- 1LAQV-REQUIMTE, Departamento de Química, Faculdade de Ciências e Tecnologia, Universidade NOVA de Lisboa, Caparica, Portugal

- 2LAQV-REQUIMTE, Departamento de Ciências e Tecnologia da Biomassa, Faculdade de Ciências e Tecnologia, Universidade NOVA de Lisboa, Caparica, Portugal

Porous carbon materials, derived from biomass wastes and/or as by-products, are considered versatile, economical and environmentally sustainable. Recently, their high adsorption capacity has led to an increased interest in several environmental applications related to separation/purification both in liquid- and gas-phases. Specifically, their use in carbon dioxide (CO2) capture/sequestration has been a hot topic in the framework of gas adsorption applications. Cost effective biomass porous carbons with enhanced textural properties and high CO2 uptakes present themselves as attractive alternative adsorbents with potential to be used in CO2 capture/separation, apart from zeolites, commercial activated carbons and metal-organic frameworks (MOFs). The renewable and sustainable character of the precursor of these bioadsorbents must be highlighted in the context of a circular-economy and emergent renewable energy market to reach the EU climate and energy goals. This mini-review summarizes the current understandings and discussions about the development of porous carbons derived from bio-wastes, focusing their application to capture CO2 and upgrade biogas to biomethane by adsorption-based processes. Biogas is composed by 55–65 v/v% of methane (CH4) mainly in 35–45 v/v% of CO2. The biogas upgraded to bio-CH4 (97%v/v) through an adsorption process yields after proper conditioning to high quality biomethane and replaces natural gas of fossil source. The circular-economy impact of bio-CH4 production is further enhanced by the use of biomass-derived porous carbons employed in the production process.

Introduction

Biogas produced from several biomasses is a renewable fuel source of methane that after proper conditioning can be injected into the gas pipeline networks or used as energy for transport (Scarlat et al., 2018; Ferella et al., 2019). However, CO2 removal from biogas is a critical step for biogas upgrading and limits its application. Upgrading technologies comprise absorption, adsorption, membrane permeation, and cryogenic strategies (Zhou et al., 2017; Kapoor et al., 2019). Among them, adsorption has attracted attention due to its environmentally friendly nature, low energy demand and capital costs (Surra et al., 2019a; Lombardi and Francini, 2020). The key element in adsorption-based processes is the need for an effective adsorbent with high adsorption capacities for the species to capture, low productions cost and low environmental impacts. Specific surface area and pore volume are the critical properties for these materials. Recent developments were achieved concerning adsorbents for CO2 removal (Zhou et al., 2017), complemented with molecular simulations (Peng and Cao, 2013) to predict/produce the best materials (Esteves et al., 2008; Surra et al., 2019b; Bernardo et al., 2020; Liu et al., 2020b). Moreover, fresh overviews devoted to the state of the art of adsorbents for CO2 removal have been focused on biomass derived porous carbons (Singh et al., 2019; Xu and Strømme, 2019; Sher et al., 2020). However, much of the research lacks the use of biomass-derived adsorbents employed themselves as key-materials to capture CO2 and upgrade biogas to bio-CH4 by adsorption-based processes (PSA), in a concept of a circular-economy (Cheng et al., 2020; Sherwood, 2020; D’Adamo et al., 2021; Kumar and Verma, 2021). Hence, this mini-review offers a succinct summary of this topic presenting the most recent literature (2020–2021) of CO2 uptake with biomass-derived porous carbons and the last 5 years literature of biocarbons application in PSA technology for biogas upgrading. The existing gaps and potential future paths are also discussed.

Biomass-Derived Porous Carbons

Converting the biomass into porous carbons involves carbonization (pyrolysis) and activation that can be of physical and/or chemical types. Physical-activation is a two-step process: the raw material is carbonized in the absence of O2 at temperatures between 400–850°C, followed by activation of the resulting char with oxidant/gasifying gases like steam, air, N2, O2, NH3, CO2 or a mixture of these gases, at temperatures around 600–1000°C (Marsh and Rodríguez-Reinoso, 2006; González-García, 2018). The activation with CO2 produces porous carbons with narrow micropore size distribution, providing optimum pore size for CO2/CH4 separation, while steam activation generates carbons with wider pore size distribution and smaller micropore volume (Marsh and Rodríguez-Reinoso, 2006). Nevertheless, in the physical-activation there is a poorer control of the porosity. The reactions during physical-activation can form surface oxygen functional groups, while activation with NH3 adds N-containing groups on carbon surface; however, this is usually coupled with other gas to provide more porosity (Tan et al., 2017). The high temperatures usually used in physical-activation represent an energetic disadvantage.

Chemical-activation can be a one-step or two-step method since the impregnation with the activating chemical (dehydrating agents and/or oxidants) can be made directly in the biomass or in the resulting char from the first step of carbonization. After impregnation, the mixture of precursor and activating agent is heated under inert atmosphere at temperatures between 400–800°C (Marsh and Rodríguez-Reinoso, 2006; González-García, 2018). As physical-activation, chemical-activation provides porosity development and functional groups at carbon surface. Acids, alkalis, and salts like H3PO4, H2SO4, ZnCl2, K2CO3, NaOH, and KOH are usually used in chemical-activations of biomass precursors (Yahya et al., 2015; González-García, 2018).

Chemical-activation usually provides biomass-derived porous carbons with high surface areas and a good control of the porosity, but washing the produced carbon to remove the residual activating agent present in the carbon matrix turns the process into a time- and energy-consuming one, and environmentally less friendly.

Tailoring Carbon Surface Chemistry

When producing biomass-derived porous carbons, it is possible to tune their properties by an appropriate choice of the precursor and activation conditions. Nonetheless, the resulting material can be further tailored, specifically the surface chemistry properties to increase the CO2 uptake capacity. Modification treatments can be envisaged to add and/or increase relevant functional groups on the surface of the carbon to enhance CO2 retention. Increasing the basicity of the carbon is the most efficient way to improve the adsorption efficiency toward CO2 uptake, namely through the removal of acidic functional groups from carbon surface and/or introduction of nitrogen groups that provide basic sites able to attract the acidic CO2 (Adelodun et al., 2015; Rashidi and Yusup, 2016). Depending on the biomass precursor and if an acid is used as activating agent, several oxygen functional groups with strong or mild acidity might be present on the carbon surface. To remove these oxygenated groups, heat treatments under inert (N2, Ar, He) or H2 atmosphere are usually performed, but this requires very high temperatures (800–1000°C) (Shafeeyan et al., 2010).

Heat treatment with ammonia can be employed at temperatures between 200 and 1000°C (Rashidi and Yusup, 2016). Since carbon surface is typically non-reactive to NH3, pre-oxidation of the surface is required prior to amination. After the treatment, the carbon surface is usually enriched with nitrogen functionalities like −NH2−, −CN, pyridinic, pyrrolic, and quaternary N2 (Shen and Fan, 2013). Nitrogen-rich biomass precursors, such as chitosan (Fujiki and Yogo, 2016), crab and prawn shell (Chen et al., 2015; Gao et al., 2016), and protein enriched biowaste (Huang et al., 2015; Shi et al., 2019), can directly provide porous carbons enriched with nitrogen functionalities.

Metal impregnation has been also employed to increase the carbon CO2 uptake capacity and selectivity, although this strategy is not usual as nitrogen-doping. Metal oxides of alkaline-earth and transition elements can provide catalytic active sites able to interact with CO2 although the presence of ultra microporosity remains an important feature.

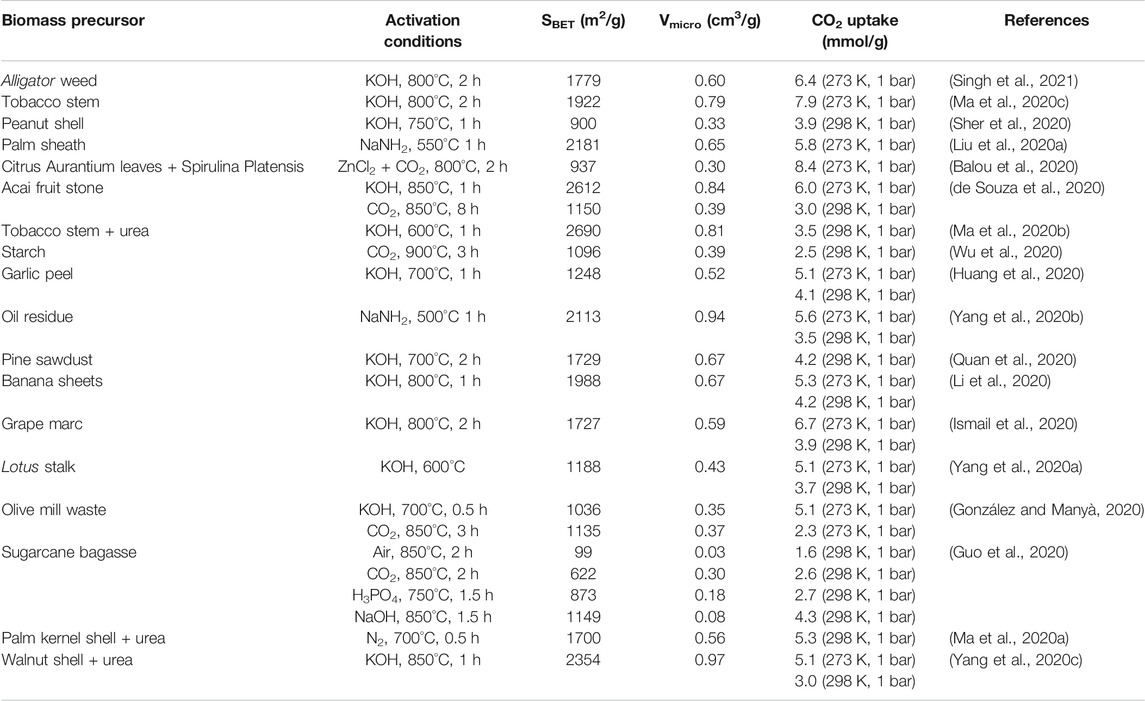

Table 1 presents the most recent works (2020–2021) dealing with biomass derived-porous carbons for CO2 uptake. The biomass precursor, activation conditions, textural properties and CO2 uptake capacity are shown. It should be highlighted that most of the studies use powder carbons, and static CO2 adsorption measurements are performed volumetrically using gas sorption apparatus or through thermogravimetric analysers. Pure CO2 or synthetic gas mixtures under controlled conditions are typically used. Dynamic CO2 adsorption breakthrough tests and real gas samples are scarcely studied for the biomass-based adsorbents, although these conditions are closer to industrial applications. Also, dynamic adsorption/desorption/regeneration cycles allow a more efficient utilization of the adsorbent capacity; however, most of the published studies do not consider this important feature. Considering the lack of knowledge about the performance of biowastes derived porous carbons in continuous flow systems and their regeneration, it is of utmost importance that studies move forward to reflect realistic applications.

Biogas Upgrading to Biomethane and CO2 Capture

The selection of a biogas upgrading technology depends mainly on plant location, investment availability, biogas composition, bio-CH4 aim quality, and plant productivity. Adsorption-based processes like Pressure-Swing Adsorption (PSA) is one of the most established know-how used in gas separation/purification/capture applications (Riboldi and Bolland, 2017). Its compacted set of fixed-bed adsorption columns, operating with pressure modulation in a cyclic mode, use the adsorbent(s) to selectively adsorb and desorb the undesired gases like CO2 in biogas (Esteves, 2005; Esteves and Mota, 2007; Augelletti et al., 2017; Canevesi et al., 2018). The selective adsorption occurs due to different equilibrium capacities of the species (equilibrium adsorbent) or distinct gas uptake rates (kinetic adsorbent) in the adsorbent’s surface. Activated carbons have demonstrated to perform effectively in relevant operating conditions, surpassing zeolites when CO2 partial pressure overpasses a certain threshold (ca. 1.7 bar) (Riboldi and Bolland, 2017). This means that what really matters is not the total CO2 adsorption capacity of the solid adsorbent at a given pressure, but the pressure difference necessary to be applied between adsorption and desorption to obtain a satisfactory gas separation in PSA (adsorption isotherms). Carbons have higher adsorption capacity than zeolites at high pressure, but zeolites are regenerated by vacuum desorption with very small pressure variation. Carbon materials have the advantages of high thermal/chemical/mechanical/moisture stabilities, electrical and heat conductivities and reasonable cost. Their affinities for CO2 can be improved with functionalization (Lee and Park, 2015). Achieve higher CO2 selectivities requires the development of better adsorbents that, additionally, need to be easy regenerable for proper application in a PSA system that, otherwise, would require reduction in partial pressures or increase in the operating temperature. Recently, MOFs appeared as potential highly selective materials for gas separation/capture (Ferreira et al., 2019; Ribeiro et al., 2019), although they still need further research related with their cost, particle shaping, and stability (structural, mechanical, moisture, aging, etc.).

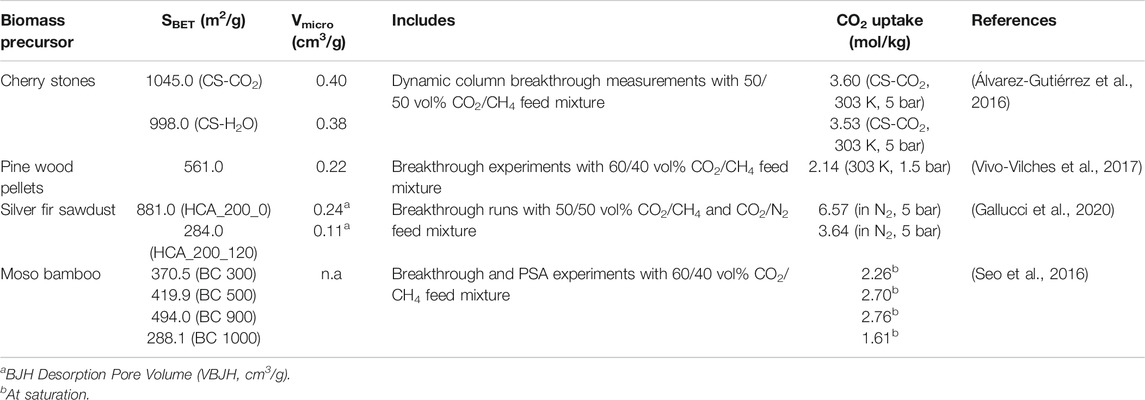

Upon this scenario, the use of porous biocarbons opens a double opportunity, in the sense that biomass turns to be a useful resource that can contribute, thereafter, to capture CO2 and separate it from biogas, aiming to upgrade it to bio-CH4 (Álvarez-Gutiérrez et al., 2014). This pathway closes the loop regarding carbon neutrality and contributes significantly to the field of renewable energy. In the last 5 years, when crossing PSA, biogas upgrading and activated carbon topics in Web of Science (WOS) Core Collection, one gets only 16 publications. Adding CO2 capture topic to this search, only nine articles are found. From those papers, only four of them are about biomass-derived porous carbons applied to PSA. Table 2 depicts those publications. The lack of research on bioadsorbents followed by their effective transfer to adsorption-based processes applied to biogas upgrading is still noticed in a sector so relevant to answer to the renewable energy and environmental concerns of the 21st century.

Despite the good potential demonstrated by porous carbons developed from cherry stones, pine wood pellets, silver fir sawdust and modo bamboo, the few studies published in the last 5 years emphasizes the need to gather more data on biomass-based activated carbons for biogas upgrading under operational conditions similar to real cases. Besides exhibiting high selectivity and optimal uptake capacity for CO2, one of the features to be considered is to obtain porous carbons with the desired particle size to be directly packed in fixed bed columns. This avoids high pressure drops in columns that turn the process unfeasible. Some of these biomass derived adsorbents are obtained as powders and therefore their shaping into pellets, granules or spheres is another challenge for the near future.

Conclusions and Potential Future Developments

A succinct mini-review of current understandings about the development of porous carbons derived from bio-wastes, focusing their application to capture CO2 and upgrade biogas to biomethane by adsorption-based processes (PSA) is carried out in this paper. Porous carbons derived from several biomass precursors as CO2 adsorbents had a huge development only in the last year of 2020, confirming that in fact this is a hot topic. However, the works were mainly directed to use pure CO2 or synthetic mixtures in static experiments, neglecting the importance of studying the dynamic behavior of the new developed adsorbents as well as their performance in regeneration cycles. Further research in this field is highly recommended. Additional assessments on the effective use of biocarbons in adsorption processes need to be undertaken and explored, especially regarding their use in the inherent dynamic PSA process operation. Moreover, shaping of the porous carbons powders is a challenge to overcome, and the impact of that shaping procedure on the efficiency of the adsorbent must also be assessed. Finally, but not less important, an interesting concept that should be explored in this subject is an integrated techno-environmental evaluation of biomethane production from biogas (obtained by biocarbons in PSA), combined with CO2 capture and storage (CCS), to check the potential for net negative greenhouse-gas emissions.

Author Contributions

MB (Conceptualization; Writing—Original Draft); NL and IF (Discussion; Writing—Review and Editing); IE (Conceptualization; Writing—Original draft; Funding acquisition).

Funding

This work was supported by the Associate Laboratory for Green Chemistry-LAQV which is financed by national funds from FCT/MCTES (UIDB/50006/2020, UIDP/50006/2020 and LA/P/0008/2020).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Adelodun, A. A., Kim, K.-H., Ngila, J. C., and Szulejko, J. (2015). A review on the effect of amination pretreatment for the selective separation of CO2. Appl. Energ. 158, 631–642. doi:10.1016/j.apenergy.2015.08.107

Álvarez-Gutiérrez, N., García, S., Gil, M. V., Rubiera, F., and Pevida, C. (2016). Dynamic performance of biomass-based carbons for CO2/CH4 separation. Approximation to a pressure swing adsorption process for biogas upgrading. Energy Fuels 30, 5005–5015. doi:10.1021/acs.energyfuels.6b00664

Álvarez-Gutiérrez, N., García, S., Gil, M. V., Rubiera, F., and Pevida, C. (2014). Towards bio-upgrading of biogas: biomass waste-based adsorbents. Energ. Proced. 63, 6527–6533. doi:10.1016/j.egypro.2014.11.688

Augelletti, R., Conti, M., and Annesini, M. C. (2017). Pressure swing adsorption for biogas upgrading. A new process configuration for the separation of biomethane and carbon dioxide. J. Clean. Prod. 140, 1390–1398. doi:10.1016/j.jclepro.2016.10.013

Balou, S., Babak, S. E., and Priye, A. (2020). Synergistic effect of nitrogen doping and ultra-microporosity on the performance of biomass and microalgae-derived activated carbons for CO2 capture. ACS Appl. Mater. Inter. 12, 42711–42722. doi:10.1021/acsami.0c10218

Bernardo, M., Correa, C. R., Ringelspacher, Y., Becker, G. C., Lapa, N., Fonseca, I., et al. (2020). Porous carbons derived from hydrothermally treated biogas digestate. Waste Manag. 105, 170–179. doi:10.1016/j.wasman.2020.02.011

Canevesi, R. L. S., Andreassen, K. A., da Silva, E. A., Borba, C. E., and Grande, C. A. (2018). Pressure swing adsorption for biogas upgrading with carbon molecular sieve. Ind. Eng. Chem. Res. 57, 8057–8067. doi:10.1021/acs.iecr.8b00996

Chen, T., Deng, S., Wang, B., Huang, J., Wang, Y., and Yu, G. (2015). CO2 adsorption on crab shell derived activated carbons: contribution of micropores and nitrogen-containing groups. RSC Adv. 5, 48323–48330. doi:10.1039/C5RA04937G

Cheng, S. Y., Tan, X., Show, P. L., Rambabu, K., Banat, F., Veeramuthu, A., et al. (2020). Incorporating biowaste into circular bioeconomy: a critical review of current trend and scaling up feasibility. Environ. Tech. Innovation 19, 101034. doi:10.1016/j.eti.2020.101034

de Souza, L. K. C., Gonçalves, A. A. S., Queiroz, L. S., Chaar, J. S., da Rocha Filho, G. N., and da Costa, C. E. F. (2020). Utilization of acai stone biomass for the sustainable production of nanoporous carbon for CO2 capture. Sust. Mater. Tech. 25, e00168. doi:10.1016/j.susmat.2020.e00168

D’Adamo, I., Falcone, P. M., Huisingh, D., and Morone, P. (2021). A circular economy model based on biomethane: what are the opportunities for the municipality of Rome and beyond? Renew. Energ. 163, 1660–1672. doi:10.1016/j.renene.2020.10.072

Esteves, I. (2005). Gas separation processes by integrated adsorption and permeation technologies. Doctoral thesis. Almada, Portugal: Universidade Nova de Lisboa—Faculdade de Ciências e TecnologiaAvailable at http://hdl.handle.net/10362/29990.

Esteves, I. A. A. C., Lopes, M. S. S., Nunes, P. M. C., and Mota, J. P. B. (2008). Adsorption of natural gas and biogas components on activated carbon. Separat. Purif. Tech. 62, 281–296. doi:10.1016/j.seppur.2008.01.027

Esteves, I. A. A. C., and Mota, J. P. B. (2007). Gas separation by a novel hybrid membrane/pressure swing adsorption process. Ind. Eng. Chem. Res. 46, 5723–5733. doi:10.1021/ie070139j

Ferella, F., Cucchiella, F., D’Adamo, I., and Gallucci, K. (2019). A techno-economic assessment of biogas upgrading in a developed market. J. Clean. Prod. 210, 945–957. doi:10.1016/j.jclepro.2018.11.073

Ferreira, T. J., Ribeiro, R. P. P. L., Mota, J. P. B., Rebelo, L. P. N., Esperança, J. M. S. S., and Esteves, I. A. A. C. (2019). Ionic liquid-impregnated metal-organic frameworks for CO2/CH4 separation. ACS Appl. Nano Mater. 2, 7933–7950. doi:10.1021/acsanm.9b01936

Fujiki, J., and Yogo, K. (2016). The increased CO2 adsorption performance of chitosan-derived activated carbons with nitrogen-doping. Chem. Commun. 52, 186–189. doi:10.1039/C5CC06934C

Gallucci, K., Taglieri, L., Papa, A. A., Di Lauro, F., Ahmad, Z., and Gallifuoco, A. (2020). Non-energy valorization of residual biomasses via HTC: CO2 capture onto activated hydrochars. Appl. Sci. 10, 1879. doi:10.3390/app10051879

Gao, F., Qu, J., Zhao, Z., Wang, Z., and Qiu, J. (2016). Nitrogen-doped activated carbon derived from prawn shells for high-performance supercapacitors. Electrochimica Acta 190, 1134–1141. doi:10.1016/j.electacta.2016.01.005

González, B., and Manyà, J. J. (2020). Activated olive mill waste-based hydrochars as selective adsorbents for CO2 capture under postcombustion conditions. Chem. Eng. Process.—Process Intensification 149, 107830. doi:10.1016/j.cep.2020.107830

González-García, P. (2018). Activated carbon from lignocellulosics precursors: a review of the synthesis methods, characterization techniques and applications. Renew. Sust. Energ. Rev. 82, 1393–1414. doi:10.1016/j.rser.2017.04.117

Guo, Y., Tan, C., Sun, J., Li, W., Zhang, J., and Zhao, C. (2020). Porous activated carbons derived from waste sugarcane bagasse for CO2 adsorption. Chem. Eng. J. 381, 122736. doi:10.1016/j.cej.2019.122736

Huang, B., Shao, H., Liu, N., Xu, Z. J., and Huang, Y. (2015). From fish scales to highly porous N-doped carbon: a low cost material solution for CO2 capture. RSC Adv. 5, 88171–88175. doi:10.1039/C5RA16745K

Huang, G., Wu, X., Hou, Y., and Cai, J. (2020). Sustainable porous carbons from garlic peel biowaste and KOH activation with an excellent CO2 adsorption performance. Biomass Conv. Bioref. 10, 267–276. doi:10.1007/s13399-019-00412-6

Ismail, I. S., Singh, G., Smith, P., Kim, S., Yang, J.-H., Joseph, S., et al. (2020). Oxygen functionalized porous activated biocarbons with high surface area derived from grape marc for enhanced capture of CO2 at elevated-pressure. Carbon 160, 113–124. doi:10.1016/j.carbon.2020.01.008

Kapoor, R., Ghosh, P., Kumar, M., and Vijay, V. K. (2019). Evaluation of biogas upgrading technologies and future perspectives: a review. Environ. Sci. Pollut. Res. Int. 26, 11631–11661. doi:10.1007/s11356-019-04767-1

Kumar, B., and Verma, P. (2021). Biomass-based biorefineries: an important architype towards a circular economy. Fuel 288, 119622. doi:10.1016/j.fuel.2020.119622

Lee, S.-Y., and Park, S.-J. (2015). A review on solid adsorbents for carbon dioxide capture. J. Ind. Eng. Chem. 23, 1–11. doi:10.1016/j.jiec.2014.09.001

Li, J., Chen, X., Gong, J., Zhu, J., and Mijowska, E. (2020). Deep insight into the pore size distribution of N-doped porous carbon materials on electrochemical energy storage and CO2 sorption. Diamond Relat. Mater. 105, 107802. doi:10.1016/j.diamond.2020.107802

Liu, F., Zhang, Y., Zhang, P., Xu, M., Tan, T., Wang, J., et al. (2020a). Facile preparation of N and O-rich porous carbon from palm sheath for highly selective separation of CO2/CH4/N2 gas-mixture. Chem. Eng. J. 399, 125812. doi:10.1016/j.cej.2020.125812

Liu, J., Chen, Q., and Qi, P. (2020b). Upgrading of biogas to methane based on adsorption. Processes 8, 941. doi:10.3390/pr8080941

Lombardi, L., and Francini, G. (2020). Techno-economic and environmental assessment of the main biogas upgrading technologies. Renew. Energ. 156, 440–458. doi:10.1016/j.renene.2020.04.083

Ma, R., Hao, J., Chang, G., Wang, Y., and Guo, Q. (2020a). Nitrogen‐doping microporous adsorbents prepared from palm kernel with excellent CO2 capture property. Can. J. Chem. Eng. 98, 503–512. doi:10.1002/cjce.23581

Ma, X., Chen, R., Zhou, K., Wu, Q., Li, H., Zeng, Z., et al. (2020b). Activated porous carbon with an ultrahigh surface area derived from waste biomass for acetone adsorption, CO2 capture, and light hydrocarbon separation. ACS Sust. Chem. Eng. 8, 11721–11728. doi:10.1021/acssuschemeng.0c03725

Ma, X., Yang, Y., Wu, Q., Liu, B., Li, D., Chen, R., et al. (2020c). Underlying mechanism of CO2 uptake onto biomass-based porous carbons: do adsorbents capture CO2 chiefly through narrow micropores? Fuel 282, 118727. doi:10.1016/j.fuel.2020.118727

Marsh, H., and Rodríguez-Reinoso, F. (2006). Activated carbon, Amsterdam, Netherlands: Elsevier Science. doi:10.1016/B978-0-08-044463-5.X5013-4

Peng, X., and Cao, D. (2013). Computational screening of porous carbons, zeolites, and metal organic frameworks for desulfurization and decarburization of biogas, natural gas, and flue gas. Aiche J. 59, 2928–2942. doi:10.1002/aic.14046

Quan, C., Su, R., and Gao, N. (2020). Preparation of activated biomass carbon from pine sawdust for supercapacitor and CO 2 capture. Int. J. Energ. Res. 44, 4335–4351. doi:10.1002/er.5206

Rashidi, N. A., and Yusup, S. (2016). An overview of activated carbons utilization for the post-combustion carbon dioxide capture. J. CO2 Utilization 13, 1–16. doi:10.1016/j.jcou.2015.11.002

Ribeiro, R. P. P. L., Antunes, C. L., Garate, A. U., Portela, A. F., Plaza, M. G., Mota, J. P. B., et al. (2019). Binderless shaped metal-organic framework particles: impact on carbon dioxide adsorption. Micropor. Mesopor. Mater. 275, 111–121. doi:10.1016/j.micromeso.2018.08.002

Riboldi, L., and Bolland, O. (2017). Overview on pressure swing adsorption (PSA) as CO2 capture technology: state-of-the-art, limits and potentials. Energ. Proced. 114, 2390–2400. doi:10.1016/j.egypro.2017.03.1385

Scarlat, N., Dallemand, J.-F., and Fahl, F. (2018). Biogas: developments and perspectives in europe. Renew. Energ. 129, 457–472. doi:10.1016/j.renene.2018.03.006

Seo, D.-J., Gou, Z., Fujita, H., Fujii, T., and Sakoda, A. (2016). Simple fabrication of molecular sieving carbon for biogas upgrading via a temperature controlled carbonization of Phyllostachys pubescens. Renew. Energ. 86, 693–702. doi:10.1016/j.renene.2015.09.006

Shafeeyan, M. S., Daud, W. M. A. W., Houshmand, A., and Shamiri, A. (2010). A review on surface modification of activated carbon for carbon dioxide adsorption. J. Anal. Appl. Pyrolysis 89, 143–151. doi:10.1016/j.jaap.2010.07.006

Shen, W., and Fan, W. (2013). Nitrogen-containing porous carbons: synthesis and application. J. Mater. Chem. A. 1, 999–1013. doi:10.1039/c2ta00028h

Sher, F., Iqbal, S. Z., Albazzaz, S., Ali, U., Mortari, D. A., and Rashid, T. (2020). Development of biomass derived highly porous fast adsorbents for post-combustion CO2 capture. Fuel 282, 118506. doi:10.1016/j.fuel.2020.118506

Sherwood, J. (2020). The significance of biomass in a circular economy. Bioresour. Technol. 300, 122755. doi:10.1016/j.biortech.2020.122755

Shi, Y., Zheng, W., Liu, H., Wang, L., and Zhang, H. (2019). Protein-derived nitrogen and sulfur co-doped carbon for efficient adsorptive removal of heavy metals. Chin. J. Chem. Eng. 27, 2581–2586. doi:10.1016/j.cjche.2018.11.017

Singh, G., Bahadur, R., Mee Lee, J., Young Kim, I., Ruban, A. M., Davidraj, J. M., et al. (2021). Nanoporous activated biocarbons with high surface areas from alligator weed and their excellent performance for CO2 capture at both low and high pressures. Chem. Eng. J. 406, 126787. doi:10.1016/j.cej.2020.126787

Singh, G., Lakhi, K. S., Sil, S., Bhosale, S. V., Kim, I., Albahily, K., et al. (2019). Biomass derived porous carbon for CO2 capture. Carbon 148, 164–186. doi:10.1016/j.carbon.2019.03.050

Surra, E., Bernardo, M., Lapa, N., Esteves, I. A. A. C., Fonseca, I., and Mota, J. P. B. (2019a). Biomethane production through anaerobic co-digestion with Maize Cob Waste based on a biorefinery concept: a review. J. Environ. Manage. 249, 109351. doi:10.1016/j.jenvman.2019.109351

Surra, E., Costa Nogueira, M., Bernardo, M., Lapa, N., Esteves, I., and Fonseca, I. (2019b). New adsorbents from maize cob wastes and anaerobic digestate for H2S removal from biogas. Waste Manag. 94, 136–145. doi:10.1016/j.wasman.2019.05.048

Tan, X., Liu, S., Liu, Y., Gu, Y., Zeng, G., Hu, X., et al. (2017). Biochar as potential sustainable precursors for activated carbon production: multiple applications in environmental protection and energy storage. Bioresour. Technol. 227, 359–372. doi:10.1016/j.biortech.2016.12.083

Vivo-Vilches, J. F., Pérez-Cadenas, A. F., Maldonado-Hódar, F. J., Carrasco-Marín, F., Faria, R. P. V., Ribeiro, A. M., et al. (2017). Biogas upgrading by selective adsorption onto CO 2 activated carbon from wood pellets. J. Environ. Chem. Eng. 5, 1386–1393. doi:10.1016/j.jece.2017.02.015

Wu, D., Liu, J., Yang, Y., and Zheng, Y. (2020). Nitrogen/oxygen Co-doped porous carbon derived from biomass for low-pressure CO2 capture. Ind. Eng. Chem. Res. 59, 14055–14063. doi:10.1021/acs.iecr.0c00006

Xu, C., and Strømme, M. (2019). Sustainable porous carbon materials derived from wood-based biopolymers for CO2 capture. Nanomaterials 9, 103. doi:10.3390/nano9010103

Yahya, M. A., Al-Qodah, Z., and Ngah, C. W. Z. (2015). Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: a review. Renew. Sust. Energ. Rev. 46, 218–235. doi:10.1016/j.rser.2015.02.051

Yang, P., Rao, L., Zhu, W., Wang, L., Ma, R., Chen, F., et al. (2020a). Porous carbons derived from sustainable biomass via a facile one-step synthesis strategy as efficient CO2 adsorbents. Ind. Eng. Chem. Res. 59, 6194–6201. doi:10.1021/acs.iecr.0c00073

Yang, Z., Guo, X., Zhang, G., and Xu, Y. (2020b). One‐pot synthesis of high N‐doped porous carbons derived from a N‐rich oil palm biomass residue in low temperature for CO2 capture. Int. J. Energ. Res. 44, 4875–4887. doi:10.1002/er.5287

Yang, Z., Zhang, G., Guo, X., and Xu, Y. (2020c). Designing a novel N-doped adsorbent with ultrahigh selectivity for CO2: waste biomass pyrolysis and two-step activation. Biomass Conv. Bioref., 1–12. doi:10.1007/s13399-020-00633-0

Keywords: biomass, porous carbons, adsorption, biogas upgrading, pressure swing adsorption, biomethane, CH4, CO2

Citation: Bernardo M, Lapa N, Fonseca I and Esteves IAAC (2021) Biomass Valorization to Produce Porous Carbons: Applications in CO2 Capture and Biogas Upgrading to Biomethane—A Mini-Review. Front. Energy Res. 9:625188. doi: 10.3389/fenrg.2021.625188

Received: 02 November 2020; Accepted: 11 February 2021;

Published: 19 March 2021.

Edited by:

Richen Lin, University College Cork, IrelandReviewed by:

Yifeng Zhang, Technical University of Denmark, DenmarkIdiano D’Adamo, Sapienza University of Rome, Italy

Valerio Paolini, National Research Council of Italy, Italy

Copyright © 2021 Bernardo, Lapa, Fonseca and Esteves. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Maria Bernardo, bWFyaWEuYkBmY3QudW5sLnB0; Isabel A. A. C. Esteves, aS5lc3RldmVzQGZjdC51bmwucHQ=

†These authors have contributed equally to this work

Maria Bernardo

Maria Bernardo Nuno Lapa

Nuno Lapa Isabel Fonseca

Isabel Fonseca Isabel A. A. C. Esteves

Isabel A. A. C. Esteves