- 1School of Civil and Hydraulic Engineering, Huazhong University of Science and Technology, Wuhan, China

- 2CNPC Research Institute of Safety and Environment Technology, Beijing, China

- 3CNPC Jinzhou Petrochemical Company, Liaoning, China

A major safety accident will be triggered when the A-annular pressure value of high pressure, high productivity and high sulfur gas well exceeded the maximum allowable value. The A-annular pressure value of high pressure high productivity and high sulfur gas well once exceeded the allowable value will trigger a major safety accident. Therefore, this paper proposed a data mining based the gas well early warning strategy by analyzing the annular pressure mechanism and the change in the pattern of instantaneous gas volume, well temperature, and annular pressure in various conditions. To summarize, the law of gas well abnormal A-annular pressure is aimed at constructing a gas well safety warning rule for gas well stable production stage and shutdown period where the initial parameters setting in the early warning rule and adjustment optimization mechanism is also determined. Lastly, with the use of historical abnormal samples, the gas well early warning strategy bought up in this paper was verified. The example shown that compared with the traditional DCS system warning strategy, the gas well safety early warning strategy can identify the abnormal A-annular pressure phenomenon 82 h in advance thus achieving production safety management.

1 Introduction

On 20 April 2010, an oil rig exploded and caught fire off the coast of Louisiana, killing 11 people and becoming the worst Marine oil spill in U.S. history, commonly known as the Deepwater Horizon Accident (Bly, 2011). As a result, the well integrity of gas Wells has been paid close attention in the development of high temperature, high pressure and high sulfur gas fields at home and abroad. These gas felds are characterized by high pressure (HP), high temperature (HT), high hydrogen sulfde (HHS) content, complex geological condition, water production and densely populated area. They are typical “three-high” gas wells (Cao et al., 2020; Wang et al., 2020; Pu, 2022) which are satisfied with the following three conditions including 1) Reservoir pore fluid pressure is not less than 70 MPa; 2) Reservoir temperature is not less than 150°C; 3) The percentage of H2S in reservoir is not less than 30 g/m3.” The working condition of gas wells has become increasingly harsh and the wellbore integrity of three-height gas wells is particularly prominent while the deepening of oil and gas exploration and development in China (Yu et al., 2018). Once the wellbore safety barrier of “three-high gas well” is damaged, formation fluid leakage, blowout and other events may be induced, which is easy to cause group death and group injury (Zhang X. et al., 2018; Zhang et al., 2019a; Yu et al., 2022). For example, in the deepwater oil and gas well Marlin A2 in the Gulf of Mexico, the production casing was seriously deformed and the tubing was destroyed (Bradford et al., 2004). At present, the cementing quality of deep gas wells in China is generally poor, and the annular pressure after cementing is prominent, which brings great safety risks to the development of gas fields. The existing pressure between gas well ring annular pressure anomaly is a sign of wellbore safety barrier damage. In order to guarantee the safety and efficient development of gas field and give early warning at the beginning of wellbore safety barrier damage, making full use of information technology for real-time monitoring and tracking the change trend of production parameters, mining the symptom of shaft safety barrier damage are of great significance to prevent the risk of fluid leakage, gas channeling and blowout.

In recent years, the intrinsic safety of the wellbore safety barrier has been given a lot of importance. To summarize, there are four methods used to detect if there are abnormalities in the annular pressure locally and abroad (Kazemi and Wojtanowicz, 2014; Zhang et al., 2019b; Zhang et al., 2022). These include fluid sample analysis, well logging analysis, pressure relief and pressure recovery characteristics, and distributed control system (also known as “DCS”). These four analytical methods can reliably detect the abnormal annular pressure phenomenon with certain deficiencies. Among them, fluid sample analysis, well logging, and annular pressure relief and pressure recovery tests are all offline analysis, which are difficult to detect abnormal annular pressure in real time. The DCS system could monitor the annular pressure state in real time by setting the annular pressure threshold, which is usually set to 80% of its allowable pressure capacity (Lili et al., 2013). In order to realize online monitoring of abnormal annular pressure, many scholars have conducted a series of simulation studies based on the monitoring of annular pressure by DCS system. Kenneth simulated the process changes of annulus pressure anomalies on the basis of the temperature and density of gases inside the annulus (Kenneth and Robert, 2018). According to the structural characteristics of well-bore, Yan et al. (2019) modified the UGS mechanics research method based on the two-fluid model. Yang et al. (2020) analyzed the variation of annular band pressure under annulus loss and eccentric annulus, and established the transient heat transfer model and fluid flow model. Although the research on the abnormal annular pressure constantly deepen, due to the complexity of the internal wellbore environment, It is not accurate to diagnose the abnormal annular pressure by relying on a single index. In view of these shortcomings, this paper proposes a dynamic early warning strategy for gas well production and operation safety based on multiple production parameters which aims to timely detect the damage events of well-bore safety barrier and move the safety management pass forward.

Most of the oil and gas wells outside the American continental shelf have existing A-annular pressure phenomenon. There are 11,498 annular pressure casing section in 8,122 wells (Zhang B. et al., 2018), and that 50% occurs in the A-annular located below the ring space that is between the production casing and the oil pipe. Therefore, this paper mainly focuses on conducting dynamic early warning research surrounding abnormal A-annular pressure. Firstly, the evolution of A-annular pressure when the well barrier is damaged was analyzed and represented. Secondly, early warning rules for abnormal A-annular pressure were constructed. At last, early warning strategy was verified using abnormal samples. The verification result shows that the early warning strategy proposed in this paper can act as a safety precaution.

2 Analysis of rules related to abnormal A-annular pressure

2.1 A-annular pressure mechanism

A-annular pressure has three origins (Bradford et al., 2004; Tao et al., 2011; Zeng et al., 2019; Zhang et al., 2021): 1.) Annular pressure caused by thermal effect in the wellbore. 2.) A-annular pressure caused by oil pipe or wellhead leakage. 3.) Annular pressure caused by sealing failure of the production casing. Among these, annular pressure caused by wellbore “physical reaction” which indicates that while the gas volume continuously increases, the temperature of the wellbore will also continuously increase. This results in that the annular pressure caused by thermal expansion is defined as normal. Whereas, annular pressure caused by oil pipe or casing leakage, unqualified cementing quality and cement ring damage are referred to as abnormal. That is, annular pressure is caused by the damage to the wellbore safety barrier.

2.2 Variation law of production parameters under different working conditions

The ring is regarded as a closed annulus, and the derivation process is as follows: At a certain depth, the pressure of a fluid or gas column enclosed in the annulus depends on the average temperature of the annulus, the volume of the closed annulus and the mass of the closed fluid or gas, and the pressure of the closed annulus is a function of them:

Where,

P is the air pressure of the ring in Mpa; T is the average temperature of the ring space in k; Vann refers to the volume of the closed annulus in m3. m is the mass of the fluid in the closed annulus in kg. By partial differentiation of the above equation, the expression of pressure change in closed annulus can be obtained as follows:

Where,

Eq. 2 shows that the thermal expansion of the fluid in the annulus, the change of the volume of the annulus and the change of the mass of the fluid in the annulus will affect the annulus pressure. For the closed annulus, ∆m = 0, the pressure of the closed annulus can be calculated as follows:

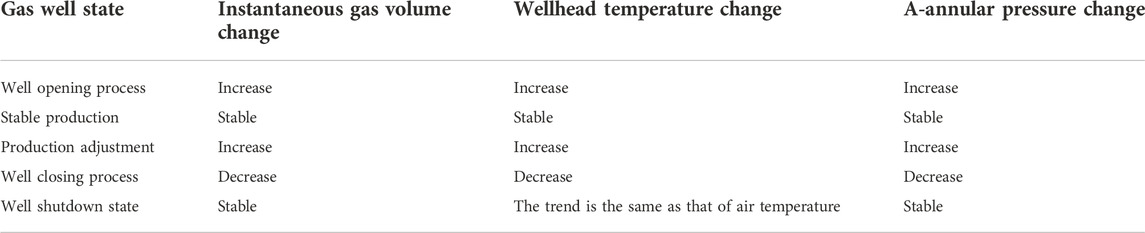

The change in parameter under the different working conditions when A-annular pressure is normal serves as a prerequisite to identify abnormal pressure phenomena. Based on the above theoretical derivation, the law of change with regards to instantaneous gas volume, wellhead temperature, and A-annular pressure in the five kind of states (well opening process, stable production, production adjustment, well closing process, well shutdown mode) (Kenneth and Robert, 2018; Yan et al., 2019; Yang et al., 2020) is listed as follows while the gas well is under normal pressure, as shown in Table 1.

The quantitative relationship between instantaneous gas volume, wellhead temperature, and A-annular pressure is not clear in the three states of well opening process, stable production, and well closing process. Thus, it is difficult to quantitatively describe the law about A-annular abnormalities in these three states. In order to guarantee a high accuracy rate, A-annular pressure research is only executed when the instantaneous gas volume and wellhead temperature are in a stable state.

3 Early warning methodology

3.1 Early warning rules

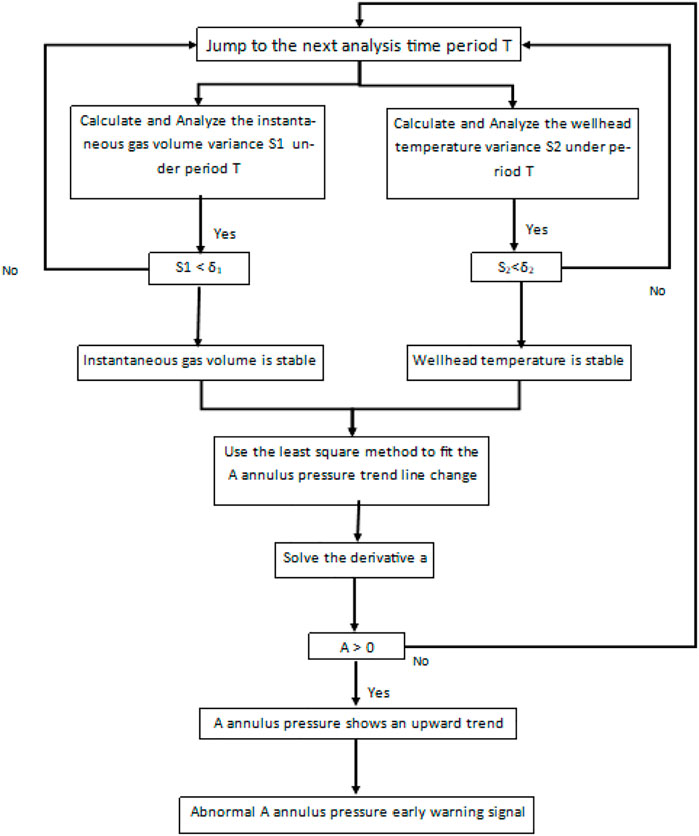

Based on the analysis of the law regarding the annular pressure mechanism and A abnormal annular pressure, an early warning rule around abnormal annular pressure was constructed. The logical diagram is shown in Figure 1 and the warning rules are described below. The meanings of parameters is shown in Table 2.

(1) Firstly, determine the period of analysis that named T;

(2) Find the variance S1 of instantaneous gas volume and variance S2 of wellhead temperature within the time period T;

(3) If you cannot satisfy both S1 < δ1 and S2 < δ2, then jump to the next analysis time period T, among them, δ1 serves as instantaneous gas volume variance limit, and δ2 serves as wellhead temperature variance limit;

(4) If S1 < δ1 and S2 < δ2, then it can be determined that at this point the gas well has satisfied both the condition of instantaneous gas volume stability and wellhead temperature stability, with this, use the least square method to create the A-annular pressure trend line change.

(5) Find the derivative of the A-annular pressure trend line change. If the derivative is α ≤ 0, then jump to the next analysis time period T to continue the analysis;

(6) If the derivative is α > 0, then it can be determined that A-annular pressure shows an upward trend indicating an A abnormal annular pressure, a warning signal should appear.

The purpose of the variance calculation in this proposal is to determine whether the instantaneous gas volume and wellhead temperature are stable or not. Thus, in the formula, sequence x is a gas well parameter—instantaneous gas volume and gas well temperature.

Assume that the data of A-annular pressure that is being monitored in real time at different times for a period of time is y0, y1 …, yn。Based on these data, an empirical formula between y and t was established

Because these points are originally not in a straight line, we can only ask for such a and b, so that the function value of

To find the derivative of the fitted trend line is to analyze and determine the rising rate of the A-annular pressure within the period. Then compare the derived derivative and allowable rate of rising, if the derivative is bigger than 0, then A-annular pressure is abnormal.

3.2 Setting of parameter for early warning rules

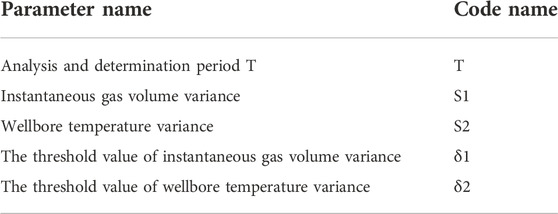

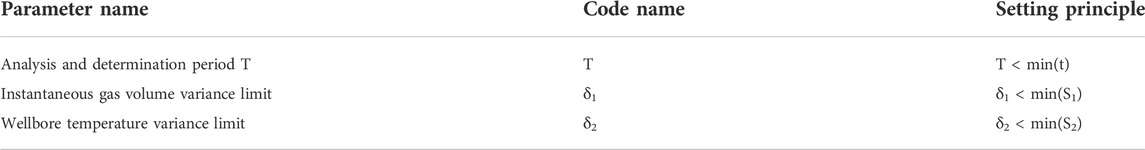

According to the description of the early warning rules, the parameters involve includes: analysis and determination period T, instantaneous gas volume variance limit δ1, and wellhead temperature variance limit δ2, a total of three parameters.

3.2.1 Basis of initial parameter setting

The initial value of the parameter needs to be determined by combining with the actual operating conditions of the gas well. Based on a statistical analysis of large amounts of data, the bases of the initial value of the analysis and determination period T, instantaneous gas volume variance limit δ1, and wellbore temperature variance limit δ2 are shown in Table 3 below.

① Basis of initial setting of analysis and determination period T. T is the rising time of the abnormal A-annular samples. Count all the rising times of abnormal A-annular samples in a certain area. T must have a value that is smaller than the rising time of the abnormal sample. Moreover, the maximum value is set by the field technician depending on the condition.

② Basis of initial setting of Instantaneous Gas Volume variance limit δ1. If the instantaneous gas volume variance limit δ1 is very small, then the instantaneous gas volume is strictly stable. Therefore, in order to reduce the rate of false early warning, sum up the smallest value of the instantaneous gas volume variance within the analysis and determination period T of a certain section. δ1 must have a value that is less than the smallest value of its statistical result.

③ Basis of initial setting of wellbore temperature variance limit δ2. Similar to setting of the instantaneous gas volume variance limit, wellbore temperature variance limit δ2 should have a value that is less than the smallest value of its statistical result.

3.2.2 Parameter adjustment optimization mechanism

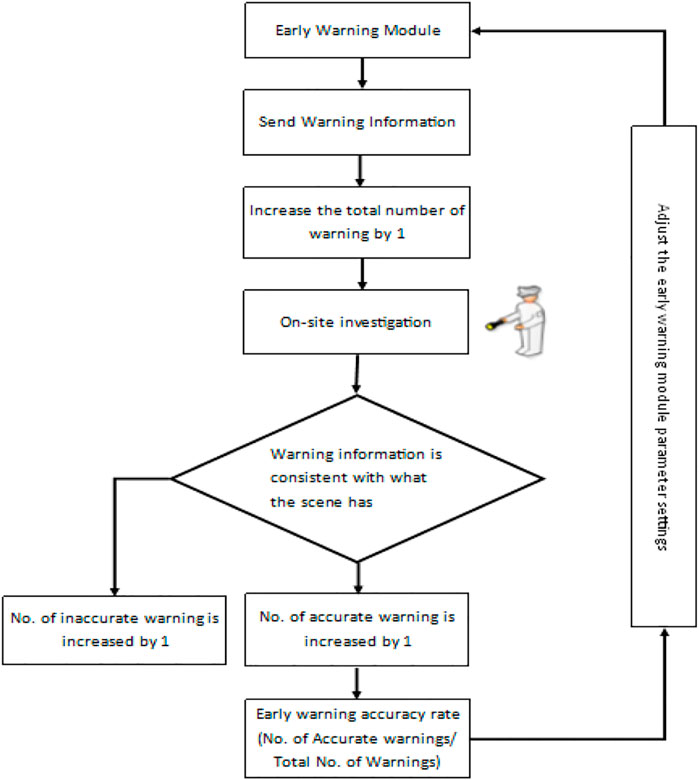

In the early usage of the warning rules, all situations that satisfy the rules will be alerted, but not all warning information is consistent with the actual state of the gas well. Thus, the total number of warnings, correct number of warnings, and warning accuracy rates are set. Parameter setting is set to open mode while field technicians adjust parameter settings based on statistical results of early warning accuracy. By continuous monitoring and modifying the optimization alert rule parameter settings, it will gradually improve the accuracy of early warnings. The adjustment and optimization mechanism is shown in Figure 2.

4 Case verification

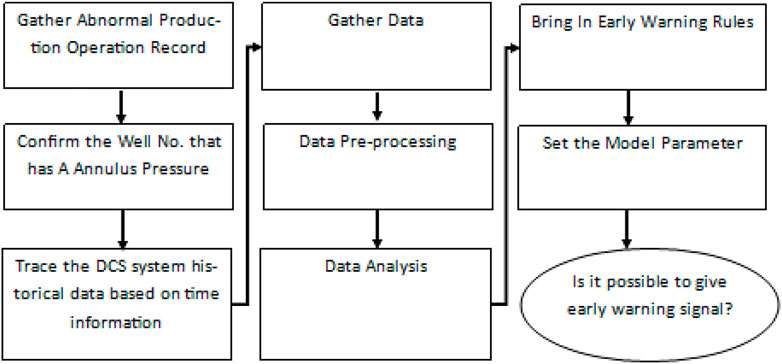

In order to verify the effectiveness of the early warning rules in this paper, the verification work was conducted by the development department. . The verification process is shown in Figure 3. First of all, in order to determine the gas well name with A abnormal annular pressure, the on-site abnormal production operation record is collected with the use of daily production results. Then with the use of the results, the stored historical data of the instantaneous gas volume, wellhead temperature, and A-annular pressure of the DCS system are traced. After which the data is executed for pre-processing and data analysis. Lastly, the early warning rules were bought in for verification analysis.

4.1 Case introduction

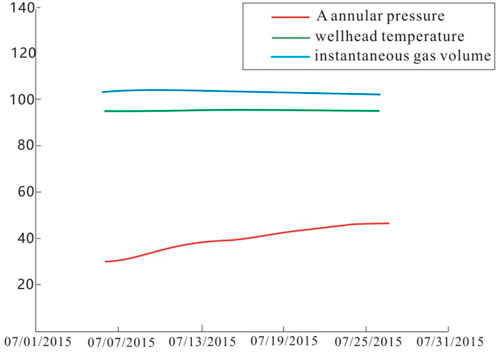

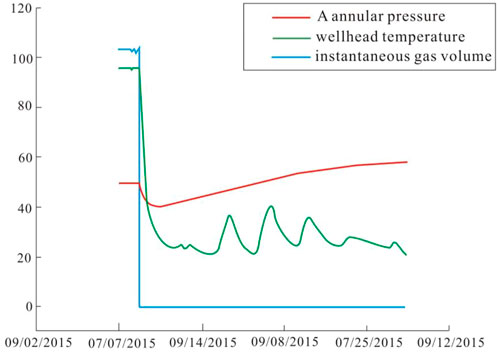

From the production daily report, the A-annular pressure of the 08# well was identified, the production parameters of the DCS system from May 2015 to May 2016 was traced including the instantaneous gas volume, wellhead temperature, and A-annular pressure. Preprocessing of data was executed and from it, the data regarding the two abnormal A-annular sample of 08# was extracted. The trend line regarding the change of production parameter of two abnormal samples was drawn in Figures 4, 5. The description of abnormal sample data No. 1 is as follows: in the stable production phase from the period 6 July 2015, 13:52:07 to 24 July 2015, 15:12:10, the A-annular pressure value has risen from 29.99 MPa to 46.36 MPa, it continued to rise slowly for about 434 h. The description of abnormal sample data No. 2 is as follows: during the good shutdown period from the period 5 September 2015, 2:30:00 to 9 September 2015, 12:30:00, the A-annular pressure value has risen from 40.15 MPa to 56.19 MPa, it continued to slowly rise for about 106 h.

4.2 Effects analysis of early warning rules

4.2.1 Using current DCS system warning strategy

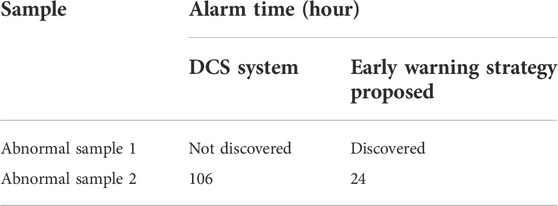

Currently, the value of A-annular pressure warning limit of the DCS system in the wellsite is 56 MPa. For abnormal sample 1, since it did not reach the DCS system warning limit, it was not discovered. For abnormal sample 2, since the DCS warning limit was reached after the annular pressure has risen for about 106 h, an alarm was triggered thus it was discovered by the technical staff.

4.2.2 Using this paper’s early warning strategy

In this paper, the analysis and determination period T was set to 24 h by the early warning rules. The collection and analysis of instantaneous gas volume and wellhead temperature data was done within 24 h. It was known that the two parameters were stable according to its statistical variance value. Then through the least square method, the A-annular pressure trend line was created accordingly while obtaining its derivative. After calculation, the derivatives of the two abnormal samples are all greater than zero. Thus, both abnormal samples can be discovered if the abnormal A-annular pressure has risen after 24 h though early warning rules.

4.2.3 Comparative analysis

This paper compares the current DCS system warning strategy and the early warning strategy proposed in this paper in the safety production application of gas wells. The results of the comparative analysis are shown in Table 4.

With the use of the paper’s early warning strategy, the abnormal A-annular pressure phenomenon of Abnormal Sample 1 was discovered; likewise, the abnormal A-annular pressure of abnormal sample 2 was discovered 82 h in advance. The verification analysis of two abnormal samples of 08# gas well, shows that the data mining based gas well safety warning rule proposed in this paper is able to predict gas well abnormal annular pressure phenomenon.

5 Limitions

In this paper, the quantitative relationship among A annulus pressure, instantaneous gas volume and wellhead temperature are used to realize the monitoring and early warning of abnormal A annulus. Because it is difficult to accurately express the quantitative relationship between instantaneous gas volume, wellhead temperature and A annular pressure in the well opening process, production adjustment process and well shut-in process, it is difficult to quantitatively describe the law of abnormal A-annular pressure during well opening process, production adjustment process and well shut-in process. In order to achieve A high accuracy, the warning model proposed in this paper is only suitable for the diagnosis and warning of abnormal A-annular pressure during the stable production stage and the shut-in stage.

6 Conclusion

The data mining based gas well safety warning rule research in this paper was able to draw the below conclusion:

(1) The paper summarizes the law of abnormal anomalous pressure of gas wells in stable production stage and shut-down period. Even if the instantaneous gas volume and wellhead temperature are stable, A-annular pressure shows an upward trend, and based on this an abnormal A-annular pressure warning rule was constructed. This provides guidance for the application of information-based data mining technology in gas well safety production.

(2) Based on the statistical analysis results of a large number of data, the parameters of the early warning rules are determined. This includes the initial basis of the analysis and determination period T, instantaneous gas volume variance limit δ1, and wellhead temperature variance limit δ2. The parameter adjustment optimization mechanism in the later stage application process was also determined.

(3) The examples have proven that the early warning strategy proposed in this paper can auto analyze and predict gas well abnormal A-annular pressure phenomenon thus achieving early warnings while taking corresponding measures according to the situation. The data mining based early warning strategy can deeply analyze the important information hidden in a large amount of real-time dynamic data, which is a breakthrough in information technology in the field of security production and application.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material, further inquiries can be directed to the corresponding author.

Author contributions

HY: formal analysis, writing—original draft preparation, writing—review and editing, funding acquisition. JQ, ScW, and SyW: formal analysis, methodology, conceptualization. BZ: methodology, conceptualization, project administration, supervision.

Funding

This research is supported by CNPC Forward-looking Basic Strategic Technology Research Projects (No. 2021DJ6504) and Research fund of the research institute directly affiliated to CNPC (2021DQ03-A6).

Conflict of interest

SWu, SWa, and JQ were employed by the company China National Petroleum Corporation.

The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Ai, S., Cheng, L., Huang, S., Liu, H., Zhang, J., and Fu, L. (2015). A critical production model for deep HT/HP gas wells. J. Nat. Gas Sci. Eng. 22, 132–140. doi:10.1016/j.jngse.2014.11.025

M. Bly (Editor) (2011). Deepwater Horizon accident investigation report (Netherlands: Diane Publishing).

Bradford, D. W., Fritchie, D. G., Gibson, D. H., Gosch, S. W., Pattillo, P. D., Sharp, J. W., et al. (2004). Marlin failure analysis and redesign: Part 1-description of failure[J]. SPE Drill. Complet. 19 (02), 104–111. doi:10.2118/88814-PA

Cao, L., Liu, H., Zhang, B., Zhang, H., Kong, C., Liu, W., et al. (2020). Well integrity evaluation and management: Development and application of real time online system in high temperature and high pressure gas wells, Tarim Oilfield[C]. Malaysia: Offshore Technology Conference Asia. OTC 30058.

Kazemi, M., and Wojtanowicz, A. K. (2014). “Development of improved testing procedure for wells with sustained casing pressure,” in SPE Annual Technical Conference and Exhibition (Amsterdam, Netherlands: Curran Associates, Inc.).

Kenneth, D., and Robert, P. (2018). Gas lift annulus pressure. Soc. Petroleum Eng. 8, 28–30. doi:10.2118/190929-MS

Lili, L., Jianyun, P., Bao, Z., Nu, Z., et al. (2013). A method determining the safety range of the annular pressure for a high-pressure gas well and its application. Nat. Gas. Ind. 33 (1), 101–104.

Pu, C. (2022). Prediction and analysis of annular pressure caused by temperature effect for HP/HT/HHS and water production gas wells in Sichuan Basin. J. Pet. Explor. Prod. Technol. 12 (2), 507–517. doi:10.1007/s13202-021-01400-1

Rocha-Valadez, T., Hasan, A. R., Mannan, S., and Kabir, C. S. (2014). Assessing wellbore integrity in sustained-casing-pressure annulus. SPE Drill. Complet. 29 (01), 131–138. doi:10.2118/169814-pa

Tao, W., Shenglai, Y., Weihong, Z., Wanjiang, B., Min, L., Yu, L., et al. (2011). Law and countermeasures for the casing damage of oil production wells and water injection wells in Tarim Oilfield. Petroleum Explor. Dev. 38 (3), 352–361. doi:10.1016/s1876-3804(11)60038-4

Wang, K., Liu, S., Liu, H., Zhang, B., Wang, Y., Tong, S., et al. (2020). Experience and lessons from production packer selection and operations in the HPHT gas fields of kuqa foreland basin, western China[C]. UAE: Abu Dhabi International Petroleum Exhibition & Conference. SPE 203263.

Wisen, J., Chesnaux, R., Werring, J., Wendling, G., Baudron, P., and Barbecot, F. (2020). A portrait of wellbore leakage in northeastern British Columbia, Canada. Proc. Natl. Acad. Sci. U. S. A. 117 (2), 913–922. doi:10.1073/pnas.1817929116

Yan, X., Yan, H., Yan, Y., Li, P., et al. (2019). Abnormal physical characteristics of UGS annular pressure based on improved Waha two-fluid model [J]. J. China Univ. Petroleum Ed. Nat. Sci. 43 (5), 146–156.

Yang, M., Yang, L. C., Wang, T., Chen, Y., Yang, C., and Li, L. (2020). Estimating formation leakage pressure using a coupled model of circulating temperature-pressure in an eccentric annulus. J. Petroleum Sci. Eng. 189, 106918. doi:10.1016/j.petrol.2020.106918

Yu, G., Chen, Y., Li, H., Liu, L., Wang, C., Chen, Y., et al. (2022). Studies on natural gas production prediction and risk quantification of Sinian gas reservoir in Sichuan Basin. J. Pet. Explor. Prod. Technol. 12 (4), 1109–1120. doi:10.1007/s13202-021-01368-y

Yu, X., Yang, J., Kan, C., Hu, C., Wu, X., Xu, F., et al. (2018). Unidirectional control mechanism of annulus trapped pressure in deepwater shaft. Acta Pet. Sin. 39 (3), 335–340. doi:10.7623/syxb201803009

Zeng, D., He, Q., Yu, Z., Jia, W., Zhang, S., and Liu, Q. (2017). Risk assessment of sustained casing pressure in gas wells based on the fuzzy comprehensive evaluation method. J. Nat. Gas Sci. Eng. 46, 756–763. doi:10.1016/j.jngse.2017.08.019

Zeng, J., Gao, D., Wang, Y., and Fang, J. (2019). Evaluation method for cement sheath sealing failure under sustained casing pressure. Chem. Technol. Fuels Oils 551, 93–104. doi:10.1007/s10553-019-01007-7

Zhang, B., Guan, Z., Lu, N., Hasan, A. R., Xu, S., et al. (2018). Control and analysis of sustained casing pressure caused by cement sealed integrity failure. Offshore Technology Conference Asia.

Zhang, B., Guan, Z., Lu, N., Hasan, A. R., Wang, Q., and Xu, B. (2019a). Trapped annular pressure caused by thermal expansion in oil and gas wells: A review of prediction approaches, risk assessment and mitigation strategies. J. Petroleum Sci. Eng. 172, 70–82. doi:10.1016/j.petrol.2018.09.041

Zhang, B., Lu, N., Guo, Y., Wang, Q., Cai, M., and Lou, E. (2022). Modeling and analysis of sustained annular pressure and gas accumulation caused by tubing integrity failure in the production process of deep natural gas wells. J. Energy Resour. Technol. 144 (6), 063005. doi:10.1115/1.4051944

Zhang, B., Xu, Z., Guan, Z., Li, C., Liu, H., Xie, J., et al. (2019b). Evaluation and analysis of nitrogen gas injected into deepwater wells to mitigate annular pressure caused by thermal expansion. J. Petroleum Sci. Eng. 180, 231–239. doi:10.1016/j.petrol.2019.05.040

Zhang, B., Xu, Z., Lu, N., Liu, H., Liu, J., Hu, Z., et al. (2021). Characteristics of sustained annular pressure and fluid distribution in high pressure and high temperature gas wells considering multiple leakage of tubing string. J. Petroleum Sci. Eng. 196, 108083. doi:10.1016/j.petrol.2020.108083

Keywords: three high gas well, A-annulus pressure, data mining, early-warning rules, parameter setting

Citation: Yan H, Qi J, Wu S, Wang S and Zhong BT (2023) Research on safety early warning of abnormal A-annular pressure of “three-high” gas wells based on data mining. Front. Earth Sci. 10:1048968. doi: 10.3389/feart.2022.1048968

Received: 20 September 2022; Accepted: 11 November 2022;

Published: 11 January 2023.

Edited by:

Guanglong Sheng, Yangtze University, ChinaReviewed by:

Xiangchao Shi, Southwest Petroleum University, ChinaChao Han, China University of Petroleum (East China), China

Nu Lu, Research Institute of Petroleum Exploration and Development (RIPED), China

Jinqiu Hu, China University of Petroleum, China

Copyright © 2023 Yan, Qi, Wu, Wang and Zhong. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: B. T. Zhong, ZGFkaXpob25nQGh1c3QuZWR1LmNu

Hongqiao Yan

Hongqiao Yan Junliang Qi3

Junliang Qi3