94% of researchers rate our articles as excellent or good

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.

Find out more

ORIGINAL RESEARCH article

Front. Earth Sci., 15 January 2025

Sec. Solid Earth Geophysics

Volume 12 - 2024 | https://doi.org/10.3389/feart.2024.1511853

This article is part of the Research TopicAdvanced Materials and Technologies for Sustainable Development of Underground ResourcesView all 44 articles

To explore the internal bearing characteristics and fracture evolution laws of discontinuous jointed rock mass in deep roadways, the −600 m main roadway in Xin ’an Coal Mine was used as the research background. The fracture fractal dimension D was employed to characterize the joint density, and an intermittent jointed roadway model, both without support and with anchor cable support, was modeled using the particle flow software PFC2D. The internal stress, deformation, and fracture characteristics of intermittent jointed surrounding rock in tunnels with different support methods and joint densities were studied from a microscopic perspective. The results indicate that during the bearing process of the bolt anchor support and unsupported roadway discontinuous jointed rock mass model, the main bearing area of both models transferred from the surface rock mass to the deep rock mass. The tensile cracks of the anchor cable support model were reduced by 57.7% compared with the unsupported model, effectively suppressed the tensile failure of the surrounding rock, and the convergence of the surrounding rock was substantially reduced. The density of intermittent joints was negatively correlated with the bearing capacity of the surrounding rock mass of roadways, and the increase of joint density the overall failure of the surrounding rock, and the possibility of roadway destabilization was increased. Importantly, the number and distribution of intermittent joints in the surface surrounding rock were closely related to the rupture characteristics of the roadways. When the load exceeded the ultimate load of the deep surrounding rock, stress fluctuation occurred due to the stress drop caused by its destruction. This fluctuation promoted the development of intermittent joints in the surface surrounding rock, increasing the risk of roadway destabilization.

The deep mining of coal is an inevitable trend in coal industry (Mao, 2020; Alber et al., 2009; Gao et al., 2020), it mainly adopts the way of well mining at present, which needs to dig a large number of tunnels in the underground (Jing et al., 2020). The surrounding rock of deep roadway can easily cause stress concentration around roadway and even cause roadway instability under high stress and high disturbance stress environment (Gao et al., 2021; Zhang et al., 2022; Wu et al., 2024a). Roadway anchor cable support is widely used in deep coal mine support projects due to its advantages of mobilizing the bearing capacity of the deep surrounding rock and improving the stress state of the surrounding rock in the anchoring area (Kang et al., 2013; Fang and Zhang, 2014; Kang, 2014; Jiang et al., 2016; Yin et al., 2016). However, a large number of discontinuous structural planes such as joints and cracks in surrounding rock destroy the integrity of rock mass and damage the stability of surrounding rock structure (Yan et al., 2016; 2013; Małkowski, 2015; Mo et al., 2019; Shen, 2014; Zhang et al., 2015). Therefore, it is of great significance to study the fracture evolution mechanism and stability control of discontinuous joint surrounding rock of deep roadway.

A large number of scholars have explored the load-bearing properties of anchor cable supports and have achieved meaningful results (Basarir et al., 2019; Wang et al., 2015; Kang et al., 2023; Janeiro and Einstein, 2010; Wang X. et al., 2023; Tao et al., 2016) further investigated the mechanism of interaction with the rock mass using NPR anchors, and proposed the non-linear design method and control technology of the anchor cable (Tao et al., 2016) researched the destabilization of the surrounding rock in deep rectangular coal roadway under different support conditions from both macro and micro aspects, and put forward the support principle of ‘strong wall to protect the roof’ (Jing et al., 2014) analyzed the deformation and fracture evolution characteristics of deep rock roadway under the coupling action of “three heights” by using field monitoring, laboratory test and numerical simulation, and proposed a distributed combined support method (Yuan et al., 2011) carried out numerical calculations for extra-thick composite roof roadway and revealed the action mechanism of anchor cable on the deep and shallow surrounding rock of roadway (Su et al., 2014). However, in practical engineering, there are a large number of discontinuous joints in the surrounding rock, and the mechanical properties of the large-scale discontinuous joints physical model under external loads are much lower than that of the complete model (Hou, 2017; Li et al., 2021; Grasselli and Egger, 2003) established a physical model of tunnel excavation in layered rock and monitored the whole process of surrounding rock deformation through thermal imaging (He et al., 2010) studied the influence of joint dip angle on the mechanical properties of jointed rock mass by using similar materials (Chen et al., 2012) studied the deformation behavior and failure mode of rock samples containing joints under unloading (Li et al., 2019).

The above information is relatively few for the research results of large-scale intermittent joint model surrounding rock. Numerical simulation provides the direction for the research and development of rock mechanics. Our university boasts a solid foundation in research related to anchoring support in tunnels and the behavior of large-scale intermittent jointed rock masses. Our expertise lies in effectively mobilizing the load-bearing capacity of deep rock in tunneling with bolt support systems and enhancing the stress state of surrounding rock in anchorage zones. Our techniques and technology are mature, placing us at the forefront internationally. We integrate numerical simulation technology seamlessly into our research, creating a mutually beneficial relationship. Based on this, the −600 m main roadway in Xin ‘an Coal Mine was taken as the research background, the fracture fractal dimension D was used to characterize the joint density, and the numerical model of the surrounding rock of the discontinuous joint roadway without support and with anchor cable support were established. The mesoscopic parameters of the numerical model were calibrated according to the physical model test results. The bearing capacity and fracture characteristics of the surrounding rock with discontinuous joints under different support methods and joint densities were studied. Additionally, the influence of joint distribution on the stability of the surrounding rock in the roadway was analyzed.

In this study, the −600 m main roadway of Xin ‘an Coal Mine was taken as the research background, which is in the shape of a semicircular straight arch, as shown in Figure 1. Due to the high stress of deep roadway and the opening dislocation of the primary discontinuous joints of surrounding rock, secondary cracks appear. The connection, interleaving and penetrating of the primary joints and secondary cracks lead to the appearance of loose blocks, resulting in the opening and sliding of discontinuous structural planes and the instability and failure of surrounding rock. To decrease harmful deformation, lower repair workload, and ensure roadway stability, it is imperative to conduct systematic research focused on the fracture evolution mechanism of discontinuous jointed rock mass and the key techniques regarding stability control.

Figure 1. Deformation of surrounding rock of roadway buried −600 m in Xin ‘an Coal Mine. (The support components on the right side undergo characteristic failure due to the action of stress).

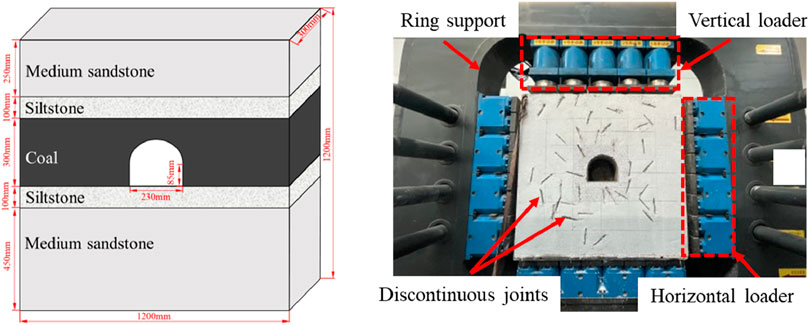

Considering the size of the roadway section and the limitations of the test size, the geometric similarity ratio was determined as CL = 20. According to the reference (Jing et al., 2022; Wu et al., 2024b; Wu et al., 2022), river sand with uniform particle size distribution, C32.5 ordinary Portland cement, gypsum and water were selected to form similar materials with bulk density of γm = 16.4 kN/m3, and the similarity ratio of bulk density was obtained as Cr = γP/γm = 1.72. The intensity similarity ratio was CR = Cγ × CL = 20 × 1.72 = 34.4. The uniaxial compressive strength, Brazilian splitting and variable Angle shear tests of coal rock samples buried at −600 m in Xin ‘an Coal Mine were tested to determine the basic mechanical parameters of in-situ raw rock. Then the mechanical parameters of similar materials were obtained from the similarity ratio (Wu et al., 2020), as shown in Table 1. The mass ratios of medium sandstone, siltstone and coal were determined as: (river sand: cement: gypsum = 8:1:1, 10:1:1, 100:7:1), respectively, through the basic mechanical tests of similar materials.

The size of the model is 1,200 mm × 1,200 mm (Figure 2), the thickness of the coal seam is 300 mm, the thickness of the direct top and the direct bottom are 100 mm, the basic top thickness is 250 mm, and the basic bottom thickness is 450 mm. The mining roadway is a semicircular straight arch roadway with a span of 230 mm and a height of 85 mm. The specific anchor cable arrangement is shown in Figure 3B. The size of the anchor used in this study is 22 mm × 3000 mm, the yield strength is 400 MPa, the elongation is 16%, and the breaking force is 225 kN. The anchor cable used in the field is 21.8 mm × 9000 mm, the yield strength is 1320 MPa, the elongation is 16%, and the breaking force is 560 kN. In the model test, 1.1 mm × 150 mm tin wire was used to simulate anchor rod, and 1.1 mm × 450 mm iron wire was used to simulate anchor cable.

Figure 2. Simulation test system for the whole process of structural instability in deep underground engineering.

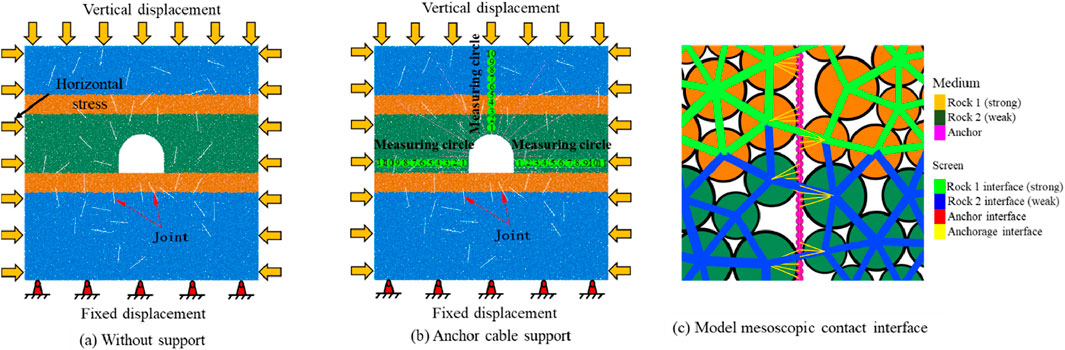

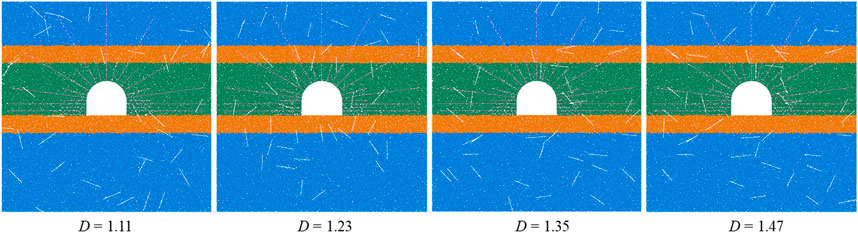

Based on the actual dimensions of the similar physical model, a 1:1 particle flow model was established for different support forms, as shown in Figure 4. The model is a plane strain model with D = 1.23 for cracks (D: It typically refers to fractal dimension, which can be used to describe the complexity and regularity of certain geometric structures or data sets. D = log(N)/log (1/ε), D is the fractal dimension; N is the minimum number of boxes needed to cover the data set; ε is the box size) and the arrangement of anchor cables is consistent with the experimental model. Measuring circles were arranged on both sides of the tunnel to monitor the internal stress evolution of the surrounding rock during the process of failure and instability as shown in Figure 4B. The maximum vertical and horizontal ground stress of the roadway are 15.73 and 24.13 MPa, respectively. And according to the similarity ratio of mechanical parameters is 34.4, the initial vertical and horizontal ground stress of the calculated model are 0.46 and 0.7 MPa respectively. Therefore, the servo mechanism was used to apply 0.46 MPa vertical stress and 0.7 MPa horizontal stress to the model, and then the particles inside the roadway were deleted. The equilibrium iterative calculation was carried out on the model, so that the model could balance under the boundary conditions of 0.46 MPa vertical stress and 0.7 MPa horizontal stress to simulate roadway excavation. After the model reaches equilibrium, the displacement loading method is adopted to vertically load the model at a speed of 0.1 m/s until it is destroyed. To analyze the influence of different D on the bearing performance and deformation failure characteristics of rock mass anchored by intermittent joints in tunnels, the D were selected as 1.11, 1.23, 1.35, and 1.47. The established particle flow model is shown in Figure 5. Particle flow simulation is a computational mechanics method used to simulate the motion and interactions of granular materials under external forces. Its fundamental principle lies in representing matter as numerous discrete small particles, calculating particle trajectories using Newton’s second law, and additionally considering interparticle interaction forces and contact force models to simulate the complex behavior of granular materials under stress.

Figure 4. Particle flow model of surrounding rock with discontinuous joint in deep roadway. (Internal stress evolution of surrounding rock during failure and instability processes in different support methods). (A) Without support. (B) Anchor cable support. (C) Model mesoscopic contact interface.

Figure 5. Particle flow models with different D. (It typically refers to fractal dimension, which can be used to describe the complexity and regularity of certain geometric structures or data sets).

The parallel bond model was used as the meso-contact between the particles of this model. Two medium models and four interface models were established. The Parallel Bond Model (PBM) is a discrete element method used to simulate the contact mechanics between particles, describing their interactions through virtual bonding contact surfaces. The model introduces bond points between particles to simulate the bonding force. When the relative displacement between particles is small, the bonding force acts to connect them; as the displacement exceeds a certain threshold, the bonding force gradually diminishes until rupture occurs. The model accounts for nonlinear effects such as elastic contact, friction, stretching, and rupture between particles, enabling precise simulation of complex mechanical processes like bonding, detachment, and failure. It is particularly suitable for modeling the mechanical behavior of granular materials, rocks, and other particulate media. The two medium models are rock and bolt respectively, and the four interfaces are similar rock interface, dissimilar rock interface, bolt cable interface and rock and bolt cable interface, respectively.

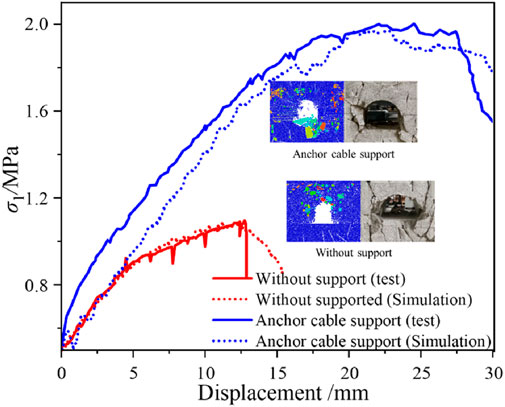

Different mesoscopic contact parameters were assigned to different mesoscopic contact interfaces. For the same rock interface, the mesoscopic contact parameters of the same rock were used. However, for dissimilar rock interfaces, such as the contact interface between coal and siltstone, mesoscopic contact parameters of rocks with weaker bonding characteristics were adopted. The meso-mechanical parameters of medium sandstone, siltstone and coal in the numerical model were calibrated by the basic mechanical parameters obtained from the model test. The trial-and-error method was used to debug microscopic parameters that were consistent with the results of model experiments. The comparison results of stress-strain curves and failure modes between physical model experiments and numerical simulations are shown in Figure 6, which are basically consistent. It shows that the numerical simulation can well reproduce the macro and micro evolution characteristics of the whole process of failure and instability of roadway surrounding rock. The final microscopic particle parameters and microscopic interface contact parameters are shown in Table 2, 3.

Figure 6. Comparison of numerical simulation and physical model test results. (It shows that the numerical simulation can well reproduce the macro and micro evolution characteristics of the whole process of failure and instability of roadway surrounding rock).

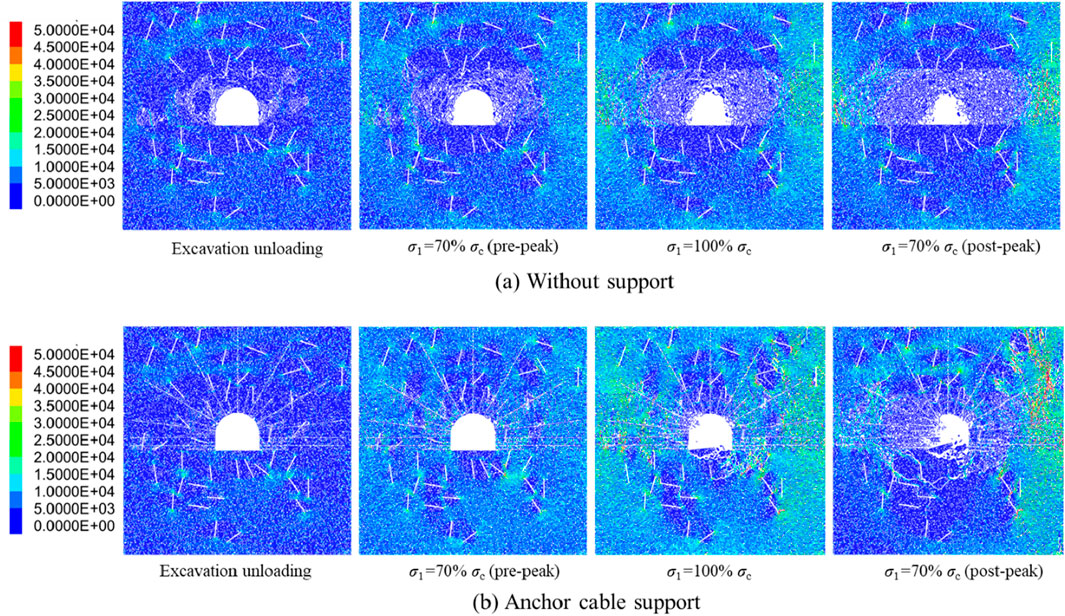

Figure 7 shows the force chain distribution of intermittent jointed surrounding rock in tunnels with D = 1.23 under different support methods, where the density and color of the force chain indicate the strength of the force chain. As shown in the figure, under the two support methods, the force chain distribution at the two sides of the roadway is sparse, indicating that the structural damage at this location is more severe during the bearing process of the roadway surrounding rock. With the application of stress, the force chain values in the deep surrounding rock significantly increased in the models under both support methods. This indicates that the main bearing area is shifting from the surface surrounding rock to the deep surrounding rock. In addition, in Figure 7B IV, the bottom plate and on the right side force chain of the roadway with anchor cable support are damaged due to the large load applied to the deep rock mass on the right side. When the stress exceeds the critical load for the failure of the deep surrounding rock, the stress drops when the deep surrounding rock breaks, accompanied by strong stress fluctuations, resulting in intensified damage to the roadway bottom plate. Localized particle dislodgement at the left gang location is inferred to be due to failure of anchorage in the surface perimeter rock at the left gang location.

Figure 7. Force chain field of surrounding rock of roadway discontinuous joint under different support methods. (Under the two support methods, the force chain distribution on both sides of the roadway is sparse, indicating that the structural damage on both sides of the roadway is more severe during the bearing process of the surrounding rock). (A) Without support. (B) Anchor cable support.

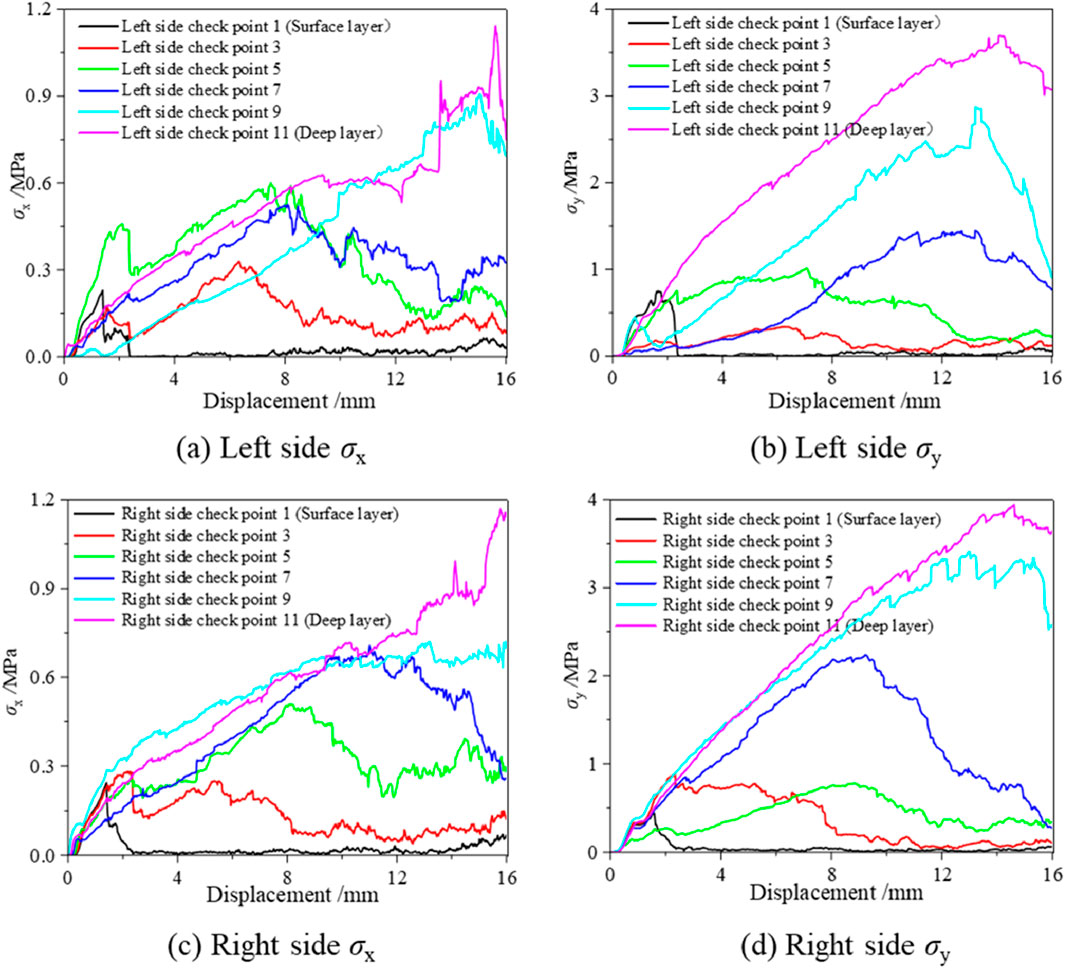

Figures 8, 9 show the internal stress evolution of the model under different support methods. The larger the measurement circle number, the closer it is to the deep surrounding rock. The stress on the side of the roadway shows a “valley” wave trend of rising first and then decreasing with the continuous displacement loading. Under continuous servo loading at the top of the roadway surrounding rock, the top load is first borne by the roof. When the bearing capacity of the roof decreases, the load is transmitted to the two walls, causing their deformation to increase. This leads to a sharp increase in the displacement of the walls, and in some cases, the collapse of the side wall causes the roof to collapse, which aligns with the engineering practice where the slab and roof fall almost simultaneously. The failure of the surrounding rock shows the sequential failure of “from the surface to the inside”, and the main bearing area shifts to the deep rock mass. In addition, the load-bearing capacity of each monitoring point in the roadway model supported by anchor cables is significantly higher than that in the model without support. The internal stress increases by 55.6%–172.7% compared to the roadway model without support. When the initial stress is applied in the no-support model, the bearing capacity and deformation of the two sides of the roadway increase sharply, leading to failure. This causes the surface surrounding rock structure to become unstable. In contrast, the anchor cable support model can effectively adjust the bearing structure of the surface surrounding rock, ensuring that the surrounding rock of the roadway remains generally stable.

Figure 8. Evolution of internal stress in the whole process of failure and instability of the surrounding rock of the discontinuous joint of the roadway without support. (A) Left side σx. (B) Left side σy. (C) Right side σx. (D) Right side σy.

Figure 9. Evolution of internal stress in the whole process of failure and instability of rock surrounding rock of discontinuous joint of roadway supported by anchor cable. (A) Left side σx. (B) Left side σy. (C) Right side σx. (D) Right side σy.

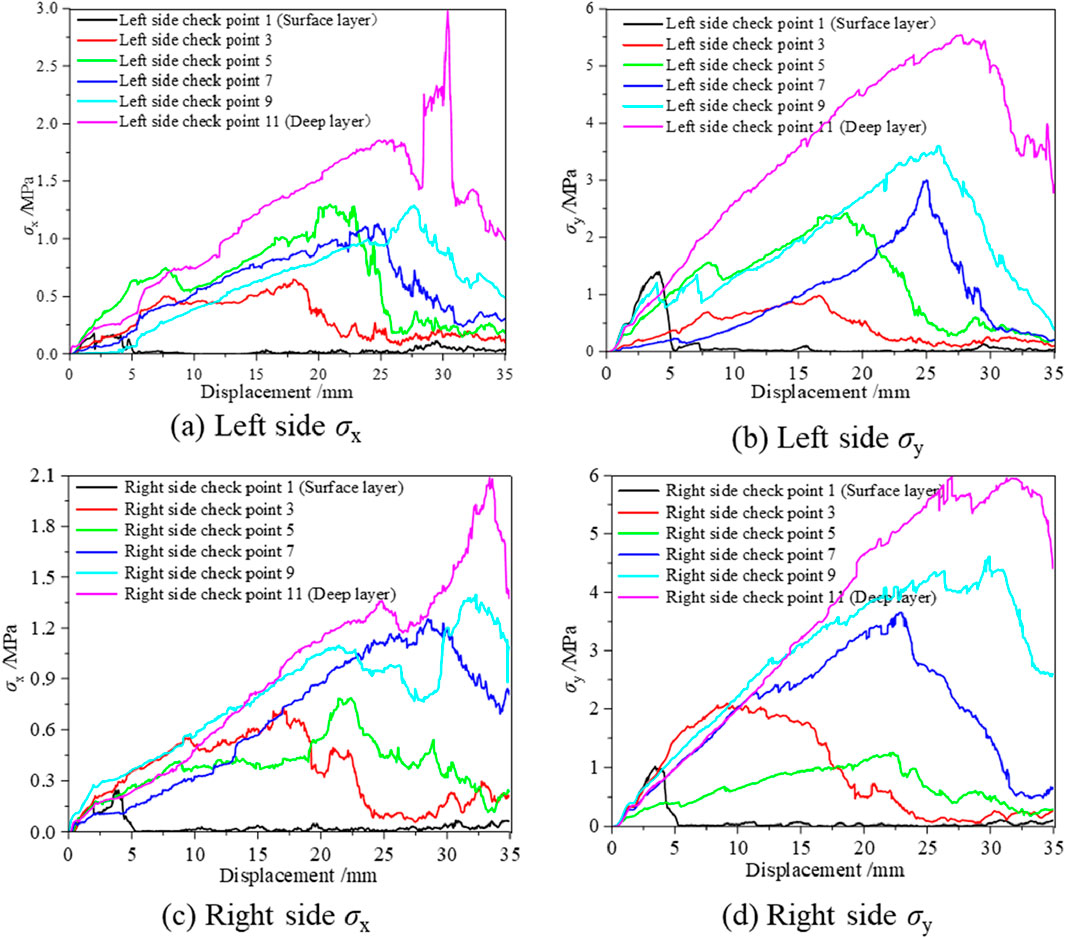

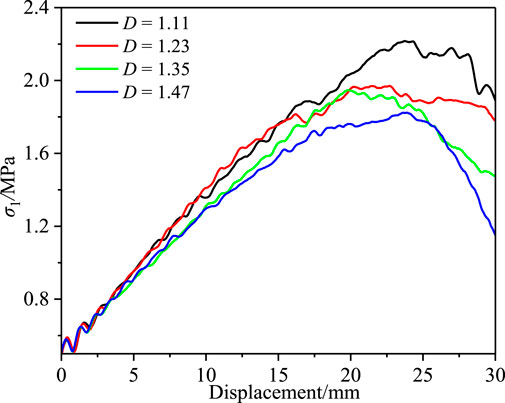

The joint density of the surrounding rock is closely related to the stability of the surrounding rock, and the number of joints increases with the increase of fractal dimension D. Figures 10, 11 show the internal stress diagram of roadway discontinuous joint anchorage surrounding rock with different D. It can be seen from Figure 10 that at σ1 = 70% σc (post-peak), the main bearing zone of the anchoring surrounding rock under different D has transited to the deep rock mass, and the surface anchoring zone under all fractal dimensions except D = 1.23 shows relatively stable force chain distribution (σc is often referred to as tensile stress or tensile strength, which is the ability of a material to resist tension in a tensile test, typically defined as the maximum tensile stress the specimen sustains before failure). In Figure 11, it can be seen that the bearing capacity of the anchored enclosure gradually decreases with increasing D, which indicates that the joint density also significantly affects the stability of the surrounding rock mass of roadways. The deformation and failure of the surrounding rock are essentially caused by secondary cracks, which result from the opening dislocation of the primary joint. The connection, interleaving, and penetration of the primary joint and secondary cracks lead to the formation of loose blocks. This, in turn, causes the opening and sliding of discontinuous structural planes, resulting in the instability and failure of the surrounding rock. It is revealed that the anchoring essence of bolt and cable is to resist the tension stress, and to connect the loose rock mass that might collapse to the surrounding rock as a whole, so that it still has a certain bearing capacity.

Figure 10. Force chain field of surrounding rock anchored by discontinuous joints of roadway with different D (σ1 = 70% σ c (post-peak)) (At σ1 = 70% σc (post-peak), the main bearing zone of the anchoring surrounding rock under different D has transited to the deep rock mass, and the surface anchoring zone under all fractal dimensions except D = 1.23 shows relatively stable force chain distribution).

Figure 11. Stress-displacement curves of roadway discontinuous joint anchorage with different D. (It can be seen that the bearing capacity of the anchored enclosure gradually decreases with increasing D, indicating that the joint density significantly affects the stability of the surrounding rock mass of the roadway).

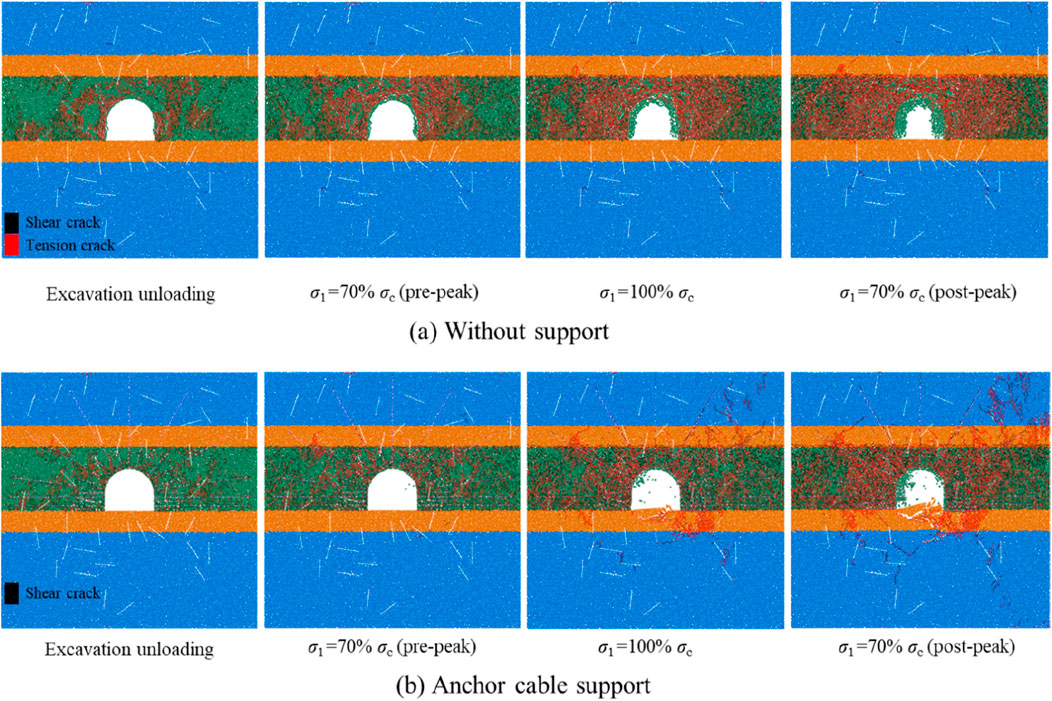

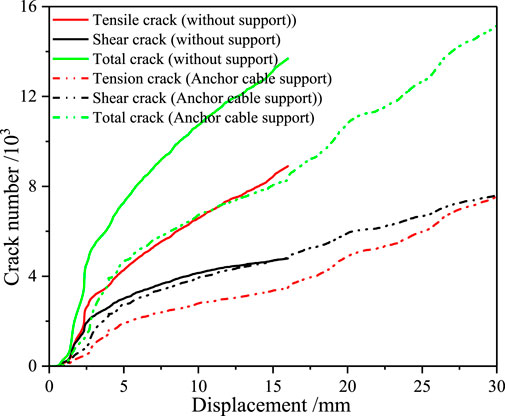

Figure 12 shows the crack field of the whole process of the instability of the surrounding rock of the discontinuous joint of the roadway under different support methods. In the process of the surrounding rock bearing the load, cracks gradually accumulate, and a large number of cracks are generated in both sides of the two supports, while in the model with anchor cable support, the anchor cables provide additional restraining force, tightly connecting the rock masses on both sides of the crack, effectively suppressing tensile failure of the surrounding rock. This, in turn, enhances the overall bearing capacity of the surrounding rock, resulting in a significant reduction in the number of cracks compared to the other model. At the beginning of loading, cracks tend to first appear in the weak interlayer. With the continuous loading, the prefabricated cracks gradually extend, and the dense cracks begin to connect and expand with each other, and the media discontinuity intensifies. The function of the anchor cable is to connect the falling block to the whole, so that it still retains a certain bearing capacity and restrains the crushing expansion and extrusion deformation of the surrounding rock. Figure 13 shows the crack evolution of surrounding rock under two support methods to further measure the influence of support methods on the stability of roadway surrounding rock. Comparison found that the number of tensile cracks was significantly reduced with the use of anchor cable support. When the displacement reaches 10mm, the number of tensile cracks in the model with anchor cable support is reduced by 57.7% compared to the model without support, indicating that anchor cable support inhibits the tensile failure of the roadway surrounding rock. This shows that the anchoring essence of bolt and cable lies in resisting tensile stress, closely connecting the loose rock mass that may collapse with the surrounding rock, so as to maintain its certain bearing capacity.

Figure 12. Surrounding rock crack field of roadway discontinuous joint under different support methods. (During the process of bearing loads on the surrounding rock, cracks gradually accumulate and a large number of cracks are generated on both sides of the two support points. In the anchor cable support model, the anchor cable provides additional constraint force, effectively suppressing the tensile failure of the surrounding rock, improving the overall bearing capacity of the surrounding rock, and significantly reducing the number of cracks). (A) Without support. (B) Anchor cable support.

Figure 13. Crack evolution in the whole process of failure and instability of the surrounding rock of the intermittent joint of the roadway under different support methods. (After the installation of anchor cables, the number of tensile cracks significantly decreases, indicating that the anchor cable support inhibits the tensile failure of the surrounding rock mass of the roadway).

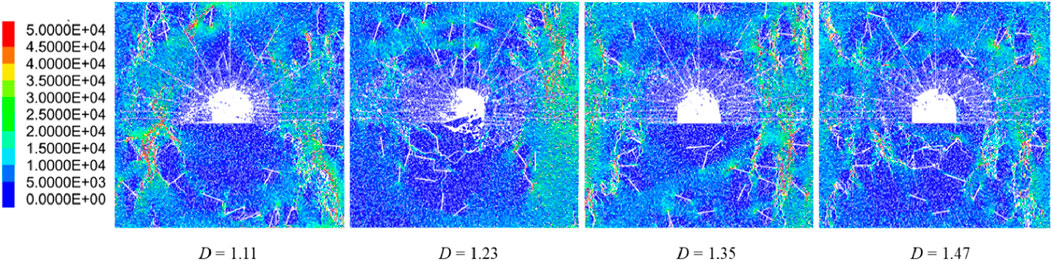

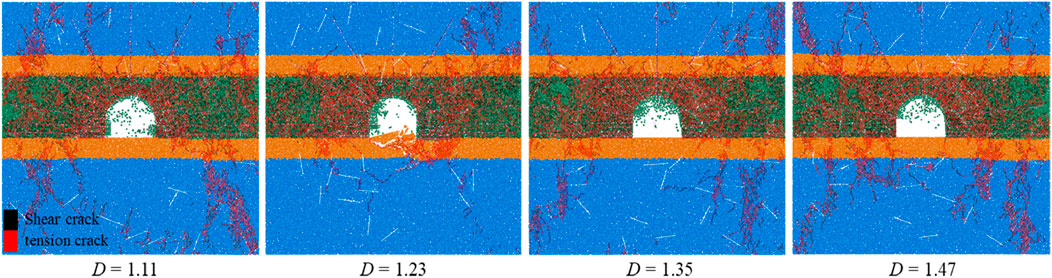

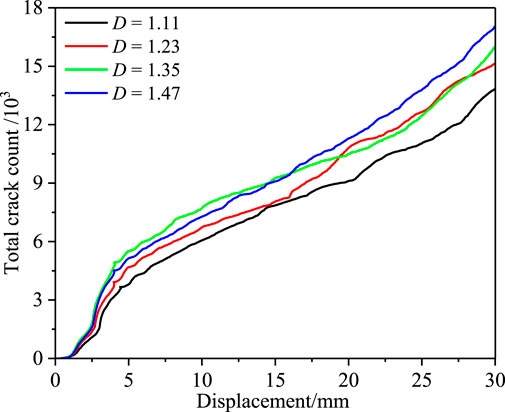

Figures 14, 15 show the crack distribution of the fractured joint anchorage surrounding rock with different fracture fractal dimensions D. As can be seen from Figure 14, under the same stress and anchorage, a large number of cracks have accumulated at both sides and roof of the anchorage roadway regardless of the D. It can be seen that the cracks are concentrated in the discontinuous joints, and a large number of cracks expand and penetrate to form macroscopic cracks. In addition, the bottom plate of the joint model with D = 1.23 is seriously damaged due to the existence of joints, which proves that joint distribution is crucial to the evaluation of the stability of roadway surrounding rock. Due to stress effects, different types of fractures form on the two sides and the top of anchored tunnels. If there is tensile deformation on both sides of the crack and it extends along the tensile direction, it is classified as a tensile fracture. If the crack appears as a shear or slip surface along the interior of the material or object, with features of slip-like movement between the crack edges, it is identified as a shear fracture. Additionally, tensile fractures are more prominently observed in anchored tunnels and occur in larger quantities, thus having a crucial impact. Figure 15 shows that the number of cracks in the anchored surrounding rock increases with increasing D. Taking the displacement loading of 20 mm as an example, 11,300 total tensile shear cracks are developed in the anchored model when D = 1.47, while 9,108 total tensile shear cracks are developed in the anchored model when D = 1.11, and the total crack number at D = 1.47 is 1.24 times that at D = 1.11. The increase in the number of cracks can easily cause the discontinuous joints to connect, which significantly weakens the overall strength of the surrounding rock. This, in turn, makes the surrounding rock more prone to collapse disasters at the roof and collapse deformation at the sides. In the process of disaster evolution of surrounding rock, microcracks sprout, connect and expand, and media discontinuity intensifies, which eventually leads to fracture penetration. Support measures should pay attention to “strong roof protection” and “collaborative support” to improve the overall bearing capacity of roadway surrounding rock.

Figure 14. Crack field of surrounding rock anchored by discontinuous joint of roadway with different D (σ1 = 70% σc (post-peak)). (Under the same stress and anchorage, a large number of cracks have accumulated at both sides and roof of the anchorage roadway regardless of the D).

Figure 15. Crack evolution in the whole process of failure and instability of the surrounding rock anchored by discontinuous joints of roadway with different D. (The number of cracks in the surrounding rock mass around the anchor increases with the increase in D. The increase in crack quantity can lead to discontinuous joint connections, which significantly weakens the overall strength of the surrounding rock, making the roof more prone to collapse and the sides more susceptible to collapse deformation).

Figure 16 gives the fracture evolution process of the surrounding rock of the discontinuous joint of the roadway under different support methods. The observation shows that the roof of the model without support is severely damaged during excavation and unloading, while the overall model of bolt-cable support is basically intact. The two sides of the model without support have great damage during the bearing process. Without the support model, the displacement of both sides of the roadway is obvious, especially when σ1 = 70% σc (post-peak), the roadway deformation is too large and the section becomes smaller. The anchor cable support effectively controls the displacement of the two walls and ensures the integrity of the anchorage area of the roadway. In addition, it is observed that the bottom plate failure under anchor bolt cable support is relatively serious. This occurs because, when the stress exceeds the ultimate load of the deep surrounding rock, the stress fluctuation caused by its failure interacts with the broken joints in the surface surrounding rock. Since the surface surrounding rock with broken joints is relatively weak, when the greater stress is transferred to the surface broken joints, the surface surrounding rock with broken joints is relatively weak. The stress concentration is easy to occur at the joint, resulting in the failure of the surrounding rock at the discontinuous joint of the floor, but the roadway structure is still not unstable.

Figure 16. Failure modes of surrounding rock of discontinuous joint of roadway under different support methods. (The roof of the model without support is severely damaged during excavation and unloading, while the overall model of bolt-cable support is basically intact). (A) Without support. (B) Anchor cable support.

Figure 17 illustrates that the failure diagram of roadway discontinuous joint anchorage surrounding rock at σ1 = 70% σc (post-peak) with different fracture fractal dimensions D (D: It typically refers to fractal dimension, which can be used to describe the complexity and regularity of certain geometric structures or data sets. D = log(N)/log (1/ε), D is the fractal dimension; N is the minimum number of boxes needed to cover the data set; ε is the box size). The damage degree of the bottom plate of the anchoring model with the fractal dimension of 1.23 is greater, while the overall damage of the anchoring model with the fractal dimension of 1.47 is serious and the supporting effect is poor. The larger the joint density, the larger the fracture development degree, the larger the deformation, the smaller the elastic deformation bearing capacity, the larger the crushing zone of the surrounding rock, the more serious the crushing deformation degree of the surrounding rock side. In order to produce the same degree of crushing zone and swelling deformation of surrounding rock, the greater the joint density, the smaller the loading pressure required. Therefore, the density of discontinuous joint surrounding rock greatly affects the overall stability of surrounding rock. Therefore, when facing the support demand of high density of deep intermittent joints, targeted support program should be adopted to reinforce the surrounding rock of the intermittent joints.

Figure 17. Failure modes of roadway discontinuous joint anchorage with different D (σ1 = 70% σc (post-peak)). (The larger the joint density, the larger the fracture development degree, the larger the deformation, the smaller the elastic deformation bearing capacity, the larger the crushing zone of the surrounding rock, the more serious the crushing deformation degree of the surrounding rock side).

In the context of existing research on discontinuous jointed rock masses and roadway stability, the results presented in this study provide valuable contributions and insights, particularly concerning the effects of different support methods on the mechanical behavior of surrounding rock. While the impact of joint density and distribution on rock mass stability has been widely studied, this study offers a more focused approach by modeling and simulating these effects under both supported and unsupported conditions. Moreover, the application of a multi-source information fusion system for real-time monitoring, as suggested for future work, adds a new dimension to rock mass behavior analysis, integrating diverse data sources for enhanced predictive capabilities.

Several studies have explored the failure mechanisms of jointed rock masses and the importance of support systems in deep roadways. For example Bejari and Hamidi (2013), investigated the influence of joint spacing and orientation on the stability of underground structures, while (Yu et al., 2020) focused on the effects of different support methods, including anchor cables, on roadway stability in fractured rock masses. These studies highlight the role of jointing in weakening rock mass strength and causing instabilities. However, these studies often treat joint distributions as uniform or idealized, without considering the more complex and heterogeneous joint patterns encountered in real-world conditions.

In contrast, this study emphasizes the random generation of joint distributions to simulate more realistic geological conditions. By combining advanced numerical modeling (using PFC2D) with field-inspired joint characteristics, this research offers a more applicable approach to understanding the behavior of surrounding rock under varying support systems. The results clearly demonstrate that anchor cable support can effectively reduce tensile failures and enhance the load-bearing capacity of surrounding rock. This finding aligns with results from other studies, but it also provides more detailed numerical evidence of how joint connectivity influences failure patterns.

Additionally, the potential for multi-source information fusion to monitor roadway stability in real-time is an innovative contribution that builds on prior work in geotechnical monitoring. For example Fang and Zhang (2014), highlighted the integration of geophysical sensors and real-time data analysis in tunnel construction. This study extends that concept by proposing a broader range of monitoring tools, including Ground Penetrating Radar (GPR), acoustic emissions, and stress sensors, for real-time assessment of rock mass stability. The fusion of these data sources can provide a more dynamic and comprehensive view of surrounding rock behavior, offering a promising direction for future research.

Compared to existing literature, this study advances our understanding by integrating both physical modeling and the potential for real-time monitoring in practical engineering contexts (Wang W. et al., 2023). have studied the impact of joint distribution on roadway stability, but these studies mainly focus on static analysis or simplified models. In contrast, this study considers the dynamic interaction between support systems, rock mass failure, and joint propagation under varying load conditions. This dynamic approach provides deeper insights into the progressive failure of surrounding rock, particularly in the presence of anchor cable support, which is less frequently modeled in jointed rock mass studies.

The modeling techniques used in this study, particularly the PFC2D particle flow code, are well-suited to simulate the complex behavior of discontinuous rock masses under stress. This is a significant improvement over simpler continuum-based models, which often overlook the intricate interactions between joints and fractures in the rock mass. The study that its use in this research to specifically model the transition of load-bearing capacity from surface to deep surrounding rock, and to examine the effect of anchor cable support, adds new insights to the existing body of knowledge.

However, this study also has some limitations. Firstly, although randomly generated joints can simulate the distribution of natural joints, they may not fully reflect the geological conditions in the actual rock mass. The direction of joints, surface roughness, and mineral composition may all have an impact on the results, and future research should combine field data to verify and improve these results. In addition, the research mainly focuses on the mechanical failure mode of surrounding rock, without considering other factors that may affect the stability of surrounding rock, such as water flow infiltration, temperature changes, or seismic effects, which may also have a significant impact on rock stability in deep mining environments.

Another limitation is that the physical properties of the surrounding rock are assumed to be homogeneous, which may not accurately reflect the spatial heterogeneity in the actual rock mass. The physical properties of surrounding rocks often exhibit spatial variations, influenced by mineral composition, stress history, and geological discontinuities. Future research can further enhance the practicality of the model by considering the spatial variability of rock masses and the coupling effects of multiple physical processes.

The results of this study are highly relevant to the broad readership of Frontiers in Earth Science, particularly for researchers and engineers working in rock mechanics, underground mining, and rock engineering. The findings related to the influence of joint density and fractal dimension on surrounding rock stability have direct practical value for designing support systems in deep mining roadways. As mining operations continue to progress to greater depths, understanding the failure mechanisms of complex jointed rock masses becomes increasingly important for ensuring the safety and economic feasibility of mining projects.

Moreover, the application of fractal dimension to quantify joint complexity and the proposal of tailored support strategies for high-density jointed rock masses also provide new insights for research in the field of rock mechanics. The suggestion for future real-time monitoring using a multi-source information fusion system holds significant value for scholars and engineers involved in mine monitoring and predictive maintenance.

This study makes a significant contribution to the literature on the stability of roadway surrounding rock in discontinuous jointed rock masses by providing a more realistic approach to joint distribution, support system modeling, and real-time monitoring. By integrating advanced numerical techniques with innovative monitoring strategies, it offers new insights into the behavior of fractured rock masses under stress. The findings not only align with previous research but also extend it by providing more dynamic and practical solutions for improving roadway stability in deep, jointed rock environments. Future research can build on these findings by further refining joint distribution models, incorporating a broader range of rock types, and validating the results with field data to ensure the robustness and applicability of the proposed solutions.

The −600 m horizontal roadway in Xin ‘an Coal Mine was taken as the background, the fracture fractal dimension was used to characterize the joint density, and the numerical model of surrounding rock roadway with discontinuous joint was established. The mesoscopic characteristics of the whole process of failure and instability of surrounding rock with discontinuous jointed rock mass in deep roadways were studied through numerical simulation.

(1) In the process of bearing loads, the main bearing area shifts from the surface surrounding rock to the deep surrounding rock. At the same time, the support significantly increases the tensile strength of the surrounding rock structure, effectively inhibiting tensile failure of the surrounding rock. Studies show that the essential function of the anchor rod and anchor cable is to resist tensile stress and connect the surrounding rock as a whole, effectively controlling the displacement of the two walls and maintaining a certain bearing capacity. From the perspective of the force chain, in the unsupported model, the force chain fractures are mainly distributed in the surface surrounding rock, and the fracture of the surface rock mass causes it to detach. However, in the anchor rod support model, the force chain fracture characteristics are similar, but the fracture occurs in the deep surrounding rock, leading to model failure. This indicates that the anchor rod-anchor cable support can effectively mobilize the bearing capacity of the deep rock mass.

(2) The discontinuous joint density has a significant influence on the instability mechanism of the roadway surrounding rock, and the bearing capacity of joint surrounding rock is negatively correlated with the fractal dimension of fracture D. With the increase of D, the total number of tensile shear cracks in the roadway anchoring model increases by 24%. When the D reaches 1.47, the overall failure of the anchoring model is serious. The increase in the number of cracks is easy to cause the discontinuous joints to connect with each other, and the overall failure of the anchorage model is serious, resulting in the failure of the deep roadway anchorage structure.

(3) The coupling effect of discontinuous joint distribution and high stress on surface surrounding rock seriously affects the fracture characteristics of the roadway. When the stress exceeds the bearing limit of the deep surrounding rock, the stress fluctuation caused by the stress drop after its failure aggravates the development of fracture structures at the interrupted joints in the surface surrounding rock. This increases the likelihood of joint penetration in the surface surrounding rock, leading to anchorage failure and a higher risk of roadway instability. This study mainly focuses on the influence of support method and joint density on the stability of surrounding rock of roadway discontinuous joint through numerical simulation. The research results show that bolt-cable support significantly reduces the number of tensile cracks, effectively controls the deformation of the surrounding rock, increases the tensile strength of the surrounding rock structure, and effectively inhibits tensile failure of the surrounding rock. The density of discontinuous joints is negatively correlated with the bearing characteristics of surrounding rock, and the distribution of joints greatly affects the fracture law of surrounding rock. The research results can provide reference for the support design of discontinuous joint surrounding rock of deep roadway.

We will use multi-source information fusion system to monitor the model in the future. In addition, the discontinuous joints in this paper are randomly generated, and if the joint distribution can be generated with the help of scientific progress and the actual field in the engineering background, the research can be more targeted.

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

CH: Writing–original draft, Writing–review and editing. GS: Writing–original draft, Writing–review and editing. JW: Writing–original draft, Writing–review and editing. BZ: Writing–original draft, Writing–review and editing. ZT: Writing–original draft, Writing–review and editing. FW: Writing–original draft, Writing–review and editing. BM: Conceptualization, Data curation, Formal Analysis, Funding acquisition, Investigation, Methodology, Project administration, Resources, Software, Supervision, Validation, Visualization, Writing–original draft, Writing–review and editing.

The author(s) declare that no financial support was received for the research, authorship, and/or publication of this article.

Authors GS and BZ were employed by China Coal (Tianjin) Underground Engineering Intelligent Research Institute Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

The author(s) declare that no Generative AI was used in the creation of this manuscript.

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Alber, M., Fritschen, R., Bischoff, M., and Meier, T. (2009). Rock mechanical investigations of seismic events in a deep longwall coal mine. Int. J. Rock Mech. Min. Sci. 46, 408–420. doi:10.1016/j.ijrmms.2008.07.014

Basarir, H., Sun, Y., and Li, G. (2019). Gateway stability analysis by global-local modeling approach. Int. J. Rock Mech. Min. Sci. 113, 31–40. doi:10.1016/j.ijrmms.2018.11.010

Bejari, H., and Hamidi, J. K. (2013). Simultaneous effects of joint spacing and orientation on TBM cutting efficiency in jointed rock masses. Rock Mech. Rock Eng. 46, 897–907. doi:10.1007/s00603-012-0314-2

Chen, X., Liao, Z., and Peng, X. (2012). Deformability characteristics of jointed rock masses under uniaxial compression. Int. J. Min. Sci. Technol. 22, 213–221. doi:10.1016/j.ijmst.2011.08.012

Fang, S., and Zhang, J. (2014). In-situ measure to internal stress of shotcrete layer in soft-rock roadway. Int. J. Coal Sci. Technol. 1, 321–328. doi:10.1007/s40789-014-0041-2

Gao, L., Gao, F., Zhang, Z., and Xing, Y. (2020). Research on the energy evolution characteristics and the failure intensity of rocks. Int. J. Min. Sci. Technol. 30, 705–713. doi:10.1016/j.ijmst.2020.06.006

Gao, M., Xie, J., Gao, Y., Wang, W., Li, C., Yang, B., et al. (2021). Mechanical behavior of coal under different mining rates: a case study from laboratory experiments to field testing. Int. J. Min. Sci. Technol. 31, 825–841. doi:10.1016/j.ijmst.2021.06.007

Grasselli, G., and Egger, P. (2003). Constitutive law for the shear strength of rock joints based on three-dimensional surface parameters. Int. J. Rock Mech. Min. Sci. 40, 25–40. doi:10.1016/S1365-1609(02)00101-6

He, M. C., Gong, W. L., Zhai, H. M., and Zhang, H. P. (2010). Physical modeling of deep ground excavation in geologically horizontal strata based on infrared thermography. Tunn. Undergr. Space Technol. 25, 366–376. doi:10.1016/j.tust.2010.01.012

Hou, C. (2017). Key technologies for surrounding rock control in deep roadway. Zhongguo Kuangye Daxue Xuebao/Journal China Univ. Min. Technol. 46, 970–978.

Janeiro, R. P., and Einstein, H. H. (2010). Experimental study of the cracking behavior of specimens containing inclusions (under uniaxial compression). Int. J. Fract. 164, 83–102. doi:10.1007/s10704-010-9457-x

Jiang, L., Sainoki, A., Mitri, H. S., Ma, N., Liu, H., and Hao, Z. (2016). Influence of fracture-induced weakening on coal mine gateroad stability. Int. J. Rock Mech. Min. Sci. 88, 307–317. doi:10.1016/j.ijrmms.2016.04.017

Jing, H., Wu, J., Yin, Q., and Wang, K. (2020). Deformation and failure characteristics of anchorage structure of surrounding rock in deep roadway. Int. J. Min. Sci. Technol. 30, 593–604. doi:10.1016/j.ijmst.2020.06.003

Jing, H., Wu, J., Meng, B., Yin, Q., and Zhao, Z. (2022). Macroscopic and mesoscopic evolution characteristics of surrounding rock of rectangular bottom coal roadway in deep during failure. J. Min. Saf. Eng. 39, 82. doi:10.13545/j.cnki.jmse.2021.0203

Jing, H. W., Yang, S. Q., Zhang, M. L., Xu, G. A., and Chen, K. F. (2014). An experimental study on anchorage strength and deformation behavior of large-scale jointed rock mass. Tunn. Undergr. Space Technol. 43, 184–197. doi:10.1016/j.tust.2014.05.006

Kang, H. (2014). Support technologies for deep and complex roadways in underground coal mines: a review. Int. J. Coal Sci. Technol. 1, 261–277. doi:10.1007/s40789-014-0043-0

Kang, H., Wu, Y., Gao, F., Lin, J., and Jiang, P. (2013). Fracture characteristics in rock bolts in underground coal mine roadways. Int. J. Rock Mech. Min. Sci. 62, 105–112. doi:10.1016/j.ijrmms.2013.04.006

Kang, Y., Hou, C., Liu, B., and Bai, W. (2023). Influence of water content on the shear strength of rock joints with clay-rich fillings. Rock Mech. Rock Eng. 56, 1437–1449. doi:10.1007/s00603-022-03158-2

Li, N., Zhou, Y., and Li, H. (2021). Experimental study for the effect of joint surface characteristics on stress wave propagation. Geomech. Geophys. Geo-energ. Geo-resour. 7, 50. doi:10.1007/s40948-021-00235-8

Li, X., Chen, Z., Weng, L., and Li, C. (2019). Unloading responses of pre-flawed rock specimens under different unloading rates. Trans. Nonferrous Metals Soc. China 29, 1516–1526. doi:10.1016/S1003-6326(19)65059-4

Małkowski, P. (2015). The impact of the physical model selection and rock mass stratification on the results of numerical calculations of the state of rock mass deformation around the roadways. Tunn. Undergr. Space Technol. 50, 365–375. doi:10.1016/j.tust.2015.08.004

Mao, S. (2020). Development of coal geological information technologies in China. Int. J. Coal Sci. Technol. 7 (2), 320–328.

Mo, S., Tutuk, K., and Saydam, S. (2019). Management of floor heave at Bulga Underground Operations – a case study. Int. J. Min. Sci. Technol. 29, 73–78. doi:10.1016/j.ijmst.2018.11.015

Shen, B. (2014). Coal mine roadway stability in soft rock: A case study. Rock mechanics and rock engineering 47, 2225–2238.

Su, X., Song, X., Li, H., Yuan, H., and Li, B. (2014). Study on coupled arch-beam support structure of roadway with extra-thick soft compound roof. Yanshilixue Yu Gongcheng Xuebao/Chinese J. Rock Mech. Eng. 33, 1828–1836. doi:10.13722/j.cnki.jrme.2014.09.013

Tao, Z., Zhang, H., Chen, Y., and Jiang, C. (2016). Support principles of NPR bolt/cable and control techniques of large-deformation disasters. Int. J. Min. Sci. Technol. 26, 967–973. doi:10.1016/j.ijmst.2016.09.002

Wang, J., Yu, B., Kang, H., Wang, G., Mao, D., Liang, Y., et al. (2015). Key technologies and equipment for a fully mechanized top-coal caving operation with a large mining height at ultra-thick coal seams. Int. J. Coal Sci. Technol. 2, 97–161. doi:10.1007/s40789-015-0071-4

Wang, W., Wu, C., Yang, Y., Peng, X., Jiang, L., and Huang, Y. (2023a). Numerical analysis on the influence of joint density on the stability of complex jointed roadway surrounding rock. Sustainability 15, 13561. doi:10.3390/su151813561

Wang, X., Zhao, Y., Zhang, X., Sun, Z., Gao, Y., and Jiang, Y. (2023b). Effects of anisotropy on strength and deformability of anthracite under high confinement. Rock Mech. Rock Eng. 56, 2157–2183. doi:10.1007/s00603-022-03140-y

Wu, J., Jing, H., Gao, Y., Meng, Q., Yin, Q., and Du, Y. (2022). Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cem. Concr. Compos. 127, 104408. doi:10.1016/j.cemconcomp.2022.104408

Wu, J., Jing, H., Yin, Q., Yu, L., Meng, B., and Li, S. (2020). Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J. Clean. Prod. 276, 123189. doi:10.1016/j.jclepro.2020.123189

Wu, J., Wong, H. S., Zhang, H., Yin, Q., Jing, H., and Ma, D. (2024a). Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement. Cem. Concr. Compos. 145, 105345. doi:10.1016/j.cemconcomp.2023.105345

Wu, J., Wong, H. S., Zhang, H., Yin, Q., Jing, H., and Ma, D. (2024b). Improvement of cemented rockfill by premixing low-alkalinity activator and fly ash for recycling gangue and partially replacing cement. Cem. Concr. Compos. 145, 105345. doi:10.1016/j.cemconcomp.2023.105345

Yan, H., He, F., Yang, T., Li, L., Zhang, S., and Zhang, J. (2016). The mechanism of bedding separation in roof strata overlying a roadway within a thick coal seam: a case study from the Pingshuo Coalfield, China. Eng. Fail. Anal. 62, 75–92. doi:10.1016/j.engfailanal.2015.12.006

Yan, S., Bai, J., Wang, X., and Huo, L. (2013). An innovative approach for gateroad layout in highly gassy longwall top coal caving. Int. J. Rock Mech. Min. Sci. 59, 33–41. doi:10.1016/j.ijrmms.2012.11.007

Yin, Q., Jing, H., Dai, D., Zhu, T., Zhao, H., and Meng, B. (2016). Cable-truss supporting system for gob-side entry driving in deep mine and its application. Int. J. Min. Sci. Technol. 26, 885–893. doi:10.1016/j.ijmst.2016.05.038

Yu, K., Ren, F., Puscasu, R., Lin, P., and Meng, Q. (2020). Optimization of combined support in soft-rock roadway. Tunn. Undergr. Space Technol. 103, 103502. doi:10.1016/j.tust.2020.103502

Yuan, L., Xue, J.-H., Liu, Q.-S., and Liu, B. (2011). Surrounding rock stability control theory and support technique in deep rock roadway for coal mine. J. China Coal Soc. 36.

Zhang, J., Kikumoto, M., Yasuhara, H., Ogata, S., and Kishida, K. (2022). Modeling the shearing behavior of discontinuous rock mass incorporating dilation of joint aperture. Int. J. Rock Mech. Min. Sci. 153, 105101. doi:10.1016/j.ijrmms.2022.105101

Keywords: deep roadway, joint surrounding rock, bearing characteristic, particle flow, faulted joints

Citation: Hu C, Song G, Wang J, Zhao B, Tao Z, Wen F and Meng B (2025) Numerical simulation of fracture evolution behaviors in deep roadway surrounding rock containing discontinuous joints. Front. Earth Sci. 12:1511853. doi: 10.3389/feart.2024.1511853

Received: 15 October 2024; Accepted: 27 December 2024;

Published: 15 January 2025.

Edited by:

Weiqiang Chen, Rice University, United StatesReviewed by:

Zhanguo Xiu, Qingdao University of Technology, ChinaCopyright © 2025 Hu, Song, Wang, Zhao, Tao, Wen and Meng. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bo Meng, bWVuZ2JvQGN1bXQuZWR1LmNu; Jiyu Wang, MjA2NDMxMzc4MkBxcS5jb20=

Disclaimer: All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article or claim that may be made by its manufacturer is not guaranteed or endorsed by the publisher.

Research integrity at Frontiers

Learn more about the work of our research integrity team to safeguard the quality of each article we publish.