- College of Water Conservancy, Shenyang Agricultural University, Shenyang, China

Due to the large quantity and wide range of solid wastes of the biomass, and the dual characteristics of pollution and resource utilization, the energy utilization of anaerobic fermentation can promote its pollution control, so the mixed fermentation technology of solid wastes of agricultural biomass was studied. Corn straw, pig manure, and kitchen waste were selected as solid wastes of agricultural biomass. A system including a temperature control device, a fermentation device and a gas gathering device is used to measure the content and pH value of biogas and methane. Physical, chemical, and biological pretreatment methods were used to strengthen the anaerobic reference of biomass, and the mixed fermentation of different biomass was used to complete the anaerobic fermentation of a variety of solid wastes of agricultural biomass. The results showed that pig manure and corn straw were suitable for medium temperature fermentation at 30°C, while cow manure and corn straw were suitable for high temperature fermentation at 60°C. In the process of anaerobic fertilization, when the ratio of cow dung to sludge is 2:1, 3:1, and 4:1 respectively, the methane content is shown as follows: (1) The first 130 days are relatively stable and then slowly decreased; (2) The first 120 days are slowly increased, and then it rises to the maximum value at 140 days and then remains unchanged; (3) It remains at 2% all the time. After the mixture of cow manure and sludge, the higher the proportion of cow manure is, the higher the pH value in the initial stage of anaerobic fertilization is. The higher the basicity of methanogens in the fermentation liquid inside the fermentation tank is, the higher the pH value of the system is, and the basicity of methanogens has a significant positive correlation with the crude protein content of biomass.

Introduction

With the rapid development of China’s economy, the living standards and lifestyle in rural areas have also undergone significant changes, which have broken the waste recycling system in traditional agricultural society, and the types and quantity of waste in rural areas have also begun to rise sharply (Natalia et al., 2019). Previously, the domestic waste in rural areas was mainly kitchen waste, and the surplus kitchen waste was used to raise livestock, and the manure produced by livestock was mostly returned to the field as organic fertilizer (Xu et al., 2017). The construction of new socialist countryside has changed the traditional life mode in the countryside, and the amount of solid wastes such as livestock manure, domestic garbage, crop straw has also increased greatly. In recent years, with the improvement of farmers’ living standards, the consumption structure has been constantly changed. For example, the large-scale use of chemical fertilizer makes the manure and domestic garbage of livestock be discarded at will. The original firewood energy has been replaced by electric energy and natural gas, and the utilization rate of rice straw is low (Zhang Q. et al., 2017). The random stacking of organic solid wastes will cause the pollution of rivers, groundwater, and other water sources in rural areas, which directly threatens the drinking water safety and health of farmers. Therefore, rural organic solid waste not only causes land occupation and pollution, but also affects human health and environmental health (Zhang et al., 2018). There are four disposal methods of organic solid wastes in rural areas, which are incineration, sanitary landfill, aerobic composting, and anaerobic fertilization. Among them, the water demand of anaerobic fertilization treatment technology is small, without power consumption, low cost, small floor area, which can recover biogas energy, and reduce pollution load. And the filtrate can be used as the additive or fertilizer of soil, which can increase the economic benefits. It is gradually becoming an important choice for countries around the world to deal with organic solid waste and produce new energy (Jongkeun et al., 2018).

Biomass refers to various organisms formed through photosynthesis, including all animals, plants, and microorganisms. Compared with traditional fossil fuels, biomass resources have the advantages of renewability and cleanness (Hong et al., 2017). Biomass resources are the basis for the development of biomass energy industry. Although there are abundant biomass resources in the world and more and more researches on biomass, most of them are still in the experimental stage and have not been widely used (Lam et al., 2018).

According to the latest statistical data, the annual output of crop waste is 6.88 × 108 t, and the total amount of resources and energy is 8.89 × 1,015 kj, equivalent to 3.04 × 108 t standard coal. Biomass solid waste has the dual characteristics of pollution and resource reuse. A large number of biomass are stacked randomly or burned in the open air, which not only causes waste of resources, but also affects the environment. However, by strengthening energy and resource utilization, pollution control can be promoted (Luc et al., 2017; Ojha et al., 2017). Acquiring bioenergy by anaerobic fertilization is one of the important ways to promote the transformation of biomass solid waste from pollution characteristics to energy. In this method, biomass solid waste is fermented under controlled conditions to produce biogas and organic fertilizer without oxygen and energy supply. Although solid wastes of agricultural biomass were fermented in the research of anaerobic fertilization by agidxis and devid, the waste used for fermentation was single, the amount of biogas entangled was small, and the effect was not ideal. In the study of anaerobic fertilization, hifinger only selected plant-based raw materials, without considering that animal manure is an important factor to promote the effect of mixed fermentation, so the fermentation technology studied is not comprehensive. In the study of anaerobic fermentation, the fermentation technology used by Qian is aerobic fermentation technology. A large number of studies show that anaerobic fertilization technology is one of the effective ways to realize the resource utilization of biomass waste (Ahamed et al., 2018; Pivoto et al., 2018; Sawan, 2018). Therefore, the solid wastes of agricultural biomass mixed fermentation technology studied in this paper are mainly composed of anaerobic fermentation. Biomass anaerobic fertilization is to effectively transform the organic matter in biomass under the assimilation of anaerobic bacteria, and finally generate methane and a small amount of carbon dioxide with economic value. It can be used for combustion and power generation, and biogas residue can be used as animal feed or land fertilizer, and biogas slurry can also be used as nutrient solution of crops. In this paper, the research results of the utilization of biomass waste resource anaerobic fermentation are reviewed, and the progress of the enhancement of biomass anaerobic fermentation by means of pretreatment, mixed fermentation of different biomass, and the addition of exogenous catalyst is also reviewed.

Materials and Methods

Test Materials

The agricultural wastes involved in this experiment include corn straw, wheat straw, rice straw, pig manure, cow manure, chicken manure, kitchen waste, and cassava residue. Among them, wheat straw and corn straw were obtained from the experimental field in the North Campus of Shaanxi recycling agricultural engineering technology center of northwest agricultural and Forestry University in the previous year; rice straw was stored by farmers near the University for nearly one year. All straws are dried in the air before being put into the fermentation tank, crushed to about 2 mm in diameter, and put into a cool and ventilated place after being screened and bagged. Pig manure, cattle manure, and chicken manure are from the farms near the North Campus of Northwest University of agriculture and forestry technology, and no antibiotics have been used in the farms in the near future (Girotto et al., 2017). The biogas slurry is taken from the biogas digester which is normally used by the farmers in Cuixigou, Yangling, Shaanxi Province as the inoculum. When the inoculum is selected, the suspended matter in the upper part of the biogas slurry is removed, and the mature biogas slurry without obvious rotten odor in the lower part is evenly mixed.

Test Equipment and Design

Test Equipment

The device system used in the experiment is designed by the laboratory of Shaanxi recycling agricultural engineering technology research center. The whole system includes temperature control device, fermentation device, and gas gathering device. The relay in the temperature control device is used to display the temperature, the fermentation device is placed in the constant temperature water tank, and the heating temperature in the water tank is controlled by the temperature controller. The temperature fluctuation range of the whole temperature control device is ± 1°C. The fermentation device and the gas gathering device are composed of a plurality of conical bottles with a volume of 1l, which are sealed with rubber plugs. Each part is connected with the rubber pipe through a glass conduit, and the discharged water is collected with a plastic pot with a capacity of 2.5 L, and the displacement is measured with a measuring cylinder. Liquictoc analyzer, Beijing Science, and Technology Development Co., Ltd.; pH detector, Shanghai Shifa science and Technology Co., Ltd.; TGL-16g high-speed desktop centrifuge, Shanghai Anting science instrument factory. In the experiment, the total solid mass fraction (TS) of all fermentation materials was 8%, the volume of fermentation bottle was 1 L, and the effective volume was 0.7 L. During the test, each treatment was set with 3 repetitions. The pH value and alkalinity content of in the erobic reference process were measured every 5 days. Solid waste anaerobic fermentation period can be divided into multiple stages, because this article study period is longer, as long as 170 days, set the test time interval is short, can cause workload, if the test time interval, the greater the cannot get representative as a result, after comprehensive consideration, this paper measured once every 5 day pH value, in order to get the typical experimental data. The daily gas production is measured at 17:00 p.m. every day after shaking the fermentation tank manually.

Experimental Reagents

Acid and alkali regulators: hydrochloric acid (HCl), sodium hydroxide (NaOH), calcium hydroxide [Ca(OH)2], sodium carbonate (Na2CO3).

Test Design

Daily biogas production (DBP).

The fermentation materials were pig manure, cow manure, and corn straw. After manual screening, the feces are put into the plastic bucket after removing the sundries, sealed and retreaded, and stirred every three days, the total retreading time is 7 days. After air drying, the straw is cut to about 1cm in length and put in a cool and ventilated place for standby. Add a little cow dung into the biogas slurry 2 days in advance, mix and seal, domesticate, and reserve. Pig manure/corn straw and cow manure/corn straw are respectively set with five levels: 1:9, 3:7, 5:5, 7:3, 9:1. The total solid content of fermentation substrate was maintained at 8%. 560g of fermentation raw materials and 140 g of acclimated biogas slurry inoculum were put into 1 L triangular glass bottle. Each treatment test is set with three repetitions. After checking the air tightness of the device, the fermentation tank is placed in a constant temperature water tank with set temperature for heating. The test temperature is 30° and 60°C, respectively. During the experiment, the fermentation raw materials and inoculum were put into the fermentation tank, and the fermentation tank was placed in the constant temperature water bath culture tank, the devices were connected, the temperature was set, and the biogas output was measured by the drainage method. The measurement time is set at 17:00 p.m. every day, shake the fermentation tank manually for 30 s to break the crust on the surface of fermentation raw materials in the fermentation tank and release the generated gas. The volume of water in the water collecting barrel was measured with the cylinder, which is the biogas output of the day.

Methane content, MC

The liquid TOC analyzer (Beijing Science and Technology Development Co., Ltd.) was used to measure methane content in gas before measuring DBP every day.

PH value

Measure the pH value of the mixed fermentation substrate every 5 days with a pH detector.

Determination of total alkalinity

Determine the total alkalinity by potentiometric titration. Potentiometric titration is based on the sudden jump of potentiometric titration curve at the end point to determine the alkalinity at a specific pH, which is not affected by the turbidity and chroma of water samples, and has a wide range of application. The specific determination steps are as follows:

(a) Accurately prepare HCl standard solution with concentration of about 0.1 mol/L, and calibrate it with reference Na2CO3 solution.

(b) Install and calibrate the potentiometer according to the instructions, and clean the electrode with distilled water.

(c) According to the above method, the water sample is centrifuged or filtered (5,000 r/min, 10 min), and 2 mL of filtrate is sucked into a 50 mL beaker with a pipette. The amount of sample should be able to consume 2–8 mL of HCl (0.1 mol/L) standard solution. The same volume of distilled water was used as blank control.

(d) The water temperature of the sample is 25 ± 2°C, the 50 mL beaker containing the sample is placed on the titration table, and a magnetic stirring rod about 1.5 cm long is put in. Stir it with a certain intensity. Note that the glass electrode needs to be placed below the calomel electrode in the beaker. Turn on the automatic titration switch and set the end point to ph3.7, and the automatic titration process starts. After the titration stops automatically, record the volume of HCl standard solution consumed in titration.

The formula for determination of total alkalinity can be expressed as follows:

Where V1 is the volume of HCl standard solution consumed by sample, ml; V2 is the volume of sample, ml; V0 is the volume of HCl standard solution consumed by titration blank control, ml; C is the accurate concentration of HCl standard solution, mol/L.

Strengthening Methods

The effect of anaerobic fertilization is not ideal when the substances (straw, energy crops, etc.) containing a large amount of cellulose and lignin are directly used, but the fermentation effect can be improved by pretreating the raw materials rich in such ingredients or mixing several raw materials (Paulina et al., 2018). In the same way, better gas production effect can be obtained by using catalyst. The enhancement of biomass anaerobic fertilization is a hot topic in the research of biomass anaerobic fertilization (Wang et al., 2017).

Pretreatment

The physical pretreatment method uses heat energy, mechanical energy, electromagnetic radiation energy, and other energy to act on the refractory biomass and release the intracellular material by destroying the cell wall. Finally, the utilization difficulty of the refractory biomass is reduced (Alarcon et al., 2017; Steven et al., 2017). Physical pretreatment mainly includes heat pretreatment, microwave pretreatment, and ultrasonic pretreatment. Heat pretreatment can destroy the cell wall of biomass, release the organic matter in the cell, and transform the insoluble organic matter into soluble organic matter, which greatly shortens the hydrolysis time and improves the biogas production efficiency. After heat treatment of food waste for 1.5 h at 80°C, anaerobic fertilization was carried out. The methane content in the gas production was 647.5 ± 10.6 mL⋅g–1VS, which was 52% higher than that of untreated. There are two mechanisms for microwave pretreatment to destroy the cell wall of biomass: (1) microwave causes molecular oscillation, which causes the temperature of biomass to rise and leads to the heating effect (Jia et al., 2018); (2) the alternating electric field generated by microwave breaks the hydrogen bond of macromolecules in the cell wall, thus damaging the cell wall structure. Different microwave intensity was used to treat straw, and then it was used for anaerobic fertilization. It was found that microwave treatment significantly promoted the anaerobic fertilization of straw. The average daily gas production of pretreated straw increased from 6.21 to 8.16 mL⋅g–1VS, which increased by 31.33%; the average concentration of methane increased from 50 to 62%. The researchers also studied the effect of microwave irradiation on the performance of anaerobic fertilization of energy, and obtained 345.16 mg⋅g–1TS gas production. The role of ultrasound is to use the whole effect in low frequency and the chemical effect in high frequency. The effect of ultrasonic pretreatment on the anaerobic fertilization of cattle manure was also studied. The results showed that the ultrasonic pretreatment with appropriate intensity had a certain promoting effect on it. After pretreatment with 250 W ultrasonic for 40 min, the gas production rate reached the optimum, which was 297.78 mL⋅g–1TS. After the sludge of paper mill was pretreated by ultrasound, its anaerobic fertilization was studied (Ling et al., 2018). The results showed that 1250 W ultrasonic pretreatment could promote the fermentation (Marzieh and Andrew, 2018; Yu et al., 2018), and the mixture of the by-product of the meat processing factory and the cow manure was pretreated by ultrasonic. The result of the anaerobic fertilization showed that the biogas production increased obviously after the ultrasonic pretreatment.

Chemical Pretreatment

Chemical pretreatment is to use some corrosive chemicals (strong acid, strong alkali, and strong oxidant, etc.) to destroy the cell wall structure and extracellular polymer of biomass. Chemicals even react with extracellular macromolecular organics to promote their degradation (Pujaningsih et al., 2017). Chemical pretreatment includes alkali pretreatment, acid treatment, and ozone pretreatment. After pretreatment of banana stem with 6% NaOH, the researchers found that the gas production of biogas increased to 357.90 mL⋅g–1VS. The researchers also pretreated wheat straw anaerobic fertilization with 4% ammonia water, and found that the removal rate of hemicellulose and cellulose can reach 42 and 20% respectively, and under the load rate of 65 g⋅L–1, the maximum biogas output of 377 mL⋅g–1 can be obtained through anaerobic fertilization. Corn straw was treated with dilute acid and then used in anaerobic dry fermentation. After 60 h of treatment, the total gas production rate is 4.76 m3⋅m–3, and the maximum methane content is 82.90%. In this paper, acid and alkali pretreatment was used to treat lemongrass and reed. The results showed that the accumulated gas production and methane content of anaerobic fertilization were significantly increased after acid-base pretreatment, and the effect of acid treatment was better than that of alkali treatment. After straw was treated with alkaline ozone, lignin was oxidized, and decomposed into small molecular organic acids, which improved the efficiency of anaerobic fertilization of straw (Yu et al., 2017).

Biological Pretreatment

The biological pretreatment of fermentation raw materials is to use microbial community to degrade lignin in straw and change the structure of lignin. The researchers domesticated a group of cellulose decomposing complex bacteria with high enzyme activity and stability, and used them to pretreat straw for anaerobic fertilization. Its gas production is 33.3% higher than that of untreated group. The results of anaerobic fertilization showed that the cumulative gas production of pretreated rape straw was 17.8% higher than that of untreated. When testing the effect of white rot fungus pretreatment on biogas production of sugarcane leaves, it was found that adding white rot fungus can accelerate the start-up rate and peak gas production of anaerobic fertilization (Zhang C. H. et al., 2017; Hu et al., 2018). With the above-mentioned pretreatment methods, the gas production effect of biomass feedstock in the anaerobic fertilization process has been improved to some extent.’

Mixed Fermentation of Different Biomass

Due to the differences in the composition of various biomass, the effect of single biomass fermentation is not ideal, and the mixed fermentation of different biomass can effectively improve the gas production effect of anaerobic fertilization. The sludge contains a large number of anaerobic microorganisms but lacks nutrients, so the sludge can be used as inoculum or raw material for mixed fermentation with other biomass (Qu, 2017; Tang et al., 2019). The researchers used a mixture of dewatered sludge and Canadian goldenrod, an imported ornamental plant, for anaerobic fertilization. The results showed that the methane production per unit volume increased by 79.5% compared with anaerobic fertilization alone. Anaerobic granular sludge, digested sludge, and excess sludge were mixed with cyanobacteria respectively, and they can effectively promote the anaerobic fertilization process. When the ratio of cyanobacteria to anaerobic granular sludge is 6:1, the gas production rate is 73 mL⋅g–1VS. When the mixed fermentation of solid wastes of the biomass with different proportion and sludge is adopted, the gas production effect is significantly improved (Liu et al., 2017). When the bean curd dregs are mixed with the digested sludge, the fermentation effect of bean curd dregs is good. When rice straw was used as the fermentation base, the fermented cow manure, pig manure, chicken manure, sludge, and anaerobic granular sludge were inoculated respectively, it was found that the above five inoculants effectively improved the gas production rate of rice straw anaerobic fertilization. In the process of anaerobic fertilization, different proportion of mixture will affect biogas quantity, methane content, pH value and alkali concentration.

When the carbon rich food waste and nitrogen rich piggery wastewater are mixed and fermented, the biogas output is 396 mL⋅g–1VS. When solid wastes of the biomass and glycerin were mixed at 50°C, anaerobic fertilization was carried out. It was found that the biogas production increased with different proportion of mixed fermentation, and the highest methane production was 640 L⋅kg–1VS. After mixing the grass and pig manure, different inoculums were added for anaerobic fertilization. The results showed that the highest methane production was 521.9 mL⋅g–1TS. When the cow manure and pear were mixed for fermentation, the biogas production was increased in different proportion, and the maximum gas production was 390.0 ± 2.0 mL⋅g–1VS. After mixing chicken manure with rice straw, it was found that the methane production was 223 ± 7 mL⋅g–1VS in the stable fermentation environment.

Different kinds of biomass are mixed for fermentation, which can make up for the shortage of single substance and create a good living environment for microorganisms. Finally, the resource utilization of biomass waste is realized.

Results

The changes of biogas amount, methane content, pH value, and alkalinity of fermentation liquid in the mixed fermentation process of solid wastes of agricultural biomass were studied in the laboratory of an Agricultural University of science and technology. A variety of solid wastes are collected in the nearby city farms. The anaerobic fertilization process was completed in the fermentation tank of the laboratory, and the multi-level treatment test under single condition was carried out. Through the gas production (the most intuitive test index), the optimal fermentation temperature, methane content, and initial pH value of each single raw material were determined. Then a variety of solid wastes of the biomass were placed in the fermentation tank respectively, and the influence of the components of biomass on the alkalinity of the fermentation liquid was analyzed in the anaerobic fertilization process.

Effect of Medium Temperature (30°C) and High Temperature (60°C) on Biogas Production of Mixed Anaerobic Fertilization

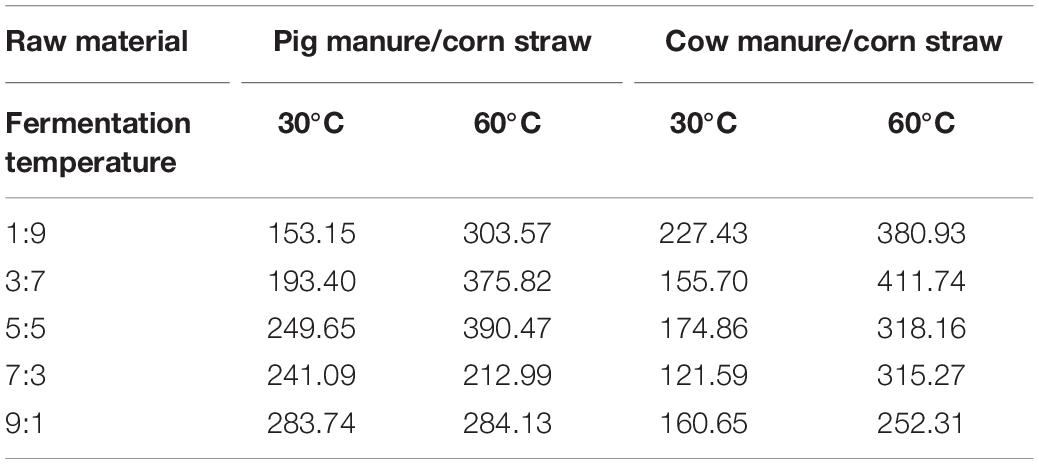

Under medium and high temperature, the unit biogas output of pig manure/corn straw, cow manure/corn straw with multi ratio for anaerobic fertilization is shown in Table 1.

Table 1. Biogas output per unit with different substrate ratio under medium and high temperature conditions (mL/g TS).

At medium temperature, the biogas output per unit of pig manure/corn straw is better than that of cow manure/corn straw. When the ratio of pig manure to corn straw is 9:1, the maximum gas production is 283.74 mL/g TS; when the ratio of cow manure to corn straw is 7:3, the minimum gas production is 121.59 mL/g TS. Under high temperature, the biogas yield of cow manure/corn straw is better than that of pig manure/corn straw. When the ratio of cow manure to corn straw is 3:7, the maximum gas production is 411.74 mL/g TS; when the ratio of pig manure to corn straw is 7:3, the minimum gas production is 212.99 mL/g TS.

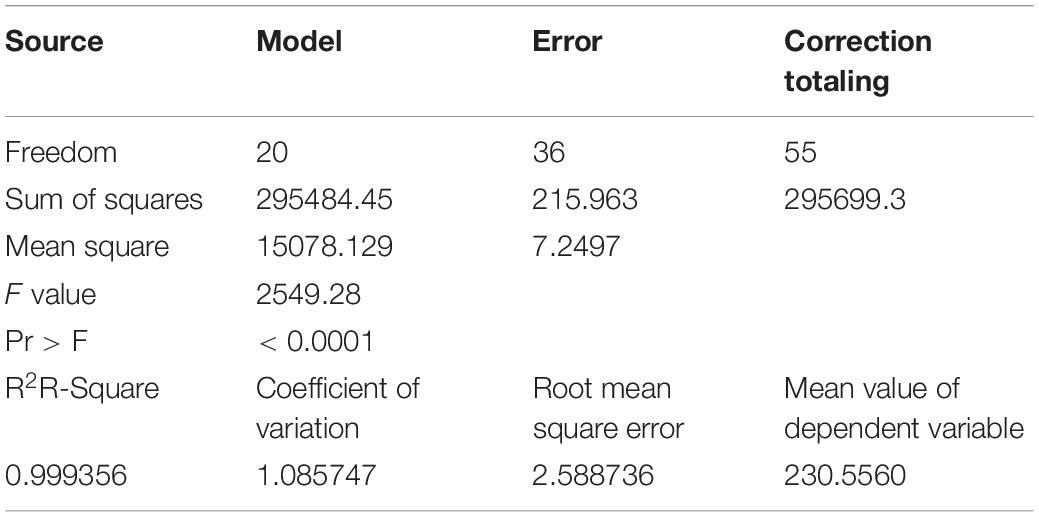

The analysis of variance of unit biogas output of two mixtures with different proportions under medium and high temperature conditions is shown in Table 2.

It can be concluded that the biogas output per unit of anaerobic fertilization is significantly different at medium and high temperature, and the high temperature fermentation is significantly higher than the medium temperature fermentation. The biogas output of pig manure/corn straw is significantly different from that of cow manure/corn straw, the former is better. When the ratio of feces to straw was 1:9, 5:5, 9:1, and 3:7, there was significant difference between the two groups. There were significant differences among the other groups.

By comparing the biogas production of pig manure/corn straw with each ratio in the middle temperature and high temperature, it can be concluded that the difference of biogas production in the middle temperature is greater than that in the high temperature. However, the biogas production per unit of cow manure/corn straw was significantly higher than that of medium temperature at high temperature, which indicated that the mixed fermentation of cow manure/corn straw was more suitable for high temperature. However, the linear relationship between the unit gas production and the ratio of each treatment is not obvious, which needs further test to verify. By comparing the methane production of mixed raw materials under the conditions of medium temperature and high temperature, it can be concluded that the type and proportion of fermentation raw materials will affect the biogas production under the same temperature. In the medium temperature condition, the mixed fermentation effect of pig manure and corn straw is quite different, and the stability of fermentation process is general; in the high temperature condition, although the gas production is improved, the fermentation starts late, and the stagnation period is prolonged. Cow dung/corn straw showed better stability, especially at high temperature, gas production, and stagnation time were significantly optimized. The results showed that the fermentation effect of pig manure/corn straw was better at medium temperature, while that of cow manure/corn straw was better at high temperature.

Methane Production of Mixture in Anaerobic Fertilization Process

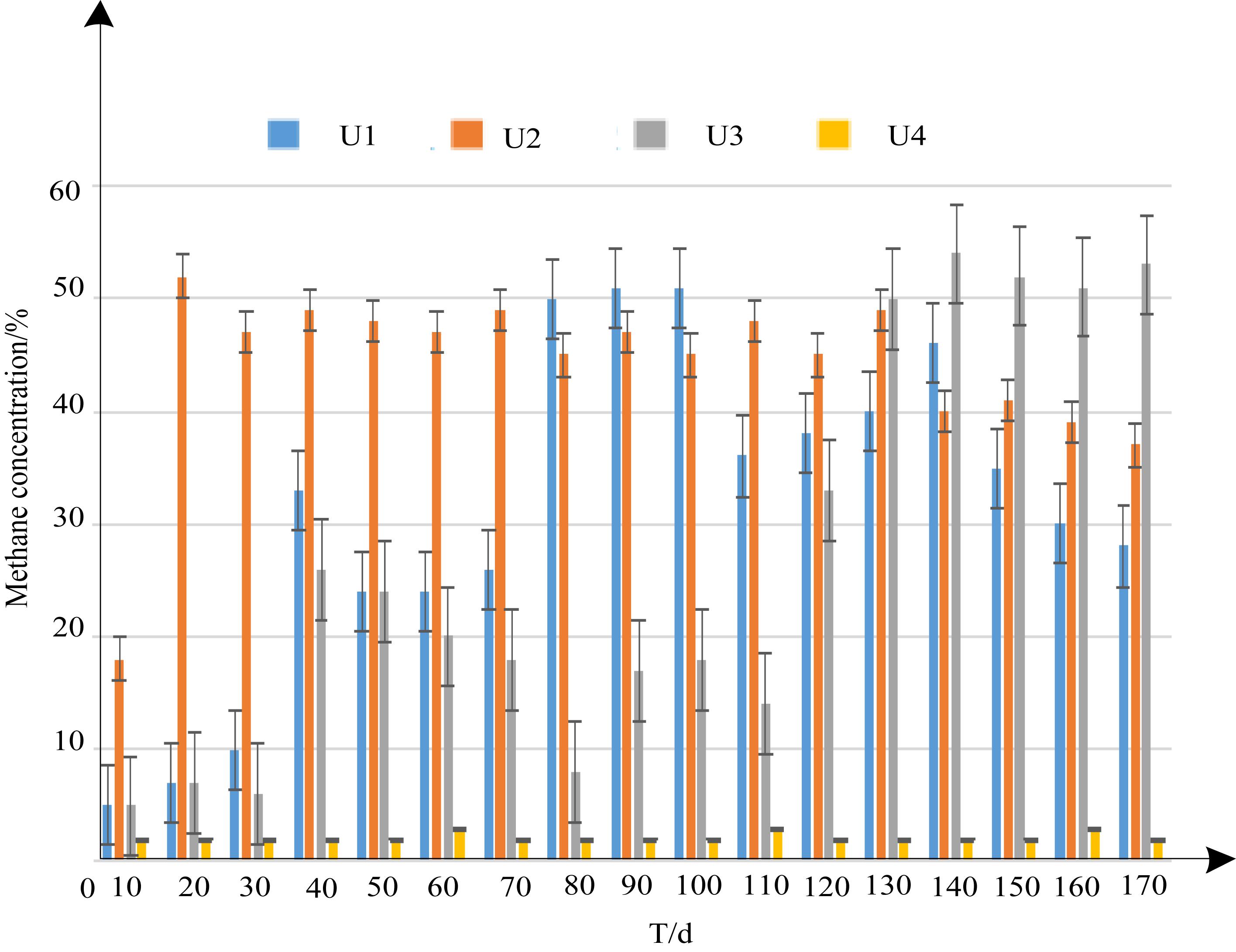

When the ratio of cow manure with sludge is 2:0, 2:1, 3:1, and 4:1, respectively, the methane content changes with the increase of fermentation time, as shown in Figure 1. It is assumed that the fermentation tanks with four proportions of cow manure and sludge are U1, U2, U3, and U4 respectively.

The methane content increased from 17.54 to 51.4% in the first 20 days after U2 feeding, which indicated that acid production was dominant in the early stage of fermentation. At the 20–130th day, the methane content increased very slowly and remained stable between 45 and 51.4% for a long time. After 131 days, it began to decline slowly, from 49.1 to 35.45%, indicating that the reaction began to enter the aging period, and methanogens began to fail. U1 and U3 were similar in the first 22 days, but U1 experienced two peaks of methane content in the whole 170 days of fermentation time, which were 33.2% at 40 days and 47.31% at 140 days. Since then, it began to decline rapidly, characterized by short peak holding time and inactive methanogenesis, which was in line with the characteristics of its non-inoculated mud. U3 experienced a relatively stagnant period from 70 to 100 days, and the methane content remained between 9.8 and 22.28%, and then began to increase rapidly, and the growth rate was much higher than that of other fermentation tanks in the same period. By the end of the experiment, the content reached 55.11%, which was the highest among the four fermentation tanks. It can be concluded that the methanogenic activity in U3 is still in a vigorous breeding period, which may be due to the addition of NaOH in the fermentation tank to regulate the pH value so that the final methanogenic bacteria in the fermentation tank is more than the acid producing bacteria. In the long process of competition between acidogenic bacteria and methanogens, more excellent methanogens were screened out, which can be obtained from the highest methane content of U2 and U3 (51.48 and 55.11%). Therefore, if no sludge is added to the anaerobic fertilization process, the methane content will slowly increase in the first half of anaerobic fertilization process, and then slowly decrease in the second half. When the ratio of cattle manure to sludge is 2:1, the methane content will be stable between 45 and 51.4% in the first 130 days, and then slowly decrease. When the ratio of cattle manure to sludge is 3:1, the methane content will rise slowly in the first 120 days, and reach the maximum value of 55% on the 140th day, and then keep stable. When the ratio of cattle manure to sludge is 4:1, the methane content will be kept at 2%, and the methane production is the least.

The Change of pH Value in Anaerobic Fermentation Process

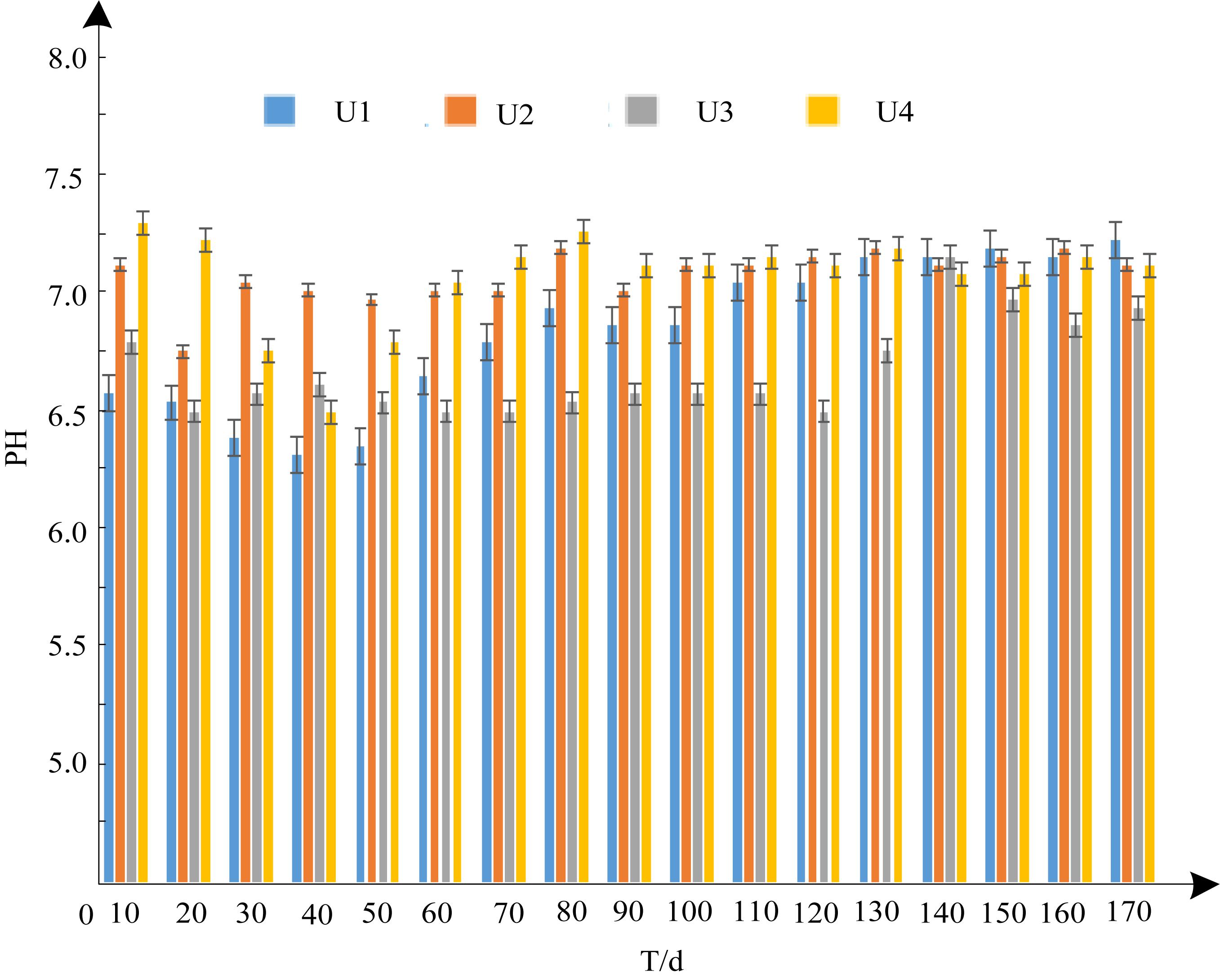

The change of pH value in anaerobic fermentation process is shown in Figure 2.

It can be seen from Figure 2 that when U3 is used to complete anaerobic fermentation, acidification occurs in anaerobic fermentation tank, and the pH of the produced leachate drops to about 5.5 in the early stage. The results showed that the acidification of straw could not be prevented at the initial stage of leachate reflux, and the microorganisms in solid phase only hydrolyzed the organic matters in leachate. A large number of acid producing bacteria increased the organic acids and decreased the pH value in the leachate, which destroyed the ecological balance of the microbial community in the solid layer. After anaerobic fertilization in U3, the leachate produced reached the highest value of 7.25 at 140 days, and then began to decline, and the hydrolysis reaction began to be active again. However, this does not affect its gas production, and after 140 days pH has been maintained above 6.5, methanogens have gradually adapted to the slightly acidic environment and can smoothly produce gas.

The pH value of the leachate produced after anaerobic fertilization in U2 is always above 7.0, and it is close to 7.25 at the end of the test. This may be due to the high water content will dilute the acid produced by hydrolysis, and alleviate the impact of acid production reaction on methanogens. In addition, high inoculation amount also has a certain ability to prevent acidification. It was found that the pH value of the leachate after U1 anaerobic fertilization decreased in the initial 40 days, which was similar to the leachate after U4 anaerobic fertilization. Then, the pH of U1 permeate began to increase suddenly within 50 days, and gradually approached to neutral. Therefore, in the mixture of cow dung and sludge, the higher the proportion of cow dung is, the higher the pH value at the beginning of anaerobic fertilization is, and in the early stage of anaerobic fertilization, the higher the proportion of cow dung will lead to the rapid decline of pH value, and then it will slowly rise to about 7.25. When the proportion of cow dung is relatively low, the pH value tends to be stable and keeps around 7.25 all the time; the pH value of cow dung without sludge is the lowest at the beginning of anaerobic fertilization, and slowly rises to about 7.25 after the initial pH value keeps stable for a period of time.

Effect of pH on the Alkalinity of Fermentation Liquid

Alkalinity is not alkali. In a broad sense, alkalinity refers to the concentration of strong alkali and weak acid salt in water. It has different forms of existence under different pH values (different number of H on weak acid roots), and can release or absorb H ions according to the environment, thus playing the role of pH change in buffer solution and reducing the pH fluctuation in the system. Alkalinity is not directly involved in the reaction. Alkalinity is an important index to measure the buffering capacity of anaerobic system, and it is also a standard to measure the pH impact resistance of the system.

In the determination of alkalinity, according to the titration end point, it can be divided into phenolphthalein alkalinity and methyl orange alkalinity. The former has a pH value of 8.3, which indicates the end point of neutralization of hydroxide in water sample and conversion of carbonate to bicarbonate; the latter has a pH value of 4.4–4.5, which indicates that the end point of neutralization of bicarbonate in water (including original bicarbonate and bicarbonate converted from carbonate) is equivalent to the pH value of just turning methyl orange into orange red. Industrial waste water or water with complex components can be used with pH = 3.7 to indicate the titration end point of total acidity.

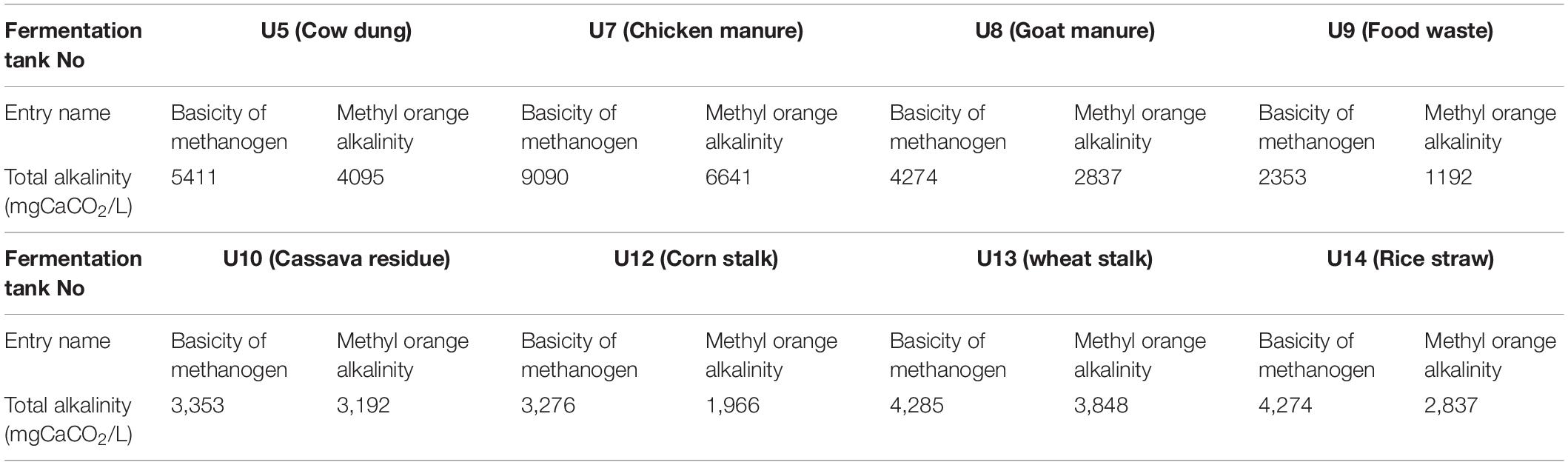

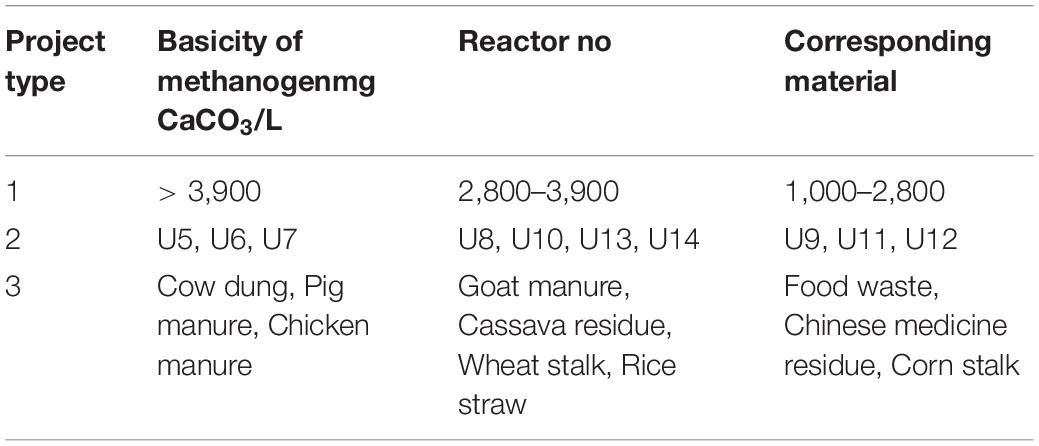

In the continuous anaerobic fertilization process, the suitable pH range for methanogens is 6.8–7.8, and the broader pH range is 6.5–8.2. Therefore, in this experiment, as a new definition, the basicity of methanogens is used, that is, in the titration measurement process of total basicity, when the pH displayed by the potential titrator reaches 6.5, the calculated basicity value. Different from phenolphthalein alkalinity and methyl orange alkalinity, methanogen alkalinity can reflect the ability to maintain the pH of the system above 6.5 in the sample to be tested, that is, the buffering ability to absorb hydrogen ions to maintain the pH of the system above 6.5. Therefore, the basicity of methanogens can better serve the experiment and production of anaerobic biogas production than that of methyl orange. Table 3 shows the daily average alkalinity value of each fermentation tank in the later stage of fermentation.

Table 3 shows that the daily average methyl orange alkalinity and methane bacteria alkalinity between the fermentation tanks are quite different. Among them, the methane bacteria alkalinity of U5, U6, and U7 were above 3,900 mg CaCO3/L, significantly higher than other fermentation tanks. This shows that the three groups of materials in the fermentation tank have strong buffer capacity and can withstand higher organic load, which is also an important reason for their pH above 7.5. There are only the fermentor with methane bacteria alkalinity above 2,800 mg CaCO3/L in U8, U10, U13, and U14. The other fermentation tanks have a CaCO3/L of 1,000–2,000 mg, of which the lowest is U9, 1,192 mg. This indicated that its buffering capacity was the weakest among 10 groups of fermentation tanks.

In addition, Table 3 also shows that the total alkalinity of the internal fermentation liquid of each group of fermentation tanks is significantly higher than their methane bacteria alkalinity. The difference amplitude between two alkalinity of each material is different. Therefore, methane bacteria alkalinity is not the direct “reduced version” of the total alkalinity, but the independent index that can truly react to the starting enzyme and stabilize the pH above 6.5. According to the methane bacteria alkalinity, 10 groups of fermentation tanks can be divided into three groups: high, medium and low, as shown in Table 4.

It can be seen from Tables 3, 4 that the higher the methane bacteria alkalinity of the fermentation liquid is, the higher the pH of the system is.

The pH can reflect the ability of the starting fermentation liquid to neutralize organic acids. Therefore, we can continue to increase the organic load of the fermentation tank to improve the production efficiency of methane in the anaerobic fermentation; on the contrary, the internal fermentation liquid of the fermentation tank has a low methane bacteria alkalinity, and its pH also decreases. This indicates that the ability of neutralizing organic acids in fermentation broth is weakening at this time. If the organic load is not reduced, it may go to rancidity, and finally lead to the failure of methane production by anaerobic fertilization. Therefore, according to the pH value and methane bacteria alkalinity of the fermentation tank, the top three groups of fermentation tanks perform best, which can continue to increase the organic load.

Although the pH of U8 showed the downward trend, it was relatively slow as a whole, so it was not suitable to continue to increase the organic load; the pH of u9, U10, and U11 showed the significant decline in the later stage of the test, so they were not suitable to continue to increase the organic load. In particular, U9 with cassava residue as the substrate has the lowest methane bacteria alkalinity, which is 1,192 mg CaCO3/L, and the pH has dropped below 7.0 at the end of the experiment. According to the above analysis, the PH value of U5 (cow dung) and U6 (pig dung) were the most stable in 10 groups of fermentation tanks.

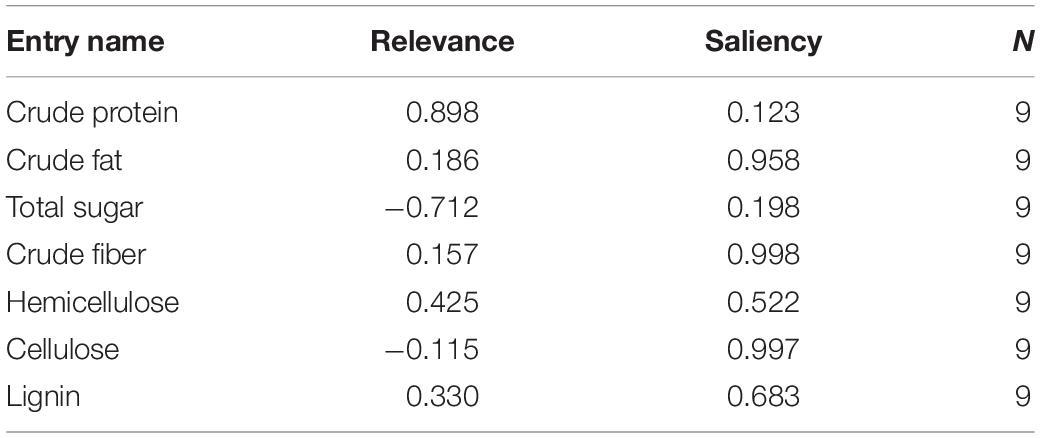

Table 5 shows the correlation between the composition of biomass and the alkalinity of fermentation liquid.

As shown in Table 5, there is only a significant positive correlation between the content of crude protein in biomass and the methane bacteria alkalinity. The results show that the higher the content of protein compounds in biomass is, the higher the alkalinity of biomass after anaerobic fertilization is.

Discussion

(1) Temperature effect. At medium temperature, the biogas output per unit of the mixture of pig manure and corn straw is higher than that of the mixture of cow manure and corn straw, and the higher the content of pig manure and corn straw is, the higher the gas production is. At high temperature, the biogas production of cow manure and corn straw is higher than that of pig manure and corn straw. When the ratio of cow manure to corn straw is 3:7, the gas production is the highest. According to the analysis of variance of unit biogas output of two different mixtures at medium and high temperature, it can be seen that the unit biogas output of pig manure/corn straw at medium temperature is significantly higher than that at high temperature, while the unit biogas output of cow manure/corn straw at high temperature is significantly higher than that at medium temperature. The results showed that the mixture of pig manure and corn straw was suitable for medium temperature fermentation, while the mixture of cow manure and corn straw was suitable for high temperature fermentation. Therefore, the medium temperature fermentation effect of pig manure/corn straw is better, and the high temperature fermentation effect of cow manure/corn straw is better. Therefore, in order to get more biogas, according to the above research, the biogas amount can be increased by increasing the fecal content under the appropriate fermentation temperature.

(2) Changes in methane content. If no sludge is added to the anaerobic fertilization process, the methane content will slowly increase in the first half of anaerobic fertilization process, and then slowly decrease in the second half. When the ratio of cattle manure to sludge is 2:1, the methane content will be stable between 45 and 51.4% in the first 130 days, and then slowly decrease. When the ratio of cattle manure to sludge is 3:1, the methane content will rise slowly in the first 120 days, and reach the maximum value of 55% on the 140th day, and then keep stable. When the ratio of cattle manure to sludge is 4:1, the methane content will be kept at 2%, and the methane production is the least. Therefore, in order to improve the methane content, based on the premise of its own fermentation time limit, choose the appropriate proportion of manure and sludge to complete the anaerobic fertilization, so as to achieve the purpose of increasing the methane content. Li Xuebing’s research on the optimization of solid waste fermentation of agricultural biomass shows that the proper pretreatment of agricultural waste can significantly improve the gas production efficiency and organic load of CO fermentation. Through response surface optimization analysis, the optimal temperature conditions of CO fermentation of cow manure and sludge are obtained. At the same time, the influence degree of different factors on the load methane production rate is analyzed. It is the initial organic load and pretreatment temperature, but this method does not study the gas production under the different mixing ratio of cow manure and sludge. The research is shallow and not deep enough. This method makes up for this very well.

(3) Change in the PH value. When the ratio of cattle manure to sludge is 3:1, the anaerobic fermentation tank is acidified. A large number of acid producing bacteria increased the organic acids and decreased the pH value in the leachate, which destroyed the ecological balance of the microbial community in the solid layer. After 140 days pH has been maintained above 6.5, methanogens have gradually adapted to the slightly acidic environment and can smoothly produce gas. When the ratio of cattle manure to sludge is 2:1, the pH value of leachate is stable and keeps above 7.0. When the ratio of cow dung to sludge is 2:0, the pH value will first slowly decrease, then suddenly increase, and finally gradually approach to neutral. Therefore, in the mixture of cow dung and sludge, the higher the proportion of cow dung is, the higher the pH value at the beginning of anaerobic fertilization is, and in the early stage of anaerobic fertilization, the higher the proportion of cow dung will lead to the rapid decline of pH value, and then it will slowly rise to about 7.25. When the proportion of cow dung is relatively low, the pH value tends to be stable and keeps around 7.25 all the time; the pH value of cow dung without sludge is the lowest at the beginning of anaerobic fertilization, and slowly rises to about 7.25 after the initial pH value keeps stable for a period of time. Therefore, in order to control the pH value in the anaerobic fermentation process, we can select the appropriate solid wastes of the biomass ratio according to the characteristics of the above pH value changes. Fang Shaohui, a Chinese scholar, conducted a study on the characteristics of biomass energy conversion by slant dry-type anaerobic fermentation of rural mixtures. During the experiment, the rural biomass waste was used as raw material for biogas dry-type anaerobic fermentation. Based on the previous research results, a small-scale orthogonal experiment was conducted with three factors, namely temperature, inoculation amount, and total solid matter content (TS). The experimental results showed that the gas production increased significantly at high temperature (50°C), the gas production quality was good, and the utilization rate of raw materials was high; the gas production increased more obviously at the inoculation rate of 10–20%. The pH change in the dry anaerobic fermentation process generally showed a trend of “first decreased and then increased, and finally tended to be stable,” and the change trend was in line with the three-stage theory. The change of pH is consistent with the results of this study, so the validity of the experimental results is verified.

(4) Alkalinity of fermentation liquid. In the detection of the alkalinity of the fermentation liquid, the concept of the alkalinity is proposed for the first time, that is, the alkalinity value calculated when the pH value drops to 6.5 in the traditional alkalinity measurement process. Compared with the traditional total alkalinity (methyl orange alkalinity), the ability of starting enzyme to stabilize the pH above 6.5 (the lowest pH tolerance line of methanogens) can be effectively reflected, which can better serve the anaerobic fertilization test. In the analysis of the correlation between the composition of biomass and the methane bacteria alkalinity, the results showed that there was only a significant correlation between the content of crude protein and methane bacteria alkalinity, that is to say, with the increase of protein compounds in biomass, the methane bacteria alkalinity in fermentation broth also increased.

Conclusion

With the continuous development of agricultural production, a large number of agricultural biomass solid wastes are generated. In order to reduce the pollution of these solid wastes to the environment and turn them into available energy, a new mixed fermentation technology of agricultural biomass solid wastes was studied in this paper. The changes of methane content and pH value, the influence of temperature on biogas production and the influence of anaerobic reference liquid on the alkalinity of fermentation liquid were analyzed when agricultural biomass solid waste was mixed in different proportion. The results showed that the mixture of pig manure and corn straw was suitable for medium temperature fermentation, and the mixture of cow manure and corn straw was suitable for high temperature fermentation. If no sludge is added in the process of anaerobic fertilization, the methane content in the first half of anaerobic fertilization will increase slowly, and the methane content in the second half will decrease slowly. When the ratio of feces to sludge is 2:1, the methane content is stable between 45 and 51.4% in 130 days, and then slowly decreases. When the ratio of cow manure to sludge was 3:1, the methane content increased slowly in the first 120 days, reached the maximum value of 55% on the 140th day, and then kept stable. When the ratio of cow manure to sludge is 4:1, the methane content is kept at about 2%, and the methane production is the least. In the mixture of cow manure and sludge, the higher the proportion of cow manure is, the higher the pH value is in the early stage of anaerobic fertilization. In the early stage of anaerobic fertilization, the higher the proportion of cow manure is, the lower the pH value will be. There was only a significant correlation between crude protein content and basicity of methanogens, that is, with the increase of protein compounds in biomass, the basicity of methanogens in fermentation broth also increased. On the basis of this study, the following suggestions are proposed:

By adjusting the proportion of agricultural biomass solid waste, the amount of biogas and methane content produced in the process of mixed fermentation can be controlled. By adjusting the proportion of agricultural biomass solid waste, the pH value of leachate and the basicity of fermentation liquid can be controlled, so that the mixed fermentation process is more smooth and the fermentation effect is more ideal.

Data Availability Statement

All datasets generated for this study are included in the article/supplementary material.

Ethics Statement

The study was approved by Shenyang Agricultural University. All authors provided written informed consent.

Author Contributions

FZ and WY studied the mixed fermentation technology of solid wastes of agricultural biomass and selected corn straw, pig manure, and kitchen waste as solid wastes of agricultural biomass. WL and ZX did the experiments, used physical, chemical, and biological pretreatment methods to strengthen the anaerobic reference of biomass, and the mixed fermentation of different biomass to complete the anaerobic fermentation of a variety of solid wastes of agricultural biomass. FZ wrote the manuscript.

Funding

This research was supported by The National Natural Science Foundation of China-Outstanding agricultural research talents and Innovation Team Project of the Ministry of Agriculture (No. 31570706).

Conflict of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

Ahamed, M. S., Guo, H., and Tanino, K. (2018). A quasi-steady state model for predicting the heating requirements of conventional greenhouses in cold regions. Inform. Process.Agric. 5, 33–46. doi: 10.1016/j.inpa.2017.12.003

Alarcon, M., Santos, C., and Cevallos, M. (2017). Study of the mechanical and energetic properties of pellets produce from agricultural biomass of quinoa, beans, oat, cattail and wheat. Waste Biomass Valorization 8, 1–8.

Girotto, F., Lavagnolo, M. C., Pivato, A., and Cossu, R. (2017). Acidogenic fermentation of the organic fraction of municipal solid waste and cheese whey for bio-plastic precursors recovery – Effects of process conditions during batch tests. Waste Manag. 70:71. doi: 10.1016/j.wasman.2017.09.015

Hong, M. Z., Xue, L. Z., and Shi, C. Z. (2017). Effects of agricultural biomass burning on regional haze in China: a review. Atmosphere 8, 15–17.

Hu, N. J., Zhou, W., and Zheng, J. L. (2018). Preparation and electrochemical performance of porous V2O5 microspheres. CJPS 42, 108–116.

Jia, W. H., Jian, W. Z., and Dong, B. W. (2018). Effect of diclofenac on the production of volatile fatty acids from anaerobic fermentation of waste activated sludge. Bioresour. Technol. 254, 7–15. doi: 10.1016/j.biortech.2018.01.059

Jongkeun, L., Kwanyong, L., Donghwan, S., Young Mo, K., Ki Young, P., et al. (2018). Hydrothermal carbonization of lipid extracted algae for hydrochar production and feasibility of using hydrochar as a solid fuel. Energy 153, 2957–2965.

Lam, S. S., Lee, X. Y., Nam, W. L., Phang, X. Y., Liew, R. K., Yek, P. N. Y., et al. (2018). Microwave vacuum pyrolysis conversion of waste mushroom substrate into biochar for use as growth medium in mushroom cultivation. J. Chem. Technol. Biotechnol. 12, 78–89.

Ling, L., Xiao, P. G., and Cheng, L. Z. (2018). Adsorption behaviors and mechanisms of heavy methane ions on municipal waste composts with different degree of maturity. Environ. Technol. 40, 1–43.

Liu, W., Xu, C. H., and Chen, Z. Y. (2017). Simulation of adaptive filtering method for target image data. CS 34, 260–263.

Luc, D. V., Simon, V. K., and Frédéric, L. (2017). Microbial ecology and process technology of sourdough fermentation. Adv. Appl. Microbiol. 100, 49–160. doi: 10.1016/bs.aambs.2017.02.003

Marzieh, G., and Andrew, A. R. (2018). The effect of mixing on fermentation of primary solids, glycerol, and biodiesel waste. Water Sci. Technol. 77, 180–196. doi: 10.2166/wst.2018.015

Natalia, H. G., Manuel, B., and Davi, B. (2019). Effects of enzymes addition on biogas production from anaerobic fermentation of agricultural biomasses. Waste Biomass Valorization 3, 1–12. doi: 10.1016/j.watres.2009.11.048

Ojha, K. S., Mason, T. J., and O’Donnell, C. P. (2017). ultrasound technology for food fermentation applications. Ultrason. Sonochem. 34, 410–417. doi: 10.1016/j.ultsonch.2016.06.001

Paulina, K., Aleksander, H., and Krzysztof, F. (2018). The study on application of biopolyols obtained by cellulose biomass liquefaction performed with crude glycerol for the synthesis of rigid polyurethane foams. J. Polym. Environ. 26, 2546–2554. doi: 10.1007/s10924-017-1145-8

Pivoto, D., Waquil, P. D., Talamini, E., Finocchio, C. P. S., Dalla Corte, V. F., and de Vargas Mores, G. (2018). Scientific development of smart farming technologies and their application in Brazil. Inform. Process. Agric. 5, 21–32. doi: 10.1016/j.inpa.2017.12.002

Pujaningsih, R. I., Mukodiningsih, S., and Pakpahan, I. (2017). Cassava waste processing technology to support the provision of alternative feed on zero waste management system of livestock. Adv. Sci. Lett. 23, 2595–2597. doi: 10.1166/asl.2017.8727

Qu, J. J. (2017). Research on the function of electronic medical record and related problems in hospital informatization management. AI 15, 226–227.

Sawan, Z. M. (2018). Climatic variables: evaporation, sunshine, relative humidity, soil and air temperature and its adverse effects on cotton production. Inform. Process. Agric. 5, 134–148. doi: 10.1016/j.inpa.2017.09.006

Steven, W., Ilona, S. H., Mohammad, J., and Taherzadeh, M. J. (2017). Biochemicals from food waste and recalcitrant biomass via syngas fermentation: a review. Bioresour. Technol. 248, 113–117. doi: 10.1016/j.biortech.2017.06.075

Tang, M., Yang, Y., and Li, X. F. (2019). Two-grid finite element discretization methods for a class of poisson-nernst-planck equations. J. Jilin Univ. 57, 71–77.

Wang, S. Q., Li, Z. H., and Wu, H. K. (2017). Design and experiment on solid heat carrier heating device heated by high temperature flue gas for pyrolysis of biomass. Trans. Chin. Soc. Agric. Eng. 6, 47–49.

Xu, H., Liang, C. Y., and Xu, J. L. (2017). Study on One-step ethanol production from CO by cautoethanogenum. Trans. Chin. Soc. Agric. Eng 18, 76–78.

Yu, L., Gordeeva, A. V., Borodin, L., and Gordeev, S. (2018). Estimating the limiting rate of dilution in technology for lactic acid production by continuous fermentation. Theor. Found. Chem. Eng. 52, 64–66. doi: 10.1134/s0040579518010050

Yu, X. L., Xu, Y. J., and Zhou, Z. X. (2017). Sparse event detection based on parallel discrete social spider optimization algorithm and compressed sensing in wireless sensor networks. JCAEIT 12, 202–208.

Zhang, C. H., Zhou, J. W., and Du, C. S. (2017). Review of control strategies of single-phase cascaded H-bridge multilevel inverter for grid-connected photovoltaic systems. JPS 15, 1–8.

Zhang, Q., Liu, H., and Hu, J. (2017). Effects of phosphate and carbonate on photo-fermentative hydrogen production of biomass straw. Trans. Chin. Soc. Agric. Eng. 33, 251–257.

Keywords: agricultural biomass, solid waste, mixed fermentation, anaerobic fermentation, pH value

Citation: Zhang F, Yu W, Liu W and Xu Z (2020) The Mixed Fermentation Technology of Solid Wastes of Agricultural Biomass. Front. Energy Res. 8:50. doi: 10.3389/fenrg.2020.00050

Received: 20 December 2019; Accepted: 12 March 2020;

Published: 16 April 2020.

Edited by:

Su Shiung Lam, University of Malaysia Terengganu, MalaysiaReviewed by:

Rock Keey Liew, Universiti Malaysia Terengganu, MalaysiaPeter Nai Yuh Yek, University College of Technology Sarawak, Malaysia

Changlei Xia, Nanjing Forestry University, China

Copyright © 2020 Zhang, Yu, Liu and Xu. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wei Yu, eXV3ZWkwNjdAMTI2LmNvbQ==

Feng Zhang

Feng Zhang Wei Yu

Wei Yu Wenhe Liu

Wenhe Liu Zhanyang Xu

Zhanyang Xu