95% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Energy Res. , 03 December 2021

Sec. Advanced Clean Fuel Technologies

Volume 9 - 2021 | https://doi.org/10.3389/fenrg.2021.796786

This article is part of the Research Topic Recent Advances in High-efficiency Development of Conventional/Unconventional Gas Reservoirs and CCUS Technologies View all 51 articles

In light of the difficulty of solid-liquid separation of waste PEM drilling fluid in the Bohai oilfield, constructing an inorganic-organic flocculation system is proposed and the processing method of destabilization technology is optimized. The biggest influence factor on the flocculation process of PEM drilling fluid was determined by designing an orthogonal test. The flocculation mechanism was researched through single factor optimization, combined with zeta potential and particle size distribution test. The results showed that the most significant factors affecting the flocculation of waste PEM drilling fluid were the dosage of inorganic flocculant CaCl2 and flocculation pH value. When the dosage of inorganic flocculant CaCl2 was 1.2% (w/v), the dosage of organic flocculant SDYJ-2 was 0.05%, the flocculation pH value was 3, and the flocculation time was 5 min, the flocculation technology reached the optimization and then the liquid yield can reach 70.96%. The mechanism of flocculation and destabilization was as follows: the inorganic flocculant of CaCl2 mainly reduced the zeta potential of clay particles through electric neutralization. 1% CaCl2 could reduce the potential mean value of drilling fluid system from -38.1 mV to -32.5 mV, and then decrease the repulsion among suspensions. Through bridging curling and electric neutralization, the organic flocculant of SDYJ-2 can absorb and wrap the clay particles after flocculation destabilization to form a network spatial structure, which made clay particles aggregate into large flocs and particles. D50 can increase by 21.5 times, when the concentration of SDYJ-2 was 0.15%.

Bohai Sea is the only semi-enclosed inland sea body in China, and the ecological environment has a serious impact on the daily life of coastal residents. With the increasingly strict requirements for environmental protection, more attention has been paid to the effective disposal of waste drilling fluid by offshore drilling (Malachosky et al., 1993; Hou-ming et al., 2012). Solid-liquid separation is one of the best methods for environmental protection due to the limitation of spatial position on offshore drilling (Wang et al., 2021). Currently, PEM drilling fluid is used in most areas of Bohai oilfield, including the advantages of low filtration loss, rheology, thermal stability, and good inhibition (Xun et al., 2011; Paul et al., 2020). However, PEM drilling fluid has high polymer content and high solid content, which make the drilling fluid system remarkably stable (Shaocheng et al., 2001; Fan et al., 2011). Wai Li et al. (Li et al., 2017) studied the solid-liquid separation technology based on chemical flocculation and centrifugation, and comprehensively investigated the effects of flocculant type, concentration, and treatment conditions on the separation degree of drilling fluid. Zhou JL et al. (2012) carried out solid-liquid separation of waste drilling fluid by centrifugation and adding surfactant, and studied the ability of surfactant enhanced washing to treat the waste drilling fluid and remove the hazardous hydrocarbons. Wang Youhua et al. (Cui et al., 2011) applied low pressure distillation technology to solid-liquid separation of drilling fluid. This process mainly contains such three steps as chemical destabilization, fold and spiral dehydration, and low pressure distillation. Field analysis results of disposed water have shown that the content of fluoride, heavy metals, oil, COD, BOD, and chromaticity can reach the class II water quality requirements of China national standards. In order to improve the flocculation destabilization efficiency and simplify the field construction for the characteristics of waste PEM drilling fluid in Bohai oilfield, this paper proposes to build an inorganic organic flocculation system, optimize the optimal treatment methods of different flocculation destabilization processes, and analyze its flocculation destabilization mechanism for waste PEM drilling fluid in Bohai oilfield.

Polyferric chloride (PFC), polyaluminum chloride (PAC-1, liquid), polyferric chloride sulfate (SPFS), polyferric chloride (PFC), polyferric sulfate (PFS), and polyaluminum chloride (PAC-2, solid) were obtained from Zibo Heying Water Purification Materials Co., Ltd. (China). CaCl2 (analytical grades) was provided by Sinopharm Chemical Reagent Co., Ltd. (China). There were SDYJ-1 emulsion, SDYJ-2 emulsion, SDYJ-3 emulsion, and SDYJ-4 emulsion, which were configured in the laboratory. Citric acid (analytical grades) and NaOH (analytical grades) were purchased from Aladdin Chemistry Co., Ltd. (China). The waste PEM drilling fluid used in the experiment was taken from the offshore drilling platform of Bohai oilfield, and the basic parameters were shown in Table 1.

Medium pressure water loss instrument and high-speed frequency conversion stepless speed mixer were purchased from Qingdao Tongchun Petroleum Instrument Co., Ltd. (China). ZNN-D68 electric six-speed viscometer was supplied by Qingdao Haitongda Special Instrument Co., Ltd. (China). TA6-3 program-controlled coagulation test mixer was provided by Wuhan Hengling Technology Co., Ltd (China). GT10-1 high-speed Bench Centrifuge was obtained from Beijing Shidai Beili Centrifuge Co., Ltd. (China). PHS-3 C T precision desktop pH meter was produced by Shanghai Dapu Instrument Co., Ltd. (China). There were beakers (150 ml), measuring cylinders (10 ml, 50, and 100 ml), and glass rods.

In the first, the method of flocculation sedimentation was applied to the waste PEM drilling fluid. A total of 100 ml of waste PEM drilling fluid taken in the beaker, and placed it in the TA6-3 program-controlled coagulation test mixer. Then the flocculant was added under high-speed stirring at 450 rpm, which was mixed evenly for 3 min after slowly stirring at 50 rpm for 3 min, and finally stood for 30 s. This was followed by the centrifugal experiment. The drilling fluid after flocculation standed was placed in the GT10-1 high-speed bench top centrifuge at the rate of 3000 rpm for 3 min. Thereafter, the volume of the supernatant was measured and the liquid yield for the waste PEM drilling fluid can be obtained by Equation (1).

where f is the liquid yield, V1 is the volume of liquid phase removed from drilling fluid, mL, and V2 is the initial drilling fluid volume, mL.

The waste PEM drilling fluid contained many gel protecting agents, which increased the solid content of surfactant in the drilling fluid and made them more difficult to flocculate and destabilize. The colloidal stability of the drilling fluid system was destroyed through adding flocculants which changed the physical and chemical properties of the drilling fluid. Promote the suspended particles in the drilling fluid to agglomerate into large flocs, separated by solid and liquid through centrifuge. Therefore, different flocculation and destabilization processes are carried out to study and analyze the flocculation effect of waste PEM drilling fluid.

CaCl2 (inorganic flocculant) and 30% cationic SDYJ-2 emulsion (organic flocculant) were designed as flocculating agent. There were four factors including CaCl2 dosage (A/(%)), SDYJ-2 emulsion dosage (B/(%)), flocculation agitation time (C/(s)), and flocculation pH value (D). In addition, each factor contained 3 levels, the factor level table is shown in Table 2.

The factors were arranged on the L9 34 orthogonal table, and then translated into the test scheme table, as shown in Table 3.

The liquid yield was taken as the reference index (Table 4) by means of the orthogonal test.

It can be obtained from Table 4 that the order of influence on the treatment of waste PEM drilling fluid was: inorganic flocculant dosage > pH > flocculation mixing time > organic flocculant dosage. Therefore, the experimental study on the optimal dosage of inorganic flocculant and flocculation pH value was carried out.

Figure 1 shows CaCl2 has an obvious effect on flocculation destabilization. When the CaCl2 dosage is less than 1.2%, with the increase of CaCl2 dosage, the liquid yield of waste PEM drilling fluid increases slowly after solid-liquid separation. For CaCl2 addition the amount was less than 1.2%, with the increase of CaCl2 dosage, the liquid yield of waste PEM drilling fluid increases slowly after solid-liquid separation. The liquid yield reaches the highest value with 63.33% for the CaCl2 addition reached 1.2%. The liquid yield showed a downward trend with the CaCl2 addition above 1.2%. Therefore, the optimum dosage of CaCl2 was 1.2%.

The experimental results of different flocculation pH for flocculation destabilization were shown in the Figure 2. The flocculation destabilization efficiency of waste PEM drilling fluid was significantly better in acidic conditions than in alkaline conditions. Under acidic conditions, with the decrease of flocculation pH value, the liquid yield increased linearly and increases greatly. In addition, when the flocculation pH value was 3, the liquid yield can reach 70.96%. The liquid yield decreases slowly with the increase of flocculation pH value under alkaline conditions.

The addition of Ca2+ can neutralize the negative charge in the waste PEM drilling fluid, so as to reduce the negative charge on the surface of clay particles and Zeta potential in the drilling fluid, resulting in the reduction of repulsion between clay particles. When the dosage of Ca2+ was too large, Ca2+ entered the adsorption layer on the particle surface, making the clay particles positively charged, and the potential changed from negative to positive, resulting in “re-charged” clay particles. The drilling fluid was again stabilized by reverse gelling and the liquid yield will show a downward trend (Zhang et al., 2005).

Because the waste PEM drilling fluid contained some organic emulsifying functional groups, the change of flocculation pH value caused the phenomenon of “inactivation” of the organic emulsifying functional groups, and the drilling fluid lost its stability under the original conditions (Hu et al., 2017). When H+ was added to PEM drilling fluid, the negative charge on clay surface can be neutralized, and the dispersive emulsification ability of organic functional groups was weakened, resulting in instability of colloidal system, local shrinkage, cementation, and dehydration of the drilling fluid. When the flocculation pH value was greater than 7, the increase of flocculation pH value created an alkaline condition for the PEM drilling fluid, which increased the Zeta potential between clay particles and the repulsive force between clay particles, making it difficult for clay particles to condense (Xie et al., 2011).

The Zeta potential of the waste PEM drilling fluid system was high, and the system was stable (Table 5), indicating that natural sedimentation and stratification will not occur. The Zeta potential of the clay particles of the system was decreased due to the addition of inorganic flocculants, reducing notably system stability. Among them, the inorganic flocculant CaCl2 had the greatest influence on the Zeta potential of the system with the average value to -32.5 mV and the standard deviation to ±0.656 mV. With the increase of the concentration of CaCl2, the Zeta potential of the drilling fluid system gradually decreased. In Table 6, the addition of concentration of CaCl2 reached 2%, the Zeta potential of the system with the average value was -29.03 mV, and the standard deviation was ±0.90 mV.

The small increase in particle size in PEM drilling fluid was accompanied by the addition of inorganic flocculants, which makes the system easier to flocculate to a certain extent (shown in Tables 7 and 8). The solid phase in the lower part of the flocculated drilling fluid is made and the floc morphology is observed under the microscope, as shown in Figures 3 and 4. The floc particle distribution of PEM drilling fluid treated with inorganic flocculant is relatively loose and has no trend of connection. Combined with the Zeta potential test results, it indicated that the inorganic flocculant mainly reduces the Zeta potential of the system through electric neutralization, reducing the stability of the PEM drilling fluid system.

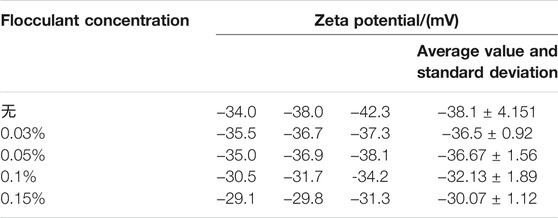

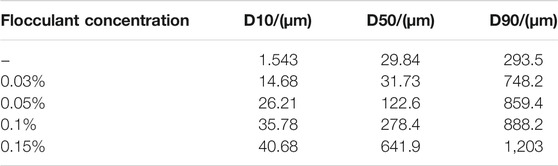

Polyacrylamide emulsions with different cationic degrees have no obvious effect on the zeta potential of the PEM drilling fluid system because of the small amount of organic flocculants, and the Zeta potential decreased slightly and slightly fluctuated as shown in Tables 9 and 10. The organic flocculant remarkably increases the particle size distributed in the PEM drilling fluid, which was more conducive to the flocculation and sedimentation of the system. In addition, as the cationic degree of the organic flocculant increases, the particle size also increases. Tables 11 and 12 showed that with the increase of SDYJ-2 emulsion concentration, the overall trend of the Zeta potential gradually decreased and the particle size increased gradually. After the lower solid phase is made, it is observed under the microscope. As shown in Figure 5, the drilling fluid particles are connected with each other to form a network structure, which is more prone to flocculation and sedimentation. When the concentration of SDYJ-2 is 0.15%, the D50 increases by 21.5 times. Jointing the Zeta potential test results, it shows that the organic flocculant mainly helps the system destabilization through bridging connection, and also partially reduces the Zeta potential of the system through electric neutralization, so as to reduce the stability of the PEM drilling fluid (Xue et al., 2008).

TABLE 11. Effect of SDYJ-2 emulsion with different concentrations on the Zeta potential of PEM drilling fluid.

TABLE 12. Effect of SDYJ-2 emulsion with different concentration on particle size distribution of PEM drilling fluid.

1) The CaCl2 dosage and flocculation pH value had the remarkable influence on the flocculation and destabilization of PEM mud through the orthogonal test, and the optimal flocculation conditions are optimized. The deliquid rate of flocculation destabilization can reach 70.96%.

2) The Zeta potential of the waste PEM drilling fluid had reduced by electric neutralization for the inorganic flocculant to reduce the repulsion between suspended solids and to lose stability; organic flocculants contain cations and long molecular chains, which wrap clay particles by bridging-bending and electric neutralization, so that suspended particles gather into large flocs and large particles.

The original contributions presented in the study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding authors.

YL: Conceptualization, methodology, investigation, writing—original draft; YZ: Supervision, validation, writing—review and editing, funding acquisition; TX: Supervision, funding acquisition; MY: Formal analysis, resources; DW: Resources; BL: Resources.

This work was financially supported by CNOOC (China) Co., Ltd. Technology Project (No: YXKY-2019-TJ-05), the National Natural Science Foundation of China (Nos. 51974351; 51704322; Major Program, No. 51991361) and the National Science and Technology Major Project of China (No. 2016ZX05040-005).

The authors YL, YZ, TX, MY and DW were employed by China National Offshore Oil Corporation (China) Co. Ltd. Author BL was employed by China Oilfield Services Co. Ltd.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Cui, Q. J., Shou-qing, N. I., and Zhao, D. C. (2011). Research on Decoloration of Integrated Process in the Disposal of Washing & Bleaching Waste Water for Straw Pulping. China Pulp & Paper Industry. China.

Hou-ming, L. I., Xue-jun, L. I., and Zhang, F. M. (2012). Application Status of Cutting Injection for Drilling Waste Treatment at Abroad (Bejing: Science Technology and Engineering). http://en.cnki.com.cn/Article_en/CJFDTotal-KXJS201228034.htm.

Hu, Z., Wang, Q., and Chen, T. (2017). Treatment and Use of Waste Drilling Fluid with Existing Solids Control Equipmen T. Drilling Fluid and Completion Fluid 34 (01), 92–95.

Li, W., Zhao, X., Cai, B., Zhang, J., Jiang, J., Guo, W., et al. Integrated Treatment and Disposal of Waste Drilling Fluid Onshore China: Laboratory Investigation and Process Design. Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference. November 16 2017. Abu Dhabi, UAE. doi:10.2118/188334-MS

Malachosky, E., Shannon, B., and Jackson, J. (1993). Offshore Disposal of Oil-Based Drilling-Fluid Waste: an Environmentally Acceptable Solution[J]. Spe Drilling & Completion 8 (4), 283–287. doi:10.2118/23373-pa

Paul, N., Suresh, L., Vaghasiya, J. V., Yang, L., Zhang, Y., Nandakumar, D. K., et al. (2020). Self-powered All Weather Sensory Systems Powered by Rhodobacter Sphaeroides Protein Solar Cells. Biosens. Bioelectron. 165, 112423. doi:10.1016/j.bios.2020.112423

Shaocheng, X., Jin, X., Zili, L., and Xiang, X. The Application of {pem} Drilling Fluid System in Environmentally Sensitivity Area. Proceedings of the SPE/IADC Middle East Drilling Technology Conference. October 24 2001. Bahrain. doi:10.2118/72307-MS

Fan, W., Zhu, H., et al. (2011). Preparation of Nano-Modified Polyacrylamide and its Application on Solid-Liquid Separation in Waste Drilling Mud[J]. Adv. Chem. Eng. Sci. 1 (2), 33–36. doi:10.4236/aces.2011.12006

Wang, K., Liu, P., Hou, X., Wang, P., Zhu, P., Hao, M., et al. Drilling and Completion Waste Reutilization and Zero Discharge Technology Used in China Bohai Bay. Proceedings of the Gas Conference and Exhibition. October 14 2021. doi:10.2118/205633-MS

Xie, S., Jiang, G., Chen, M., Deng, H., Wang, R., Xu, Y., et al. (2011). Using Chemical Strengthening Separation-Harmless Technology for the Treatment of Waste Oil-Based Drilling Fluid. Chin. J. Environ. Eng. 5 (2), 425–430.

Xue, Y., Ma, Y., and Li, G. (2008). Offshore Waste Drilling Fluid Treatment. Pet. Drilling Tech. (05), 12–16.

Xun, H. M., Zhou, M., and Lijiang, M. A. (2011). A Complete Set of Technique for Quick Hole Blasting of Large Cross Rock Roadway in Deep Well with High Stress. Coal Engineering. India.

Zhang, J., Wang, J., Yuan, H., and Luo, J. (2005). Solidification Treatment of Drilling Waste Water and Mud in West Sichuan Oil/gas fields. Nat. Gas Industry 25(11), 94–96+156157.

Zhou, J. L., Yue, Q. S., Yang, L. P., Zhu, Y. H., and Wu, H. T. (2012). Solid-liquid Separation Technology of Waste Drilling Fluid in Offshore Oilfields. J. Oil Gas Tech.34(9)

Keywords: PEM drilling fluid, inorganic-organic flocculation system, liquid yield, electric neutralization, bridging-curling

Citation: Liu Y, Zhang Y, Xie T, Yue M, Wang D and Li B (2021) The Study of Optimization of Flocculation and Destabilization Technology of Waste PEM Drilling Fluid in Bohai Oilfield. Front. Energy Res. 9:796786. doi: 10.3389/fenrg.2021.796786

Received: 17 October 2021; Accepted: 01 November 2021;

Published: 03 December 2021.

Edited by:

Xun Zhong, Yangtze University, ChinaReviewed by:

Fuhao Zhao, China University of Petroleum (Huadong), ChinaCopyright © 2021 Liu, Zhang, Xie, Yue, Wang and Li. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yang Liu, MjUxMTM1MTk1MkBxcS5jb20=; Dongsen Wang, d2FuZ2RzNUBjbm9vYy5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.