94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci. , 18 March 2025

Sec. Geohazards and Georisks

Volume 13 - 2025 | https://doi.org/10.3389/feart.2025.1561516

This article is part of the Research Topic Natural Disaster Prediction Based on Experimental and Numerical Methods View all 10 articles

Introduction: The Dahongshan copper mine presents complex mining challenges due to its gently dipping, thin to medium thickness copper and iron orebodies occurring in parallel interbedded layers with moderately stable surrounding rock.

Methods: To address these challenges and optimize mining operations, a “copper and iron co-mining” model was proposed. This model was implemented using a two-step sublevel open stoping with backfilling mining technology. Key supporting technologies developed include: an economic cut-off grade model for co-mining; a strength model of cemented backfill coupled with layered precision backfilling technology; a fundamental theory of continuous high-concentration steady-state sand discharge from vertical silos leading to multi-silo parallel continuous high-concentration steady-state sand discharge technology; and a strength and structural design model for retaining walls enabling rapid construction using shotcrete retaining walls.

Results: This integrated technology achieves safe, efficient, and economical mining of the Dahongshan copper mine’s gently dipping, multi-layered, thin to medium thickness, low-grade orebodies. It effectively extends the mine’s service life and demonstrates significant application results, economic benefits, and social benefits.

Discussion: The research results from the Dahongshan copper mine are of great significance for advancing mining theory and possess high application and promotion value for similar mining operations facing comparable challenges.

The increasing difficulty in mining due to significant variation in ore body grade and thickness as well as the large number of interbedded rocks and the challenge of removing them has forced the underground mining to take the path of high efficiency. To improve the efficiency of mining, academician Gu (2004) proposed two-step mining in 2004 and developed high-intensity mining with continuous advancement of the working face.

Numerous scholars have also conducted practical research on two-step mining. Lu et al. (2021) proposed a two-step mining and filling method to improve the efficiency of filling mining, which can achieve the maximum parallel operation of mining and filling. Ajayi et al. (2022) investigated the optimal sequence of roadway excavation based on an automated continuous filling mining method to control formation displacement at higher productivity. Based on theoretical calculations and numerical simulation methods, Guo and Miao, 2022 analyzed the changes in stress, displacement, and plastic zone of roof plate and pillar during two-step mining along the inclination. Zhou et al. (2008) proposed the concept of two-step mining for underground bauxite mining environment reconstruction, which provides a new idea for the development and utilization of underground ore bodies that are complicated and difficult to be mined and have prominent water hazards. To reduce the number of underground operators and to improve the production efficiency and safety, Zhao et al. (2021) investigated the downward medium-deep hole dropping subsequent filling two-step mining method. Nie et al. (2020) proposed the concept of cluster two-step mining to safely and efficiently mine the strip vein groups, and investigated the reasonable range of the safety span of the roof plate in the mining process. To solve the problems of high mining depletion rate, poor roof safety, and high production cost, Gao et al. (2013) proposed the two-step mining method of comprehensive wall-cutting and filling of rhombic unit of downhill ramp and applied it in Jiguozhuang gold mine. Yao (2017) carried out research on continuous high-intensity mining of multilayer gently inclined ore bodies by combining multiple research tools, which increased the ore recovery rate while ensuring the safety of stope operation. Niu et al. (2016) used hierarchical fuzzy analysis to determine a multi middle section two-step mining scheme, which effectively improved the production capacity of low-grade ore bodies by optimizing the step-by-step mining. Chen et al. (2019) carried out a technical study on the two-step mining of adjacent sharply and gently inclined ore bodies, and proposed a calculation formula for reasonable step-by-step mining by analyzing the disturbance in the mining process, which is of theoretical significance for the two-step mining of multi-layer ore bodies. During two-step mining operations, dynamic loads significantly impact the damage and stability of the surrounding rock. Several scholars have investigated the dynamic response mechanisms of rock under the impact loads of blasting, which offers valuable guidance for optimizing the parameters of the two-step mining process (Wang et al., 2024; Hu et al., 2024; Li et al., 2024; Zuo et al., 2024).

The mining conditions of the ore bodies studied above are relatively simple, and most of them only consider a single factor and a single production condition of the ore body to optimize two-step mining. Based on the complex features of the multilayer gently inclined thin to medium-thick low-grade ore body in the Dahongshan Copper Mine, this paper integrates the ore body and the secondary delineation to treat stope, pillar, and goaf as a whole, and then carries out an engineering case study on the 385 middle section.

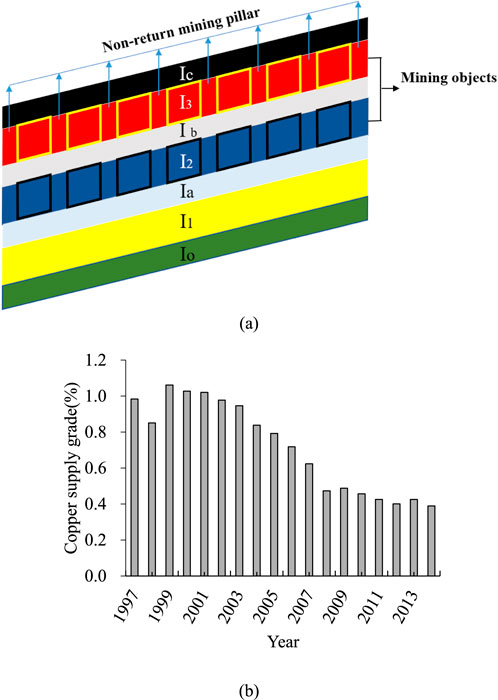

Dahongshan Copper Mine is a submarine volcanic eruption sedimentary metamorphic deposit. There are three iron-bearing copper ore bodies (I3, I2, I1) and four copper-bearing iron ore bodies (Ic, Ib, Ia, Io). From top to bottom, they are Ic→I3→Ib→I2→Ia→I1→Io, respectively. The ore body is thin to medium-thick layered, with a dip angle of 20°–35°. The ore body and surrounding rock are moderately stable with developed structure and joint fissures, and copper and iron occur in parallel in gently inclined to inclined layers, as shown in Figure 1. The main metal minerals in the ore are chalcopyrite and magnetite, while the main gangue minerals are carbonatite (mainly dolomite) and biotite (Jin and Yu, 2020; Zhang et al., 2019).

Due to the interbedded copper-iron phenomenon in the ore body, there are many stones of markedly different grades and thicknesses, so it is difficult to remove the stones in mining. Mixed mining easily leads to low ore grade and poor benefit, while separate mining seriously restricts the production capacity and causes large ore loss.

The first and second phases of Dahongshan Copper Mine (mining orebodies above level 500) adopt the separate copper and iron mining. The sublevel open stope mining method used mainly mines I3 and I2 copper ore bodies, where copper is mined and iron is thrown (Wang, 2010; Liu, 2010; Chen, 2003), as shown in Figure 2A. The I3 ore body is mined first, and then the I2 ore body is mined after filling. Facts have proved that the separate copper and iron mining seriously restricts the production capacity, with a large dilution loss. The actual ore recovery rate is only 46%, and the dilution rate is as high as more than 30%, resulting in the rapid consumption of mine resources. At the same time, the overall ore grade shows a decreasing trend year by year, with a large decline from 1.061% in 1999 to 0.488% in 2009, as displayed in Figure 2B. It indicates that Dahongshan Copper Mine has entered the stage of large-scale low-grade lean ore mining (Li, 2018).

Figure 2. Production situation of Dahongshan copper mine: (A) Schematic diagram of separate copper and iron mining (B) Selected ore grade in Dahongshan copper mine over the years.

Because of the decline of mined copper grade and the continuously increasing mining cost for sublevel open stope method, under the given mine production target conditions, the mine production must follow the road of large-scale and high efficiency to overcome the cost pressure caused by the reduction of copper grade. After 2009, Dahongshan Copper Mine has been committed to the development of mixed copper and iron mining technology. After mixed mining, the true and vertical thicknesses of the ore body reached 35–60 m and 40–70 m, respectively. This makes the multi-layer gently inclined and medium-thick ore body to regularly form a gently inclined and extremely thick large ore body, which creates the necessary conditions for adopting the “large-scale, high-efficiency, and low-cost” mining method. On the basis of this test, the large-diameter deep hole lateral caving open stope and subsequent filling method was successfully applied (Hu and Sun, 2014; Li et al., 2011; Zeng et al., 2014), as shown in Figure 3. The mine output has been steadily increased and the mining cost has been reduced.

This method forms the stope structure of “high pillar and large open stope”, the stope design parameters such as stope span and pillar size are unreasonable, and the width ratio of the room to the pillar is too large. The room span is 35 m, the width of some stopes are about 40 m, while that of the pillar is only 8–10 m. The actual thickness of the pillar is smaller due to large-scale blasting and other reasons. The actual thickness of most pillars is less than 7 m, making the span ratio of the stope to the pillar more than 5:1. Especially in the case of high pillar, the stability of the pillar itself is difficult to be ensured. Due to the increase of stope parameters, the long stope mining and charging cycle duration lead to the roof caving of the stope, resulting in dilution and difficulty in ore extraction at the later stage of the stoping (Huang et al., 2022). The design of a 10-m wide pillar without recovery will cause an ore loss of 20%–22%, and every 5 years of mining results in the loss of 1 year’s ore volume, which is unreasonable (Hu, 2019). As the mine enters the middle and late stage, it is particularly important to realize the efficient utilization of mineral resources and to extend the service life of the mine on the premise of ensuring the mine output and profit. After 2013, based on the concept of copper mining, Dahongshan Copper Mine proposed to comprehensively consider the adjacent multiple panels as a whole “large area” and then proposed the two-step mining method (Liao and Yan, 2020; Yan et al., 2022).

After the ore body is enclosed, the disc area is divided into primary and secondary stopes, which are arranged along the strike of the ore body, as shown in Figure 4. The length of mine stopes along the strike is 50–100 m, the widths of the primary and secondary stopes mine stopes are 20–25 m and 20–25 m, respectively. The primary stopes are mined first, and then the block stone-tailings sand cementation is filled to form the inter-filling pillar support structure, while the secondary stopes are mined again, and then the tailings filling is undertaken in the following steps. The mine adopts the sectional mining mode of cutting the roof and extracting the ore from the floor. The mine roof is dominated by rock drilling operations, and the floor is contacted in sections. Long bar chambers are arranged at the roof of the mine stope along the inclination of the ore body, with dimensions of 3.0 × 3.3 m and a width of 3 m between the chambers. The roof cutting operation is performed at the upper part of the ore body of I3. A large-diameter deep hole lateral collapse technique is used, where 165 mm holes are drilled vertically down the shaft with a T150 rock drill. Mining alignment trunks, mine access roads, and riffle channels were cut in the ore body floor. In the rift channel, SIMBA1354 rock drilling trolley is used to drill upward fan-shaped holes with a diameter of 76 mm. The spacing between the ore exit approaches is 8–12 m, and the ore is discharged in sections by flat-bottomed shovelling machine. After the mine is discharged from the stope, the goaf is filled immediately. The primary stopes are filled with low-strength tailings sand cement (with a grey-sand ratio of 1:6-1:12), and concrete retaining walls are used to make the bottom loading approach and the rock drilling chamber liaison channel airtight. The filling pipeline is led to the stope from the upper filling roadway and filling borehole, and the goaf of the primary stopes must be filled with top filling. The primary stopes mine stope are filled with graded tailings (Li, 2018; Wang, 2017; Li et al., 2021).

The district is arranged along the strike of the ore body, and it is divided into primary and secondary stopes, as shown in Figure 5. The span of the primary stopes are 12–15 m along the strike, while that of the secondary stopes are less than 35 m along the strike. The length of the mining stope along the strike is the stage-slope length with a maximum of 126 m. The primary stopes are mined first, and then the blocks and tailings are cemented to fill the stope to form rib pillar support structure, while the secondary stopes are mined again, and then the tailings are filled in. The mining mode in this case is basically the same as that of the layout along the strike. The rock drilling in the mine stope mainly adopts the T150, and the bottom is formed by sector deep hole blasting to form a V-shaped trench, and the ore is discharged by the flat-bottomed load-haul-dump unit (Li, 2018; Wang, 2017; Li et al., 2021).

The 48–54 line area in the 385 middle section of the Dahongshan Copper Mine that adopted the two-step mining recovered an additional 1,037,918 t of ore. The ore loss rate was 14.48%, and the ore dilution rate was 8.13%. The development ratio was 3.96 m per kiloton (m/kt). Compared to the original mining method, the loss rate decreased by 12.19%, the dilution rate decreased by 1.87%, and the development ratio decreased by 1.14 m/kt. The copper grade was 0.61%, with a recovery rate of 91.83%, resulting in an additional 5,814.239 tons of copper metal. At a sales price of 58,533.45 CNY/t, the revenue from copper metal sales reached 340.3275 million CNY. The iron grade was 24.62%, with an iron recovery rate of 33% and an iron concentrate grade of 65%. This yielded 129,733.3628 tons of new iron concentrate, which, at a sales price of 879.57 CNY/t, generated revenue of 1,141.096 million CNY. The total sales revenue amounted to 454.437 million CNY.

In the area, the volume of cemented backfill was 351,800 cubic meters. The average cement consumption per cubic meter of slurry was 160.60 kg, with a unit cost of 63.58 CNY/m3. The cement consumption per cubic meter of backfill was 191.40 kg, with a unit cost of 75.69 CNY/m3. The total cost of cemented backfill, primarily composed of material costs (such as cement, tailings, etc.) and system operating costs, amounted to 26.6277 million CNY. When allocated per ton of ore, the backfilling cost was 25.65 CNY.

The original total mining cost of the Dahongshan Copper Mine was 211.06 CNY/t, primarily composed of costs related to mining, beneficiation, ventilation, hoisting, transportation, taxes, labor, management, and depreciation. The production cost of the additional ore consists of the total mining cost and the backfilling cost, amounting to 236.71 CNY/t. The total production cost of the additional ore in the area was 245.6856 million CNY.

In summary, by adopting the two-step mining method in the B48-54 line area at the 385 level of the Dahongshan Copper Mine, the additional profit reached 208.7515 million CNY.

For the continuous high-concentration and stable sand discharge technology based on parallel connection of vertical multiple sand silos, the utilization rate of tailing sand reaches 70.17%, with an increase of 2.24%. The usage of new tailing sand is 98,400 t/a, and the overflow discharge is reduced by 98,400 t/a. The production cost of 2,855,348.05 CNY/a can be saved by increasing water return volume, saving electricity, producing slurry water, reducing overflow discharge, and reducing downhole drainage.

The use of rapid construction technology for wet-sprayed retaining wall increases construction efficiency by 67% and reduces cost by 20% over the cast-in-place concrete retaining wall, saving 952,000 CNY/a.

After exploration and application in the test area of 48–54 lines in the 385 middle section, the technology has been generalized and applied in the area of B12-26 lines in the 385 middle section, 48–58 lines in the 285 middle section, and 10–24 lines in the 285 middle section.

In view of the technical problems in the mining of multi-layer thin to medium-thick low-grade ore bodies, Dahongshan Copper Mine proposed a multi-layer ore body mining mode, which used the marginal economic mining circle grade model of multi-layer ore bodies to carry out the secondary delineation of the ore body. The average grade of the ore after the delineation was bound to be lower, but it could regularize the multi-layer thin to medium-thick ore body into a very thick and large ore body. Large-scale mining is the prerequisite for realizing the comprehensive utilization of low-grade mineral resources. The essence of this technology is to consider the ore stope, pillar, and goaf as a whole (Wang, 2017; Cai, 2009). After the ore body is enclosed, it is divided into primary and secondary stopes. The primary stopes are mined first and then the secondary stopes are mined. The primary stopes are filled to form an artificial pillar to cement the support structure formed by the artificial pillar, which provides a safe and reliable working environment for the secondary stopes (Cao et al., 2015; Wei et al., 2018; Liu et al., 2019; Lan et al., 2019; Yang et al., 2018). After the mining the secondary stopes, the goaf formed by stoping is filled. Non-cemented filling is generally used for save the filling cost. The purpose of two-step mining is: (1) to replace the ore pillar with cemented pillar to maximize ore recovery; (2) to realize the simultaneous mining operation of non-adjacent multiple stopes to improve the production capacity of the mining area; (3) to apply non-cemented filling into the mine stope to effectively reduce the filling cost.

To realize the two-step mining of multi-layer thin to medium-thick low-grade ore bodies, the following key problems need to be addressed, including (1) the basis of ore body enclosing; (2) guarantee of efficient mining of ore body; (3) whether the supporting frame formed by the cemented filling body in The primary stopes can provide a safe and reliable working environment; (4) how to realize rapid filling in large-scale goaf and to ensure the connection between mining and filling; and (5) how to ensure the stability of the retaining wall under high pressure.

To solve the above problems, five basic theories are constructed.

(1) The theory of economic and mining recyclable grade of mixed copper and iron mining boundary. The essence of this theory is to analyze the intrinsic relationship between ore value, mining and processing costs, and economic benefits, thereby constructing a marginal economic cut-off grade model for combined mining of copper and iron ores. This model provides a decision-making basis for determining whether to adopt “combined mining” or “separate mining” for gently inclined, multi-layered, thin to medium-thick, low-grade ore bodies.

(2) Stope structure optimization theory. This theory essentially involves analyzing the stability of stope structures under different combinations of primary and secondary mining steps. By controlling the amount of cemented backfill in the primary mining step, the structural parameters of the stope are ultimately determined, thereby providing a design basis for stope structure planning.

(3) Strength theory of large volume vertical cemented backfill. The essence of this theory is to construct a strength design model for cemented backfill by analyzing the changes in stress state of the cemented backfill during the extraction process of adjacent mining rooms, combined with the mechanical effects, stability factors, and typical failure modes of the cemented backfill. This provides a design basis for the rational design of cemented backfill strength.

(4) Theory of continuous high concentration and stable sand discharge of vertical sand bin. The essence of this theory is to establish a technical model for continuous high concentration and stable sand discharge of vertical sand bin by analyzing the dynamic settlement characteristics of tailings, the self-compacting mechanism of tailings, the conditions for high-concentration fluidized discharging, and the conditions for material dynamic balance. This model is intended to improve the operational performance of sand storage bins and enhance the concentration of discharged sand.

(5) Strength and structural design theory of filling retaining wall. The essence of this theory is to establish a design method for the thickness of retaining walls by analyzing the stress distribution in the walls under the pressure of filling materials. This provides a design basis for the rational design of retaining wall structures.

Four key technologies have been developed: (1) Two-step Sublevel Open Stoping with Subsequent Backfilling technology; (2) cemented backfill layered precise filling technology; (3) continuous high-concentration and stable sand discharge technology based on parallel connection of vertical multiple sand silos; and (4) rapid construction technology of filling retaining wall.

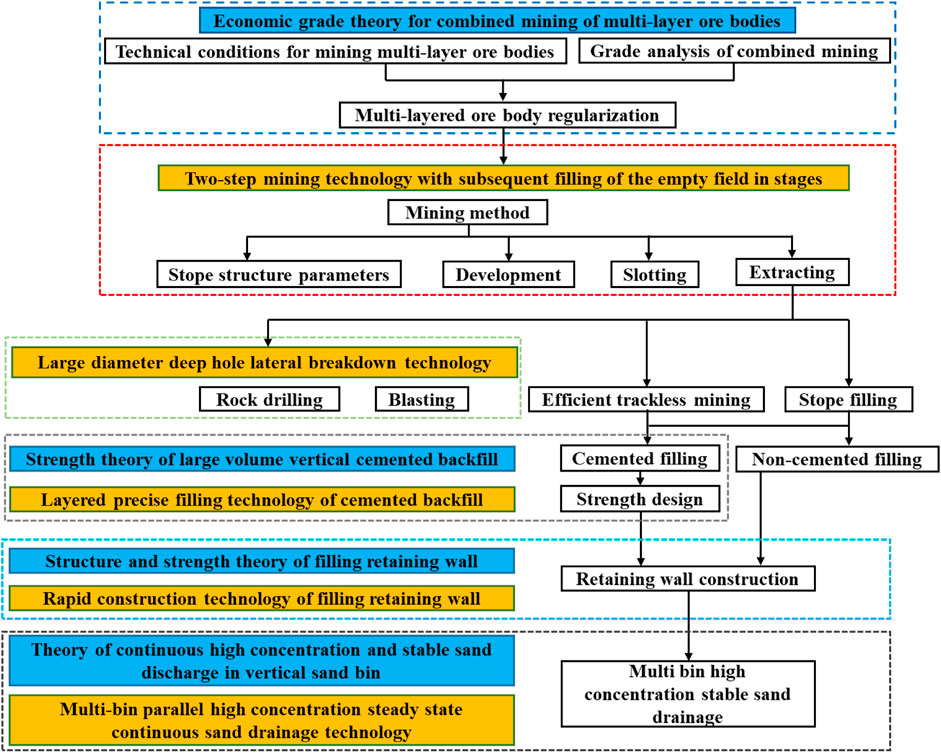

The basic principle of two-step Sublevel Open Stoping with Subsequent Backfilling technology of multi-layer thin to medium-thick low-grade ore bodies is to conduct the secondary delineation of the ore body through the analysis of the recyclable grade of marginal economic co-mining. The enclosed ore body is planned as a whole according to the open stope and subsequent filling two-step mining technology, and the amount of cemented filling is strictly controlled. The large-diameter deep hole lateral caving technology and the flat bottom trackless ore drawing technology are used for rapid mining of the ore body. The continuous high-concentration and stable sand discharge technology based on parallel connection of vertical multiple sand silos is used to rapidly fill the goaf in the secondary stopes. The layered precise filling technology is adopted to implement cemented filling for the primary stopes to control its cemented filling cost. The rapid construction technology of filling retaining wall is used to shorten the preparation time of the stope and to ensure the stability of the retaining wall. The details of the process are illustrated in Figure 6.

Figure 6. Technical system of two-step mining of multi-layer thin to medium-thick low grade ore body.

The integration and secondary delineation of the multi-layer gently inclined medium-thick copper iron ore body in Dahongshan Copper Mine by using the “mixed copper and iron mining” mode will inevitably reduce the comprehensive mining grade to a certain extent, but it can transform the gently inclined medium thick ore body into a gently inclined thick large ore body and create the necessary conditions for the “large-scale, high-efficiency, and low-cost” mining method. Therefore, it is necessary to determine the marginal economic closing grade of copper and iron mining in multi-layer ore body, and to judge the reserves, mining costs, and comprehensive benefits.

The mixed copper and iron mining will produce a large number of low-grade copper bearing iron ores, which will incur costs. However, it can significantly improve the recovery rate of copper and iron resources, reduce the dilution rate, and increase the mining efficiency through large-scale and efficient mining. At the same time, it can dilute the development and preparation costs caused by separate mining to reduce the mining costs. The marginal economic closing grade of mixed copper and iron mining in the mine is as shown in Equation 1 (Li, 2018):

where

In general, “mixed copper and iron mining” is not a technical scheme in itself. It is a new resource integrated mining mode formed on the basis of a new understanding of the importance of mineral resources, and it is the adjustment of the overall mining idea of mineral deposit mining. The main support technology for “mixed copper and iron mining” is still the large-diameter deep hole lateral caving open stope and subsequent filling method.

The supporting framework formed by the stable cemented filler is the safety guarantee of the recycling stope. How to scientifically and reasonably determine the strength of the cemented filler is the key of the field subsequent filling method, and also relates to the realistic requirements of reducing the filling cost. According to the analysis of the influence of changes in the mining steps of the two-step airfield subsequent filling method on the force state of the cemented filling body and the current research status of the role of the filling body, it is believed that the mechanical role of the cemented filling body is mainly manifested in improving the force state of the roof rock body to support the broken rock body of the roof, providing lateral limiting pressure for the sliding tendency of the unloaded rock block of the side gangs, resisting the closure of the stope, and restricting the tailings sand flow, as shown in Figure 7. Based on the strength design viewpoint of “self-supporting artificial mining pillar”, a strength model is established under the assumption that one side of the cemented body is adjacent to the air and the other side is subject to the lateral pressure of tailings sand (Wang, 2017; Wang et al., 2019; Wang et al., 2021a; Wang and Qiao, 2015; Wang et al., 2016; Wang et al., 2014).

(1) Cohesion modelling of cemented fillings, as shown in Equation 2:

(2) Uniaxial compressive strength modelling of cemented fillings, as shown in Equation 3:

(3) Shear strength modelling of cemented fillings:

The expressions of each parameter are:

where

Filling retaining wall is an essential process in open stope subsequent filling mining method. Its stability affects the filling progress of the stope, and is more related to underground production safety. The retaining wall structure in the Dahongshan Copper Mine is designed by adopting the traditional slurry statics and the Rankine classic earth pressure theory (Xue and Feng, 2008; Li, 2016; Yu and Zhou, 2004) as well as referring to the relevant theory of waterproof gate chamber (Zhang, 1989) in the roadway engineering volume of the mining design manual, where the factor of safety is adopted as 1.5-2.5. Based on the above design basis, Dahongshan Copper Mine selects the cast-in-place reinforced concrete wall. According to the filling height of the goaf, the thickness of the ore drawing horizontal retaining wall at the bottom of the stope is designed to be 1.5–2.0 m, and the thicknesses of the retaining wall for the connection channel of central drilling chamber and hanging wall roof cutting chamber are designed to be 1.2–1.5 m and 1.0–1.2 m, respectively. The retaining wall shall be cast by formwork erection on site, and the concrete shall be cured for at least 7–10 days after the erection of the retaining wall, as shown in Figure 8. This kind of retaining wall has large design strength, redundant structure, large quantities, and high cost. According to mine statistics, the average cost is 17,110 CNY/block.

Therefore, based on the force analysis of the retaining wall, it is of great significance to design a reasonable structure and develop a low-cost retaining wall that is easy to be erected and has a short concrete curing duration, so as to ensure the progress of mining back and reduce production costs. On this basis, Dahongshan Copper Mine has developed a rapid construction technology for filling retaining wall.

Through the analysis of stress and boundary conditions of the later filling enclosed retaining wall in the large open space, the retaining wall is simplified as a fixed rectangular thin plate, and the approximate solution of the energy principle is used to solve the stress of the retaining wall. Combined with the ultimate bearing capacity of concrete, the thickness of the concrete retaining wall is analyzed, and a model of the strength and thickness of the enclosed retaining wall is established (Li and Qiao, 2017; Huang et al., 2014b; Huang, 2014a; Wang et al., 2021b), as shown in Figure 9.

The forces in the retaining wall are calculated using the following equation (Wang et al., 2021b):

where

The thickness of the retaining wall is designed using the following equation (Wang et al., 2021b):

where

The original working mode of the vertical sand silo filling system of Dahongshan Copper Mine is as follows. Multiple sand silos are filled simultaneously using low-flow natural sand sedimentation and intermittent alternating filling operation. Inside the silos, high-pressure wind is used to loosen the tailings sand, high-pressure water is used to make slurry, and gravity is used to release the sand by self-flow. According to mine statistics, the working performance index of the filling system in this working mode is poor. (1) Overflow running mixing is serious, with a loading flow rate of vertical sand silo of 300 m3/h, a sand loading concentration of 35%, an overflow concentration of 22%, and a utilization rate of tailings sand of only 67.93%. (2) The system utilization rate is low, where the loading time of vertical sand silo sand is more than 20 h, the sand discharge time is only 4 h, and the utilization rate of effective filling time of single sand silo is only 16.67%. (3) The concentration of sand discharge is too low, where the average sand discharge concentration of vertical sand silo is only 64.6%.

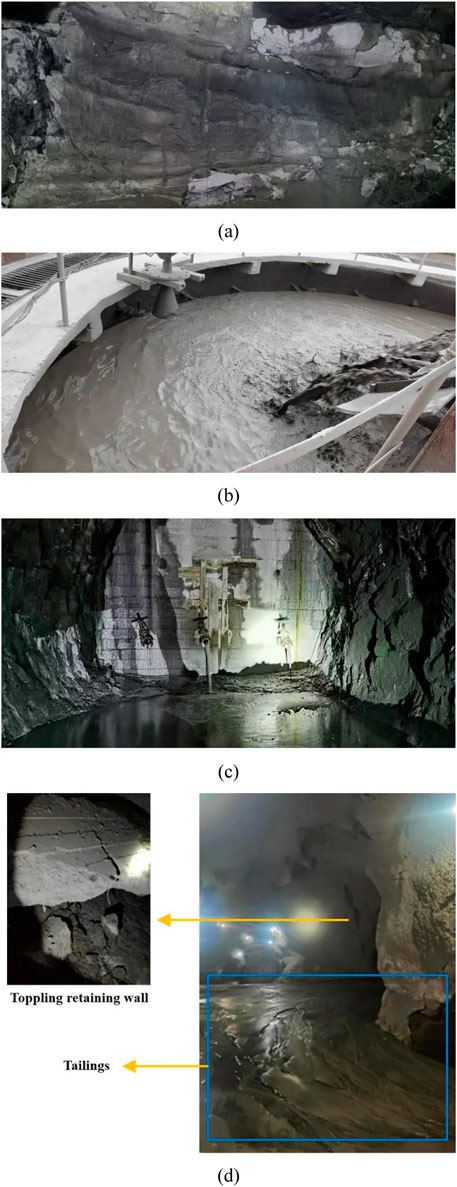

The above three problems triggered three impacts. (1) T The adoption of a two-step mining method leads to an increase in the volume of void filling, necessitating a tailings utilization rate of at least 70% to meet the underground backfilling requirements. (2) The sand discharge concentration is too low, the cemented slurry segregates seriously, and the layering phenomenon of the filling body is obvious, which affects the stability. and (3) A long dewatering duration and a larger dewatering volume in the stope put forward a higher requirement for the confined retaining wall. The details are shown in Figure 10.

Figure 10. General situation of filling system in Dahongshan Copper mine: (A) Backfill stratification, (B) Cloudy overflow, (C) Stope dehydration, (D) Retaining wall toppling.

Aiming at the problems in the application of vertical sand silo filling system and the weakness of basic theoretical research, the dynamic settlement characteristics of tailings sand, self-compacting mechanism of tailings sand, shear thinning gravity discharge mechanism, and dynamic material balance in the Dahongshan Copper Mine are studied in depth, which breaks through the traditional operation mode to facilitate the development and successful application of the continuous high-concentration and stable sand discharge technology based on parallel connection of vertical multiple sand silos.

The settling velocity of tailings sand under different slurry concentration conditions is analyzed based on the static settling test of tailings sand. The solid flux corresponding to different concentrations of tailings sand is calculated according to the definition of solid flux, while the optimal feeding concentration of vertical sand silo is determined by the maximum solid flux. The theoretical maximum processing capacity of the vertical sand silo is calculated according to the actual cross-section size of the vertical sand silo and the maximum solids flux, and the feed flow rate of the vertical sand silo is determined in combination with the feed concentration (Wang et al., 2020; Ren, 2017; Wang et al., 2022; Shu et al., 2020).

The dynamic sand loading test is carried out according to the designed feed concentration and flow rate of tailings sand, and the relationship between the overflow concentration and the loading height is monitored, so as to determine the loading height and the overflow concentration corresponding to the actual maximum processing capacity of the vertical sand silo. Meanwhile, the research on the compacting characteristics of the tailings sand is performed to obtain the relationship between the volume concentration of tailings sand and the sand loading height. According to the principle of dynamic material balance, the actual maximum processing capacity of vertical sand silo is obtained (Wang et al., 2020; Ren, 2017; Wang et al., 2022; Shu et al., 2020). Detailed parameters are shown in Figure 11.

According to the principle of self-flow discharge of activated compacted tailings sand in vertical sand silo, the critical working pressure of high-pressure activation medium is proposed to be the sum of the overlying effective stress of tailings sand and the yield stress of the slurry. Then, the calculation method of the activation medium work flow parameters for diluting tailings sand to the required concentration under the condition of meeting the processing capacity of vertical sand silo is presented from the requirement of filling quality (Wang et al., 2020; Ren, 2017; Wang et al., 2022; Shu et al., 2020).

Taking the 385 middle section as an example, the ore loss rate of mixed copper and iron mining is calculated to be 20%, and the mixed mining mode can recover an additional 6.788 million tons of stone, 28,251 tons of copper, and 1,223,554 tons of iron compared with the separate mining mode. According to the technical indicators of mineral processing, the copper recovery rate and iron recovery rate are calculated at 93% and 30%, respectively. Under the mixed mining mode, the copper content of the recovered concentrate is 26,273.59 t, and the iron concentrate volume is 592,042.25 t (the grade of iron concentrate is 62.5%). Based on the average price of copper of 53,000 CNY/t, the sales price of iron concentrate of 570 CNY/t, the cost of copper concentrate of 30,000 CNY/t, and the cost of iron concentrate of 450 CNY/t, the profit and tax of copper in concentrate is 604.2927 million CNY, while that of iron concentrate is 71.0451 million CNY, so the total profit and tax of copper and iron products is 675.3378 million CNY, as shown in Table 1. The mixed copper and iron mining mode is obviously superior to the separate mining mode (Li, 2018).

On the other hand, if the production capacity of the middle section is calculated at 4,000 t/d, the service life of the middle section can be extended by 5.14 years under the mixed mining mode, which is equivalent to building another 385 middle section and saving a development project of the middle section.

As shown in Figure 12, the overall thickness of the ore body in the separate mining mode is between 6 and 20 m. In the mixed mining mode, the true thickness of the ore body reaches 35–60 m, and the vertical thickness is 40–70 m. The thickness of the ore body in the mixed mining mode is more than 12 m greater than the sum of the thickness of the two mining layers in the separate mining mode, and it even reaches more than 25 m in some areas.

To achieve the profitability of mineral resources mining, the proportion of cemented filling volume in the two-step mining programme of Dahongshan Copper Mine is strictly controlled to be not more than 30%, while the cost of cemented filling body shall not exceed 85 CNY/m3. Therefore, in the primary stopes filling design, the filling cost needs to be strictly controlled.

After the mining stope is finished, the goaf is quickly scanned to collect the information, including the morphology of the goaf, the structure size, and the volume of the goaf, etc. The goaf is designed to be filled in layers to save the cost. The strength model is used to design the required strength of the filling body. Considering the feasibility of on-site operation, the layered height is designed to be 10–15 m. The filling ratio is selected according to the designed strength of the filling body in layers, and the filling scheme is designed in conjunction with the filling capacity of the system. The layered filling volume is designed according to the layered volume as well as the slurry sinking and shrinking characteristics. During the actual filling process, the layers are filled according to the preset layer filling volume, and at the end of filling, the goaf is swept again to determine whether the designed layered filling height is reached.

After the completion of stope mining, the goaf is rapidly scanned to collect information, including the morphology of the goaf, structural dimensions, and goaf volume. The strength model is used to design the required strength of the backfill. To maximize cost savings in backfilling, the goaf is designed for layered filling, while considering the feasibility of on-site operations, with a designed layer height of 10–15 m. Based on the designed strength of the layered backfill, the backfill mix ratio is selected. The basic parameters of the cemented tailings slurry with different mix ratios for the Dahongshan Copper Mine are shown in Table 2.

Based on the selected backfill mix ratio and in conjunction with the system’s backfilling capacity, a backfilling plan is formulated. The stratified backfilling volume is designed according to the volume of each layer and the slurry sedimentation characteristics. During the actual backfilling operation, the stratified backfilling is executed based on the predetermined volume for each layer. Once backfilling is completed, the mined-out area is scanned again to verify whether the designed stratified backfilling height has been achieved.

Taking the strength design of the B17Ⅱcemented backfill in the 385 middle section as an example, the stope has a length of 25.08 m, a width of 12 m, and a height of 37.26 m. Equations (4) and (5) are used to calculate the required strength of the cemented backfill. The bulk density of the cemented backfill is 0.022 MN/m3, with an internal friction angle of 40°. The surrounding rock has a bulk density of 0.03061 MN/m3, an internal friction angle of 36°, and a Protodyakonov coefficient of 8. The tailings have a bulk density of 0.017 MN/m3 and an internal friction angle of 20°. The cohesion between the cemented backfill and the surrounding rock is 0.64 MPa, with an internal friction angle of 40°. The calculated strength result is shown in Figure 13.

Based on the stope scanning results and the strength calculation results, a stratified backfilling plan has been designed as shown in Figure 14.

The design parameters of the filling scheme are listed in Table 3.

The 385 Middle B17 II, pillar was filled with cemented slurry of 10,414 m3, of which the consumptions of cement, tailings sand, and water were 1,715 t, 12,575 t, and 5,520 t, respectively, with an average slurry concentration of 72.13% and a total cost of 674,007 CNY., The average material consumption of slurry is 165 kg/m3 of cement, 1,207 kg/m3 of tailings sand, and 530 kg/m3 of water. The unit price of slurry is 64.72 CNY/m3, and the unit price of filling body is 80.90 CNY/m3.

Taking the 44–46 panel at the 285 level of the Dahongshan Copper Mine as an example, this panel is a Phase II stope. After the completion of mining, tailings backfilling is employed. The extraction level is at an elevation of 300m, the middle drilling level at 335m, and the top drilling level at 370 m. The standard cross-section of the drift is 4.2 m in width and 3.6 m in height. Equation (6) is used to calculate the forces acting on the bulkhead. The calculation parameters and results are presented in Table 4.

The thickness of the retaining wall was calculated using Equation (7). The calculation parameters and results are shown in Table 5.

The retaining wall adopts wet spraying process. The main longitudinal bar adopts 16 mm round steel with a spacing of 600 mm, the main transverse bar adopts 14 mm round steel with a spacing of 500 mm. A design of two layers of bars is adopted, with a row spacing of 200–250 mm. The main bars are inserted into the rock body of 500 mm, and the 6.5 mm secondary bars are uniformly arranged between the main bars. The bar crosses are tied up with steel wires. The sackcloth is tied to the steel mesh, and then the steel mesh is fixed to the longitudinal and transverse bars with the tied sackcloth (the degree of steel mesh is Φ10 mm-100 mm × 100 mm). The back wall of the filled retaining wall, which consists of steel mesh, sackcloth, as well as longitudinal and transverse bars, is formed from the inside to the outside of the stope. The exact construction process is shown in Figure 15.

The concrete grade of the Dahongshan Copper Mine is C25, and the cement type is the ordinary Portland cement with a strength grade of 42.5. Coarse aggregate employs hard and durable pebble or gravel with a particle size not greater than 10 mm. Fine aggregate is hard and durable medium-coarse sand or coarse sand, with a fineness modulus greater than two and a sand rate of 50%–60%. The Bonner imitation steel fiber, the Xianfa early-strength water reducing agent, and the Shengtai alkali-free accelerator are adopted. The mixing ratios of concrete is summarized in Table 6. The mixing time of concrete should not be less than 5 min, the RSM series concrete wet spraying unit with wet spraying working pressure not less than 0.4 MPa and wet spraying speed not more than 6 m3/h is adopted.

A total of 10 retaining walls are constructed in the district, of which six are at the ore output level, two are at the middle rock drilling roadway, and two are at the roof rock drilling level. Taking the construction of the retaining wall at the ore output level as an example, the construction time can be controlled within 5 days, and the cost can be saved by more than 20%.

From the viewpoint of construction process, the durations of drilling and laying steel bar are basically the same. The improved efficiency of the shotcrete retaining wall is mainly reflected in the time saved in mould erection, concrete pouring, and concrete curing. The improved efficiency of retaining wall construction provides favorable conditions for “enhanced filling” in the district.

From the cost point of view, the amounts of steel used for the two processes are basically the same, and the cost reduction of the shotcrete retaining wall is mainly due to the saving in the amount of concrete used, the reduction in the number of construction workers, and the improvement in construction efficiency. The auxiliary materials of imitation steel fiber, water reducing agent, and accelerator are added.

To demonstrate the rationality of the retaining wall structural design method and evaluate the stability of the designed retaining wall, the tailings pressure exerted on the retaining wall was continuously monitored during the stope backfilling process, as shown in Figure 16. The monitoring results indicate that the measured pressure on the retaining wall was generally lower than the theoretical calculations. Throughout the backfilling process, no slurry leakage or seepage was observed on the surface of the retaining wall, demonstrating good integrity and stability. To date, no structural damage has been detected.

A single sand silo has a low sand discharge flow rate and is not equipped for independent underground filling. Therefore, multiple sand silos need to be considered for parallel filling. Considering the need to completely deal with the tailings sand discharged from the plant, three 9 m vertical sand silos need to be working at the same time. Each vertical sand silo is independent of each other, so when three silos are connected in parallel, they must discharge the tailings sand at the same time to access the well filling pipeline. There is a need to build a confluence device that is connected to the well filling pipeline to meet the requirements, as shown in Figure 17. Also, it is necessary to replace the pipe from the bottom of the vertical sand silo to the end of the confluence device with a 100 mm diameter pipe to meet the requirements of the critical flow rate of the tailings sand.

Up to now, the continuous high-concentration and stable sand discharge technology based on parallel connection of vertical multiple sand silos has been serving mine underground filling for 4 years, achieving a cumulative total of 7.2 million m3 of goaf filled, an average sand discharge concentration of 70.37%, and a tailings sand utilization rate of 70.17%. Compared with the original technical indexes of the operation mode of the vertical sand silo of the Dahongshan Copper Mine, the sand discharge concentration and the utilization rate of tailings sand are increased by 5.77% and 2.24%, respectively.

In the two-step mining method, as the roof of the extraction area is continuously exposed, the stress state of the roof is persistently disturbed, inevitably affecting the stability of the rock mass due to stress variations. To conduct an in-depth analysis of the roof stability, during the mining process at the 385 level, panoramic borehole imaging technology was employed to monitor and investigate the propagation of fractures in the surrounding rock of the roof in both the primary stope B51 and the secondary stope B48-51.

The monitoring results of the loosening zone at the top of the primary stope B51 indicate that, as shown in Figure 18, the mining operations progressively advance, the formation of new fractures in the surrounding rock of the roof is minimal, while the extent of damage to existing cracks has increased. Nevertheless, the integrity of the roof rock mass remains well-preserved, falling within the range of relatively intact to intact. The scope of the loosening zone is limited, and its development rate is slow, suggesting that the overall stability of the roof is favorable.

The monitoring results of the roof in the secondary stope B48-51 reveal that, as shown in Figure 19, prior to the commencement of stoping, the initial state of the borehole wall already exhibited numerous fine cracks. As the mining operations progressively advanced, there was a notable increase in the formation of new fractures within the surrounding rock of the roof, accompanied by a further intensification of damage to pre-existing cracks and fractured zones. Although no roof collapse occurred during the mining process, the stability of the roof was significantly compromised.

From the analysis of the monitoring results, it is evident that the stability of the surrounding rock at the top of the primary stope is superior to that of the secondary stope during mining. The primary reason for this disparity lies in the differing boundary conditions under which the two are mined. When the primary stope is being mined, it is surrounded by unmined secondary stopes, which provide substantial support to the surrounding rock, thereby enhancing the stability of the roof. In contrast, during the mining of the secondary stope, the surrounding area has been replaced by cemented backfill. Compared to the in-situ rock mass, the cemented backfill has lower strength, reduced stiffness, and greater deformation, significantly diminishing its ability to support the roof and leading to a decrease in roof stability. Consequently, the inferior stability of the roof during the mining of the secondary stope is essentially due to the mechanical properties of the cemented backfill being insufficient to provide support equivalent to that of the rock mass.

(1) To achieve the efficient utilization of multi-layered thin to medium-thick low-grade ore bodies, the Dahongshan Copper Mine, based on the “copper-iron co-mining” model, has constructed a boundary economic co-mining grade model through the analysis of input and output balance in ore production. This model facilitates the transformation of multi-layered thin to medium-thick low-grade ore bodies into gently inclined thick and large ore bodies. Although the ore grade is reduced, it creates the necessary conditions for a “large-scale, high-efficiency, low-cost” mining method.

(2) Based on the principle of two-step mining, a comprehensive planning approach is adopted for the co-mining ore body, integrating the stope, pillars, and goaf treatment into a unified consideration. This strategy minimizes ore loss and achieves pillarless two-step mining of the ore body. The primary supporting technology for two-step mining remains the large-diameter deep-hole lateral blasting open stope subsequent backfilling method, which has been proficiently applied at the Dahongshan Copper Mine.

(3) To ensure the safe extraction of the secondary stopes, a strength model for the primary stope cemented backfill was established by analyzing the mechanical behavior and stress distribution of the cemented backfill. Based on the relationship between height and strength, precise stratified backfilling was implemented for the primary stopes, significantly reducing the cost of cemented backfill.

(4) To ensure the mining-backfilling cycle and to release the regional production capacity to a great extent, with the goal of improving the backfilling system’s capability and backfill quality, a theoretical framework for continuous high-density steady-state sand discharge from vertical sand silos was established by studying the mechanisms of tailings gravity settling and thickening, self-compacting tailings shear thinning, and dynamic material balance. Additionally, a multi-silo parallel continuous high-density steady-state sand discharge technology was developed, providing technical support for rapid goaf backfilling.

(5) To reduce the construction time of retaining wall while ensuring their structural stability and lowering construction costs, a structural design model for the retaining wall was established based on thin plate theory by analyzing the stress state of the retaining wall. Utilizing wet shotcrete technology, a rapid construction technique for wet shotcrete retaining wall was developed.

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

P-LX: Conceptualization, Writing–original draft. JW: Methodology, Writing–original draft. K-PH: Conceptualization, Project administration, Writing–review and editing. D-PQ: Data curation, Writing–review and editing. T-yY: Methodology, Writing–review and editing.

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research was supported by Yunnan Fundamental Research Projects (Grant Nos 202301AU070185, 202001AU070062). In addition, part of the funds came from the Talent Training Fund of Kunming University of Science and Technology (No. KKZ3202021040).

Authors P-LX was employed by Yunnan Tin Industry Datun Tin Mine.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Ajayi, S. A., Ma, L., and Spearing, A. J. S. (2022). Ground stress analysis and automation of workface in continuous mining continuous backfill operation. Miner. (2075-163X) 12 (6), 754. doi:10.3390/min12060754

Cao, S., Du, C.-F., Tan, Y.-Y., and Fu, J.-X. (2015). Mechanical model analysis of consolidated filling pillar using stage-delayed backfill in metal mines. Rock Soil Mech. 36 (08), 2370–2376. doi:10.16285/j.rsm.2015.08.033

Chen, Q.-F., Yang, C.-Y., and Xiao, T.-Q. (2019). Analysis of mining disturbance relationship and synergistic step between two adjacent orebodies. Metal. Mine (07), 1–7. doi:10.19614/j.cnki.jsks.201907001

Chen, Y.-L. (2003). Research on mining process engineering technology of Dahongshan Copper Mine. Kunming, China: Kunming University of Science and Technology.

Gao, M.-J., Li, S.-Z., Wang, Y., and Liu, X.-G. (2013). Study of mining method for complicated inclined and thin vein of Jigezhuang gold mine in Shangdong province. Gold Sci. Technol. 21 (01), 49–52.

Gu, D.-S. (2004). The development tendency of mining science and technology of underground metal mine. Gold 25 (01), 18–22.

Guo, Y.-H., and Miao, Y.-C. (2022). Study on stope stability in continuous mining of long-dip, thin orebody by room-pillar method. Mining and Minerals Daily, 24–25.

Hu, C. (2019). Optimization practice on the ore loss rate and dilution rate of Dahongshan copper Mine. Mod. Min. 35 (06), 90–92+107.

Hu, T., Li, X.-L., Wang, J.-G., Ma, J., Hu, Q., and Zuo, T. (2024). Fracture behavior and fracture surface smoothness of rock-like model subjected to axial decoupling spherical charging. Eng. Fract. Mech. 311, 110549. doi:10.1016/j.engfracmech.2024.110549

Hu, Z.-X., and Sun, H.-S. (2014). Discussion on the mining process of “combined mining and separation” of slowly inclined Cu and Fe multi-layer ore body in Dahongshan copper Mine. China Metal. Bull. (S1), 27–30.

Huang, J.-J. (2014a). Research and application of strength models for backfill retaining walls. Kunming, China: Kunming University of Science and Technology. [Master’s thesis].

Huang, J.-J., Qiao, D.-P., Sun, H.-S., and Yang, X. (2014b). Calculation and optimizing analysis of the force of filling airtight-wall for underground mined-out area. Metal. Mine (10), 32–36.

Huang, Y.-M., Li, Z.-L., and Li, Z.-B. (2022). Practice of roof control technology in Dahongshan copper Mine. Value Eng. 41 (31), 100–102. doi:10.3969/j.issn.1006-4311.2022.31.031

Jin, X., and Yu, C. (2020). Mineralization enrichment regularity and ore prospecting of associated gold-silver for Dahongshan iron-copper deposit. Mod. Min. 36 (06), 30–34.

Lan, M., Liu, Z.-X., and Li, X.-B. (2019). Multi-objective optimization and multi-attribute decision making on structural parameters of stage backfilling stope. J. Central South Univ. Sci. Technol. 50 (02), 375–383. doi:10.11817/i.issn.1672-7207.2019.02.017

Li, G.-T. (2018). Research and application of mining technology for gently inclined multi-layer thin to medium-thick ore body in Dahongshan. Kunming, China: Kunming University of Science and Technology. [Master’s thesis].

Li, G.-T., Ai, C.-L., Lu, G.-Y., and Sun, H.-S. (2011). Application of large-diameter long-hole side caving technology in Dahongshan copper Mine. Nonferrous Met. Min. Sect. 63 (05), 8–10+22. doi:10.3969/i.issn.1671-4172.2011.05.003

Li, G.-T., and Qiao, D.-P. (2017). Filling retaining wall strength model of tailing and its application in large goaf. Nonferrous Metal. Eng. 7 (03), 88–92. doi:10.3969/i.issn.2095-1744.2017.03.018

Li, X.-L., Yan, S.-Q., Wang, J.-G., and Li, Q. (2024). Influence of slot width in cartridge on crack propagation and energy concentration under explosion load. Rock Mech. Rock Eng. 58, 1707–1721. doi:10.1007/s00603-024-04199-5

Liao, Q.-Y., and Yan, T. (2020). Economic analysis of cemented pillars in continuous mining of middle 285 section of Dahongshan copper Mine. World Nonferrous Met. (02), 49–51.

Liu, G.-S., Yang, X.-C., and Guo, L.-J. (2019). Models of three-dimensional arching stress and strength requirement for the backfill in open stoping with subsequent backfill mining. J. China Coal Soc. 44 (05), 1391–1403. doi:10.13225/.j.cnki.jccs.2019.6025

Liu, R. (2010). Research on the pillar mining technology of Dahongshan copper ore. Kunming, China: Kunming University of Science and Technology

Lu, B., Li, Y., Fang, S., Lin, H., and Zhu, Y. (2021). Cemented backfilling mining technology for gently inclined coal seams using a continuous mining and continuous backfilling method. Shock Vib. 2021. doi:10.1155/2021/6652309

Nie, X.-X., Gan, Q., Gao, J., and Feng, S.-S. (2020). Research on safety roof span in continuous mining of gold vein group under synergistic concept. Gold Sci. Technol. 28 (03), 337–344. doi:10.11872/i.issn.1005-2518.2020.03.176

Niu, W.-J., Chen, Q.-F., and Liu, Y.-Z. (2016). Step calculation method for multi stage synergistic mining of low grade large-thick ore-body. Metal. Mine (09), 23–29.

Ren, W.-C. (2017). Research on the model of continuous high-density stable sand discharge in vertical sand silos. Kunming, China: Kunming University of Science and Technology. [Master’s thesis].

Shu, Z.-X., Ren, W.-C., and Sun, H.-S. (2020). “A method for constructing and applying a continuous high-density steady-state sand discharge model for ultra-fine tailings,” in Vertical sand silos (CN106570298B)–06-26.

Wang, J. (2017). Strength model of collodion for continuous mining after filling in empty field and its application. Kunming, China: Kunming University of Science and Technology. [Master’s thesis].

Wang, J., Li, G.-T., and Qiao, D.-P. (2021a). Method of constructing strength model for two-step air field subsequent filling of large volume filling body.

Wang, J., and Qiao, D.-P. (2015). Strength model of cementing filling body under lateral pressure. Int. Inf. Eng. Associations、Allantis Press. doi:10.2991/mmeceb-15.2016.168

Wang, J., Qiao, D.-P., and Deng, T. (2014). Strength design of cemented high pillars in Dahongshan copper Mine and its engineering practice. Gold 35 (08), 41–46. doi:10.11792./hj20140809

Wang, J., Qiao, D.-P., and Han, R.-S. (2019). Strength model of cemented backfill in subsequent filling at the stage of open stope and its application. Rock soil Mech. 40 (03), 1105–1112. doi:10.16285/j.rsm.2017.1771

Wang, J., Qiao, D.-P., and Han, R.-S. (2020). Consecutive discharge tailings model of vertical sand silo and its application. Chin. J. Nonferrous Metals 30 (01), 235–244. doi:10.11817/j.ysxb.1004.0609.2020-35704

Wang, J., Qiao, D.-P., and Li, G.-T. (2016). Computing method of lateral pressure of incompact milltailings with subsequent filling. J. Kunming Univ. Sci. Technol. Nat. Sci. Ed. 41 (05), 27–32. doi:10.16112/j.cnki.53-1223/n.2016.05.005

Wang, J., Qiao, D.-P., and Li, G.-T. (2022). An optimization method for dynamic high-density fluidized sand discharge technology in vertical sand silos, 08-09.

Wang, J., Zeng, Q.-T., and Zhang, X. (2021b). A method of constructing a model of confined retaining wall filled with non-glued sand after a large empty field. CN113742828A.

Wang, J.-C. (2010). Optimisation of structural parameters of the segmented airfield method mining in Dahongshan Iron Mine Ⅰ copper ore belt. Kunming, China: Kunming University of Science and Technology.

Wang, J.-G., Zhou, Z.-Q., Ma, J., and Li, X. (2024). Study on the influence of slit pipe wall thickness on the rock breaking effect of slit charge explosion. Fatigue and Fract. Eng. Mater. Struct. 12, 4545–4559. doi:10.1111/ffe.14443

Wei, X.-M., Guo, L.-J., and Li, C.-H. (2018). Study of space variation law of strength of high stage cemented backfill. Rock Soil Mech. 39 (S2), 45–52. doi:10.16285/j.rsm.2018.1419

Xue, D.-J., and Feng, Z.-L. (2008). Practical handbook of retaining wall design. Beijing: China Architecture and Building Press.

Yan, T., Liao, Q.-Y., and Li, Z.-L. (2022). Application of staged open field post-minging filling continuous minging method in multi-layer gently dipping orebodies. China Molybdenum Ind. 46 (03), 20–23.

Yang, L., Qiu, J.-P., and Sun, X.-G. (2018). Research and application on strength model of cemented backfill pillar for stage subsequent filling mining method. J. Central South Univ. Sci. Technol. 49 (09), 2316–2322. doi:10.11817/j.issn.1672-7207.2018.09.026

Yao, N. (2017). Research on stability of stope structure with complicated exploitations of multi-layer gently inclined thin to mid-thick deposit. [Master’s thesis]. Wuhan, China: Wuhan University of Science and Technology.

Yu, X.-C., and Zhou, M.-L. (2004). Design manual of retaining structures. Beijing: China Architecture and Building Press.

Zeng, Q.-T., Wang, L.-G., and Yu, J. (2014). Mining process of copper-iron combined mining in slowly inclined medium-thick multilayer ore body of Dahongshan copper Mine. Nonferrous Met. Eng. 4 (04), 57–60. doi:10.3969/j.issn.2095-1744.2014.04.014

Zhang, D.-B., Cha, S.-C., Zhang, W.-P., et al. (2019). Study on the occurrence regularity of gold in the ore belt No.Ⅰ of Dahongshan copper deposit, Yunnan. Mineral Resour. Geol. 33 (05), 851–860.

Zhang, F. M. (1989). Mining design manual - shaft and tunnel engineering volume. Beijing: China Architecture and Building Press.

Zhao, X.-D., Zeng, N., and Chen, Y.-M. (2021). Design of the medium-deep hole caving and subsequent filling continuous mining technology in underground unmanned mining area of Sanshandao gold mine. Gold Sci. Technol. 29 (02), 200–207. doi:10.11872/j.issn.1005-2518.2021.02.134

Zhou, K.-P., Chen, Q.-F., and Hu, J.-H. (2008). Concept of the mining environment reconstructing continuous mining in underground bauxite. J. Guangxi Univ. Nat. Sci. Ed. 33 (02), 168–172. doi:10.13624/j.cnki.issn.1001-7445.2008.02.006

Keywords: two-step mining, economic grade, backfill strength, continuous backfilling, retaining wall

Citation: Xu P-L, Wang J, Hou K-P, Qiao D-P and Yang T-y (2025) Two-step sublevel open stoping with backfilling technology and application for low-grade orebody. Front. Earth Sci. 13:1561516. doi: 10.3389/feart.2025.1561516

Received: 16 January 2025; Accepted: 26 February 2025;

Published: 18 March 2025.

Edited by:

Wenling Tian, China University of Mining and Technology, ChinaReviewed by:

Jing Bi, Guizhou University, ChinaCopyright © 2025 Xu, Wang, Hou, Qiao and Yang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Wang Jun, a211c3R3YW5nakAxNjMuY29t

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.