- 1School of Geoscience and Technology, Southwest Petroleum University, Chengdu, China

- 2China Railway Eryuan Engineering Group Co., Ltd., Chengdu, China

The YL Tunnel of the Chongqing–Kunming high-speed railway project, a key project of the whole line, is a typical ultra-long deep tunnel facing geologic problems, such as rock bursts, large deformation, water inrush, and toxic or harmful gas leakage, among which high ground stress results in the most serious damage. This study incorporates existing studies and materials, as well as data on ground stress obtained through tests using the hydrofracturing technique. The areas with rock bursts and large deformations were divided accordingly, and preventive measures were expounded. The results showed that the areas predicted as high risk of severe rock burst were D1K338 + 945–D1K339 + 025 and D1K339 + 075–D1K339 + 220, which is of significance when constructing the whole Chongqing–Kunming high-speed railway and may even be instructive in railway construction in the southwest region of China.

Introduction

The Chongqing–Kunming (YU–KUN) high-speed railway is one of the longest railway passages on the Beijing–Kunming high-speed railway. It connects east and west China, and once completed, it can facilitate interaction between north and southwest China, and is of great significance to economic growth and national defense construction. The YL tunnel of the YU–KUN high-speed railway is a key project of the whole line, and it is a typical ultra-long deep buried tunnel facing geologic challenges, such as rock bursts, large deformation, water inrush, and toxic or harmful gas leakage, among which rock bursts and large deformation induced by high-stress environments result in the most serious damage. Analyzing and finding solutions to high ground stress in tunnels of the same type is significant to the construction of such tunnels on high-speed railway lines, and even more so in the greater southwest region (Wang et al., 2020).

High ground stress causes two main problems: large deformation of soft rock and rock bursts. Researchers have already investigated the generation mechanism, operating principles, and prediction and prevention measures for such problems (Liu, 2020). The large deformation of soft rock is generally divided into two categories according to the formation mechanism (Aydan et al., 1993): plastic deformation caused by the stress redistribution from tunnel excavation exceeding the strength of the surrounding rock and expansion caused by the chemical reaction between some minerals in the surrounding rock and water. Anagnostou (1993) found that the main factors causing large deformation of soft rock are in situ stress and rock strength. Tan and Wen (1983) attributed the large deformation of the surrounding rock to five aspects: the plastic wedge, expansion of the surrounding rock, rheology, expansion, and deflection. Brox and Hagedorn (1999) point out that stress redistribution caused by tunnel excavation is an important factor that causes large deformation of the surrounding rock in a weak geological environment. He et al. (2007) proposed a failure mechanism of soft rock tunnel deformation according to the rock mass structural plane, force source, and molecular structure of the rock mass itself. Kovačević et al. (2021) used particle swarm optimization to evaluate the long-term deformation of soft rock tunnels on the basis that particle swarm optimization has fast convergence and strong searching capability. Research, to a certain extent, makes the large deformation of soft rock more predictable. Zivaljevic and Tomanovic (2021) carried out long-term creep tests of cyclic loading and gradual unloading on soft rock specimens, making clear the influence of historical loading and unloading on soft rock creep based half on theory and half on empiricism. Zhao et al. (2011) inspected the supporting system of the weak surrounding rock of the Tianpingshan Mountain deep-buried tunnel and analyzed its stress characteristics. Li (2011) analyzed the characteristics of the damaged surrounding rock and support structures in the Maoyushan Mountain Tunnel and proposed that the primary support be closed quickly, and to construct the secondary lining when the time was right, concluding that reserving space for possible deformation and the release of stress in advance are key to tunnel construction in areas where there are chances of soft rock large deformation. Li et al. (2015) analyzed the large deformation of soft rock on the Lanzhou–Chongqing railway line and found a pattern of soft rock deformation in the tunnel, and provided suggestions on the classification standards of deformation of soft rock. Sun et al. (2020) used the Muzhailing highway super-long tunnel to field test different support schemes. These were compared and analyzed, and it was concluded that high prestressed constant resistance and large-deformation anchor cable support measures were more effective in controlling the large deformation of the surrounding rock.

Wang and Huang (1998) experimentally discussed the deformation and failure characteristics of rocks and their rock burst effects under different unloading rates. Xiao and Pan (2005) used rosin to simulate similar materials in experimental research and proposed a rock burst stiffness formula. Wang et al. (1998), Qian (2014), He et al. (2007), Wu et al. (2019), and Peng et al. (2014) carried out research on the prediction of rock bursts through quantitative calculations, numerical simulations, fuzzy mathematics, and acoustic emissions. Ahmad et al. (2021) used J48 and random forest algorithms to predict the risk of rock burst based on multiple engineering examples and made comparisons with other algorithms. They concluded that the random forest algorithm is more accurate than the empirical models (J48 and the artificial network method). Adoko et al. (2013) studied 174 rock bursts and predicted rock bursts with five different models based on the fuzzy inference system and adaptive neuro-fuzzy inference system, and concluded that the results of the adaptive neuro-fuzzy inference system model were more accurate. Gong et al. (2020) compared 20 rock burst proneness criteria with laboratory tests and concluded that using the residual elasticity index as the rock burst proneness criterion is more reasonable and accurate.

However, we suggest that there are still some shortcomings in existing theories that need to be further studied. Previous research focused on the occurrence mechanism of two types of geological disasters, but rarely considered the coupling effect with other disasters in the complex geological environment, which often increases the risk of disasters and deviates greatly from the prediction results in practical engineering. Therefore, combined with existing research, this study evaluated, analyzed, and predicted the high ground stress problem of the YL tunnel, put forward construction suggestions and prevention measures, and conducted a qualitative analysis of the amplification effect of various disasters in the aforementioned environment. Based on global research, this study investigated the difficulties resulting from high ground stress in the YL Tunnel and put forward suggestions for preventing rock bursts and other geohazards encountered during construction.

Methods

Overview of the Project

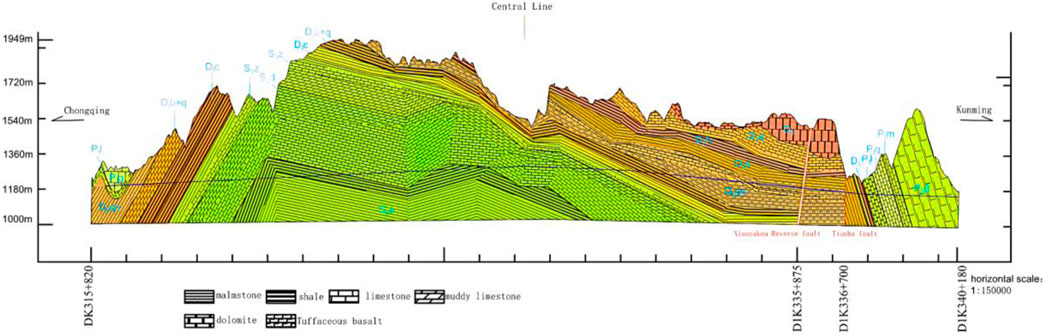

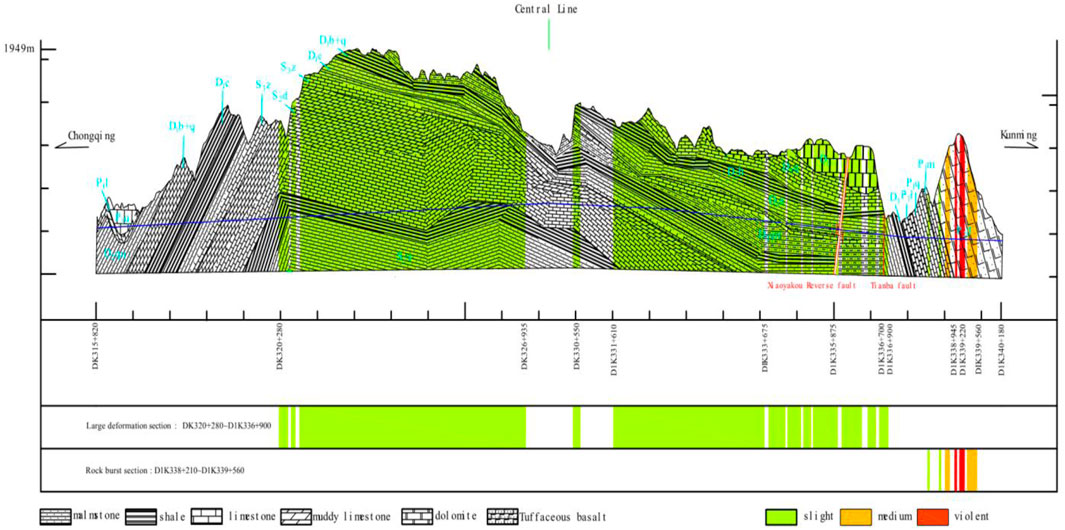

The YU–KUN high-speed railway begins at the Chongqing West railway station, runs through Chongqing, Sichuan, Guizhou, and Yunnan, and ends at the Kunming South railway station. The YL Tunnel is in the Yunnan section of the railway line and has a total length of 24,367 m and a maximum buried depth of approximately 908 m. The tunnel crosses mainly the Silurian, Devonian, Carboniferous, Permian, and overlying Quaternary Holocene strata. Various types of rock can be found in the tunnel area, including sandstone, mudstone, shale, marl, limestone, and dolomite, with marl and coal lines in between. According to the plate structure, the tunnel is in the Yangtze sub-plate of the primary geotectonic unit, bordered by the Xiaojiang fault, and the railway line crosses the East Yunnan fold belt of the Yangtze sub-plate and Kangdian paleo-uplift. The area is dominated by “duo”-shaped structural traces, anisotropy extends in the N 40°–60° E direction, and the fold axis planes all slant northwest. The tunnel first passes through the Longchi anticline, and then the Chalu syncline, the Tianba fault, and finally the Xiaoyakou reverse fault (Figure 1).

The tunnel passes through the stratum (P1L) of the Liangshan Formation and contains a layer of lenticular and bead-shaped coal with large and unstable thickness variations (generally ranging from 0.2 to 3 m).

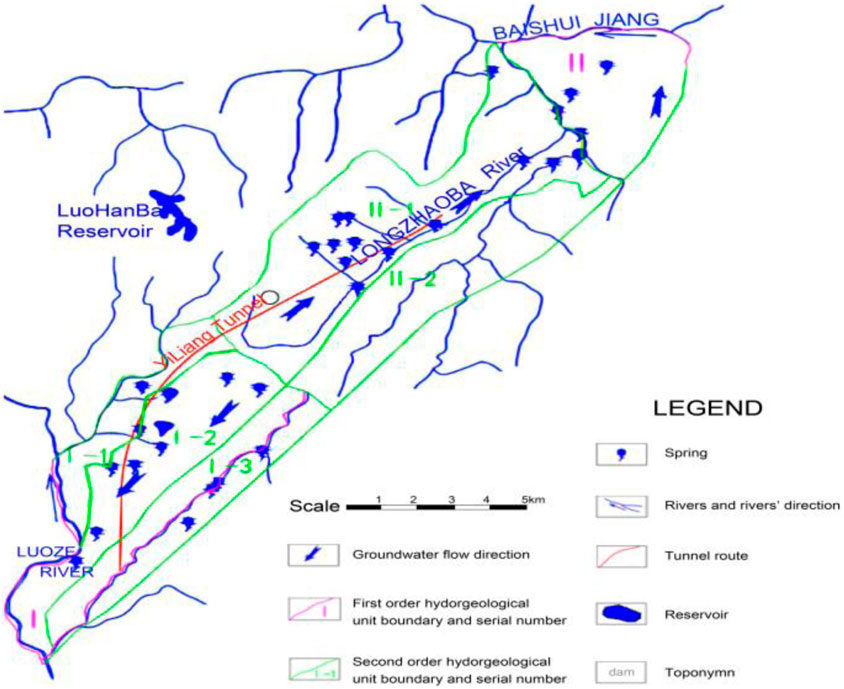

The groundwater system is well developed in the tunnel area and mainly includes pore water, bedrock fissure water, and karst water. According to the hydrogeological unit division map, the YL tunnel traverses are the Luoze River hydrogeological unit (I) and the secondary Liangshuijing–Wangxiangtai hydrogeological unit (Ⅱ-1). In both units, the tunnel body passes through the vertical seepage zone to the seasonal variation zone with high water pressure and medium/strong karst development (Figure 2).

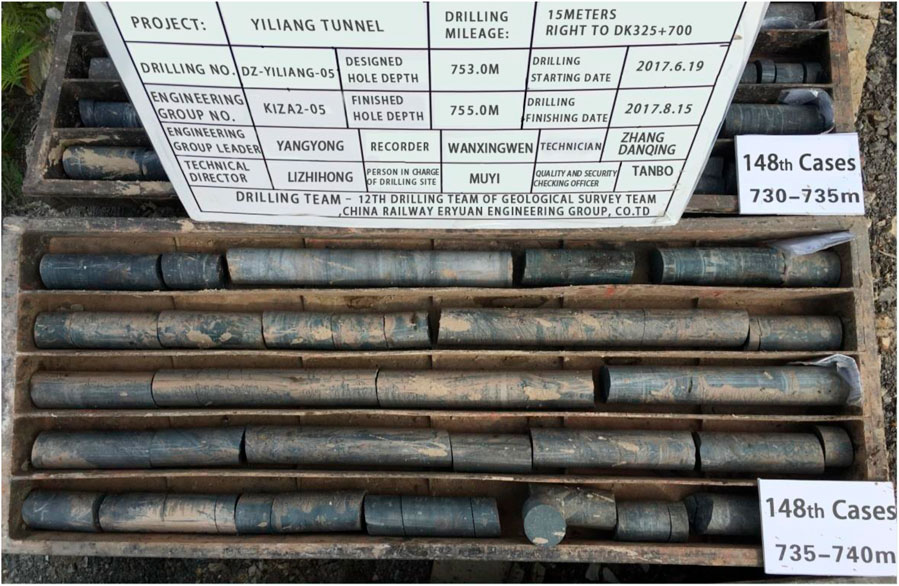

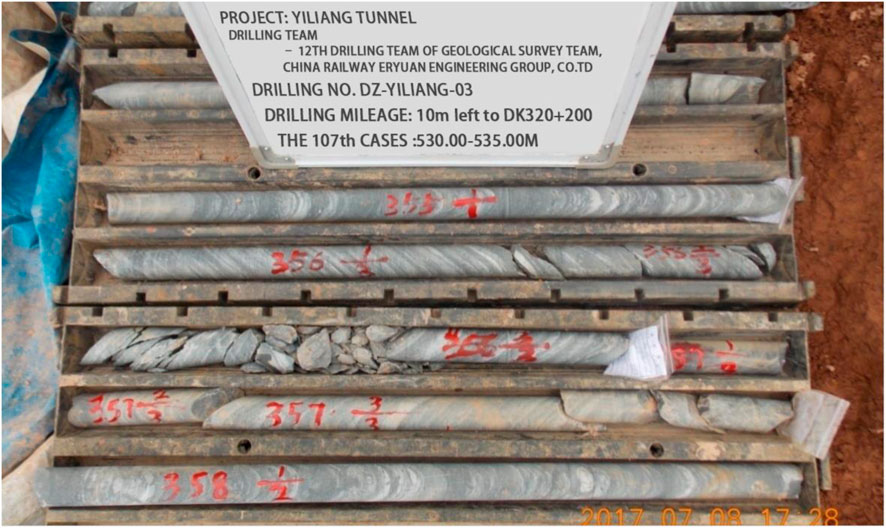

Engineering geological problems in the tunnel site area include karst, rock burst, large deformation of soft rock, bedding bias, high ground temperature, toxic and harmful gases, and rock piles. Damage to the tunnel caused by high ground stress is particularly prominent (Figures 3, 4).

Results

Ground Stress Test

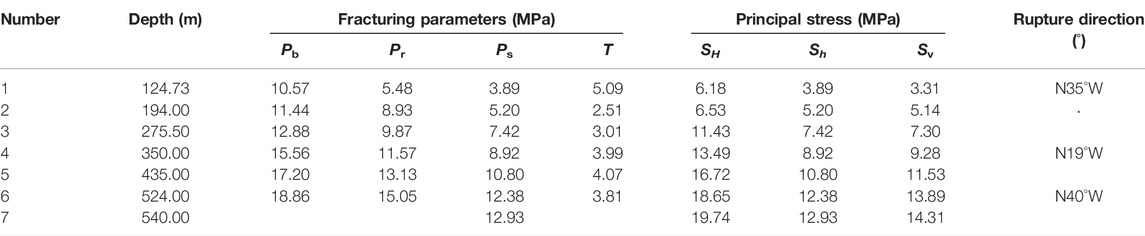

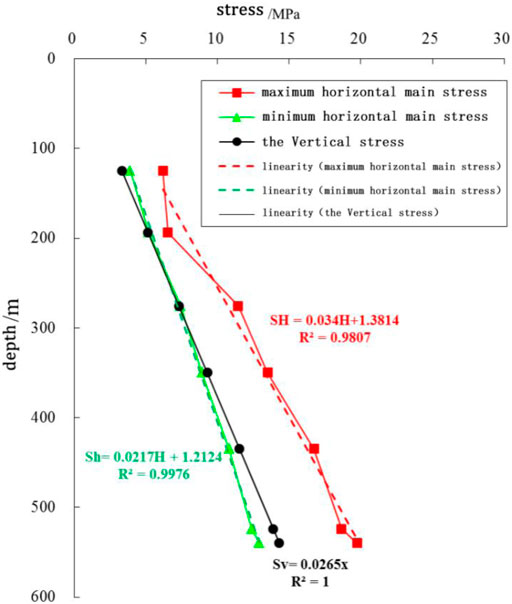

1) Based on the measurements of borehole DZ-YL-03, it can be inferred that the maximum horizontal principal stress near the hole (540 m) was approximately 19.74 MPa, the minimum principal stress was approximately 12.93 MPa, and the vertical stress was 14.31 MPa. The overall distribution range of the principal stress direction was near N32°W, and the dominant direction of the principal stress was within the proximity of NNW, which is consistent with the direction of the regional tectonic stress field (Table 1; Figure 5).

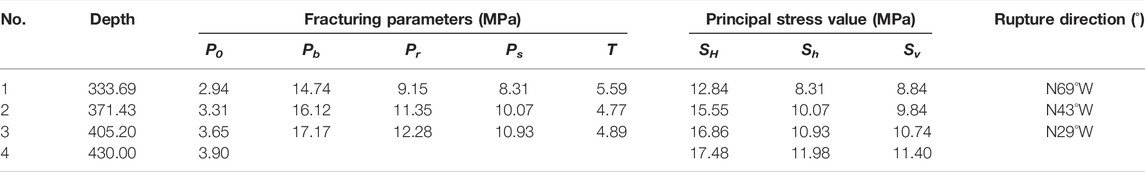

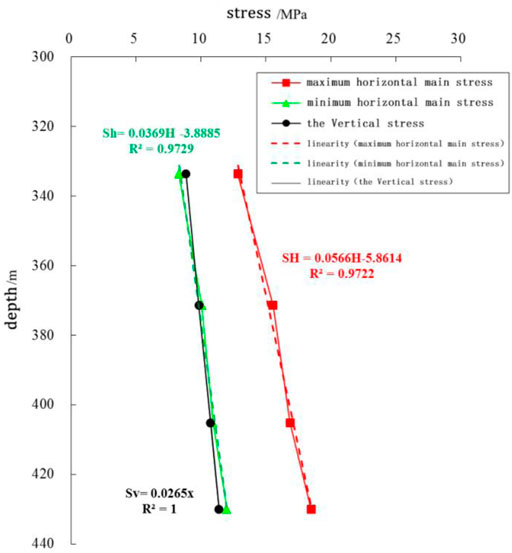

2) According to the measurement results of borehole DZ-YL-08, the maximum horizontal principal stress at the buried depth of the 430 m tunnel was 17.48 MPa, the minimum horizontal principal stress was 11.98 MPa, and the vertical stress was 11.40 MPa. The maximum horizontal principal stress direction near the cave body was N31°W, and the dominant direction was NNW (Table 2; Figure 6).

Problems and Countermeasures

Predicting Large Deformation of Soft Rock and Countermeasures

In areas where the surrounding rocks are weak, fractured, or of high horizontal stress, an engineering disaster that frequently occurs during construction is surrounding rock invading the tunnel, which is due to large and long-lasting surrounding rock deformation. The geological conditions in this area are complex and folds are well developed. The main soft rocks are shale, carbonaceous shale, mudstone, and coal seams, which are the basic conditions for large deformation. According to the test results and theoretical analysis of Anderson’s fault theory, the type of stress field near the test area was S_H > S_h > SV. The tectonic stress was dominant, and the maximum horizontal principal stress was the maximum principal stress, which indicated that at the test depth, the stress field was dominated by horizontal principal stress, which was beneficial to the development and activity of thrust faults, and was a favorable condition for the formation of large deformations of soft rock.

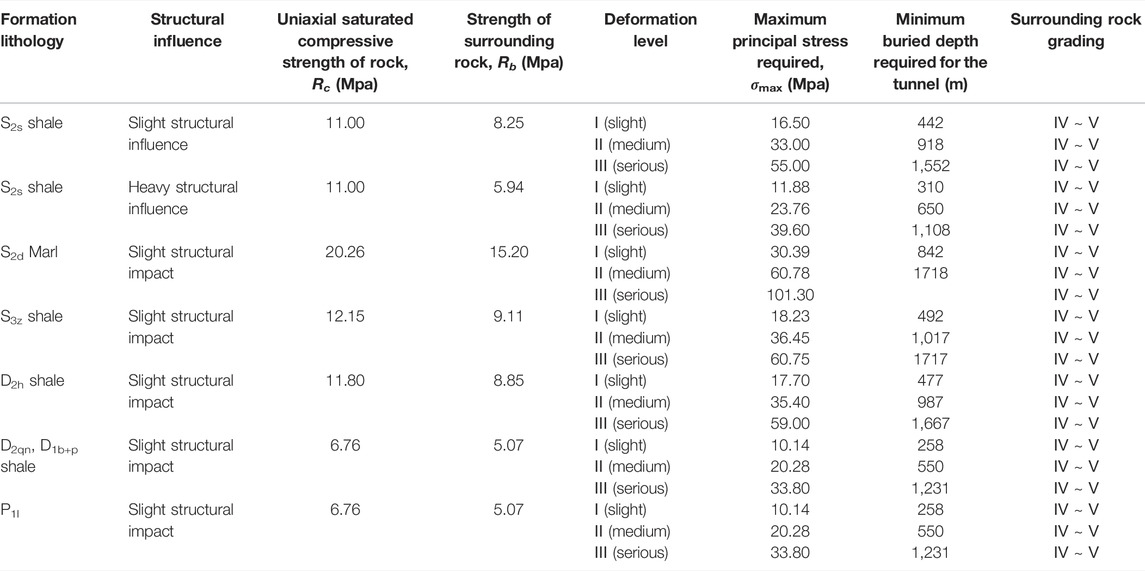

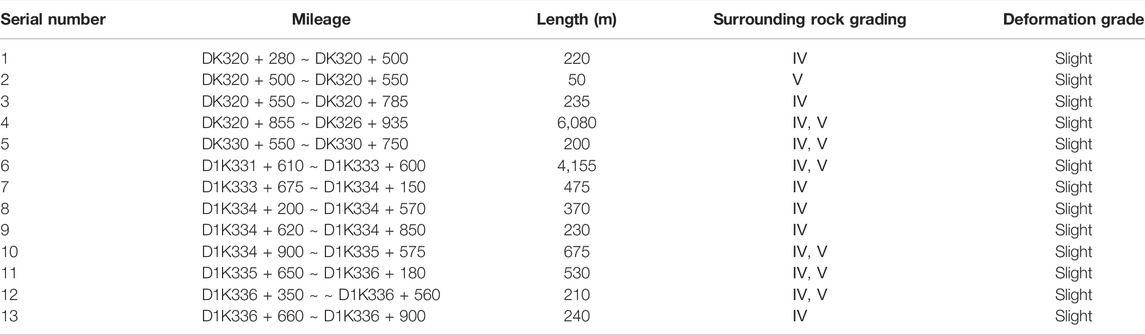

Table 3 is based on the linear relationship between the crustal stress and the burial depth in the ground stress results of hole DZ-YL-03, and the interpolation method. It indicates the burial depth required for the large deformation of soft rock in various stratum lithologies. Table 4 (based on Table 3) indicates a list of large deformation sections in the soft rock in the YL tunnel and shows areas in the tunnel prone to large deformation.

According to Tao et al. (2006) and Mei et al. (2014), at present, tunnels that have suffered serious damage from the deformation of soft rock in China are located on the Lanzhou–Xinjiang and Chengdu–Lanzhou railway lines. For a soft rock tunnel with large deformation, the cross-sectional shape should be optimized, an oval or nearly circular inner profile can be adopted, and a certain reasonable amount of deformation should be left around to release the ground stress to prevent the invasion of the second lining clearance after the initial support deformation. From the experience of the Chengdu–Lanzhou railway line, the steel frame should be delaminated and applied step by step during construction (Li and Tan, 2018). Second, it is necessary to strengthen the initial support, timely lining, combined with prestressed anchor and steel mesh to form a prestressed protection system. This would improve the uneven support and limit the deterioration of the surrounding rock. U-shaped steel arch frames could be used for ultra-deep and high ground stress tunnels to give full play to its advantages of high bearing capacity and good shaping (Li, et al., 2016). Construction should achieve short excavation and strong support, reduce the disturbance to the surrounding rock during construction, strictly control the excavation length, pre-support the weak surrounding rock, insert the grouting bolt, and strengthen the broken surrounding rock.

Predicting Rock Burst and Countermeasures

Rock burst refers to rock that lies in high crustal stress, being affected by tunnel excavation or similar activities, and is ejected from the parent rock in a violent manner because the strong excavation on the rock surface changes its original limit equilibrium. Rock bursts usually occur where crustal stress is high and rocks are hard, following which the construction environment worsens; it affects the whole tunnel construction and severely hazards construction staff as well as equipment. The main hard rocks in this section include limestone and basalt, which are the primary influences for rock bursts.

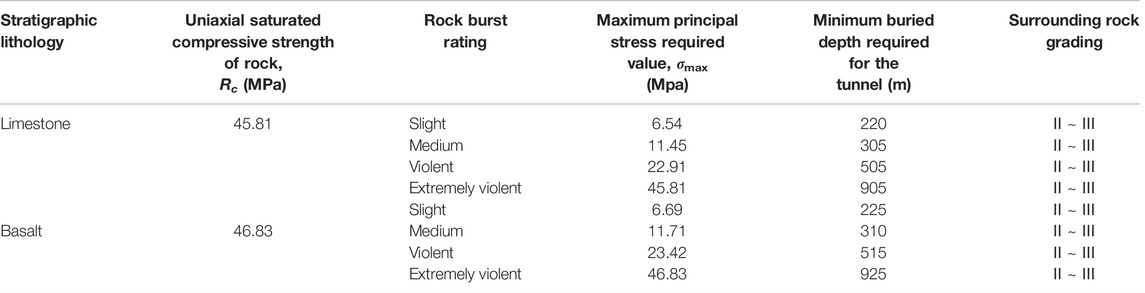

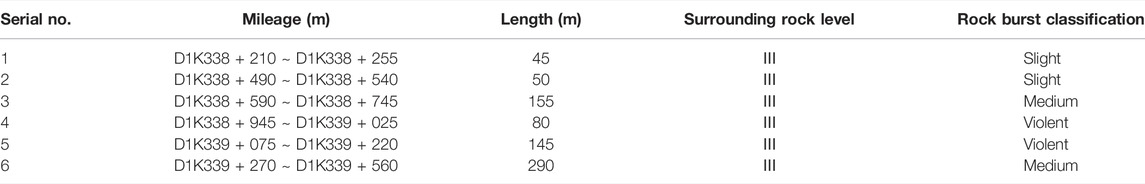

According to the Chinese Tunnel Design Code regarding the classification of high crustal stress, rock bursts may occur when a tunnel is buried in limestone and basalt sections with a buried depth greater than 220 and 225 m, respectively. According to the linear relationship between ground stress and burial depth in the ground stress results of hole DZ-YL-08, the burial depth required for rock bursts occurring in different types of rock was obtained by the interpolation method, as shown in Table 5.

According to Table 5, when the tunnel buried depth was greater than 220 m in limestone and 225 m in the basalt section, there was a possibility of rock burst (Table 6).

The main approaches to rock burst prevention and control are divided into three types: “release,” “protection,” and “early warning.” Priority is given to active protection, supplemented by passive protection.

The main purpose of the release would be to change the surrounding rock conditions. For this project, the water gun should be used to spray water on the tunnel face and around the tunnel wall timeously after excavation to reduce rock mass temperature, wet the rock mass, improve the rock mass shaping, slow release the surrounding rock pressure, and reduce the intensity of the rock burst. At the same time, deep-hole pre-splitting blasting should be used to destroy the integrity and continuity of hard rock strata with many cracks to relieve stress. Especially during rock burst section excavation, it would be necessary to manually break the roof, induce roof caving, reduce the impact strength of the roof, and slow down the generation of high stress and accumulation of high elastic energy.

Protection would mainly be through bolt, steel mesh, shotcrete, and other methods to ensure initial support. This type of anchor should not only meet strength requirements but also meet deformation capacity. At present, energy-absorbing anchors such as conical bolts and D-bolts are widely used in tunnel excavation, and rigid anchors are still needed when excavating high-ground stress tunnels with poor geological conditions. Recently, a type of deformation control bolt has emerged, which can reduce the failure difficulty of bolts under large deformations. There is a theory of overall protection, that is, energy absorption support devices, which can solve the problems of large deformation, rock burst, and roof fall of large surrounding rocks, but there are few examples of expensive applications.

Thus far, rock burst prediction remains a difficult task. The acoustic emission prediction method is commonly used in engineering to detect the elastic waves produced by rock deformation or fracture, and the far-infrared technique is used to observe the abnormal temperature changes around the surrounding rock to judge the rock fracture process. Early warning should be combined with geological data, in situ stress data, and field test results in order to obtain relatively accurate prediction results (Figure 7).

Discussion

With social development and economic growth, ultra-long deep tunnels such as the YL Tunnel are being increasingly needed, but this also means that there are an increasing number of engineering geological problems (Zhu et al., 2019). The main problems caused by the high ground stress in the YL Tunnel included the large deformation of soft rock and rock bursts. The current and commonly used method to predict hazards caused by high ground stress is to measure the initial ground stress, and interpret the results comprehensively in accordance with hydraulic fracturing, the stress-relief method, and the stress-recovery method.

However, an increasing number of engineering accidents in construction show that obvious discrepancies exist between predictions and actual measurements. To uncover the reasons behind this, this study conducted an analysis from two aspects. First, when making predictions, disturbances in the surrounding rock were not considered. For example, in complex structural areas, the surrounding rock itself stores considerable elastic potential owing to the multistage geological tectonic stress field. When the tunnel is excavated at this point, the surrounding rock disturbance causes the deformation energy to be released to the empty surface, resulting in engineering hazards. Especially in soft rock areas where rocks are weak and cracks develop, any water adsorption causes expansion and therefore determines its poor anti-disturbance ability. The rock in this area is extremely sensitive to construction disturbances, such as blasting and excavation, and is prone to engineering problems beyond prediction. Second, the amplification effects caused by the coupling of geohazards were not considered because the engineering geological conditions of the tunnel site were not determined by a single condition, and the problems generated under multiple geological conditions were often more complicated. Such tunnels not only face unusually complex structural, high ground stress, and, active fracture issues, but also more complex engineering hazards caused by the coupling of multiple engineering geological issues.

The abovementioned geological conditions also make it difficult to make risk predictions in the tunnel, resulting in obvious discrepancies between predictions based on measurements as well as experiments and actual construction. The coupling effect between different hazards often has an amplification effect, leading to more serious geological engineering problems. As for the YL Tunnel, the possible amplified hazards may include coupling among large deformations, groundwater, and harmful gases caused by high ground stress.

The coupling amplification effect of different hazards is not discussed in this study but will be the focus of future research. This study only discusses similar problems that this type of tunnel may encounter.

Large Deformation of Soft Rock Under Complex Geological Environment

High ground stress is related to the strength of the surrounding rock. In other words, when the ratio of the maximum ground stress inside the surrounding rock to the strength of the surrounding rock reaches a certain level, large deformation of the soft rock may occur. Therefore, the deeper the tunnel is buried does not necessarily mean a higher possibility of large deformation of the soft rock. Conversely, when the burial depth is shallow, large deformation of the soft rock may occur when the strength of the surrounding rock is very low. Carbonaceous shale, mudstone, shale, and other weak rock formations in the YL Tunnel are widely distributed, the horizontal stress in the tunnel is relatively high, and groundwater is abundant. Under these circumstances, the self-carrying capacity of soft rocks is likely to be reduced, resulting in deformation when the carrying capacity is reduced to a certain level. This study concluded that large deformations could occur mainly based on geological conditions, rock mechanical properties, structural conditions, and ground stress measurements. However, when passing through a fracture zone or a section with rich groundwater, the conditions for changing the sections of the surrounding rock are more complex. For example, basalt rock sandwiched between thin-layered and lenticular tuff is relatively soft, and it is easy to soften into plastic clay after being exposed to water or soaked in water. The engineering hazards caused by this will inevitably be unexpected.

Poisonous and Harmful Gases Under Large Deformation Conditions

There are many pores and fissures in a natural rock mass, which divide the rock mass into anisotropic discontinuous porous media. These fissures not only affect the mechanical properties of the rock mass itself but also provide a place for gas and groundwater seepage. When a large deformation disaster of soft rock occurs, the mechanical properties of the rock mass will change, and at the same time, the permeability characteristics and seepage field of the surrounding rock will change, which will aggravate the escape of harmful gases.

Conclusion

Engineering geological problems in the YL Tunnel of the Chongqing–Kunming high-speed railway include karst, rock burst, large deformation of soft rock, bedding bias, high ground temperature, toxic and harmful gases, and rock piles. Among these, the tunnel damage caused by high ground stress is particularly prominent.

Based on field surveys, spot and indoor tests, engineering geology profiles, hydrogeological data, and ground stress data, the high-risk sections of the tunnel prone to large deformations of soft rock and rock bursts were predicted accordingly. The following areas were most prone to rock burst: D1K338 + 945–D1K339 + 025, D1K339 + 075–D1K339 + 220. The prevention and countermeasures were presented in this study. We present relevant prevention measures and construction suggestions. The tunnel body passes through the vertical seepage zone to the seasonal variation zone, with medium to strong karst development and high water inrush risks. In addition, there is a risk of gas diffusion when the tunnel body passes through coal-bearing strata.

The coupling of multiple undesirable geological processes often has an amplifying effect and is typically uncertain, irregular, and unpredictable. Obvious discrepancies exist between predictions and actual measurements in similar sections of tunnel construction. When constructing ultra-long and deep tunnels, such as the YL Tunnel, special attention should be paid to the coupling of multiple undesirable geological effects. To prevent hazards from occurring, a detailed analysis should be conducted based on geological data, and any risks should be predicted and monitored in advance.

Data Availability Statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author Contributions

YL and YZ: conceptualization, formal analysis, and data curation; PS: writing—review and editing; YL: writing—original draft preparation; GZ, PQ, and LT: methodology. All authors have read and agreed to the published version of the manuscript.

Funding

The work was financially supported by the Science and Research Project of China Railway Eryuan Engineering Group Co., Ltd. [Grant No.: Kan-20-ChengYu-03 (081)] and the Open Experiment Fund of Southwest Petroleum University (Grant No.: 2020KSZ02009).

Conflict of Interest

GZ and LT were employed by the company China Railway Eryuan Engineering Group Co., Ltd.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s Note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors, and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Adoko, A. C., Gokceoglu, C., Wu, L., and Zuo, Q. J. (2013). Knowledge-based and Data-Driven Fuzzy Modeling for Rockburst Prediction. Int. J. Rock Mech. Min. Sci. 61, 86–95. doi:10.1016/j.ijrmms.2013.02.010

Ahmad, M., Hu, J.-L., Hadzima-Nyarko, M., Ahmad, F., Tang, X.-W., Rahman, Z. U., et al. (2021). Rockburst Hazard Prediction in Underground Projects Using Two Intelligent Classification Techniques: A Comparative Study. Symmetry 13 (4), 632. doi:10.3390/sym13040632

Anagnostou, G. (1993). A Model for Swelling Rock in Tunnelling. Rock Mech. Rock Engng 26 (4), 307–331. doi:10.1007/bf01027115

Aydan, Ö., Akagi, T., and Kawamoto, T. (1993). The Squeezing Potential of Rocks Around Tunnels; Theory and Prediction. Rock Mech. Rock Engng 26, 137–163. doi:10.1007/bf01023620

Brox, D., and Hagedorn, H. (1999). Extreme Deformation and Damage during the Construction of Large Tunnels. Tunn. Undergr. Space Technol. 14 (1), 23–28. doi:10.1016/S0886-7798(99)00010-3

Gong, F.-q., Wang, Y.-l., and Luo, S. (2020). Rockburst Proneness Criteria for Rock Materials: Review and New Insights. J. Cent. South Univ. 27 (10), 2793–2821. doi:10.1007/s11771-020-4511-y

He, M. C., Miao, J. L., Li, D. J., and Wang, C. G. (2007). Experimental Study on Rockburst Process of Deep Granite Samples. Chin. J. Rock Mech. Eng. 5, 865–876. doi:10.3321/j.issn:1000-6915.2007.05.001

Kovačević, M. S., Bačić, M., Gavin, K., and Stipanović, I. (2021). Assessment of Long-Term Deformation of a Tunnel in Soft Rock by Utilizing Particle Swarm Optimized Neural Network. Tunn. Undergr. Space Technol. 110, 103838. doi:10.1016/j.tust.2021.103838

Li, G. L., Liu, Z. C., and Zhu, Y. Q. (2015). Study on the Law of Large Compression Deformation and Classification Standard of High In-Situ Stress Soft Rock Tunnels on Lanyu Railway. Mod. Tunn. Technol. 52 (01), 62–68. doi:10.13807/j.cnki.mtt.2015.01.009

Li, L., and Tan, Z. S. (2018). Characteristic and Mechanism Research for Large Deformation Problem in Squeezing-Shattered Soft Rock Tunnel. Chin. J. Rock Mech. Eng. 37 (S1), 3593–3603. doi:10.13722/j.cnki.jrme.2017.0050

Li, L., Tan, Z. S., Yu, Y., Jiang, B., and ang Zhang, M. J. (2017). Experimental Study on Primary Lining Form of Tunnels in Phyllite on Chengdu-Lanzhou Railway. China Civ. Eng. J. 50 (S1), 19–24. doi:10.15951/j.tmgcxb.2017.s1.004

Li, S. C., Wang, X., Wang, Q., Li, W. T., Wang, F. Q., and Yang, W. M. (2016). Mechanical Property Research and Failure Characteristics of U-type Confined Concrete Arch in Deep Roadway. Eng. Mech. 33 (01), 178–187. doi:10.6052/j.issn.1000-4750.2014.07.0630

Li, T. C. (2011). Construction Control Technology for High Ground Stress Soft Rock and Large Deformation of Maoyushan Tunnel. Mod. Tunn. Technol. 48 (02), 59–67. doi:10.13807/j.cnki.mtt.2011.02.014

Liu, R. (2020). Research on Control Method of Pollutant Total Amount of Water Quality Based on Fuzzy Mathematics. Earth Sci. Res. J. 24, 191–199. doi:10.15446/esrj.v24n2.87248

Mei, Z. R., Li, C. F., Zhang, J. W., and Du, J. (2014). “Large Deformation Mechanism and Control Technology of High Ground Stress Soft Rock Tunnel on Cheng-Lan RailwayTunnel and Underground Engineering Branch of china Civil Engineering Society,” in 2014 China Tunnel and Underground Engineering Conference (CTUC) and Proceedings of the 18th Annual Conference of Tunnel and Underground Engineering Branch of China Civil Engineering Society (Hangzhou: China Civil Engineering Society), 15–23.

Peng, Y. H., Peng, K., Zhou, J., and Liu, Z. X. (2014). Prediction of Classification of Rock Burst Risk Based on Genetic Algorithms with SVM. Amm 628, 383–389. doi:10.4028/www.scientific.net/amm.628.383

Qian, Q. H. (2014). Definition, Mechanism, Classification and Quantitative Forecast Model for Rockburst and Pressure Bump. Rock Soil Mech. 35 (01), 1–6. doi:10.16285/j.rsm.2014.01.028

Sun, X. M., Zhang, B., Zhang, Y., Qiao, X. B., Wang, Z. J., and Tao, Z. G. (2020). Field Tests and Research of Large Deformation Control Measures for Soft Rock Tunnel with High Geostress. IOP Conf. Ser. Earth Environ. Sci. 570 (4), 042006. doi:10.1088/1755-1315/570/4/042006

Tan, T., and Wen, X, M. (1983). Swelling Rocks and Stability of Tunnels. Chin. J. Rock Mech. Eng. 2 (1), 1–10.

Tao, B., Wu, F. Q., Guo, Q. L., Guo, G. M., and Yang, X. Y. (2006). Research on Rheological Law of Weak Surrounding Rock of Wushaoling Deep-Buried Long Tunnel under High Ground Stress Environment. Chin. J. Rock Mech. Eng. (09), 1828–1834. doi:10.3321/j.issn:1000-6915.2006.09.014

Wang, S., Wang, X., Chen, M., Xie, W., Zhang, Z., and Yang, L. (2020). Shear Damage Mechanism and Early Warning Study of Shale Standard Layer Casing. Earth Sci. Res. J. 24, 225–229. doi:10.15446/esrj.v24n2.87932

Wang, X. N., and Huang, R. Q. (1998). Rock Unloading Failure Characteristics and Rockburst Effect. Mt. Res. 16 (04), 281–285.

Wang, Y. H., Li, W. D., Li, Q. G., Xu, Y., and Tan, G. H. (1998). Comprehensive Evaluation Method of Fuzzy Mathematics for Rockburst Prediction. Chin. J. Rock Mech. Eng. 05, 15–23. doi:10.3321/j.issn:1000-6915.1998.05.003

Wu, S., Wu, Z., and Zhang, C. (2019). Rock Burst Prediction Probability Model Based on Case Analysis. Tunn. Undergr. Space Technol. 93, 103069. doi:10.1016/j.tust.2019.103069

Xiao, X, C., and Pan, Y, S. (2005). Mathematical Model and Numerical Simulation of Coal-Bed Methane Percolation Flow Equation Considering Slippage Effects. Chin. J. Rock Mech. Eng. 24 (16), 2966–2970. doi:10.3321/j.issn:1000-6915.2005.16.026

Zhao, Y., Liu, J. Y., and Tian, S. M. (2011). Experimental Study on the Mechanical Characteristics of the Support System of Deep-Buried Tunnels with Weak Surrounding Rocks. Chin. J. Rock Mech. Eng. 30 (08), 1663–1670.

Zhu, H. H., Yan, J. X., and Liang, W. H. (2019). Challenges and Development Prospects of Super-long and Ultra-deep Mountain Tunnels. Engineering-London 5 (03), 76–95. doi:10.1016/j.eng.2019.04.009

Keywords: geohazards, ground stress, geologic problems, deep-buried tunnels, prevention measures

Citation: Liu Y, Zhang Y, Su P, Zhang G, Qiu P and Tang L (2022) Risk Prediction of Rock Bursts and Large Deformations in YL Tunnel of the Chongqing–Kunming High-Speed Railway. Front. Earth Sci. 10:892606. doi: 10.3389/feart.2022.892606

Received: 09 March 2022; Accepted: 30 May 2022;

Published: 06 July 2022.

Edited by:

Chong Xu, Ministry of Emergency Management, ChinaReviewed by:

Aiguo Xing, Shanghai Jiao Tong University, ChinaMing Zhang, China University of Geosciences Wuhan, China

Copyright © 2022 Liu, Zhang, Su, Zhang, Qiu and Tang. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Peidong Su, bGx1d3hsQDEyNi5jb20=

Yuxuan Liu1

Yuxuan Liu1 Peidong Su

Peidong Su