- 1College of Safety Science and Engineering, Xi’an University of Science and Technology, Xi’an, Shaanxi, China

- 2Shaanxi Key Laboratory of Prevention and Control of Coal Fire, Xi’an University of Science and Technology, Xi'an, Shaanxi, China

In this paper, polymer colloid and fly ash colloid fire extinguishing materials are selected. Through experimental preparation and water precipitation characteristics research, colloid fire extinguishing materials and optimal concentration ratio suitable for Binchang mining area are selected to effectively control the fire area. The results show that, the higher the concentration of polymer colloidal powder mixed with water, the shorter the gelling time. After the fly ash is mixed with the gelling agent and water, when the concentration ratio of fly ash to water remains the same, the greater the concentration of the gelling agent, the shorter the gelling time. After the colloid is left standing for 24 h, the smaller the concentration is, the more water is precipitated, and the higher the water precipitation rate is. Through comparison, it was found that when the polymer colloid was selected as the fire extinguishing material, with the concentration ratio of polymer colloid material to water being 3.5%–4%: 96.5%–96%, effective control could be achieved over the fire zones in the goaf of Binchang mine. The research is of great reference value for the control of mine fires.

1 Introduction

China is rich in coal resources, with its output and consumption being among the world’s highest (Qi and Kuan, 2011). The disasters in mines are complex and of various types, and fires caused by spontaneous combustion of coal are one of the most serious mine disasters (Querol et al., 2011; Liu et al., 2020; Onifade and Genc, 2020), which can easily cause casualties, environmental pollution and property losses (Deng et al., 2017; Wu et al., 2018; Li et al., 2019; Song et al., 2020). Data show that fire incidents caused by spontaneous combustion of coal account for more than 90% of the mine fires (Su et al., 2016; Ma et al., 2022). With the improvement of the safety level of coal mines, the spontaneous combustion of coal seams is mainly managed by the principle of “prevention first and prevention and treatment combined” (Zhang, 2018; Liu et al., 2022), which has put forward higher requirements for the fire extinguishing materials used in mines.

At present, grouting technology is the most widely used technology to inhibit coal spontaneous combustion because of its low cost (Colaizzi, 2004; Wen et al., 2017). The grouting technology mainly includes slurry grouting, gel, three-phase foam, polymer colloids and other materials (Liang et al., 2016). Domestic and foreign researchers have carried out a lot of research on the grouting technology and its application in fire extinguishment, and achieved certain results. Based on the existing prevention and control measures taken in Lijiata Coal Mine, Chen (2020) proposed an emergency response plan for preventing spontaneous combustion of coal by using fly ash thickened colloid to wrap the broken coal body and block the leaking air. Li et al. (2005) applied the fire prevention and extinguishing technology of pipe-network-type composite colloid injection to successfully control the large fire zone with complicated air leakage situation in Shuangyashan Dongrong No.3 Mine, which ensured the normal use of the rail going up the mountain and the safety of the whole mine. Wang et al. (2017) developed a control plan based on fly ash colloid grouting according to the characteristics of the spontaneous combustion of coal in the Ewirgol Coal Mine, which helped successfully extinguish the natural fires in this mine. Yang et al. (2020) found that the fly ash composite colloid isolation technology can be used to quickly deal with the complex fire zones in Huashan Mine and the spreading and escalating fires there. In response to the signs of spontaneous combustion of coal pillars in the main tunnel of Huangling No. 2 Coal Mine in Shaanxi Province, Yan (2015) used the polymer colloid fire prevention technology to effectively deal with abnormal high-temperature areas. Shi et al. (2018) analyzed the potential application of the optimal concentration of surfactant in stabilizing fly ash suspension to delay coal spontaneous combustion.

Fly ash used for grouting fire extinguishing can play the role of isolation, encapsulation and cooling (Zhao et al., 2019). Polymer colloid has the comprehensive characteristics of water retention, cooling, plugging and inhibition (Zhang et al., 2011). The interface properties of fly ash and polymer colloid material matrix are different. Most researchers at home and abroad only study the fire extinguishing technology for a certain material. In this paper, the water precipitation and water loss of two kinds of fire extinguishing materials, the polymer colloid fire extinguishing agent and the fly ash colloid fire extinguishing agent, after being placed at different concentrations for 24 h are studied experimentally. The optimal fire extinguishing material and its concentration ratio suitable for Binchang mining area are selected, and the amount of glue injected into the filling roadway is calculated. The reasonable injection process is adopted. The research conclusion can play a good role in controlling the spontaneous combustion of loose accumulation coal in underground goaf.

The subsequent sections of this paper are organized as follows: Section 2 introduces the overview of the fire zones. Grouting of ignition points in the working face for fire extinguishment is elaborated in Section 3. Section 4 is dedicated to the experimental study. Discussion is evaluated in Section 5. And Section 6 describes the implementation of the fire prevention and extinguishment project. Finally, conclusions are given in Section 7.

2 Overview of the fire zones

Binchang Mine Field is located in the north of Taiyu anticline, in which the main minable coal seams are prone to spontaneous combustion of coal. In the mines of this mine field, the fully mechanized top coal caving is mostly adopted for the coal mining, resulting in large amount of float coal in the goafs, so it is necessary to focus on preventing the fires caused by spontaneous combustion of float coal in the goaf. The coal seam structure in the mining area is complex, with developed endogenous fissures, and the coal seam thickness is 12 m. In the process of tunnel excavation, due to the local high pressure of the mine, the top coal body is relatively broken, forming air leakage ways which constantly supply oxygen, which has made it possible for heat storage. When the temperature in the deep part of top coal is above 60°C, the CO concentration will continue to increase and gradually spread along the working face. Therefore, it can be judged that there are abnormal high-temperature areas in the mine field, which have high risks of spontaneous combustion of coal.

3 Grouting of ignition points in the working face for fire extinguishment

3.1 Problems and solutions

The design and good application of mine fire prevention and control is a complex, systematic process. At present, there are some problems in the fire prevention and extinguishment technology and equipment adopted in Binchang Mine Field and the basic research on spontaneous combustion, specifically as follows: 1) with the increase of mining depth, the mining process suffers more obvious disturbances, and the geothermal gradient increases significantly, but there is little research on the coupling effect of the spontaneous combustion of deep coal seams under the influence of hot air pressure; 2) in terms of monitoring and early warning, China lacks an integrated fire monitoring and warning system against both internal and external causes, and it is imperative to establish such an integrated monitoring and prevention technology system for coal mine fires that organically combines early fire monitoring and warning and expert decision-making and analysis; 3) in terms of fire control, besides high costs, the current fireproof materials are not pertinent enough to completely control the high-temperature areas, resulting in frequent re-ignitions, and the professional equipment used by personnel are not intelligent enough; 4) in terms of emergency rescue of mine fires, there has been a lack of explosion hazard detection and control technologies in semi-enclosed areas and special monitoring equipment for opening and closing of fire zones to deal with the wide range of and complex situations involved in the chain reaction disasters caused by fires; 5) facing the worldwide problem—detection of hidden fire sources, the drilling method used is costly and wasteful. The isotope radon measurement method can be easily affected by air leakage, and the remote sensing method is also susceptible to surface radiation, lithology and geological structures of overlying strata.

So far, China has made great progress in the monitoring and early warning of mine fires, the management of mine fires, the emergency rescue of fire incidents, the comprehensive evaluation methods for fire hazards resulting from internal and external causes in coal mines based on the Internet big data platform, and the corresponding management platform technologies and equipment: 1) in terms of emergency rescue, small instruments such as gas analyzers for detection of coal mine disasters have been developed, among which, the portable infrared coal temperature monitoring device can provide in-situ monitoring and analysis underground, and the developed gas explosion-proof material can achieve the explosion risk prediction and rapid protection against the catastrophic environment of fire zones. 2) in terms of fire prevention and control, the technologies of monitoring the ignition points in hidden areas by electronic control and infrared remote sensing methods have been developed, and new types of aerosol and foam inhibitors and microorganisms have also been worked out for fire extinguishment, large-aperture fire-fighting drilling equipment have been developed against large-aperture and loose coal bodies, short-distance composite inert gas cooling and air plugging technologies have been explored for shallow buried coal seams, and rapid cooling and fire-extinguishing equipment and technologies, for high-temperature coal bodies.

3.2 Management plan

The coal seam in the affected working face has an inclination length of 220 m and a thickness of 12 m, the length of the mining area is 3 m, and that of the venting area is 9 m, with 40 m not topped. The overall bottom length of the drill holes is 6 m, and there are three rows of drill holes. According to the conditions of the goaf, the grouting technology was adopted, which can effectively control the spontaneous combustion of loose coal body in the goaf.

The polymer colloid has the advantages of fast gelation speed, simple process and less corrosive to the equipment, which can effectively improve the water content in the fire extinguishing agent and greatly improve the fire extinguishing efficiency. The fly ash gelling agent can accumulate a large amount of water after swelling in water, so that the mixed slurry has great heat storage capacity and good thermal stability. After dehydration, it can be stored in water again, which has a good effect in preventing and controlling coal seam spontaneous combustion fire. Therefore, polymer colloid fire extinguishing agent and fly ash colloid fire extinguishing agent were selected.

4 Experimental study

4.1 Experimental principle

In this experiment, polymer colloid fire extinguishing agent and fly ash colloid fire extinguishing agent are used to control the spontaneous combustion fire of loose accumulation coal in underground goaf. After grouting in the goaf, the loose coal in the lower layer of the accumulation body is wrapped by the water precipitation of the colloid, and the heat in the loose coal-fired body is replaced by the good thermal conductivity of the water, and the colloid deposited in the upper layer is used to absorb the replacement heat. Through these two experiments, the heat in the loose self-fired coal body is removed to achieve a good cooling effect.

4.2 Process of the experiment

4.2.1 Experimental materials

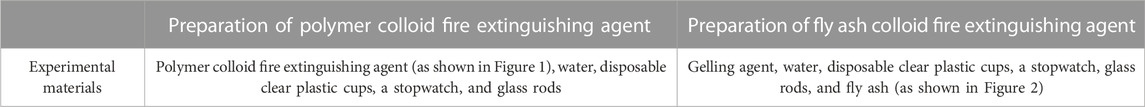

The experimental materials required for the preparation of polymer colloid and fly ash colloid fire extinguishment agents are shown in Table 1.

TABLE 1. Experimental materials required for preparation of polymer colloid and fly ash colloid fire extinguishing agents.

4.2.2 Steps of the experiment

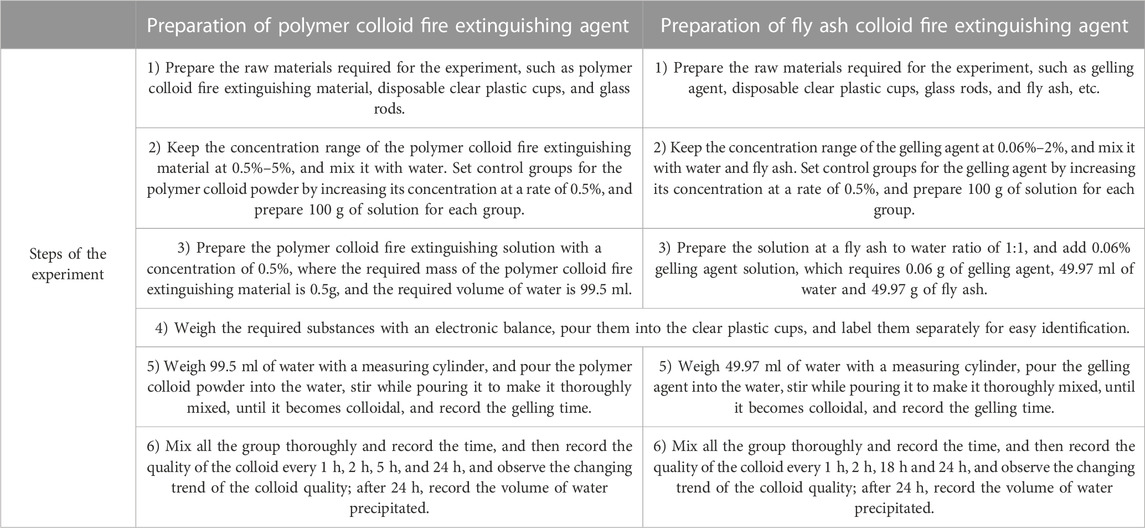

The steps for the preparation of polymer colloid and fly ash colloid fire extinguishing agents are shown in Table 2.

TABLE 2. Steps for the preparation of polymer colloid and fly ash colloid fire-extinguishing agents.

Figure 3 and Figure 4 compare the water precipitation performance of polymer colloid and fly ash colloid fire extinguishing agents with different concentrations, respectively. It can be clearly seen that when the concentrations are different, the water precipitation of the polymer colloid and the fly ash colloid fire extinguishing agents is quite obvious.

FIGURE 3. Comparison of water precipitation properties of the polymer colloid fire extinguishing agent with different concentrations (From left to right, the concentrations of polymer colloid fire extinguishing materials are 0.5%, 2.5% and 4.5%, respectively).

FIGURE 4. Comparison of water precipitation properties of fly ash colloid fire extinguishing agent with different concentrations (From left to right, the concentration ratios of fly ash to water are 1:1, 1:1.5, 1:2, 1:2.5 and 1:3, respectively).

4.3 Experimental results

All colloids can retain water—they can make a certain amount of water retained in the colloidal network framework and lose its fluidity. The colloid fire extinguishing agent makes full use of the water retention property to extinguish fires with water and also makes up for the shortcoming of flowing water, that is, it is highly fluid and unable to extinguish fires at high places such as the tops of the tunnels and working faces. The more stable the structure of the colloid, the greater the force between the colloid and water, and the slower the water loss rate at a high temperature, which is very conducive to prevention and extinguishment of coal mine fires. If the water loss rate of the colloid is too high, the colloid structure will be unstable and have a shorter useful life, making it difficult to achieve the desired fire-extinguishment effect. The calculation of water loss rate and water precipitation rate of colloidal materials is helpful to study the water retention properties of the two colloidal materials.

The formula for calculating the water loss rate is as follows:

where, Y is the water loss rate of the polymer colloid fire extinguishing agent, M1 is the mass reduction, and M2 is the total mass.

The formula for calculating the water precipitation rate is as follows:

where, P is the water precipitation rate of the polymer colloid fire extinguishing agent, V1 is the mass reduction, and V2 is the total mass.

4.3.1 Water loss rate/water precipitation rate of the polymer colloid fire extinguishing agent

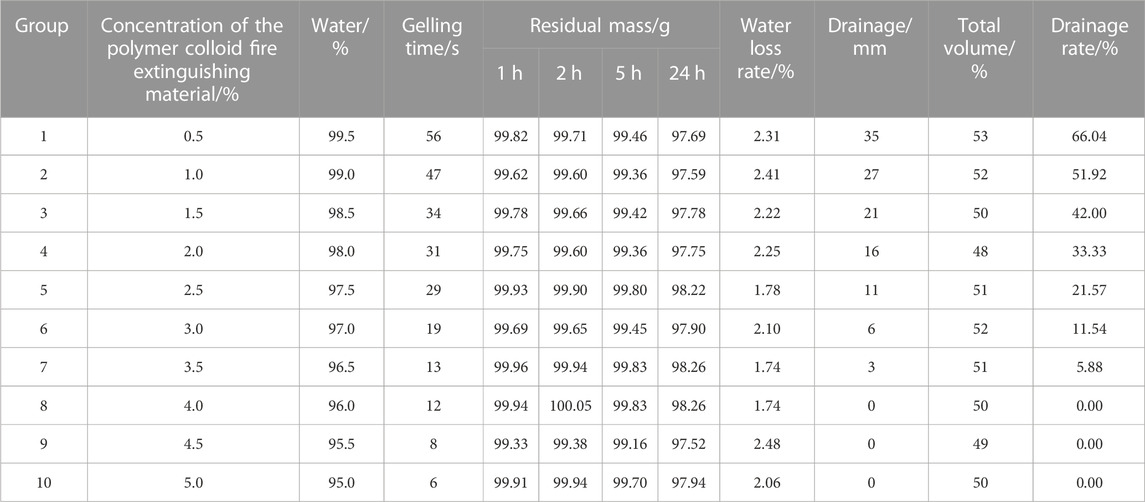

According to Eq. 1 and Eq. 2, the calculation results of the water loss rate and water precipitation rate of the polymer colloid fire extinguishing agent are shown in Table 3.

TABLE 3. Calculation results of the water loss rate and water precipitation rate of the polymer colloid fire extinguishing agent.

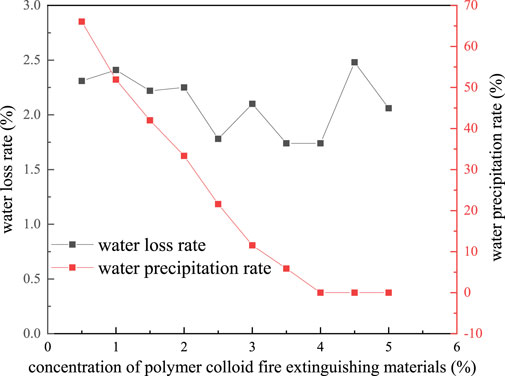

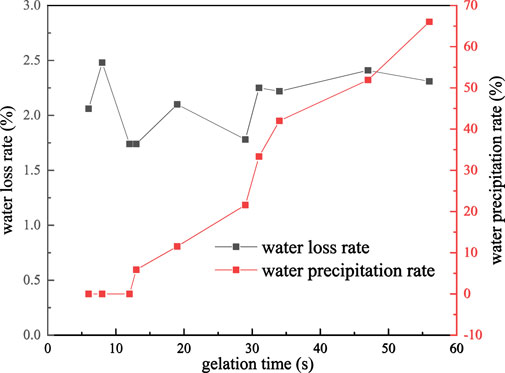

Figure 5 shows the changes of water loss rate and water precipitation rate of the polymer colloid fire extinguishing agent with different concentrations, and the effect of gelling time of polymer colloid fire extinguishing material on water loss rate and water precipitation rate is shown in Figure 6. It can be seen from Figure 5 and Figure 6: 1) After the polymer colloid powder was mixed with water, the higher the concentration, the shorter the gelling time. 2) After the colloid was left standing for 24 h, the smaller the concentration, the more the water precipitated, and the higher the water precipitation rate. 3) When the concentration of the polymer colloid fire extinguishing material was 4.5% and the concentration of water 95.5%, the water loss rate was the highest—2.48%, indicating that its water retention performance was the worst. When the concentration of the polymer colloid fire extinguishing material was 3.5% and the concentration of water 96.5%, or when the concentration of the polymer colloid fire extinguishing material was 4% and the concentration of water 96%, the water loss rate was the lowest—1.74%, indicating that its water retention performance reached the best level. According to the experimental results, it can also be found that the polymer colloid after gelation has the following properties: 1) lower water loss and better water precipitation. 2) higher fluidity before gelation, and water precipitation after gelation, making it able to seal fluids.

FIGURE 5. Changes in the water loss rate and water precipitation rate of the polymer colloid fire extinguishing agent with different concentrations.

FIGURE 6. Changes in the water loss rate and water precipitation rate of the polymer colloid fire extinguishing agent with different gelling time.

4.3.2 Water precipitation rate/water loss rate of the fly ash colloid fire extinguishing agent

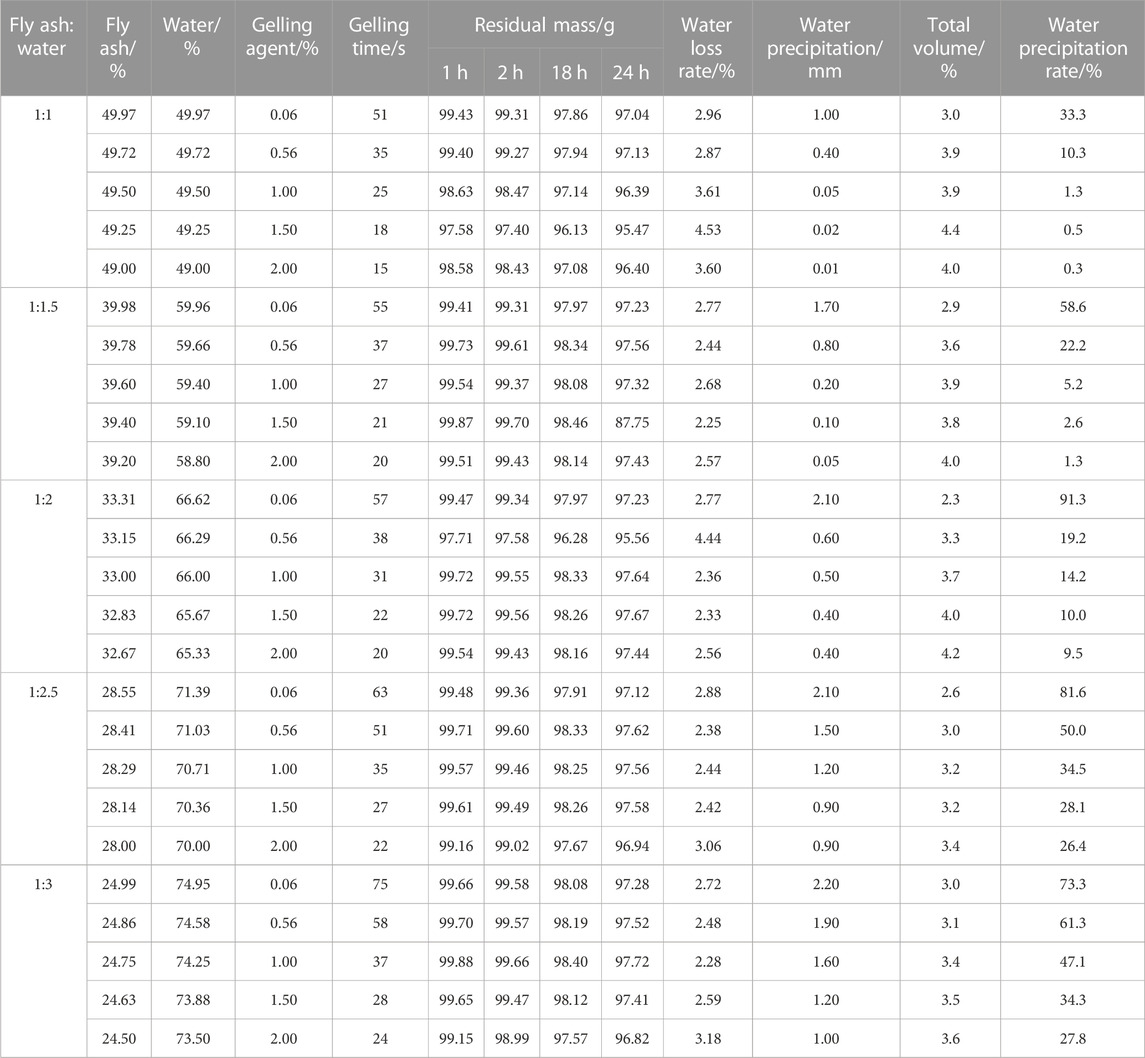

According to Eq. 1 and Eq. 2, the calculation results of the water loss rate and the water precipitation rate of the fly ash colloid fire extinguishing agent are displayed in Table 4.

TABLE 4. Calculation results of the water loss rate and water precipitation rate of the fly ash colloid fire extinguishing agent.

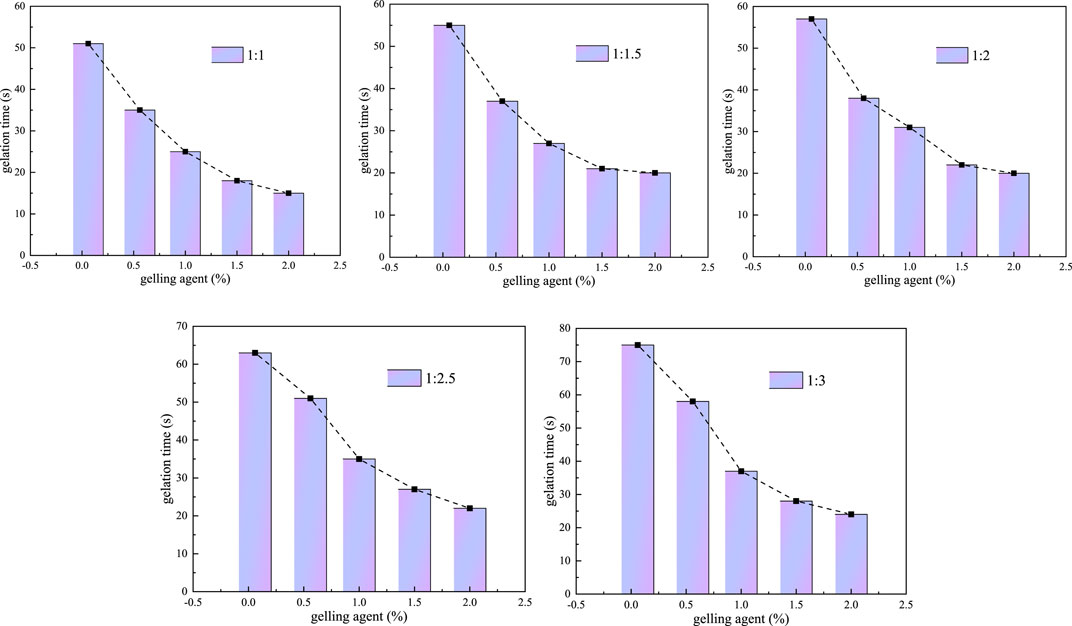

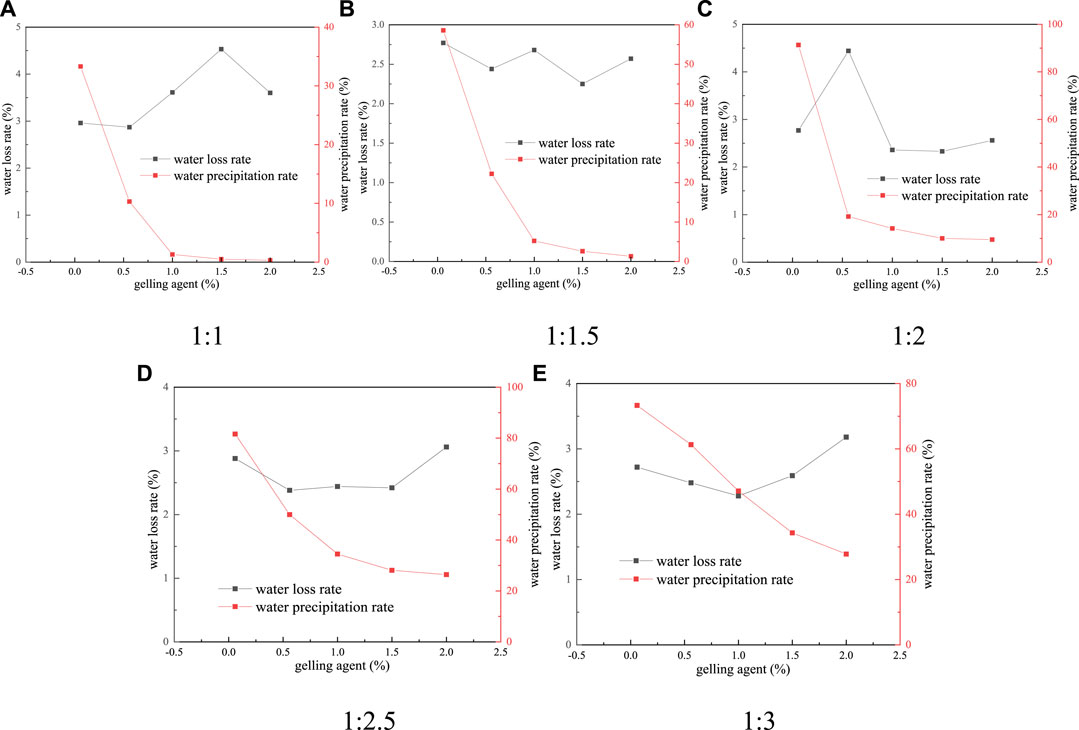

Figure 7 is the variation curves of the gelling time with the concentration of the gelling agent under different concentration ratios of fly ash and water. As can be observed in Figure 7, after the fly ash was mixed with the gelling agent and water, when the concentration ratio of fly ash and water remained the same, the greater the concentration of the gelling agent, the shorter the gelling time. When the concentration of the gelling agent remained the same, the greater the concentration of water mixed with fly ash, the longer the gelling time. The changes in the water loss rate and water precipitation rate under different concentration ratios of fly ash to water are shown in Figure 8. After the colloid was left standing for 24 h, the smaller the concentration, the more water precipitated, and the higher the water precipitation rate. Through comparison of the water loss rate and water precipitation rate under different concentration ratios, it can be found that when the concentration ratio of fly ash to water was 1:1, and the concentrations of fly ash and water were both 49.25%, the water loss rate reached the maximum—4.53%, but the water precipitation rate was 0.5%, which was not the lowest level, indicating that its water retention performance was not the best. When the concentration ratio of fly ash to water was 1:1.5, the concentration of fly ash was 39.40%, and the concentration of water 59.10%, the water loss rate was the smallest—2.25%, but the water precipitation rate was 2.6%, which was not the highest, indicating that its water retention performance was not the best, either.

FIGURE 7. Variation curves of the gelling time with the concentration of the gelling agent under different concentration ratios of fly ash and water.

FIGURE 8. (A-E) represent concentration ratios of fly ash and water of 1:1, 1:1.5, 1:2, 1:2.5 and 1:3, respectively.

5 Discussion

Based on the two experimental results, we can make the following analysis and discussion: 1) When the polymer colloid to water concentration ratio in the polymer colloid fire extinguishing agent is 4.5%: 95.5%, the water loss rate is the highest and the water retention is the poorest. However, when the concentration ratio is 3.5%–4%: 96.5%–96%, the water loss rate is the lowest and the water retention is the best. 2) When the concentration ratio is 5%:95%, the gelling time is the shortest, but its water retention is not the best. When the concentration ratio of the two is 0.5%:95%, the gelling time is the longest, but the effect is not obvious, and the water retention effect is not the best, either. 3) In the experiment where the fly ash was mixed with water and gelling agent, it can also be found that when the ratio of fly ash, water and gelling agent leads to the shortest or longest gelling time, the water retention may not be the best or the worst.

Both polymer colloid and fly ash colloid fire extinguishing agents have their own advantages. The fly ash colloid material has been used for a longer time, and has the advantages of low price, non-toxicity and good permeability, but it also has its disadvantages—large consumption, long gelling time, inability to be accumulated in high places, poor fluidity, easiness to block pipelines and easy cracking of the gel layer. While the polymer gel material has good fluidity, good fire prevention and extinguishment effect, and high strength of the gel layer, but it is more costly. In the traditional fly ash slurry, water only adheres to the surface of the fly ash particles, and since the fly ash slurry has no three-dimensional network structure, the water retention performance of the traditional fly ash slurry is poor. Through comparison of the advantages and disadvantages of the two types of materials, the polymer colloid fire extinguishing agent was finally chosen to effectively control the spontaneous combustion of loose coal in the goaf of Binchang mining area.

6 Implementation of the fire prevention and extinguishment project

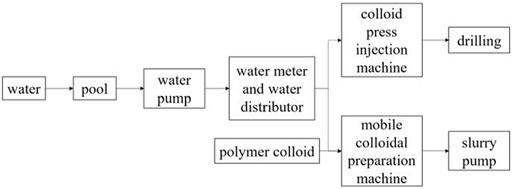

6.1 Colloid injection system and process

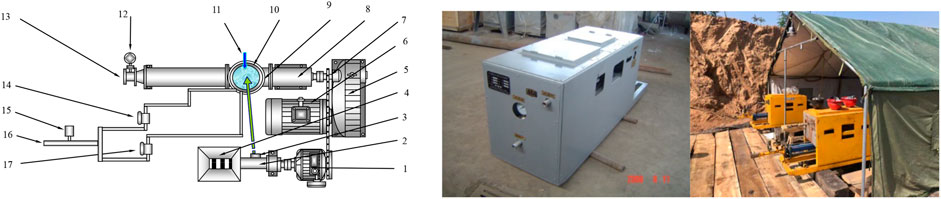

The grouting and colloid injection system mainly consist of the ground portable grouting and colloid injection fire prevention and fire extinguishing system developed by the coal fire disaster prevention innovation team at Xi’an University of Science and Technology, supported by the portable fire prevention and extinguishment devices for mine use. The project was implemented in a targeted manner. The process flow of the colloid injection system is shown in Figure 9. The structure and function principle of the portable fire prevention and extinguishment devices for mine use are presented in Figure 10.

FIGURE 10. 1-belt speeder, 2-polymer fire extinguishing agent quantitative feeding assembly, 3-colloid material outlet, 4-material tank, 5-reducer, 6-explosion-proof motor, 7-transmission chain, 8-screw pump, 9-screw pump inlet (mixture box), 10-ring water curtain tube, 11-water glass entrance, 12-seismic pressure gauge, 13-screw pump outlet, 14-hand wheel water valve “a”, 15-water flowmeter, 16-water inlet, 17-hand wheel water valve “b”.

6.2 Design and arrangement of glue injection drilling

The colloid injection project used “polymer colloid” as the main fire extinguishing medium. Based on the distance of 5 m between the top of the two boreholes, it can be calculated that about 44 boreholes should be drilled, and each borehole must be drilled into the goaf. The total amount of colloid injected was calculated as follows: 9 (goaf) × 220 (inclination length of the working face) × 6 (overall bottom length of the drilling holes) × 1.5 (fill factor) = 17,820 m3, and the colloid injection volume for each drilling hole was about 405 m3. Through 44 fire extinguishing boreholes, polymer colloid fire extinguishing agent was poured from high to low to fill the loose coal in the goaf to achieve cooling and oxygen barrier.

In order to achieve the desired effect of colloid injection, the fire extinguishing holes must be arranged with the underground goaf as the center. By reference to the detection results of the fire zones, the drilling positions should be arranged above the goaf and the tunnel if possible, and avoid coal pillars. The holes should be finished at the bottom plate of the coal seam, which was to be injected with colloid. In order to first control the fire sources deep in the fire zones, the holes should be arranged on the ground from east to west and south to north, with deep holes first and then shallow ones.

6.3 Notes for injection process

(1) Before the colloid injection, the air volume of the affected working face was adjusted first, and the air volume was reduced from 230 m³/s to 180 m³/s to reduce the air leakage to the roof of coal seam. Considering the fluidity of the colloid, the direct injection into the float coal on the roof may cause the polymer colloid to flow into the tunnel, leading to the fall of the top coal and creating larger voids, thereby affecting the fire extinguishing effect. Therefore, it is necessary to spray cement mortar on the two sides and roof of the tunnel within the fire zone first, and then densely drill holes in the roof of the tunnel to ensure the effectiveness of the colloid injection process.

(2) The colloid injection equipment was placed in the tunnel near the fire source, and through control of the valve, the colloid was injected alternately, so as to ensure the continuity of colloid injection. Then the two base solutions were pushed into the mixer by two mud pumps to make the two solutions evenly mixed, and then into the colloid injection holes through the colloid output pipes. Injection can be carried out into two holes at the same time.

(3) For a situation where the coal has spontaneously ignited and there is an open flame, the polymer colloid is required to form a gel quickly after being mixed at the sprayer outlet. Therefore, it is necessary to use two feeding systems of the same model to transport the two raw materials A and B to the ignition site, and mix them with the sprayer to quickly form a gel to cover the fire zone.

(4) During colloid injection into the holes, in a large goaf, the parameters of colloid injection should be adjusted in time to minimize the consumption of colloid provided that the desired effect can be achieved. During the colloid injection, there should be technical construction personnel both above surface and underground to make timely adjustments to any abnormal situations that occur and record the adjustments. For different areas, the colloid filling process is slightly different, and adjustments should be made according to the actual situation.

6.4 Application of polymer colloid fire extinguishing materials during the withdrawal period

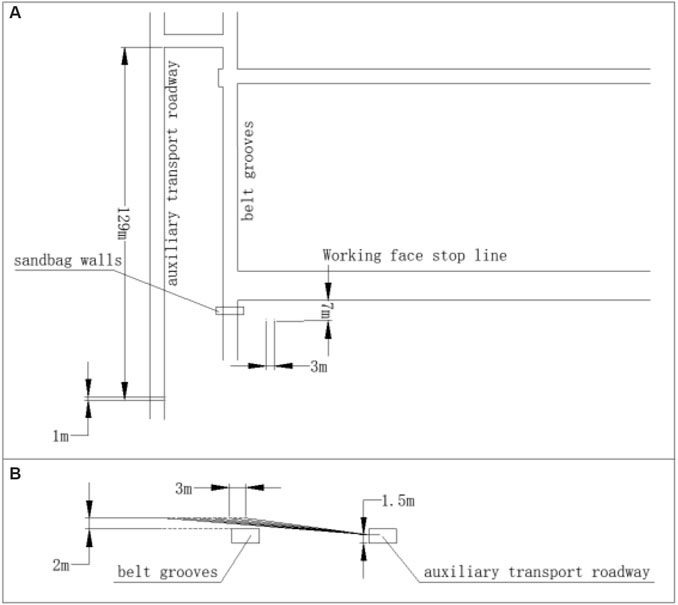

By injecting polymer colloid material into the air inlet end of the goaf, the cracks of the residual coal in the roof are blocked to form a colloid isolation zone to prevent air leakage to the upper part of the goaf. At the same time, the colloid isolation zone and the loess isolation wall at the air inlet end form a plugging barrier together, and the plugging effect is more obvious. Figure 11 is the schematic diagram of the inlet end injection.

FIGURE 11. Schematic diagram of the inlet end injection (A) and (B) are the top view and main view of glue injection drilling construction, respectively).

A grouting pipe with a diameter of 108 mm and a one-inch injection pipe are embedded in the isolation wall, and polymer colloids are poured into the wall to seal the inlet end of the inner side of the isolation wall.

The polymer colloid material integrates the properties of plugging, cooling, resistance and consolidation of water, and solves the problem of slurry leakage and loss in traditional grouting. It is suitable for underground sealing plugging and large-area glue injection fire prevention and extinguishing such as final mining line and goaf. In view of the field situation of the working face in Binchang mining area, the polymer colloid fire prevention and extinguishing technology is adopted. Practice has proved that the gel injection effect is good.

7 Conclusion

This paper selected two kinds of fire extinguishment materials—polymer colloid and fly ash colloid, and conducted experimental research on the water precipitation and water loss of the above two types of colloids after 24-h standing at different concentrations, and the polymer colloid fire extinguishing material is used in Binchang mining area. The following conclusions are drawn:

(1) After the polymer colloid powder is mixed with water, the higher the concentration, the shorter the gelling time. After the colloid is left standing for 24 h, the smaller the concentration is, the more water is precipitated, and the higher the water precipitation rate is. The water loss of the polymer colloid is lower after gelation, and on the other hand, the water precipitation is better. It is more fluid before gelation, and precipitates water after gelation

(2) After the fly ash is mixed with the gelling agent and water, when the concentration ratio of fly ash and water remains the same, the greater the concentration of the gelling agent, the shorter the gelling time. When the concentration of the gelling agent remains the same, the higher the concentration of water mixed with the fly ash, the longer the gelling time.

(3) Through comparison of the water precipitation and water loss performance of the two materials and their respective advantages and disadvantages, the polymer colloid fire extinguishing agent was selected to effectively control the spontaneous combustion of loose coal in the goafs of a mine in Binchang mining area.

(4) The colloid injection process mainly consisting of ground mobile grouting and colloid injection system was adopted for fire prevention and extinguishment in a mine of Binchang mining area, supported by portable colloid injection devices. A total of 44 holes were arranged, with a colloid injection of 405 m3 into each hole, to fill the loose coal bodies in the goafs, which achieved cooling and oxygen barrier, and effectively prevented and extinguished fires in the fire zones. In the future, we can work hard on material ratio and optimization, and continue to explore new fire extinguishing materials or composite colloidal materials suitable for fire prevention and extinguishing in Binchang mining area.

Data availability statement

The original contributions presented in the study are included in the article/supplementary material, further inquiries can be directed to the corresponding author.

Author contributions

The author confirms being the sole contributor of this work and has approved it for publication.

Conflict of interest

The author declares that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Chen, K. (2020). Study on preparation of fly ash thickened colloid and fire-extinguishing properties. China University of Mining and Technology. Beijing, China.

Colaizzi, G. J. (2004). Prevention, control and/or extinguishment of coal seam fires using cellular grout. Int. J. coal Geol. 59 (1-2), 75–81. doi:10.1016/j.coal.2003.11.004

Deng, J., Li, B., Xiao, Y., Ma, L., Wang, C. P., Lai-Wang, B., et al. (2017). Combustion properties of coal gangue using thermogravimetry–Fourier transform infrared spectroscopy. Appl. Therm. Eng. 116, 244–252. doi:10.1016/j.applthermaleng.2017.01.083

Li, J. L., Lu, W., Cao, Y. J., Kong, B., and Zhang, Q. S. (2019). Method of pre-oxidation treatment for spontaneous combustion inhibition and its application. Process Saf. Environ. Prot. 131, 169–177. doi:10.1016/j.psep.2019.08.013

Li, Q. J., Zhang, X. H., Fan, X. Y., and Feng, D. Q. (2005). Application of fly ash composite colloid fire prevention technology in Dongrong No. 3 Mine. Min. Saf. Environ. Prot. 32 (2), 45–47. doi:10.1111/j.1744-7909.2005.00136.x

Liang, Y. T., Hou, X. J., Luo, H. Z., Tian, F. C., and Yu, G. S. (2016). Development countermeasures and current situation of coal mine fire prevention and extinguishing in China. Coal Sci. Technol. 44 (6), 1–6. doi:10.13199/j.cnki.cst.2016.06.001

Liu, Y., Wen, H., Guo, J., Jin, Y., Wei, G., and Yang, Z. (2020). Coal spontaneous combustion and N2 suppression in triple goafs: A numerical simulation and experimental study. Fuel 271, 117625. doi:10.1016/j.fuel.2020.117625

Liu, Z. Z., Jiang, S., Tian, B., Zhu, K., and Lin, W. H. (2022). Mining subsidence monitoring based on InSAR method fusing multi-threshold target. Acadlore Trans. Geosciences 1 (1), 22–32. doi:10.56578/atg010104

Ma, L., Zhang, Y., Wang, J., Wang, J., and Zhou, C. (2022). Fire-prevention characteristics of an active colloid prepared from stimulated fly ash component. ACS omega 7 (2), 1639–1647. doi:10.1021/acsomega.1c03299

Onifade, M., and Genc, B. (2020). A review of research on spontaneous combustion of coal. Int. J. Min. Sci. Technol. 30 (3), 303–311. doi:10.1016/j.ijmst.2020.03.001

Qi, Z., and Kuan, G. (2011). Exploration on the relationship between coal resource and China's economy development: The ANLYSIS based on econometric model. Value Eng. 30 (9), 171–172. doi:10.14018/j.cnki.cn13-1085/n.2011.09.017

Querol, X., Zhuang, X., Font, O., Izquierdo, M., Alastuey, A., Castro, I., et al. (2011). Influence of soil cover on reducing the environmental impact of spontaneous coal combustion in coal waste gobs: A review and new experimental data. Int. J. Coal Geol. 85 (1), 2–22. doi:10.1016/j.coal.2010.09.002

Shi, Q., Qin, B., Bi, Q., and Qu, B. (2018). Fly ash suspensions stabilized by hydroxypropyl guar gum and xanthan gum for retarding spontaneous combustion of coal. Combust. Sci. Technol. 190 (12), 2097–2110. doi:10.1080/00102202.2018.1491845

Song, Z., Huang, X., Jiang, J., and Pan, X. (2020). A laboratory approach to CO2 and CO emission factors from underground coal fires. Int. J. Coal Geol. 219, 103382. doi:10.1016/j.coal.2019.103382

Su, H. T., Zhou, F. B., Song, X. L., Shi, B. B., and Sun, S. H. (2016). Risk analysis of coal self-ignition in longwall gob: A modeling study on three-dimensional hazard zones. Fire Saf. J. 83, 54–65. doi:10.1016/j.firesaf.2016.04.002

Wang, Y. C., Liu, Y. F., and Guo, J. (2017). Application of fly-ash compound gel technique for coal spontaneous combustion prevention in roadway fire control. Coal Technol. 36 (5), 196–198. doi:10.13301/j.cnki.ct.2017.05.074

Wen, H., Yu, Z., Fan, S., Zhai, X., and Liu, W. (2017). Prediction of spontaneous combustion potential of coal in the gob area using CO extreme concentration: A case study. Combust. Sci. Technol. 189 (10), 1713–1727. doi:10.1080/00102202.2017.1327430

Wu, Z., Hu, S., Jiang, S., He, X., Shao, H., Wang, K., et al. (2018). Experimental study on prevention and control of coal spontaneous combustion with heat control inhibitor. J. Loss Prev. Process Industries 56, 272–277. doi:10.1016/j.jlp.2018.09.012

Yan, Z. (2015). Shanxi Huangling Application of fire prevention technology with polymer colloid in Huangling No.2 colliery. Jiangxi Coal Sci. Technol. 3, 45–47.

Yang, P., Liang, G. D., Yu, G. S., Zhang, X. Q., and Duan, T. (2020). Application of fly ash colloid isolation control technology in complex fire area of Huashan Mine. Saf. Coal Mines 51 (8), 82–86. doi:10.13347/j.cnki.mkaq.2020.08.016

Zhang, D., Cai, W. W., Zou, Y., and Shi, Q. Q. (2011). Analysis of polymer gel fire-fighting technology principle and development situation. Coal Technol. 30 (11), 252–254.

Zhang, L. (2018). Application of fire prevention beam tube monitoring technology for in fully mechanized coal working face of close distance coal seam. Coal Eng. 50 (S1), 100–102.

Keywords: spontaneous combustion of coal, polymer colloid, fly ash colloid, water precipitation characteristics, fire zone management

Citation: Shang Y (2023) Experimental research on the water precipitation performance of polymer colloid and fly ash colloid and their applications as fire extinguishing materials in mines. Front. Earth Sci. 11:1133732. doi: 10.3389/feart.2023.1133732

Received: 29 December 2022; Accepted: 01 March 2023;

Published: 10 March 2023.

Edited by:

Zhibo Zhang, University of Science and Technology Beijing, ChinaReviewed by:

Chenchen Wang, China University of Mining and Technology, Beijing, ChinaBotao Li, Xi’an University of Science and Technology, China

Copyright © 2023 Shang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Yuyang Shang, MTU5OTEyMjA5NzdAMTYzLmNvbQ==

Yuyang Shang

Yuyang Shang