- Department of Sciences and Technologies, University of Sannio, Benevento, Italy

The monitoring of slopes’ dynamics is essential to ensure the safety of infrastructures exposed to landslide risk and to develop mitigation strategies. However, it is not always possible to perform proper and slope-distributed monitoring due to the high cost of professional instruments. In this context, we developed a low-cost Arduino©-based wire extensometer for landslide monitoring. This instrument is capable of measuring the bi-directional distance between two fixed points, which is useful in landslide areas to observe linear displacements over time. Traditional wire extensometers are equipped with potentiometers, which allow measuring only finite displacements. Instead, our low-cost extensometer exploits a capacitive rotary encoder, which is able to measure infinite displacements. In addition, the new instrument can measure both wire lengthening and shortening, thanks to a spring-loaded winding system. Furthermore, the instrument’s settings can be modified to reach a millimetric resolution. The device - developed on an Internet of Things (IoT) project - is equipped with an online data transmission system and with a data-log system for local data storage. Laboratory and field tests were carried out with the aim of evaluating the instrument’s accuracy and reliability. Preliminary results demonstrate the great potential of this low-cost sensor for displacement measuring in the field of landslide monitoring.

1 Introduction

The monitoring of slopes’ dynamics is essential to ensure the safety of facilities exposed to landslide risk and to develop mitigation activities. The availability of spatially and timely distributed information about a mass movement (Kjekstad and Highland, 2009; Winter et al., 2016; Cruden, 1991) is a key factor for hazard management. In the last decades, the widespread use of new technologies had a key role in modern solutions developing in the field of landslides monitoring (Thirugnanam et al., 2022; Casagli et al., 2023), although their use is often limited by the high costs of commercial equipment (Dei Cas et al., 2021). Nowadays, low-cost solutions for slope monitoring can represent a solid alternative to professional systems (Fang et al., 2024).

Among the measurable parameters involved in slope instability, surface deformations are crucial to assess the activity of a landslide and related risk management. For this purpose - among the different monitoring systems - wire extensometers (Dunnicliff, 1993; Dei Cas et al., 2021) can be a valid solution when shear surfaces outcrop (Corominas et al., 2005; Intrieri et al., 2012; Guerriero et al., 2017; Pasquaré Mariotto et al., 2021). Generally, professional wire extensometers are equipped with potentiometers (Li and Meijer, 1998; Zhang et al., 2005) - namely, analogic sensors - which are able to measure a defined displacement value along a unique direction. These features - combined with the high costs of these systems (∼EUR 1000) - represent a limiting factor for their widespread use.

To address these shortcomings, (Guerriero et al., 2017), developed and tested a low-cost wire extensometer, which, however, in a few days of experiment, reached the maximum measurable displacement, showing the main drawback of the potentiometric sensor using. Different authors (Afandi et al., 2018; Setiono et al., 2023) tested wire extensometers based on the optical rotary encoder technology, finding that this kind of device has a low-speed limit for displacement measuring.

This technical note presents a new low-cost bi-directional wire extensometer that, unlike the previous systems, is based on the capacitive rotary encoder technology (Zheng et al., 2015). This sensor is able to measure infinite displacements along two directions. The prototype - developed on an Internet of Things (IoT) project - is equipped with an online data transmission system and a local storage data-log system. The device was firstly assessed in a climate-controlled environment through laboratory tests and successively was installed at the Grillo landslide (Southern Italy) with the aim to evaluate - through the comparison with multi-temporal Global Navigation Satellite System (GNSS) measurements performed - the reliability of the instrument in field conditions.

2 Materials and methods

2.1 The device

The device is composed of several modules: (a) rotary encoder, (b) data processing-storage-transmission system, (c) measuring system, and (d) power supply accommodated into a frame composed of a double waterproof plastic box (Supplementary Figure S1).

All the electronic components are fixed in the inner box (20 × 15 × 8 cm), while on the outer box (30 × 22 × 14 cm), a pulley is inserted in the rotary encoder’s housing and kept in position by a bearing. This solution allows the reinforcement of the overall structure and protects the vulnerable parts against weathering.

2.1.1 Rotary encoder

The rotary encoder is a digital sensor that is able to turn mechanical motion into electrical waves. The encoder’s rotation generates two electrical square waves that generally are 90° out of phase, allowing to determine the rotation’s direction and the linear displacement. This sensor allows counting infinite displacements, and - because of its capacity to turn clockwise and counterclockwise - it is able to measure along two directions.

Rotary encoders can be equipped with several technologies, such as optical, magnetic and capacitive. In this study, a CUI DEVICES AMT 10 capacitive rotary encoder was chosen (Supplementary Figures S2A, B). This type of encoder is composed of a rotor, a fixed transmitter and a fixed receiver. The motion of the rotor compared to the transmitter generates electric signals used to determine the position and the rotation direction of the encoder. The sensor’s resolution can be set by changing the number of electric pulses generated by the encoder for each revolution (PPR, “Pulses Per Revolution”). The resolution can range from 48 PPR to 2048 PPR simply by acting on 4 DIP switches housed in the encoder’s case (Supplementary Figure S2A).

The chosen rotary encoder - characterized by lightweight, stiffness, simple structure and low power consumption - presents a high reliability if compared with the optical (Afandi et al., 2018; Setiono et al., 2023) and magnetic technologies (Shuanghui et al., 2009). Thanks to this innovative technology, the power demand for capacitive encoders is reduced to about 10% of optical and magnetic technologies, resulting in important power savings that are essential in harsh conditions. In addition, capacitive technology is widely used for motors’ rotational speed measurements, allowing low and high-speed displacement observations (up to 15.000 revolutions per minute), in contrast with optical encoders, which can measure lower-speed displacements. Capacitive technology requires less maintenance than optical ones, which need to be periodically cleaned from dirt and dust to avoid accuracy losses over time. Moreover, magnetic technology has several limitations, such as electromagnetic field interferences, lower resolutions and accuracies and narrower working temperature ranges.

2.1.2 Data processing-storage-transmission system

The system for data processing, storage and transmission (Supplementary Figure S1) is composed of a series of modules, in particular: a power controller that sets the voltage of the input current; a Real Time Clock (RTC) with a 3 V coin cell battery backup (it allows the system to pick up data with specific timing and consequently to associate date and time to them); a micro SD card slot for the local data storage; a SIM 800l GPRS GSM module that provides to send the data online thanks to a SIM card; an Arduino electronic board with the task to manage the entire system and communicate with the rotary encoder. An Arduino Nano Every board was chosen for the compact size and the low price: this miniature-sized module is powered by an ATMega 4809 AVR processor and an ATSAMD11D14A ARM Cortex M0+ to act as a bridge between USB and the main AVR processor (https://docs.arduino.cc).

The device has been programmed using the Arduino IDE (Integrated Development Environment), an open-source software. The programming code is composed of a series of blocks (Supplementary Figure S3) that create a cyclic scheme of commands. The first one is the “GENERAL SETUP” block, which allows the system to start and check all the electronic components. After this, the system goes into the “IDLE” block, where it is able to read the rotary encoder’s measurements. In the “WRITE” block, the Arduino board stores the measurements in the micro SD card. Then, there is the “CONNECTION STARTUP” block, where the device’s internet connection is enabled. In the “FILE LIST” block, it is checked if some files are written and waiting for the online transfer. If it is true, it enters the “FILE TRANSMISSION” block, which is dedicated to sending files online. This part of the workflow ends when all the files on the waiting list are sent online. At the end of the transmission, the system turns off the internet connection (“END OF CONNECTION” block) and returns to the “IDLE” block. The data transmission block is programmed to send the data to a web server (PHP protocol). The code was developed to collect all the editable parameters (ID sensor, sending data frequency, web server address, encoder functions) in a single window to facilitate setup activities, especially for field operations.

An error management section was developed in the programming code to enhance systems’ reliability, especially for data transmission architecture. When the device starts, the Arduino board is programmed to check the GSM module’s correct functioning by waiting for its “OK” message: if the GSM module does not send it immediately (broken module or cables disconnected), malfunction is detected and the system goes into “offline mode”, where only local data storage is enabled. In this way, unnecessary power consumption is avoided, preserving the system until the operator’s technical assistance. If Arduino receives the “OK” message, “online mode” is enabled, and the GSM module starts a series of 30 network connection attempts. Once it completes 30 attempts without succeeding in network connection, the system goes again into “offline mode” and only local data storage is enabled until the operator’s manual reset is done.

If the device is powered, the local data storage function is always enabled: observed data remain stored in a micro SD card after malfunction eventualities (connection failure or even system shutdown).

This system is suitable for areas where telephone network coverage is sufficient to guarantee data transmission. Alternatively, it is possible to use a radio transceiver that provides to send data to a GSM modem router installed on the nearest network-covered site.

2.1.3 Measuring system.

The infrastructure of the measuring system (Figure 1) is composed of (a) two steel tubular poles, (b) the pulley and (c) the winding system.

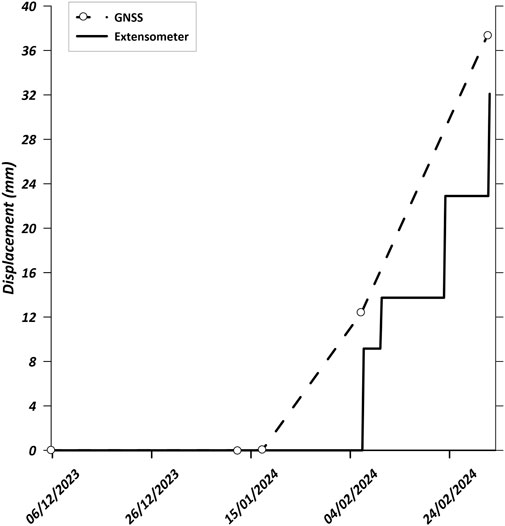

Figure 1. (A) Overview of the Grillo earth flow and its location in Southern Italy (B); Installation setting and landslide local condition.

The two steel poles are linked by a special wire made of invar. This metal alloy - composed of 36% of nickel, 64% of iron and small amounts of carbon and manganese - is characterized by a very high corrosion resistance and a negligible thermal expansion coefficient (around 0.5 x 10−6°C between 20°C and 50°C) (https://lkalloy.com).

The pulley is 3D printed in plastic material and accommodates the invar wire with the function to rotate when a linear displacement variation occurs between the two poles; this rotation is transferred from the pulley to the rotary encoder, which is capable of turning it into a certain number of electric pulses per each pulley’s revolution. Finally, the Arduino board reads these electric pulses and turns them into the real linear displacement. The number of electric pulses per revolution (PPR) generated by the encoder can be set in a range that goes between 48 and 2,048 PPR by changing the position of DIP switches located on the encoder’s case. By changing the number of the encoder’s PPR and modifying the pulley’s diameter, the resolution of the extensometer can be set. In this case, a 48 PPR setting and a 70 mm diameter pulley were chosen, leading the system to a resolution of 4.58 mm. The Arduino board was programmed to directly provide 4.58 mm of displacement per each electric pulse detected, guaranteeing a prompt data analysis without using any other kind of data processing or algorithms. A constant tension on the wire is required for the correct operation of the extensometer; this is provided by a handmade, low-cost spring-loaded winding system. It is composed by an internal metal spring housed in a rotating drum, that accommodates the invar wire. Thanks to the metal spring’s tension, this system allows measurements of both wire lengthening and shortening to be performed, without the need to make any further changes to the infrastructure.

2.1.4 Power supply

Considering the open-field installation, a solar system was chosen to power the device. The power supply is composed of a 30 W solar panel linked to a 12 V, 10 Ah battery. A 12 V, 10 Amp solar charge controller was used to manage the power supply unit. To operate safely, the Arduino board needs a voltage lower than 12 V; for this purpose, a DC-DC converter was used to set and stabilize the power line at around 7 V. The device’s power consumption was bench-tested using a FUTURA ELETTRONICA AL3005 power supply unit. A maximum absorption peak of 0.14 A at 12.5 V was observed during the online data transmission process, and 0.06 A at 12.5 V was recorded the rest of the time (“IDLE” function). Considering an average absorption of 0.10 A, the overall current drainage is 30 Wh. The 30 W solar panel and the average local solar radiation of 4.6 h per day can provide 138 Wh per day: this amount of energy, well over the device’s request, is enough to keep the battery charged over time. In case of solar panel failure, the 10 Ah battery could guarantee an autonomy of around 100 h with the average device’s current drainage. If more autonomy is required, a second battery linked in parallel to the first one can be added without making any other changes to the system. Past field applications showed that this kind of power supply architecture, in the presence of similar current absorptions, can last for several years without problems (no need to replace batteries, solar panels or charge controllers).

2.2 Laboratory tests

The potential effects of the temperature and humidity variation on the device’s electronic components were tested through a climatic chamber (Supplementary Table S1). This equipment is capable of testing electronic devices by simulating field conditions (Van Geel et al., 2015; Ruzza et al., 2018). The device was left in the zero-millimeter position the whole time.

The device’s electronic components (rotary encoder and data processing-storage-transmission system) were directly exposed to temperature and humidity variations by removing them from their protective external frame (double waterproof plastic box) to maximize the effectiveness of the tests. In particular, the components were carefully placed on the electrically insulated racks of the climatic chamber, and they were powered during tests by getting the cables across the chamber’s dedicated silicone plugs. A step-by-step procedure of laboratory tests is reported in Supplementary Figure S4.

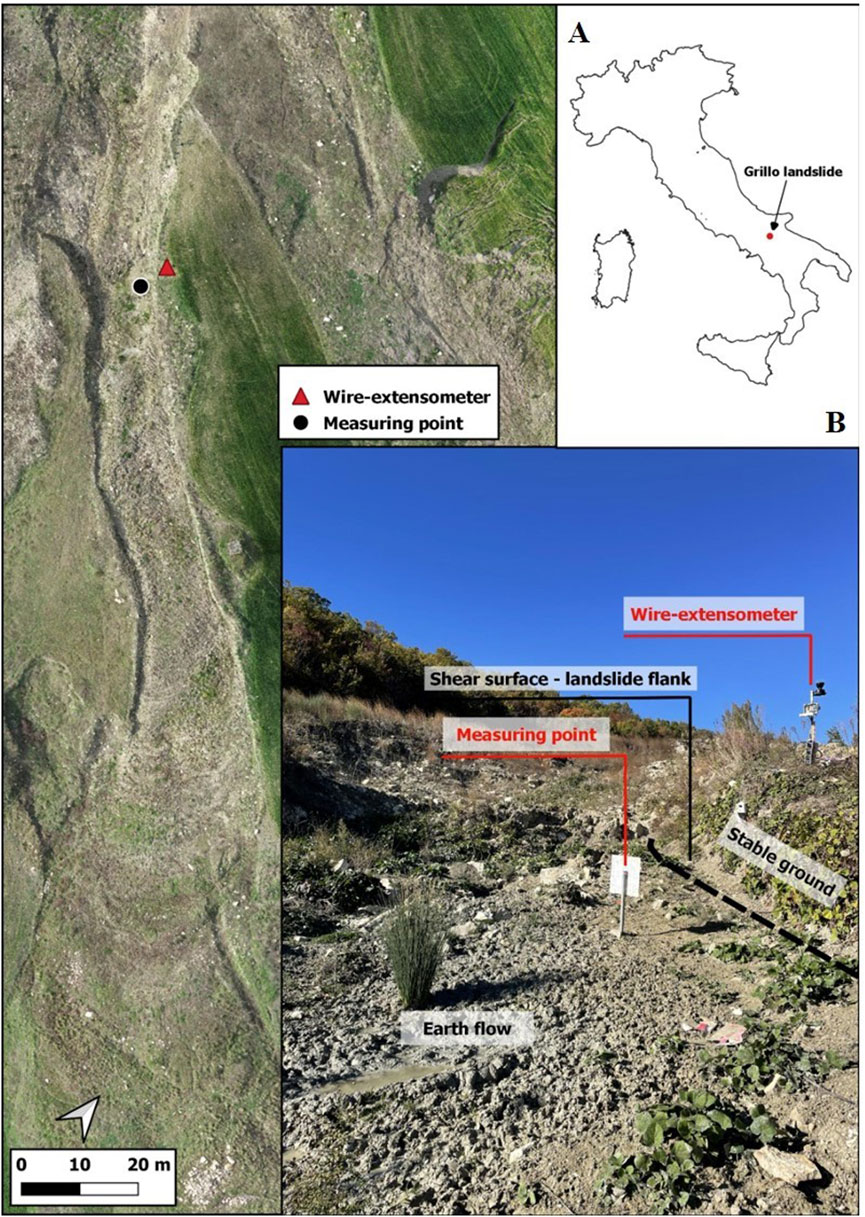

First of all, a thermal efficiency experiment was conducted (Figure 2): the device was tested in a −10°C + 80°C range. A temperature of −10°C was reached in the first part of the test. Then, the components were heated to reach a maximum temperature of about 80°C. The total test duration was 40 min, and the sampling rate was set to provide measurements every 2 s.

Figure 2. Correlation between the linear displacement measured and temperature values recorded during the thermal efficiency test.

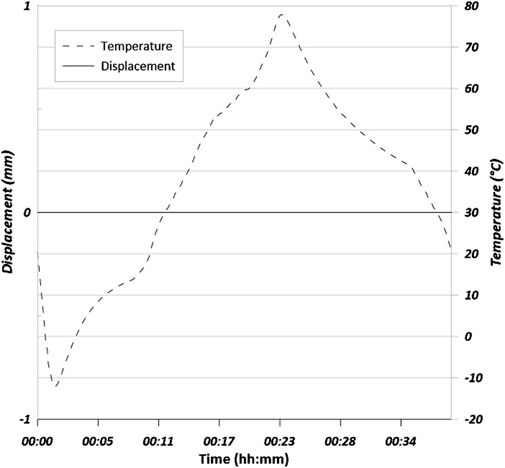

Then, a humidity test was performed (Figure 3). The climatic chamber was set to increase the humidity levels from about 30% (laboratory humidity levels) to a maximum of approximately 98%. Then, it was left in these conditions overnight, performing 14 h of testing. Measurements were collected every 5 s up to 11 min - during the increase in humidity stage - and every 60 s for the rest of the experiment.

Figure 3. (A) Correlation between the linear displacement measured and humidity values recorded during the humidity test before the device’s insulation upgrades; (B) focus on the increase in humidity stage (from minute 0–11); (C) Correlation between the linear displacement measured and humidity values recorded during the humidity test successively the device’s insulation upgrades; (D) focus on the increase in humidity stage (from minute 0–11).

Subsequently, an 80-gram bag of silica gel desiccant was placed in the device’s box. In addition, polyurethane foam was sprayed on the interior walls of the plastic box, and a handmade cover composed of extruded polystyrene panels was used for the outside of the box to reduce the thermal excursion and consequently, the risk of internal condensate formation. Then, a further humidity test - following the same workflow as the first one - was carried out.

2.3 Field test

The bi-directional wire extensometer was successively installed at the Grillo landslide (41°14′32″ N, 15°15′51″ E) in Montaguto municipality, Southern Italy (Figure 1). This mass movement - classified as an earth flow (Hungr et al., 2014) and involving clay flysch material (Pinto et al., 2016; Mazza et al., 2023a) - exhibited relevant movements between April 2022 and June 2023 (Mazza et al., 2023b).

The device was installed along the left flank of the earth flow - where a well-defined shear surface outcrops (Figure 1B) - using two 2 m long and 5 cm diameter steel tubular poles driven into the ground for a depth of at least 50 cm, and stabilized by metallic tie rods. The first one was installed in the transport zone, while the second one was placed outside the landslide perimeter, in a stable area. They were linked using a 6-meter-long invar wire. The position of these elements was defined with the aim of measuring the landslide’s main direction movement.

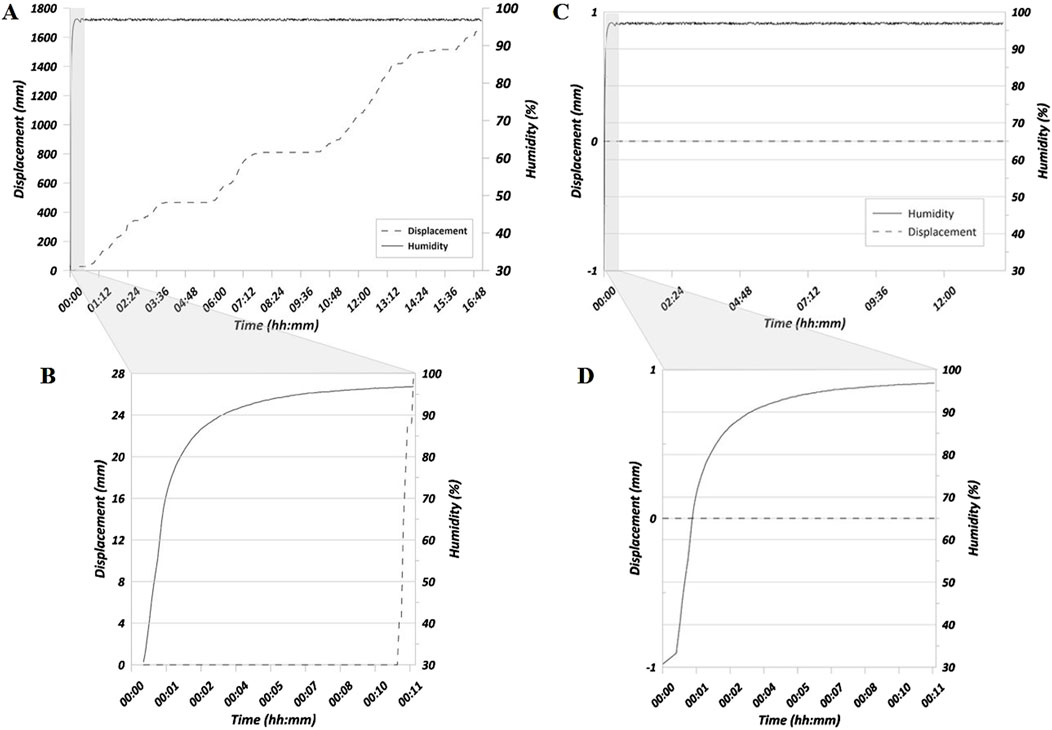

The monitoring campaign started on 06 December 2023 and ended on 03 March 2024 with an acquisition frequency of 6 h. The data recorded were compared with multi-temporal Global Navigation Satellite System (GNSS) measurements, performed using a mobile GNSS station (Supplementary Table S2). This station was mounted on a 2 m high pole and the measurements were carried out by a local area correction, recording the position of the transport zone’s steel tubular pole for each campaign survey, being careful to put of the lower end of the instrument on a predefined spot, in contact with the steel pole (Supplementary Figure S5). A total of 6 survey campaigns were performed.

- 6 December 2023.

- 13 January 2024.

- 18 January 2024.

- 26 January 2024.

- 7 February 2024.

- 3 March 2024.

3 Results and discussion

3.1 Laboratory tests

Figure 2 shows the results of the thermal efficiency experiment. In particular, during the cooling stage, the temperature was brought from +20°C (starting point) to −10°C (at minute 3): 0 mm of linear displacement were measured. Then, during the heating stage, the temperature was brought from −10°C (at minute 3) up to +80°C (at minute 25): also in this stage, 0 mm of linear displacement were read. Therefore, this experiment showed that the device was not affected by thermal drift in the observed range, reporting a total linear displacement of 0 mm from start to finish.

Figure 3 shows the device’s behavior during the humidity test before and after the device’s insulation upgrades. Focusing on the test performed before the insulation’s upgrades (Figures 3A, B), during the increase in humidity stage (from minute 0–11) that brought the moisture from 30% up to about 98%, it is possible to observe that the device was perfectly stable. When 98% of moisture was reached, the graph showed a stepwise pattern of increasing linear displacement, measuring a total of 1,653 mm at the end of the test. Thus, the data acquired from this experiment reveal a clear correlation between linear displacement and humidity levels, showing that this climatic parameter can negatively affect the device’s correct functioning.

This sensitivity to the wet conditions observed in the laboratory test is probably dependent on the capacitive technology of the rotary encoder.

The results of the humidity test after the device’s insulation upgrades (Figures 3C, D) show that no more correlation between moisture and linear displacement was found: 0 mm were observed during the entire experiment. This behavior demonstrates the efficiency of the solutions adopted on the device in terms of moisture insulation, which allowed it to solve the capacitive technology issues in wet conditions. Therefore, even in the presence of significant levels of field humidity (90% or higher), the bi-directional wire extensometer’s proper functioning was not compromised.

3.2 Field test

Data comparison resulting from the device’s field test is shown in Figure 4. The bi-directional wire extensometer measured a maximum displacement value of 32 mm, while the GNSS measurements showed a value of 38 mm, resulting in an overall 6% difference between the two data sets. In particular, for the first 3 GNSS surveys, a displacement of 0 mm was measured by the two systems: this coherence showed the device’s measurements stability, proving that the insulation technique adopted was able to solve the sensor’s moisture drift. Observing the GNSS survey campaign performed on 07 February 2024, the device was able to measure 9.16 mm of linear displacement, which, compared to 12 mm of the GNSS system, results in a difference of 16% between the two techniques. The last measurements (03 March 2024) showed a displacement of 32.1 mm for the wire extensometer and 38 mm for the GNSS technique, resulting in a difference of 13% between the two data sets. Thus, a slight underestimation trend was detected by using wire extensometer measurements. However, considering the test covered a short period (around 3 months), merely prolonged observations could evaluate the device’s stability in the long term.

Moreover, it is worth noting that all the tests were performed using a resolution of 4.58 mm. However, this value - suitable for landslide monitoring applications - can be changed by choosing the diameter of the pulley and by acting on 4 DIP switches housed in the rotary encoder’s case. These switches set the number of electric pulses generated by the encoder for each revolution (PPR, “Pulses Per Revolution”). Therefore, considering that the number of PPR can range from 48 to 2,048, our device could be able to measure displacements with even higher resolutions. This capability could represent a relevant innovation for this kind of monitoring system, extending its use for structural health monitoring. In addition, unlike wire extensometers based on potentiometric technology, the capacitive rotary encoder allows counting infinite displacements along two directions. Indeed, our device - being equipped with a handmade spring-loaded winding system that guarantees constant tension on the extensometer’s wire-could be able to measure both lengthening and shortening without the need to make any further changes to the system. Exploiting this feature, our wire extensometer could be easily installed in all geo-structural settings, both in distensive and compressive kinematic contexts.

Furthermore, by implementing a “do-it-yourself approach”, our bi-directional wire extensometer’s overall cost is around 400 euros (Supplementary Table S3), considerably cheaper than professional solutions (starting from around 1,500 euros to almost 10,000 euros). Thus, with the average cost of a single professional device, we can produce at least three low-cost wire extensometers. However, low-cost components are more susceptible to failure and a small budget for more frequent assistance could be necessary. In particular, periodic inspections of the device’s components should be performed: a checklist and a spare parts list to bring for eventual quick repairs are provided in Supplementary Table S4 for on-field inspections. For this purpose, the device’s electronic parts were developed to be easily replaceable in case of failure.

4 Conclusion and future improvements

A low-cost bi-directional wire extensometer - based on Arduino© technology and equipped with a capacitive rotary encoder - was developed for landslide monitoring.

The tests showed that a proper insulation technique can solve the device’s moisture drift. In addition, laboratory tests assessed the device’s correct functioning in a temperature range from −10 to +80°C and for more than 90% humidity, guaranteeing proper functioning in extreme environmental conditions. Combining the stability and the low-cost features, the bi-directional wire extensometer can be considered a valid alternative to professional devices, especially in large-scale monitoring contexts where a network of multiple installations is required. In addition, the spring-loaded winding system - which also allows the bi-directional wire extensometer to perform shortening measurements without the necessity of any other adjustment - could be tested and used for future installations in compressive contexts.

Nevertheless, although our solution to mitigate the sensitivity of the device to the wet conditions appeared to be resolutive, some improvements - such as the use of a little electric fan installed on the device’s box with the function to create a continuous air circulation - can be studied and applied for further laboratory and field tests with the aim to increase the durability of the system. Additional power consumption could be limited by programming the device to turn on the electric fan only for short intervals during the day. Moreover, information about power supply voltage could be integrated into online data transmitted to monitor the system’s functioning and, in case of problems, perform technical assistance before total power failure.

A further improvement could be represented by experimentation with a sensors’ network linked to an online platform capable of applying machine learning and IA for predictive analysis. Using linear displacement data collected on landslide’s strategic points, this technology could be able to predict future scenarios by learning from historical data collected, leading to a faster decision-making process.

Finally, the bi-directional wire extensometer was tested for a short period (around 3 months): very small displacement data were recorded, and prolonged observations are required to evaluate the device’s stability in the long term.

Data availability statement

The raw data supporting the conclusions of this article will be made available by the authors, without undue reservation.

Author contributions

DC: Conceptualization, Investigation, Methodology, Software, Writing–review and editing, Resources. DM: Conceptualization, Data curation, Methodology, Software, Writing–review and editing. FG: Supervision, Writing–review and editing. PR: Supervision, Writing–review and editing, Funding acquisition.

Funding

The author(s) declare that financial support was received for the research, authorship, and/or publication of this article. This research activity was funded by the LIVES project (PRIN 2022 prot. 20224ZNHPA, Resp. PR).

Acknowledgments

The authors wish to thank Matteo Fiorucci and Pengju An for their constructive comments that helped to improve this manuscript.

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

Supplementary material

The Supplementary Material for this article can be found online at: https://www.frontiersin.org/articles/10.3389/feart.2024.1494067/full#supplementary-material

References

Afandi, M. I., Adinanta, H., Setiono, A., and Widiyatmoko, B. (2018). High resolution extensometer based on optical encoder for measurement of small landslide displacements. J. Phys. Conf. Ser. 985, 012007. doi:10.1088/1742-6596/985/1/012007

Casagli, N., Intrieri, E., Tofani, V., Gigli, G., and Raspini, F. (2023). Landslide detection, monitoring and prediction with remote-sensing techniques. Nat. Rev. Earth Environ. 4, 51–64. doi:10.1038/s43017-022-00373-x

Corominas, J., Moya, J., Ledesma, A., Lloret, A., and Gili, J. A. (2005). Prediction of ground displacements and velocities from groundwater level changes at the Vallcebre landslide (Eastern Pyrenees, Spain). Landslides 2, 83–96. doi:10.1007/s10346-005-0049-1

Cruden, D. M. (1991). A simple definition of a landslide. Bull. Int. Assoc. Eng. Geol. 43, 27–29. doi:10.1007/BF02590167

Dei Cas, L., Trigila, A., and Iadanza, C. (2021). Linee Guida per il monitoraggio delle frane. Linee Guida SNPA 32/2021.

Dunnicliff, J. (1993). Geotechnical instrumentation for monitoring field performance. John Wiley and Sons.

Fang, K., Dong, A., Tang, H., An, P., Wang, Q., Jia, S., et al. (2024). Development of an easy-assembly and low-cost multismartphone photogrammetric monitoring system for rock slope hazards. Int. J. Rock Mech. Min. Sci. 174, 105655. ISSN 1365-1609. doi:10.1016/j.ijrmms.2024.105655

Guerriero, L., Guerriero, G., Grelle, G., Guadagno, F. M., and Revellino, P. (2017). Brief Communication: a low-cost Arduino®-based wire extensometer for earth flow monitoring. Nat. Hazards Earth Syst. Sci. 17, 881–885. doi:10.5194/nhess-17-881-2017

Hungr, O., Leroueil, S., and Picarelli, L. (2014). The Varnes classification of landslide types, an update. Landslides 11, 167–194. doi:10.1007/s10346-013-0436-y

Intrieri, E., Gigli, G., Mugnai, F., Fanti, R., and Casagli, N. (2012). Design and implementation of a landslide early warning system. Eng. Geol. 147–148, 124–136. doi:10.1016/j.enggeo.2012.07.017

Kjekstad, O., and Highland, L. (2009). “Economic and social impacts of landslides,” in Landslides - disaster risk reduction. Editors K. Sassa, and P. Canuti (Berlin, Heidelberg: Springer), 573–587. doi:10.1007/978-3-540-69970-5_30

Li, X., and Meijer, G. C. M. (1998). A novel low-cost noncontact resistive potentiometric sensor for the measurement of low speeds. IEEE Trans. Instrum. Meas. 47, 776–781. doi:10.1109/19.744348

Mazza, D., Cosentino, A., Romeo, S., Mazzanti, P., Guadagno, F. M., and Revellino, P. (2023a). Remote sensing monitoring of the pietrafitta earth flows in southern Italy: an integrated approach based on multi-sensor data. Remote Sens. 15, 1138. doi:10.3390/rs15041138

Mazza, D., Romeo, S., Cosentino, A., Mazzanti, P., Guadagno, F. M., and Revellino, P. (2023b). The contribution of digital image correlation for the knowledge, control and emergency monitoring of earth flows. Geosciences 13, 364. doi:10.3390/geosciences13120364

Pasquaré Mariotto, F., and Oppizzi, P. (2021). “Extensometer-based monitoring of active deformation at the khoko landslide (jivari, Georgia),” in Building knowledge for geohazard assessment and management in the caucasus and other orogenic regions. Editors F. L. Bonali, F. Pasquaré Mariotto, and N. Tsereteli (Dordrecht, Netherlands: Springer Nature), 443–450. doi:10.1007/978-94-024-2046-3_24

Pinto, F., Guerriero, L., Revellino, P., Grelle, G., Senatore, M. R., and Guadagno, F. M. (2016). Structural and lithostratigraphic controls of earth-flow evolution, Montaguto earth flow, Southern Italy. J. Geol. Soc. 173, 649–665. doi:10.1144/jgs2015-081

Ruzza, G., Guerriero, L., Revellino, P., and Guadagno, F. M. (2018). Thermal compensation of low-cost MEMS accelerometers for tilt measurements. Sensors 18, 2536. doi:10.3390/s18082536

Setiono, A., Qomaruddin, A., Afandi, M. I., Adinanta, H., Rofianingrum, M. Y., Suryadi, Y., et al. (2023). Wire extensometer based on optical encoder for translational landslide measurement. Int. J. Adv. Sci. Eng. and Inf. Technol. 13, 17–23. doi:10.18517/ijaseit.13.1.15636

Shuanghui, H., Yong, L., and Minghui, H. (2009). Study on a novel absolute magnetic encoder. IEEE Int. Conf. Robotics Biomimetics, 1773–1776. Bangkok. doi:10.1109/ROBIO.2009.4913270

Thirugnanam, H., Uhlemann, S., Reghunadh, R., Ramesh, M. V., and Rangan, V. P. (2022). Review of landslide monitoring techniques with IoT integration opportunities. IEEE J. Sel. Top. Appl. Earth Observations Remote Sens. 15, 5317–5338. doi:10.1109/JSTARS.2022.3183684

Van Geel, J. L. W. A., Bosma, R., van Wensveen, J., and Peruzzi, A. (2015). Thermistors used in climatic chamber at high temperature and humidity. Int. J. Thermophys. 36, 569–576. doi:10.1007/s10765-014-1753-7

Winter, M. G., Shearer, B., Palmer, D., Peeling, D., Harmer, C., and Sharpe, J. (2016). The economic impact of landslides and floods on the road network. Procedia Eng. 143, 1425–1434. doi:10.1016/j.proeng.2016.06.168

Zhang, X. D., Kang, L. Y., and Diao, W. F. (2005). The principle of the Potentiometer and its Applications in the vehicle steering. IEEE Int. Conf. Veh. Electron. Saf., 20–24. doi:10.1109/ICVES.2005.1563607

Keywords: landslide monitoring, capacitive rotary encoder, wire extensometer, low-cost sensors, Arduino©, Internet of Things (IoT)

Citation: Cifaldi D, Mazza D, Guadagno FM and Revellino P (2025) A new IoT low-cost bi-directional wire extensometer for landslide monitoring. Front. Earth Sci. 12:1494067. doi: 10.3389/feart.2024.1494067

Received: 10 September 2024; Accepted: 16 December 2024;

Published: 08 January 2025.

Edited by:

Wen Nie, Jiangxi University of Science and Technology, ChinaCopyright © 2025 Cifaldi, Mazza, Guadagno and Revellino. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Davide Mazza, ZG1henphQHVuaXNhbm5pby5pdA==

Daniele Cifaldi

Daniele Cifaldi Davide Mazza

Davide Mazza Francesco Maria Guadagno

Francesco Maria Guadagno Paola Revellino

Paola Revellino