- 1CHN Energy Yulin Energy Qing Longsi Colliery, Yulin, Shanxi, China

- 2State Key Laboratory of the Gas Disaster Detecting Preventing and Emergency Controlling, Chongqing, China

- 3China Coal Technology and Engineering Group Chongqing Research Institute, Chongqing, China

- 4Anhui University of Science and Technology, Huainan, Anhui, China

Coal and gas outbursts are a potentially fatal hazard that must be managed when mining gassy coal seams. Mining-induced stress plays an important role in outbursts, while elastic potential is accumulated to provide energy for an outburst. In this study, a large-scale true triaxial (LSTT) apparatus was developed to conduct experiments and to understand the outburst mechanism and mining-induced geo-stress evolution law. In the LSTT experiments, coal and gas outbursts resulted from both stress and gas pressure and occurred in a limited balance area. Under the action of mining-induced stress, surrounding rock and coal are compressed. Thus, a large amount of elastic potential is accumulated to provide energy for a coal and gas outburst. Mining-induced stress promotes the development and expansion of the fracture in the coal body, which results in coal wall deformation and damage. The four types of coal wall instability are bodily movement of coal wall, layered separation of coal wall, collapse of coal wall, and break of coal wall. This study develops a classification scheme and management strategies for outbursts.

Introduction

Coal and gas outbursts are complicated dynamic disasters. They are potentially indiscoverable lethal hazards that must be focused on carefully when mining gassy coal seams (Litwiniszyn, 1985; Skoczylas, 2012; Lei et al., 2022; Zhang et al., 2022; Zou et al., 2022). China is rich in coal, but short of gas and oil. Consequently, for a long time, coal has played a central role in China’s primary energy production and consumption structure (Yuan, 2016). In the last 20 years, China has averaged 50 pairs of coal mine outbursts and more than 300 outburst accidents every year. Gas and coal and rock mass become more complex as the mining depth, geo-stress, gas pressure and content increase, as ground temperature rises with depth, and as the coupling geo-stress increases (Fan et al., 2017; Fan et al., 2019; Zhou et al., 2019).

The mechanism of a coal and gas outburst has been extensively studied by means of theoretical analysis, laboratory test, numerical simulation, and field tests in major coal-producing countries (Aguado and Nicieza, 2007). Outburst mechanisms can be summed up in several aspects, as follows: outburst center hypothesis, unified instability theory of outburst and rock burst, rheological hypothesis, spherical shell instability hypothesis and combination hypothesis (Wang et al., 2017; Jin et al., 2018; Sun et al., 2018). It has been widely considered that the combination hypothesis can well describe the whole outburst process. It is also generally believed that geo-stress and gas pressure provide energy sources for the occurrence and development of an outburst, and the physical and mechanical properties of the coal and rock reflect the ability of coal and rock to resist destruction (An and Cheng, 2014; Jiang et al., 2015; Guo et al., 2016; Yin et al., 2016; Wang et al., 2018a; Wang et al., 2019; Zhao et al., 2020). The complex mining conditions in a deep mine (e.g., high geo-stress, gas pressure, and ground temperature) lead to the new characteristics of a coal and gas outburst, such as high energy, high intensity, and difficulty to prevent and control. At the same time, it presents obvious coupling characteristics of coal, rock, and gas dynamic disaster (Aguado and Nicieza, 2007; Xue et al., 2014; Chunli et al., 2015; Hu et al., 2015; Zhai et al., 2016; Fan et al., 2021). The outburst mechanism was recently studied using experimental technology (Li et al., 2017; Wang et al., 2017; Wang et al., 2018b; Ding and Yue, 2018; Yang et al., 2018).

Researchers have recently developed different scale simulation test systems (according to different research objectives). Zhao et al. (2016) explored the geo-stress and the way it impacts the outburst and stated the influence of geo-stress and gas content on outburst under different mining depths. A small-scale coal and gas outburst device has been developed, and the control of coal and gas outburst in gas-enriched areas and the related research on coal and gas outburst spallation have been carried out with this device (Tu et al., 2016). In the study of the permeability distribution of a coal body affected by mining, the changes of permeability from the area not affected by mining activities to the coal wall area of the working face in front of the mining are successively divided into decreasing area, increasing area, and sudden increasing area (An and Cheng, 2014). Xue et al. (2011) analyzed the influence of water content on coal and gas outbursts and stated that the intensity of a coal and gas outburst is negatively correlated with the water content of a coal body. Fisne et al. and Nie et al. discussed the relationship between the outburst and geological parameters, and the outburst’s strength, particle size distribution, and failure of the pore shape of the outburst coal were studied (Zhang et al., 2022). They also studied how the variation of stress in a stress concentration area has an important influence on protrusion. Li et al. (2017) made several groups of simulation tests on an outburst and studied the influence of the exposed area of gas-containing coal on the outburst, especially in the case of uncovering coal. Liu and Cheng (2014) simulated coal and gas outburst accidents due to the change of the stress environment when uncovering coal underground. They then discussed the evolution law of stress in the process of coal and gas outburst, and the influence of structural factors on a coal and gas outburst. Peng et al. (2012) considered that failure condition and law of coal with different strengths under stress-gas pressure. Taking Tianfu Sanhui No. 1 Mine as the engineering background, the process of coal and gas outburst under mining conditions was simulated based on the similarity theory experiment, and the space-time evolution law of air pressure in the outburst process was analyzed (Xu et al., 2010). Fedorchenko and Fedorov (2012) demonstrated the development law of acoustic signal and the development of a crack during an outburst. PFC3D and FLAC3D have been used to analyze the control of protrusion by effective stress in different zones, and the different stages of crack burst were discussed (Zhao et al., 2022a). Lu et al. and Xu et al. analyzed the desorption of adsorbed gas in the process of outburst, from the microscopic view (Lu et al., 2011). It is considered that the cause of coal and gas outburst is the failure and instability of the coal body that is caused by the gas pressure gradient, and the free gas is involved in the process of coal and gas outburst in the form of work done by expansion (Xie et al., 2017; Zhao et al., 2022b). The first condition for adsorbed gas to participate in the outburst work is to quickly transform into free gas during the burst. The process of adsorbed gas in an outburst involves the desorption of adsorbed gas from the pore surface, diffusion of gas in the pore, and seepage of gas in a fracture system (Ding et al., 2019; Fan et al., 2020; Liu et al., 2020; Jianshe et al., 2021; Liu et al., 2021; Zhao et al., 2022c; Zhou et al., 2022; Zhu et al., 2022).

When coal-gas mixture meets a fire source in a roadway, it can lead to a gas explosion, coal dust explosion, and so on, which can seriously endanger the miners’ safety and cause huge economic loss. The coal and gas outburst mechanism has been studied extensively in major coal-producing countries by means of theoretical analysis, laboratory test, numerical simulation, and field tests. However, experimental data are still limited. Therefore, mining-induced stress monitoring, observation, and evolution require further research—direct observations are especially lacking. Therefore, in this paper we will examine mining-induced stress in outbursts using a self-developed large-scale true triaxial (LSTT) apparatus. Using the LSTT apparatus, we launch an outburst experiment to replay the outburst accident at Dingji coal mine, Anhui Province, China. Even when gas extraction reaches the standard, coal and gas outburst accidents dominated by stress can still occur from time to time. This has seriously restricted the safe mining of coal. Therefore, it is of great significance to study the coupling mechanism of stress, gas, and coal; the coal and gas outburst mechanism; and prevention theory under the condition of high ground stress in deep mining.

Experimental

Experimental apparatus

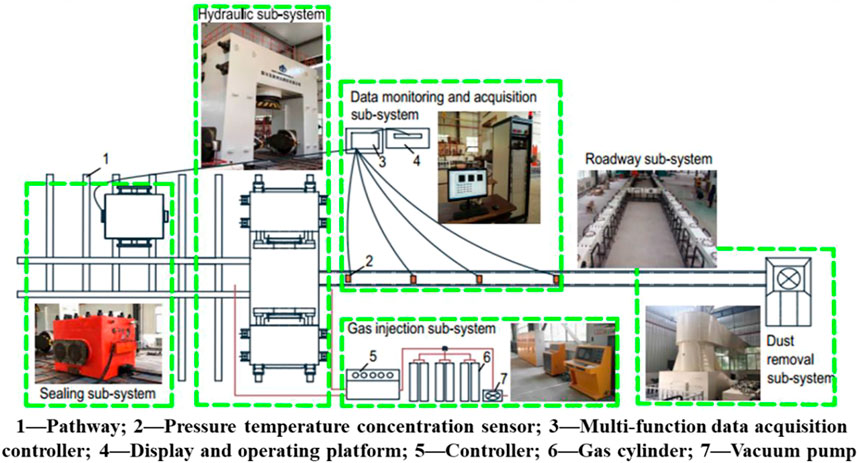

It is of great value to reduce the number of deep coal and gas outburst accidents through research with high similarity in the laboratory. Analysis of experimental data can lead to a deeper understanding of the stages of gestation, excitation, development, and termination of a deep coal and gas outburst. It can also provide data to support the discussion of the mechanism of a deep coal and gas outburst. The outburst simulating device consists of a pathway sub-system, hydraulic sub-system gas, injection sub-system, roadway sub-system, data monitoring and acquisition sub-system, and dust removal sub-system (as shown in Figure 1). The vertical loading pressure of the mechanical loading system is 3,000 t. The maximum working pressure is 25 MPa. Meanwhile, the horizontal symmetrical loading pressure is 2000 t, and the maximum working pressure is 16.7 MPa. The external dimensions of the box are 2.2 m × 1.8 m × 1.5 m. A sealing ring is used to seal the box, forming an empty size of 0.8 m × 1.1 m × 1.5 m. The simulated roadway is a square with a section side length of 0.3 m, with sensor installation, and ash removal and observation window, which can resist the impact damage of 6 MPa experimental gas. This setup can simulate a horizontal plane angle of 10°, 20°, and 90°; a vertical plane angle of 10° and 20°, and its combination turn; and a 90° bifurcated roadway layout.

Coal samples and gas source

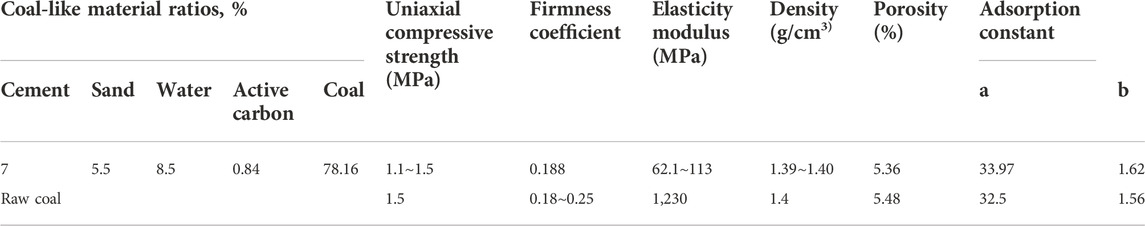

The test model is the “4•19″ outburst accident of the 1,331 1) transport roadway heading face in Dingji Mine. According to the preliminary analysis of the coal mine field investigation, the direct cause of this accident is that the coal seam of the accident working face is buried 870 m deep, which is a deep mine with large ground stress. This has the basic conditions for the occurrence of gas dynamic disasters, mainly caused by ground stresses such as rock burst, and coal and gas outburst. Pulverized coal, cement, sand, activated carbon and water were selected as the main raw materials to simulate coal materials. The basic parameters of the similar materials are listed in Table 1. The fixed process parameters were determined as follows: the molding pressure is 25 MPa, the loading mode is load loading, there are five pressed layers, the pressure holding time is 30 min, and the curing time is 7 days.

Experimental design

Outburst experiments mainly included collecting basic parameters, loading with similar materials, testing airtightness, linking the chamber with the roadway, and starting the experiment. The experiments are generally divided into non-adsorbent gas and adsorbent gas. In the outburst test, carbon dioxide is generally used as the test gas to ensure the experimental safety. In our experiment, carbon dioxide was selected as the adsorption gas, with an adsorption time of about 15 days. We assumed that the materials reached adsorption equilibrium when the adsorption equilibrium was determined by pressure-retaining adsorption for 3 days.

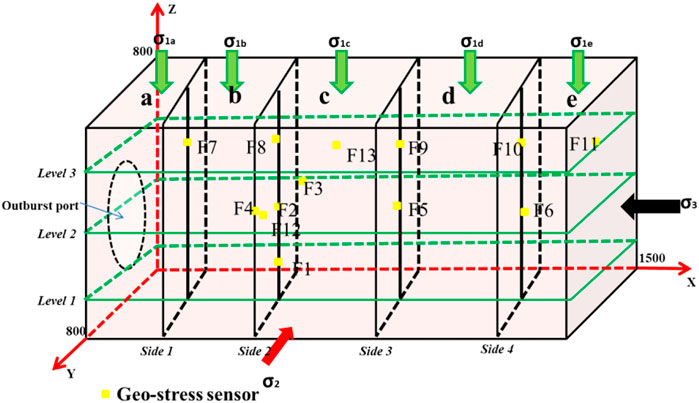

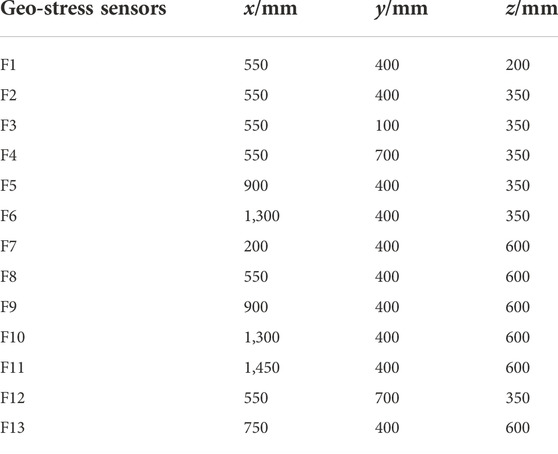

To facilitate sensor positioning, a three-dimensional axis is established with the lower left-hand corner of the direction of the protruding mouth as the origin of the coordinates. The X-axis is perpendicular to the protruding mouth, the Y-axis is parallel to the protruding mouth, and the vertical direction is the Z-axis. The coordinates of the vertices of the box are (0,0,0), (1500,0,0), (0,800,0), (0,0,800), (1500,800,0), (1500,0,800), (0,800,800), and (1500,800,800) (Figure 2) (Table 2).

Results and discussion

Experimental results

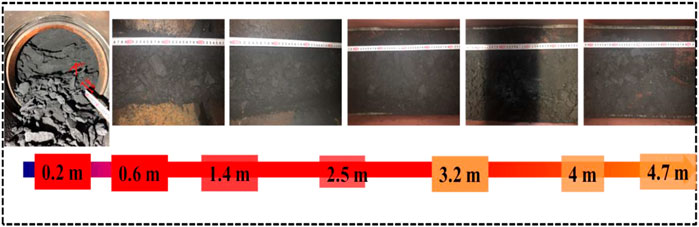

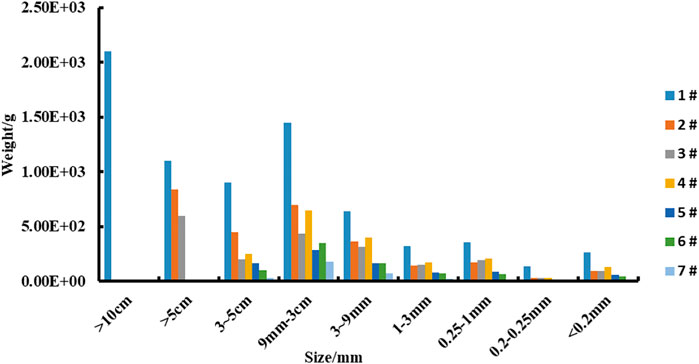

After the outburst, the complete coal body is broken under the action of geo-stress, and a large amount of broken coal is thrown into the simulated roadway under the action geo-stress and gas pressure, which is consistent with the outburst site. After the thrown broken coal runs for several meters in the roadway under the action of gas airflow, the samples are accumulated in the simulated roadway after energy depletion. In the test, the pressure hole is wedge-shaped and semicircular with a large mouth and a small cavity, with a width of about 0.3 m and a depth of about 0.4 m. Figure 3 shows that the broken coal is piled up in the roadway, and a large number of broken coal samples are piled up near the outburst mouth. At the same time, a relatively large volume of broken coal is piled up within 2 m from the outburst mouth. The pulverization degree of the protruding coal body shows two characteristics: the pulverization rate of the coal body near the outburst mouth is small, and the pulverization degree of the coal body far from the protruding mouth is high. In the area where pulverized coal is relatively concentrated in the simulated roadway, the pulverization rate of coal is relatively large. This may be related to the higher collision frequency of particles in the area with higher pulverized coal mass distribution in the process of pulverized coal and gas flow transport (Figure 4).

Stress distribution in front of the working face

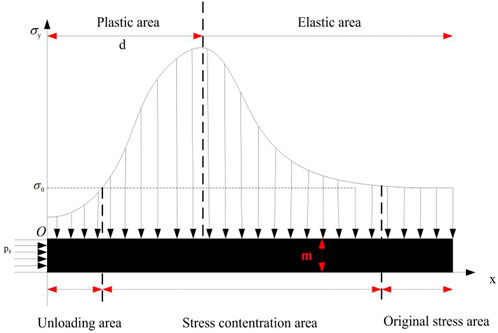

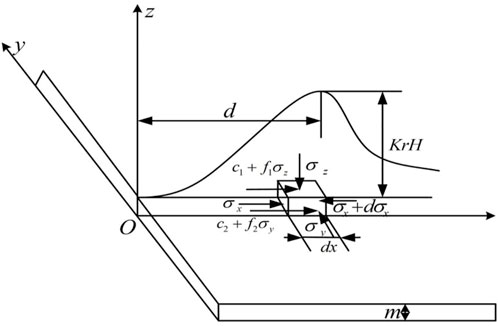

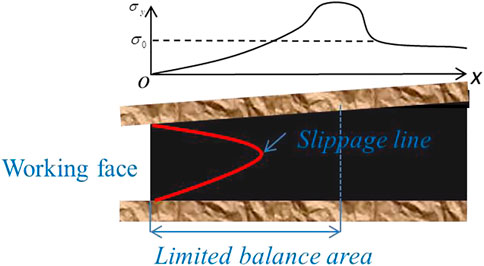

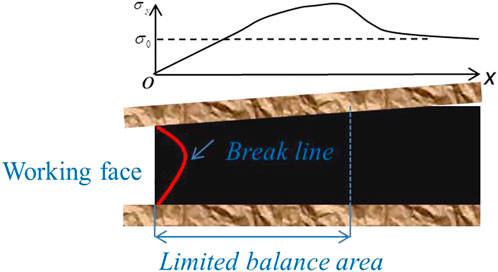

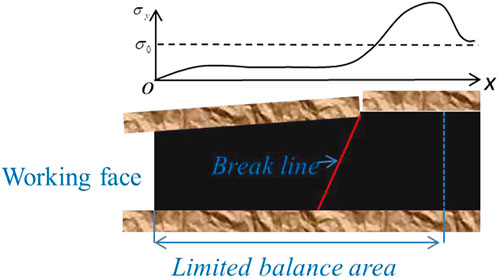

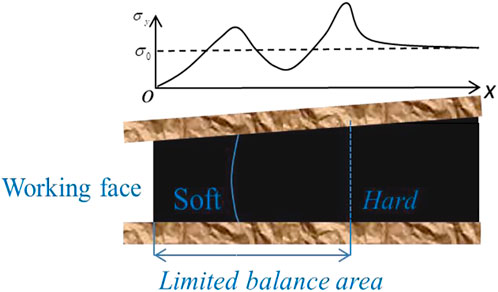

From the energy accumulation stage to the initiation stage in the process of outburst, the coal and rock mass system gradually evolves from the equilibrium state to the sudden instability process, which results from the non-linear features of the coal and rock mass system (material non-linearity and geometric non-linearity). Instability usually occurs in the limited balanced area of supporting pressure in front of the coal wall. Therefore, stress-strain status research facilitates the exploration of the deformation failure mechanism in the outburst. Previous research suggests that there are unloading areas, stress concentration areas, and original stress areas in front of a working face. The area from coal wall to stress peak is always called a limited balance area (d), as shown in Figure 5.

A unit width of

where

This is simplified as:

Ignoring the shear stress

where

Supposing that the coal wall is subjected to a counterforce

and substitute

The area from coal wall to stress peak is defined as a limited balance area (d), and the stress in the peak

where

Stress evolution rules during the process of an outburst

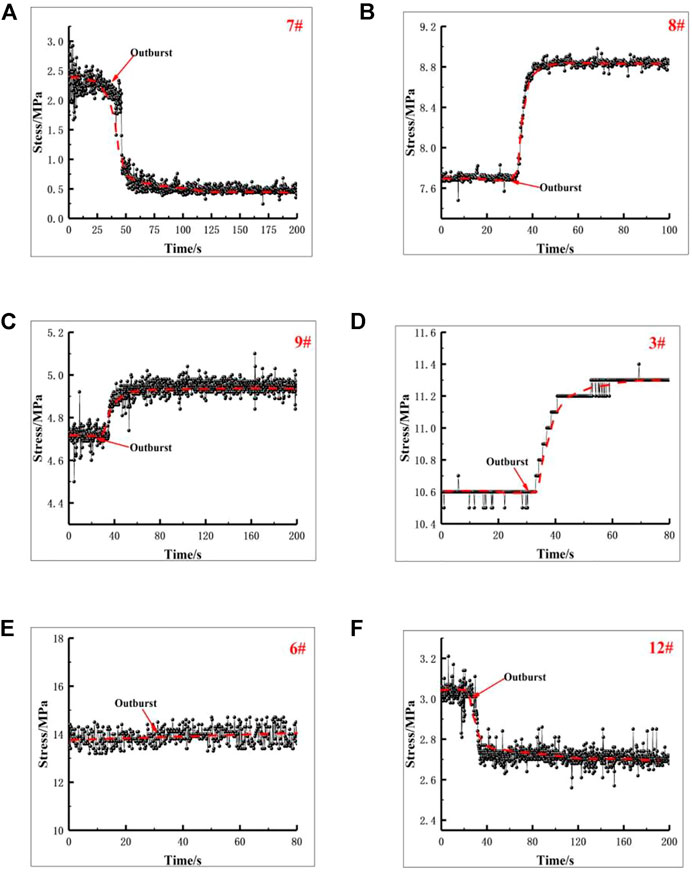

The outburst process is divided into four stages: preparation, initiation, development, and termination. After an outburst occurs, coal is thrown out from the coal wall, and an initial outburst hole is formed on the coal wall. Geo-stress around the coal wall may be redistributed, and the stress state is variable depending on conditions (as shown in Figure 7). After the outburst, the vertical stress near the hole wall rapidly decreases (as shown in Figure 7A) and geo-stress decreases from 2.5 MPa to 0.5 MPa. However, vertical stress far from the hole wall gradually increases (as shown in Figures 7B–D). Stress sensor #8 shows that the geo-stress increased from 7.7 MPa to 8.8 MPa (as shown Figure 7B). Stress sensor #9 shows that the geo-stress increased from 4.7 MPa to 5.9 MPa (Figure 7C). Stress sensor #3 shows that the geo-stress increased from 10.6 MPa to 11.3 MPa (as seen in Figure 7D). The high geo-stress makes the coal near the coal hole wall reach a plastic state in a short time, the peak of the tangential stress shifts to the deep part, and radial stress rapidly decreases. The failure occurrence rule in a coal wall is developed from the position of exposed surface of coal wall to the deep part, and upward and downward from the vertical center of the coal seam. However, Figure 7E shows that the original stress remained stable throughout the original stress region. We conclude that the coal hole wall, which is exposed as a result of the outburst, had higher geo-stress. Horizontal stress near the outburst hole quickly decreased from 3.1 MPa to 2.8 MPa (as shown in Figure 7F). Stress evolution demonstrates the coal damage rules. Ejected coal, in the center, was caused by vertical stress but damaged coal, at the bottom and roof of the coal wall, was caused by shear stress.

Outburst instability models of a coal wall

We have analyzed the process of initial mining from the coal wall, the stress distribution in the limited balance area, and the stress evolution rules. The failure occurrence rule in the coal wall was developed from the position of the exposed surface of the coal wall to the deep part, and upward and downward from the vertical center of the coal seam. Based on the stress evolution rules during the process of an outburst, the following four basic types of coal wall instability are given: 1) bodily movement of coal wall, 2) layered separation of coal wall, 3) collapse of coal wall model, and 4) break of coal wall model. The typical condition for this instability model is that the overburden load of the coal seam is large enough and the roof of the coal seam is hard. In this way, the width of the limiting balance zone of the coal seam becomes longer and the roof is not easily broken (as shown in Figure 8). A wider ultimate balance zone of supporting pressure is related to the greater shear strain of the coal wall. The capacity of the coal seam to resist the external force of the horizontal direction toward the mining space is extremely weakened, and the cracks in the coal seam are gradually expanded. In addition, the high-pressure gas in the coal seam can cause an overall movement of the sliding line of some coal bodies or may even throw the coal away from the wall. A side-falling model is a common form of instability, which occurs in coal seams with high brittleness and strength. The depth of the coal wall may be very small, which will not cause a coal and gas outburst. However, when the depth of the sides is larger, it is best to change to a coal wall extrusion model (Figure 9).

Collapse of the coal wall may frequently occur in a coal mining face. The typical instability condition is that the roof of the coal seam in front of the face has a fracture structure. Residual strength rapidly decays after coal wall collapse. The action of gas pressure, high-speed failure, and extrusion or ejection to the mining space lead to the initial launch of the outburst (Figure 10). The typical conditions for the break of the coal wall model are that the working face enters soft coal from hard coal or that the stone door is cracked. The hard coal seam exposed in front of the working face will bear high vertical support pressure and horizontal thrust exerted by the weak coal seam inside, which results in a huge elastic potential energy in the coal seam. If disturbed, a lot of elastic potential energy may be released (Figure 11).

Effect of mining-induced stress on outburst

Mining-induced stress and gas pressure play different roles at different stages of an outburst. Mining-induced stress plays an important role in the process of a coal and gas outburst. Under the action of ground stress, surrounding rock and coal are compressed. Therefore, a large amount of elastic potential is accumulated to provide energy for a coal and gas outburst. Mining-induced stress promotes the development and expansion of the fracture in the coal body, which results in deformation and damage. Permeability is also impacted by mining-induced stress. High mining-induced stress coupled with low permeability results in a high gas pressure gradient.

As mining depth increases, geo-stress plays an increasingly important role in coal and gas outburst disasters. The distribution of the stress field in the process of a coal and gas outburst plays a crucial role in the gestation and excitation of a coal and gas outburst and determines the occurrence and development process of a gas outburst to a certain extent. The influence of geo-stress on a coal and gas outburst is mainly manifested in the plastic failure stage of the coal body. The plastic failure of the coal body under the action of stress leads to a series of conditions, such as strain field, gas migration field, and mechanical property field of coal body change. On one hand, the stress field affects the compressed coal skeleton and makes the coal accumulate an elastic potential. On the other hand, when the local stress exceeds the strength limit of the coal body, it will cause the coal body to crack or even destabilize, which results in the initial failure of the coal.

The failure of coal under the action of geo-stress is a necessary but not sufficient condition for an outburst. When the coal fails under the action of geo-stress and the gas pressure cannot cause the crack to expand and destroy, then the damaged coal will not be thrown out and a protrusion will not occur. The gas pressure will then gradually disappear, and the coal and rock mass near the crack will be stable under the support of spherical and radial stresses. If the gas pressure can continue to act on the fracture tip after the coal body is destroyed under the action of geo-stress, then the initial fracture develops continuously, and the gas pressure can make the destroyed coal and rock mass throw out. A coal and gas outburst will then inevitably occur.

Conclusion

In this paper, the influence of stress on a coal and gas outburst is studied by means of theoretical analysis and physical experiment, based on stress-dominated physical simulation test and parameter response of several physical fields. We analyzed mining-induced stress evolution rules in the outburst process. Mining-induced stress plays an important role in the process of a coal and gas outburst.

1) In the test, the pressure hole is wedge-shaped and semicircular with a large mouth and a small cavity, with a width of about 0.3 m and a depth of about 0.4 m. The broken coal is piled up in the roadway, and a large number of broken coal samples are piled up near the outburst mouth. At the same time, a relatively large volume of broken coal is piled up within 2 m from the outburst mouth.

2) An outburst occurs in a limited balance area. Under the action of mining-induced stress, surrounding rock and coal are compressed. Therefore, a large amount of elastic potential is accumulated to provide energy for a coal and gas outburst. Mining-induced stress promotes the development and expansion of a fracture in the coal body, which results in deformation and damage. Four typical types of coal wall instability are given: bodily movement of coal wall, layered separation of the coal wall, collapse of the coal wall model, and a break of the coal wall model.

Data availability statement

The original contributions presented in the study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author.

Author contributions

All authors listed have made a substantial, direct, and intellectual contribution to the work and approved it for publication.

Funding

This work was supported by the Joint Fund for Regional Innovation and Development (U21A20110), Chongqing Research Program of Technical Innovation and Application Development (cstc2019jscx-gksbX0076), Guizhou Science and Technology Plan Project (Guizhou scientific and technological cooperation support (2021) General 398), and Major Special Topics of China Coal Technology Engineering Group Chongqing Research Institute (2021ZDZX05).

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Publisher’s note

All claims expressed in this article are solely those of the authors and do not necessarily represent those of their affiliated organizations, or those of the publisher, the editors and the reviewers. Any product that may be evaluated in this article, or claim that may be made by its manufacturer, is not guaranteed or endorsed by the publisher.

References

Aguado, M. B. D., and Nicieza, C. G. (2007). Control and prevention of gas outbursts in coal mines, Riosa-Olloniego coalfield, Spain. Int. J. Coal Geol. 69, 253–266. doi:10.1016/j.coal.2006.05.004

An, F. H., and Cheng, Y. P. (2014). An explanation of large-scale coal and gas outbursts in underground coal mines: The effect of low-permeability zones on abnormally abundant gas. Nat. Hazards Earth Syst. Sci. 14, 2125–2132. doi:10.5194/nhess-14-2125-2014

Chunli, Y., Yiliang, Z., Xiangchun, L., Yangyang, M., and Feifei, Z. (2015). Gas concentration distribution law in the roadway after coal and gas outburst. Appl. Mech. Mat. 713-715, 314–318. doi:10.4028/www.scientific.net/amm.713-715.314

Ding, X., Xiao, X. C., Lv, X. F., Wu, D., and Xu, J. (2019). Mechanical properties of bump-prone coal with different porosities and its acoustic emission-charge induction characteristics under uniaxial compression. Adv. Civ. Eng. 2019, 1–18. doi:10.1155/2019/7581061

Ding, Y., and Yue, Z. Q. (2018). An experimental investigation of the roles of water content and gas decompression rate for outburst in coal briquettes. Fuel 234, 1221–1228. doi:10.1016/j.fuel.2018.07.143

Fan, C., Elsworth, D., Li, S., Zhou, L., Yang, Z., and Song, Y. (2019). Thermo-hydro-mechanical-chemical couplings controlling CH 4 production and CO 2 sequestration in enhanced coalbed methane recovery. Energy 173, 1054–1077. doi:10.1016/j.energy.2019.02.126

Fan, C. J., Yang, L., Wang, G., Huang, Q. M., Fu, X., and Wen, H. O. (2021). Investigation on coal skeleton deformation in CO2 injection enhanced CH4 drainage from underground coal seam. Front. Earth Sci. (Lausanne). 9, 766011. doi:10.3389/feart.2021.766011

Fan, C., Li, S., Elsworth, D., Han, J., and Yang, Z. (2020). Experimental investigation on dynamic strength and energy dissipation characteristics of gas outburst-prone coal. Energy Sci. Eng. 8 (4), 1015–1028. doi:10.1002/ese3.565

Fan, C., Li, S., Luo, M., Du, W., and Yang, Z. (2017). Coal and gas outburst dynamic system. Int. J. Min. Sci. Technol. 27, 49–55. doi:10.1016/j.ijmst.2016.11.003

Fedorchenko, I. A., and Fedorov, A. V. (2012). Gas-dynamic stage of the coal and gas outburst with allowance for desorption. J. Min. Sci. 48, 15–26. doi:10.1134/s1062739148010030

Guo, H. J., Cheng, Y. P., Ren, T., Wang, L., Yuan, L., Jiang, H. N., et al. (2016). Pulverization characteristics of coal from a strong outburst-prone coal seam and their impact on gas desorption and diffusion properties. J. Nat. Gas Sci. Eng. 33, 867–878. doi:10.1016/j.jngse.2016.06.033

Hu, Q. T., Zhang, S. T., Wen, G. C., Dai, L. C., and Wang, B. (2015). Coal-like material for coal and gas outburst simulation tests. Int. J. Rock Mech. Min. Sci. 74, 151–156. doi:10.1016/j.ijrmms.2015.01.005

Jiang, C. L., Xu, L. H., Li, X. W., Tang, J., Chen, Y. J., Tian, S. X., et al. (2015). Identification model and indicator of outburst-prone coal seams. Rock Mech. Rock Eng. 48, 409–415. doi:10.1007/s00603-014-0558-0

Jianshe, L., Zhao, W., Zhou, J., Yan, Z., Wang, K., Xu, C., et al. (2021). Influence of deep magma-induced thermal effects on the regional gas outburst risk of coal seams. Int. J. Coal Sci. Technol. 8 (6), 1411–1422. doi:10.1007/s40789-021-00452-2

Jin, K., Cheng, Y. P., Ren, T., Zhao, W., Tu, Q. Y., Dong, J., et al. (2018). Experimental investigation on the formation and transport mechanism of outburst coal-gas flow: Implications for the role of gas desorption in the development stage of outburst. Int. J. Coal Geol. 194, 45–58. doi:10.1016/j.coal.2018.05.012

Lei, Y., Cheng, Y. P., Wang, L., Ren, T., and Li, Q. Y. (2022). Potential infrasonic tremors in coal seam systems: Implications for the prediction of coal and gas outbursts. Fuel, 326, 125000. doi:10.1016/j.fuel.2022.125000

Li, H., Feng, Z. C., Zhao, D., and Duan, D. (2017). Simulation experiment and acoustic emission study on coal and gas outburst. Rock Mech. Rock Eng. 50, 2193–2205. doi:10.1007/s00603-017-1221-3

Litwiniszyn, J. (1985). A model for the initiation of coal-gas outbursts. Int. J. Rock Mech. Min. Sci. Geomechanics Abstr. 22, 39–46. doi:10.1016/0148-9062(85)92592-6

Liu, Q. Q., and Cheng, Y. P. (2014). Measurement of pressure drop in drainage boreholes and its effects on the performance of coal seam gas extraction: A case study in the jiulishan mine with strong coal and gas outburst dangers. Nat. Hazards (Dordr). 71, 1475–1493. doi:10.1007/s11069-013-0957-7

Liu, T., Lin, B., Fu, X., and Liu, A. (2021). Mechanical criterion for coal and gas outburst: A perspective from multiphysics coupling. Int. J. Coal Sci. Technol. 8 (6), 1423–1435. doi:10.1007/s40789-021-00447-z

Liu, Y. B., Ba, Q. B., He, L. P., Shen, K., and Xiong, W. (2020). Study on the rock-breaking effect of water jets generated by self-rotatory multinozzle drilling bit. Energy Sci. Eng. 8, 2457–2470. doi:10.1002/ese3.679

Lu, T. K., Zhao, Z. J., and Hu, H. F. (2011). Improving the gate road development rate and reducing outburst occurrences using the waterjet technique in high gas content outburst-prone soft coal seam. Int. J. Rock Mech. Min. Sci. 48, 1271–1282. doi:10.1016/j.ijrmms.2011.09.003

Peng, S. J., Xu, J., Yang, H. W., and Liu, D. (2012). Experimental study on the influence mechanism of gas seepage on coal and gas outburst disaster. Saf. Sci. 50, 816–821. doi:10.1016/j.ssci.2011.08.027

Skoczylas, N. (2012). Coal seam methane pressure as a parameter determining the level of the outburst risk – laboratory and in situ research/ciśnienie złożowe jako parametr określający stan zagrożenia wyrzutami metanu I skał – badania laboratoryjne I kopalniane. Archives Min. Sci. 57, 861–869. doi:10.2478/v10267-012-0056-8

Sun, H., Cao, J., Li, M., Zhao, X., Dai, L., Sun, D., et al. (2018). Experimental research on the impactive dynamic effect of gas-pulverized coal of coal and gas outburst. Energies 11, 797. doi:10.3390/en11040797

Tu, Q. Y., Cheng, Y. P., Guo, P. K., Jiang, J. Y., Wang, L., and Zhang, R. (2016). Experimental study of coal and gas outbursts related to gas-enriched areas. Rock Mech. Rock Eng. 49, 3769–3781. doi:10.1007/s00603-016-0980-6

Wang, C. J., Yang, S. Q., Yang, D. D., Li, X. W., and Jiang, C. L. (2018). Experimental analysis of the intensity and evolution of coal and gas outbursts. Fuel 226, 252–262. doi:10.1016/j.fuel.2018.03.165

Wang, F., He, J., Liang, Y., Luo, Y., Liao, Z., and Li, L. (2018). Study on the permeability characteristics of coal containing coalbed methane under different loading paths. Energy Sci. Eng. 6, 475–483. doi:10.1002/ese3.221

Wang, F., Liang, Y., and Zou, Q. (2019). Correlation between coal and gas outburst risk and adsorption properties of coal seams. Energy Sci. Eng. 7, 974–985. doi:10.1002/ese3.326

Wang, G., Li, W., Wang, P., Yang, X., and Zhang, S. (2017). Deformation and gas flow characteristics of coal-like materials under triaxial stress conditions. Int. J. Rock Mech. Min. Sci. 91, 72–80. doi:10.1016/j.ijrmms.2016.11.015

Xie, G., Yin, Z., Wang, L., Hu, Z., and Zhu, C. (2017). Effects of gas pressure on the failure characteristics of coal. Rock Mech. Rock Eng. 50, 1711–1723. doi:10.1007/s00603-017-1194-2

Xu, J. A., Peng, S. J., Zhang, D. D., Yang, H. W., and Tao, Y. Q. (2010). Analysis on the effect of gas pressure on coal and gas outburst disaster. Disaster Adv. 3, 442–446.

Xue, S., Wang, Y. C., Xie, J., and Wang, G. (2011). A coupled approach to simulate initiation of outbursts of coal and gas - model development. Int. J. Coal Geol. 86, 222–230. doi:10.1016/j.coal.2011.02.006

Xue, S., Yuan, L., Wang, Y. C., and Xie, J. (2014). Numerical analyses of the major parameters affecting the initiation of outbursts of coal and gas. Rock Mech. Rock Eng. 47, 1505–1510. doi:10.1007/s00603-013-0425-4

Yang, D. D., Chen, Y. J., Tang, J., Li, X. W., Jiang, C. L., Wang, C. J., et al. (2018). Experimental research into the relationship between initial gas release and coal-gas outbursts. J. Nat. Gas Sci. Eng. 50, 157–165. doi:10.1016/j.jngse.2017.12.015

Yin, G. Z., Jiang, C. B., Wang, J. G., Xu, J., Zhang, D. M., and Huang, G. (2016). A new experimental apparatus for coal and gas outburst simulation. Rock Mech. Rock Eng. 49, 2005–2013. doi:10.1007/s00603-015-0818-7

Yuan, L. (2016). Control of coal and gas outbursts in huainan mines in China: A review. J. Rock Mech. Geotechnical Eng. 8, 559–567. doi:10.1016/j.jrmge.2016.01.005

Zhai, C., Xiang, X. W., Xu, J. Z., and Wu, S. L. (2016). The characteristics and main influencing factors affecting coal and gas outbursts in Chinese Pingdingshan mining region. Nat. Hazards (Dordr). 82, 507–530. doi:10.1007/s11069-016-2195-2

Zhang, X., Tang, J. P., Pan, Y. S., and Yu, H. H. (2022). Experimental study on intensity and energy evolution of deep coal and gas outburst. Fuel, 324, 124484. doi:10.1016/j.fuel.2022.124484

Zhao, B., Cao, J., Sun, H. T., Wen, G. C., Dai, L. C., and Wang, B. (2020). Experimental investigations of stress-gas pressure evolution rules of coal and gas outburst: A case study in Dingji coal mine, China. Energy Sci. Eng. 8 (1), 61–73. doi:10.1002/ese3.509

Zhao, B., Wen, G., Ma, Q., Sun, H., Yan, F., and Nian, J. (2022b). Distribution characteristics of pulverized coal and stress–gas pressure–temperature response laws in coal and gas outburst under deep mining conditions. Energy Sci. Eng. 10 2205–2223. doi:10.1002/ese3.1129

Zhao, B., Wen, G., Nian, J., Ma, Q., Fan, C., Lv, X., et al. (2022a). Numerical simulation study on the multi-physical field response to underground coal and gas outburst under high geo-stress conditions. Minerals 12, 151. doi:10.3390/min12020151

Zhao, P., He, B., Zhang, B., and Liu, J. (2022). Porosity of gas shale: Is the NMR-based measurement reliable? Petroleum Sci. 19, 509–517. doi:10.1016/j.petsci.2021.12.013

Zhao, W., Cheng, Y., Jiang, H., Jin, K., Wang, H., and Wang, L. (2016). Role of the rapid gas desorption of coal powders in the development stage of outbursts. J. Nat. Gas Sci. Eng. 28, 491–501. doi:10.1016/j.jngse.2015.12.025

Zhou, B., Xu, J., Peng, S., Geng, J., and Yan, F. (2019). Test system for the visualization of dynamic disasters and its application to coal and gas outburst. Int. J. Rock Mech. Min. Sci. (1997). 122, 104083. doi:10.1016/j.ijrmms.2019.104083

Zhou, L., Zhou, X., Fan*, C., and Bai, G. (2022). Coal permeability evolution triggered by variable injection parameters during gas mixture enhanced methane recovery. Energy 252, 124065. doi:10.1016/j.energy.2022.124065

Zhu, Z., Wu, Y., and Han, J. (2022). A prediction method of coal burst based on analytic hierarchy process and fuzzy comprehensive evaluation. Front. Earth Sci. 9, 834958. doi:10.3389/feart.2021.834958

Keywords: gas outburst, mining-induced stress, mass distribution characteristics, outburst instability models, geo-stress evolution law

Citation: Shang S, Zhang Q, Zhao Y, Diao Y, Yin J, Che Y, Kang X and Zhao B (2023) Experimental research of the geo-stress evolution law and effect in the intact coal and gas outburst process. Front. Earth Sci. 10:1036165. doi: 10.3389/feart.2022.1036165

Received: 04 September 2022; Accepted: 20 September 2022;

Published: 09 January 2023.

Edited by:

Chaojun Fan, Liaoning Technical University, ChinaReviewed by:

Qingyi Tu, Anhui University of Science and Technology, ChinaLipeng He, Chongqing University, China

Xin Ding, Liaoning Technical University, China

Copyright © 2023 Shang, Zhang, Zhao, Diao, Yin, Che, Kang and Zhao. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) and the copyright owner(s) are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Bo Zhao, emhhb2JvOTFAY3F1LmVkdS5jbg==

Shaoyong Shang1

Shaoyong Shang1 Bo Zhao

Bo Zhao