equally important to make biobased production technologies competitive with contemporary approaches. This RT has published 6 high-quality articles that provide insights into the related metabolic pathways and omics-based system metabolic features of the strains, bioprocesses optimization, and TEA. This will provide a common understanding and a platform for further research efforts to develop high-performance, stable, high-tolerant biocatalysts and optimal and efficient bioprocesses.

Author contributions

HZ, SB, MR, A-SN, MA, and MX contributed to the conception and design of the study. HZ wrote the first draft, while other authors reviewed this draft with necessary corrections or additions. All authors have read the manuscript and approved the submitted version.

Funding

The authors are thankful to the Foreign Expert Program, Ministry of Science and Technology, China (No. QNJ20200214015 and QN2022014005L), and the Innovation and Entrepreneurship Program of Jiangsu Province (No. SSCBS20210929).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Keywords: biocatalysis, biomass processing, bioconversion, biobased chemical, bioenergy

Citation: Zabed HM, Bankar SB, Rehan M, Nizami A-S, Alam MA and Mofijur M (2022) Editorial: Design and application of biocatalysts for biofuel and bio-based material production. Front. Energy Res. 10:1030795. doi: 10.3389/fenrg.2022.1030795

Received: 29 August 2022; Accepted: 05 September 2022;

Published: 26 September 2022.

Edited and reviewed by:

Haiping Yang, Huazhong University of Science and Technology, ChinaCopyright © 2022 Zabed, Bankar, Rehan, Nizami, Alam and Mofijur. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Hossain M. Zabed, emFiZWRjdGdiZEB5YWhvby5jb20=, emFiZWRAdWpzLmVkdS5jbg==

Hossain M. Zabed

Hossain M. Zabed Sandip B. Bankar

Sandip B. Bankar Mohammad Rehan

Mohammad Rehan Abdul-Sattar Nizami

Abdul-Sattar Nizami Md. Asraful Alam

Md. Asraful Alam M. Mofijur

M. Mofijur