- 1Institute of Geotechnical Engineering, Xi’an University of Technology, Xi’an, China

- 2Loess Soil Mechanics and Engineering Key Laboratory of Shaanxi Province, Xi’an, China

Layers with low permeability are an important factor affecting the stability of tailings dams. In order to analyze the influence of the weak permeability interlayer on the seepage stability of the dam, this paper establishes a numerical analysis model of the tailings dam with the weak permeability interlayer. The seepage stability of the dam slope is calculated and analyzed for the location, thickness, number, and intervals of mud intercalation on the seepage stability of the dam slope. The weakly permeable interlayers at different locations form different saturation lines in the dam. When the weak permeability interlayer is located in the middle of the dam, the height of the saturation line is the highest, and the corresponding stability safety factor is the smallest. When the weak permeability interlayer moves up or down, the buried depth of the saturation line increases, and the safety factor increases. However, when the weak permeability interlayer is located above the drainage prism, the overall slip along the weak permeability interlayer is incidental to the increase in dam height. When the thickness of the weak permeability interlayer changes, the safety factor of the dam has a positively high significance related to the leakage. When the location of the weak permeability interlayer changes, the safety factor of the dam has no obvious correlation with the leakage. With the increase of the thickness and number of weak pemeability interlayer and the decrease of the intervals of mud intercalation, the height of the saturation line gradually increases, and the safety factor of the dam gradually decreases. Through the location of the sliding surface, it is found that the sliding surface eventually destabilizes through the lowest low-permeability interlayer.

1 Introduction

“Tailings reservoir” mostly refers to the facilities that are dammed at a valley mouth to accumulate tailings slag produced in the process of mining and tunneling, beneficiation, and waste or other industrial waste generated in the smelting process. The wet discharge method is often used in the construction of tailings reservoirs in China. Due to the different ore characteristics and fabric components at different time periods, vertical deposition occurs while the slurry flows horizontally in the process of ore drawing into the dam. The flow and sedimentary process of slurry are affected by factors such as slag concentration, flow rate, particle size, and ore drawing mode (Azam et al., 2007; Duan et al., 2022). The dam structure formed by slag deposition has significant spatiotemporal variability, which leads to great mechanical properties and permeability coefficient of tailings, forming many low-permeability interlayers (Tynybekov and Aliev, 2007; Southard et al., 2010; Chen et al., 2019; Liu et al., 2022a; Zhang et al., 2022a). This dam does not have the characteristics of artificial structures such as earth-rock dam obvious material partition. The seepage field of the dam body is affected by this low-permeability interlayer, which leads to the serration of the saturated surface becoming zigzagged and violently lifted. This low-permeability interlayer also has the characteristics of low strength, which will also affect the stability of the dam body (Yin et al., 2011; Yu et al., 2014; Chen 2016; Yang et al., 2021; Liu et al., 2022b; Zhang et al., 2022b).

The saturation line is the lifeline of the tailings reservoir (Xie et al., 2009; Yin et al., 2010; Yu et al., 2011; Lin et al., 2014). The elevation of the saturation line is extremely unfavorable to the stability of the tailings dam, which is the key factor affecting the stability of the tailings reservoir (Gens and Alonso, 2006; Azam and Li, 2010; Xie et al., 2014; Qiao et al., 2015). Many factors can cause the infiltration line to rise. Among them, there are many factors that lead to the rise of the location of the saturation line. Among them, the external factors include rainfall (Duan and Yuan, 2008), reservoir elevation (Liang et al., 2010), topography (Lu and Cui, 2006), and ore drawing mode (Zhang et al., 2016; Liang et al., 2017). The fine-grained interlayer structure is usually called lenticle in the dam (Yuan et al., 2013) and the drainage blocking caused by chemical reactions (Wu, 2008), which are caused by the differences in physical and chemical properties of minerals mined and the emission mode at different time periods. The model test and numerical simulation are generally used to study the influence of the change of infiltration surface on the stability of tailings dams. Jing et al. (2011) simulated the coupling characteristics of saturation line and stress and the development process of dam failure by indoor model test, so as to reveal the collapse mechanism and burst mode of tailings dams affected by flooding. Through the indoor dam model test, Deng et al. (2011) analyzed the characteristics of the stress field and pore-pressure field in the dam body by a numerical test based on the distribution characteristics of tailings particles and the variation law of saturation line in the process of dam accumulation. Through numerical simulation, Yin et al. (2003) analyzed the relationship between the variation of infiltration surface and the stability of dam slope under different rainfall patterns. Li Q. et al. (2017) studied the correlation between the distribution characteristics of the seepage field and the failure mode of the dam body based on typical tailing reservoir engineering. Li Z. P. et al. (2017) took the depth of saturation line as the safety index of dam and analyzed the influence of a lenticle on the dam through an orthogonal test. These researches have improved the understanding of the evolution law of the infiltration surface and the sensitivity of stability factors of the tailings dam, and these results are mostly limited to a specific tailings dam, which provides ideas for further systematic research of the influence characteristics of a certain factor.

The existing research on the factors affecting the saturation surface of tailings reservoir and the influence of saturation surface on the stability of dam body has made the rich achievement, which improves understanding of the infiltration surface and stability of tailings dam and changes from passive disaster relief to active disaster prevention. At present, for the evaluation of the dam slope stability, tailing slag of different natures within the dam is mostly studied in the form of equivalent division or directly regarded as lenses. However, the difference in physical and chemical properties of mining ores in different periods leads to the weakly permeable layer formed by slag deposited in the reservoir. It is rare to study the influence of the weak permeable layer on the seepage stability of the tailings dam. In this paper, the influence of the low-permeability interlayer—which is completely different from lenticle formed in the process of damming—on the distribution of the saturation line is studied by numerical simulation method based on the engineering example of a tailings reservoir. The relationship among low permeability interlayer, saturation line, and the stability of the tailings dam is analyzed to provide a reference for the construction and stability evaluation of tailings reservoirs.

2 Numerical model establishment

The tailings pond is a valley-type tailings pond, which is composed of an initial dam and a tailings accumulation dam and is filled by the upstream accumulation method. The present situation of the damn is the initial dam with dam bottom elevation of 2,153 m, dam axis length of 118 m, dam height of 40.6 m, dam crest width of 3.0 m, and dam crest elevation of 2,193.6 m. The initial dam slope ratio is 1:2.5. A horseway is set on the top of the initial dam with a width of 4.0 m. The slope ratio of the tailings accumulation dam is 1:4. The sub-dams are formed by the tailings’ coarse sand deposited on the sedimentary beach. The height of each sub-dam is 4.375 m, the width of the sub-dam top is 3 m, and the stack height of the final tailings accumulation dam is 74.4 m. The total height of the tailings accumulation dam is 115.0 m, and the crest elevation of the tailings accumulation dam is 2,268 m, which belongs to the grade II tailings dam.

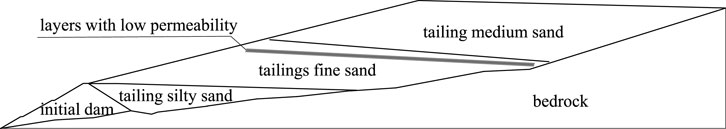

According to the engineering geological investigation report of the tailings dam and the tailings samples obtained in the field, there are four main types of tailings dam materials, including tailings fine sand, tailings coarse sand, tailing silty sand, and tailing medium sand. The accumulation dam is formed by the accumulation of tailings coarse sand, and there are weak permeable interlayers with different locations and uneven thickness in its interior. According to the sedimentary characteristics and engineering survey data of the tailings dam, the tailings dam material is divided into four layers. The material regions diagram and calculation parameters are shown in Figure 1 and Table 1 respectively.

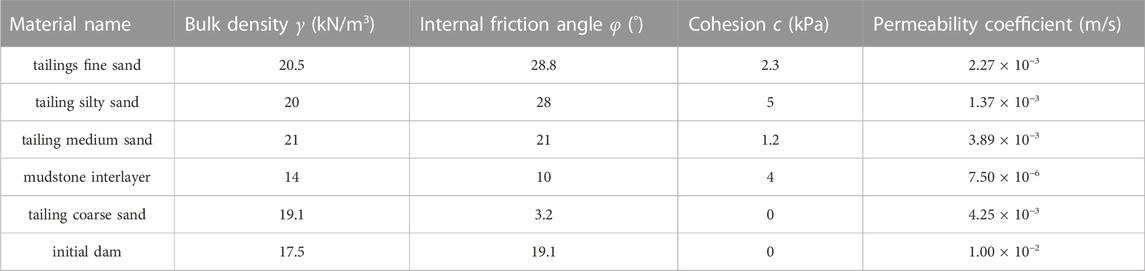

The proposed tailings dam is a second-class reservoir with a dry beach length of 125 m and an upstream water level elevation of 2,265 m. Since the initial dam is a permeable rock-fill dam, the downstream head boundary is a free permeable surface at the toe of the initial dam. The bottom of the numerical model is set as an impervious boundary. The maximum height is 115 m, the dam length is 655m, and the average size of the unit side length is 1 m of the calculation model. The model is divided into 55,358 units and 55,924 nodes. The calculation model is shown in Figure 2.

3 Stability analysis of seepage of tailings dam by weak permeability interlayer under different working conditions

Due to the different quality of minerals mined in different periods, there are spatial differences in the discharge and storage of tailings reservoirs. Multiple low-permeability interlayers with different locations, thicknesses, numbers, and intervals are formed in the dam, which will affect the seepage field and stability of the dam.

3.1 Analysis of weak permeability interlayer location

The influence of the location of a single weak permeability interlayer with a certain thickness on the seepage stability of the tailings dam is analyzed, which reveals the influence of low-permeability interlayers at different locations on the saturation line and the safety factor of the tailings dam.

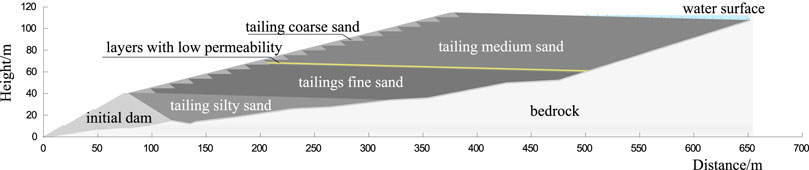

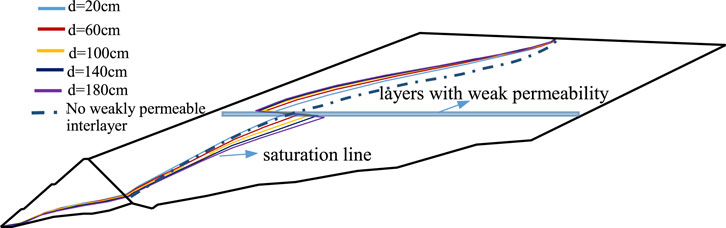

The variation of the saturation line with the location of the weakly permeable interlayer is shown in Figure 3, in which L is the distance from the weakly permeable interlayer to the dam top. Figure 3 shows that the distribution characteristics of the saturation line are significantly changed by the low-permeability interlayer. In the upper part of the low-permeability interlayer, the saturation line is significantly higher than that of the non-weak permeability interlayer, while in the lower part of the non-low-permeability interlayer, it is mutational retreat. The infiltration line located in the lower part of the weak permeability sandwich decreases, and these lowering points are basically in the same position. The saturation line at the lower part of the weakly permeable interlayer decreases and is basically in the same location. It shows that the influence law of a single weakly permeable interlayer on the saturation line is the same. Due to the sudden change in permeability coefficient, only the upper and lower saturation line locations are staggered at the front and back, the original trend does not change. The size of the sudden change of the saturation line in the weak permeability interlayer changes with the location of the interlayer. The closer to the dam top, the greater the sudden change. The back withdrawal characteristics are shown on the dam top. In the middle of the dam, the saturation line is mainly characterized by forward uplift. The closer to the drainage prism, the smaller the sudden change, and the back withdrawal of the saturation line is not obvious. Due to the effect of a weak permeable interlayer on the uplift of the saturation surface, the depth of the saturation surface is the shallowest in the middle of the dam slope, which affects the stability of the dam. Therefore, it is necessary to pay attention to the weak permeable interlayer here.

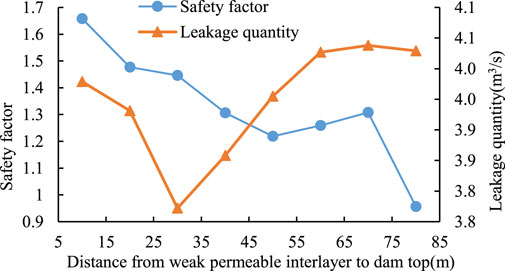

When the single weak permeability interlayer in the horizontal direction is at different locations of the dam body, the influence on the safety factor of the dam slope is shown in Figure 4. Figure 4 shows that the influence of different locations of low permeability interlayers on the safety factor of the dam can be divided into two stages. When the distance between the weak permeability interlayer and the top of the dam increases from 10 m to 50m, the safety factor of the dam decreases from 1.658 to 1.219. At this stage, the weak permeability interlayer is located near the middle of the dam. When the distance increases from 50 m to 80m, the safety factor increases from 1.219 to 1.356. At this stage, the stability of the dam slope is improved. The results show that there is a critical height of the weak permeable interlayer in the dam body. When the location of the single weak permeable layer formed by the ore drawing is at the critical height with the increase of the dam body, the safety factor of the dam slope is the smallest, which should be avoided in practical engineering.

FIGURE 4. The curve between weak permeability interlayer position and leakage with the safety factor.

By analyzing the relationship between the leakage of the dam and the location of the weak permeable interlayer, the safety factor, the leakage, and the location of the weak permeable interlayer first show a decrease then an increase. The development rule of the leakage and the height of the weak permeable interlayer is not consistent with the development of the safety factor with the height of the weak permeable interlayer. When the leakage is the smallest, the low-permeability interlayer is located at two-thirds of the dam height, which conforms to the impermeability characteristics of the low-permeability interlayer. This location is not the most dangerous to the dam. As the height of the low-permeability interlayer decreases, the leakage increases. When the low-permeability interlayer is located above half the height of the dam, the safety factor decreases, and the leakage still increases. The results show that the leakage quantity of the tailings dam is not consistent with the evolution characteristics of the safety factor of the dam slope. When the tailings dam has a permeable interlayer, the leakage cannot be used as an index to judge the stability of the dam. Attention should be paid to the selection of factors in the early warning of tailings dam safety and stability.

As the location of the weak permeability interlayer gradually moves down along the dam crest, the safety factor presents the rule of decreasing first, then increasing and decreasing again. When the weak permeability interlayer is located in the middle of the dam body, it has a great influence on the stability and safety of the dam body. The corresponding safety factor is small, and the dam slope is prone to instability. When the weak permeability interlayer is located in the upper part of the dam, the weak permeability interlayer has little effect on the stability and safety of the dam. In this case, the safety factor of the dam slope is large, which is only calculated by the arc search method. When the weak permeability interlayer is located in the lower part of the dam, which is 80 m away from the top of the dam, the whole dam slips along the weak permeability interlayer with lower strength. In this case, the failure is not the circle sliding of the dam slope, but the overall slip failure. Therefore, it is necessary to pay particular attention to the damage caused by the weak permeability interlayer located in the lower part of the dam.

3.2 Analysis of thickness of a weak permeable interlayer

In practical engineering, the thickness of weak permeability interlayer of tailings ranges from tens of centimeters to several meters, which is determined by the sedimentary characteristics of tailings. According to the above study, when the weak permeability interlayer is located in the middle of the dam, the stability safety factor is the smallest, resulting in tailings dam slope instability. Therefore, it is very important to study the influence of the thickness of the weak permeability interlayer at a certain location on the stability of the dam. When the location of a low-permeability interlayer is fixed, the influence of the low-permeability interlayer on the saturation line and stability of the tailings dam is analyzed by changing the thickness of the low-permeability interlayer, which reveals the influence of low-permeability interlayers with different thicknesses on the saturation line and safety factor of a tailings dam.

The variation of the saturation line with the thickness of the weakly permeable interlayer is shown in Figure 5, in which d is the thickness of the weakly permeable interlayer. Figure 5 shows that the height of the saturation line in the upper part of the weakly permeable interlayer gradually increases with the increase of the interlayer thickness. This is because the saturation line in the upper part of the weak permeability interlayer will be raised. The thicker the interlayer is, the more obvious the saturation line is raised. The saturation line in the lower part of the weak permeability interlayer gradually decreases with the increase of the interlayer thickness, forming the characteristics of the upper extension and the lower retreat, which affects the stability of the dam. The thicker the low-permeability interlayer is, the more violent the infiltration surface abrupt change, which leads to the rapid extension of the upper part of the low-permeability interlayer to the dam slope and the retreat of the lower part to the inside of the dam body. This can easily to cause the infiltration surface to seep out from the slope, which makes the local slope prone to slip, affecting the stability of the dam slope.

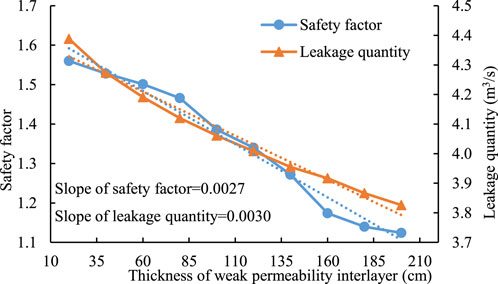

The influence of different thicknesses of a single weakly permeabile interlayer in a horizontal direction on the safety factor of a dam is shown in Figure 6. Figure 6 shows that it is reflected that the safety factor of the dam decreases gradually with the increase of the interlayer thickness. When the thickness of a low-permeability interlayer is 140 cm, the safety factor of the tailings reservoir is 1.272. When the thickness of a low-permeability interlayer is greater than 140 cm, the safety factor decreases sharply. This is because the weak permeability interlayer generally belongs to the saturated muddy interlayer. Compared with coarse-grained tailings outside the interlayer, the mechanical strength and deformation modulus are lower. In particular, the thicker weak permeability interlayer is easy to soften and muddy in water, which reduces the shear strength and is not adverse to the anti-sliding stability of the dam. Therefore, the thickness of the low-permeability interlayer has a very important influence on the stability of the dam. In the process of tailings drawing, it should be avoided to form a thicker weak permeability interlayer in the middle of the dam, so as to ensure the safety of the tailings dam.

FIGURE 6. The curve between low-permeability interlayer thickness and leakage with the safety factor.

The results show that the safety factor and leakage decrease linearly with the increase of the thickness of the weak permeability interlayer in the case of a single horizontal weak permeability interlayer, and the slope of decreasing is close. There is a high correlation between the safety factor and the thickness of the weakly permeable interlayer, and the leakage is also highly correlated with the thickness of the weakly permeable interlayer. It provides a key index for the safety warning of tailings dam filling with a low-permeability interlayer. It is known that the dam filling material is a low-permeability material, and the leakage of the tailings dam decreases during the filling process, which may indicate that the thickness of the low-permeability layer formed by the filling material needs to be paid attention to.

3.3 Analysis of the number of low-permeability interlayers

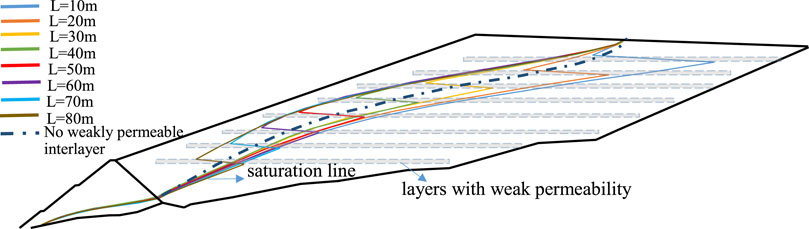

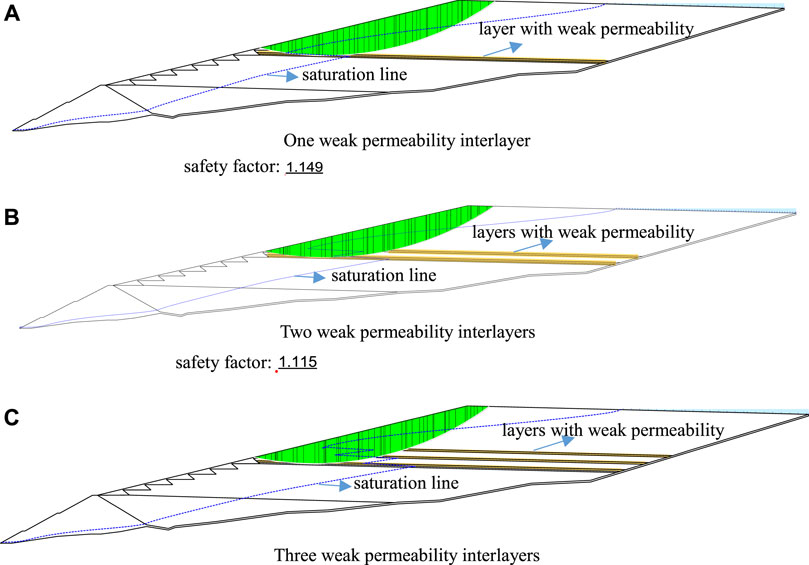

Due to the complexity of tailings engineering, it is also very difficult to determine the sedimentary characteristics of tailings. In the process of tailings ore drawing, the tailings material in the mineral pulp is deposited in turn according to the coarse, medium, and fineparticles of its mud. The sedimentary process is very complicated, and multiple low-permeability interlayers are generally formed in the process of accumulating tailings material. Therefore, it is particularly important to analyze the influence of the number of low-permeability interlayers on the stability of the tailings dam. In this paper, two and three weak permeability interlayers with a spacing of 5 m and a thickness of 1 m are set at a distance of 50 m from the top of the dam to study the influence of the number of interlayers on the stability of the tailings dam. The results of the number of weakly permeable interlayers on the saturation line and the safety factor of the dam are shown in Figure 7.

FIGURE 7. The curve of the number of low-permeability layers and safety factor. (A) One weak permeability interlayer. (B) Two weak permeability interlayers. (C) Three weak permeability interlayers.

Figure 7 shows that as the number of low-permeability interlayers increases, the safety factor of the dam slope decreases. The number of low-permeability interlayers increases from 1 to 3, and the safety factor decreases from 1.220 to 1.115. With the increase in the number of weak permeability interlayers, the saturation line has undergone multiple turns in the low-permeability interlayer, which significantly causes the saturation line to be raised. The more the number of low-permeability interlayers, the more obvious the uplift of the saturation line. The excessive number of interlayers may cause the infiltrate line to overflow on the dam slope. The low-permeability interlayer has poor permeability and low strength, resulting in the decrease of the safety factor, the landslide of the slope, and affecting the safe operation of the dam. In order to ensure the stability of the dam, vertical drainage facilities should be added to make the water stored between multiple weak permeability interlayers run through and lower saturation line of the dam.

3.4 Analysis of interlayer spacing of weakly permeable interlayer

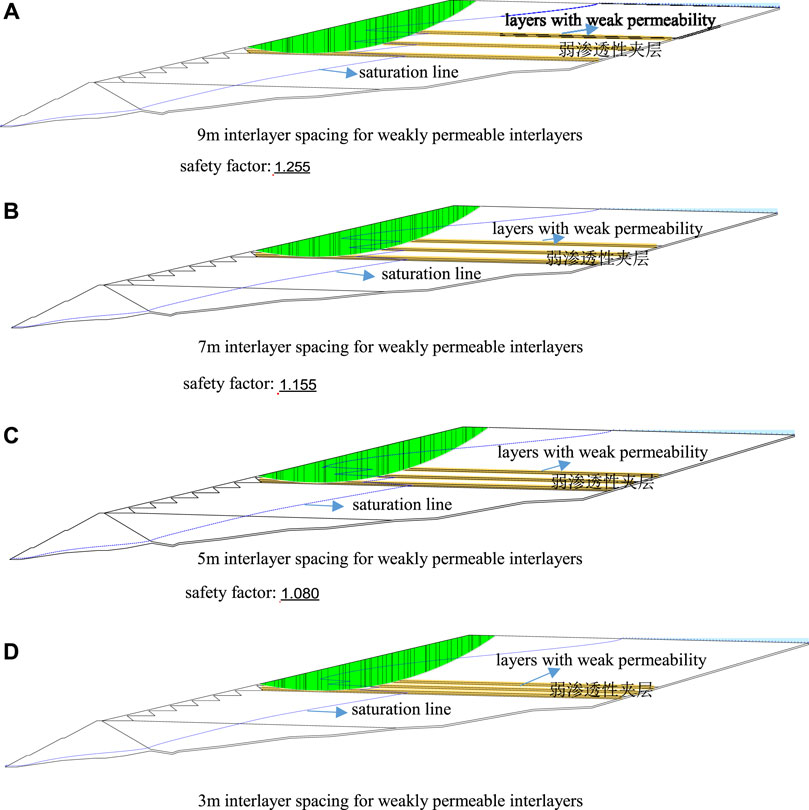

When there are several low-permeability interlayers in a tailings reservoir, the interlayer spacing of weak permeability interlayers varies greatly. In this study, three low-permeability interlayers that are 50 m away from the top of the dam with an interlayer thickness of 1 m were used as models to analyze the influence of the interlayer spacing of multiple low-permeability interlayers on the stability of the dam slope, which reveal the influence law of the safety factor and the saturation line of the dam with different spacing of low-permeability interlayers in Figure 8.

FIGURE 8. The curve of the interlayer spacing of low-permeability layer and safety factor. (A) 9 m interlayer spacing for weakly permeable interlayers. (B) 7 m interlayer spacing for weakly permeable interlayers. (C) 5 m interlayer spacing for weakly permeable interlayers. (D) 3 m interlayer spacing for weakly permeable interlayers.

Figure 8 shows that the safety factor of the dam slope decreases gradually with the decrease of interlayer spacing of weak permeability interlayer. When the interlayer spacing of the weak permeability interlayer is 5 m, the safety factor of the dam slope is 1.255. When the interlayer spacing is 3m, the safety factor is 1.080. In this situation, the tailings dam slope is close to instability, and the height of the saturation line gradually increases with the decrease of the interlayer spacing of the low-permeability interlayers. The reason is that the interlayer spacing continues to decrease, resulting in multiple low-permeability interlayers and intermediate dams forming a low-permeability belt. The saturation line through the interlayer is severely blocked, resulting in the saturation line is continuously raised. In addition, the low-permeability interlayer is easy to soften, prone to mudding, and has low shear strength, which ultimately leads to slope instability.

The above comprehensive analysis of the location, thickness, number, and spacing of the low-permeability interlayers on the safety factor of the dam slope and the shape of the landslide found that when there is a low-permeability interlayer in the dam, sliding arc exit general shear along the weak permeability interlayer.

When there are several weak permeability interlayers, the sliding zone often passes through the upper interlayer, and shear failure occurs along the bottom weak permeability interlayer, which indicates that low-permeability interlayers are the key factor to controlling the instability of the dam slope.

4 Conclusion

The influence of low-permeability interlayers on seepage fields and safety factor is studied by establishing a two-dimensional finite element model of a tailings dam. This paper analyzes the relationship between the location, thickness, and spacing of weakly permeable interlayers and the saturation line and the stability of dam slope, and reveals the evolution mechanism of coupling influence between saturation line, seepage flow, and safety factor of the dam slope. The conclusions are as follows.

(1) The location of the low-permeability interlayer in the dam body has a significant influence on the saturation line. When a low-permeability interlayer is located in the middle of the dam, the saturation line rises significantly and is closest to the dam slope, which affects the instability of the dam. When the low-permeability interlayer is located at the top of the dam, the saturation line is far from the dam slope, which has little effect on the stability and safety of the dam, and the corresponding safety factor is large. When the low-permeability interlayer is located at the upper part of the drainage prism, the tailings dam is the most dangerous. The overall slip failure along the weak permeability interlayer may occur, which needs special attention.

(2) The safety factor of the dam slope continues to decrease with the increase of the thickness of the weak permeability interlayer. The saturation line on the upper part of the weak permeability interlayer will be raised. The thicker the interlayer, the more obvious the uplift of the saturation line. A low-permeability interlayer can easily cause slope instability and affects the stability of the dam.

(3) The safety factor of the tailings dam slope continues to decline with the increase of the number of interlayers. Multiple low-permeability interlayers will cause the saturation line to undergo multiple turns in the interlayer, causing the saturation line to be raised. The greater the number of low-permeability interlayers, the more obvious the uplift of the saturation line, which seriously affects the stability of the dam.

(4) When the interlayer spacing is large, it has little influence on the stability of the tailings dam, and the lift height of the saturation line is relatively low. However, if the spacing between low-permeability interlayers is small, the upper and lower weak permeability interlayers may form a whole, and the saturation line will rise, which will rapidly reduce the safety of the tailings dam and easily lead to the sliding failure of the dam slope.

(5) Through the stability calculation under different working conditions, it is found that the slip surface of the dam slope is cut out along the lowermost weak permeability interlayer, which is independent of the number and spacing of the low-permeability interlayer.

Data availability statement

The raw data supporting the conclusion of this article will be made available by the authors, without undue reservation.

Author contributions

HL provided overall guidance on the article as well as wrote this paper. MY and TD modified the article language.

Funding

This work was supported by the Loess Soil Mechanics and Engineering Key Laboratory of Shaanxi Province Foundation (13JS073), and the Natural Science Foundation of Shaanxi Province (2017JM5059).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Azam, S., and Li, Q. R. (2010). Tailing dam failures: A review of the last one hundred years. Geotech. News 28 (4), 50–54.

Azam, S., Chalaturnyk, R. J., and Scott, J. D. (2005). Geotechnical characterization and sedimentation behaviour of laterite slurries. Geotechnical Test. J. 28 (6), 1–11. doi:10.1520/GTJ12511

Chen, Q. L., Zhang, C., Yang, C. H., Chang, K. M., Zhen, K. P., and Daemen, J. (2019). Strength and deformation of tailings with fine-grained interlayers. Eng. Geol. 256, 110–120. doi:10.1016/j.enggeo.2019.04.007

Chen, S. S. (2016). Problems and countermeasures of safety evaluation of tailing pond. Chin. J. Geotechnical Eng. 38 (10), 1869–1873. doi:10.11779/CJGE201610016

Deng, T., Wan, L., and Wei, Z. A. (2011). Stacking model test of Wenzhuang tailings reservoir and its stability analysis. Rock Soil Mech. 32 (12), 3647–3652. doi:10.16285/j.rsm.2011.12.035

Duan, Z. J., Li, Q. M., Zhao, X. Y., Yu, Y. Z., and Shi, H. (2022). Experimental study on optimization of ore-drawing parameters for fine grained tailings dams constructed by upstream method. Chin. J. Geotechnical Eng. 44 (08), 1474–1482. doi:10.11779/CJGE202208012

Duan, Z. Y., and Yuan, B. (2008). Collapse analysis and comprehensive treatment of a mine tailings dam due to rain storm and flood impounding. Mech. Pract. 30 (2), 40–44+34.

Gens, A., and Alonso, E. E. (2006). Aznalcóllar dam failure. Part 2: Stability conditions and failure mechanism. Geotechnique 56 (3), 185–201. doi:10.1680/geot.2006.56.3.185

Jing, X. F., Yin, G. Z., Wei, Z. A., Li, X. S., and Wang, M. L. (2011). Model experimental study of collapse mechanism and broken mode of tailings dam. Rock Soil Mech. 32 (5), 1377–11384+1404. doi:10.16285/j.rsm.2011.05.039

Li, Q., Zhang, L. T., and Qi, Q. L. (2017). Three-dimensional instability characteristics and stability analysis of a tailing dam based on fluid-solid coupling theory. J. Basic Sci. Eng. 25 (3), 558–567. doi:10.16058/j.issn.1005-0930.2017.03.012

Li, Z. P., Peng, Z. B., He, Z. M., and Yuan, W. (2017). Simplification method of lenticles and its impact on safety of tailings dam. J. Central South Univ. Sci. Technol. 48 (5), 1326–1334. doi:10.11817/j.issn.1672-7207.2017.05.027

Liang, B., Bai, Y. P., and Jin, J. X. (2010). Influence of the water level rising on tailings dam stability. J. Water Resour. Water Eng. 21 (4), 11–14.

Liang, B., Lv, Z. Q., Jin, J. X., and Wu, P. F. (2017). Model experimental study of effect of slurry draining speed on tailings delocation. J. Exp. Mech. 32 (6), 880–887.

Lin, X. S., Chen, D. Q., and He, F. (2014). Calculation of monitoring warning value of tailing dam’s saturation line and dry beach. J. Water Resour. Water Eng. 25 (4), 65–68. doi:10.11705/j.issn.1672-643X.2014.04.014

Liu, N., Li, N., Li, G., Song, Z., and Wang, S. (2022a). Method for evaluating the equivalent thermal conductivity of a freezing rock mass containing systematic fractures. Rock Mech. Rock Eng. 55, 7333–7355. doi:10.1007/s00603-022-03038-9

Liu, N., Li, N., Wang, S., Li, G., and Song, Z. (2022b). A fully coupled thermo-hydro-mechanical model for fractured rock masses in cold regions. Cold Regions Sci. Technol. 205, 103707. doi:10.1016/j.coldregions.2022.103707

Lu, M. L., and Cui, L. (2006). Three-dimensional seepage analysis for complex topographical tailings dam. Rock Soil Mech. 27 (7), 1176–1180. doi:10.16285/j.rsm.2006.07.032

Qiao, L., Qu, C. L., and Cui, M. (2015). Effect of fines content on engineering characteristics of tailings. Rock Soil Mech. 36 (4), 923–927+945. doi:10.16285/j.rsm.2015.04.002

Southard, J. B., Boguchwal, L. A., and Romea, R. D. (2010). Test of scale modelling of sediment transport in steady unidirectional flow. Earth Surf. Process. Landforms 5 (1), 17–23. doi:10.1002/esp.3760050103

Tynybekov, A. K., and Aliev, M. S. (2007). The ecological condition of Kadji-Sai uranium tailings. Environ-mental Secur. Public Saf. 47, 187–195. doi:10.1007/978-1-4020-5644-4_16

Wu, J. (2008). Mechanism and process simulation for chemical clogging of the tailings dam. Shanghai: Shanghai Jiao Tong University for the Degree of Doctor of Philosophy.

Xie, X. Y., Tian, W. Q., and Wang, Y. H. (2009). The safety analysis of current situation and management countermeasure on tailing reservoir in China. J. Saf. Sci. Technol. 5 (2), 5–9. doi:10.16031/j.cnki.issn.1003-8035.2014.03.038

Xie, Y. D., Wu, G. L., Jin, X. G., Chen, S. Q., and Wang, L. (2014). Analysis on stability of the fill dam in Wujiagou tailing pond. Chin. J. Geol. Hazard Control 25 (3), 49–55.

Yang, C. H., Zhang, C., Li, Q. M., Yu, Y. Z., Ma, C. K., and Duan, Z. J. (2021). Disaster mechanism and prevention methods of large-scale high tailings dam. Rock Soil Mech. 42 (1), 1–17. doi:10.16285/j.rsm.2020.1653

Yin, G. Z., Li, G. Z., Wei, Z. A., Wan, L., Shui, G., and Jing, X. (2011). Stability analysis of a copper tailings dam via laboratory model tests: A Chinese case study. Miner. Eng. 24 (2), 122–130. doi:10.1016/j.mineng.2010.10.014

Yin, G. Z., Li, Y., Wei, Z. A., Jing, X. F., and Zhang, Q. K. (2010). Regularity of the saturation lines´ change and stability analysis of tailings dam in the condition of flood. J. Chongqing Univ. 33 (3), 72–75+86.

Yin, G. Z., Wei, Z. A., and Wan, L. (2003). Numerical simulation analysis about seepage field of Longdu tail bay. Chin. Rock Soil Mech. 24 (2), 25–28. doi:10.16285/j.rsm.2003.s2.006

Yu, G. M., Song, C. W., Pan, Y. Z., Li, L., Li, R., and Lu, S. B. (2014). Review of new progress in tailing dam safety in foreign research and current state with development trend in China. Chin. J. Rock Mech. Eng. 33 (1), 3238–3248. doi:10.13722/j.cnki.jrme.2014.s1.091

Yu, G. M., Song, C. W., Wu, Y. X., Pan, Y. Z., and Li, R. (2011). Engineering characteristics and key problems of security monitoring informatization for tailings dams. Chin. J. Geotechnical Eng. 33 (1), 49–53.

Yuan, W., Li, X. C., Bai, B., Li, X. C., and Wang, H. B. (2013). Parameter sensitivity analysis of lenticle impacting on tailing dam safety. Chin. J. Central South Univ. Sci. Technol. 44 (3), 1174–1182.

Zhang, D. M., Zheng, B. B., Yin, G. Z., Dai, J. X., and Tang, F. J. (2016). Model tests on upstream dam-building method using concentrated and classified tailings. Chin. Rock Soil Mech. 37 (7), 1832–1838+1867. doi:10.16285/j.rsm.2016.07.002

Zhang, Y., Fan, S., Yang, D., and Zhou, F. (2022b). Investigation about variation law of frost heave force of seasonal cold region tunnels: A case study. Front. Earth Sci. 9, 806843. doi:10.3389/feart.2021.806843

Keywords: tailings reservoir, weakly permeable interlayer, safety factor, saturation line, sliding surface, stability analysis

Citation: Li H, Yang M and Dang T (2023) Influence of mud intercalation on the stability of seepage flow in tailings dams. Front. Earth Sci. 11:1115003. doi: 10.3389/feart.2023.1115003

Received: 03 December 2022; Accepted: 02 January 2023;

Published: 19 January 2023.

Edited by:

Zhanping Song, Xi’an University of Architecture and Technology, ChinaCopyright © 2023 Li, Yang and Dang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Min Yang, eWFuZ21pbjAwNjlAMTI2LmNvbQ==

Hongru Li

Hongru Li Min Yang

Min Yang Tong Dang1,2

Tong Dang1,2